#Chemical regulatory compliance South Korea

Explore tagged Tumblr posts

Text

Freyr provides South Korean chemical regulatory services in accordance with K-REACH (AREC) regulations. For compliant market entry, these services include product registration, notification, classification, and local representative services.

#Chemical Regulatory Services South Korea#Chemical product registration South Korea#K_REACH#Chemical Control Act (CCA)#Chemical Registration South Korea#Chemical regulatory compliance South Korea#Chemical safety consulting South Korea#Chemical Regulations South Korea#Biocide Regulations South Korea#South Korea Chemical Regulation

0 notes

Text

Bottling and Packaging Line Solution

Company Overview: Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Bottling and Packaging Line Solution in Ahmedabad, Gujarat, India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. A Bottling and Packaging Line Solution is an integrated system designed to streamline the entire process of filling, capping, labeling, inspecting, and packaging bottles. It is used across industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals, ensuring that liquid and semi-liquid products are efficiently packaged for distribution. These automated systems help businesses reduce production time, minimize human error, and ensure high-quality standards for every product. Similar Name of Bottling and Packaging Line Solution: Automated Bottling and Packaging System, Bottle Filling and Packing Line, Integrated Packaging and Bottling Solution, Liquid Packaging Line System, Complete Bottling Line Setup, Turnkey Packaging and Bottling Solutions, Customizable Bottling and Packaging Equipment, Automated Beverage Bottling Line, Filling and Packaging Machinery Solutions, Industrial Bottling and Packaging System. Why Choose Bottling and Packaging Line Solutions? Increased Efficiency: Automation minimizes manual labor, reducing human error and increasing throughput. Consistency and Quality Control: Advanced systems ensure uniform filling, sealing, and packaging. Scalability: Modular designs allow you to upgrade or expand systems as your business grows. Cost Savings: Streamlined processes reduce waste, energy use, and operational costs. Compliance and Safety: Modern solutions adhere to strict regulatory standards, safeguarding consumer health and brand reputation. Applications of Bottling and Packaging Line Solution: Food and Beverage Pharmaceuticals Cosmetics and Personal Care Chemicals Agricultural Products What is a bottling and packaging line solution? A bottling and packaging line solution encompasses machinery and processes designed to automate the filling, sealing, labeling, and packaging of liquid products. How do I determine the right capacity for my production line? Capacity depends on your current production volume and future growth projections. Consulting with a professional provider can help you determine the optimal configuration. Shiv Shakti Machtech is a Bottling and Packaging Line Solution and an exporter worldwide, including to Algeria, Angola, Antigua, Barbuda, Argentina, Armenia, Australia, Austria, The Bahamas, Bahrain, Bangladesh, Belarus, Belgium, Belize, Benin, Bhutan, Bolivia, Botswana, Brazil, Brunei, Bulgaria, Burkina Faso, Cambodia, Cameroon, Canada, Central African Republic, Chad, Chile, Colombia, Congo, Democratic Republic of the Congo, Costa Rica, Cuba, Cyprus, Denmark, Dominica, Ecuador, Egypt, Guinea, Ethiopia, Fiji, Finland, France, The Gambia, Georgia, Germany, Ghana, Greece, Guyana, Hungary, Iceland, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, South Korea, North Korea, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Libya, Malawi, Malaysia, Maldives, Mali, Mauritania, Mauritius, Mexico, Moldova, Monaco, Mongolia, Morocco, Mozambique, Myanmar (Burma), Namibia, Nepal, Netherlands, New Zealand, Niger, Nigeria, Norway, Oman, Panama, Peru, Philippines, Poland, Portugal, Qatar, Romania, Russia, Rwanda, Saint Lucia, Saudi Arabia, Senegal, Serbia, Singapore, Slovakia, Somalia, South Africa, Spain, Sri Lanka, Sudan, South Sudan, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Togo, Tunisia, Turkey, Uganda, Ukraine, United Arab Emirates (UAE), United Kingdom, United States, Uruguay, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Yemen, Zambia, and Zimbabwe. For further details or inquiries, feel free to reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Algeria#Angola#Antigua#Argentina#Armenia#Australia#Austria#Bahrain#Bangladesh#Barbuda#Belarus#Belgium#Belize#Benin#Bhutan#Bolivia#Botswana#BottlingandPackagingLineSolution#BottlingandPackagingLineSolutioninGujarat#BottlingandPackagingLineSolutioninIndia#Brazil#Brunei#Bulgaria#BurkinaFaso#Cambodia#Cameroon#Canada#CentralAfricanRepublic#Chad

2 notes

·

View notes

Text

Growth of the Electronic Chemicals CDMO & CRO Market: A Game-Changer for the Electronics Industry

The electronics industry has seen phenomenal growth in recent years, spurred by the demand for advanced technologies in sectors such as semiconductors, optoelectronics, and energy storage solutions. At the heart of this progress is the increasing reliance on high-purity electronic chemicals—a critical component in manufacturing processes. To keep pace with rapid advancements and ever-changing consumer expectations, many companies are turning to Contract Development and Manufacturing Organizations (CDMOs) and Contract Research Organizations (CROs). These specialized firms provide tailored solutions, bridging the gap between innovation and execution while helping businesses stay competitive. Let’s take a closer look at the dynamics of the Electronic Chemicals CDMO & CRO Market and its transformative potential.

Market Overview

CDMOs and CROs have become indispensable partners in the electronics industry. By offering expertise in chemical formulation, scalability, and compliance with stringent regulatory standards, these organizations enable manufacturers to focus on core competencies while accelerating their product development timelines. Furthermore, the outsourcing of critical processes allows businesses to optimize costs and reduce operational risks.

One region leading this market revolution is Asia-Pacific, a powerhouse for technological innovation and manufacturing excellence. The region’s growth trajectory is fueled by foreign investments and a robust ecosystem of research and development (R&D).

Key Applications and End-Uses

Optoelectronics

Optoelectronic devices—including LEDs, lasers, and photodetectors—require precision-engineered chemicals to achieve optimal performance. With the increasing adoption of smart lighting and optical communication technologies, the need for innovative chemical solutions has grown exponentially.

Discrete Semiconductors

Widely used in power management systems across industries like automotive and industrial electronics, discrete semiconductors depend on advanced chemicals for processes such as etching, doping, and wafer cleaning. CDMOs and CROs bring the necessary technical expertise to develop these specialized materials.

Integrated Circuits (ICs)

As the electronics industry embraces miniaturization and enhanced functionality, ICs play a pivotal role in high-performance computing and IoT devices. CDMO & CRO collaborations ensure that photolithography and deposition processes meet the stringent demands of modern IC manufacturing.

Battery Manufacturing

The global shift towards renewable energy and electric vehicles has driven demand for high-purity electrolytes and advanced coating materials. CDMOs and CROs are investing heavily in R&D to support next-generation battery technologies, which are essential for sustainable energy storage.

Sensors

Sensors underpin advancements in IoT, automotive safety, and industrial automation. Their precision and reliability hinge on the availability of ultra-pure chemicals, a niche well-served by CDMO and CRO partnerships.

Asia-Pacific’s Growing Dominance

The Asia-Pacific region has emerged as a key player in the global electronic chemicals market, thanks to its unique blend of technological prowess and manufacturing expertise. Key drivers of growth in the region include:

Technological Advancements: Cutting-edge innovations in semiconductor and electronics manufacturing.

Foreign Investments: Global corporations are increasingly channeling resources into Asia-Pacific to capitalize on its skilled workforce and infrastructure.

Rising Consumer Demand: The proliferation of consumer electronics, electric vehicles, and renewable energy projects has created a thriving demand for electronic chemicals.

Countries like China, South Korea, and Japan are spearheading this growth, leveraging their strong R&D frameworks and established supply chains.

Emerging Trends in the Market

Sustainability at the Forefront

The electronics industry is gradually transitioning to greener and more sustainable chemical solutions, driven by environmental regulations and consumer preferences.

Integration of AI and Automation

Artificial intelligence is revolutionizing the chemical manufacturing process, enabling better quality control, predictive maintenance, and process optimization.

Collaborative Ecosystems

Strategic partnerships between manufacturers, CDMOs, and CROs are fostering innovation and expediting time-to-market for groundbreaking technologies.

To know more Download PDF Brochure :

The rapid expansion of the Electronic Chemicals CDMO & CRO Market offers significant opportunities for:

Optoelectronics Manufacturers seeking customized chemical solutions for cutting-edge technologies.

Semiconductor Producers aiming to optimize processes and reduce operational costs.

Battery Developers exploring innovative materials for energy storage systems.

Sensor Manufacturers focused on enhancing precision and reliability.

Investors poised to capitalize on the surging demand for high-purity electronic chemicals.

Conclusion

The Electronic Chemicals CDMO & CRO Market is at the forefront of transforming the global electronics landscape. By offering tailored solutions to address complex manufacturing challenges, CDMOs and CROs enable companies to innovate and stay competitive. With the Asia-Pacific region leading the charge, the market is set to grow exponentially, driven by advancements in semiconductors, optoelectronics, and energy storage technologies. For stakeholders across the electronics value chain, now is the time to embrace these partnerships and seize the opportunities this dynamic market has to offer.

As the industry continues to evolve, the collaboration between manufacturers and CDMO/CRO organizations will remain a cornerstone of progress, fueling innovation and sustainability for years to come.

#Electronic Chemicals Market#CDMO#CRO#Electronics Industry#Market Growth#Chemical Manufacturing#Semiconductor Chemicals#Electronics Innovation#Industry Trends

0 notes

Text

Understanding K-REACH Registration: The Role of Chemical Regulatory Consultants

South Korea’s K-REACH (Korean Registration, Evaluation, Authorization, and Restriction of Chemicals) is a cornerstone of chemical safety regulation in the region. It mandates the registration and evaluation of chemical substances to ensure public health and environmental protection. For businesses aiming to access South Korea’s vibrant market, understanding K-REACH compliance is crucial. This is where chemical regulatory consultants become indispensable.

What is K-REACH?

K-REACH is South Korea’s comprehensive chemical regulatory framework, modeled after the EU’s REACH regulation. It applies to manufacturers, importers, and companies placing chemicals in the South Korean market. The regulation covers both existing and new chemical substances, with specific registration requirements depending on the tonnage and hazard profile of the substance.

Compliance involves several steps:

Pre-registration: Notification of intent to manufacture or import chemicals.

Substance Registration: Submission of detailed data, including chemical properties, toxicological information, and risk assessments.

Post-registration obligations: Continuous monitoring, reporting, and adherence to any restrictions or bans.

Challenges of K-REACH Compliance

Navigating K-REACH can be complex and time-consuming. Key challenges include:

Data Requirements: Generating and compiling extensive technical data.

Communication: Coordinating with upstream suppliers for accurate substance information.

Regulatory Updates: Keeping pace with evolving requirements and deadlines.

Why Partner with Chemical Regulatory Consultants?

Chemical regulatory consultants specialize in guiding companies through the complexities of K-REACH registration. Here’s how they add value:

Expertise and Experience: Consultants have deep knowledge of K-REACH requirements and local regulatory landscapes, ensuring accurate and efficient compliance.

Customized Strategies: They provide tailored solutions, from data gap analysis to full registration services.

Risk Mitigation: Consultants help identify potential compliance risks and implement strategies to address them proactively.

Time and Resource Optimization: By outsourcing regulatory tasks, companies can focus on their core operations while ensuring compliance.

Selecting the Right Consultant

When choosing a chemical regulatory consultant for K-REACH compliance, consider:

Proven Track Record: Look for consultants with a history of successful K-REACH registrations.

Local Expertise: Knowledge of South Korean regulatory nuances is critical.

Comprehensive Services: Ensure they offer end-to-end support, including dossier preparation, submission, and post-registration monitoring.

Conclusion

Complying with K-REACH is a vital step for businesses aiming to operate in South Korea’s chemical market. While the process can be daunting, partnering with experienced chemical regulatory consultants simplifies compliance and reduces risks. By leveraging their expertise, businesses can ensure seamless market entry and maintain regulatory adherence in an ever-evolving landscape.

If your organization seeks reliable guidance on K-REACH registration, consulting with chemical regulatory experts is not just an option—it’s a strategic necessity.

0 notes

Text

Navigating the Industrial Services Sector: Competitive Analysis and Trends

The global industrial services market size was estimated at USD 32.65 billion in 2023 and is projected to grow at a CAGR of 6.5% from 2024 to 2030. This growth can be attributed to the rapid progress in industrial automation, IoT, and AI significantly boosting demand for sophisticated industrial services. Companies are increasingly integrating these technologies to improve operational efficiency, reduce downtime, and enhance productivity. This technological integration not only optimizes processes but also enables the development of more advanced and reliable industrial services.

There is also a growing emphasis on predictive maintenance, which relies on data analytics and real-time monitoring to anticipate equipment failures and optimize maintenance schedules. The adoption of predictive maintenance solutions helps industries reduce operational costs and extend the lifespan of machinery, thus driving demand for these services. Increasing industrialization, especially in emerging economies, contributes to the expanding market. Regions such as Asia-Pacific are experiencing significant growth in manufacturing and production activities, leading to higher demand for industrial services. This industrial expansion in emerging markets is a key factor in overall market growth.

Stringent regulatory requirements also play a crucial role. Compliance with safety and environmental regulations necessitates regular maintenance and servicing of industrial equipment, ensuring a steady demand for industrial services to maintain compliance and avoid penalties. These regulatory pressures drive the need for ongoing maintenance and upgrades.

Industrial Services Market Report Highlights

Based on type, the operational improvement & maintenance segment led the market with the largest revenue share of 47.65% in 2023, due to its critical role in enhancing efficiency, reducing downtime, and prolonging equipment lifespan.

Based on application, the distributed control system(DCS) segment led the market with the largest revenue share of 20.14% in 2023, due to its essential role in managing complex industrial processes with high reliability and precision.

Based on end use, the oil and gas segment led the market with the largest revenue share of 28.36% in 2023. It is expected to maintain its dominance from 2024 to 2030, due to the sector's substantial reliance on industrial services for operational efficiency, safety, and regulatory compliance.

North America dominated the industrial services market share of 34.66% in 2023, primarily due to its advanced industrial infrastructure and high level of technological adoption. The presence of key industries, including oil and gas, pharmaceuticals, and manufacturing, drives significant demand for industrial services.

Global Industrial Services Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2017 to 2030. For this study, Grand View Research has segmented the global industrial services market report based on type, application, end-use, and region.

Type Outlook (Revenue, USD Million, 2017 - 2030)

Engineering & Consulting

Installation & Commissioning

Operational Improvement & Maintenance

Application Outlook (Revenue, USD Million, 2017 - 2030)

Distributed Control System (DCS)

Programmable Controller Logic (PLC)

Supervisory Control and Data Acquisition (SCADA)

Electric Motors & Drives

Valves & Actuators

Manufacturing Execution System

Others

End Use Outlook (Revenue, USD Million, 2017 - 2030)

Oil and Gas

Chemicals

Automotive

Pharmaceuticals

Others

Regional Outlook (Revenue, USD Million, 2017 - 2030)

North America

US

Canada

Mexico

Europe

UK

Germany

France

Asia Pacific

China

Japan

India

South Korea

Australia

Latin America

Brazil

Middle East and Africa (MEA)

KSA

UAE

South Africa

Order a free sample PDF of the Industrial Services Market Intelligence Study, published by Grand View Research.

0 notes

Text

Failure Analysis Market — Forecast(2024–2030)

Overview

As the technology is evolving the tools for identifying and correction of failure has becoming easy and increase in usage of technology is driving the failure testing market With the complexity of electronic devices and materials continuously increasing, there’s a growing demand for more advanced analytical techniques in failure analysis. This includes techniques such as scanning electron microscopy (SEM), transmission electron microscopy (TEM), focused ion beam (FIB) microscopy, X-ray imaging, and spectroscopy. These techniques enable finer resolution, deeper analysis, and greater accuracy in identifying failure modes, thereby driving the adoption of sophisticated failure analysis solutions. Many companies are increasingly outsourcing their failure analysis needs to specialized service providers. Outsourcing offers several advantages, including access to expertise and equipment not available in-house, faster turnaround times, and cost savings. Additionally, as failure analysis becomes more specialized and requires highly skilled personnel and expensive equipment, outsourcing provides a more efficient and cost-effective solution for many organizations. As a result, the market for failure analysis services is witnessing significant growth, with specialized firms catering to a wide range of industries and applications.

These trends reflect the evolving needs and challenges in failure analysis and are driving innovation and growth in the market. However, it’s essential to consult more recent sources to confirm if these trends persist or if there have been new developments since my last update.

Request Sample

The report: “Failure Analysis Market — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the Barium Sulphate Industry. Market.

By Product: Transmission Electron Microscope, Focused Ion Beam Systems, Scanning Electron Microscopy, Dual Beam Systems, Others

By Test: Fractography, Metallography, Mechanical Testing, Chemical Analysis and Testing, NDT, Weld Testing, Microstructure Evaluation, Adhesive Identification, Coating

Contamination, Thermal Mapping, Electrical Overstress (EOS)/Electrostatic Discharge (EDS), Regulatory Compliance Testing, Others

By Techniques: Fault Tree Analysis (FTA), Common-Mode Failure Analysis, Failure Modes Effect Analysis (FMEA), Failure Modes, Effects and Criticality Analysis (FMECA), Functional Failure Analysis, Sneak Circuit Analysis, Software Failure Analysis, Others

By Technology: Broad ion milling, Focused ion milling, Relative ion etching, Secondary ion mass spectroscopy, Energy dispersive X-Ray Spectroscopy

By Application: Bio Science Cellular Biology, Neuroscience, Bio Medical, Others. Electronics: Semiconductors, Others. Renewable Energy: Solar, Wind. Agriculture: Machinery & Tools. Oil and Gas, Machinery & Tools. Commercial Aerospace.

Defense: Marine, Aerospace, Ground. Automotive: Automotive Materials Testing, Automotive Plastics and Polymers Physical Testing, Automotive Exterior Testing and Expertise, Automotive Interior Testing and Expertise. Construction. Chemical and Pharmaceutical. Healthcare Equipment. Food & Beverage. Mining. Polymer. Paper & Fiber material. Ceramic & Glass. Nanofabrication. Others.

By Geography: By Geography: North America (US, Canada and Mexico), Europe (UK, France, Germany, Italy, Spain, Russia, Netherlands, Belgium, and Rest of Europe), APAC (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, Rest of South America), and RoW (Middle East and Africa).

Inquiry Before Buying

Key Takeaways

• Evaluate market potential through analyzing growth rates (CAGR %), Volume (Units) and Value ($M) data given at country level — for product types, end use applications and by different industry verticals.

• Understand the different dynamics influencing the market — key driving factors, challenges and hidden opportunities.

• Get in-depth insights on your competitor performance — market shares, strategies, financial benchmarking, product benchmarking, SWOT and more.

• Analyze the sales and distribution channels across key geographies to improve top-line revenues.

• Understand the industry supply chain with a deep-dive on the value augmentation at each step, in order to optimize value and bring efficiencies in your processes.

• Get a quick outlook on the market entropy — M&A’s, deals, partnerships, product launches of all key players for the past 4 years.

• Evaluate the supply-demand gaps, import-export statistics and regulatory landscape for more than top 20 countries globally for the market.

Failure Analysis Market Segment Analysis — By Application

The automotive sector has seen notable technological advancements such as Advanced Driver Assistance Systems (ADAS), connected vehicles, Internet of Things (IoT) devices, and smart sensors. These innovations play a crucial role in preventing potential accidents caused by malfunctions in critical vehicle components. According to a June 2022 report from the World Health Organization (WHO), around 1.3 million lives are lost annually due to road traffic accidents, with 20 to 50 million individuals sustaining non-fatal injuries Potential causes of automotive device failures include aspects like product design, manufacturing processes, material source contamination, product packaging, mishandling, and incorrect calibration. These factors underscore concerns about the manufacturing quality of automotive parts and the necessity for proactive measures to mitigate incidents.The Asia-Pacific region has experienced significant growth in the automotive sector, fueled by increasing demand for both passenger and advanced vehicles. The region’s high population density contributes to elevated usage of passenger vehicles, thus driving market expansion. In 2022, China’s automotive industry alone produced approximately 23.8 million passenger cars, as reported by the International Organization of Motor Vehicle Manufacturers (OICA).

Failure Analysis Market Segment Analysis — Electronics & Semiconductor

The dominance of the electronics and semiconductor application segment in the failure analysis market is evident, holding the largest share. This is primarily attributed to the escalating demand for miniature transistor chips, Nano electronics, and optoelectronics across various industries. The electronics and semiconductor sector is emerging as a pivotal player, fueled by the rising adoption of robotics and automation in the manufacturing of electronic devices. This surge in automation has led to a requirement for high-density, integrated, and miniaturized devices to facilitate the production of smart devices, wearables, and intelligent industrial equipment. As a result, the need for robust failure analysis solutions within this sector has become increasingly pronounced, driving the dominance of the electronics and semiconductor segment in the market.

Failure Analysis Market Segment Analysis — Geography

During the projected period, the Asia Pacific region is expected to demonstrate the highest Market Share of 45 % The significant mass production of electronic goods such as smartphones, tablets, sensors, industrial equipment, wearables, and white goods in China and Taiwan is set to propel the expansion of the failure analysis market in this area. Japan holds a prominent position as the primary market for microscopy equipment in the Asia Pacific region. Major industry players like Nikon, JEOL Ltd., Olympus, and Hitachi High-Technologies are headquartered in Japan, enjoying strong patronage from major research institutions, pharmaceutical companies, and biotechnology firms. In China, the manufacturing sector is actively embracing industrial robots to automate and modernize various manufacturing processes. This transition has created a demand for monitoring device failures, presenting fresh growth prospects for the failure analysis market in the country.

Failure Analysis Market Share (%) By Region, 2023

Buy Now

Drivers — Failure Analysis Market

Fusion of Microscopy and Spectroscopy

The integration of microscopy with spectroscopy is poised to unlock significant opportunities across research communities, offering a wide array of applications. For instance, merging Raman spectroscopy with either atomic force microscopy or optical microscopy provides intricate insights into nanoscale properties and composition. The combined techniques synergize to facilitate precise sample alignment, efficient optical signal transfer from microscope to spectrometer, and accurate focusing of excitation light at the detection point.The potential of amalgamating microscopy technologies has led to innovations like the DXR2 Raman Imaging Microscope by Thermo Fisher Scientific. This instrument seamlessly integrates an optical microscope with a Raman spectrometer, allowing for the acquisition of both traditional optical and petrochemical images

Challenges — Failure Analysis Market

Elevated Ownership and Maintenance Expenses

There has been a noticeable shift in microscopy usage trends, with traditional models gradually being replaced by high-end alternatives such as electron microscopes, scanning probe microscopes, and digital microscopes. This transition is fueled by the advanced features, superior resolution, and magnification capabilities offered by these modern instruments. However, a significant barrier to their widespread adoption lies in their high cost, which can range from USD 25,000 to USD 2 million. This pricing hurdle limits their accessibility in settings like hospitals, pathological laboratories, and small-scale industries. Furthermore, the ongoing expenses associated with microscope maintenance add to the overall ownership costs. For instance, maintenance costs for a transmission electron microscope can fall within the range of USD 15,000 to USD 100,000 per year. These steep expenses often necessitate heavy reliance on government and private research funding, consequently restraining market growth to a certain extent.

Market Landscape

Failure Analysis Market Segment Analysis Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the Window Films Market. Major players in the Failure Analysis Market are

Hitachi High-Tech, Intertek, JEOL, Motion X, TESCAN, ZEISS, A&D Company, Carl Zeiss SMT, FEI, Thermo Fisher Scientific and Others.

0 notes

Text

Chemical Manufacturing Software Market: Impact of Digitalization on Efficiency and Innovation

Introduction to Chemical Manufacturing Software Market

The Chemical Manufacturing Software Market focuses on delivering advanced software solutions for chemical companies to streamline operations, ensure compliance, and improve efficiency. These solutions help with inventory management, production scheduling, quality control, and regulatory reporting. As the chemical industry adopts digital transformation, the demand for integrated systems like ERP, MES, and automation tools grows. Key trends include IoT integration, real-time analytics, and cloud-based platforms. Industry challenges revolve around scalability, cost, and customization needs to meet complex manufacturing processes.

The Chemical Manufacturing Software Market is Valued USD 914 Million by 2024 and projected to reach USD 1652.29 Million by 2032, growing at a CAGR of 6.8% During the Forecast period of 2024-2032.This software enables businesses to optimize production, inventory management, and regulatory adherence, allowing them to improve overall efficiency. The rise of Industry 4.0, coupled with innovations in AI and IoT, is reshaping the landscape of chemical manufacturing, increasing the demand for more advanced and flexible software solutions.

Access Full Report :https://www.marketdigits.com/checkout/3603?lic=s

Major Classifications are as follows:

By Software Type

Enterprise Resource Planning (ERP) Software

Product Lifecycle Management (PLM) Software

Quality Management Software

Others

By Deployment

On Cloud

On Premises

By Application

Large Enterprises

SMEs

Key Region/Countries are Classified as Follows:

◘ North America (United States, Canada,) ◘ Latin America (Brazil, Mexico, Argentina,) ◘ Asia-Pacific (China, Japan, Korea, India, and Southeast Asia) ◘ Europe (UK,Germany,France,Italy,Spain,Russia,) ◘ The Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, and South

Key Players of Chemical Manufacturing Software Market

Aquilon ERP, Aspen Technology Inc, AVEVA , BatchMaster ERP, Dassault Systèmes, Datacor Chempax, Deskera ERP, Emerson Electric Co, GE DIGITAL, Honeywell International Inc, IFS Applications, Intellect eQMS, MasterControl Solutions, Inc,Odoo, QuickBooks Enterprise, Rockwell Automation, Royal 4 Systems, Sage Group plc, SAP SE, Vicinity Manufacturing and Others

Market Drivers in Chemical Manufacturing Software Market

Several key drivers are accelerating growth in the Chemical Manufacturing Software Market:

Digital Transformation: Chemical companies are investing in digital technologies to optimize production processes and reduce operational costs.

Regulatory Compliance: Strict environmental and safety regulations require companies to adopt software that ensures accurate reporting and tracking of chemicals.

Automation: Growing adoption of automation in chemical plants is increasing the need for software to manage real-time production and supply chain operations

Market Challenges in Chemical Manufacturing Software Market

The Chemical Manufacturing Software Market faces several challenges:

Integration Complexity: Chemical manufacturing processes are highly complex, and integrating software with legacy systems can be difficult and costly.

Customization Needs: No two chemical plants are the same, which means software often needs significant customization to meet individual operational requirements.

High Implementation Costs: The upfront cost of deploying robust software solutions can be prohibitive for small- to mid-sized companies.

Market Opportunities in Virtual Machines Market

The Virtual Machines Market presents several growth opportunities, particularly as businesses continue to embrace cloud computing and virtual environments for flexibility and cost savings. Virtual machines allow companies to run multiple operating systems on a single physical machine, improving resource allocation and reducing hardware costs. In industries like chemical manufacturing, virtual machines offer the benefit of scalability and disaster recovery. Additionally, advancements in virtualization technology and the growing adoption of hybrid cloud models open new avenues for innovation and market expansion.

Conclusion

The Chemical Manufacturing Software Market is poised for strong growth as digitalization, regulatory compliance, and sustainability drive demand for advanced solutions. While challenges around integration and cost remain, the potential for innovation and efficiency gains is substantial. At the same time, the Virtual Machines Market offers complementary opportunities, especially as companies look to virtual environments to enhance their operational flexibility. Together, these trends are shaping the future of the chemical manufacturing landscape.

0 notes

Text

Global Market Trends for Colorless Polyimide Films: Forecasts and Predictions

Introduction to Colorless Polyimide Films Market

Colorless polyimide films are high-performance materials known for their excellent thermal stability, electrical insulation, and optical clarity. Used in various applications such as electronics, aerospace, and automotive industries, these films offer superior performance in demanding environments. The market for colorless polyimide films is driven by the increasing demand for advanced materials in technology sectors. As electronics become more compact and complex, the need for efficient, reliable insulation materials grows. Additionally, the aerospace industry’s focus on lightweight, durable materials further fuels market expansion. Key players in this market are investing in innovations to enhance film properties and applications.

Market overview

The Colorless Polyimide Films Market is Valued USD 152.8 billion by 2024 and projected to reach USD 10,037.2 Million by 2030, growing at a CAGR of CAGR of 59.20% During the Forecast period of 2024–2032.This growth is fueled by the expanding use of these films in flexible electronics, advanced packaging, and other high-tech applications.

Access Full Report : https://www.marketdigits.com/checkout/3504?lic=s

Major Classifications are as follows:

By Type:

50 m

31–50 m

21–30 m

20 m

By application:

Flexible Displays

Flexible Solar Cells

Flexible Printed Circuit Boards

Lighting Equipment

Others

By end-use industry:

Data Security

Electronics

Solar Energy

Medical

Others

Key Region/Countries are Classified as Follows: ◘ North America (United States, Canada, and Mexico) ◘ Europe (Germany, France, UK, Russia, and Italy) ◘ Asia-Pacific (China, Japan, Korea, India, and Southeast Asia) ◘ South America (Brazil, Argentina, Colombia, etc.) ◘ The Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, and South Africa)

Major players in Colorless Polyimide Films Market:

DuPont, Kaneka Corporation, Kolon Industries Inc., SK Innovation Co., Ltd., Sumitomo Chemical Company Ltd., Wuhan Imide New Materials Technology Co., Ltd., Industrial Summit Technology Corporation, NeXolve Holding Company, Wuxi Shunxuan New Materials Co., Ltd., Suzhou Kinyu Electronics Co., Ltd., Changchun Gao Qi Polyimide Material Co., Ltd., Zymergen Inc., Dr. Dietrich Muller GmbH and Others.

Market Drivers in Colorless Polyimide Films Market:

Technological Advancements: Continuous innovation in electronics, including flexible displays and wearable technology, requires materials with high thermal stability and electrical insulation, driving demand for colorless polyimide films markets.

Miniaturization of Electronics: The trend toward smaller, more compact electronic devices increases the need for efficient, thin, and durable insulating materials, boosting the demand for polyimide films.

Aerospace Industry Growth: The aerospace sector’s need for lightweight and high-strength materials for components and insulation supports the growth of polyimide films.

Market challenges in Colorless Polyimide Films Market:

High Production Costs: The manufacturing of polyimide films involves complex processes and high-quality raw materials, leading to elevated production costs. This can limit market growth, especially in cost-sensitive applications.

Raw Material Prices: Fluctuations in the prices of raw materials used in polyimide film production can impact overall costs and profitability.

Competition from Alternative Materials: The development of alternative materials with comparable or superior properties, such as other high-performance polymers, can pose a threat to the market for polyimide films.

Regulatory Compliance: Adherence to stringent environmental and safety regulations can increase operational costs and affect market dynamics.

Market opportunities in Colorless Polyimide Films Market:

Growth in Flexible Electronics: The increasing use of flexible and wearable electronics creates a demand for colorless polyimide films market due to their excellent flexibility, thermal stability, and clarity.

Advancements in Aerospace Applications: Expanding aerospace and defense sectors require lightweight, durable materials for advanced applications, creating opportunities for polyimide films.

Expansion of Electric Vehicles (EVs): The rise of EVs and their need for high-performance insulation materials for batteries and electronic systems presents a growing market for colorless polyimide films.

Future trends in Colorless Polyimide Films Market:

Integration with Flexible Electronics: As flexible electronics and wearables continue toevolve, the demand for colorless polyimide films market with enhanced flexibility and durability is expected to grow. Innovations in film technology will likely cater to these advanced applications.

Advancements in Manufacturing Techniques: Improved manufacturing processes and technologies, such as roll-to-roll processing and advanced coating techniques, may reduce production costs and enhance film properties.

Increased Adoption in Automotive Sector: With the rise of electric and autonomous vehicles, there will be a growing need for high-performance insulation materials for batteries and electronic components, driving demand for polyimide films.

Conclusion:

In conclusion, the colorless polyimide films market is poised for significant growth driven by technological advancements, increasing demand for high-performance materials, and expanding applications across industries such as electronics, aerospace, and automotive. Despite facing challenges such as high production costs and competition from alternative materials, the market presents numerous opportunities through innovations in manufacturing, sustainability trends, and the development of new applications. Future trends indicate a continued evolution towards more flexible, durable, and eco-friendly films, which will further fuel market expansion. Overall, the colorless polyimide films market is set to thrive as industries seek advanced materials to meet the demands of modern technology and applications.

#colorless polyimide films market demand#colorless polyimide films market share#colorless polyimide films market size#colorless polyimide films market trend

0 notes

Text

South Korea Inflight Advertising Market Players & Forecast (2024-2032)

The inflight advertising market in South Korea is on the rise, with several key players shaping its future from 2024 to 2032. Understanding the major players and their strategies is crucial for navigating this evolving market and capitalizing on emerging opportunities.

Key Market Players

Korea Aerospace Industries (KAI): As a leading aerospace manufacturer in South Korea, KAI plays a significant role in inflight advertising through its aircraft and technology partnerships. KAI’s focus on advanced inflight entertainment systems provides a platform for integrating innovative advertising solutions.

Hanwha Aerospace: Hanwha Aerospace, known for its expertise in aerospace technology, is actively involved in developing and supplying components for inflight entertainment systems. Its commitment to technological innovation positions it as a key player in the inflight advertising market.

Lotte Chemical: Although primarily a chemical manufacturer, Lotte Chemical is expanding into the aerospace sector by providing advanced materials for inflight entertainment systems. Its involvement in this space contributes to the development of high-performance advertising platforms.

Market Forecast and Trends

The South Korean inflight advertising market is expected to grow at a compound annual growth rate (CAGR) of approximately 5-7% from 2024 to 2032. This growth is driven by advancements in inflight entertainment technology, increasing passenger engagement, and a growing focus on digital advertising solutions.

Opportunities:

Technological Innovation: Investing in cutting-edge inflight entertainment technologies can offer new advertising opportunities and improve market positioning.

Partnership Opportunities: Collaborations with airlines and technology providers can enhance advertising solutions and expand market reach.

Data Utilization: Leveraging passenger data to deliver targeted and personalized ads can enhance engagement and ROI.

Request Free Sample Report - Receive a free sample report to preview the valuable insights and data we offer.

Challenges:

Competitive Pressure: The competitive landscape requires continuous innovation and differentiation to stay ahead.

Regulatory Compliance: Ensuring compliance with aviation and advertising regulations is essential for operating in the market.

About US

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Services. MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions. To stay updated with technology and work process of the industry, MRFR often plans & conducts meet with the industry experts and industrial visits for its research analyst members.

Contact us:

Market Research Future (part of Wants tats Research and Media Private Limited),

99 Hudson Street,5Th Floor, New York, New York 10013, United States of America

Sales: +1 628 258 0071 (US) +44 2035 002 764 (UK)

Email: [email protected]

0 notes

Text

Conformal Coating Market in the Food and Beverage Industry: Trends, Opportunities, and Challenges

With a surge in technological advancements and the proliferation of intricate electronic devices, the Conformal Coating Market stands at the forefront, catering to the burgeoning demand for protection and longevity.

Understanding Conformal Coating

Conformal coatings are thin polymeric films applied to electronic circuits and assemblies to protect them from harsh environments. These coatings offer a shield against moisture, dust, chemicals, and other contaminants, thereby enhancing the reliability and lifespan of electronic devices. The market encompasses various types of coatings, including acrylic, silicone, urethane, and epoxy, each tailored to specific application requirements.

Market Dynamics

1. Technological Advancements

Innovation remains the cornerstone of the conformal coating market, with continuous research and development efforts driving the introduction of advanced formulations. These innovations focus on improving properties such as adhesion, flexibility, and chemical resistance, thus expanding the application scope across diverse industries.

2. Rising Demand from Electronics Sector

The proliferation of electronic devices across industries such as automotive, aerospace, healthcare, and consumer electronics fuels the demand for conformal coatings. As electronic components become increasingly compact and complex, the need for reliable protection against environmental stressors becomes more pronounced, driving the market growth.

3. Regulatory Compliance

Stringent regulations regarding environmental protection and workplace safety necessitate the adoption of compliant conformal coating solutions. Manufacturers are compelled to adhere to guidelines and standards such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), thereby shaping the market landscape.

Key Market Segments

1. By Type

Acrylic Coatings: Known for their versatility and cost-effectiveness, acrylic coatings find widespread use in electronics applications.

Silicone Coatings: Renowned for their superior thermal stability and flexibility, silicone coatings cater to demanding environments such as automotive and aerospace.

Urethane Coatings: Offering excellent chemical resistance and durability, urethane coatings are ideal for rugged applications.

2. By Application

Consumer Electronics: From smartphones to wearables, conformal coatings play a pivotal role in safeguarding delicate electronic components from everyday wear and tear.

Automotive Electronics: With the advent of electric vehicles and advanced driver-assistance systems (ADAS), the automotive sector emerges as a significant consumer of conformal coatings.

Medical Devices: Conformal coatings ensure the reliability and longevity of critical medical devices, safeguarding patient health and well-being.

Regional Insights

1. North America

As a hub of technological innovation, North America commands a significant share of the conformal coating market. The region's robust electronics industry, coupled with stringent quality standards, propels the adoption of advanced coating solutions.

2. Europe

Europe remains at the forefront of environmental regulations, driving the demand for eco-friendly and compliant conformal coatings. The region's emphasis on sustainability and product quality fosters market growth and innovation.

3. Asia Pacific

The rapid industrialization and expanding electronics manufacturing sector in Asia Pacific fuel the demand for conformal coatings. Countries like China, Japan, and South Korea are witnessing a surge in production volumes, driving market expansion.

Future Outlook

The future of the conformal coating market is poised for exponential growth, fueled by technological advancements, expanding end-user industries, and evolving regulatory landscapes. As manufacturers strive to meet the growing demand for reliable and durable electronic components, the market is primed for innovation and diversification.

Conclusion

In a world increasingly reliant on electronic devices, the importance of conformal coatings cannot be overstated. As technology advances and industries evolve, the need for robust protection against environmental factors becomes more pronounced. The conformal coating market, with its array of innovative solutions and steadfast commitment to quality, stands ready to meet the challenges of tomorrow's electronics landscape.

0 notes

Text

Filling Line - End to End Packaging Solution

Company Overview: Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Filling Line - End to End Packaging Solution in Ahmedabad, Gujarat, India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. Filling lines are advanced, automated systems that optimize packaging efficiency for various industries, such as food and beverages, pharmaceuticals, chemicals, and cosmetics. From product filling to capping, labeling, and sealing, these systems provide a seamless, end-to-end packaging solution. Process of Filling Lines: Filling lines follow a systematic, step-by-step process to ensure efficient product packaging: Product Feeding: The raw material or liquid is fed into the system, often from bulk storage tanks. Filling: The system accurately measures and dispenses the product into containers or bottles. Capping: The system automatically places and tightens caps or lids onto the filled containers. Sealing: The system seals containers using heat or adhesives to ensure product integrity. Labeling: The system applies custom labels to containers for branding and regulatory compliance. Inspection: The system conducts quality checks to ensure that the packaging meets standards. Cartoning & Palletizing: The system groups, boxes, and prepares packaged items for shipping. Applications of Filling Lines: Food & Beverage Industry Pharmaceutical Industry Cosmetics & Personal Care Chemical Industry Agricultural Products What is a filling line? A filling line automates the process of filling containers with liquids, powders, or granules. It can include processes like capping, labeling, and packaging for a complete solution. What industries use filling lines? Industries like food and beverage, pharmaceuticals, cosmetics, and chemical manufacturing commonly use filling lines. Can a filling line handle multiple product types? Yes, our filling lines are versatile and can handle various product types, including liquids, semi-liquids, powders, and viscous materials. Shiv Shakti Machtech is a Filling Line - End to End Packaging Solution and an exporter worldwide, including to Algeria, Angola, Antigua, Barbuda, Argentina, Armenia, Australia, Austria, The Bahamas, Bahrain, Bangladesh, Belarus, Belgium, Belize, Benin, Bhutan, Bolivia, Botswana, Brazil, Brunei, Bulgaria, Burkina Faso, Cambodia, Cameroon, Canada, Central African Republic, Chad, Chile, Colombia, Congo, Democratic Republic of the Congo, Costa Rica, Cuba, Cyprus, Denmark, Dominica, Ecuador, Egypt, Guinea, Ethiopia, Fiji, Finland, France, The Gambia, Georgia, Germany, Ghana, Greece, Guyana, Hungary, Iceland, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, South Korea, North Korea, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Libya, Malawi, Malaysia, Maldives, Mali, Mauritania, Mauritius, Mexico, Moldova, Monaco, Mongolia, Morocco, Mozambique, Myanmar (Burma), Namibia, Nepal, Netherlands, New Zealand, Niger, Nigeria, Norway, Oman, Panama, Peru, Philippines, Poland, Portugal, Qatar, Romania, Russia, Rwanda, Saint Lucia, Saudi Arabia, Senegal, Serbia, Singapore, Slovakia, Somalia, South Africa, Spain, Sri Lanka, Sudan, South Sudan, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Togo, Tunisia, Turkey, Uganda, Ukraine, United Arab Emirates (UAE), United Kingdom, United States, Uruguay, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Yemen, Zambia, Zimbabwe. For further details or inquiries, feel free to reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Algeria#Angola#Antigua#Argentina#Armenia#Australia#Austria#Bahrain#Bangladesh#Barbuda#Belarus#Belgium#Belize#Benin#Bhutan#Bolivia#Botswana#Brazil#Brunei#Bulgaria#BurkinaFaso#Cambodia#Cameroon#Canada#CentralAfricanRepublic#Chad#Chile#Colombia#Congo

2 notes

·

View notes

Text

Genset Battery Market Growth and Global Industry Status by 2033

The global genset battery market is expected to grow from USD 14563.51 million in 2023 to USD 23273.61 million in 2033, at a CAGR of 4.8% during 2024-2033

Introduction

The Genset Battery Market plays a pivotal role in ensuring reliable backup power supply for critical applications in various sectors, including commercial, industrial, and residential. As an essential component of generator sets (gensets), genset batteries provide the necessary starting power to initiate the engine and standby power during utility outages. This analysis delves into the functioning of genset batteries, examines their working principles, and outlines their key objectives in backup power systems.

Analysis of the Genset Battery Market

The Genset Battery Market is influenced by several factors:

Demand from End-Use Industries: The demand for genset batteries is driven by end-use industries such as telecommunications, healthcare, data centers, manufacturing, and construction, where uninterrupted power supply is critical for operations.

Regulatory Compliance: Compliance with safety standards, environmental regulations, and industry certifications impacts the design, manufacturing, and deployment of genset batteries, driving market dynamics and product innovation.

Technological Advancements: Advances in battery chemistry, energy storage technologies, and smart monitoring systems contribute to the evolution of genset batteries, enhancing performance, reliability, and operational efficiency.

Market Competition: Intense competition among battery manufacturers, genset suppliers, and energy storage companies influences pricing strategies, product differentiation, and market penetration strategies in the genset battery market.

Working of Genset Batteries

Genset batteries function through a simple yet crucial process:

Charging: Genset batteries are charged either through an external charger or through the genset's alternator when the engine is running. During charging, electrical energy from the external source or the alternator is converted and stored as chemical energy within the battery.

Discharging: When the genset is called upon to provide backup power, the battery discharges its stored energy to power the starter motor, initiating the engine's combustion process. Additionally, the battery provides standby power during utility outages until the genset reaches its rated output.

Recharging: Once the engine starts and the genset begins generating electricity, the alternator recharges the battery by converting mechanical energy into electrical energy, restoring the battery's charge level for subsequent use.

Receive the FREE Sample Report of Genset Battery Market Research Insights @ https://stringentdatalytics.com/sample-request/genset-battery-market/14122/

Market Segmentations:

Global Genset Battery Market: By Company

Cummins

EnerSys

Exide

Leoch International

Amara Raja Batteries

Generac

Kohler

Global Genset Battery Market: By Type

Lead-Acid Batteries

NiCd Batteries

Global Genset Battery Market: By Application

Residential

Commercial

Industrial

Regional Analysis of Global Genset Battery Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Genset Battery market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Genset Battery Market Research Report @ https://stringentdatalytics.com/purchase/genset-battery-market/14122/?license=single

Objectives of Genset Batteries

The primary objectives of genset batteries include:

Reliable Starting Power: Genset batteries must reliably provide the necessary starting power to initiate the engine combustion process, ensuring prompt response during emergencies or power outages.

Standby Power Supply: Genset batteries serve as a reliable source of standby power during utility outages, ensuring uninterrupted operation of critical loads until the genset reaches full capacity and transfers load.

Long-Term Durability: Genset batteries are designed to withstand frequent charge-discharge cycles, temperature fluctuations, and environmental conditions, ensuring long-term durability and operational reliability in demanding applications.

Low Maintenance: Genset batteries should require minimal maintenance, with features such as low self-discharge rates, sealed construction, and robust design to reduce the need for frequent inspections and service interventions.

Compatibility and Integration: Genset batteries must be compatible with a wide range of genset models, configurations, and control systems, facilitating seamless integration into existing backup power systems and applications.

Conclusion

The Genset Battery Market plays a critical role in ensuring reliable backup power supply for a wide range of applications and industries. Through continuous analysis, understanding of working principles, and alignment with key objectives, stakeholders in the genset battery market can drive innovation, enhance performance, and meet the evolving needs of customers in an increasingly dynamic and demanding power landscape.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Linkedin | Facebook | Twitter | YouTube

0 notes

Text

Global Heat Resistant Polymer Market: Growth Drivers and Competitive Landscape

The global heat resistant polymer market size was valued at USD 17.9 billion in 2023 and is anticipated to grow at a CAGR of 9.9% from 2024 to 2030. This growth is driven by the increasing demand from the electronics and electrical industries, where these polymers are essential for manufacturing components that can withstand high temperatures. The shift of the automotive sector towards lightweight and fuel-efficient vehicles has spurred the use of heat-resistant polymers in engine components and under-the-hood applications.

The aerospace industry relies heavily on these materials for their durability and performance in extreme conditions. The advancements in polymer technology and the rising trend of miniaturization in various sectors are propelling market growth. Regulations play a significant role in shaping the global heat resistant polymer market. Stringent environmental policies, such as the European Union’s REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulation, mandate using safer and more sustainable materials, driving the demand for eco-friendly heat resistant polymers.

In addition, fire safety standards, such as the U.S. UL 94 flammability rating, require materials to meet specific flame retardancy criteria, influencing the development and adoption of flame-retardant polymers. In the automotive sector, regulations to reduce vehicle emissions and improve fuel efficiency, such as the Corporate Average Fuel Economy (CAFE) standards in the U.S., encourage using lightweight, high-performance polymers. These regulatory frameworks ensure safety and environmental compliance and stimulate innovation and growth within the heat resistant polymer market.

Heat Resistant Polymer Market Report Highlights

The fluoropolymers segment accounted for 31.9% of the market revenue in 2023, attributed to their exceptional heat and chemical resistance. This makes them valuable in demanding industrial applications, especially in the automotive and aerospace sectors.

The automotive segment dominated the market in 2023. Heat resistant polymers are extensively used in various automotive applications, including under-the-hood components such as engine covers, air intake manifolds, and radiator end tanks.

The aerospace and defense segment is expected to grow at the fastest CAGR over the forecast period from 2024 to 2030 driven by the aerospace industry’s stringent requirements for materials that can perform reliably under extreme conditions, including high temperatures, pressure, and exposure to aggressive chemicals.

The UK heat resistant polymer market is experiencing steady growth, driven by the country’s focus on innovation and high-performance materials.

Global Heat Resistant Polymer Market Segmentation

This report forecasts revenue & volume growth of the Heat Resistant Polymer market and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global agrochemicals market report based on application, end use and region:

Product Outlook (Volume, Kilo Tons; Revenue, USD Million, 2018 - 2030)

Fluoropolymer

Polyphenylene Sulfide

Polyimides

Polybenzimidazole

Polyether Ether Ketone

Others

End Use Outlook (Volume, Kilo Tons; Revenue, USD Million, 2018 - 2030)

Transportation

Electronics & Electrical

Others

Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Mexico

Europe

UK

Germany

France

Italy

Spain

Russia

Denmark

Sweden

Norway

Asia Pacific

Japan

China

India

Thailand

South Korea

Latin America

Brazil

Argentina

Middle East & Africa

South Africa

Saudi Arabia

UAE

Order a free sample PDF of the Heat Resistant Polymer Market Intelligence Study, published by Grand View Research.

0 notes

Text

2032, Fuel Marker Market Growth and Research Report by Reports and Insights

The Reports and Insights, a leading market research company, has recently releases report titled “Fuel Marker Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2031.” The study provides a detailed analysis of the industry, including the global Fuel Marker Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Fuel Marker Market?

The global fuel marker market is expected to register a revenue CAGR of 4.6% during the forecast period.

What are Fuel Marker?

A fuel marker is a chemical additive included in petroleum products like gasoline and diesel to signify their source, quality, or tax status. While these markers are typically invisible, they can be identified and analyzed using specialized equipment. By aiding in the distinction between legally and illegally sourced fuels, fuel markers assist authorities in combating fuel fraud, such as smuggling and tax evasion. Moreover, they help ensure adherence to environmental regulations and quality standards by verifying the genuineness and composition of fuel products.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2066

What are the growth prospects and trends in the Fuel Marker industry?

The fuel marker market growth is driven by various factors. The global fuel marker market is on a notable growth trajectory, primarily fueled by the escalating demand to tackle fuel fraud while ensuring adherence to fuel quality standards and tax regulations. This growth is propelled by the stringent regulatory frameworks and enforcement actions adopted by governments worldwide to address challenges like fuel smuggling, tax evasion, and environmental issues. As a result, there is an increasing adoption of fuel markers by petroleum companies, governments, and regulatory bodies to authenticate the origin, quality, and tax compliance of fuels, thereby stimulating market expansion. Furthermore, continuous technological advancements, including the development of more advanced marker formulations and detection techniques, are further propelling the market forward. Hence, all factors contribute to fuel marker market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Marker Type:

Molecular Markers

Isotopic Markers

Nano-Markers

Others

Application:

Tax Compliance

Fuel Adulteration Detection

Quality Control

Supply Chain Security

Environmental Regulations

End-User:

Oil & Gas Industry

Government Agencies

Fuel Producers

Fuel Distributors

Others

Technology:

Spectroscopy

Chromatography

Mass Spectrometry

Polymerase Chain Reaction (PCR)

Others

Formulation:

Liquid Markers

Powder Markers

Solvent-Based Markers

Others

Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

The U.K.

France

Spain

Italy

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Who are the key players operating in the industry?

The report covers the major market players including:

DieselDye

SGS Fuel Marking

Tracerco

GMP SA

SICPA

Allexis

Authentix

Innospec Inc.

John Hogg & Co Ltd.

The Dow Chemical Company

View Full Report: https://www.reportsandinsights.com/report/Fuel Marker-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

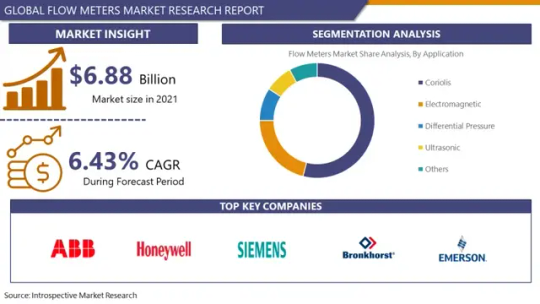

Flow Meters Market: Global Industry Analysis and Forecast 2023 – 2030

Global Flow Meters Market was valued at USD 6.88 Billion in 2021 and is expected to reach USD 10.64 Billion by the year 2028, at a CAGR of 6.43% .

The flow meters market is witnessing robust growth propelled by increasing demand from various industries such as oil and gas, water and wastewater, chemicals, and pharmaceuticals. Flow meters play a critical role in measuring the flow rate of liquids or gases in pipelines, aiding in process optimization, efficiency enhancement, and regulatory compliance. With technological advancements, the market is experiencing a shift towards digital flow meters equipped with advanced features like remote monitoring, wireless connectivity, and data analytics capabilities.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/15846

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

Leading players involved in the Flow Meters Market include:

ABB Ltd, Siemens AG, Bronkhorst High-Tech BV, Honeywell International Inc., Emerson Electric Co., SICK AG, Omega Engineering Inc. (Spectris PLC), Christian Bürkert GmbH & Co. KG, TSI Incorporated, Keyence Corporation, Sensirion AG, Azbil Corporation, Endress+Hauser AG, KROHNE Messtechnik GmbH and Other major Players.

If You Have Any Query Flow Meters Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/15846

Segmentation of Flow Meters Market:

By Technology

Coriolis

Electromagnetic

Differential Pressure

Ultrasonic

Others

By End-User

Oil & Gas

Water & Wastewater

Chemical & Petrochemical

Food & Beverage

Power Generation

Pulp & Paper

Other

Market Segment by Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

What to Expect in Our Report?

(1) A complete section of the Flow Meters market report is dedicated for market dynamics, which include influence factors, market drivers, challenges, opportunities, and trends.

(2) Another broad section of the research study is reserved for regional analysis of the Flow Meters market where important regions and countries are assessed for their growth potential, consumption, market share, and other vital factors indicating their market growth.

(3) Players can use the competitive analysis provided in the report to build new strategies or fine-tune their existing ones to rise above market challenges and increase their share of the Flow Meters market.

(4) The report also discusses competitive situation and trends and sheds light on company expansions and merger and acquisition taking place in the Flow Meters market. Moreover, it brings to light the market concentration rate and market shares of top three and five players.

(5) Readers are provided with findings and conclusion of the research study provided in the Flow Meters Market report.

Our study encompasses major growth determinants and drivers, along with extensive segmentation areas. Through in-depth analysis of supply and sales channels, including upstream and downstream fundamentals, we present a complete market ecosystem.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=15846

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assisting our clients to grow and have a successful impact on the market. Our team at IMR is ready to assist our clients to flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, that specializes in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyse extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1047

Email: [email protected]

#Flow Meters#Flow Meters Market#Flow Meters Market Size#Flow Meters Market Share#Flow Meters Market Growth#Flow Meters Market Trend#Flow Meters Market segment#Flow Meters Market Opportunity#Flow Meters Market Analysis 2023

0 notes

Text

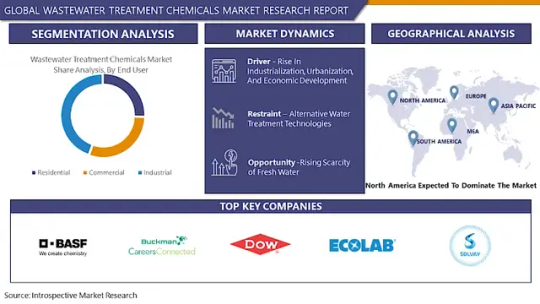

Wastewater Treatment Chemicals Market: Global Industry Analysis and Forecast 2023 – 2030

The Global Market for Wastewater Treatment Chemicals Estimated at USD 13.48 Billion In the Year 2022, Is Projected To Reach A Revised Size Of USD 22.31 Billion By 2030, Growing At A CAGR Of 6.5% Over The Forecast Period 2023-2030.

The wastewater treatment chemicals market plays a pivotal role in addressing the global water crisis by facilitating the purification of wastewater before its safe discharge into the environment. With rapid industrialization, urbanization, and increasing environmental regulations worldwide, the demand for effective wastewater treatment solutions continues to escalate. Wastewater treatment chemicals encompass a diverse range of products including coagulants, flocculants, disinfectants, pH adjusters, and others, each serving a specific purpose in the treatment process. Industries such as municipal, industrial manufacturing, oil & gas, and pharmaceuticals heavily rely on these chemicals to ensure compliance with environmental standards and mitigate pollution risks.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/16614

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

Leading players involved in the Wastewater Treatment Chemicals Market include:

BASF SE (Germany), Ecolab (U.S.), Solenis (U.S.), Kemira Oyj (Finland), Baker Hughes (Germany), The Dow Chemical Company (U.S.), Cortec Corporation (U.S.), Buckman (U.S.), Solvay S.A (Belgium), Kurita Water Industries (Japan), Veolia (France), Somicon ME FZC (UAE), Toray Industries, Inc. (India), Daiki Axis (India), and Other Major Players

If You Have Any Query Wastewater Treatment Chemicals Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/16614

Segmentation of Wastewater Treatment Chemicals Market:

By Type

Coagulants & Flocculants

Corrosion & Scale Inhibitors

Chelating Agents

Biocides & Disinfects

By End-User

Residential

Commercial

Industrial

By Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

What to Expect in Our Report?