#Cellular Rubber Market

Explore tagged Tumblr posts

Text

Cellular Rubber Market Dynamics: An In-Depth Examination of Key Players

Definition:

Cellular rubber, often referred to as foam rubber or sponge rubber, is a versatile material characterized by its open-cell structure. This rubber variant is made by introducing gas into a rubber compound during its production, creating a cellular matrix with interconnected voids. These voids make cellular rubber lightweight and flexible, allowing it to compress and expand under pressure. Cellular rubber finds applications across various industries, thanks to its unique properties, including cushioning, insulation, and sealing capabilities.

Market Overview & Scope:

The cellular rubber market has witnessed steady growth in recent years, owing to its extensive range of applications. Its ability to effectively seal out moisture, air, and dust, along with its shock-absorbing and insulating qualities, make it an essential material in industries like automotive, construction, electronics, and aerospace. The market's scope encompasses a wide array of product types, including natural rubber, neoprene, silicone, and EPDM (ethylene propylene diene monomer) cellular rubber.

Moreover, the cellular rubber market is not confined to a specific geographic region but has a global presence. Companies and manufacturers worldwide contribute to this market, ensuring a diverse and competitive landscape. Its versatility and adaptability make cellular rubber a key component in various products, from gaskets and seals to automotive weatherstripping and acoustic insulation.

Market Growth:

The cellular rubber market has experienced consistent growth over the years, driven by increasing demand for lightweight, durable, and high-performance materials. As industries continue to prioritize energy efficiency and noise reduction, cellular rubber's role in improving insulation and sealing solutions has become increasingly significant. Additionally, the expansion of the automotive sector, coupled with growing construction and electronics industries, has further propelled the demand for cellular rubber products.

With advancements in material technology and manufacturing processes, cellular rubber has evolved to meet the demands of emerging markets. Its ability to adapt to new applications, such as in renewable energy and medical devices, is expected to contribute to sustained growth in the coming years.

Market Industry:

The cellular rubber market industry encompasses a wide range of players, including raw material suppliers, manufacturers, distributors, and end-users. Manufacturers in this sector continuously innovate to produce cellular rubber with tailored properties and specifications, ensuring it meets the unique requirements of various applications.

In the automotive industry, cellular rubber is employed in gaskets and seals to provide enhanced weatherproofing and noise reduction. In the construction sector, it is used for insulation and sealing purposes, helping improve energy efficiency and building durability. The electronics industry relies on cellular rubber for vibration isolation and protection against moisture and electromagnetic interference. The aerospace sector utilizes cellular rubber for lightweighting and shock absorption in critical components.

Market Trends:

Several key trends influence the cellular rubber market's trajectory. Sustainability and environmental consciousness have become paramount, leading to a shift towards eco-friendly cellular rubber formulations. This trend aligns with the broader sustainability goals of many industries, as they seek to reduce their carbon footprint.

Furthermore, customization and the development of niche applications are on the rise. Manufacturers are increasingly tailoring cellular rubber products to meet specific requirements in sectors like healthcare, renewable energy, and consumer goods.

As technology advances, so does the cellular rubber industry. Smart materials with embedded sensors and self-healing capabilities are emerging, opening up new possibilities in sectors like transportation and infrastructure.

In conclusion, the cellular rubber market is characterized by its versatility and adaptability, with a broad scope that encompasses various industries. It continues to experience growth, driven by the increasing demand for efficient sealing, insulation, and lightweight materials, and is shaped by industry trends that emphasize sustainability, customization, and technological innovation.

0 notes

Text

#Cellular Rubber Market share#Cellular Rubber Market size#Cellular Rubber Market price#Cellular Rubber Market forecast

0 notes

Text

Saucony x Bodega Unveil Exclusive Sneaker Collaboration: Limited-Edition Launch

Saucony, a leading global performance running lifestyle brand, has just announced its first collaboration of the year with its long-time partner and renowned curator of fashion and streetwear, Bodega. The limited-edition Bodega x Saucony Grid Shadow 2 'Jaunt Woven' sneaker combines stone-washed 18oz canvas, hemp, and cotton with rope laces, embodying a design ethos inspired by aimless adventure. The color scheme, reminiscent of earth tones and organic textures, features hints of Acid Lime and Red Alert, making it perfect for the new-age hippie.

Jason Faustino, Saucony's Senior Brand Marketing Manager, explains, "We took a signature Saucony design that has only previously been sold in athletic shoe materializations and focused on a connection to the earth using all-natural materials. The design journey was aimed at mellowing out and breaking away from the stress and pressure of footwear design set by a long lineage of collaborations with Bodega, resulting in a premium release for free spirits."

The sneaker, primarily made from woven hemp and featuring natural hues, owes its definition to the contrasting weaves. The subtle distinctions in grain, from the loose gauge weave used on the toe and mid-foot to the cellular overlays and plain-woven tongue, serve as the perfect focal point.

Bodega adds, "We're excited to kick off our first footwear collaboration of 2024 with our friends at Saucony. Given the storied history and creativity between the brands, it's fitting to return to the essence of our partnership, building our Grid Shadow 2 'Jaunt Woven' from the Earth up. The laid-back aesthetic and focus on materials solidifies the 'Jaunt Woven' as the next chapter in our collaborative story that we think will become a favorite in any sneaker lover's collection."

Inspired by nature and stripped away of the unnecessary, the sneaker boasts environmentally friendly design elements, including a molded EVA midsole cushioning with a speckled heel that looks like waves pulling you toward a recycled gum rubber outsole. The recycled mesh tongue, collar liner, and brushed nylex footbed cover contribute to both style and sustainability.

This release marks another milestone in the long lineage of successful collaborations between Saucony and Bodega. Bodega has been curating the finest selection of footwear, apparel, and accessories for men and women since 2006, through both brick-and-mortar and e-commerce retail.

To shop the collection, visit bdgastore.com beginning Friday, Feb. 23, and saucony.com beginning March 1.

4 notes

·

View notes

Text

3D Printing Materials Market Valued at USD 2,836.6 Million in 2025

Exploring the Dynamic World of 3D Printing Materials Market 2034

The world of 3D Printing Materials Market has come a long way since its inception, evolving from a niche technology to a mainstream manufacturing process. At the heart of this transformation is the ever-expanding universe of 3D printing materials. These materials are not just a means to an end; they are pivotal in defining what can be created, how it can be produced, and what industries can benefit from this cutting-edge technology. In this blog, we will delve into the key aspects of the 3D printing materials market, exploring the types, applications, and future trends shaping this exciting field.

Sample copy report:

https://wemarketresearch.com/reports/request-free-sample-pdf/3d-printing-materials-market/1338

Types of 3D Printing Materials

Thermoplastics: Thermoplastics are among the most widely used materials in 3D printing. They are known for their ease of use, affordability, and versatility. Popular thermoplastics include:

PLA (Polylactic Acid): Known for its eco-friendly nature and ease of printing, PLA is a favorite among hobbyists and beginners.

ABS (Acrylonitrile Butadiene Styrene): This material offers greater strength and durability, making it ideal for functional prototypes and end-use parts.

PETG (Polyethylene Terephthalate Glycol): Combining the ease of printing with durability, PETG is commonly used in applications requiring resistance to impact and moisture.

Resins: Resins are liquid materials that solidify under UV light and are used primarily in SLA (Stereolithography) and DLP (Digital Light Processing) printers. They offer high resolution and detail, making them suitable for applications such as jewelry and dental products. Key types include:

Standard Resins: Ideal for detailed models and prototypes.

Tough Resins: Engineered for increased durability and impact resistance.

Flexible Resins: Designed to produce parts with rubber-like properties.

Metals: Metal 3D printing is used for high-performance applications in industries such as aerospace, automotive, and medical. Metal powders, such as titanium, aluminum, and stainless steel, are used in processes like SLM (Selective Laser Melting) and EBM (Electron Beam Melting). Metal 3D printing offers:

High Strength-to-Weight Ratio: Essential for aerospace and automotive components.

Complex Geometries: Allows for the creation of intricate designs that are difficult to achieve with traditional manufacturing methods.

Composites: Composite materials combine thermoplastics with reinforcing fibers, such as carbon fiber or glass fiber, to enhance strength and rigidity. These materials are used in applications where lightweight and high strength are critical, including in the automotive and sports equipment industries.

Innovations Driving the 3D Printing Materials Market

The 3D printing materials market is experiencing rapid innovation, driven by advancements in technology and changing industry needs. Here’s a closer look at some of the latest innovations that are transforming the landscape of 3D printing materials:

Nanomaterials: Nanotechnology is making waves in the 3D printing industry by enabling the creation of materials with enhanced properties at the nanoscale. Nanomaterials can improve strength, durability, and thermal resistance, making them ideal for high-performance applications. For example, incorporating nanoparticles into polymers can enhance their mechanical properties, leading to more robust and reliable printed parts.

Bio-inks and Bioprinting: Bioprinting is revolutionizing the medical and research fields by enabling the creation of living tissues and organs. Bio-inks, which are made from natural and synthetic biopolymers, are used in this process to print cellular structures. These materials can be tailored to support cell growth and tissue development, opening up new possibilities for regenerative medicine and personalized healthcare.

Applications of 3D Printing Materials Market

The versatility of 3D printing materials market has led to their adoption across various sectors:

Aerospace: Lightweight and durable materials are used to manufacture complex parts and components, reducing overall weight and fuel consumption.

Healthcare: Custom prosthetics, implants, and dental products are tailored to individual patients using biocompatible materials.

Automotive: 3D printing enables rapid prototyping and production of lightweight parts, enhancing vehicle performance and reducing time-to-market.

Consumer Goods: Customized products, from eyewear to home decor, benefit from the flexibility and personalization offered by 3D printing.

Future Trends in 3D Printing Materials Market

As the 3D printing industry continues to evolve, several trends are likely to shape the future of 3D printing materials:

Biodegradable and Sustainable Materials: There is a growing focus on developing eco-friendly materials that reduce environmental impact. Innovations in biodegradable plastics and recycling processes are set to make 3D printing more sustainable.

Advanced Metal Alloys: The development of new metal alloys with enhanced properties will open up new possibilities for high-performance applications in industries such as aerospace and defense.

Multi-Material Printing: Advances in multi-material printing technologies will allow for the creation of complex objects with varying properties in a single print, expanding the range of applications and functionalities.

Smart Materials: The integration of materials that respond to environmental changes (such as temperature or pressure) will lead to the development of "smart" products with adaptive capabilities.

Benefits of 3D Printing Materials Market Report:

Analyst Support: Get your query resolved by our expert analysts before and after purchasing the report.

Customer Satisfaction: Our expert team will assist with all your research needs and customize the report.

Inimitable Expertise: Analysts will provide deep insights into the reports.

Assured Quality: We focus on the quality and accuracy of the report.

Conclusion

The 3D printing materials market is a dynamic and rapidly evolving field, driven by continuous innovation and Technological Advancements. From thermoplastics and resins to metals and composites, the variety of materials available today provides limitless possibilities for creators and manufacturers alike. As we look to the future, emerging trends and new material developments promise to further revolutionize the industry, offering exciting opportunities for growth and transformation across various sectors. Whether you're a hobbyist, a designer, or an industry professional, staying informed about these advancements will be key to leveraging the full potential of 3D printing technology.

#3D Printing Materials Analysis#3D Printing Materials Demand#Market Insights 3D Printing#3D Printing Materials Future

0 notes

Text

0 notes

Text

Azodicarbonamide Price Trend, Chart and Report

Azodicarbonamide, often abbreviated as ADA, is a chemical compound primarily used as a blowing agent in the production of foamed plastics and rubber. Despite its widespread industrial applications, azodicarbonamide has garnered attention due to health and safety concerns associated with its use in food products. Understanding the Azodicarbonamide Price Trend is essential for industries reliant on its production and consumers wary of its presence in various goods.

Health and Safety Concerns

Azodicarbonamide has been the subject of controversy due to its potential health risks. In some countries, including the European Union and Australia, its use as a food additive is banned due to concerns about its breakdown products, which may include semicarbazide, a compound classified as a potential carcinogen. Additionally, inhalation of azodicarbonamide dust during its handling in industrial settings may cause respiratory issues.

Enquire For Regular Prices: https://www.procurementresource.com/resource-center/azodicarbonamide-price-trends/pricerequest

Industrial Applications

Despite its health concerns, azodicarbonamide continues to be widely used in industrial processes. Its primary function as a blowing agent makes it invaluable in the production of foamed plastics and rubber materials. By generating gas when heated, azodicarbonamide expands the polymer matrix, resulting in a cellular structure that enhances the material's insulation properties and reduces weight.

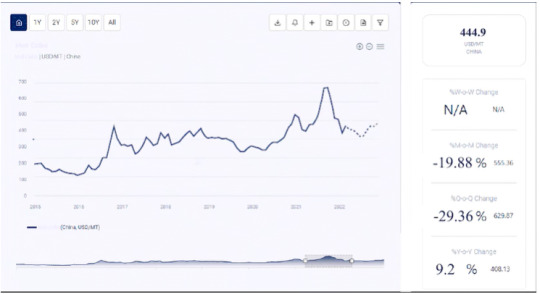

Price Trends of Azodicarbonamide

The price of azodicarbonamide fluctuates based on several factors, including raw material costs, market demand, and regulatory developments. The availability and cost of precursor chemicals used in its synthesis, such as urea and azobisisobutyronitrile (AIBN), significantly influence its price. Additionally, changes in regulations impacting its use in food and industrial applications can affect market dynamics and prices.

Factors Influencing Azodicarbonamide Prices

Several factors contribute to the volatility of azodicarbonamide prices. Fluctuations in crude oil prices influence the cost of raw materials, while shifts in demand from industries such as packaging, automotive, and construction impact market conditions. Regulatory changes regarding its use in food products and increased scrutiny of its safety profile may also affect demand and pricing.

Impact on Industries and Consumers

The price trends of azodicarbonamide have implications for both industries and consumers. Industries reliant on foamed plastics and rubber, such as packaging manufacturers and automotive suppliers, closely monitor price fluctuations to manage production costs and maintain competitiveness. Consumers, particularly those concerned about food safety, may seek alternatives to products containing azodicarbonamide, influencing purchasing decisions and market demand.

Future Outlook for Azodicarbonamide Prices

The future trajectory of azodicarbonamide prices is influenced by various factors, including regulatory developments, technological advancements, and market demand. As concerns about its safety persist, regulatory agencies may impose stricter regulations or bans on its use in certain applications, affecting market dynamics and prices. Technological innovations in alternative blowing agents or manufacturing processes could also impact the demand and pricing of azodicarbonamide in the long term.

The future trajectory of azodicarbonamide prices is influenced by various factors, including regulatory developments, technological advancements, and market demand. As concerns about its safety persist, regulatory agencies may impose stricter regulations or bans on its use in certain applications, affecting market dynamics and prices. Technological innovations in alternative blowing agents or manufacturing processes could also impact the demand and pricing of azodicarbonamide in the long term.

Given the increasing scrutiny on chemical additives in consumer products and growing awareness of health and safety issues, the demand for azodicarbonamide may face challenges. Regulatory agencies are likely to continue monitoring its use closely, potentially introducing new restrictions or labeling requirements. Additionally, consumer preferences for more natural and sustainable alternatives could drive a shift towards alternative blowing agents or manufacturing methods.

Technological advancements in polymer chemistry and materials science may lead to the development of safer and more cost-effective alternatives to azodicarbonamide. Researchers are exploring novel blowing agents with lower environmental impact and improved performance characteristics. These innovations could disrupt the market for azodicarbonamide and influence its pricing dynamics in the coming years.

Conclusion

Azodicarbonamide plays a crucial role in the production of foamed plastics and rubber materials, despite concerns about its safety and regulatory restrictions in some regions. Monitoring price trends and understanding the factors influencing azodicarbonamide prices is essential for industries reliant on its use and consumers cautious of its presence in various products. As regulatory scrutiny and consumer awareness continue to shape market dynamics, stakeholders must adapt to evolving trends and considerations surrounding azodicarbonamide.

0 notes

Text

What is Hydrogen Peroxide?

Hydrogen peroxide, a chemical that contains water and oxygen, acts as a versatile antibacterial agent. The chemical synthesis of H2O2 was discovered in 1818, and in 1894 Richard Wolfenstein developed a method for its commercial production, which showed an important milestone in its high availability

Hydrogen Peroxide 6%

The antimicrobial activity of this compound is well documented. Able to destroy 99.9% of various microorganisms including viruses such as COVID-19, Hydrogen Peroxide 6% exhibits antibacterial, antifungal, antiviral, antimycobacterial and antibacterial properties Its versatility extends to drugs a for low and high disinfection, depending on its concentration in homes, commercial establishments, schools , health In service industries and is suitable for use in a variety of environments

Notably, hydrogen peroxide provides superior protection for humans and pets in addition to being 50 % environmentally friendly. In effect, excess oxygen attacks microorganisms and damages their membranes, DNA, and other cellular components, rendering them defenceless This feature is the relative defence against hydrogen peroxide establishing itself as the best choice for disinfection and cleaning.

The Centers for Disease Control and Prevention (CDC) supports the use of hydrogen peroxide for disinfection, and provides guidelines for use at concentrations as low as 0.05% for routine cleaning Dosing is recommended of 7.5% for high disinfection, which takes 30 minutes at 20 degrees Celsius is available. It is now mandatory to maintain the same volume for six hours at the same temperature to achieve sterilisation. With a two-year shelf life, hydrogen peroxide is effective for up to 21 days after manufacture.

In its purest form, hydrogen peroxide appears as a pale blue liquid that is slightly thicker than water and has a bitter taste. Originally thought to be unstable due to unsuccessful attempts to separate pure H2O2 from water, this instability was investigated using the required impurities, especially transition-metal salts, which cause rapid decomposition

Hydrogen Peroxide 50%

In some cases, hydrogen peroxide 50% decomposes into water and oxygen, especially when exposed to metallic salts such as nickel, iron, manganese, chromium, copper, and so on. Because it is incombustible, its naturally hot nature can cause it to decay spontaneously, releasing heat and oxygen. Furthermore, its strong oxidising properties can cause spontaneous combustion upon contact with organic matter.

Hydrogen Peroxide 3%

Hydrogen peroxide in various strengths can be found in pharmacies, supermarkets and commercial markets. Typical levels include 3%, commonly used for household items, and 6% for hair whitening. More than 8% to 10% of water finds applications in textiles and paper for bleach, rocket fuel, foam, rubber, and organic chemicals commercially available can range from 50% to even 90%, but consumers must use due to their high volatility and skin-. Caution should be taken due to potential hazards such as eye irritation

Despite its minor drawbacks, hydrogen peroxide 6% is still an effective disinfectant and sanitizer at a cost of 6 % less. Its proven effectiveness continues to make it the highest ranking of disinfectants and cleaners available.

#succession#across the spiderverse#welcome home#wally darling#the mandalorian#the owl house#ted lasso#taylor swift#super mario#star wars

0 notes

Text

The Future of Electric Screwdrivers

This report highlights key production, revenue and gross margin trends among players in the global Electric Screwdriver Market. Additionally, it analyses recent developments such as acquisitions or partnerships within this space.

Manufacturers should prioritize product innovation to introduce advanced features that meet industry requirements and expand into emerging markets to increase sales and boost growth.

1. Robotics

While many small business owners may believe that automated screw driving is only cost-effective for large corporations, robot screw driving has become affordable and accessible to everyone. Although initial costs can be high, most manufacturers find they save enough labor costs with robot screw driving that the investment pays for itself in no time at all.

Manufacturers utilize robotic screwdrivers due to the need for flexibility, quality and throughput. Furthermore, manufacturers aim to track every screw they torque — such as its seat torque, depth of drive or cross threading performance.

2. Artificial Intelligence

Thinking machines have long captivated mankind. Artificial Intelligence has already had a great effect on our daily lives; yet its future remains unclear.

Stripped screw connections can be an issue in End of Life battery systems due to environmental influences and improper maintenance practices. Industrial electric screw drivers and nut runners evaluate unfastening operations binaryly; either OK (ok) or NOK (not okay).

This paper introduces a novel supervised learning-based approach for detecting stripped screw connections during the positive locking phase of unfastening using intrinsic data during positive locking phase of unfastening process. Multilayer perceptrons and convolutional neural networks have proven highly accurate at detecting screw connection state independent of screw drive type and size; its results demonstrate high accuracy and reliability of proposed method.

3. Internet of Things

The global Electric Screwdriver market is highly competitive, with key players focused on product innovation and strategic partnerships to increase their share. IoT integration and wireless connectivity technologies have contributed significantly to its expansion.

Contrasting with traditional screwdrivers that only offer one button and switch, these new devices come equipped with motion sensors and NB-IoT modules that connect to a cellular network allowing real-time updates on their status and location.

4. Automation

Imagine your product moving down your assembly line, stopping at each station that requires different-drive-size screws, where an operator uses different tools to fasten them. Now imagine this process being automated to save time and improve quality!

WEBER’s screwdriving systems make this possible. Equipped with a lightweight payload robot and intelligent screwdriver technology, these solutions allow you to address unique assembly challenges.

5. Energy efficiency

Electric screwdrivers not only make for faster screw fastening than manual versions, but they can also significantly reduce hand fatigue thanks to features like trigger locks and soft or rubberized handles. Some models even allow users to control torque settings more effectively for enhanced control.

Torque settings enable you to tighten and loosen screws without applying excessive force on the tool, as well as decrease the chance that overtightened screws could damage what you are assembling or fixing.

Electric screwdriver batteries are typically measured in milliamp hours (mAh) or amp hours (1Ah). A higher number indicates more runtime; most cordless screwdrivers utilize lithium-ion batteries that can be removed and recharged separately.

0 notes

Text

Cellular Rubber Market Growth, Emerging Business Trends and Research Forecast From 2023-2030

Cellular rubber, also known as sponge rubber or foam rubber, is a type of elastomer material that is characterized by its cellular structure. It is produced by introducing gas bubbles into a liquid rubber compound and then solidifying it through vulcanization or chemical curing.

The cellular structure of rubber is created by incorporating a blowing agent into the rubber compound. When the compound is heated, the blowing agent releases gas, which forms bubbles throughout the material. These bubbles give cellular rubber its unique properties, such as low density, high flexibility, and excellent cushioning and insulation capabilities.

Cellular rubber is commonly used in various applications where its properties are advantageous. Some common uses include:

Sealing and gasketing: Cellular rubber is often used to create seals and gaskets in applications where airtight or watertight seals are required. The compressibility and resilience of the material make it ideal for filling gaps and preventing leakage.

Automotive industry: Cellular rubber is used in automotive applications for sealing doors, windows, and hoods. It helps to provide a tight seal, reducing noise, vibration, and harshness (NVH) levels inside the vehicle.

Cushioning and padding: The soft and flexible nature of cellular rubber makes it suitable for cushioning and padding purposes. It is used in products such as mattresses, pillows, seat cushions, and shock-absorbing materials.

Insulation: Cellular rubber's closed-cell structure provides excellent thermal and acoustic insulation properties. It is used in HVAC (heating, ventilation, and air conditioning) systems, pipes, and other applications where insulation is required.

Packaging and shipping: Cellular rubber is used for protective packaging to cushion delicate items during transportation. It helps to absorb shocks and vibrations, protecting the packaged goods from damage.

Sports and leisure: Cellular rubber is utilized in various sports and leisure applications, such as insoles, yoga mats, exercise mats, and flotation devices, due to its cushioning and shock-absorbing properties.

The cellular rubber market is a segment of the global rubber industry that focuses on the production, distribution, and consumption of cellular rubber materials. The market for cellular rubber has been witnessing steady growth in recent years due to the increasing demand from various end-use industries.

Here are some key factors driving the cellular rubber market:

Growing demand in automotive industry: The automotive sector is one of the major consumers of cellular rubber. The use of cellular rubber in automotive sealing systems, gaskets, and NVH applications has been increasing to enhance comfort, reduce noise, and improve fuel efficiency.

Expansion in construction and infrastructure: The construction industry utilizes cellular rubber for insulation, weatherstripping, and sealing applications. The rapid growth of the construction sector, particularly in developing regions, has contributed to the increased demand for cellular rubber.

Packaging and consumer goods: The use of cellular rubber in protective packaging materials, such as cushioning foams, has witnessed significant growth due to the expansion of the e-commerce industry and the need for safe transportation of goods.

Energy efficiency and insulation requirements: With a growing focus on energy efficiency and insulation in buildings and industrial applications, the demand for cellular rubber as a thermal and acoustic insulator has increased.

Technological advancements: Advancements in cellular rubber manufacturing techniques, such as improved blowing agents, advanced molding processes, and better material formulations, have expanded the range of applications and performance capabilities of cellular rubber.

Environmental regulations and sustainability: The shift towards eco-friendly and sustainable materials has driven the demand for cellular rubber, as it is often recyclable and offers potential energy-saving benefits.

The cellular rubber market is competitive, with several key players operating globally. These companies are involved in research and development activities to develop innovative products and expand their product portfolios. Additionally, strategic collaborations, mergers and acquisitions, and investments in emerging markets are common strategies employed by market players to gain a competitive edge.

Some of the major companies operating in the global cellular rubber market include PANA Foamtec GmbH, GCP, Monmouth Rubber & Plastic Corp, Monmouth Rubber & Plastics Corp, Stockwell Elastomerics, Rogers Foam Corp, American Foam Rubber, LP, Saint Gobain Performance Plastics, Foam Rubber LLC, Metro Industries, and Ace Hose & Rubber Co. McMaster-Carr.

The cellular rubber market has been experiencing steady growth over the past few years, and it is expected to continue growing at a healthy rate in the coming years. Several factors contribute to the growth of the cellular rubber market:

Increasing demand from end-use industries: The demand for cellular rubber is rising across various end-use industries such as automotive, construction, packaging, and consumer goods. The automotive industry, in particular, is a significant driver of growth due to the need for sealing systems, gaskets, and NVH solutions. The expanding construction sector and the growing e-commerce industry also contribute to the market's growth.

Technological advancements and product innovations: Ongoing advancements in cellular rubber manufacturing techniques, including improved blowing agents and enhanced material formulations, have resulted in the development of high-performance products. Manufacturers are focusing on developing cellular rubber with improved properties such as higher durability, better insulation, and increased resistance to chemicals and temperature variations. These innovations are driving market growth by expanding the range of applications and increasing customer adoption.

Energy efficiency and sustainability initiatives: Increasing awareness of energy efficiency and sustainability has led to the adoption of cellular rubber as an insulation material in buildings, HVAC systems, and industrial applications. Cellular rubber offers excellent thermal and acoustic insulation properties, which can help reduce energy consumption and improve overall energy efficiency. Additionally, cellular rubber is often recyclable and contributes to sustainability efforts, further driving its demand.

Growing construction and infrastructure activities: The construction industry is a significant consumer of cellular rubber products for applications such as weatherstripping, gaskets, and sealing materials. The rapid growth of the construction sector, particularly in emerging economies, is fueling the demand for cellular rubber. Infrastructure development projects, including transportation and utilities, also contribute to market growth.

Increasing urbanization and lifestyle changes: Urbanization and changing lifestyles have led to a rise in consumer demand for comfort, convenience, and improved living standards. Cellular rubber products, such as cushioning foams for mattresses, pillows, and seating applications, cater to these demands, driving market growth.

Regional market expansion: The cellular rubber market is expanding globally, with emerging economies witnessing significant growth due to industrialization, urbanization, and infrastructure development. Asia-Pacific, in particular, is a key region for market growth, driven by countries like China, India, and Southeast Asian nations.

The demand for cellular rubber in the market is influenced by various factors and driven by the needs of different industries. Here are some key factors impacting the demand for cellular rubber:

Automotive industry: The automotive sector is a major consumer of cellular rubber products. The demand for cellular rubber in this industry is driven by the need for sealing systems, gaskets, vibration dampening, and noise reduction. As the automotive industry continues to grow, particularly in emerging economies, the demand for cellular rubber is expected to increase.

Construction and infrastructure: The construction industry is a significant consumer of cellular rubber for applications such as weatherstripping, sealing, and insulation. The demand for cellular rubber in construction is driven by factors such as energy efficiency requirements, infrastructure development projects, and the need for sound and thermal insulation in buildings.

Packaging and consumer goods: Cellular rubber is used in packaging materials to provide cushioning and protection during transportation. With the rise of e-commerce and the need for safe packaging, the demand for cellular rubber as a protective packaging material has increased. Additionally, cellular rubber is used in consumer goods such as mattresses, pillows, and seating cushions, driving demand from the consumer goods industry.

Industrial applications: Cellular rubber finds applications in various industrial sectors for insulation, sealing, and gasketing purposes. Industries such as HVAC (heating, ventilation, and air conditioning), appliances, electronics, and machinery utilize cellular rubber for its thermal and acoustic insulation properties, as well as its ability to provide sealing solutions.

Energy efficiency and sustainability: Increasing emphasis on energy efficiency and sustainability in various industries has driven the demand for cellular rubber. Cellular rubber's thermal insulation properties contribute to energy conservation in buildings, HVAC systems, and industrial applications. Moreover, cellular rubber is often recyclable, aligning with sustainability initiatives.

Emerging markets: The demand for cellular rubber is growing significantly in emerging markets, particularly in Asia-Pacific and Latin America. Rapid industrialization, urbanization, and infrastructure development in these regions are driving the demand for cellular rubber in various applications.

Cellular rubber finds a wide range of applications across various industries due to its unique properties. Some of the key applications of cellular rubber include:

Sealing and gasketing: Cellular rubber is commonly used for sealing and gasketing applications due to its excellent compressibility and resilience. It is used in industries such as automotive, aerospace, appliances, and machinery to create airtight and watertight seals.

Automotive industry: Cellular rubber is widely used in the automotive sector for applications such as weatherstripping, door and window seals, gaskets, and NVH (noise, vibration, and harshness) solutions. It helps to provide a tight seal, reduce noise transmission, and improve comfort in vehicles.

Insulation: Cellular rubber's closed-cell structure makes it an excellent thermal and acoustic insulator. It is used in HVAC systems, pipes, appliances, and construction applications to provide insulation and energy efficiency.

Cushioning and shock absorption: Cellular rubber's flexible and resilient nature makes it suitable for cushioning and shock-absorbing applications. It is used in products such as mattresses, pillows, seat cushions, shoe insoles, sports equipment, and packaging materials to provide comfort and protect against impacts and vibrations.

Packaging and shipping: Cellular rubber is used as a protective packaging material to cushion fragile items during transportation. It absorbs shocks and vibrations, reducing the risk of damage to the packaged goods.

Construction and building industry: Cellular rubber is used in the construction industry for applications such as weatherstripping, expansion joints, sealing profiles, and insulation. It helps to seal gaps, prevent air and water leakage, and provide thermal and acoustic insulation in buildings.

Electrical and electronics: Cellular rubber is utilized in electrical and electronics applications for gasketing, sealing, and vibration isolation. It helps to protect sensitive electronic components from environmental factors and reduce vibrations that can impact performance.

Marine and offshore applications: Cellular rubber is resistant to water, chemicals, and UV radiation, making it suitable for marine and offshore applications. It is used for sealing, gasketing, insulation, and vibration isolation in marine equipment, offshore structures, and shipbuilding.

Aerospace industry: Cellular rubber is employed in the aerospace industry for sealing, gasketing, vibration damping, and insulation applications. It helps to meet stringent requirements for safety, performance, and weight reduction in aerospace components and systems.

Medical and healthcare: Cellular rubber is used in medical and healthcare applications such as prosthetics, orthopedic devices, medical equipment, and protective padding. It provides comfort, cushioning, and protection in these applications.

The cellular rubber market offers several advantages, making it a preferred choice in various industries. Here are some key advantages of cellular rubber:

Lightweight: Cellular rubber has a low density due to its cellular structure, making it lightweight. This property is beneficial in applications where weight reduction is desired, such as automotive and aerospace industries, as it helps improve fuel efficiency and reduce overall weight without compromising on performance.

Excellent cushioning and shock absorption: Cellular rubber exhibits excellent cushioning and shock-absorbing properties, making it suitable for applications where impact protection is required. It helps absorb and dissipate energy from impacts, reducing the risk of damage to products, machinery, or structures. This advantage is valuable in applications like packaging, automotive components, sports equipment, and protective padding.

Flexibility and resilience: Cellular rubber is highly flexible and resilient, allowing it to adapt to various shapes and recover its original form after compression. This property enables it to provide effective sealing and gasketing solutions, filling gaps and irregularities to create a tight and reliable seal. It also contributes to the comfort and durability of products like mattresses, seat cushions, and footwear.

Thermal and acoustic insulation: The closed-cell structure of cellular rubber provides excellent thermal and acoustic insulation properties. It helps to minimize heat transfer and sound transmission, making it suitable for insulation applications in buildings, HVAC systems, pipes, and industrial equipment. Cellular rubber can contribute to energy efficiency and noise reduction.

Chemical and weather resistance: Cellular rubber exhibits resistance to various chemicals, oils, weathering, and UV radiation. This property makes it suitable for use in demanding environments, such as marine, offshore, automotive, and industrial applications, where exposure to harsh conditions is common. Cellular rubber can maintain its performance and integrity over extended periods.

Versatility in material formulation: Cellular rubber can be formulated with different materials and additives to achieve specific properties and meet diverse application requirements. This versatility allows for customization of cellular rubber products in terms of density, hardness, flame retardancy, electrical conductivity, and other performance characteristics.

Easy fabrication: Cellular rubber is easy to fabricate into desired shapes and sizes. It can be cut, molded, extruded, or die-cut, making it adaptable to various manufacturing processes and enabling the production of complex shapes and intricate designs. This ease of fabrication contributes to cost-effectiveness and efficient manufacturing processes.

Environmental sustainability: Cellular rubber is often recyclable, contributing to environmental sustainability. It can be reused or recycled into new products, reducing waste and promoting a circular economy.

These advantages make cellular rubber a versatile and desirable material in several industries, providing benefits such as weight reduction, impact protection, sealing efficiency, insulation, and resistance to harsh conditions.

0 notes

Text

Polymer Foam Market Poised for Steady Growth and Promising Future by 2029

Polymer Foam Market size was valued at US$ 94.96 Bn. in 2021 and the total Polymer Foam revenue is expected to grow at 4.7% from 2022 to 2029, reaching nearly US$ 137.12 Bn.

Polymer Foam Market Overview

A number of elements are examined in the report, including the impact of domestic and localized players on the marketplace, rising sales pockets, changes in the marketplace regulations, strategic analysis of the Polymer Foam Market , market size, market class growth, utility niches, and dominance, product approvals, new product introductions, and geographies.

A foam made of polymers, which can be liquid or solidified, is referred to as polymeric foam. Due to its outstanding strength-to-weight ratio, superior thermal and acoustic insulating properties, capacity for energy absorption, and strong cushioning and comfort properties, polymeric foam has seen a sharp increase in demand in recent years. Expanded rubbers, cellular elastomers, or sponges make up polymeric foams.

Download Free Sample Report @ https://www.maximizemarketresearch.com/request-sample/24731

Market Scope

Polymer Foam Market the report gives an in-depth understanding and knowledge of trends, dynamics, and other issues. The study pinpoints the most significant developments that will have an impact on the industry. It assists in identifying the information included in the study, as well as assessing the competitive landscape of important firms, market dynamics, and other things that can help you determine whether your current marketing plans are on track and how to improve them.

The qualitative and quantitative data in the Polymer Foam Market report assist decision-makers in determining which market segments, regions, and variables driving the market are likely to develop at higher rates, as well as major opportunity areas.

Polymer Foam Market Segmentation

The segment for polystyrene foam is anticipated to expand at a CAGR over the course of the forecast period. It is used in many different products, such as carpets, pillows, and furniture. It has a sizable clientele as a result of its exceptional qualities, which include insulation, high energy dissipation, moderate flame and sound transfer, and lightweight. It is anticipated that the demand for building applications will increase as a result of the rising demand for residential and commercial space in Southeast Asian countries like Singapore, Korea, and Indonesia.

Due to the growing use of polymer foam for soundproofing, flooring, pipes, molding, and wire & cables during the forecast period, the building and construction segment is anticipated to expand a CAGR . The furniture and bedding industry is likely to grow as a result of rising demand from applications such as carpet padding, fibers, seat cushions, bed padding, and furniture.

Get Full Toc @ https://www.maximizemarketresearch.com/request-sample/33278

Key Players • BASF SE • Rogers Corporation • The Dow Chemical Company • Recticel NV/SA • Sealed Air Corporation • Huntsman International LLC • Armacell International S.A. • Zotefoams plc • Covestro AG • JSP Corporation • Kaneka Corporation • Hanwha Chemical Corporation • Arkema • Borealis AG • Sabic • Toray Industries, Inc. • Synthos • Celanese Corporation • Sekisui Alveo

Regional Analysis

Europe, North America, Asia-Pacific, the Middle East and Africa, and Latin America are the five regions that make up the Polymer Foam Market . The regional analysis provided in our report helps you understand the Polymer Foam Market in different regions. Every region has different factors such as political, geographic, economic, etc. which are affecting the Polymer Foam Market . Local and regional development plans are often affected by the performance of Polymer Foam Market . The reports help in planning the market strategies which are suitable and appropriately applicable according to specific countries and regions in the market.

Key Questions answered in the Polymer Foam Market Report are:

What is Polymer Foam Market ?

What is the forecast period of the Polymer Foam Market ?

What is the competitive scenario of the Polymer Foam Market ?

Which region held the largest market share in the Polymer Foam Market ?

What are the opportunities for the Polymer Foam Market ?

What are the restraining factors in the Polymer Foam Market ?

Who are the key players of the Polymer Foam Market ?

To Gain More Insights into the Market Analysis, Browse Summary of the Research Report @ https://www.maximizemarketresearch.com/request-sample/33278

Key offerings:

Market Share, Size, and Forecast by Revenue|2022-2029

Market Dynamics- Growth drivers, Restraints, Investment Opportunities, and key trends

Market Segmentation: A detailed analysis by Polymer Foam Market

Landscape- Leading key players and other prominent key players.

About Maximize Market Research:

Maximize Market Research is a multifaceted market research and consulting company with professionals from several industries. Some of the industries we cover include medical devices, pharmaceutical manufacturers, science and engineering, electronic components, industrial equipment, technology, and communication, cars, and automobiles, chemical products and substances, general merchandise, beverages, personal care, and automated systems. To mention a few, we provide market-verified industry estimations, technical trend analysis, crucial market research, strategic advice, competition analysis, production and demand analysis, and client impact studies.

Contact Maximize Market Research:

3rd Floor, Navale IT Park, Phase 2

Pune Banglore Highway, Narhe,

Pune, Maharashtra 411041, India

+91 96071 95908, +91 9607365656

0 notes

Link

0 notes

Text

Global Cellular Rubber Market Report 2021 - Industry Share, Trends, Growth Insights, SWOT and PESTLE analysis by Top Key Vendors and Forecast to 2026

Global Cellular Rubber Market Report 2021 – Industry Share, Trends, Growth Insights, SWOT and PESTLE analysis by Top Key Vendors and Forecast to 2026

Global Cellular Rubber Market Report also provides exclusive crucial statistics,data, trends and competitive details in this niche sector. The Global Cellular Rubber Market is a professional and comprehensive report on the Cellular Rubber industry.The report notice the key patterns and market drivers in the flow situation and offers on-the-ground experiences. With tables and figures helping…

View On WordPress

0 notes

Text

3D Printing Materials Market Analysis, Trends and Dynamic Demand by Forecast 2024 to 2033

Exploring the Dynamic World of 3D Printing Materials Market

The world of 3D Printing Materials Market has come a long way since its inception, evolving from a niche technology to a mainstream manufacturing process. At the heart of this transformation is the ever-expanding universe of 3D printing materials. These materials are not just a means to an end; they are pivotal in defining what can be created, how it can be produced, and what industries can benefit from this cutting-edge technology. In this blog, we will delve into the key aspects of the 3D printing materials market, exploring the types, applications, and future trends shaping this exciting field.

Sample copy report:

https://wemarketresearch.com/reports/request-free-sample-pdf/3d-printing-materials-market/1338

Types of 3D Printing Materials

Thermoplastics: Thermoplastics are among the most widely used materials in 3D printing. They are known for their ease of use, affordability, and versatility. Popular thermoplastics include:

PLA (Polylactic Acid): Known for its eco-friendly nature and ease of printing, PLA is a favorite among hobbyists and beginners.

ABS (Acrylonitrile Butadiene Styrene): This material offers greater strength and durability, making it ideal for functional prototypes and end-use parts.

PETG (Polyethylene Terephthalate Glycol): Combining the ease of printing with durability, PETG is commonly used in applications requiring resistance to impact and moisture.

Resins: Resins are liquid materials that solidify under UV light and are used primarily in SLA (Stereolithography) and DLP (Digital Light Processing) printers. They offer high resolution and detail, making them suitable for applications such as jewelry and dental products. Key types include:

Standard Resins: Ideal for detailed models and prototypes.

Tough Resins: Engineered for increased durability and impact resistance.

Flexible Resins: Designed to produce parts with rubber-like properties.

Metals: Metal 3D printing is used for high-performance applications in industries such as aerospace, automotive, and medical. Metal powders, such as titanium, aluminum, and stainless steel, are used in processes like SLM (Selective Laser Melting) and EBM (Electron Beam Melting). Metal 3D printing offers:

High Strength-to-Weight Ratio: Essential for aerospace and automotive components.

Complex Geometries: Allows for the creation of intricate designs that are difficult to achieve with traditional manufacturing methods.

Composites: Composite materials combine thermoplastics with reinforcing fibers, such as carbon fiber or glass fiber, to enhance strength and rigidity. These materials are used in applications where lightweight and high strength are critical, including in the automotive and sports equipment industries.

Innovations Driving the 3D Printing Materials Market

The 3D printing materials market is experiencing rapid innovation, driven by advancements in technology and changing industry needs. Here’s a closer look at some of the latest innovations that are transforming the landscape of 3D printing materials:

Nanomaterials: Nanotechnology is making waves in the 3D printing industry by enabling the creation of materials with enhanced properties at the nanoscale. Nanomaterials can improve strength, durability, and thermal resistance, making them ideal for high-performance applications. For example, incorporating nanoparticles into polymers can enhance their mechanical properties, leading to more robust and reliable printed parts.

Bio-inks and Bioprinting: Bioprinting is revolutionizing the medical and research fields by enabling the creation of living tissues and organs. Bio-inks, which are made from natural and synthetic biopolymers, are used in this process to print cellular structures. These materials can be tailored to support cell growth and tissue development, opening up new possibilities for regenerative medicine and personalized healthcare.

Applications of 3D Printing Materials Market

The versatility of 3D printing materials market has led to their adoption across various sectors:

Aerospace: Lightweight and durable materials are used to manufacture complex parts and components, reducing overall weight and fuel consumption.

Healthcare: Custom prosthetics, implants, and dental products are tailored to individual patients using biocompatible materials.

Automotive: 3D printing enables rapid prototyping and production of lightweight parts, enhancing vehicle performance and reducing time-to-market.

Consumer Goods: Customized products, from eyewear to home decor, benefit from the flexibility and personalization offered by 3D printing.

Future Trends in 3D Printing Materials Market

As the 3D printing industry continues to evolve, several trends are likely to shape the future of 3D printing materials:

Biodegradable and Sustainable Materials: There is a growing focus on developing eco-friendly materials that reduce environmental impact. Innovations in biodegradable plastics and recycling processes are set to make 3D printing more sustainable.

Advanced Metal Alloys: The development of new metal alloys with enhanced properties will open up new possibilities for high-performance applications in industries such as aerospace and defense.

Multi-Material Printing: Advances in multi-material printing technologies will allow for the creation of complex objects with varying properties in a single print, expanding the range of applications and functionalities.

Smart Materials: The integration of materials that respond to environmental changes (such as temperature or pressure) will lead to the development of "smart" products with adaptive capabilities.

Benefits of 3D Printing Materials Market Report:

Analyst Support: Get your query resolved by our expert analysts before and after purchasing the report.

Customer Satisfaction: Our expert team will assist with all your research needs and customize the report.

Inimitable Expertise: Analysts will provide deep insights into the reports.

Assured Quality: We focus on the quality and accuracy of the report.

Conclusion

The 3D printing materials market is a dynamic and rapidly evolving field, driven by continuous innovation and technological advancements. From thermoplastics and resins to metals and composites, the variety of materials available today provides limitless possibilities for creators and manufacturers alike. As we look to the future, emerging trends and new material developments promise to further revolutionize the industry, offering exciting opportunities for growth and transformation across various sectors. Whether you're a hobbyist, a designer, or an industry professional, staying informed about these advancements will be key to leveraging the full potential of 3D printing technology.

#3D Printing Materials Market Demand#3D Printing Materials Market Scope#3D Printing Materials Market Analysis#3D Printing Materials Market Trend

0 notes

Text

The Cellular Rubber Market is Expected to Expand Over the Forecast Period Due to a Variety of Factors

Asia Pacific and North America are predicted to be the most promising for growth due to the region's substantial rubber and automotive sectors. The Asia Pacific area is likely to see relatively substantial value growth as a result of customisable dwellings that adapt to unique needs. Furthermore, the motor industry's investments are gradually expanding. India and China are two important Asian Pacific countries that are increasing their manufacturing sectors, with India being a major exporter of cellular rubber. During the projected period, these factors are expected to boost the cellular rubber market.

Additionally, cellular rubber foam blanks are used for the transportation and installation of solar components. Additionally, cellular rubber is used in the space industry for engine and light seals. As a consequence, these factors are expected to drive the cellular rubber market forward throughout the forecast period.

Read More:

https://blogger-veritas.blogspot.com/2022/06/global-cellular-rubber-market-analysis.html

0 notes