#CO2 Laser Cutting Machine

Explore tagged Tumblr posts

Text

8 sets 1810 laser cutting machine shipped to Uzbekistan. WhatsApp/wechat: 0086-13599259031.

0 notes

Text

CO2 Laser Cutting Machine in Singapore

Signvec is a premier manufacturer and supplier of cutting-edge CO2 laser cutting machines in Singapore. Renowned for their precision and reliability, Signvec's laser cutting machines are at the forefront of industrial innovation. With a commitment to quality craftsmanship and advanced technology, they offer tailored solutions to meet diverse cutting needs across various industries. Trusted by businesses for their efficiency and accuracy, Signvec stands as a leader in the laser cutting machine market, delivering exceptional performance and unmatched value.

In Order To Find Out More Details Laser Cutting Machine Please Be Touch With Us Today Onwards..!

#CO2 Laser Cutting Machine#CO2 Laser Cutter#CO2 Laser Cutter Singapore#Laser Cutting Machine#Laser Cutter#Cnc Laser Cutter#Cnc Laser Cutting Machine

0 notes

Text

Co2 Machine - Sparkle Laser

In an period where discuss quality concerns are on the rise, finding successful arrangements to filter indoor spaces has gotten to be more basic than ever. Enter Shimmer Laser's inventive CO2 Machine—an progressed discuss filtration framework outlined to revolutionize the way we breathe inside. Let's investigate the highlights and benefits of this groundbreaking innovation:

Accuracy Filtration Innovation: The CO2 Machine utilizes cutting-edge laser-based filtration innovation to successfully expel destructive poisons from indoor discuss. By focusing on carbon dioxide (CO2), unstable natural compounds (VOCs), and other contaminants at the atomic level, this gadget guarantees that the discuss you breathe is clean, new, and free from pollutions. Say farewell to indoor poisons and hi to a more advantageous living environment.

Savvy Sensor Integration: Prepared with shrewdly sensors, the CO2 Machine ceaselessly screens key discuss quality parameters, counting CO2 levels, temperature, and stickiness. This real-time information permits the gadget to alter its filtration settings powerfully, guaranteeing ideal execution in any environment. Whether it's a active office space or a cozy domestic setting, the CO2 Machine adjusts to changing conditions to provide reliable, high-quality discuss filtration.

Calm and Energy-Efficient Operation: Not at all like conventional discuss purifiers that can be boisterous and energy-intensive, the CO2 Machine works unobtrusively and productively, much obliged to its progressed laser innovation and energy-saving highlights. Whether it's running within the foundation amid work hours or overnight whereas you rest, this gadget guarantees a quiet and undisturbed indoor environment whereas expending negligible vitality. Say farewell to boisterous fans and hi to quiet, energy-efficient discuss decontamination.

Smooth and Compact Plan: With its smooth and compact plan, the CO2 Machine consistently coordinating into any indoor space without diminishing from its aesthetics. Whether it's mounted on a divider or put watchfully on a tabletop, this gadget complements any décor whereas conveying effective discuss decontamination execution. Say farewell to bulky, unattractive purifiers and hi to a advanced, moderate arrangement for clean, sound discuss.

Flexible Applications: From homes and workplaces to schools and healthcare offices, the CO2 Machine is appropriate for a wide run of indoor situations. Whether you're looking to progress discuss quality in a little loft or a expansive commercial building, Shimmer Laser offers customizable arrangements custom fitted to your particular needs. Say farewell to indoor discuss contamination and hi to a breath of new discuss, wherever you're .

In conclusion, Shimmer Laser's CO2 Machine may be a game-changer within the world of indoor discuss decontamination. With its progressed filtration innovation, savvy sensor integration, calm operation, and smooth plan, this gadget offers a prevalent arrangement for clean, solid indoor situations. Say farewell to indoor discuss contamination and hi to a brighter, more advantageous future with the CO2 Machine by Shimmer Laser.

0 notes

Text

CO2 Laser Cutting Machine Manufacturers and Suppliers

Shenzhen Sijiahua Keji is the world's largest CO2 Laser Cutting Machine Manufacturer and supplier. This machine is used for cutting or engraving and marking on wood, textiles, and papers. It is also used for industrial application & prototyping, sign marking, and in aerospace industries. For operating windows, 7 to 10 are used. For more details call us at +86-18025348056.

0 notes

Text

Use High Powered CO2 Laser Cutting Machine to Engrave Cut Materials

Laser cutting equipment is a popular choice in industrial and manufacturing settings to accurately cut different materials and metals, including steel, brass, copper, acrylic, wood, plastic, paper, and cloth. The process is economically viable and very effective for industrial growth.

Process of CO2 laser cutting:

A CO2 laser cutting machine is a technologically advanced equipment that uses a high-powered carbon dioxide laser beam to engrave, mark, or cut metals or materials. A combination of gases consisting of carbon dioxide, nitrogen, helium, and hydrogen is used in laser cutting. The CO2 molecules are charged and start emitting laser light that is, in turn, focused through mirrors and lenses to fall on the material. The material then melts and vaporizes to take the desired shape.

No contact process:

The CO2 laser cutter does not come directly in contact with the cut material. The laser head never touches the material; thus, fragile materials are not damaged, warped, deformed, or distorted during the process. Also, the wear and tear is reduced dramatically because of no physical contact. The machine continues to perform for years, thus helping improve large-scale production rates.

Moreover, these machines can easily cut materials, metals, non-metals, and other composites. The laser cutting machines are value for money and an investment for years. Also, you can create delicate pieces with intricate designs, smooth edges, and small holes repeatedly identically with different power levels.

Types of machines:

There are two types of laser cutters: fiber laser cutting machines and CO2 laser cutters. CO2 laser machines are ideal for wood, plastics, and non-metals, whereas fiber lasers can cut different metals seamlessly and smoothly. It’s the need that decides the machine type to be chosen. You need to analyze every step and then decide because fiber laser cutters are an investment of a lifetime.

In a CO2 laser cutter, the process of reflection through mirrors is used to shine bright light onto the material that has to be cut. CO2 lasers are flexible because they can cut through non-metals and a much more comprehensive range of materials. These laser cutters make smooth surface finishing and straight-line cutting easy jobs.

The CO2 laser technology uses user-friendly computerized software that anybody can run efficiently. The design is pre-decided, and details are fed into the computer. The fiber laser from the CO2 laser machine focuses on the material, and the light shines on it pre-determinedly. The high-powered ray of light slowly melts, burns, and vaporizes the excess material away. The desired effects are left behind.

Cutting, marking, discolouring, hollowing, etching, etc, is done according to the design provided. The method of CO2 laser cutting is dependable, rapid, and an excellent option for marking serial numbers, marking graphs, logos, trademarks, or internal coding. The high heat, melting, and vaporization make the desired engravings. Carry out your research online before you pick a machine. Read about all the features before you choose yours. Request a quote from a reliable firm selling these tools to own the best.

Google Site

1 note

·

View note

Video

youtube

STARMA cnc setting manual CCD camera of co2 laser cutting machine

#youtube#STARMA cnc setting manual CCD camera of co2 laser cutting machine This video to show how to setting the parameters of the CCD camera of Co2

2 notes

·

View notes

Link

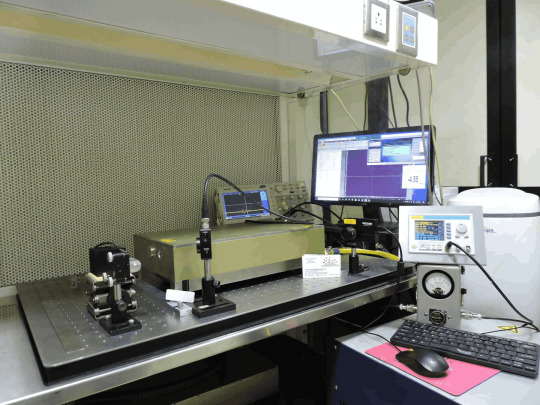

C. And C. Laser Engineering Pvt Ltd. is known for offering all kinds of industrial laser solutions and a range of Scientific and Industrial Laser Products and Services. This includes Industrial Products right from small components, and various spares of laser systems to the installation of complete laser workstations along with maintenance and servicing.

We provide laser workstations with or without material handling systems that are used for laser marking, laser engraving, deep engraving, laser welding, laser cutting, nanosecond micro-machining, and ultra-micro-machining.

We also offer laser-based solutions using Nano–Pico – Femtosecond, IR, Green, UV and DUV lasers.

We have more than 30 years of experience in the laser industry and with this vast experience and range of laser technology available, we are able to provide high-quality laser services and laser systems in the industry.

We provided lasers and services as well for our principal namely –

Control Laser Corporation,

Iradion MegaWatt Lasers QPC Lasers Amplitude Lasers (Continuum), PhotoScribe Uptek

The Scientific range of products from C. And C. Laser Engineering have various applications and some of them are LIDAR, Macromolecules research, Laser microprobes analysis, Fiber Bragg grating diagnostics, Laser-Induced Breakdown Spectroscopy (LIBS), laser flash photolysis, Synchronized pumping of other lasers, Interferometry, Biological imaging, Materials process research.

Our laser marking job work and laser engraving job work is acknowledged and appreciated for their precision, details, and uniformity on any metals and non-metals.

Our prime goal is to offer the best and excellent services and quality products to our customers and always put in our best efforts to achieve that objective.

#lasers#laser technology#laser applications#laser marking#laser welding#laser cutting#laser engraving#micromachining#lidar#iradion lasers#co2 lasers#fiber laser#uv laser#laser systems#laser machines

4 notes

·

View notes

Text

Laser Cutting Sandpaper with REDSHIFT CO2 Laser Cutter 160100 130W

𝐑𝐞𝐝𝐒𝐡𝐢𝐟𝐭 𝐋𝐚𝐬𝐞𝐫, 𝐲𝐨𝐮𝐫 𝐨𝐧𝐞-𝐬𝐭𝐨𝐩 𝐬𝐨𝐥𝐮𝐭𝐢𝐨𝐧 𝐩𝐫𝐨𝐯𝐢𝐝𝐞𝐫 𝐟𝐨𝐫 𝐥𝐚𝐬𝐞𝐫 𝐦𝐚𝐜𝐡𝐢𝐧𝐞𝐬 𝐚𝐧𝐝 𝐬𝐩𝐚𝐫𝐞 𝐩𝐚𝐫𝐭𝐬.

👉Visit our website to get more information: 🔹https://redshiftlaser.com 🔹Email [email protected] 🔹WhatsApp / WeChat +86 16727286207

#lasercutting#sandpaper#lasercutter#lasercuttingmachine#co2 laser#laser cutting#laser cutting machine#laser cutter#abrasives

4 notes

·

View notes

Text

Small 40w CO2 Laser Engraver

CO2 laser engraving and cutting machine is a versatile piece of equipment that uses a carbon dioxide (CO2) laser beam to engrave and cut a wide range of materials. CO2 laser engravers can be used for both engraving and cutting tasks. Engraving involves marking the surface of a material, creating designs, text, or images. Cutting involves slicing through the material to create shapes or intricate patterns.

It is commonly used in industries such as signage, woodworking, crafts, and manufacturing for applications such as engraving, cutting, etching, and marking.CO2 laser engraving cutting machines are popular due to their versatility, precision, and ease of use. They find applications in various industries and are commonly used for creating signage, personalizing products, prototyping, artistic designs, and small-scale production.

40w CO2 Laser Engraver

40W CO2 laser engraver refers to a laser engraving machine that utilizes a 40-watt carbon dioxide (CO2) laser tube as its primary source of energy for engraving and cutting various materials. CO2 laser engravers are versatile tools widely used for engraving and cutting a variety of materials, including wood, acrylic, leather, paper, fabric, glass, and certain types of plastics.

The 40W rating indicates the power output of the CO2 laser tube. Higher wattage generally allows for faster engraving and cutting speeds and the ability to work with thicker materials.

Carbon dioxide laser is a gas molecular laser, the working substance is CO2 gas, auxiliary gases are nitrogen helium, xenon and hydrogen, etc., because the energy conversion efficiency of this laser is as high as 25%, it is often a high-power output laser, carbon dioxide laser wavelength 10.6 microns, is impossible to see infrared light, good stability, widely used.

Using the most advanced DSP control technology in the world, the first industry-leading continuous and fast curve cutting function and the shortest machining path optimization function, greatly improving work efficiency. Automatic light attenuation compensation for the whole process of engraving, to ensure that different areas of cutting to maintain consistency, fast cutting control software design and high-speed motion buffer function, can improve production efficiency.

CO2 lasers are used to engrave text & patterns and cut shapes & contours in clothing, fashion, garment, shoes, bags, toys, embroidery, electronic appliances, molds, models, arts, crafts, advertising, decorations, packaging, and printing.

Here are some key points about CO2 laser engraving cutting machine :

Laser Source: These machines utilize a CO2 laser tube as the energy source. CO2 lasers produce a high-intensity beam at a wavelength of around 10.6 micrometers, which is well-suited for engraving and cutting a variety of non-metallic materials.

Engraving: CO2 laser engraving machines use the laser beam to vaporize or remove the surface layer of a material, creating detailed and precise engravings. They can engrave various materials such as wood, acrylic, leather, fabric, paper, glass, stone, and certain plastics.

Cutting: CO2 laser cutting machines use the laser beam to melt or vaporize the material along a predetermined cutting path. This allows for precise and clean cuts in materials like acrylic, wood, plywood, MDF, rubber, fabric, leather, and certain plastics. However, they are not suitable for cutting metals.

Working Area and Table: co2 laser engraver come in various sizes, with different working areas to accommodate different material sizes and project requirements. The machine usually has a table or platform where the material is placed for engraving or cutting.

Precision and Speed: co2 laser engraver offer excellent precision and speed. The focused laser beam allows for intricate and detailed designs, while the high-speed cutting capabilities enable efficient production. The precision and speed can be adjusted based on the material and desired outcome.

Software and Control: CO2 laser engraving cutting machines are typically controlled by specialized software that allows users to design or import graphics, adjust settings, and create cutting or engraving paths. The software often supports vector-based file formats such as SVG, AI, DXF, and others.

Material Compatibility: co2 laser engraver can work with a wide range of non-metallic materials. In addition to the materials mentioned earlier, they can also engrave or cut materials like cork, rubber, foam, paperboard, ceramic, and more. However, materials with high reflectivity, such as mirrors or certain metals, are not suitable for CO2 lasers.

Safety Features: Safety is an important aspect when using 40w co2 laser engraver. They usually feature protective enclosures with safety interlocks to prevent accidental exposure to the laser beam. Additional safety measures may include laser power control, ventilation systems to remove fumes, and warning indicators.

iGOLDENCNC is the world-leading laser equipment manufacturer and service provider with a worldwide sales and service network and a broad network. Product resources guarantee that we can provide the most advanced laser technology and professional customer service. Over the past three years, we have provided a variety of cutting solutions for a wide range of industries, 2 years warranty is the best guarantee.

A CO2 laser cutting machine is an automated smart cutting tool kit that uses a glass laser tube to produce light beam, and works with a numerical control system to irradiate the beam to the surface of the object, and at the same time release high energy to melt and evaporate the surface of the object, thereby realizing the plan of cutting and engraving. The beam is a column of very high intensity light, of a single wavelength, or color. In the case of a typical carbon dioxide laser, that wavelength is in the Infra-Red part of the light spectrum, so it is invisible to the human eye.

The beam is only about 3/4 of an inch in diameter as it travels from the resonator, which creates the beam, through the machine’s beam path. It may be bounced in different directions by a number of mirrors, or “beam benders”, before it is finally focused onto the plate. The focused beam goes through the bore of a nozzle right before it hits the plate. Also flowing through that nozzle bore is a compressed gas, such as Oxygen or Nitrogen. Generally speaking, higher power is used for cutting, lower power is used for engraving. The power is adjustable during operation. Turn it down for engraving and turn it up for cutting. The level of power will also affect the depth of engraving and the thickness of cutting.

0 notes

Text

Co2 Laser Cutting Machine

In the realm of crafting and design, precision is paramount. Enter CO2 Laser Cutting Machine, the unsung heroes behind some of the most intricate and impeccable creations. Let's embark on a journey to unravel the magic of these remarkable machines and their transformative impact on the world of crafting.

Precision Personified: CO2 laser cutting machines are synonymous with precision. With their high-powered lasers, they can cut through a myriad of materials with unparalleled accuracy, from paper-thin fabrics to thick acrylics. This precision allows crafters to achieve intricate cuts and detailed designs with ease, elevating the quality of their creations to new heights.

Versatility Redefined: What sets CO2 laser cutting machines apart is their versatility. Unlike traditional cutting methods that require different tools for different materials, CO2 laser machines can effortlessly switch between materials, from wood and leather to glass and rubber. This versatility opens up a world of possibilities for crafters, enabling them to explore new techniques and experiment with diverse materials.

Unleashing Creativity: CO2 laser cutting machines are not just tools; they are catalysts for creativity. With the ability to cut, engrave, and etch with precision, these machines empower crafters to bring their wildest ideas to life. Whether it's creating intricate papercut artworks, personalized wedding invitations, or custom signage, the only limit is the crafter's imagination.

Efficiency and Speed: In the fast-paced world of crafting, efficiency is key. CO2 laser cutting machines offer unparalleled speed and efficiency compared to traditional cutting methods. With their automated processes and high cutting speeds, these machines can produce intricate designs in a fraction of the time, allowing crafters to focus on what they do best – creating masterpieces.

Sustainability in Crafting: As the world becomes increasingly eco-conscious, sustainability is becoming a top priority for crafters. CO2 laser cutting machines are inherently sustainable, producing minimal waste and consuming less energy compared to traditional cutting methods. By optimizing material usage and reducing the need for manual labor, these machines help crafters minimize their environmental footprint while maximizing their creative output.

In conclusion, CO2 laser cutting machines are revolutionizing the world of crafting, offering unparalleled precision, versatility, and efficiency. With their ability to unleash creativity and elevate craftsmanship to new heights, these machines are empowering crafters to create masterpieces that captivate the imagination and inspire awe. As the crafting industry continues to evolve, the magic of CO2 laser cutting machines will continue to shape the way we create and express ourselves for generations to come.

0 notes

Text

Is CO2 Laser Cutting Machine Demand of Many Industries, but How?

You have heard many times about carbon dioxide, but in this scenario, you will see how CO2 is useful for us and what parameters you should consider while choosing CO2 Laser Cutting Machine Manufacturers. CO2 laser cutting machine is equipped with many features that enable it to do manufacturing and fabrication by cutting and shaping materials over the surface of metal, wood, acrylic, plastic, and textiles. For more details call us at +86-18025348056.

0 notes

Text

Metal Mastery: Truway Machinery's Cutting-Edge Metal Laser Cutting Machine in Mumbai

Truway Machinery unveils its Metal Laser Cutting Machine in Mumbai, setting new benchmarks in precision metal fabrication. Our advanced technology ensures impeccable cuts, intricate designs, and rapid production, empowering industries with unmatched efficiency and quality. Experience the future of metal cutting with Truway Machinery in Mumbai.

0 notes

Text

Tech Marvels: Explore MadBytes' CNC Machinery Collection

In an era where precision, speed, and innovation reign supreme, the realm of manufacturing and fabrication has been significantly revolutionised by CNC (computer numerical control) machinery. MadBytes, a trailblazing technological hub, stands at the forefront of this revolution, offering an impressive collection of CNC routers and laser cutting machines. Among their standout offerings are the CNC Router Machine, Co2 Laser CNC Machine, and Fiber Laser Cutting Machine, each representing the pinnacle of technological advancement and efficiency.

The CNC Router Machine: Precision Redefined

MadBytes' CNC Router Machine embodies the epitome of precision and versatility in material cutting and carving. Crafted to cater to various industries, from woodworking to sign making and metalworking, this machine executes designs with unparalleled accuracy. Its computer-controlled system meticulously translates digital designs into tangible creations, ensuring consistency and intricate detailing. With MadBytes' CNC Router, artisans and industrialists alike can explore limitless possibilities, transforming raw materials into exquisite masterpieces with finesse.

Co2 Laser CNC Machine: Powering Creativity with Precision

For those seeking precision cutting and engraving capabilities, MadBytes' Co2 Laser CNC Machine stands as an unrivalled marvel. Harnessing the power of laser technology, this machine delivers immaculate cuts across various materials, including wood, acrylic, and even metal. The precision and speed offered by this cutting-edge device empower creators to fashion intricate designs and prototypes with remarkable intricacy and efficiency. From intricate filigree patterns to detailed engraving, the Co2 Laser CNC Machine is a beacon of innovation, elevating craftsmanship to unprecedented levels.

Fiber Laser Cutting Machine: Efficiency Redefined

MadBytes' Fiber Laser Cutting Machine represents the pinnacle of efficiency in industrial cutting. Designed to tackle diverse materials with unmatched precision, this machine utilises high-powered lasers to swiftly and accurately slice through metals, plastics, and composites. Its speed and precision make it an indispensable asset in industries demanding high-volume production without compromising on quality. The Fiber Laser Cutting Machine from MadBytes exemplifies the convergence of technology and productivity, setting new benchmarks in industrial manufacturing.

Why choose Madbytes Industry Pty Ltd?

Amidst a myriad of options, MadBytes emerges as a beacon of reliability and innovation in the realm of CNC machinery. Their commitment to technological excellence, coupled with a penchant for customer satisfaction, distinguishes them in the market. Offering a range of cutting-edge CNC solutions, MadBytes caters to the diverse needs of industries and individual creators alike. Moreover, their dedication to providing top-notch customer support and after-sales service ensures a seamless experience for every client, from procurement to operation.

Embracing the Future with Madbytes Industry Pty Ltd

As technology continues to evolve, MadBytes remains at the forefront, propelling industries and creative endeavours forward with its remarkable CNC machinery collection. Whether it's precision carving with the CNC Router Machine, intricate detailing with the Co2 Laser CNC Machine, or swift, high-volume production with the Fiber Laser Cutting Machine, MadBytes offers a gateway to unparalleled craftsmanship and industrial efficiency.

In conclusion, MadBytes' CNC machinery collection stands as a testament to the fusion of technology and innovation, enabling individuals and industries to embark on a journey of limitless possibilities. With their state-of-the-art equipment and unwavering commitment to excellence, MadBytes invites all enthusiasts and professionals to embrace the future of manufacturing and fabrication.

Visit https://madbytes.com.au/ today and witness the marvels of CNC technology redefining precision, creativity, and efficiency.

#CNC Router Machine#Co2 Laser CNC Machine#Fiber Laser Cutting Machine#CNC Machine Manufacturer#CNC Machine Suppliers

1 note

·

View note

Text

CO2 Laser Tube:- Discover precision in metal fabrication with an Automatic CNC Bending Machine. Experience efficiency with a Fiber Laser Cutting Machine for impeccable cuts. Transform ideas into vibrant prints at a leading Digital Printing Shop in Sharjah, offering top-notch custom printing solutions. For more info visit us. https://fortune7.ae

0 notes

Text

CO2 Laser Cutting and Engraving Machine

iGOLDEN laser engraving machine offers precise and aesthetical engraving and cutting of non-metal materials. The machine primarily uses CO2 gas along with electricity to produce a laser beam that can cut through or engrave most materials. A glass tube helps to focus laser beam onto the surface of the material, the beam goes down the tube and out the nozzle through focus lens. Once the beam exits the tube, it comes in contact with the surface of the material to be engraved. The speed can be controlled to ensure smooth and reliable engraving moreover the worktable it comes with is able to work with hard materials such as wood, acrylic etc. The machine comes with a control panel that displays the progress of the graphics.

iGOLDEN laser engraving machine is widely used for fine engraving and cutting, hollow carving of acrylic, leather, paper, MDF, rubber, organic board, two-color board, wood board, bamboo products, glass, cloth, resin, plastic, rubber, ceramic tile, crystal, bamboo, organic glass and other non-metallic materials. The machine can cut and engrave various texts, graphics, images, trademarks, etc. CO2 laser engraving machine is suitable for both home and commercial purposes.

Features of Laser Engraving Machine

Safety Protection: It will automatically cut off the power when the top access door is open, which protects the operator from any harm by the laser, increasing the safety, stability, and reliability of use and maintenance.

Water Cooling Protection: To avoid any damage to the laser tube the machine will not fire the laser if the cooling water flow is not detected.

Red-dot Positioning: the machine uses a red light indication method to achieve precise positioning of the laser beam.

Breakpoint Continuous Engraving: In case of any power cut the machine will continue working from where it left off last .

Worktime Preview Function: It can demonstrate real working time with accuracy up to the millisecond level, and also support dynamic display of machining path and coordinate points, real-time display and tracking of machining progress.

A CO2 laser engraver is an automatic etching system that uses a 10.6 μm wavelength CO2 laser beam to act on the surface of the substrate to vaporize the excess material to form pits, so as to make an engraved project. It is a carbon dioxide gas laser engraving cutting machine that uses the computer to control the X-Y console to drive the engraving head to move and control the switch as required. The CAD/CAM software generates a file from the designed pattern or text and stores it in the computer.

This is the LCD control panel,User Friendly LCD control panel allows the user to quickly change selected program and modify machine operational conditions. You can Start, Stop, Pause, Reset, Datum, Test Fire, Outline engrave project area, Move the X or Y axis, LCD Viewing Display, Z-Axis up/down, Control Interior light.

Laser Tube

The standard laser tube is 80w. wood laser engraving machine supplies high quality 80-180w laser tube for your choice, you can choose according to your work and the workpiece thickness.

The laser output is stable. The discharge tube is catalyst coated,the working life is much increased. Compared to similar product, the tube body length is shorter, the laser beam mode is better, the cutting speed is higher.

Laser Engraving Machine Applications

Compared with manual wood engraving machines and hand wood engraving tools, laser wood engraving machines have greatly improved the working efficiency for your laser engraving business plans. They can make the engraved surface more smooth and round, quickly reduce the temperature of the engraved non-metallic material, and reduce the deformation and internal stress of the engraved project. It can be widely used in the field of fine engraving of various non-metal materials. So far, you can meet laser engraved wood projects everywhere in the world, and it has become a common power tool in our daily work. Now, it is widely used in woodworking, sign making, advertising industry, crafts making, toys making, shoes, clothing, mold making, construction industry, printing industry, packaging industry, decorations, leather industry. The nonmetal laser engraver is suitable for woods (hard wood, soft wood, plywood, MDF, veneer, coniferous wood), leather, acrylic, textile, fabric, cardboard, rubber, paper, plastic, bamboo, ABS, PVC, fiber and composite materials.

How Many Types of Laser Engraving Machines?

Laser engraving machines are classified as laser wood engraver machines, metal engraver machines, leather engraver machines, stone engraver machines, fabric engraver machines, plastic engraver machines, rubber engraver machines, paper engraver machines, glass etching machines, acrylic engraver machines based on the engraving materials. Laser engraving systems are defined as CO2 laser systems, fiber laser systems (the best tool to engrave metal), and UV laser systems (the best tool to etch glass) based on the sources.

Laser engraving tables are divided into mini types, handheld types, compact types, desktop types, portable types, 2×3 engraving tables, 2×4 engraving tables, 4×4 engraving tables, 4×8 engraving tables, 5×10 engraving tables, large format engraving tables according to the working area. These kits are classified as home kits, hobby kits, commercial kits, industrial kits based on applications. These kits are defined as laser jewelry engravers, pen engravers, iPhone engravers, gun engravers, ring engravers, signage engravers, art engravers, logo engravers, cup engravers based on industries. If you are working for 3D engraving, the rotary engraver kit is the best solution.

How does a CO2 Laser Cutting Machine Work?

You may want to know how to laser cut leather, how to laser cut fabric at home, or how to laser engrave acrylic. But first, Co2 laser cutter how it works?

Laser machine tool lies in laser beams. CO2 laser machine uses a CO2 laser tube with a CNC system to irradiate the laser beam to the surface of the object. At the same time, the glass laser tube releases high energy heat to melt and evaporate the object surface to achieve CNC CO2 laser cutting and engraving. And in a CO2 laser engraving machine, light is produced when an electric current is passed through a gas-filled tube with mirrors at both ends. One mirror is fully reflective, while the other only lets some light through. Next, these mirrors direct the laser beam into the material to be cut. And the gas is usually a mixture of carbon dioxide, nitrogen, hydrogen, and helium.

In addition, CO2 laser beam is a very high-intensity beam of light. It is a kind of infrared ray with a single wavelength or color, which is invisible to the human eye. When the Co2 laser beam passes through the beam path from the resonator, its diameter is only about 3/4 of an inch. So, it may be reflected in different directions by many mirrors or “beam benders” before it is finally focused on the plate. And the focused CO2 laser beam passes through the nozzle hole before hitting the plate, as well as the compressed gas such as oxygen or nitrogen. Besides, higher CO2 laser power is for cutting and lower CO2 laser power is for engraving. Actually, the CO2 laser power is adjustable during operation. Laser power also affects the depth of CO2 laser engraving and the thickness of CO2 laser cutting.

0 notes

Text

High precision fiber laser cutting machine

More details about lasers can contact Grace Qian at whatsapp:+86 13117226300

A professional precision fiber laser cutting and microhole laser processing equipment for sheet metal and superhard materials, with fast cutting speed, one-time molding, smooth incision and good verticality, without subsequent grinding and processing. product feature The whole machine is surrounded by closed anti-laser radiation design, reducing dust pollution and reducing the impact on the…

View On WordPress

0 notes