#CFDsimulations

Explore tagged Tumblr posts

Text

youtube

How do engineers ensure that Computational Fluid Dynamics (CFD) simulations are accurate and reliable? The answer lies in Verification and Validation (V&V), two essential processes that guarantee the correctness and trustworthiness of CFD models. In this video, we break down the concepts of V&V in simple terms: Verification ensures that the equations are solved correctly by eliminating computational errors and numerical instabilities. Validation ensures that the results match real-world data, proving the model’s accuracy in practical applications. From verifying mesh refinement to validating simulations against wind tunnel data, these steps play a crucial role in industries like aerospace, civil engineering, and environmental design. Learn how V&V builds confidence in CFD models and why it’s critical for designing safer cities, efficient aircraft, and much more.

If you’re interested in speaking with our experts from Scania, Mercedes, and Nissan, and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/4fAf4z4

#CFD#ComputationalFluidDynamics#VerificationAndValidation#Engineering#FluidDynamics#CFDSimulations#AerospaceEngineering#CivilEngineering#EngineeringInsights#SkillLync#youtube#cad#mechanicalengineering#Youtube

0 notes

Text

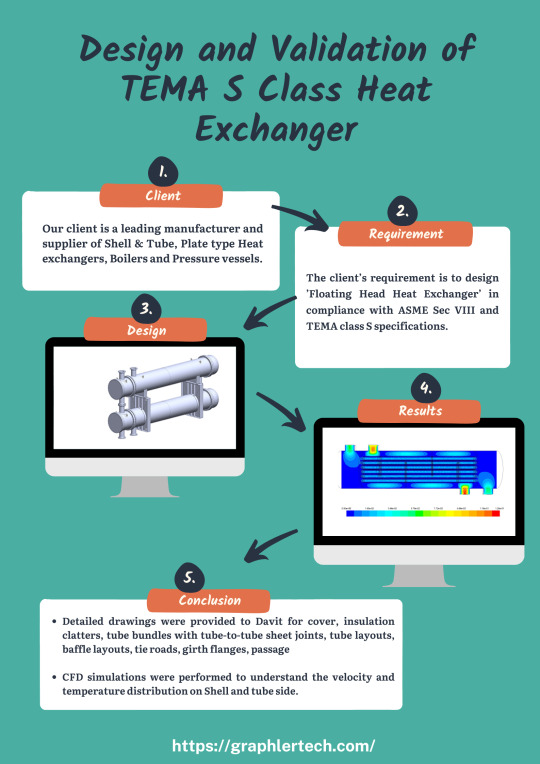

Design and Validation of TEMA S Class Heat Exchanger

Designing and validating TEMA S-Class heat exchangers. Get expert tips and insights!

You can come up with new routes by teaming up with a leading Stress Analysis Services Partner or Product Design Companies with a good reputation.

0 notes

Text

WHAT´S NEW Simcenter STAR CCM+ 2302 https://www.prolim.com/whats-new-simcenter-star-ccm-2302/

Discover the potential of Simcenter STAR-CCM+ 2302 and unlock advanced capabilities for your CFD simulations. Benefit from improved multiphase modeling, efficient workflows, and accelerated solver performance. Elevate your engineering simulations to new heights with our cutting-edge software.

We value your feedback and encourage you to share your thoughts. For further details, please feel free to reach out to us at [email protected].

#ThinkPROLIM#DigitalTransformation#TodayMeetsTomorrow#PLMSolutions#SiemensPLM#SimcenterSTARCCM+#CFDsimulations#EngineeringSimulation#InnovationinEngineering

0 notes

Text

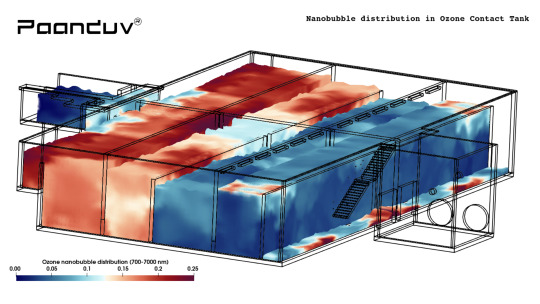

#cfd#simulation#waterandenvironment#cfdsimulation#computationalphysics#nanobubbletech#nanobubble#watertank#ozonewatertank#watercfd

0 notes

Photo

SERVICIOS DE SIMULACIÓN DE FLUIDOS #cfdsimulation #autodesk #hydraulics #uguayaquil #Guayaquil #quito #Ucsg #MIT #fem #Ingeniera #Cuenca #Machala https://www.instagram.com/p/BTos6lpF4x1/?igshid=NGJjMDIxMWI=

0 notes

Link

A computational fluid dynamics (CFD) model representing the effect of wafters in a totally enclosed electric machine is presented, introducing the most relevant theoretical assumptions and simplifications. The validation of the model is conducted through experimental measurements. From the CFD imulationdata, a second-order response surface is developed using statistical tools, from which the wafters’ influence on the convective heat transfer from the stator end windings is predicted. Wafter design criteria are obtained from the response surface information. Finally, a specific case is analysed, showing through CFDsimulations that temperatures in the machine are reduced by including wafters in the design.

#electricity #dynamics #machine #assumptions

0 notes

Text

Design and Validation of TEMA S Class Heat Exchanger

Our client is a leading manufacturer and supplier of Shell & Tube, Plate type Heat exchangers, Boilers and Pressure vessels. The client’s requirement is to design ’Floating Head Heat Exchanger’ in compliance with ASME Sec VIII and TEMA class S specifications.

What we Delivered:

3D CAD Model as per Client’s requirement/specifications

General Arrangement Drawings

Fabrication drawings

Machine drawings of various components

Parts drawings of various components

Detailed Bill of materials

CFD simulations to ensure customer’s design criteria is met

FE simulations to ensure structural integrity during lifting, transportation.

Design Specifications:

The Floating Head Heat Exchanger is designed for:

Pressure rating: Shell side: 38 kg/sq. cm, and Tube side: 30 kg/sq. cm

Temperature rating: Shell side: 150 °C and Tube side: 110 °C

Fluid capacity, Shell side: 2.8 cu.m., and Tube side: 1.8 cu.m

No. of passes: shell side (cross flow) and tube side (10).

Design wind reluctance: 50 m/s as per IS 875 Part 3

Seismic design code: IS: 1893-2005

Insulation thickness is 15/50 mm.

Gross weight of Heat exchanger (empty): 13 tons

Through simulations, we were able to provide nozzle loads, wind seismic data, bolt torque and forces, and welding stresses and forces.

Detailed drawings were provided to Davit for cover, insulation clatters, tube bundles with tube-to-tube sheet joints, tube layouts, baffle layouts, tie roads, girth flanges, passage partitions, gaskets, hold points, name plates, etc.

Finally, all design information, like native 3D CAD data, drawings and simulation reports, was submitted to the customer.

CFD Analysis validation:

CFD simulations were performed to understand the velocity and temperature distribution on Shell and tube side. The heat exchanger was simulated with operating temperature and pressure. The intensity of turbulence, heat transfer rate was studied and the results are reported to ensure that the design is in compliance with requirement and efficiency of the system is achieved.

The best way to obtain the accurate information is to consult an experienced CFD Consulting Services or Structural Analysis Services provider.

0 notes

Text

Design and Validation of TEMA S Class Heat Exchanger

Step-by-step methods for designing and validating TEMA S-Class heat exchangers. Get expert tips and insights!

0 notes

Text

youtube

What You’ll Learn: ✅ How to calculate forces acting on an EV: rolling resistance, drag, hill climbing, and acceleration. ✅ Estimating motor power and torque requirements. ✅ The role of drive cycles in EV motor design. ✅ Classification of electric vehicle motors. ✅ Key factors influencing motor choice: speed, torque, efficiency, cost, and thermal performance. ✅ How efficiency contour plots inform motor utilization and design.

💡Check out the previous episodes of this series here: https://www.youtube.com/playlist?list=PL9-f9hWLZS61I2GoQAXCVwwYLclPNZZwA

you’re interested in speaking with our experts and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/3B5vIaM

#skilllync#youtube#mechanicalengineering#cfd simulation#cfdsimulation#ansys#ansysfluent#3D ansys#Youtube

0 notes

Text

youtube

Ever wondered how physical quantities like temperature, force, and stress are described in physics and engineering? It all starts with scalars, vectors, and tensors! From simple magnitudes to complex relationships, these concepts are fundamental to understanding motion, material behavior, and much more. In this video, we’ll break down: Scalars: Quantities with only magnitude. Vectors: Magnitude with direction, like velocity or force. Tensors: Advanced concepts that describe complex interactions.

Learn how these foundational concepts play a key role in science and engineering.

If you’re interested in speaking with our experts from Scania, Mercedes, and Nissan, and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/408z2KK

#PhysicsConcepts#ScalarsVectorsTensors#EngineeringBasics#PhysicsExplained#MaterialScience#Motion#ForceAnalysis#SkillLync#EducationalContent#CFD#cfdsimulation#Youtube

0 notes

Text

youtube

What is a wake region, and why is it so crucial in aerodynamics? In this video, we delve into the fascinating world of fluid dynamics to explore the wake region—the area of recirculating flow behind a moving or stationary object.

Discover how this phenomenon impacts everything from drag and stability to the efficiency of vehicles and structures. Using examples like flow over cylinders and vehicles, we’ll explain why wake regions create low-pressure zones, induce drag, and shed vortices.

Learn why studying and controlling wake regions is vital in external aerodynamics, ensuring better performance and stability at high speeds.

If you’re interested in speaking with our experts from Scania, Mercedes, and Nissan, and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/3VTn6ex

Hit like and subscribe for more deep dives into aerodynamics, fluid dynamics, and engineering concepts!

#Aerodynamics#WakeRegion#FluidDynamics#DragReduction#VortexShedding#VehicleDesign#EngineeringConcepts#Airflow#ExternalAerodynamics#StrouhalNumber#CFDSimulation#SkillLync#EngineeringFundamentals#FluidBehavior#youtube#mechanicalengineering#cad#Youtube

0 notes

Text

youtube

Turbulence is everywhere—from air flowing over airplanes to water rushing in rivers—and modeling it is crucial for fluid dynamics. In this video, we explore the key approaches to turbulence modeling: Direct Numerical Simulation (DNS), Large Eddy Simulation (LES), Reynolds-Averaged Navier-Stokes (RANS), and Detached Eddy Simulation (DES). Learn how DNS provides unmatched detail, LES balances accuracy with cost, RANS simplifies turbulence for industrial applications, and DES combines the best of both worlds. Discover how these methods are used in industries like aerospace, automotive, and energy to optimize performance and efficiency.

If you’re interested in speaking with our experts from Scania, Mercedes, and Nissan, and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/4fAf4z4 Don’t forget to like, share, and subscribe for more insights into fluid dynamics and engineering innovation!

#TurbulenceModeling#FluidDynamics#CFD#Engineering#LES#RANS#DES#NavierStokes#AerospaceEngineering#AutomotiveEngineering#Turbulence#CFDSimulation#SkillLync#EngineeringInsights#youtube#cad#mechanicalengineering#Youtube

0 notes

Text

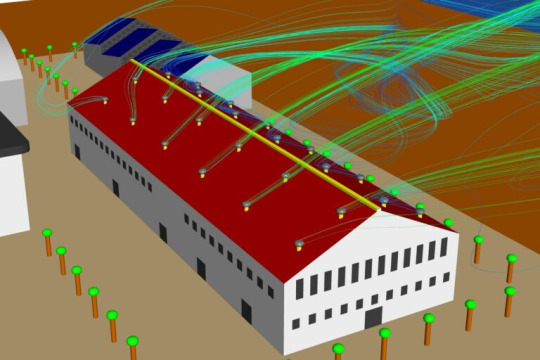

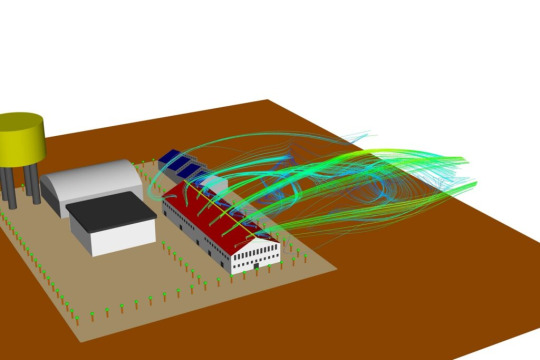

#BuildingVentilationDesign#CDFAnalysis#CFDAnalysisServices#CFDSimulation#Sustainablebuildingdesign#CFD Analysis

0 notes

Text

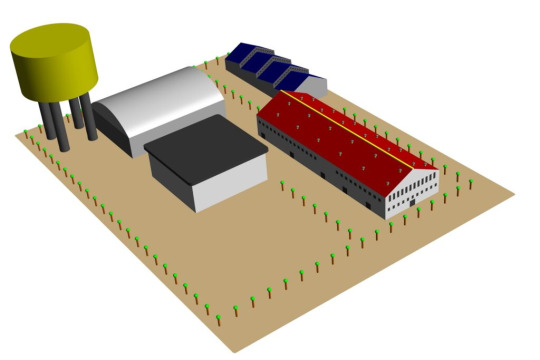

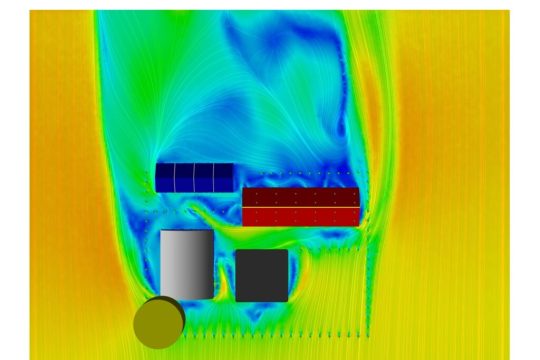

Power of CFD simulation to predict ventilation behavior in Manufacturing units

Introduction:

In recent years, stringent indoor air quality and thermal comfort is gaining importance in design of Industrial buildings. This study aims to find the optimal ventilation system and designed intently to improve energy efficiency and indoor air quality. CFD codes were used to simulate every category of the industrial complex in order to validate the actual building in a typical summer day and the results were compared.

Scope for CFD Analysis

To compare and evaluate the ventilation effectiveness of Turbine ventilators vs. Centrifugal upblast ventilators.

To discharge exhaust air to eliminate interference with other equipment or human activity.

To understand the flow pattern inside the building and position the ventilators to get the desired ACPH (Air Changes per Hour).

Thermal distribution at the working plane (150 cm from ground) to determine human comfort level.

The conditions –ParameterValuesArea of target building25,560 SqftTotal area of Industrial complex80,000 SqftProcess heat load150 KW (Averaged from various sources)U-Value of Galvanized Aluminum Steel sheet1.45 BTU/hr-Sqft-FAmbient Temperature37 CAmbient pressure1 AtmWind velocity3.5 m/s

Our approach and methodology –

The whole industrial complex is modelled as per 2-D draft sheets and material properties assigned as per specifications.

Trees, tarmac roads and landscape are considered for the analysis since the roughness can disturb the flow.

Large Eddy Simulation (LES) turbulent model is used since the feature can solve explicitly for larger eddies and also solve for smaller eddies, swirls and vortices by using Sub-Grid Scale model.

Wind tunnel around the Industrial complex is modelled as per standards to simulate real case scenario.

Conclusion –

With more complex designs, stringent safety requirements and ever-increasing energy concerns, designing for Energy efficient manufacturing units has become critical for Architects and LEED consultants. Using CFD empowers Engineers to optimize building design, especially in early stages when changes can be implemented efficiently and cost-effectively.

CFD simulation is a powerful tool that can accurately predict ventilation behavior in manufacturing units. This technology enables engineers to simulate and analyze the airflow, temperature distribution, and contaminant dispersion within the facility.

At Graphler Technology solutions, we provide industry-leading CFD Analysis Services, Engineering Animation Services and Pressure Vessel Analysis Services. We can help manufacturers to optimize their ventilation systems for improved air quality, worker comfort, and energy efficiency. With the power of CFD, many companies can make informed decisions about their ventilation systems and improve their overall manufacturing operations.

0 notes

Text

Discover the power of CFD simulation for predicting ventilation behaviour in manufacturing units through predictive modelling and explore the benefits of using CFD simulation.

0 notes

Photo

SERVICIOS DE SIMULACIÓN DE FLUIDOS #cfdsimulation #autodesk #hydraulics #uguayaquil #Guayaquil #quito #Ucsg #MIT #fem #Ingeniera #Cuenca #Machala

0 notes