#Bulk Handling Systems

Explore tagged Tumblr posts

Text

Conveyor screws

Irregular material flow can disrupt operations and decrease productivity. Sodimate Inc. specializes in high-quality conveyor screws, designed for smooth, consistent material transport. Our solutions minimize clogs and ensure optimal system performance. Contact us today to find the best conveyor screw solution for your needs!

0 notes

Text

Unlocking the Power of Bulk Handling Systems in Manufacturing

Introduction

In the realm of modern manufacturing, the efficiency of processes often hinges on the seamless movement and management of materials. Bulk handling systems have emerged as a critical component in optimizing the manufacturing workflow, ensuring that materials are transported, stored, and processed with minimal disruption. These systems are designed to manage large quantities of materials, such as powders, grains, and liquids, which are often integral to industries like food processing, chemicals, and pharmaceuticals.

Bulk handling systems are not merely operational tools; they are the backbone of manufacturing efficiency. By automating and streamlining material handling, businesses can experience greater productivity, reduced labor costs, and improved safety. This article delves into the various facets of bulk handling systems, their benefits, and how they can revolutionize manufacturing processes.

What Are Bulk Handling Systems?

At their core, bulk handling systems are a network of equipment designed to manage the movement of bulk materials in a manufacturing or processing environment. These systems encompass a wide range of technologies, including conveyors, elevators, pneumatic systems, and silo storage units, all working in concert to ensure materials flow seamlessly from one point to another.

The importance of bulk handling systems lies in their ability to move large quantities of materials quickly and efficiently, often without the need for manual intervention. In industries where time is money, having a reliable and fast system in place can significantly improve production times and reduce the risk of human error.

Components of Bulk Handling Systems

The design of bulk handling systems varies based on the nature of the materials being handled and the specific needs of the manufacturer. However, there are several common components that are integral to most systems:

Conveyors: These are used to move materials along a predetermined path, often in a continuous manner. Conveyors can be belt-driven, screw-driven, or even operate on rollers, depending on the type of material being transported.

Elevators: Bulk elevators are designed to lift materials vertically. This is particularly useful when dealing with bulk materials that need to be transported to higher levels or stored in silos.

Pneumatic Systems: Pneumatic conveying uses air pressure to move powders or granular materials through pipelines. This is ideal for handling materials that are prone to contamination or those that need to be kept dry.

Silos and Hoppers: These storage solutions are essential for holding bulk materials before they are processed or shipped out. Silos are typically used for long-term storage, while hoppers are used for short-term storage and dispensing.

Dust Collection Systems: As bulk materials are moved, they can often generate dust, which can pose a risk to both safety and air quality. Dust collection systems, including local exhaust ventilation systems (LEV), are installed to capture and remove harmful dust particles from the air.

The Benefits of Bulk Handling Systems

The advantages of implementing a bulk handling system in manufacturing are multifaceted. For industries where materials need to be moved quickly and efficiently, these systems offer considerable benefits that go beyond just speed and productivity.

Increased Efficiency and Reduced Labor Costs

By automating the movement of bulk materials, businesses can drastically reduce the amount of manual labor required in the production process. Employees no longer need to manually move materials from one area to another, which frees them up for more valuable tasks.

Additionally, the automation of these processes reduces the risk of errors and ensures that materials are handled in a consistent manner. With fewer people involved in material handling, the risk of accidents or workplace injuries is also significantly lowered, making the manufacturing environment safer.

Enhanced Safety and Compliance

Safety is a key consideration in any manufacturing environment. Bulk handling systems can improve safety in several ways. First, by reducing manual labor, workers are less likely to be exposed to dangerous tasks, such as lifting heavy loads or working in hazardous conditions. Second, bulk handling systems are often equipped with safety features, such as emergency stop buttons, sensors, and alarms, that can quickly address any malfunctions or accidents.

Moreover, many bulk handling systems are designed to comply with industry standards and regulations, ensuring that businesses remain compliant with safety and environmental requirements. For instance, the use of a well-maintained LEV system can ensure that harmful dust is efficiently removed from the air, preventing potential health hazards and meeting regulatory guidelines.

Optimized Inventory Control

A crucial element in manufacturing is the management of raw materials. With bulk handling systems, businesses can improve their inventory control by ensuring that materials are stored and moved in an organized manner. Automation systems can track the flow of materials, providing real-time data on inventory levels, usage, and storage. This data can then be used to predict when new materials are needed, reducing the risk of stockouts or overstocking.

Improved Product Quality

For industries that process sensitive materials, maintaining quality standards is paramount. Bulk handling systems can help ensure that materials are handled gently and consistently, reducing the risk of contamination or damage. For example, pneumatic conveying systems, which are gentle on materials, can prevent the degradation of powders or fragile substances, ensuring that the quality of the final product is maintained.

Scalability and Flexibility

Another key advantage of bulk handling systems is their scalability. As manufacturing demands grow, bulk handling systems can be easily expanded or adapted to meet the changing needs of the business. Whether it’s adding more storage capacity with additional silos, increasing the throughput with additional conveyors, or implementing more advanced dust collection systems, bulk handling systems can be customized and scaled up to accommodate growth.

The Role of SEPCOM in Bulk Handling Systems

Incorporating a reliable system for handling waste and byproducts is also critical to a comprehensive bulk handling solution. SEPCOM is a specialized system designed to separate solids from liquids efficiently. It plays a crucial role in bulk handling operations that involve wet or semi-solid materials, such as in the food and beverage industry or chemical manufacturing.

SEPCOM systems use advanced separation technology to extract solid materials from liquid streams, ensuring that waste is properly disposed of or repurposed. By implementing a SEPCOM system, manufacturers can reduce waste, optimize resource use, and enhance the sustainability of their operations.

How to Ensure Optimal Performance of Bulk Handling Systems

While the installation of a bulk handling system can deliver substantial benefits, it’s crucial to ensure that these systems are properly maintained and regularly updated. One important aspect of bulk handling system maintenance is the installation of local exhaust ventilation (LEV) systems. These systems remove harmful dust and airborne particles, preventing workplace hazards and promoting a healthier environment for employees.

Furthermore, regular LEV testing is essential to ensure that the system operates efficiently. Testing helps identify any issues or inefficiencies in the system, allowing for timely repairs or upgrades. Routine maintenance of conveyors, elevators, and other components of the bulk handling system is also essential to prevent downtime and maintain consistent performance.

Conclusion

Bulk handling systems are a critical asset in the modern manufacturing landscape. From improving efficiency and reducing labor costs to enhancing safety and ensuring compliance with industry regulations, these systems offer unparalleled advantages for businesses seeking to optimize their operations. By integrating components like conveyors, elevators, pneumatic systems, and dust collection units, manufacturers can create a robust, efficient, and safe workflow that supports their long-term growth and sustainability.

For those looking to implement or upgrade their bulk handling systems, it is essential to work with experienced professionals who can tailor solutions to specific needs. Whether it’s lev system installation, implementing a SEPCOM waste management system, or testing and maintaining existing equipment, these systems can unlock significant potential for manufacturing operations. The future of manufacturing is undoubtedly automated, and bulk handling systems are at the heart of this transformation.

0 notes

Text

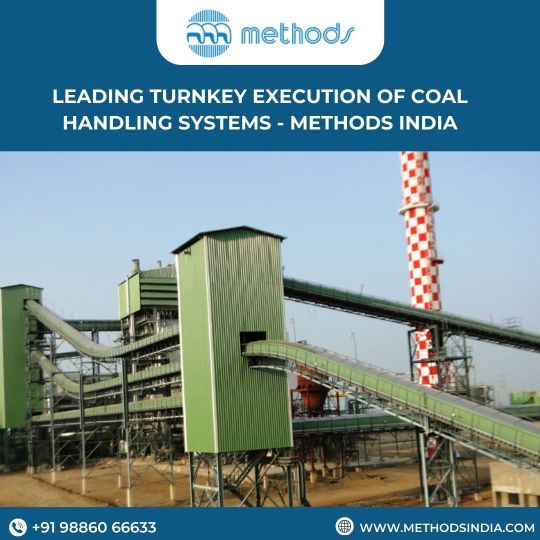

Leading Turnkey Execution of Coal Handling Systems - Methods India

In the realm of material handling, Methods India stands out as a leader in providing Turnkey execution of Coal Handling Systems. The products from Methods India are made with a focus on efficiency, safety, and simplicity. This allows for simple maintenance, which guarantees smooth operation. These turnkey solutions are designed to make moving and storing bulk materials easier.

The organization's dedication to quality has secured its standing as one of the top players in the bulk material handling sector. Find out how Methods India's innovative ideas can help you streamline your coal handling operations.

To contact us, Click on the link below- https://methodsindia.com/contact-information/

#Turnkey execution of Coal Handling Systems#Turnkey execution of Bulk Material Handling Systems#Independent Design House#Bagasse Handling Systems#Bulk material handling equipment manufacturers in Bangalore

2 notes

·

View notes

Text

Margo Industries – Leading Manufacturer of Pneumatic Conveying Systems in India

Discover Margo Industries, specializing in designing and manufacturing advanced pneumatic conveying systems for efficient bulk material handling across various sectors, including plastics, chemicals, and food processing. Contact us today to optimize your material transport solutions.

#vacuum conveying system#bulk material handling#powder conveying#pneumatic conveying#granular material transport#vacuum conveying solutions

0 notes

Text

Pneumatic Conveying System | Efficient Bulk Material Handling | Margo Industries

Explore Margo Industries' advanced pneumatic conveying systems designed for efficient bulk material handling. Improve productivity and reduce downtime with our reliable and customizable solutions. Learn more at Margo Industries.

#pneumatic conveying systems#bulk material transport#material handling solutions#pneumatic transport systems#pneumatic conveying equipment#efficient material handling#industrial conveying systems#automated bulk transport#Margo Industries

0 notes

Text

#PneumaticConveying#IndustrialFabrication#ConveyingSystems#FabricationExperts#HighQualityManufacturing#EngineeringSolutions#MaterialHandling#PneumaticSolutions#Automation#IndustrialInnovation#pneumatic conveyor systems#lump breaker#bulk materials handling#macawberindia#bulkmaterialhandling#dense phase pneumatic conveying system#macawber engineering

0 notes

Text

Pneumatic conveyor | Pneumatic conveyor manufacturer | Pneumatic conveying system | pneumatic material handling | bulk material handling

youtube

Enquiry : [email protected]

Contact : 95851 31112

Website: https://altomech.com/pneumatic-conveying-system.php

#pneumatic conveyor#pneumatic conveyor manufacturer#bulk material handling#pneumatic conveying system#pneumatic conveyor system#pneumatic conveying system manufacturers#pneumatic conveying companies#pneumatic powder transfer system#vacuum pneumatic conveying system#pneumatic conveyor systems#pneumatic conveyors#pneumatic grain conveying systems#manufacturer#altomech#Youtube

0 notes

Text

Transforming the Landscape of Bulk Material Management through Structural and Mechanical Design

Across the vast expanse of industrial operations, where bulk material management is paramount, Little P.Eng. Engineering has etched a significant mark. The firm's reputation in structural and mechanical design extends beyond just equipment, touching several critical aspects of material management. This article will delve into how Little P.Eng. Engineering is transforming four pivotal sectors: Material Handling Facilities & Building, Bulk Material Transport, Bulk Material Treatment, and Bulk Material Transfer.

Little P.Eng. Engineering is an American / Canadian company that provides economical bulk material handling engineering services that are designed to meet the specific needs of our customers. We have a long history of partnering with supervisors, engineers, planners, and vendors, across a wide variety of industries to provide bulk material handling engineering solutions and systems that improve safety and productivity. Whether you need help designing, installing or maintaining any aspect of your bulk material system, we have the skills and experience to meet your needs.

Our bulk material handling engineering specialists can re-engineer and upgrade existing systems while providing customer solutions and processes. We work with customers through every part of the engineering process to create a one-stop destination for all their needs.

We also work to provide superior customer service that extends well beyond the initial installation or execution of a solution. Our customers can contact us and receive immediate assistance whenever needed for continued support that keeps businesses up and running without having to worry about delays or downtime.

1. Material Handling Facilities & Building

Material handling facilities are the heartbeats of many industries. From mining to agriculture and manufacturing, they facilitate the smooth and efficient movement of bulk materials.

Understanding Infrastructure Needs: Little P.Eng. Engineering begins its design process with a comprehensive study of the client's requirements. The aim is to understand the volume of material to be handled, the rate of throughput, and the kind of materials involved.

Structural Integrity: Buildings designed for material handling need robust foundations. Little P.Eng. ensures that every facility they design can withstand the tremendous loads and stresses associated with bulk material handling.

Optimized Workflow Design: Beyond just structural integrity, Little P.Eng. focuses on creating a streamlined workflow within these buildings. Through the strategic placement of equipment, chutes, conveyors, and storage areas, they ensure that materials move seamlessly, minimizing disruptions and maximizing efficiency.

Innovation at the Forefront: Little P.Eng. is known for incorporating innovative solutions like automated sorting systems, advanced ventilation systems, and sustainable energy solutions, making these facilities both state-of-the-art and environmentally responsible.

2. Bulk Material Transport

Once materials are sourced and sorted, they need to be transported. Little P.Eng. Engineering has a vast portfolio of solutions tailored to this very requirement.

Vehicle Design: Depending on the type of material, the firm designs transport vehicles, whether trucks, railcars, or even conveyor systems. Their designs emphasize both capacity and safety, ensuring that large volumes can be transported without risks.

Infrastructure Design: Little P.Eng. also specializes in designing transport-related infrastructure. This includes everything from loading and unloading docks to advanced conveyor belt systems and even pneumatic transport solutions.

Addressing Challenges: Transporting bulk material is fraught with challenges like spillage, degradation, and contamination. Little P.Eng.'s designs account for these challenges, providing solutions such as sealed transport containers and dust suppression systems.

3. Bulk Material Treatment

Treatment of bulk materials, whether it's refining, purification, or simply grading, is a complex process. Little P.Eng.'s role in this domain is critical.

Treatment Facility Design: Little P.Eng. engineers facilities where bulk materials undergo various treatment processes. Their designs accommodate equipment like crushers, separators, graders, and more, ensuring they operate at optimal capacities.

Safety and Compliance: Treatment processes can sometimes involve chemicals or generate waste. Little P.Eng. prioritizes safety and regulatory compliance, designing facilities that minimize environmental impact and risks to workers.

Energy Efficiency: Many treatment processes are energy-intensive. Recognizing this, Little P.Eng. incorporates energy-saving solutions, from efficient machinery layouts to the use of alternative energy sources, thus driving down operational costs.

4. Bulk Material Transfer

Transferring bulk materials from one point to another, or even from one mode of transport to another, is a task that requires precision and speed.

Transfer Point Design: Little P.Eng. is adept at creating transfer points that minimize material loss. Whether it's transferring grain from a truck to a silo or coal from a railcar to a ship, their designs ensure smooth transitions.

Material Integrity: When transferring materials, there's a risk of contamination or degradation. Little P.Eng. addresses this by designing enclosed transfer systems or integrating rapid sealing mechanisms.

Automation and Technology: In an age of technology, Little P.Eng. leverages advanced automation systems in their transfer point designs. This not only speeds up the transfer process but also reduces human errors.

Little P.Eng.'s Journey to Excellence

At its core, Little P.Eng. Engineering’s success can be attributed to its comprehensive approach. Instead of viewing these four sectors in isolation, they consider them parts of a holistic system. Their designs, thus, seamlessly integrate across the spectrum, from handling facilities to transfer points.

Client-Centric Approach

Little P.Eng. has always prioritized the unique requirements of its clients. They understand that every industry and even individual businesses within those industries can have varying needs. This client-centric approach has resulted in solutions that aren't just efficient but are also tailored to the specific challenges and objectives of their clientele.

Embracing Future Challenges

As the world continues to evolve, so do the challenges associated with bulk material management. Little P.Eng. Engineering, with its commitment to research, innovation, and adaptability, is well-equipped to tackle these challenges head-on.

With a growing demand for efficiency, safety, and sustainability, industries will find in Little P.Eng. a partner that's not just equipped to meet these demands but one that's committed to exceeding expectations.

In the world of bulk material management, Little P.Eng. Engineering stands tall, not just as a solution provider but as an innovator and trailblazer. Through their expertise in structural and mechanical design across the four critical sectors detailed in this article, they're not just shaping industries but also the very future of bulk material management.

Little P.Eng. Engineering’s Bulk Material Handling Team is a dynamic and diverse group with experience in conveying systems – mechanical and pneumatic; chutes transfers, dust control & collection, etc. Our experience in material handling for the power and manufacturing industries will provide rapid development of realistic concepts, and reliable designs which optimize operating and maintenance cost for your project. Our goal will be to not only deliver successful design to the field but to provide you with the information you need to make informed decisions to meet your objectives.

Industries served through our Bulk Material Handling Engineering Services

Grains

Mining

Mills

Metals

Manufacturing

Maintenance

Fabrication

Agriculture

Packaging

Safety

Fire & Explosion

Ship/Barge Loading & Unloading

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

We offer the following Engineering Services within our Bulk Material Handling Engineering Services :

Discrete Element Modeling (DEM)

Calculation based modeling

Allows for visualizing results

Particle velocity

Forces (shear and normal) and moments (bending and torsional)

Acceleration and material scatter

More than just flow simulation of bulk materials

wear Patterns

Mixing

Center loading

DEM Benefits

Reduced Dust Levels

Reduced Noise

Reduced Chute Plugging

Better Conveyor Tracking (Center Loading)

Reduced Belt Cover Wear

Reduced Chute Wear

Reduced Equipment Wear

Structural Engineering Services

Foundation Design

Concrete Structure Design

Steel Structure Design

Piping Engineering Services

Bulk material handling engineering specifically focuses on the design, processing, and transportation of bulk materials, which can include items such as ores, coal, minerals, and grains, among others. These materials often present unique challenges due to their bulk nature, including issues related to flowability, abrasiveness, corrosiveness, weight, and other specific characteristics. Here are the various aspects of bulk material handling engineering services:

Storage Solutions:

Design and layout of silos, bins, and stockpiles

Assessment of material flow properties to reduce issues like bridging or rat-holing

Conveyor Systems:

Design and optimization of belt, screw, chain, and pneumatic conveyors

Selection of appropriate conveyor belts, idlers, and drives

Loading and Unloading Systems:

Railcar and truck loading/unloading facilities

Ship and barge loading/unloading equipment

Reclaiming Systems:

Design of stacker-reclaimers, bucket wheel reclaimers, and scraper reclaimers

Size Reduction Equipment:

Crushers, grinders, and milling equipment

Sizers and chutes to manage particle sizes

Screening and Sorting:

Vibrating screens, trommels, and sorters

Density separation using jigs or cyclones

Feeding and Metering Equipment:

Feeders for accurate and controlled material flow

Rotary valves, weigh feeders, and volumetric feeders

Material Transfer:

Chutes, hoppers, and gates

Transfer tower and junction house design

Dust Control and Suppression:

Dust collection and filtration systems

Wet suppression and foam suppression systems

Safety and Environmental Considerations:

Explosion and fire protection in dusty environments

Erosion control and spill prevention

Flow Aids and Devices:

Vibrators and air cannons to aid material flow

Flow liners and internal coatings

Bulk Material Testing:

Evaluating flowability, abrasiveness, and other material properties

Moisture content and material density testing

Rail and Marine Infrastructure:

Rail siding design and layout

Port and harbor infrastructure for bulk material export/import

Automation and Controls:

Automated monitoring of material levels in bins and silos

Control systems for conveyor speed, material flow, and routing

Maintenance and Wear Protection:

Wear liners and abrasion-resistant materials

Maintenance strategies and schedules

Bulk Material Transport:

Pipeline transport for slurry and other bulk fluids

Pneumatic transport systems for powders and granules

Economic Analysis:

Cost estimation for bulk material handling projects

Return on investment (ROI) calculations

Regulatory Compliance and Standards:

Ensuring designs meet relevant industry standards

Adherence to safety and environmental regulations

Continuous Improvement and Upgrades:

Evaluation of existing systems for performance enhancement

Retrofitting and upgrading older infrastructure

Consultation and Advisory Services:

Providing expertise on specific bulk material challenges

Assisting with vendor and equipment selection

Given the unique nature and challenges of handling bulk materials, these services are essential to ensure efficient, safe, and economical processing, transportation, and storage. Properly designed and managed systems reduce product loss, minimize environmental impacts, and ensure safety while optimizing costs.

Tags:

Little P.Eng. Engineering

Structural design

Compliance

Mechanical design

Energy efficiency

Single-boom spreaders

Bulk material transfer

Bulk material transport

Client-centric approach

Environmental impact

Material handling

Treatment facilities

Conveyor systems

Infrastructure design

Pneumatic transport

Refining

Material grading

Transfer points

Dust suppression

Material contamination

Bulk material degradation

Silo design

Loading docks

Workflow optimization

Advanced ventilation systems

Risk assessment

Sustainable engineering

Material integrity

Client testimonials

Automation in material handling

Bulk Material Handling & Processing

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Little P.Eng. Engineering#Structural design#Compliance#Mechanical design#Energy efficiency#Single-boom spreaders#Bulk material transfer#Bulk material transport#Client-centric approach#Environmental impact#Material handling#Treatment facilities#Conveyor systems#Infrastructure design#Pneumatic transport#Refining#Material grading#Transfer points#Dust suppression#Material contamination#Bulk material degradation#Silo design#Loading docks#Workflow optimization#Advanced ventilation systems#Risk assessment#Sustainable engineering#Material integrity#Client testimonials

0 notes

Text

Powder Transfer Systems: Aishin's Solutions for Efficient Material Handling

Powder transfer systems are essential for modern industrial processes, revolutionizing material handling and transfer. In various industries like pharmaceuticals, food processing, and chemical manufacturing, efficient and precise powder handling is crucial for overall productivity, product quality, and workplace safety.

Overview of Powder Transfer Systems

Powder transfer systems are specialized systems crafted for the controlled handling and transfer of powders or granular materials. Precision and automation in powder transfer systems significantly reduce human error and variability, enhancing efficiency and ensuring the consistency of the final product. The ability to control parameters like flow rates and dosages optimizes production workflows, minimizing waste and contamination risks.

Industries are embracing powder transfer systems. In pharmaceuticals, these systems manage active pharmaceutical ingredients with precision. The food and beverage sector relies on them for accurate mixing, while in chemical manufacturing, they handle and transfer various powdered chemicals. The versatility of powder transfer systems makes them indispensable for controlled powder handling in critical production processes across industries.

Types of Powder Transfer Systems:

Powder transfer systems include two types, pneumatic conveying systems and mechanical transfer systems. Each type possesses distinctive features and applications. Pneumatic conveying systems use compressed air to transfer bulk materials like powder and granules through a closed pipe whereas mechanical transfer systems involve the transfer of materials using machinery like belts, rollers, brackets, and motors.

Understanding the unique features of each system aids in selecting the most suitable one for specific tasks. Factors such as the type of powder, required transfer distance, and overall operational efficiency play a important role in the decision-making process. Aligning system attributes with application requirements is essential for optimal performance.

Common Challenges in Powder Transfer

Common challenges in powder transfer processes include clogging and particle segregation, which can lead to downtime and contamination risks. Powder characteristics, such as size, shape, and moisture content, influence transfer efficiency. Fine particles may cause dusting, and cohesive powders can lead to poor flow and clogging. Overcoming these challenges requires specialized equipment design, vibrational assistance, and segregation-prevention techniques.

Aishin's Solutions to Powder Transfer Challenges:

Aishin, a global leader in material handling and powder transfer systems, has manufacturing facilities in Japan, Thailand, China, and India. Their comprehensive range of equipment includes bag dumping stations, rotary valves, knife gate valves, butterfly valves, silo/hoppers, mechanical transfer systems, pneumatic transfer systems, bin scrapers, dosing systems, lump breakers, and more. Aishin excels in addressing challenges associated with powder transfer such as clogging and particle segregation, and also in handling adhesive materials. Their scraper rotary valve is proven effective in overcoming difficulties posed by sticky materials during transfer processes. Aishin is renowned for Japanese engineering and is a leading rotary valve manufacturer in the industry.

Conclusion

Powder transfer systems are vital for industries, ensuring precise handling of powdered materials across sectors. Aishin, as a global leader in material handling equipment, is adept at addressing powder handling challenges. Trust Aishin to resolve powder transfer-related issues, ensuring operational efficiency, product quality, and workplace safety in your industrial processes.

#powder handling#material handling#equipment#powder#powder transfer#pneumatic conveying system#powder transfer system#valves#rotary valves#bulk material handling

0 notes

Text

Choosing Loss-In-Weight Feeder : Factors To Consider

When choosing a loss-in-weight feeder for your business, it's important to focus on factors like accuracy, reliability, and material compatibility. Understanding the key differences between volumetric and gravimetric feeders can help you make the right decision. Check out our full blog to learn more factors to consider while choosing the loss-in-weight feeder.

#hopper feeder#bulk bag discharger#screw conveyor#industrial equipment#flue gas treatment#bulk material handling#sodimate#bulk handling systems#activated carbon#bulk handling

0 notes

Text

SEPCOM Solutions for Smarter and Cleaner Waste Processing

Introduction

The global demand for efficient and sustainable waste management systems has surged, driven by increasing environmental concerns and stricter regulations. SEPCOM solutions stand at the forefront of innovation, offering smarter and cleaner waste processing methods that not only enhance efficiency but also contribute significantly to environmental conservation. By integrating cutting-edge technology with practical applications, SEPCOM transforms the waste processing landscape, making it both eco-friendly and economically viable.

The Evolution of Waste Processing

Traditional waste processing systems often rely on labor-intensive methods that fail to maximize resource recovery or minimize environmental impact. Over time, industries have recognized the need for solutions that blend performance with sustainability. Enter SEPCOM — a game-changing approach that optimizes waste separation and management.

At its core, SEPCOM utilizes a highly effective screw press separator. This system excels in the separation of solids and liquids, making it indispensable in sectors such as agriculture, biogas production, and industrial waste management. With its innovative design, the SEPCOM screw press separator minimizes waste, recovers valuable resources, and significantly reduces the environmental footprint of waste processing operations.

How SEPCOM Enhances Waste Management

The brilliance of SEPCOM lies in its adaptability and precision. Unlike conventional methods, it processes waste with unparalleled efficiency, ensuring that both solid and liquid components are managed optimally.

Resource Recovery: SEPCOM is engineered to extract maximum value from waste. By separating components effectively, it enables the recovery of nutrients and materials that can be reused in various applications. For example, in agriculture, the solids separated by SEPCOM can be repurposed as high-quality compost, while the liquids serve as nutrient-rich fertilizers.

Eco-Friendly Design: Sustainability is a cornerstone of SEPCOM solutions. Its design emphasizes minimal energy consumption and reduced greenhouse gas emissions, aligning with global environmental goals.

Versatility Across Industries: From food processing plants to biogas facilities, SEPCOM’s versatility makes it a preferred choice for diverse waste management needs. Its robust build and innovative features ensure reliable performance even under challenging conditions.

Integrating SEPCOM with Advanced Systems

To amplify the benefits of SEPCOM, it is often integrated with other advanced systems, such as bulk handling systems and local exhaust ventilation systems. These integrations streamline operations, enhance efficiency, and improve safety standards.

Bulk Handling Systems: The combination of SEPCOM with state-of-the-art bulk handling systems ensures seamless movement and storage of waste materials. This synergy eliminates bottlenecks, reduces spillage, and optimizes workflow.

Local Exhaust Ventilation Systems: Waste processing environments can pose health risks due to airborne contaminants. A properly designed and maintained local exhaust ventilation system mitigates these risks, ensuring cleaner air and a safer workspace. SEPCOM’s integration with these systems further enhances its eco-friendly credentials.

Streamlining Operations with SEPCOM

Efficiency in waste processing is not merely about technological sophistication; it also depends on proper installation and maintenance. SEPCOM’s performance is significantly enhanced when supported by a well-planned LEV system installation. Proper installation ensures that waste processing units operate at peak efficiency, minimizing downtime and maximizing output.

By integrating SEPCOM with other complementary systems, businesses can achieve a cohesive waste management strategy that is both effective and sustainable. This holistic approach addresses waste at every stage, from collection to resource recovery.

The Future of Waste Processing with SEPCOM

SEPCOM represents a paradigm shift in waste processing, but its potential extends far beyond current applications. As technology evolves, SEPCOM is poised to incorporate advancements such as AI-driven monitoring systems and IoT-enabled sensors. These innovations will provide real-time data insights, enabling predictive maintenance, optimizing resource utilization, and further reducing operational costs.

Moreover, SEPCOM’s commitment to sustainability aligns seamlessly with global efforts to combat climate change. By promoting circular economy principles, it not only reduces waste but also contributes to a regenerative industrial model where resources are reused and recycled.

Conclusion

In an era where environmental consciousness and operational efficiency are paramount, SEPCOM solutions emerge as a beacon of innovation in waste processing. Its sophisticated design, adaptability, and integration potential make it an invaluable asset across industries. By coupling SEPCOM with advanced systems like local exhaust ventilation and bulk handling systems, businesses can unlock unprecedented efficiency and sustainability. As we move toward a cleaner, smarter future, SEPCOM stands ready to lead the charge, redefining waste management for a better tomorrow.

0 notes

Text

Choose the Bulk Material Handling Equipment with Methods India

Elevate your industrial efficiency with Methods India's efficient Bulk Material Handling systems, putting general safety first. Our latest technologies are made to maximize material flow while maintaining the strictest safety regulations.

Being a reputable brand in the field, Methods India takes pride in providing innovative and dependable systems that increase output while lowering risks. Our unlimited strategy promises the general safety of your material handling procedures, offering a smooth and safe working environment.

Select Methods India for high solutions that successfully optimize your industrial processes by balancing efficiency and safety.

For more information , Visit our site - https://methodsindia.com

#Bulk material handling#Bulk material handling systems#Bulk material handling manufacturers#Steel Fabrication Works#Bagasse Handling System

2 notes

·

View notes

Text

Custom Pneumatic Conveyors & Material Handling Solutions - Margo Industries

Find the perfect pneumatic conveyor and powder handling solution with Margo Industries. Our customizable systems meet the demands of industries like food, pharmaceuticals, and chemicals for efficient material handling

#vacuum conveying system#bulk material handling#powder conveying#pneumatic conveying#granular material transport#vacuum conveying solutions

0 notes

Text

Pneumatic Conveying Systems for Efficient Material Transport | Margo Industries

Discover Margo Industries' cutting-edge pneumatic conveying systems designed for efficient, cost-effective bulk material transport. Our solutions ensure smooth operation and reduced maintenance. Learn more at Margo Industries.

#pneumatic conveying systems#bulk material transport#material handling solutions#pneumatic transport systems#pneumatic conveying equipment#efficient material handling#industrial conveying systems#automated bulk transport#Margo Industries

0 notes

Text

0 notes

Text

Mr. And Mrs. Claus

25 Days of Ficmas

Relationship: Tom “Iceman” Kazansky x Reader

Fandom: Top Gun

Request: No

Warnings: Fluff

Word Count: 1,574

Main Masterlist: Here

Top Gun Masterlist: Here

Summary: Oh the running joke on the base about the one couple that likes to decorate for the holidays…

Consider Donating: Here

Ah, government housing. It was not always a great thing, but sometimes you gotta make it great. Which is exactly what the Kazansky’s were doing five days before Christmas. They would have done it sooner but Tom did not get back into the house until a couple days ago from his last deployment.

“Honey, are you sure you’re fine up there?” Mrs. Kazansky called, holding the bulk of the lights her husband was stringing up.

“Yes, sweetie. I’m fine.” Tom answered, focused on attaching the twinkling strands to the edges of the outside of the house. Somehow, he had yet to fall from the height he was delicately perched at. A slippery patch had formed on the next ladder rung up, causing him to shake and wobble the thing. Panicking, she rushed forward and steadied the ladder.

With a shaking breath, Kazansky looked down at his wife along with a nervous smile. “I’m fine, sweetie.”

“Are you sure we couldn’t have called some friends to come help you?” Feeding her husband more lights, she tried to calculate how long it would be before they were done with dangerous activity.

“My name is literally ‘Iceman’. I think I can handle some twinkle lights.”

“Suddenly, I’m not so sure.”

And yet, she continued to spot her husband, making sure that he did not end up falling off that ladder. Northern California was quite cold for this time of year, more so than you would think. But it was all worth it in the end. A gorgeous array of colors lit up their house now. Setting the death trap ladder aside, Tom stood back and held his wife in his arms as they both looked upon the house.

A wreath sat on their front door, the green standing out against the plain grey of the house. It was all they could afford to do in terms of time and money, but it was perfect. It was theirs.

“One day, when we get us a big ole house, I’m gonna decorate the entire outside of it.” Tom whispered, pressing his lips against her head. Turning to face her husband, she smiled as she buried her reddening nose into his neck.

“That’ll be wonderful, Tommy.”

Deciding that the outside was beautiful and admiring it for a bit, the couple went inside to begin making the inside resemble the outside. After Tom had gotten the tree up in the corner of the living room, he set about dropping garland and different wall decorations about the house. In the meantime, she started on the ornaments for the tree.

Over the past three years that they had lived together, they had found a system that worked for them. It probably also helped that they were both so similar and could practically read each other’s minds at this point. This was their favorite time of year. Each chance they got to spend it with each other was a blessing. It had happened before that Tom was deployed during the holidays. Those years were always hard, but she would try and go home to spend the days with family.

However in the middle of decorating, Mr. Kazansky had just finished adding the strand of garland around the tree when a knock came to the door. The couple looked between them in confusion. Neither had been expecting company today. Tom made his way over to the door where he looked through the peephole. Maverick and Slider stood outside of the door, bouncing on their feet. Pulling open the door, the men all greeted each other with glee and were ushered inside.

“Hey! There’s our favorite Kazansky,” Slider called, wrapping the woman in a hug.

Chuckling at his words, she happily returned the embrace. “Hey, Slider.”

“Hey, Mav.” She added, poking her head around the body that was slightly crushing her.

“Hello, favorite,” Maverick teased, taking her from Slider’s grasp. All the while, Tom sat there with hands on his hips.

“I’m right here, you know?” He said, exasperated.

As if on cue, and perfectly in sync, the other two men turned towards their buddy with matching smirks. “We know.”

Mrs. Kazansky giggled, pulling herself from Maverick’s arms to go to her husband once more. Mr. Kazansky was less amused, but still welcomed his wife into his grasp.

“You two are jokers. So very funny. What are you two doing here?” Releasing his wife, Iceman stayed in the foyer of their home with the two men. His wife went over and kept working on their tree, specifically setting aside the tree topper for Tom to put on later.

“We came to see if you had gotten the new deployment details yet.” Slider pipped up. With a sigh, she continued working on the tree, but with less enthusiasm.

“No, when did these come in?” Tom asked, briefly looking over at his wife.

“Yeah. You’re stepping in for Santa this year with all your holiday cheer,” his RIO jested with a smile. There was a collective sigh of relief from the Kazansky’s.

“Oh, ha ha, Slide. Listen, just because I’ve got a wife and you don’t…” he trailed off, playfully shoving the man. Everyone took a minute to laugh at the joke, however, Maverick spoke up seriously.

“Yeah, but we are getting a new deployment soon, Ice. Have you checked the mail?” And just like that, the mood was brought down again.

“To be honest, I haven’t left the house much today or yesterday. But, I’ll go look.”

As Tom left, Slider went with him, and Maverick was about to. That was until he noticed how upset she was, still putting ornaments on the tree. Pete chose to stay back and picked up a decoration to help out while he could.

They did not speak to each other for a few minutes. Her husband and his best friend took their conversation outside, leaving nothing but silence in their wake. Illuminated by the lights on the tree, Mrs. Kazansky was trying hard to keep the tears from her eyes.

“He’ll be fine, ya know?” Mitchell said after a while.

“What?” Her hand paused its placement of the bobble in it for a moment.

“He’ll be okay. You know that Slider and I wouldn’t let anything happen to Ice.”

She sighed deeply. Placing the ornament on the tree, she still refused to look at the man. “When do you leave?”

“The second at 0800.” Her lips pursed as she continued her task. She was not sure whether or not it was a good thing that Pete was helping her, and making it go faster.

“Well,” she breathed, walking away from the tree and to the couch nearby, “at least I have him for the holidays.”

Maverick paused his help, and came over to sit next to her on the sofa. She was resting her elbows on her knees, hands clasped together, and a pensive expression. There were so many thoughts running around both of their minds, but none seemed to quite jump out.

“You okay?” That was all that he could say, and even that did not seem like enough.

“Yeah,” she exhaled sharply, “yeah. We’ll be fine.” While her words tried to be reassuring, that expression she carried was anything but.

“Hey,” Maverick started, placing a hand on her shoulder, “I know it sucks now, but soon, Ice will move up in the Navy and you wont have to deal with this anymore more. Just gotta stick it out a little longer.”

“I know. It’s just… not pleasant. Knowing that he’ll be gone soon.” She lamented, resting her head on his shoulder. Maverick hugged her close as, just then, Iceman and Slider came back in. And they were arguing about- something. Even the two that were already int he house could not understand what about until later in the conversation.

“Absolutely not, Ron. Ain’t no way.” Tom protested, setting the mail down on the kitchen island.

“Come on, man. It’s funny.” The RIO countered, obviously enjoying whatever it was.

“What are you two arguing about now?” Mrs. Kazansky piped up, not a stranger at all to these kinds of confrontations.

“Nothing, dear-“

“I proposed a new call sign, just for the holidays.”

Shaking her head, she began to chuckle as she stood to join the two men now bickering in her kitchen. Briefly, she registered Pete following after her. Wrapping her arms around her husband’s stomach, she pressed a kiss to his shoulder.

“What name, Sli?”

With a smirk, Kerner looked at his front-seater with glee. “Mr. Claus.”

All at once, her husband groaned, Maverick started laughing, she tried to suppress her giggles and Slider was just standing there proudly.

“Oh, that’s good.” Pete was wiping his eyes as his voice kicked up an octave.

“That- that makes her Mrs. Claus.”

This sent Mitchell and Kerner deeper into fits of laughter. Mr. Kazansky groaned again, dropping his head down in defeat. Mrs. Kazansky just sighed at their antics.

“If I ever find out that you have uttered that name on base…” Iceman warned, shooting pointed looks at the men.

“Believe me. You will never find out that we told anyone.” Maverick smirked, near beaming with joy.

“I’m gonna kill them,” Tom whispered to his wife.

“Not yet,” she replied.

Do not ever ask why the first week back from the holiday break Maverick and Slider were cleaning Iceman’s gear while he relaxed. No one needs to know the story.

#rebelliousstories#writing#25 days of christmas 2024#25 days of ficmas 2024#25 days of ficmas#25 days of christmas#top gun imagine#top gun iceman#top gun#tom kazansky x reader#tom kazansky imagine#tom iceman kazansky#tom kazansky#iceman x reader#iceman fanfiction#iceman imagine#iceman val kilmer

215 notes

·

View notes