#Brass Wire Screen

Explore tagged Tumblr posts

Photo

Brass Filter Mesh

Brass Filter Mesh is a popular type of wire mesh. It is also widely known as brass wire mesh for its material.

1: Introduction (1) A cutting-edge solution. (2) Crafted from high-quality brass material. (3) Unparalleled durability and longevity. (4) Exquisite mesh design for optimal performance. (5) Versatile applications across industries. (6) Engineered for efficient filtration processes. (7) Superior corrosion resistance for longevity. (8) Precision manufacturing ensures uniformity. (9) Unmatched reliability in filtering applications. (10) Ideal for liquid and gas filtration needs. (11) Brass construction guarantees sturdiness. (12) Promotes seamless flow in filtration systems. (13) Boosts system efficiency and productivity. (14) Engineered to withstand harsh conditions. (15) Your gateway to premium filtration.

2: Key Features (1) Finely woven brass threads for effectiveness. (2) Singular mesh design for easy maintenance. (3) Resistance to chemical and environmental factors. (4) Each mesh offers consistent filtration precision. (5) Ideal for fine particle separation. (6) High-temperature resistance for diverse applications. (7) Customizable sizes to fit varied systems. (8) Promotes excellent fluid and gas flow. (9) Minimizes clogging for uninterrupted processes. (10) Low-pressure drop ensures energy efficiency. (11) Brass composition inhibits bacterial growth. (12) Easy to install, saving time and effort. (13) Cost-effective solution for long-term use. (14) Enhanced structural integrity for reliability. (15) Elevating filtration standards with this wire screen.

3: Applications and Industries (1) Widely employed in oil and gas industries. (2) Crucial in pharmaceutical manufacturing processes. (3) Automotive sector relies on its precision. (4) A staple in water treatment facilities. (5) Enhances efficiency in chemical processing. (6) Essential for food and beverage production. (7) Used in HVAC systems for clean air circulation. (8) Agriculture benefits from soil filtration. (9) Power plants utilize for fluid purification. (10) Marine industry employs for seawater filtration. (11) Instrumentation relies on precise filtration. (12) Aerospace applications for fuel filtration. (13) Petrochemical refineries ensure purity with it. (14) Mining operations benefit from its robustness. (15) Transforming diverse industries.

4: Choosing Brass Filter Mesh for Your Needs (1) Optimal choice for long-lasting filtration solutions. (2) Brass construction guarantees product longevity. (3) Versatility meets the demands of various industries. (4) Seamless integration into existing systems. (5) Enhanced performance for critical applications. (6) Customizable options for specific requirements. (7) Cost-effective investment in system efficiency. (8) Industry-approved for reliability and effectiveness. (9) Low maintenance ensures hassle-free operation. (10) Resilient against harsh environmental conditions. (11) Precision engineering ensures consistent results. (12) Unparalleled quality for superior filtration. (13) A wise and enduring investment. (14) Boosts overall system productivity. (15) Elevate your filtration standards with this screen mesh.

The product Brass Filter Mesh appeared first on Alex Wire Mesh.

#Brass Filter Mesh#Brass Mesh#Brass Mesh Cloth#Brass Mesh Screen#Brass Screen Mesh#Brass Wire Cloth#Brass Wire Grid#Brass Wire Mesh#Brass Wire Screen#Copper Mesh#Copper Mesh Cloth#Copper Mesh Screen#Copper Net#Copper Screen#Copper Screen Mesh#Copper Wire Cloth#Copper Wire Grid#Copper Wire Mesh#Copper Wire Net#Copper Wire Screen

0 notes

Photo

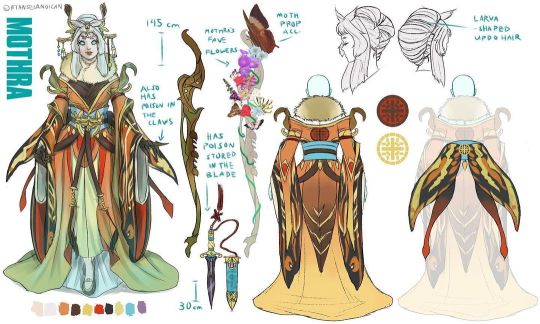

Mothra & Godzilla from @btanselanoican’s gijinka D&D/fantasy kaiju series // Cosplayers: @strangecatcosplay & @Fooprawn // photos: Ejen Chuang

My Mom is a skilled sewist and used to make Halloween costumes for my sisters and I when we were young. My sister was born on Halloween so we always had costumes and fun celebrations. That started my fascination with dressing up in costume and I always had fun doing it.

As I got older, my Mom taught me how to sew. In 2010 I saw Alice in Wonderland, and fell in love with the costume designs Colleen Atwood brought to the screen.

My Mom helped me a lot with making an Alice cosplay, and I went to my first anime convention. I had never been to one, and after that I wanted to go to more. I fell in love with the fun process of making cosplays and have been doing it since. It's a huge part of my life now, and I met both of my partners through cosplay.

Godzilla movies have a special place in my heart. I always loved sci-fi and fantasy, monsters and crazy costumes. Mothra and Battra are my favorites, so when I saw the designs by btanselanoican, I was inspired. It brought back a sense of nostalgia and happiness while making parts of the cosplays. I still have more details that I want to add and fix, but my Mothra cosplay is one of my favorite projects I have worked on in a long time.

It was a long process, and involved many different materials. For Mothra, I started with the wig. It involved a lot of cotton batting and white felt to build up the shape without adding a lot of weight, then shaping the wig fibers over that. I made the antennae out of wire and painted felt. The earrings are made of cut brass and painted beads. For the dress, it was a lot of patterning by pinning fabrics to my dressform, making a first draft, then using that to cut the actual fabric. I made a corset and skirt, and then the robe/dress piece that wraps over that. The skirt started out white, but was then dyed to the right colors. The sleeves were the hardest part to figure out. They were dyed and painted by hand, before being sewn to the dress. There are also a lot of appliqued gold fabric pieces on the dress. I made the belt, and all the shiny belt petals are also hand-cut brass pieces.

The wings are made of wire and old tights, that I then stitched, painted, and shaped to fit along my back.

The staff is made from a PVC pipe and foam base, then I added the electronics. There are green LEDs, and a small 10rpm motor that makes the moth wings move. I covered everything with foam strips, making them look like wood and vines. There are compartments made of foam and magnets, that way I can get to the battery pack or motor if I need to. I then added the paint and flowers. The moths are made of foam, pipe cleaners, painted posterboard, and faux fur. The moth wings are attached to the motor via some old ukulele strings. The monofilament keeps its shape and is light, but also strong. It's fed through old metal brakeline tubing that goes through the staff.

For Godzilla, it was a lot of use of canvas cotton. We found these huge canvas dropcloths at the hardware store, and they were surprisingly soft, but sturdy, after washing them. They have a thick woven texture and take fabric dye really well. We used that for making Godzilla's pants and shirt. The cape was made of thick cotton, cut, weathered, and painted. The spine has LEDs in it that go up into the hood. His chest and hip armor is all actual leather, patterned by hand and stitched together. The chainmail on the hip armor is hand made as well. His arm and leg armor is more canvas and layers of thick fabric. His shoes are leather and layered canvas and cotton. They are made by hand, and if you look on the bottom they have a Godzilla footprint.

All the "claws" on his hand armor and foot pieces are made of bamboo from the backyard. All of the woven rope pieces are cotton wrapped fleece, braided together for a thick and lightweight rope.

The sword is PVC and foam for a base. The lights are two different sets: a LED string light set, and a neopixel setup. The neopixels were soldered by hand, and are controlled by a command board that also controls a speaker. We set it to play Godzilla's roar with custom light animations. It has a plastazote foam to diffuse the lights, and then more EVA foam on top.

When I saw the designs I fell in love with the props, the attention to detail, and the use of color. Plus, I have always loved Dungeons and Dragons, so putting them into that universe was such a wonderful idea. I also look for fun challenges when it comes to props, and Mothra's staff was so beautiful. I couldn't resist.

Having experience in textile studies has helped me so much with my understanding of how different fabrics work with dyes. I used a lot of dye techniques for different parts of these cosplays. Godzilla's pants and shirt were dyed, Mothra's skirt was dyed two different times, the sleeves were dyed, painted with more dye, and then painted again. I don't think I would have been able to make my Mothra cosplay the way I wanted to without that prior knowledge and experience.

The best part is the magic staff. I am so proud of how it turned out and the way the moths move makes me so happy!

The only thing that I get tired of is that occasionally I run into things with the wire wings, and the long dress can make it hard to go through crowds in convention halls.

#mothra#godzilla#fan expo New Orleans#comic con#cosplay#cosplay interview#cosplayfeature new Orleans

187 notes

·

View notes

Text

SUMMIT OF DIVISIONS (R.I.P Märchen & Pixel SyndicateEdition)

youtube

— (All) —

Here we go (here we go), east and west

Connecting divisions (divisions) with this microphone

Old and young, come together and make our voices a chorus

The battle is locals vs. Chuohku

Here we go (here we go), you and me

Right and left, me and you

Overcoming blood relations and troublesome connections

Anyway, this party, let's get it on

A night where shocking oaths crowd around

The no.1 mic that aims at our days

Let us drink and sing, get wired as we like

A party night limited to only one stage, make love

Hop, skip, and jump, taking the initiative asap

Let's get started

Reverberating sound and hearts

If we don't have fun, there's no point

Let's go!

— (Queen Card) —

Don’t be afraid, come closer, Baby

to a land where norms are forgotten, magic happens

They said, "don't you feel a little lonely living in your own world?"

But don't you feel helpless living in other's worlds?

How can someone who looks like danger and sin

taste so good and holy just like the heavens?

The one that you sought, we’re making it hot

The land of dreams feels good to me

Come on in

— (Black Cat, Reiaki Suzubayashi) —

Sometimes I just need a break from my own thoughts

In my head, my thoughts twist and form into knots

You sleep to dream while I'm awake to live mine

I'm outta my mind, it's a dark and scary mind

— (Hex 13, Miku Shirazuki) —

In the dark two shadows reaching through

their hands meet and light spills in a flood like a

hundred gold urns pouring out the sun

All the way up up up in the air yo

— (Rush Hour, Anika Kiyozaki) —

Uh everyday I'm winnin’

Akihabara's lights never stay dimming

I'm aiming for the thoughts, I got your head spinnin'

Whether it's on the tracks or the clinic where you relax

The world now that you living in

is all just an illusion

Your strings have loosened Uh-huh

All hands on deck, Syndicate, raise your mics

Instincts take over

We swallow you whole,

— (Ready or Not, Shian Meizono) —

I found you gotchu in my line of sight

Are you flirting or trying to start a damn fight

How bad can a good girl get

Be careful with how you tread

Don’t run you will only get caught tired

— (Screen Shot, Makina Setsukura) —

See you yap yap with it Just the opening gambit

I heard you’re a player

Nice to meet you I’m the game

Enemies I keep slaying

Only way to win is to keep playing

— (All) —

Here we go (here we go), east and west

Connecting divisions (divisions) with this microphone

Old and young, come together and make our voices a chorus

The battle is locals vs. Chuohku

Here we go (here we go), you and me

Right and left, me and you

Overcoming blood relations and troublesome connections

Anyway, this party, let's get it on

A night where shocking oaths crowd around

The no.1 mic that aims at our days

Let us drink and sing, get wired as we like

A party night limited to only one stage, make love

Hop, skip, and jump, taking the initiative asap

Let's get started

Reverberating sound and hearts

If we don't have fun, there's no point

Let's go!

Bukuro! (Hey!)

Yokohama! (Ho!)

Minato! (Hey!)

Nagoya! (Ho!)

Shibuya! (Hey!)

Shinjuku! (Ho!)

Akiba! (Hey!)

Osaka! (Ho!)

— (MC B.B, Ichiro Yamada) —

All in all, we're bad motherfuckers

We're seriously unique, so it's a traffic jam of characters

Clashing our hilts against each others', rattle rattle

From learning from each other, to I gotcha again

— (Mr. Hc, Samatoki Aohitsugi) —

A locust leading the underground

Goodbye to the empty-headed kiddy rappers

The bell tolls for me, brass knuckles

Even if you line up a bunch of small fry, it's still 0 points

— (Queen Card) —

You want a battle from me

I'll give you a war, it's like Beauty and Beast

You know I'll be the designer of your catastrophy

Go hard, take the mic,

I'm the Queen, I'm swordlike

— (Rush Hour, Anika Kiyozaki) —

Bet you got your hopes high up, thinking you can beat me

Well think again, everything I oversee

Treat me like a joke, I'll run you over like it's funny

I'll laugh in your face. Bitch, my victory tastes like honey

— (Easy R, Ramuda Amemura) —

From Shibuya, Shinjuku, Hama and Bukuro

With Nagoya, Osaka, Minato, Akiba, we'll cause great fear

The iron rule is to stan while you still can

Today, it seems like around here is where we should run off

— (ill-DOC, Jakurai Jinguji) —

A warped rondo, an elaborate skit

A vaccine panacea overdose, end of examination

With the past, NO WAR

Let's change with the night's crescendo, checkmate

— (Tragic Comedy, Sasara Nurude) —

Final countdown of one thousand days

Held by the beat, this heart is steel

Fated for battle until we burn up

You're not allowed to stop this flow

— (Evil Monk, Kuko Harai) —

The anchor for these complicated guys

If it was a different day, we'd be taking each others' territory

Taking a mic in hand, deciding the last shot

I'll change this place into an energy vortex

— (All) —

Here we go (here we go), east and west

Connecting divisions (divisions) with this microphone

Old and young, come together and make our voices a chorus

The battle is locals vs. Chuohku

Here we go (here we go), you and me

Right and left, me and you

Overcoming blood relations and troublesome connections

Anyway, this party, let's get it on

A night where shocking oaths crowd around

The no.1 mic that aims at our days

Let us drink and sing, get wired as we like

A party night limited to only one stage, make love

Hop, skip, and jump, taking the initiative asap

Let's get started

Reverberating sound and hearts

If we don't have fun, there's no point

#hypnosis mic#hypnosis mic oc#hypmic#hypmic oc#hypnosis mic arb#hypmic arb#minato division#r.i.p märchen#queen card#reiaki suzubayashi#miku shirazuki#akihabara division#pixel syndicate#anika kiyozaki#shian meizono#makina setsukura#summit of divisions#youtube#Youtube

9 notes

·

View notes

Text

Train in Vain: Chapter 7 Target Acquired

Summary:

For your new friends, you boldly go where no Saturday night has taken you before, but you might just be in over your head.

Notes:

If you can't tell I really enjoy scene-setting. There will be stuff that happens next chapter I promise lol.

TWs: afab Reader. Alcohol mentions and drinking mentions. Drug and drug dealing mentions. Potential danger.

You hadn’t realized how cold the night had become until you found yourself confidently stalking away from the circle of people. The close proximity of your two large friends had radiated warmth and security through your body all night. Now, all alone, the frigid air took its opportunity to bite through any exposed flesh that it could find. Your initial high of resolve was violently harshed by the sharp gusts of wind which seemed to target your hands and ankles spitefully. Your gate shorted and velocity slowed as you burrowed your icy fingers in your armpits. Your shoulders hunched slightly against the rushes of night air in a futile attempt to concentrate your waning heat and bolster your similarly diminishing assuredness.

You’d seen wires in TV shows and movies. It was a simple enough mic and receiver that Tashigi had taped to your belly. What your Hollywood exposure to government espionage hadn’t shown you was how damn itchy and uncomfortable wires were against bare skin. The plastic and metal contraption rubbed against your core as you walked. It suddenly hit you that you might have to use the restroom while wired, but before you could even think about being embarrassed over the potential scenario, you’d reached the door to the bar.

You grabbed the metal handle and the heavy door swung open with aggressive help from the wind. The bell above you clanged sharply in contact with the door, announcing your arrival. The place was a pretty classicly unimpressive one-room dive. The dark-stained wooden bar jutted out from the left side of the room and ran the length of the establishment, heavy wooden bar stools dotting its path here and there. The backsplash of the bar was a long and warped mirror with tarnish that marked its age and wear. Along the right wall were uncomfortable-looking booths made out of the same dark-stained wood that made the place look even dimmer than it already was. The lone chandelier that hung in the center of the long room was antique brass and probably hadn’t been cleaned since it was installed. Two of its electric faux candles flickered erratically at distinctly different paces, almost immediately giving you a headache. Some Dean Martin song crooned cornily through muffled speakers from somewhere you couldn’t pinpoint.

The booze selection was as spectacular as the bar itself, that is to say, not at all. There were only two rows of bottles behind the bar counter and you didn’t spot anything which looked even remotely like top-shelf liquor. There were just two patrons inside. One was sitting at a barstool near the door and didn’t react whatsoever to your loud entrance. You could see in the reflection of the mirror that the man was, for lack of a better term, absolutely blotto. He stared at his reflection, eyes puffy and red while sipping beer slowly from a tallboy can. The man was middle-aged, chin and face darkened with stubble, still wearing his coat and flat-brimmed cap despite the bar being a fairly decent temperature inside.

The other patron was a younger man lounging at one of the middle booths. He had positioned himself as best he could to get comfortable on the rigid wooden bench seat. His legs were splayed out into the walking aisle and he mindlessly scrolled on his phone while sipping from a pint glass. He looked up at you briefly but almost immediately returned his gaze to the phone screen.

After a brief pause, you walked to the middle of the bar and slid onto one of the wooden stools. You leaned on your elbows, purposefully keeping your coat on and purse over your shoulder. Hopefully, you’d get upstairs quickly. You noticed two wooden doors at the right end of the bar; you assumed one led upstairs and one led to a bathroom but couldn’t tell which one was which. There was also a small saloon door behind the bar just to your right which you would’ve normally assumed led to a kitchen but you couldn’t imagine this place serving food.

A tall man slinked through the saloon doors as he dried a dingy pint glass with an old rag. He immediately noticed you, locking your gaze with a jovial smile.

“Welcome. What can I get ya?” He offered with obviously phony enthusiasm.

The man was probably in his fifties and sported a long grey beard with equally long grey hair. He wore a dark purple buttonup and a bright yellow tie adorned with happy red flowers. His eyeglasses were pink-rimmed and shaped like stars. Everything about the man’s appearance should’ve amused you but something about him put you on edge. He seemed dangerous despite attempting to convey the contrary.

You were about to stammer out an “um” when you stopped yourself, realizing that a drug dealer would probably be more self-assured. You clenched your muscles, bracing.

“I’m here about the job opportunity,” you said nonchalantly letting your voice be somewhat drowned out by whatever corny, probably Perry Como-sung lovesong that was now seeping out of the walls.

The bartender raised an eyebrow at you skeptically.

“What name should I give our manager?” He replied, placing the opaque pint glass down on the counter.

“Monet,” you replied, not breaking his gaze.

“You’re Monet? The one I’ve heard about?” He asked, obviously unimpressed.

“What, disappointed?” You countered quickly.

“No, just...I had heard you weren’t coming.” The man looked at you suspiciously.

You were worried that if you let him stare at you long enough he might discover something to prove that you were a fraud. Luckily, you frequently felt like a fraud in your normal life due to chronic anxiety so you were practiced in staying cool under prying eyes.

You let a sigh pass noisily out your nostrils as you rested your chin in your right hand.

“Does Joker really have time for this?” You asked, exasperated.

The man set his jaw and squinted at you. You felt your heart rate quicken and sunk your right moler into the side of your tongue to distract yourself with pain. The warm taste of iron pooled around your tooth. This was an old tactic you used when you wanted to keep a straight face despite overwhelming emotion; never letting childhood bullies see you cry was finally paying off.

The man opened his mouth to say something further but never got the chance. From the left door at the end of the bar, the most disgusting-looking person you’d ever seen barged into the room.

“Nyeh, Disco, I need you to close the bar for these interviews—” The large, soggy-looking man made eye contact with you and stopped.

You used this interruption to your advantage. You stood up calmly and approached the looming man despite your fear and the moist sheen reflecting off his skin.

“I’m Monet. It’s good to finally meet you.” You said offering the man your hand.

The looming figure leaned towards you and grabbed your hand with both of his. Every hair from every pore on your body shot upwards. You’d never felt skin this wet before. The sensation wasn’t like he’d just washed his hands or had been in a pool; the dampness was thick like the sludge that accumulated around the old drainpipe in your shower. Your body betrayed you. Your eyes widened with shock but you bit down harder on your tongue to keep yourself from making a sound. The man had bent over to get face-to-face with you but didn’t seem to notice your reaction. Mucus trailed from his nostrils, jiggling buoyantly as he breathed.

“Nyeh, Trebol. Nice to meet you. Now that we’ve met we can get married. Behehe. Kidding.” Trebol winked at you and retracted his right hand to push up his glasses which had slid down his slick nose. “Nyeh, follow me. Dof—uh Joker is starting soon.” He said letting go of your hand and turning to walk back up the stairs.

Thanking gods that you did not believe in for your immense luck and for Trebol letting go of your hand, you turned to wave at Disco. You saw that the two patrons had already left the bar and Disco stood in the middle of the room. He stared at you sternly as you followed Trebol up the stairs.

--

The stairway was dark and longer than you had anticipated. You worried for a moment that Trebol had seen through your ruse and was leading you into a cell or to a dead end with a firing squad. Your fear toyed with your brain as you silently followed the enormous man up the stairs. All of a sudden, you emerged into a large, brightly lit room.

Shockingly, the dim stairway had led you into the middle of a grand foyer. The floors were hardwood and sparkled immaculately underneath your feet. The ceilings were high with crisp, eggshell crown molding and the walls were painted an elegant shade of maroon.

“Nyeh, you can put your coat in there.” Without slowing down, Trebol motioned to a large coat closet on your right.

“N—no I’m alright,” You stammered. You needed to pull yourself together but the contrast between the bar and this foyer was already staggering.

You toddled behind Trebol as he continued out of the foyer. Your jaw dropped. It was a grand ballroom with two large crystal chandeliers. All around the room were casino-style card tables with people who looked like waiters manning each.

Beautiful women in floor-length ball gowns hung off the arms of men in smoking jackets. There were only around twenty people there, but it was still a shocking change of pace from downstairs. Everyone was either playing cards or chatting in small groups. Frank Sinatra sang from surround-sound speakers and a fire cracked and popped happily in the grand fireplace. There was a small sitting area off to the right side of the room in front of the fireplace with emerald-upholstered fainting couches and high-backed chairs. There were stairs leading up at the end of the room along with multiple hallways leading in different directions.

You clenched your teeth to prevent shock from painting your face. Trebol led you around the left side of this room. A few of the beautiful women and beautifully dressed men stared at you as you passed. Trebol turned and led you down a hallway to the left.

The hallway entered into another, much smaller room divided into two sections by furniture. On the right side was a large, ornately carved desk with a chess set mid-game and many different cell phones laid out on top of it. On the left was a seating area with five chairs all pointed at the right side of the room.

Three people were already seated in the chairs on the left. The one furthest from the door was an older woman. She was wearing a bright purple dress and cat-eye glasses with a beaded chain that swept down behind her ears and around her neck. Her hair was dyed bright red and she wore a large, gaudy string of pearls. The man sitting in the middle was an unassuming middle-aged man with a crew cut. He was dressed in a white collared shirt and black slacks. Despite seeming fairly ordinary, he was large and had an intensity about his quiet demeanor. The person seated most closely to the door was another large man with long, blonde hair and bicep muscles bulging out of his tight, black t-shirt. He sat with one long arm over the back of his chair. He cocked his head towards you and Trebol as you stepped into the room. The bicep man’s, crazy, intense eyes and evil grin would’ve drawn your gaze if you weren’t already staring at the man behind the desk.

He was huge. Probably bigger than Kid. (Why were all the men you met tonight so INEXPLICABLY LARGE?) The enormous man’s bottle-blond hair was styled upwards into peaks framing his handsome, almost pretty, face. He wore pink, cat-eye sunglasses despite it being night and him being indoors. You’d normally have thought this was incredibly stupid but it somehow made him seem even more intimidating because you could not clearly determine where he was looking. His white collared shirt was unbuttoned and untucked from his pink, silk suitpants revealing an intensely chiseled musculature. He lounged in his armchair, legs spread and arms slumped over the sides lazily. Across the back of the chair, a pink feather boa coat was draped. A beautiful whisp of a woman in a blue, backless dress was seated daintily on his right thigh. The woman was rubbing his wide shoulders with her petite left hand. You stared into his sunglasses as you saw him tilt his head towards you. You knew this was your target. You knew this was Joker.

#one piece x reader#one piece fanfic#eustass kid x killer x reader#eustass kid x reader#killer one piece x reader#one piece modern au#killer x reader

15 notes

·

View notes

Note

⏰ for n :]

SEND A ⏰ TO SEE INTO ONE OF MY MUSES' MEMORIES. = always accepting!

int main() { std::ifstream file("3402.txt"); if (file.is_open()) { std::string line; while (std::getline(0001.txt)) { std::cout << "[WD-ID: Cyn] has been acting different lately. N-0#’s eyes linger on her as she passes down the hall, watching her until she’s out of sight. he looks back at the brass vase he’s methodically polishing, ventilation systems whirring in a sigh. i wish she would talk to me. something happened, i just know it.

yet he doesn’t know what. he could probably chalk it up to master and mistress being harsh, but the facts don’t add up. [WD-ID: Cyn] was always somewhat skittish. she wouldn’t be caught out of line. she’s far too sneaky and clever. lately, however, she’s far less fleeting. she’s not around Tessa as much either, which is saddening but ultimately understandable. maybe [WD-ID: Cyn] felt left out and decided to branch off entirely. she might be doing her own thing. it would explain her sudden confidence.

something happened. he knows it. [WD-ID: Cyn] moves differently, with a strange assurance in herself that was not there before. she talks to herself when she thinks nobody is listening. her optics are off-color, which is not so bad—perhaps Tessa replaced her screen—but there’s something in her stare that makes his core distribute a little more energy to his servos. ( she sometimes watches him with a sort of curiosity, as if sizing him up. it makes him feel small in the same way that mistress’s sparing glances do. )

N-0# gently places the vase down, moving to clean the photo next to it. he begins to wipe dust off the frame. he’s probably overthinking it. [WD-ID: Cyn] seems more sure of herself. that’s a good thing. she doesn’t talk to him frequently like she used to. that’s alright, people change! it’s not as if he’s anything special, either. he’s encouraged her to talk to other drones, so she may have! the thought of [WD-ID-Cyn] making friends causes a small smile to appear on his muzzle.

regardless, he’s proud of her sudden bolster of confidence. he’s simply a little worried. there seems to be some tension in the air when she shows up—N-0# knows [WD-ID: V-II]’s posture and voice well enough to tell her wires become a little more shot in [WD-ID: Cyn]’s presence, and [WD-ID: J-##] and Tessa both watch [WD-ID: Cyn] like hawks. sometimes they make motions to each other when [WD-ID: Cyn] isn’t looking. he isn’t fluent in all of their silent communication, but he knows enough to understand that they’re talking about [WD-ID: Cyn].

something happened. he knows it. the butler’s fans whirr in a low exhale as he cleans the glass protecting the picture. he moves the cloth off to the side. there’s several yellow glowing dots reflected in the glass, gazing at him from over his shoulder. N-0#’s digital brow furrows in concern and he rotates his head a hundred and eighty degrees to glance in that direction.

there’s nothing there.

he shakes his head and places the picture down. he probably needs to recalibrate his optics. there’s been a lot of stress on his systems lately. N-0# drapes the cleaning-cloth over his forearm and turns to advance down the hall. perhaps tonight he can invite [WD-ID: Cyn] to a movie hangout and get her to tell him what’s on her mind." <<; std::endl; } };

2 notes

·

View notes

Text

Botsona descriptions! This is extremely self indulgent and mostly for my own sake, so I'm tucking it behind a cut.

Default/futuristic: Chrome body with digitigrade legs; limbs are detached and connected with some kind of glowing force at the joints. Segmented tail. Body shape just on the feminine side of androgynous. Screen for a face with a minimalist geometric expression in glowing blue. Hair is a holographic rainbow lionfish mane. Wearing a skater dress with a neural network pattern.

late century retro: Lots of transparent purple plastic ala the original iMac. Floating joints have more of a ball and socket look to them. Similar face, but low res CRT in neon colors. Wearing a fitted 20 GOTO 10 shirt and an asymmetrical skirt with a circuit board design. The hair is less holographic and more cyberlocs/rainbow wires.

early century retro: Brass body instead of chrome. Face is a cyan oscilloscope (so the facial features are drawn out of one connected line.) Features on the top of the head suggest goggles. Hair is made of paper punch tape, and extrudes in different color to show emotions. Big ol' windup key in the back. Wearing a 1950s style cocktail dress with vacuum tube schematic pattern.

Fantasy: Crystal construct, face is basically an emoticon made of glowing magic runes on the polished front face. Lots of magical energy threading through the whole body. Hair is made of magical rainbow lightning that's cool to the touch. Wearing a wrap dress printed with shifting sigil formulae.

9 notes

·

View notes

Text

I had some Legend of Zelda Thoughts and do you guys think the pieces of the triforce feel like things?

Like, Wisdom. Is it water? Soft pages of paper? Bright screens of tech? It probably tastes like vegetables. Wisdom sounds like woodwinds, strings, monotone ramblings, and sheet music. I bet if you touched it, you'd be able to see all the things you already knew fall into place, and sort your thoughts and feelings as easily as little wooden blocks.

Power definitely feels warm. It's the texture of raw foods and bending wire. It probably has a texture like rubber, something with stretch. I think everyone knows Power is loud, it's the beating of drums and a fanfare of brass. It definitely has a weight to it, but I bet that you could hold it easily and never tire.

Courage probably feels like... Trying? It's burnt food that slowly gets better, abyssal scores that turn into something good with studying, and it sounds like a middle school band. It's a hard choice. It's many hard choices. Courage is a carbonated drink. Something caffeinated that makes you feel giddy. I bet holding it feels like a lucky charm.

2 notes

·

View notes

Text

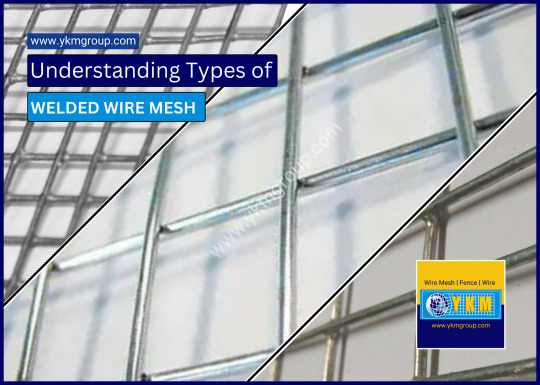

Exploring Wire Mesh: Applications, Benefits, and Types

Bhansali Wire Mesh is one of the leading Wire Mesh Manufacturers in India. Wire mesh, also known as wire fabric or wire cloth, is a highly versatile material used across industries for a variety of applications. With its grid-like structure, strength, and flexibility, wire mesh plays a vital role in sectors such as construction, agriculture, filtration, and even interior design. In this blog, we will explore what Wire Mesh is, its key benefits, popular types, and how it is applied in different industries.

What Is Wire Mesh?

Wire mesh supplier in India is a network of interwoven, welded, or interconnected wires that form a grid pattern. It can be made from various materials, including stainless steel, galvanized steel, brass, aluminum, or plastic. Available in different sizes, thicknesses, and patterns, wire mesh is known for its strength, durability, and adaptability to specific needs.

Key Features of Wire Mesh

Durability: It is resistant to wear and tear, ensuring long-term performance.

Strength: Wire mesh can handle high stress and pressure, making it suitable for heavy-duty applications.

Corrosion Resistance: Stainless steel and galvanized wire mesh offer excellent resistance to rust and corrosion, even in harsh environments.

Lightweight: Certain types of wire mesh, such as aluminum and plastic mesh, are lightweight and easy to handle.

Customizable: Available in various sizes and designs, wire mesh can be tailored to specific applications.

Types of Wire Mesh

Wire mesh supplier comes in multiple forms, each designed for specific purposes:

Welded Wire Mesh: This type of mesh is created by welding wires at their intersections, forming a rigid and strong grid. It is commonly used for fencing, reinforcement, and partitions.

Rectangular Wire Mesh: Rectangular Wire Mesh Manufacturer in India is highly competitive and dynamic with quality and customer satisfaction.

Square Wire Mesh: Square Wire Mesh Suppliers in India ensure that they have a good understanding of customer needs to provide high-quality products that meet the required industry standards.

Crimped Wire Mesh: Featuring wires that are crimped before weaving, this mesh is highly stable and used in sieves, mining, and industrial filters.

Stainless Steel Wire Mesh: Stainless Steel Wire Mesh is a popular choice for many industrial and commercial applications because of its corrosion resistance and strength.

Cities We Supply Wire Mesh

Wire Mesh Manufacturer in Ahmedabad

Wire Mesh Manufacturers in Kolkata

Wire Mesh Manufacturers in Raipur

Wire Mesh Manufacturers in Rajkot

Wire Mesh Manufacturer in Delhi

Applications of Wire Mesh

Wire Mesh Manufacturer has diverse uses across a range of industries:

Construction:

Reinforcing concrete in buildings and bridges.

Used as safety barriers, fencing, and partitions.

Agriculture:

Protecting crops and plants.

Constructing animal enclosures and chicken coops.

Filtration and Screening:

Separating solids and liquids in industrial processes.

Used in oil and gas, food processing, and wastewater treatment.

Automotive Industry:

Integrated into air filters, grilles, and reinforcement components.

Interior Design:

Decorative purposes such as room dividers, wall panels, and modern furniture.

Security:

Installed in windows, doors, and enclosures for added protection.

Gardening and Landscaping:

Used as trellises, plant support, and fencing solutions.

Benefits of Wire Mesh

Versatility: Wire mesh can be adapted for a wide range of applications, from heavy industry to delicate filtration systems.

Cost-Effectiveness: Its durability reduces replacement and maintenance costs over time.

Sustainability: Metal wire mesh is often recyclable, making it an eco-friendly option.

High-Performance Material: With resistance to environmental factors and mechanical stress, wire mesh offers reliable performance in demanding conditions.

0 notes

Text

Choosing the Right Wire Mesh: Tips from the Experts

Wire mesh is a versatile material widely used in various industries, from construction and agriculture to interior design and DIY projects. Its durability, flexibility, and functionality make it an essential component for many applications. However, choosing the right wire mesh for your project can be challenging, given the vast options available. This guide provides expert insights to help you make an informed decision.

Wire mesh, also known as wire cloth or wire fabric, consists of interconnected wires arranged in a grid-like pattern. The wires can be made from various materials, such as stainless steel, aluminum, copper, or galvanized steel. The grid structure can be woven or welded, depending on the application.

Key Factors to Consider When Choosing Wire Mesh

Material Type

The material of the wire mesh affects its strength, corrosion resistance, and lifespan. Here are some popular choices:

Stainless Steel: Ideal for projects requiring corrosion resistance, such as marine or chemical environments.

Galvanized Steel: Affordable and durable, suitable for outdoor applications like fencing.

Aluminum: Lightweight and resistant to rust, commonly used in aerospace or decorative designs.

Copper: Great for aesthetic purposes or applications needing high electrical conductivity.

Mesh Type

Wire mesh comes in two main types: woven and welded.

Woven Wire Mesh: Made by weaving wires together in a specific pattern, offering flexibility and precision. Best for filtration or sieving applications.

Welded Wire Mesh: Created by welding the intersections of the wires, resulting in a rigid structure. Ideal for fencing or structural reinforcements.

Mesh Size

Mesh size refers to the number of openings per linear inch. A smaller mesh size means finer openings, suitable for filtration or screening, while larger sizes work for applications like animal enclosures or construction reinforcement.

Top Applications of Wire Mesh

Construction

Wire mesh is essential in construction for purposes like concrete reinforcement, scaffolding, and fencing. It enhances the structural integrity of buildings and prevents cracks.

Agriculture

Wire mesh is widely used in livestock enclosures, crop protection, and storage bins. Its durability ensures long-term protection against animals and environmental elements.

Interior Design

From modern room dividers to decorative wall panels, wire mesh adds a unique, industrial-chic aesthetic to interiors. Stainless steel or copper meshes are particularly popular for this use.

Industrial Use

In industries, wire mesh is often employed for machine guards, filtration systems, and conveyor belts. Its strength and heat resistance make it indispensable in harsh environments.

Benefits of Using Wire Mesh

Durability

Wire mesh can withstand extreme conditions, including heat, moisture, and physical stress.

Versatility

With various materials, sizes, and types, wire mesh is adaptable to countless applications, from heavy-duty industrial needs to elegant home decor.

Cost-Effectiveness

Wire mesh offers long-term value by reducing the need for frequent replacements, especially when choosing high-quality materials like stainless steel or galvanized steel.

Top Wire Mesh Manufacturers in India

Wire mesh is an essential component in industries ranging from construction and agriculture to filtration and home improvement. India, a global hub for manufacturing excellence, is home to some of the best wire mesh manufacturers offering a wide variety of products tailored to diverse needs. This comprehensive guide explores the top wire mesh manufacturers in India, highlighting their strengths, expertise, and innovations.

Wire mesh, often referred to as wire cloth or wire fabric, is a grid-like structure made from intersecting wires. These wires can be made of materials like stainless steel, galvanized steel, aluminum, brass, or copper. Wire mesh is commonly used for reinforcement, separation, filtration, and decorative purposes.

Timex Metals stands out as a top choice for demister pads in India. We combine industry expertise with a commitment to quality, producing demister pads that meet stringent industrial standards. Every product we manufacture undergoes rigorous quality checks, ensuring that it meets durability and performance expectations.

Selecting the right demister pad manufacturer makes a difference in product performance and longevity. Quality materials, customization options, and support are essential factors that reliable manufacturers provide.

For More Details:

Website: timexmetals.com

Product: Wire Mesh Supplier in India

Other Product: Mesh Demister Manufacturers in India.

0 notes

Text

5 Essential Types of Wire Mesh for Industrial Applications

Wire mesh is everywhere. From the fences surrounding your property to the sieves in your kitchen, it’s a versatile material with endless applications. It is manufactured by weaving or welding metal wires into a mesh, creating a grid like pattern. Its history dates back centuries when rudimentary wire netting was used for basic filtering and containment purposes. Over time, technological advancements have transformed it into a precision engineered material with diverse industrial applications.

What is Wire Mesh?

Wire mesh is a grid-like structure made by weaving or welding metal wires together. These meshes can vary in size, thickness, and material, making them suitable for a wide range of uses.

Historical Evolution of Wire Mesh

The origins of wire mesh can be traced to the 16th century when blacksmiths crafted rudimentary mesh for sieves. The Industrial Revolution brought innovations like mechanized weaving and welding, paving the way for mass production. Today, wire mesh has become indispensable in industries requiring strength, durability, and adaptability.

Types of Wire Mesh: A Comprehensive Guide

Wire mesh is a versatile material used across numerous industries. The diverse types of wire mesh serve various purposes, from industrial to decorative applications. Understanding the differences between the types of wire mesh is essential to select the right product for your needs.

This article explores the five main types of wire mesh: woven wire mesh, welded wire mesh, expanded wire mesh, hexagonal wire mesh, and knitted wire mesh. We will delve into their manufacturing processes, features, and common applications.

Woven Wire Mesh

Woven wire mesh is created by interweaving wires over and under each other, much like a traditional fabric weave. This type of mesh is known for its precision and uniformity, making it ideal for applications requiring accurate filtration or screening.

Types of Woven Wire Mesh Weave

Plain Weave: The plain woven mesh weave is the simplest weave pattern with each warp wire alternates over and under the weft wire.

Twill Weave: The twill woven weave mesh allows a higher wire density by weaving one wire over two and under two wires.

Dutch Weave: The dutch wire mesh weave is designed for very fine filtration, this weave uses a combination of larger warp wires and finer weft wires.

Materials Used

Common materials for woven wire mesh include stainless steel, epoxy coated, nickel, aluminium, brass, copper, low carbon etc.

Applications of woven wire mesh type

Industrial Filtration: Used in oil refineries, water treatment plants, and chemical processing for separating solids from liquids or gases.

Screening and Sieving: Essential in mining, agriculture, and food processing industries.

Architectural Uses: Applied in decorative facades, partitions, and balustrades.

Key Features and Benefits of woven wire mesh

Uniform Openings: Ensures consistency, ideal for filtration and separation tasks.

Flexibility: Can be bent or molded to fit intricate designs.

Corrosion Resistance: Especially when made from stainless steel or coated materials.

Welded Wire Mesh

Welded wire mesh is made by fusing wires together at their intersections using an electric welding process. This creates a sturdy and durable structure that resists deformation.

Features of Welded Wire Mesh

Rigid Structure: The welding process makes the mesh extremely stable.

Customization: Available in various wire diameters, aperture sizes, and finishes.

Corrosion Resistance: Often treated with galvanization or PVC coating to enhance durability.

Materials Used

Typical materials include stainless steel, galvanized steel, and low-carbon steel.

Applications

Construction: Used in concrete reinforcement, retaining walls, and fencing.

Agriculture: Commonly applied in animal enclosures, cages, and trellises.

Industrial Uses: Found in machine guards, storage racks, and partitions.

Fencing: Offers security for residential and commercial properties.

Animal Enclosures: Ensures durability and protection in cages and pens.

Expanded Wire Mesh

Expanded wire mesh is produced by cutting and stretching a metal sheet to create a diamond-shaped pattern. This process eliminates waste and produces a lightweight yet strong product.

Features of Expanded Wire Mesh

High Strength-to-Weight Ratio: Ideal for lightweight construction.

Ventilation: Allows air and light to pass through while maintaining structural integrity.

Non-slip Surface: Frequently used in walkways and stair treads.

Applications of expanded wire mesh

Security: Used in window guards, safety grilles, and fencing.

Ventilation: Ideal for air and light filtration in HVAC systems.

Decorative Uses: Frequently applied in modern architectural designs and furniture.

Hexagonal Wire Mesh

Hexagonal wire mesh is characterized by its honeycomb-like pattern, is a staple in fencing and containment. Common materials include galvanized steel and PVC-coated wires.

Features of Hexagonal Wire Mesh

Flexibility: Can be easily shaped and bent without breaking.

Lightweight: Facilitates easy installation and handling.

Corrosion Resistance: Often coated with PVC or galvanized for durability.

Durability and Cost-Effectiveness: The hexagonal pattern ensures flexibility and strength while remaining an affordable option for various applications. Its lightweight nature simplifies installation.

Materials Used

Materials include galvanized steel, PVC-coated steel, and stainless steel.

Applications

Agriculture: Used for fencing poultry, animal enclosures, and garden protection.

Construction: Used in gabions to stabilize slopes, reinforce plastering work and create rockfall protection barriers and prevent soil erosion.

Crafts and DIY Projects: Used in sculptures, floral arrangements, and other creative applications.

Knitted Wire Mesh

Knitted wire mesh by looping wires together, similar to the process of knitting fabric. This creates a flexible and compressible material suitable for specific applications.

Features of Knitted Wire Mesh

Elasticity: Allows the mesh to stretch and return to its original shape.

High Filtration Efficiency: Excellent for removing contaminants in automotive and industrial applications.

Heat and Corrosion Resistance: Suitable for harsh industrial settings.

Damping and Sealing: Absorbs vibrations and seals gaps in automotive and aerospace industries.

Gasketing: Acts as a sealing material in automotive and aerospace industries.

Environmental Protection: Used in mist eliminators to reduce air pollution.

Materials Used

Common materials include stainless steel, copper, aluminium, and Monel.

Applications

Filtration: Used in oil mist separators, air filters, and demisters.

Gasketing: Acts as a sealing material in automotive and aerospace industries.

Soundproofing: Reduces noise in industrial machinery.

Factors to Consider When Choosing Wire Mesh

Material Selection

Different materials like stainless steel, copper, and aluminum cater to specific needs, such as corrosion resistance or conductivity.

Mesh Size and Thickness

The size of the openings and the thickness of the wires determine the mesh’s strength and suitability.

Durability Requirements

Consider factors like load-bearing capacity and environmental conditions when choosing a wire mesh type.

Conclusion

Wire mesh is a vital component in countless industries and applications. By understanding the different types—woven, welded, expanded, hexagonal, and knitted—you can choose the perfect mesh for your needs.

0 notes

Text

I have an idea for a light switch

Now, to be clear this is theoretical and just something I'd want for me, not to sell or anything, and there's a lot of kinks I'd have to work out

Anyway, so certain touch screens use electric input from our bodies, right? So my thought is trying to find a way to use a brass or copper plate like you have around a switch, and make it so that touching it turns the light on and off

I want this for a few reasons

Reason one, I want either copper or brass plates anyway for their anti microbial properties, but having this nasty plastic piece sticking out... I don't like it

Also, when you have paired light switches say for the top and bottom of a stairwell, dislike that very much. One ends up in the up state and the other in the down state? Horrible, hate it. I ignore it, but I hate it. No switch, means none of that, it's either off or on

...I suppose those are actually the only two reasons, but I'd also like to engrave the plates, and also see if there was a way to include a dimmer switch in it by like... you touch low it's dim, touch high it's high kinda thing

Not something I'll be doing tomorrow, probably not something I'll ever manage, but I just... I feel like there's some way to wire things up as a variation on normal light switches where you could use having a metal plate to at the very least turn things off and on when you tap it

1 note

·

View note

Text

What Is Architectural decorative Mesh and Its Applications?

What Is Architectural Decorative Mesh?

Architectural decorative mesh, often referred to as architectural wire mesh, is a versatile and innovative material used in various architectural applications. It is typically made from high-tensile, grade 316 stainless steel and is produced using a weaving process similar to that of fabric production. The material consists of several individual wires woven on large looms, resulting in a flexible yet durable mesh that can be adapted for numerous design purposes.

The mesh is commonly produced from 80% recycled materials, making it an environmentally friendly option for architects seeking sustainable building solutions. Despite its initial appearance of rigidity, architectural mesh becomes quite flexible when tensioned over certain lengths, allowing it to be used creatively in both interior and exterior applications.

Applications of Architectural Decorative Mesh

Façades: Architectural mesh is frequently used as a façade material due to its sleek and modern appearance. It can transform the look of arenas, commercial buildings, conference centers, educational institutions, parking garages, stadiums, theaters, and more. The mesh façade can appear reflective or transparent depending on lighting conditions and viewing angles.

Canopies: Mesh elements are ideal for creating canopies that deflect or filter sunlight. This helps in moderating indoor climates by providing shade during summer while maintaining warmth during winter months. Despite offering sun protection, these canopies allow transparent views from inside the structure.

Infill Panels: Used in balustrades and other infill panels like balconies and staircases, architectural mesh provides safety while adding aesthetic value with its textile elegance. The corrosion-resistant stainless steel ensures durability and stability.

Free Forms: Due to its luxury appeal and versatility, architectural mesh is perfect for free-configuration projects such as aviaries or exhibitions where unique shapes are required.

Ceilings: Interior applications include using mesh for ceilings to combine aesthetics with functionality by concealing technical installations while offering protection.

Walls: Mesh panels serve as excellent choices for interior walls by accentuating room features or serving as focal points themselves.

Acoustic Applications: Architectural mesh aids in creating acoustically effective environments by scattering sound waves through its round wires which also support other acoustic materials.

Security Screens & Partitions: Its strength makes it suitable for security screens and partitions that require both durability and visual appeal.

Protective Grilles & Enclosures: Used as protective grilles or enclosures around sensitive areas or equipment due to its robust nature.

Decorative Elements: With custom weaves available in various alloys including brass and bronze options besides stainless steel; the decorative potential of this material is vast allowing architects to create eye-catching designs indoors or outdoors.

More details visit — https://decorativemesh.in/blogs/What-is-architectural-decorative-mesh-and-its-applications.html

0 notes

Link

Check out this listing I just added to my Poshmark closet: Red And White Beaded Fringe Tassel Earrings.

0 notes

Text

How to Choose the Right Testing Sieves for Your Application

Selecting the appropriate testing sieve for your application is crucial to achieving accurate and reliable particle size analysis. Testing sieves are essential tools in industries such as pharmaceuticals, food processing, construction, and mining, where precise material classification and quality control are vital. Here’s a detailed guide on how to choose the right testing sieves for your specific needs.

Understand Your Material

The first step in selecting a testing sieve is to understand the characteristics of the material you are testing. Consider the particle size distribution, the nature of the material (e.g., fine powders, granules, or aggregates), and any specific properties such as moisture content or abrasiveness. This information will help you determine the appropriate sieve mesh size and material.

Determine the Required Mesh Size

Mesh size is a critical factor in sieve selection. It refers to the number of openings per linear inch in the sieve screen. The mesh size you need depends on the particle size range you are analyzing. For fine powders, you will need sieves with smaller mesh sizes (higher mesh numbers), while coarser materials require sieves with larger openings (lower mesh numbers). It’s important to choose a mesh size that will effectively separate your material into the desired fractions.

Consider Sieve Material

Testing sieves are available in various materials, including stainless steel, brass, and plastic. Stainless steel sieves are highly durable and resistant to corrosion, making them suitable for most applications. Brass sieves are often used for dry sieving of non-abrasive materials. Plastic sieves are lightweight and may be suitable for certain applications where metal sieves are not ideal. Choose a sieve material that is compatible with your material and testing environment.

Assess Sieve Construction Quality

The quality of the sieve construction can significantly impact its performance and longevity. Look for sieves with a robust frame and uniform, tightly woven mesh. The sieve should be free from defects such as loose wires or uneven openings. High-quality construction ensures accurate results and extends the lifespan of the sieve.

Compliance with Standards

Ensure that the testing sieves you choose comply with relevant industry standards and regulations, such as ASTM, ISO, or other applicable standards. Compliance guarantees that the sieves meet specific quality and performance criteria, ensuring consistency and reliability in your testing processes.

Evaluate Sieve Stack Compatibility

If you plan to use multiple sieves in a stack, ensure they are compatible in terms of size and fit. Sieves should nest securely to prevent material loss and ensure accurate separation. Compatibility with existing equipment, such as sieve shakers, is also important for efficient testing.

Consider Your Testing Environment

The environment in which you will be using the sieves can influence your choice. For example, if you are working in a wet or corrosive environment, stainless steel sieves are preferable due to their resistance to rust and corrosion. For dry, non-abrasive materials, brass or plastic sieves might be suitable. By carefully considering these factors, you can choose the right testing sieve that meets your specific application needs, ensuring accurate and reliable particle size analysis.

0 notes

Text

2024 - Top Quality Wire Mesh Manufacturers

Wire Mesh Manufacturers

Sulesh Wooven Wire Mesh is a rising name in the wire mesh industry, known for its high-quality products and reliable manufacturing. With years of experience, they have established themselves as a leading Wire Mesh Manufacturers and distributor of wire cloth/mesh, offering a wide range of products and processing capabilities. Their expertise in sourcing and stocking a vast selection of wire cloth products, including various alloys like brass, copper, stainless steel, and others, makes them a preferred choice for industrial applications.

Wire Mesh

Wire Mesh Manufacturers, Sulesh Wooven Wire Mesh is committed to providing customized solutions to meet specific industry requirements. They offer processing capabilities such as precision cutting, calendering, heat treating, cleaning, and coating, ensuring that their wire mesh products are tailored to the unique needs of different applications. Whether it's for petrochemical processing, screen printing, pharmaceutical manufacturing, or food and beverage processing, their wire mesh materials are selected based on specific application requirements, demonstrating their versatility and adaptability.

Wiremesh

Sulesh Wooven Wire Mesh's dedication to quality is reflected in their ability to provide custom solutions for applications requiring extraordinary reinforcement, specialty shapes, or non-standard openings. This level of customization, combined with their wide range of material grades and processing capabilities, positions them as a top choice for industries such as automotive manufacturing, pulp and paper, flooring, home appliance, and HVAC, among others.

Wire Mesh

If you want to know more about our product how they are useful for your work , please contact us today . Our team is always here to help and find best solutions for your specific needs.

Visit:- https://www.wiremeshdelhi.com/welded-wire-mesh.html

Address : H.O:K-245, Pushta Road, Karawal Nagar, Shahdara, Delhi-94 K-46, Sector-5, Bhawana, Delhi-39

Twitter :- https://twitter.com/mesh_wire28439

0 notes

Text

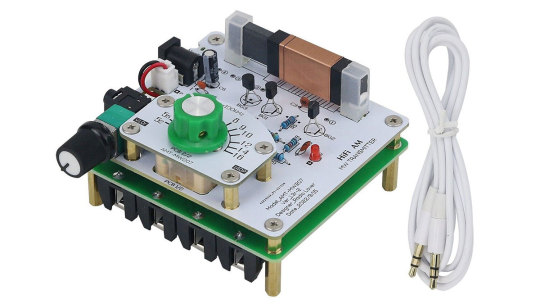

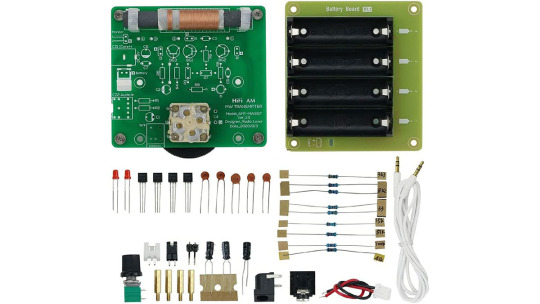

The new life for your old AM radio (DIY micro power AM MW transmitter AMT-MW207)

Are you the type of person who likes listening to good ol' radio like I do? Unfortunately, medium-wave broadcasting has decayed in the last few decades. There's nothing in many areas, even at night when medium wavelengths work best. That’s why the radios from our childhood stay unused and collect dust.

Today, we will make a small medium-wave radio transmitter that can help you check and configure AM radio receivers and listen to music through them if you connect an MP3 player or smartphone.

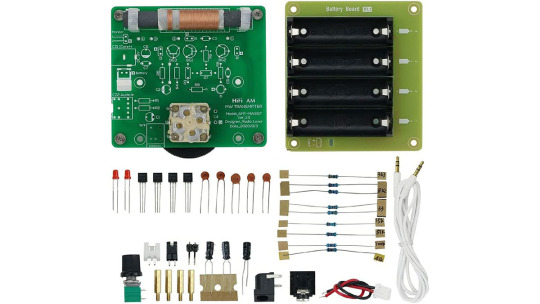

The power of this transmitter is 0.0005 watts, and the range is about 3 feet, so you won't disturb your neighbors or need a license for it. The transmitter is AMT-MW207 and was developed by an enthusiast under the nickname "Radio Lover". The circuit is proven to work perfectly and stays unchanged, but the layout of the PCBs can be different. For example, here is the newest and perhaps most nice-looking version 1.3 revision 2, dated September 15, 2022.

I've assembled ver. 1.2 rev. 7. It has a green board, no frequency scale, and the wavelength adjustment knob is located at the very bottom of the board. I consider these differences to be purely aesthetic. The transmission frequency can be viewed much more accurately on the screen of a separate frequency meter or oscilloscope.

Older versions are less convenient to attach the testing hook of the oscilloscope to, and they have no cutouts in the back of the PCB for winding up excess wire. The differences are generally insignificant; all versions of the transmitter work and sound the same.

The DIY kit was designed and kitted with passion: brass fittings, high-quality AA battery holders, and neat resistor value markings.

The potentiometer volume knob was not forgotten either; they also got me a good 3.5 mm TRS-TRS cable. In fact, this is an important detail. You sure can twist the variable resistor's shaft without a handle. Still, you won’t be able to connect a player or a laptop if there is no connecting cable. You won’t be able to try out a freshly assembled device, which will ruin the mood.

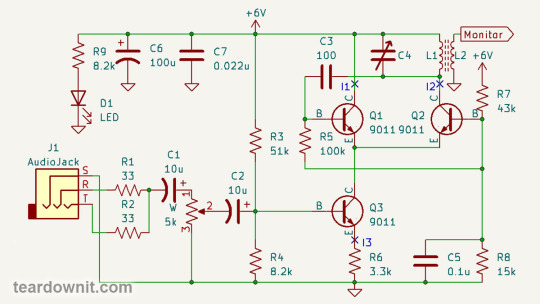

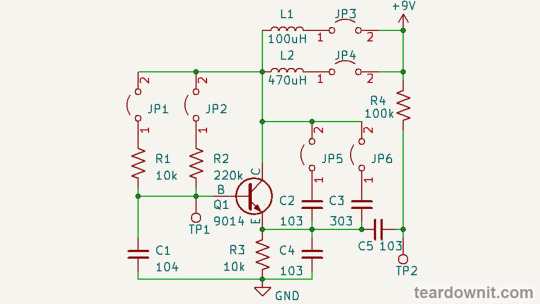

The transmitter circuit is simple yet elegant. Transistors Q1 and Q2 are a long-tailed pair, and Q3 is its current stabilizer.

A transistor current stabilizer is an emitter follower whose load is a resistor R6.

According to Ohm's law, the current through this resistor will be equal to the voltage across it divided by its resistance. The voltage at the emitter of a transistor connected to a circuit with a common collector is similar to the voltage at the base minus Vbe.

Vbe, the voltage between the base and the emitter for a particular transistor, is an almost constant value. Nothing is ideal, so Vbe actually depends on the temperature and base current, but these influences are tiny and can be ignored.

R3 and R4 together are a voltage divider. With a supply voltage of 6 volts, the current through this divider is 6V / (R3 + R4) = 6V / 59.2 kOhm = 101 µA. We neglect the base current of transistor Q3, which is connected in parallel with R4. I will explain why later.

The voltage at R4 is 101 µA * 8.2 kOhm = 828 mV. As Vbe = 0.63 V, resistor R6 gets the remaining 199 mV. Then, the current through it will be 60.3 µA.

The emitter current of transistor Q3 is the sum of its collector and base currents. The collector current is β times the base current, where β is the current gain coefficient of the transistor.

The average value of β for the 9011 transistor is 90. That is, the collector current is 60.3 µA * (β-1)/β = 60.3 µA * 89/90 = 59.63 µA.

The base current is 60.3 µA / β = 0.67 µA, less than 0.7% of the R3R4 divider current. Therefore, the base current can be neglected even in such a microampere case due to the fact that Q3 is connected as an emitter follower.

That is, it has a very high input impedance. It can even be calculated: Rin = Vin / Ib = 199 mV / 0.67 µA = 297 kOhm.

Even if our transistor has twice the current gain, β = 180, then the input resistance of such a stage with a common collector at an emitter current of 60 μA is twice as high and equals 594 kOhm.

So, the base current of Q3 is almost zero, and the collector current is almost equal to the emitter. The emitter follower has a high input impedance and can also serve as a voltage-to-current converter and a stable current generator.

This can be useful in many cases, for example, when powering LEDs. Or for generators of linearly varying voltage, their capacitors are charged with a stabilized current. Hence, the voltage across them increases linearly. In the era of cathode-ray oscilloscopes, such generators were used to deflect the beam horizontally.

In addition to the constant voltage from the divider R3R4, an audio signal is supplied to the base of transistor Q3. Identical resistors R1 and R2 mix stereo down to mono. Capacitors C1 and C2 let alternating current pass through and block direct current.

Potentiometer W regulates the amplitude of the signal. With the same voltage divider as R3R4, only the ratio of the resistances of the upper and lower branches can be changed by turning the knob.

So, transistors Q1 and Q2 form a differential amplifier. The total current of these two transistors, set by the current stabilizer on Q3 and modulated by the incoming audio signal, is redistributed between Q1 and Q2, depending on the voltage difference at their bases.

Collector Q1 is connected to the power supply positive terminal. Thus, the output of the differential amplifier is the collector of Q2, the inverting input is the base of Q2, and the non-inverting input is the base of Q1.

Resistors R7 and R8 set a constant bias for the bases of Q1 and Q2. Let's assume that the input impedance of each of the inputs of the differential amplifier is 100 kOhm.

Then, the current I1 will be twice as high as the current I2. After all, base Q2 is directly connected to the node between R5 and R7, and base Q1 base is connected through resistor R5 with a resistance equal to the input. That is, the base current, and therefore the collector current, for Q1 will be half as low.

We get a system of equations: I2 = I1 * 2; I1 + I2 = I3 = 60 µA.

The solution to the system of equations is I1 * 3 = 60 μA; I1 = 20 µA; I2 = 40 µA. These are precisely the reference current values that the author of the scheme mentioned in his explanations.

Older versions of the board, if you look closely, had jumpers for you to connect a multimeter as a microammeter and adjust the operation modes of transistors with trim potentiometers, which should be soldered in place of R3, R5, and R7.

However, judging by everyone's experience, these transmitters work perfectly with the included resistors and need no tweaking. Therefore, jumpers were removed from the new versions, but the holes for trim pots were left on the PCB.

The load of the differential amplifier is the LC resonant tank L1C4, and the output is connected to the non-inverting input through capacitor C3. The inverting input is grounded for alternating current by capacitor C5.

We have the Colpitts generator, which we've studied in the previous post! The only difference is that it is assembled not on one transistor but on a three-transistor differential amplifier.

C4 is a variable capacitor for adjusting the oscillation frequency, and L1 is a ferrite rod wound coil of the transmitting magnetic antenna.

The L2 coil connects an oscilloscope, frequency meter, or spectrum analyzer. You can also try connecting an external antenna to it to increase the transmission range. This won't help much because the operating currents of our transmitter are only tens of microamps, but it won't hurt either.

youtube

This transmitter sounds high-quality. Of course, you can clearly hear that this is an AM radio because this is indeed a real AM radio! The quality of FM transmission is much higher, which is one of the main reasons that it has replaced good old AM.

The sine wave on the oscilloscope screen looks nice at first glance. But if we look closely, we will see that the upper half-wave is slightly pointed, and the lower one is rounded and even a little flattened.

From an article about a homemade tube amplifier, we already know that such a waveform indicates a significant presence of the second harmonic and a small admixture of the third harmonic. For a powerful transmitter, this would be bad, but for a compact one, it is fine.

By the way, the eight-transistor superheterodyne in the video is also a DIY project. If you are interested, I can write another post on this and my other radios with a detailed description.

0 notes