#Biodigester Bacteria

Explore tagged Tumblr posts

Text

Septozyme BFB (Biodigester, Septic Tank, Pit, Sewage, Compost Bacteria & Enzymes)

Septozyme BFB is a unique anaerobic enzyme formulation that specifically selects the strains of Bacilli species, producing endospores upon starvation, a novel bioaugmentation technology. It helps to degrade the sludge in the digester which in turn helps in getting clear water. Septozyme BFB is used in reducing BOD, and COD levels as well as reducing the sludge volume odor, and color in the…

View On WordPress

#Biodigester Bacteria#Biodigester Chemical#Biodigester Enzymes#Biodigester Septic Bacteria#Biodigesters Chemical#Compost Digester#Drains Chemical#Pit Latrine Digester Bacteria#Pit Latrine Digester Chemical#Pit Latrine Digester Enzymes#Septic Tank Bacteria#Septic Tank Chemical#Septic Tank Enzymes#Septozyme BFB#Sewage Sludge Treatment Bacteria#Sewage Sludge Treatment Chemical#Wastewater Chemical

0 notes

Text

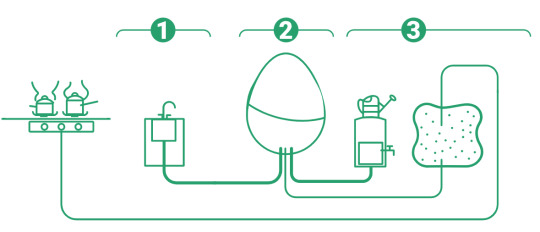

Kieran, a longtime mechanical engineer, had just invented Ireland’s first micro-scale anaerobic biodigester.

What does one even do with a micro-scale anaerobic biodigester?

Well, this particular anaerobic biodigester takes care of nearly 100% of your food waste.

You feed in all your scraps and waste – even hard-to-compost foods like cooked meats, dairy, cakes and liquids go in. Then the anaerobic bacteria get to work breaking down the waste.

After that, out come two very different ready-to-use products: a biogas for cooking and a nutrient-rich liquid fertiliser for gardening.

Food waste goes in. Gas and fertiliser come out.

‘We were never really into gardening or growing food. That was the biggest thing to change with the digester,’ Kieran says.

‘During lockdown, we set up the polytunnel and started using the fertiliser from the egg to grow tomatoes and courgettes. Because not only have you got a way to get rid of your food waste, you’ve also got a way to grow more food. And the taste was extraordinary. We had loads of tomatoes so we gave them to friends. They couldn’t get over how tasty they were compared to what they were buying from shops.’

Fiona and Kieran have only seen positives come out of using the egg. They love cooking with the biogas they produce themselves, and having no bill for fertiliser.

#solarpunk#solar punk#reculture#solarpunk aesthetic#solarpunk AF#mygug#ireland#solarpunk innovation#biodigester#food waste into cooking gas and fertilizer#circular food

49 notes

·

View notes

Text

Vale Encantado’s sanitation problems have become a central issue for the Vale Encantado Cooperative, an organization created in 2007 in an effort to generate employment and income for local residents. Sustainable tourism-related activities offered by the Cooperative were threatened by the contamination in the water and forest.

Otávio Barros, president of the Cooperative and of the Residents’ Association, began researching alternative ways to treat the community’s waste and sewage. As a result of Barros’ search, Vale Encantado’s first biodigester was installed in 2014 to serve the Cooperative’s restaurant.

Biodigesters function as large containers where the organic material deposited is consumed by bacteria. The process generates at least three byproducts: biogas, liquid biofertilizer and fertilizer.

The first biodigester installed for the Cooperative’s restaurant operates using food waste to supply biogas to the Cooperative’s kitchen.

The second biodigester, built in 2015, integrates a biosystem to treat sewage, and depends in part on a root zone filter. Although it was designed to serve all 28 houses, so far only five homes in Vale Encantado have had their sewage channeled into this biodigester, which is already able to produce biogas to meet the energy demands of one family.

This English subtitled documentary is the latest contribution to the series on energy justice and efficiency in Rio’s favelas. About the artist: Illustrator Yara Santos is a student of generalist design at the University of São Paulo (USP). Born and raised in the periphery of São Paulo, she seeks to represent elements of the black and peripheral culture in which she is inserted into her art. Most of her production is centered on digital techniques.

#solarpunk#solarpunk business models#solarpunk business#solar punk#reculture#brazil#favela#biodigestor#community kitchen#cooperative#video#documentary

4 notes

·

View notes

Text

WHAT IS A BIO SEPTIC TANK AND HOW DOES IT WORK?

In the area of sustainable living and eco-aware practices, bio septic tanks have emerged as a modern answer for waste management. In this comprehensive guide, we delve into the sector of bio septic tanks, that specialize in their advantages, installation system, and upkeep suggestions. Whether you are a homeowner in Chennai or actually interested in environmentally-pleasant alternatives, understanding bio septic tanks is crucial.

What Is a Bio Septic Tank?

A bio septic tank, also referred to as a bio-digester tank or biodigester, is an innovative sewage treatment device that makes use of natural tactics to treat and control family waste. Unlike conventional septic tanks that depend upon chemical compounds or power, bio septic tanks employ organic digestion of organic depend through bacteria and enzymes.

Benefits of bioseptic tanks:

Environmentally friendly. Bio-septic tanks are ecologically benign due to the fact they rent herbal approaches to decompose waste, decreasing environmental impact.

Reduced Maintenance: Bioseptic tanks require much less protection and additives than conventional septic tanks.

Odor Control: These structures are meant to minimize smells, ensuing in a greater fine surroundings.

Space efficiency: A bioseptic tank is often smaller than a traditional machine, making it proper for smaller packing containers.

Fewer costs: Bioseptic tanks might be extra fee green in the long time because of fewer preservation and working charges.

How Does Bio Septic Tanks Work?

The system within a bio septic tank is a charming example of nature's personal waste management device. Here's a simplified breakdown of the way those tanks function:

Inlet: Wastewater from your property enters the bio septic tank.

Separation: Solid waste settles at the lowest, forming sludge, even as lighter materials like grease flow to the top, growing scum.

Digestion: Bacteria and enzymes in the tank wreck down the natural count in the sludge and scum.

Treatment: The handled effluent, that's now cleaner, exits the tank and is similarly handled inside the drain area or leach subject.

Filtration: Through natural strategies, the soil inside the drain discipline filters out any ultimate impurities, permitting smooth water to go back to the groundwater.

Installation of Bio Septic Tanks

When thinking about putting in a bio septic tank, it is important to seek advice from experts like Global Enterprises in Chennai. This is an overview of the set up manner:

Site Inspection: A professional assesses your home to determine the best vicinity for the tank and drain area.

Excavation: The region for the tank and drain discipline is excavated and prepared.

Tank Placement: The bio septic tank is cautiously hooked up, ensuring right positioning and connections.

Piping: Pipes are laid to attach the tank to your property's plumbing gadget.

Backfilling: Once the entirety is in vicinity, the area is backfilled and compacted.

Testing: The machine is examined to make certain it is functioning effectively and meets regulatory standards.

Maintenance Tips for Bio Septic Tanks

While bio septic tanks require less renovation than traditional structures, everyday care remains important for most reliable performance:

Monitor Water Usage: Be aware of water consumption to save you overwhelming the device.

Avoid Harsh Chemicals: Refrain from using harsh chemical substances or antibacterial merchandise that could harm the beneficial micro organism inside the tank.

Regular Pumping: Periodic pumping of the tank is necessary to get rid of collected sludge and scum.

Professional Inspections: Schedule recurring inspections through specialists to trap any problems early.

Protect Drain Field: Avoid planting bushes or shrubs near the drain field to save you root intrusion.

Global Enterprises: Your Partner in Bio Septic Tanks in Chennai

At Global Enterprises, we focus on green answers for waste control, which includes bio septic tanks in Chennai. Our group of professionals is devoted to supplying sustainable, efficient, and fee-effective options for owners and businesses alike. Whether you're seeking to set up a new bio septic tank or need protection offerings, we're right here to assist you each step of the manner.

Conclusion

In end, a bio septic tank is a current, environmentally-pleasant solution for handling family waste. From its herbal strategies to the advantages it offers, information how those structures work can empower house owners to make knowledgeable choices approximately their sewage treatment desires. Global Enterprises stands as a reliable accomplice in Chennai, presenting information in bio septic tanks to promote sustainable dwelling and a cleaner environment.

If you are equipped to embody the advantages of a bio septic tank for your house in Chennai, contact Global Enterprises nowadays. Let's collaborate to reap a greener and more sustainable future.

1 note

·

View note

Text

Biogas plant for home: A Sustainable Solution for Home Energy Needs

What is a biogas plant for home?

A biogas plant for home is a small-scale system that utilizes organic waste, such as kitchen scraps, food leftovers, garden waste, and animal manure, to produce biogas. The process takes place in a biodigester, which is a sealed container that facilitates the decomposition of organic matter by bacteria in the absence of oxygen. As the waste breaks down, it produces biogas, primarily composed of methane (CH4) and carbon dioxide (CO2), along with trace amounts of other gases.

Setting up a biogas plant at home:

Setting up a biogas plant for home use requires careful planning and consideration. The following steps provide a general overview of the process:

a. Site selection: Choose an appropriate location for the biogas plant, considering factors such as accessibility, availability of organic waste, and space requirements.

b. Biodigester construction: Construct or acquire a biodigester suited to your needs. Biodigesters can be made from various materials, including concrete, plastic, or fiberglass.

c. Feedstock preparation: Collect organic waste materials such as food scraps, vegetable peels, and animal manure. Chop or blend them to increase their surface area and enhance decomposition.

d. Feeding the biodigester: Add the prepared organic waste into the biodigester, ensuring an appropriate mix of carbon-rich (e.g., food waste) and nitrogen-rich (e.g., animal manure) materials.

e. Gas collection and utilization: Connect the biodigester to a gas collection system and a gas storage unit. The collected biogas can be utilized for cooking, heating, or generating electricity through biogas stoves, heaters, or microturbines.

Benefits of a biogas plant for home:

a. Renewable energy source: Biogas is a clean and renewable energy source that reduces reliance on fossil fuels and lowers greenhouse gas emissions.

b. Waste management: By utilizing organic waste materials, a biogas plant helps divert waste from landfills, mitigating the environmental impact associated with waste decomposition.

c. Cost savings: Biogas production can significantly reduce household energy expenses, particularly for cooking and heating purposes.

d. Fertilizer production: The residue left after the digestion process, known as digestate, is an excellent organic fertilizer that can be used in gardens or agricultural activities.

e. Self-sufficiency: A biogas plant empowers homeowners to generate their energy, reducing dependence on external energy providers and fostering a sense of self-sufficiency.

A biogas plant for home offers an innovative and sustainable solution to meet energy needs while simultaneously addressing waste management challenges. By converting organic waste into valuable biogas and organic fertilizer, homeowners can contribute to a cleaner environment and reduce their ecological footprint. While setting up and maintaining a biogas plant may require initial investment and effort, the long-term benefits make it a worthwhile endeavor for those committed to sustainable living and responsible energy consumption.

0 notes

Text

Bio Digester Tanks

With high population densities in rural and urban regions, India is among the most populated nations in the world. As a result, treating and managing human waste has emerged as one of the nation's biggest problems today. According to studies, less than 30% of Indians have access to safe, sanitary facilities. Most rural homes practice open defecation, which puts them at risk for several illnesses, including cholera, dysentery, hepatitis, diarrhoea, and hepatitis.

What is Bio Digester Tank?

A biodigester tank is an ecologically sustainable long-term waste and sewage treatment method, enabling us to recycle water and generate biogas. The device consists of a sealed chamber where microorganisms decompose organic material (often wastewater waste) without oxygen.

With the aid of bacterial inoculums, with DIPLAST, you can get the Best bio digester tanks in Mohali, a comprehensive waste management system that converts solid human waste into biogas and clean water. This LLDPE tank has an intake of human waste and exits for treated effluent and biogas. Four chambers of the biodigester lengthen the waste stream, enhancing contact duration, sedimentation, and degradation. Depending on the number of users, the availability of water, and the current geo-climatic circumstances, the proportions and internal layouts may change. Human faeces is transformed into water and methane when it comes into touch with microorganisms.

How does it work?

Three chambers make up a biodigester tank. When human excreta or faecal matter enters the first chamber through the toilet outlet, the microbial consortium begins feeding on the organic waste and begins the breakdown process. Additionally, the section separates the waste into solid and liquid forms. When the first chamber is complete, the water spills into the second chamber, where treatment is performed to remove almost 90% of the trash. The effluent from the last chamber is thought to be 98% clean, pathogen-free, and free of innocuous byproducts, making it safe to use for irrigation.

The system has to follow a few broad guidelines to function:

So that no gas or water may enter the chamber uncontrollably or exit it, the container must be completely shut. In this manner, the soil is safeguarded, and the oxygen-free environment required to initiate the anaerobic digestion process is secured.

The tank needs to be built with a sturdy foundation that ensures its long-term stability.

Insulation is necessary for the biodigester to maintain a constant temperature within the chamber and aid in fermentation.

For everyone's health and safety, all materials utilized should be corrosion-resistant.

Advantages of using a biodigester tank:

DIPLAST Biodigester / Bio tank Benefits

Methane may be converted into biogas and used for heating or cooking if captured.

You create a premium lawn and garden fertilizer.

You get to clean up wastewater and reuse it in agricultural processes.

In the long term, you save money and utilize all resources to their fullest potential.

Simple in structure

Little maintenance is necessary.

Toilet tanks don't emit any unpleasant odours.

Effluent is devoid of solid trash and foul odours.

90% decrease in organic matter

No need to add bacteria or an enzyme

0 notes

Text

Bamoyeast BFB (Biodigester, Septic Tank, Pit, Sewage, Compost Bacteria & Enzymes)

Bamoyeast BFB is the BEST PIT LATRINE DIGESTER CHEMICAL, biodigester bacteria, biodigester, septic tank bacteria, biodigester enzyme, and septic tank chemical as it is an EFFICIENT biological enzymatic and microorganism-based formulation (containing beneficial bacteria/ multi-enzymes). Bamoyeast BFB eliminates odors generated from landfills, which include, household organic waste(garbage), pit…

View On WordPress

#Bamoyeast BFB#Biodigester Bacteria#Biodigester Chemical#Biodigester Enzymes#Biodigester Septic Bacteria#Biodigesters Chemical#Compost Digester#Drains Chemical#Pit Latrine Digester Bacteria#Pit Latrine Digester Chemical#Pit Latrine Digester Enzymes#Septic Tank Bacteria#Septic Tank Chemical#Septic Tank Enzymes#Sewage Sludge Treatment Bacteria#Sewage Sludge Treatment Chemical#Wastewater Chemical

0 notes

Text

Production of Cooking Gas from Cow Dung.

Cooking gas can be produced from cow dung with the aid of anaerobic bacteria which are capable of breaking down the carbohydrate substance in the waste into methane, in the absence of oxygen gas.

Essential Materials for the production are;

Biodigester which can be made using 20/25 litres keg.

3/4 Polyvinyl chloride(PVC) pipe.

Burnsen Burner/ Gas Valve.

T-Valve.

3/8 PVC Hose.

Funnel.

Tyre tube.

Nec…

View On WordPress

0 notes

Text

General Mills Commits to 100% Renewable Electricity Globally by 2030

General Mills set a goal of 100% renewable electricity by 2030 as part of the RE100 global corporate initiative. To achieve this, the company is investing in renewable energy efforts to support the company’s environmental objectives. Examples include two large-scale wind farms which will produce renewable energy credits (RECs), and anaerobic digestion (which captures and uses methane from waste to generate electricity). Internationally, the company is investigating renewable projects where it has energy-intensive operations.

“Signing on to a movement like RE100 extends our commitment to renewable electricity globally, across our supply chain,” said John Church, chief supply chain officer at General Mills. “We know we’re able to drive more widespread action and impact when we make bold commitments. And we’re proud to be among those corporations that are taking the initiative to use scale for good because together, we can secure more measurable and meaningful results.”

Full value chain targets

In 2015, General Mills was the first company across any sector to publish a goal approved by the Science Based Targets initiative (SBTi) to reduce absolute greenhouse gas emissions across the company’s full value chain (Scopes 1, 2 and 3) by 28% by 2025. Through 2019, General Mills has reduced the greenhouse gas emissions of its extended value chain by 14% compared to its 2010 baseline.

Biogas renewables

The renewable energy projects currently underway, as well as those yet to be implemented, will enable the company to reduce Scope 2 emissions in its global operating facilities. Projects underway thus far include:

In North America, the company has a 1.6 megawatt generator fueled by the anaerobic biodigester at its Murfreesboro plant in Tennessee. Self-renewing bacteria in the biodigester convert plant process wastewater from its yogurt and dough production into the biogas fuel. Power and heat from the generator are fed directly back into the yogurt processing facility to reduce its annual grid power and natural gas purchases by up to 20%.

In South America, the company has a 335 kilowatt biogas regeneration plant at its Paranavai Yoki location. This plant is one of the largest manufacturing plants in Brazil where electric power is produced from biogas generated by the site’s wastewater treatment system. The power is used by the plant with any excess sent to the local electric utility, reducing the company’s power spend by 30%.

In Europe, the company has a 195 kilowatt capacity biogas regeneration plant at its Arras, France Häagen-Dazs production facility. The plant uses electric power produced from generators that are fueled by renewable biogas from the site’s process wastewater treatment system. When the plant doesn’t use it, the power generated from the biogas is sold to the local utility grid, while heat in the form of hot water is recovered to reduce natural gas consumption at the ice cream plant.

“We are pleased to welcome General Mills to RE100,” said Sam Kimmins, head of RE100. “It is great to see such an influential business commit to 100% renewable electricity globally. General Mills’ leadership sends a strong signal to the wider industry that corporations can make a major contribution to the creation of tomorrow’s clean, resilient energy systems.”

Wind renewables

In 2017, General Mills signed a 15-year virtual power purchase agreement with RES Americas for 100 megawatts of the Cactus Flats wind project in Concho County, Texas. In fiscal 2019, this project generated RECs equivalent to about one third of electricity usage at General Mills owned manufacturing locations in the U.S. And in 2019, General Mills signed another 15-year power purchase agreement with Roaring Fork Wind, LLC, a joint venture partnership between RES and Steelhead Americas, for 200 megawatts of its Maverick Creek wind project in central Texas. The wind farm will produce RECs for General Mills that, together with Cactus Flats will equal 100% of the electricity used annually at the company’s owned U.S. facilities.

“We have a responsibility to use our scale for good, and people and planet are our primary considerations,” said Mary Jane Melendez, chief sustainability and social impact officer for General Mills. “We continue to seek out and invest in solutions and programs that will restore and regenerate our natural resources which we are all dependent upon.”

General Mills is listed on the 2019 Dow Jones Sustainability Index, and the 2019 CDP A List Awards for Climate and Water.

For more information on General Mills’ ambitious climate commitment and progress, read the company’s 2020 Global Responsibility Report.

About General Mills

General Mills is a leading global food company whose purpose is to make food the world loves. Its brands include Cheerios, Annie's, Yoplait, Nature Valley, Häagen-Dazs, Betty Crocker, Pillsbury, Old El Paso, Wanchai Ferry, Yoki, BLUE and more. Headquartered in Minneapolis, Minnesota, USA, General Mills generated fiscal 2019 net sales of U.S. $16.9 billion. In addition, General Mills’ share of non-consolidated joint venture net sales totaled U.S. $1.0 billion.

About RE100

Led by The Climate Group in partnership with CDP, RE100 is a collaborative initiative bringing together the world’s most influential businesses committed to 100% renewable power. Renewables are a smart business decision, providing greater control over energy costs while helping companies to deliver on emission reduction goals. RE100 members, including Global Fortune 500 companies, have a total revenue of over US$5.4 trillion and operate in a diverse range of sectors – from information technology to automobile manufacturing. Together, they send a powerful signal to policymakers and investors to accelerate the transition to a clean economy. Learn more at RE100.org.

source: https://www.csrwire.com/press_releases/44988-General-Mills-Commits-to-100-Renewable-Electricity-Globally-by-2030?tracking_source=rss

0 notes

Text

Agua Miel: From Pollutant to Organic Fertiliser

Washed processing may result in a cleaner tasting coffee, but it dirties more water than any other processing method, using up to 20 cubic metres of water per tonne of cherry in some instances. When this happens, the acidic and sweet agua miel that it creates enters waterways, where the resulting pollution load can be several times greater than that of urban sewage.

However, just like dried coffee fruit husks can be repurposed into cascara tea, agua miel can be transformed from a damaging pollutant into a variety of valuable products.

While some businesses use it to create honey or biogas, producers can easily use it by transforming it into an organic fertiliser. I spoke to several Colombian smallholders about how they do it – and why coffee exporters and roasters should be supporting this process.

Picking coffee on Edilberto Coronado’s farm, Finca Buena Vista, Colombia. Credit: The Coffee Quest US

What is Agua Miel?

In a fresh coffee cherry, the seed or bean makes up less than half of its total weight. During washed processing, the cherries are de-pulped, fermented, and then have their mucilage removed with turbulent water, before being dried. During wet processing, over 80% of the harvest’s volume is left behind as organic waste.

The resulting wastewater consists of fermenting sugars from the cherry pulp, mucilage, and pectins. Its gel texture comes from the undigested mucilage and pectic substances in the water.

The primary environmental effect of this wastewater entering other water sources is that high amounts of oxygen will be needed to break down the organic waste present, creating anaerobic conditions that kill off animal and plant life.

While no long-term studies have been conducted on the impact of coffee wastewater on human health, studies indicate that when it contaminates potable water sources, it can cause problems. A 2008 study assessing the effect of wastewater from a coffee processing plant in Ethiopia’s Zimma zone found that people living near the plant who consumed the polluted water experienced nausea, eye and skin irritation, breathing problems, and stomach pain.

While disposing of wastewater on land is cheap and easy, it still creates waste and contaminants that can reach ground and surface water through percolation and runoff. The process will also emit greenhouse gases, making it less environmentally friendly.

For this reason, anaerobic digestion is an eco-friendly alternative for treating coffee processing wastewater, as it can remove the bulk of its organic load and suspended solids. With this process, the wastewater is fed into an oxygen-free machine built for this purpose. It’s then heated and as time passes, bacteria decompose its mass into sugars and organic acids. These organic acids are then converted to biogas.

This system requires less land, reduces bad odours and pathogens, and results in organic fertiliser being produced as an end product.

Asociación La Victoria’s eco-washer, fermentation tank, and compost pile in Santa Maria, Huila, Colombia. Credit: The Coffee Quest US

Cleaner Water, Healthier Soil

Coffee that is grown using long term monoculture (which is when a single crop is grown without rotation) and with full sun exposure, often experiences poor growth and low yields. The sun exposure and direct heat also dries the soil, reduces its density, and encourages erosion.

Continuous coffee cropping obstacles can often be attributed to poor quality soil, as it can cause toxic substances to accumulate, soil properties to deteriorate, pathogens to build up, and native microbiota to be disturbed. Without providing additional nutrients to compromised soil using fertiliser, coffee yields will remain low.

Research indicates that large amounts of organic fertiliser that can be recovered using anaerobic digestion. This can be used to replenish soil requiring fertilisation while reducing pollution at the same time.

To see what it looks like when farmers adopt this process, I spoke to Andrés Perdomo Centeno, who is the Producer and Head of Asociación La Victoria, a collective of specialty coffee growers in Santa Maria, Huila, Colombia. His farm has partnered with exporter The Coffee Quest US, and local environmental organisation Fusamdes to neutralise the environmental impact of their farms.

Coffee Quest US Owner Stephen Levene explains that as local farmers share a watershed with a nearby national park, residual water often ends up in its rivers. They’ve provided farmers with ecowashers to convert wastewater into a paste that can be processed. Andrés believes that creating fertiliser from subproducts of washed processing tackles more than one environmental challenge at a time, by eliminating water pollution and recovering soil conditions.

Research shows that using organic fertiliser to improve soil properties can both increase yields and reduce the need for inorganic fertiliser, saving farmers money. As cascara and agua miel are rich in nutrients like nitrogen, phosphorus, potassium, and calcium, here’s how farmers transform it into fertiliser.

A tank collects the wastewater solids, which sink, and the more concentrated sugars, which float. Both will later be incorporated into fertiliser. Credit: Bosque Colibrí

How it Works

As most producers don’t have access to large-scale equipment for anaerobic digestion, they rely on processes that use less technology. According to Gabriel Vélez, Technical Director of Coffee at Café de Santa Bárbara in Medellín, Colombia, many of these lower-tech processes work in the same way.

He explains that the agua miel from the first few washes is placed in a plastic or cement tank, where the more concentrated sugars float to the top, and solids sink to the bottom. Both are captured and mixed with cascara for composting. At this stage, some producers take the concentrated sugars and mix them with lime or ash to adjust the pH, creating foliar fertilisers.

The process can look different from one producer to the next. For Carlos Andrés Ossa, an Organic Producer and Coordinator of the Bosque Colibri Natural Reserve, there are two stages. First is a dehydration process, where he leaves a cascara mixture to dry for two weeks in a drainage pit.

As the mixture decomposes, he collects the agua miel that leaches out. Once evaporation has left only solids behind, he reincorporates the cascara, adding rock flour to create a richer, more powerful mixture. The cleaner water left behind can then be further purified in a variety of ways, using anaerobic filtration, biodigesters, or plant-based biofilters.

“After three months, you’ll have a potent compost of black soil that you can reincorporate into the production cycle,” explains Carlos. “It’s the simplest way to add value to the subproducts traditionally thrown out.”

After purification, the wastewater from Carlos’ washing process is returned to the stream on his farm. Credit: Bosque Colibri

Using Ecomills & Ecowashers

Carlos says that with the use of certain technologies, you can extract even more value from mucilage, and make the process more efficient. He is referring to ecomills and ecowashers, which can reduce water use from 40 litres per kilo to as little as half a litre.

The ecomill and ecowasher use the same washing technology, but the ecowasher is sold as a separate, portable unit, whereas the ecomill consists of several machines that de-pulp, ferment, and wash coffee in one integrated system.

With both machines, the beans are fermented and then transported through a rotating cylinder that scrapes off the mucilage. It then cleans the coffee using a small amount of water. Less water goes in and a smaller amount of concentrated wastewater comes out, which can then be dehydrated into a paste or a cake.

This dehydrated paste can then be dried and made into compost or substrate for growing orchids. The fertiliser produced can be applied to coffee plants, as well as indigenous shade and fruit trees as part of reforestation efforts.

That’s a lot of added value – and reduced waste. So why aren’t more producers doing it?

Carlos’ anaeróbico filter uses sand, asphalt cloth, and gravel to purify wastewater from the third wash. Credit: Bosque Colibri

Covering The Costs of Eco-friendly Processes

Even basic, low-technology ways to process agua miel come at a cost in terms of equipment and labour. With coffee prices remaining at just over a dollar a pound, many producers are struggling to break even and feed their families – let alone invest in what’s necessary for processing agua miel on their farms.

This is where exporters and roasters can step in. It’s important for both parties to realise that there is a relationship between coffee quality and environmental sustainability and that by preserving good environmental conditions, favourable conditions can be created for high-quality coffee to be grown. It’s therefore in their best interests to support producers in their waste management endeavours.

This can be facilitated in many ways, but the simplest may be to ensure that producers are paid a fair price for their coffee. As Stephen says, “The first and most important thing for us is to pay the farmer as high a price as we can, based on quality. He adds that “we work with them to increase the value of their coffee, and once we’ve built a long-term relationship, then we try to work together on creating systems that are more ecologically sustainable.”

With climate change a current reality, and coffee production under threat, it’s not only producers who’ll have to deal with the consequences of reduced yields and quality.

After four months in a compost pit, Carlos’ cascara-based fertiliser will be ready to use. Credit: Bosque Colibri

For members of the coffee supply chain, supporting producers in their waste processing efforts can be the first step in ensuring that coffee quality and integrity remains high – and that producers and the planet can afford to keep producing it for years to come.

Enjoyed this? Read Can Coffee Quality & Environmental Sustainability Go Hand in Hand?

Written by Kristen Lee Cronon. All quotes from Andrés Perdomo Centeno, Gabriel Vélez, and Carlos Andrés Ossa translated from Spanish by the writer. Feature photo caption: After four months in a compost pit, Carlos’ cascara-based fertiliser will be ready to use. Feature photo credit: Bosque Colibri

Want to read more articles like this? Sign up for our newsletter!

The post Agua Miel: From Pollutant to Organic Fertiliser appeared first on Perfect Daily Grind.

Agua Miel: From Pollutant to Organic Fertiliser published first on https://espressoexpertweb.weebly.com/

0 notes

Text

Refined rock curing plan

I was a microbiologist, so I highly value diversity in a microbiome. Like...a lot.I really want my was-dry rock to be thoroughly populated with a diverse set of bacteria/etc before they go into the tank. But I don’t really want to get collect pests from everyone by buying rock rubble from everyone in town. So, I’ll cure my rock with a smorgasbord (It’s Oktoberfest!) of bottled bacterial products and my own nano tank (that hopefully doesn’t have pests).

So, materials list first:

Buy a gyre that will go in the display and a heater (set to about 70, probably. bacteria won’t care and it saves a little power)

Buy two 55g drums (used). cut the top off and tinker to make the cut top into a makeshift lid.

Buy the rock I’ll be using (probably a mix of life rock shapes, XL arches, shapes).

(later) Pull loose rocks from nano plus one of the big rocks to go in the new curing tub.

Initial additives (first week...ish):

Dr Tims one and only

Brightwell Microbacter 7

Instant ocean Biospira

TLF biopronto

Longer term additives (after the first week of curing):

Prodibio bioclean or biodigest+bioptim

Live Rock Enhance Brightwell Microbacter clean

Dr Tims Waste away

vibrant

0 notes

Text

Top Sources of Probiotics

Probiotics are dietary supplements or foods that contain "good bacteria" that are similar to the microorganisms already found in your body. While your body contains enough of these microorganisms to keep you healthy, taking supplements or eating foods with this "good bacteria" can be beneficial.

Probiotics may help with the treatment of diarrhea, urinary tract infections, irritable bowel syndrome, reduce bladder cancer recurrence, reduce lactose intolerance, reduce negative effects of antibiotics, prevent eczema in children, and enhance immune system response. At this time researchers are still studying the effects of probiotics. The following are the top ten food sources of probiotics:

Yogurt

Chocolate

Cheese

Sauerkraut

Tempeh

Cottage cheese

Wine

Beer (microbrew)

Pickles (brine-cured, without vinegars)

Wheat Grass

The list for probiotic sources is growing as more is discovered. While food is the best source of probiotics, there are also dietary supplement s. These supplements are not recommended for people with immune system deficiency, gastrointestinal damage, young children, and pregnant women.

HealthAdviceWorld says it is always important to consult a physician or dietitian before starting any supplement. The following are the top 5 probiotic dietary supplements:

1.) P2 BioDigest

Not only does P2 BioDigest contain probiotics, it also comes complete with prebiotics, digestive enzymes, and dietary fibers. This supplement is proven to enhance immunity, promote good digestion, lower cholesterol, maintains regularity, and increases energy. The pills are easy to swallow and melt in your mouth, requiring no water. You can purchase P2 BioDigest for free with the payment of shipping and handling from www.p2biodigest.com.

2.) Mega Acidophilus Probiotics

Mega Acidophilus probiotics supports intestinal health by encouraging intestinal micro flora balance and promotes the healthy functioning of the intestinal system. In addition, this supplement contains Citrus Pectin. You can purchase 100 capsules of Mega Acidophilus for $18.99 from Vitamin World.

3.) GNC Ultra Probiotic Complex 25

Each capsule of Ultra Probiotics contains 25 billion active and live cultures. This supplement helps boost immune health, reduce bloating, reduce stomach discomfort, and aid in improving irregularity. You can purchase 30 capsules of this product for $26.99 from GNC.

4.) Culterelle Probiotic

Culterelle Probiotic is an all natural supplement featuring Lactobacillus GG, which is the strongest form of probiotics. It is strong enough to survive stomach acid and give maximum results. Each capsule contains 10 billion active and live cultures. Culterelle is also available for kids. You purchase 30 capsules of Culterelle Probiotic for $22.99 from CVS.

0 notes

Text

How to SPEED CYCLING Process.

In this discussion, I will MAINLY be focusing on the Products and method to SPEED UP the cycling process.

The “General Rule” is to cycle the tank as long as possible, usually about 3-5 weeks.

These depend on 3 MAIN factors:

1. Type/brand of soil used.

2. Filtration

3. Bacteria(Type/Brand)

These are the MAIN brands/product I use to setup a NEW tank using ADA Amazonia soil:

1. Bacteria

- Lowkey Speed Sand

- Biodigest

- B4 (POWERFUL but Quite expensive)

*INFO: SMW and Lowkeys Type S are use to tweak TDS and gH respectively.

*INFO: All product above can be found at Aquarist Chamber and Fishybussiness.

————————————————————————

STEP by STEP for Setting up NEW tank(45x45x36cm) using ADA Amazonia Soil and UGF+Sponge filter as Filtration:

1. Lay soil on UGF plate and sprinkle a packet of LOWKEYS Speed sand in between(layers).

*INFO: Its fine to OVERDOSE.

2. Fill up tank with CYCLED WATER from an existing tank which is RUNNING WELL as much as you can.

3. Fill up the rest of tank to the desired height with RO/DI Water.

*NOTE: If theres no cycled water, Its ok to filled up with RO/DI water.

4. Squeeze MATURED Sponge Filters from a existing tank into the new setup.

*NOTE: Matured Sponge filter MUST be from the same tank as where the cycled water is taken.

*INFO: Place New sponge filter in the existing tank(Same source where cycled water is use) to let it Mature. When it’s ready to setup new tank, it can be use to speed up cycling process.

5. Dose 1x Vial of Biodigest per week for the next 2 weeks.

6. In WEEK3, do a 50% WC. Top up the tank with CYCLED WATER.

*NOTE: Ensure CYCLED water is from the same tank during setting up and IS RUNNING WELL.

7. After 3-5days, do a 10-20% WC with RO/DI water, adjust parameters and add shrimps.

*NOTE: Please check Ammonia Level using SERA or any other brands(liquid) if you worried about it.

There are other products used by local Hobbyist who use different products to achieve the same goals.

These are some of the local Breeders/hobbyist in SG who I trust and they are willing to help hobbyist:

1. FRAN09(Home Breeder)

3. Demin(MADSHRIMP)

5. Shuan Poh(Shrimps Affair)

6. Darrick(Shrimps Affair)

7. Steve Su(Home Breeder)

The brand/type of products & methods mention above is NOT a standard way to breed shrimp successfully or tank “die die” will cycle shorter BUT just a recommendation and guidelines.

At the end of the day, you need to understand the BASIC. Actually the BASIC is all you need to keep and breed shrimp successfully.

***General Rule: Keep setup as SIMPLE as possible and cycle tank LONGER is always the BEST.

Here are some of the links you will find useful:

1) MADSHRIMP

2) Aquarist Chamber

3) FishyBusiness

I hope this will help hobbyist out there:)

Thank you😇😇😇

0 notes

Text

Biodigester Bacteria

Biodigester bacteria enzymes are microorganisms that are used to break down organic waste and convert it into useful products such as methane gas and compost. These enzymes are commonly used in biodigester systems, which are designed to process organic waste in an environmentally friendly and sustainable way. In this blog, we will explore the role of biodigester bacteria enzymes in the…

View On WordPress

0 notes

Text

Biodigester Bacteria Enzymes

Biodigester bacteria enzymes are microorganisms that are used to break down organic waste and convert it into useful products such as methane gas and compost. These enzymes are commonly used in biodigester systems, which are designed to process organic waste in an environmentally friendly and sustainable way. In this blog, we will explore the role of biodigester bacteria enzymes in the…

View On WordPress

0 notes