#Best Synthetic Engine Oil

Explore tagged Tumblr posts

Text

Discover the Ultimate Performance Upgrade: Best Synthetic Engine Oil"

Take your engine's performance to the next level with the best synthetic engine oil available on the market. Crafted using state-of-the-art technology and premium-quality ingredients, this synthetic oil offers superior lubrication, heat resistance, and wear protection. Whether you're an avid motorcycle enthusiast or a casual rider, trust in this top-tier synthetic oil to optimize your engine's performance and extend its lifespan. With its advanced formula, you can confidently push your engine to its limits, knowing it's protected by the best synthetic engine oil.

0 notes

Text

Top Benefits of Synthetic 15w40 Diesel Engine Oil

This synthetic 15w40 Diesel Engine Oil has good durability, and its finishing is such that long life performance is achieved in extreme temperatures. Its formula cuts down on wear and tear. It increases the fuel efficiency of diesel engines and provides better resistance to oxidation. Conventional oils cannot compare with this oil as it is best suited for heavy-duty applications that may have a longer life and reduce maintenance costs over time.

#Synthetic 15w40 Diesel Engine Oil#Best Diesel Engine Oil 5w30#Lubricants Suppliers Located In Missouri#High-Quality Lubricants#Diesel Fuel Cleaner Additive#Lube Oil Additives

1 note

·

View note

Text

Your search for fully synthetic engine oil for your car ends here with Veedol. Find the best car engine oil and lubricants that are specific to your needs here.

0 notes

Text

Shop Gulf Ultrasynth X Plus 5W-30 fully synthetic car engine oil for premium hatchbacks, and mid-size & executive sedans at most competitive price today!

0 notes

Text

Precision Unleashed: Elevate Your Racing Experience with ROFEIBI's Supreme Racing Moto Brake Fluid

In the adrenaline-pumping world of motorcycle racing, every element plays a crucial role in achieving optimal performance. From the sleek design of the bike to the expertise of the rider, every detail matters. One often overlooked but essential component is the brake system, and in the realm of racing, precision is key. Enter ROFEIBI's Racing Moto Brake Fluid – a game-changer that takes braking performance to a whole new level.

Unveiling ROFEIBI's Racing Moto Brake Fluid:

When it comes to racing, standard brake fluids may fall short of meeting the demands of high-performance motorcycles. ROFEIBI's Racing Moto Brake Fluid steps in to bridge this gap, offering a specially formulated solution designed to enhance precision, responsiveness, and overall braking efficiency.

Unmatched Precision

ROFEIBI's Racing Moto Brake Fluid is engineered to provide unmatched precision during critical moments on the race track. Its advanced formula ensures rapid and consistent brake response, allowing riders to navigate tight corners and execute swift maneuvers with confidence. The fluid's low compressibility ensures that every input from the brake lever translates into immediate and precise braking action.

Racing Engine Oil Frequently Asked Questions (FAQs) – Your Quick Guide to Key Questions

High-Temperature Performance

Racing scenarios often subject brake systems to extreme temperatures, pushing standard brake fluids to their limits. ROFEIBI's Racing Moto Brake Fluid is formulated to withstand these high temperatures, preventing brake fade and maintaining consistent performance even under intense racing conditions. This feature is a game-changer, ensuring that riders can push their bikes to the limit without compromising on braking efficiency.

Enhanced Wet Boiling Point

In unpredictable weather conditions, such as sudden rain showers during a race, maintaining optimal brake performance becomes even more critical. ROFEIBI's Racing Moto Brake Fluid boasts an enhanced wet boiling point, ensuring reliable braking even when exposed to moisture. This characteristic is particularly valuable in racing situations where the track conditions can change rapidly.

Corrosion Resistance

Racing Moto Brake Fluid goes beyond just enhancing performance; it also provides superior protection against corrosion. The fluid's corrosion-resistant properties help extend the lifespan of critical brake components, ensuring that the braking system remains in peak condition over the long haul. This is a crucial aspect for racers who demand durability and reliability from their equipment.

Compatibility with Racing Systems

Designed with racing motorcycles in mind, ROFEIBI's Racing Moto Brake Fluid is compatible with advanced braking systems commonly found in high-performance bikes. Whether your bike is equipped with ABS or other cutting-edge braking technologies, this fluid seamlessly integrates, maximizing the effectiveness of these systems and providing a competitive edge on the track.

Conclusion

ROFEIBI's Racing Moto Brake Fluid emerges as a must-have for motorcycle enthusiasts and racers alike, elevating the braking experience to unprecedented levels of precision and reliability. As the demand for high-performance products continues to grow, the strategic use of keywords ensures that this exceptional brake fluid remains at the forefront of online searches, connecting with riders who are eager to enhance their racing experience. Beyond brakes, ROFEIBI's Racing Moto Brake Fluid is the epitome of precision in the thrilling world of motorcycle racing.

#moto racing engine oil#racing motor oil#best moto racing engine oil#best motor oil for racing#best racing motor oil#motorcycle racing oil#synthetic motor racing oil for bike#racing bike engine oil#best engine oil for drag racing#best motorcycle racing oil#best synthetic racing motor oil#best synthetic motor racing oil#high performance moto racing oil#moto racing engine oil manufacturer#moto racing engine oil dealer#fully synthetic racing bike oil#pao based synthetic motor racing oil#ester moto racing engine oil#best motorcycle racing engine oil#motor racing engine oil company#racing motor engine oil#racing motor engine oil manufacturer#racing motor engine oil dealer#racing motor engine oil supplier#racing motor lubricants#racing moto lubricants manufacturer#racing moto lubricants dealer#racing moto lubricants supplier#racing moto lubricant supplier#premium lubricant supplier for racing bikes

0 notes

Text

"In Washington D.C., a sophisticated sewage treatment plant is turning the capital’s waste into a form of capital: living capital that is fertilizing the gardens of farms of the Mid-Atlantic region and saving vast quantities of resources.

Described by the workers’ there as a “resource recovery plant,” D.C. Water run a biogas plant and high-quality fertilizer production in the course of their dirty duty to ensure the city’s waste finds a safe endpoint.

The nation’s capital is exceptional at producing waste from the toilet bowls of the 2.2 million people who live, work, and commute through the city and its suburbs.

Reporting by Lina Zeldovich reveals that rather than trucking it all to a landfill, D.C. Water extract an awful lot of value from the capital crap, by looking at it as a resource to send through the world’s largest advanced wastewater treatment plant, which uses a “thermal hydrolysis process” in which it is sterilized, broken down, and shipped off for processing into “Bloom,” a nitrogen-rich, slow-release fertilizer product.

The other “Black Gold”

At their facility in southwest Washington, huge aeration tanks percolate the poo of everyone from tourists to the President. After it’s all fed into enormous pressure cookers where, under the gravity of six earth atmospheres and 300°F, the vast black sludge is rendered harmless.

Next this “Black Gold,” as Zeldovich described it, is pumped into massive bacterial-rich tanks where microbes breakdown large molecules like fats, proteins, and carbs into smaller components, shrinking the overall tonnage of sewage to 450 tons per day down from 1,100 at the start of the process.

This mass-micro-munching also produces methane, which when fed into an onsite turbine, generates a whopping 10 megawatts of green energy which can power 8,000 nearby homes. [Note: Natural gas (which is mostly methane) is definitely greener than coal and oil, but it still causes a significant amount of emissions and greenhouse gases.] The 450 tons of remaining waste from the D.C. feces are sent into another room where conveyor belts ring out excess fluid before feeding it through large rollers which squash it into small congregate chunks.

D.C. Water sends this to another company called Homestead Gardens for drying, aging, and packaging before it’s sold as Bloom.

“I grow everything with it, squashes, tomatoes, eggplants,” Bill Brower, one of the plant’s engineers, tells Zeldovich. “Everything grows great and tastes great,” he adds.

“And I’m not the only one who thinks so. We’ve heard from a lot of people that they’ve got the best response they’ve ever seen from the plants. Particularly with leafy greens because that nitrogen boost does well with leafy plants. And the plants seem to have fewer diseases and fewer pests around—probably because Bloom helps build healthy soils.”

While farms around the country are facing nutrient depletion in soils from over-farming, turning to synthetic fertilizers to make up the difference, introducing more such thermal hydrolysis plants could truly revolutionize the way humans look at their feces—as a way of restoring the country’s soils rather than polluting them. As Mike Rowe would say, it only takes a person who’s willing to get their hands dirty."

-via Good News Network, November 23, 2021

Note: You can buy this fertilizer yourself here!

#older news but still relevant#you can go buy this fertilizer yourself!#sewage#sanitation#fertilizer#sustainability#circular economy#sustainable agricuture#nitrogen#waste#waste management#waste disposal#good news#hope#hope posting#washington dc#dc#united states#district of columbia#urban farming#solarpunk#urban gardening#environmentalism#farming#rooftop garden#gardening#edible gardening#toilet#soil#soil quality

128 notes

·

View notes

Text

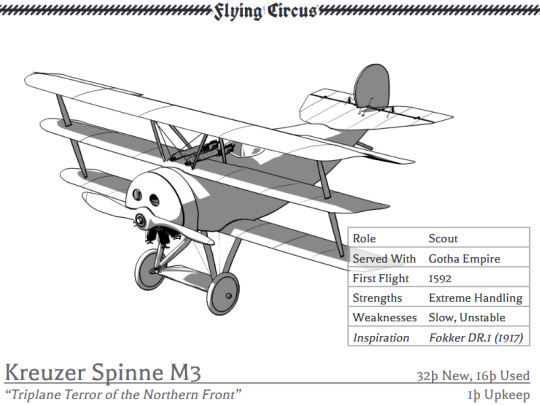

Kreuzer Spinne M3 - "Triplane Terror of the Northern Front"

Role: Scout Served With: Gotha Empire First Flight: 1592 Strengths: Extreme Handling Weaknesses: Slow, Unstable Inspiration: Fokker DR.1 (1917)

Description:

Lacking rotary fighters put the Gotha Empire at a distinct disadvantage going into the war in Macchi. The Macchi Singvogels were massively more agile than the Kobra MCs. Eventually, Gotha had to bite the bullet, despite the lack of available castor oil.

The M3 was limited to a mere 110hp engine, so it was made lean and mean: metal framed, closed cowl, and with triple wings for maximum lift. Its secret weapon was birch cantilever spars instead of tension wires for greatly reduced drag. The M3 served many of Gotha’s best aces in large ‘Wolf Pack’ squadrons in the second half of the war, making them quite sought after by post-war pilots.

Despite their excellent characteristics, the M3’s reliance on synthetic lubrication gave them chronic overheating problems in the northern heat, causing an early retirement from service which preserved a great many machines.

9 notes

·

View notes

Text

Mechanic Guru Asks: Car Mythbusters - Fact or Fiction?

The internet is a treasure trove of information, but it can also be a breeding ground for myths and misinformation. When it comes to car care, separating fact from fiction is crucial to keeping your vehicle running smoothly and avoiding costly repairs.

Here at Mechanic Guru, we're busting some common car care myths to empower you with the knowledge to make informed decisions for your car.

Myth 1: You only need to change your oil every 5,000 miles.

Fact: Oil change intervals vary depending on factors like your driving habits, oil type, and car model. Consult your owner's manual for the recommended service schedule. Modern synthetic oils often allow for longer intervals (sometimes up to 10,000 miles), but severe driving conditions like frequent stop-and-go traffic might necessitate more frequent changes.

Myth 2: Using higher octane gas gives your car more power.

Fact: Octane rating measures a fuel's resistance to knock (premature detonation). Unless your car's engine is specifically designed for high-octane fuel, using it won't provide any performance benefits. In fact, it can even be a waste of money, as your engine won't be able to take full advantage of the higher octane. Always stick to the octane rating recommended by your car manufacturer.

Myth 3: Topping off fluids is always a good thing.

Fact: Overfilling fluids like oil or coolant can be just as detrimental as running low. Overfilled crankcases can put stress on engine seals, while overflowing coolant reservoirs can lead to leaks and overheating issues. Always refer to your owner's manual for proper fluid levels and filling procedures.

Myth 4: Revving your engine before driving warms it up faster.

Fact: Modern engines with fuel injection don't require aggressive revving to warm up. In fact, it can put unnecessary stress on the engine. The best approach is to simply start your car and allow it to idle for a minute or two before driving gently until the engine reaches operating temperature.

Myth 5: You can skip tire rotations if your car has all-wheel drive (AWD).

Fact: Even in AWD vehicles, tires wear unevenly due to factors like cornering and individual suspension components. Regular tire rotations (every 5,000-7,000 miles) are essential to maximize tire life and maintain proper handling for all-wheel drive vehicles as well.

Stay Informed, Stay Empowered

By debunking these common car care myths, you're equipped to make informed decisions for your vehicle. Remember, Mechanic Guru is always here to be your trusted source for car care knowledge. If you have any questions or concerns, don't hesitate to leave a comment below or visit our website for more resources!

2 notes

·

View notes

Text

Nickel 200 Wires Exporters in UAE

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is a Wires provider and exporter of Nickel 200 wires. We Manufacture them open in custom nuances, plans, lengths, thickness, widths, and that is only a brief gander at something more prominent. We are known Exporters in the general market of ferrous and nonferrous things. Our clients can intercessors for nickel wires as shown by their application necessities.

Nickel 200 Wires are made with the assistance of the different Amalgam affiliations like carbon, manganese, silicon, copper, sulfur, chromium, iron, nickel, nitrogen, etc. too. These nickel wires ought to have physical and mechanical properties like thickness, loosening up point, flexibility, yield strength, astonishing rigid nature, broadening, warm conductivity, electrical conductivity, and modulus of extension. These wires are made with different decisions like broadness, shape, size, length, width, thickness, types, structures, condition, surface, application, standard, finish, obstacles, etc. as well. These wires are accessible in many sorts, for example, reshape wire, made never-ending wire.

Nickel 200 Wires are material in various organizations, for instance, offshore oil entering undertakings, petrochemicals industry, power age plant, drug industry, substance gear, seawater equipment, drug equipment, special engineered industry, paper industry, pound industry, heat exchanger, and condenser. These wires are also significant in many general purposes like valves, shaft, shipbuilding, structure advancement, transportation equipment, range improvement, radiator parts, and various temperature-safe things.

Nickel 200 Wires are made with the best material and incredible mechanical and real properties. These wires are a good blend of formability, usefulness, welding, and resistance from the high temperatures. These wires are outrageous, hard, and made with the protected material to work at high temperatures. These wires are furthermore protected against the entire expansive disintegration like gap utilization, stress breaking, pitting block, and impact disintegration. These wires are protected in the oxidizing, decreasing and unprejudiced circumstances. These wires have the low electrical and warm conductivity that helps the wires with contradicting the electric.

Nickel 200 Wires need to go through many tests after the creation from the business, for example, erupting test, straightening test, large scale test, miniature test, hydrostatic test, ultrasonic test, pitting test, radiography test, hardness test, synthetic test, mechanical test, PMI test, etc too.

For more information : Visit our website : https://www.merakimetals.ae/ Contact us : +971-523973687, +971-48801107, +971-48240333 Email : [email protected]

#Nickel 200 Wires Manufacturers in UAE#Nickel 200 Wires Suppliers in UAE#Nickel 200 Wires Stcokists in UAE#Nickel 200 Wires Exporters in UAE

3 notes

·

View notes

Text

Best Synthetic Engine Oil: Keep Your Car Running Smoothly

Are you seeking methods to maintain your automobile operating smoothly and the best synthetic engine oil? Look nowhere else! In addition to improving performance and fuel efficiency, synthetic engine oil is developed to offer improved engine protection. It is designed to reduce oil consumption and provide better wear protection. You can maintain your engine running smoothly and extend its life using synthetic engine oil.

0 notes

Text

The Best Choice: Synthetic 15W40 Diesel Engine Oil

Synthetic 15W40 Diesel Engine Oil protects the engine and works very well. It is designed to work in very hot and very cold temperatures, reduce wear, and increase fuel efficiency. This oil helps the engine last longer, especially for heavy-duty diesel vehicles. Using Synthetic 15W40 Diesel Engine Oil means cleaner operation, better lubrication, and improved engine performance overall. Source url:-

#diesel fuel cleaner additive#synthetic 15w40 diesel engine oil#lube oil additives#high-performance lubricants

0 notes

Text

Selecting fully synthetic engine oil over organic or semi-synthetic options is a wise choice for engine longevity, improved performance, and enhanced protection. While organic and semi-synthetic oils offer some benefits, fully synthetic oil stands out due to its superior qualities, such as reduced friction, increased efficiency, and better resistance to extreme conditions. It's a top choice for those who want to ensure their engine operates at its best. To know more about high temperature grease, click here: https://bit.ly/fully-synthetic-engine-oil-vs-semi-synthetic-engine-oil

#engine oil#bike engine oil#best engine oil for bike#Fully Synthetic engine oil#lubricants#automotive#Greases

0 notes

Text

Quick Oil Change Lehi: Keep Your Engine Running Smoothly with Maven Mechanics Lehi

Is your car telling you it's time for an oil change again? At Maven Mechanics Lehi, we know that keeping your engine running smoothly is essential for your vehicle's longevity and performance. But what makes a quick oil change so crucial, and why should you trust us with this task? Let's break it down.

Why Regular Oil Changes Matter

Oil is to your car what water is to your body. It’s the lifeblood of your engine, reducing friction, preventing wear, and cooling engine components. Without regular oil changes, your car's engine could overheat or suffer from increased wear and tear. According to the Car Care Council, timely oil changes can increase your engine's lifespan and efficiency.

Skipping oil changes? That's like skipping brushing your teeth — you might get away with it for a while, but eventually, the problems will catch up with you. It might lead to decreased fuel efficiency, loss of power, and even costly repairs. Don't ignore it!

Choose Maven Mechanics for a Quick Oil Change in Lehi

At Maven Mechanics Lehi, we pride ourselves on speed and efficiency without sacrificing quality. Our expert team is dedicated to providing quick, reliable, and thorough oil changes. We understand that your time is valuable, and we strive to get you back on the road as soon as possible.

Why choose us? Our commitment to using only the highest-quality oils and filters ensures that your car gets the best treatment. Plus, our skilled technicians have a keen eye for spotting potential issues early on, giving you peace of mind.

The Process at Maven Mechanics

Wondering what happens when you bring your car to us? Here's a glimpse into our seamless process:

Initial Inspection - Our service begins with a complimentary inspection. We assess the overall health of your engine and check for leaks or other concerns.

Oil Change - Using top-grade oils and filters, we efficiently replace your engine oil, ensuring optimal performance.

System Check - We examine other fluid levels, such as windshield washer fluid and coolant, to ensure everything is in tip-top shape.

Final Touches - Before you leave, we give your vehicle a courtesy check, including tire pressure, lights, and wiper blades.

Every step is meticulously planned, ensuring that your visit is quick yet comprehensive.

Benefits of Choosing Maven Mechanics

Does choosing the right service provider really make a difference? Absolutely! Here's why Maven Mechanics stands out:

Expertise and Experience - Our certified technicians are seasoned professionals with years of experience in engine maintenance. They're not just mechanics; they're passionate about cars and committed to top-notch service.

Convenience and Speed - Our quick oil change service is designed with your busy schedule in mind. Relax in our comfortable waiting area, complete with complimentary Wi-Fi and refreshments, while we work on your vehicle.

Customer Satisfaction - We believe in building long-term relationships with our clients, which is why we focus on personalized service and customer satisfaction. Just ask any of our loyal customers!

Environmentally Friendly - At Maven Mechanics, we responsibly dispose of used oil and strive to minimize our environmental impact.

Understanding Engine Maintenance with Maven Mechanics Lehi

Engine maintenance goes beyond just oil changes. Regular checks and upkeep can help prevent major issues down the line. At Maven Mechanics, we offer a range of engine maintenance services tailored to your vehicle's needs. From tune-ups to timing belt replacements, our comprehensive approach ensures your engine runs as smoothly as a well-rehearsed symphony.

Common Myths About Oil Changes

Have you heard that synthetic oil causes leaks, or that you need to change your oil every 3,000 miles? Let's debunk these myths.

Synthetic Oil Myths - Many people believe synthetic oil can damage their engines by causing leaks. In reality, synthetic oil is designed to resist breakdown and offers superior lubrication, especially in extreme temperatures.

Mileage Misconceptions - Modern engines and oils have come a long way. While the 3,000-mile rule was gospel for older cars, many new vehicles can go 5,000 to 7,500 miles between oil changes. Always check your owner's manual for specific recommendations.

Get Started with Maven Mechanics Today

Ready to experience a hassle-free oil change? Contact us at 801-210-9233 or visit Maven Mechanics Lehi for your next service. Our team is eager to assist you and ensure your engine runs like a dream.

Join Our Community

Become part of our thriving community of vehicle enthusiasts. Follow us on social media for tips, tricks, and exclusive deals. Trust Maven Mechanics Lehi to keep your engine humming and your spirits high.

Remember, a well-maintained engine is not just a necessity; it's a choice. Choose wisely. Choose Maven Mechanics Lehi.

0 notes

Text

In the revving world of dirt bike racing, the choice of synthetic motor racing oil can make the difference between victory and defeat. As ester moto racing lube suppliers and manufacturers continue to push the boundaries of innovation, riders have access to lubricants that can withstand the extreme conditions of off-road racing. By understanding the challenges faced by dirt bikes and making informed decisions when selecting engine oil, enthusiasts can unlock the full potential of their machines and experience the thrill of high-performance racing. Embrace the power of synthetic motor racing oil and conquer the dirt with confidence.

#synthetic ester racing engine oil manufacturer#synthetic ester racing engine oil dealer#synthetic ester racing engine oil distributor#synthetic ester racing engine oil supplier#best motorcycle racing oil#best synthetic racing motor oil#best synthetic racing oil#high performance racing oil#racing engine oil manufacturer#racing engine oil dealer#fully synthetic racing motorcycles oil#pao based synthetic racing oil

0 notes

Text

Comprehensive Car Service in Dubai and Abu Dhabi: A Guide to Oil Changes, Engine Repair, and More

Maintaining a car is essential for a smooth and safe driving experience. In bustling cities like Dubai and Abu Dhabi, where daily commutes and long drives are common, keeping your vehicle in top-notch condition is crucial. Regular car servicing not only extends your car’s life but also ensures better performance, fuel efficiency, and safety. Whether you need a routine oil change, an engine repair, or a comprehensive car check-up, understanding the importance of each service will help you keep your car running smoothly.

In this guide, we’ll explore the essential car services available in Dubai and Abu Dhabi and why Service My Car stands out as one of the best service providers for quality car care.

1. Oil Change Service

One of the most frequent and essential maintenance tasks for any car is an oil change. The oil in your car’s engine lubricates moving parts, reducing friction and preventing overheating. Over time, oil degrades and loses its effectiveness, which can lead to engine wear and potential damage. Regular oil changes help maintain engine efficiency and prolong its lifespan.

In Dubai and Abu Dhabi, most service centers recommend an oil change every 5,000 to 10,000 kilometers, depending on your car’s make and model. Service centers often offer synthetic and conventional oil options and will recommend the best type for your vehicle based on the manufacturer’s specifications. When done by experienced technicians, an oil change is quick and can improve your car’s fuel efficiency and overall performance.

2. Engine Repair Services

The engine is the heart of any vehicle, and any issue with it can severely impact performance. Whether it’s strange noises, a loss of power, or engine warning lights, prompt engine repair is essential. Common engine repair services include fixing leaks, replacing worn-out parts, tuning the engine, and checking for any signs of wear and tear.

In Dubai and Abu Dhabi, many professional service centers offer advanced diagnostic tools to identify and address engine issues. Skilled mechanics will conduct thorough inspections to ensure that your engine runs smoothly. From minor repairs to full engine overhauls, having a reliable service provider is key to keeping your vehicle in top shape.

3. Transmission Service and Repair

The transmission is another crucial component that requires regular maintenance. Transmission services include fluid checks, cleaning, and, if necessary, a full rebuild or replacement. In Dubai’s and Abu Dhabi’s high temperatures, transmission fluid can degrade faster, so regular checks are recommended.

Service My Car provides expert Transmission Services with skilled technicians who can diagnose and resolve issues like slipping gears, delayed shifts, and transmission leaks. Addressing these issues early can prevent costly repairs down the road.

4. Brake Inspection and Repair

Ensuring that your brakes are in perfect working condition is essential for safety. Brake inspection involves checking the brake pads, rotors, and fluid levels to ensure optimal performance. A squeaking noise when braking or a spongy pedal feel may indicate issues with your brake system.

In Dubai and Abu Dhabi, many service centers, including Service My Car, offer comprehensive brake services. Their expert mechanics check for worn-out parts, perform replacements, and test the braking system to ensure everything works smoothly.

5. Battery Testing and Replacement

Extreme heat can affect car batteries, making them more prone to issues in regions like the UAE. A weak battery can cause starting issues and may leave you stranded. Routine battery testing ensures that your car battery is functioning properly, and replacement is recommended if there are signs of wear or a reduced charge.

Service My Car provides battery testing and replacement, helping you avoid potential inconveniences. Their technicians can test your battery and, if needed, install a new one quickly and efficiently.

6. AC Service and Repair

Given the UAE’s hot climate, a well-functioning air conditioning system is essential for a comfortable driving experience. Car AC services include refrigerant refilling, leak detection, compressor checks, and filter replacement.

Service My Car offers specialized AC servicing to keep your vehicle cool, ensuring that the AC system operates efficiently. Their skilled technicians are equipped with the latest tools to diagnose and fix AC-related issues, ensuring you stay comfortable on the road.

7. Tire and Wheel Alignment Services

Regular tire checks and alignment are vital for safety, stability, and fuel efficiency. Service centers offer tire rotation, balancing, and replacement services to ensure that your tires are in good shape and properly aligned.

At Service My Car, the tire and alignment services include a full inspection to check for wear and tear, alignment correction, and tire balancing to help you maintain control over your vehicle, improve gas mileage, and reduce tire wear.

8. Suspension Repair and Maintenance

The suspension system affects ride quality and stability. If you notice excessive bouncing, uneven tire wear, or difficulty steering, it may be time for a suspension check. Dubai and Abu Dhabi's roads can be challenging, making it essential to keep your suspension in top condition.

Service My Car offers suspension repair and maintenance to ensure that your car’s handling remains smooth and safe. Technicians inspect components like shock absorbers, struts, and springs to ensure everything works as it should.

9. Full Car Diagnostics and Check-ups

Regular car diagnostics are essential to identify potential issues before they become major problems. Advanced diagnostics tools can check for faults in various systems, providing a detailed report of your car’s health.

At Service My Car, comprehensive car diagnostics and check-ups are performed by experienced mechanics who use state-of-the-art equipment to spot any hidden issues. These check-ups are crucial for ensuring your car is reliable and performing at its best.

Why Choose Service My Car in Dubai and Abu Dhabi?

Service My Car has earned a stellar reputation for providing top-notch car servicing in the UAE. With a dedicated team of experts, advanced diagnostic equipment, and a commitment to quality, they stand out as a reliable partner for all your Car service needs. Their extensive service menu ensures that every aspect of your car’s maintenance, from oil changes to engine repairs, is covered with expertise and care. Their commitment to customer satisfaction and transparent pricing makes them a preferred choice for car owners in Dubai and Abu Dhabi.

Conclusion

Regular car servicing is essential for maintaining the longevity and performance of your vehicle, especially in Dubai and Abu Dhabi's challenging climate. From oil changes to engine repairs, every service plays a role in keeping your car safe and reliable. Choosing a professional, experienced service provider like Service My Car ensures you receive high-quality care and can drive with peace of mind.

#Car service#car service dubai#car service abu dhabi#engine repair#car suspension services#dubai#uae#abu dhabi

1 note

·

View note

Video

youtube

Best lubricants Manufacturer in UAE| Prado, Akzoil, RIDA| Oil Company UAE

UAE, proudly API certified and ranked among the top oil companies on Google! Our premium quality products are trusted worldwide under our rapidly growing brands—Rrida, Akzoil, and Prado—offering competitive prices you can count on. Our extensive product range includes: Synthetic engine oils Gasoline and diesel engine oils Automotive gear oils Coolants and brake fluids Industrial and marine lubricants ATF and greasesFor inquiries or more information, visit www.ridalubs.com or contact us at 056 103 1399 Delivering excellence, every drop! #RidaLubricants #UAE #APIcertified #EngineOils #IndustrialLubricants #MarineLubricants #TopQuality #CompetitivePrices #Rrida #Akzoil #Prado

0 notes