#Bendable Laminate

Explore tagged Tumblr posts

Text

1 mm Laminate vs. Veneer: Which One Should You Choose for Your Home? – Amulya Mica

Amulya Mica’s collection of 1 mm laminates, including innovative textures like fabric laminate texture and PVC sunmica sheet, offers the perfect blend of style and functionality for any modern home.

#1 mm laminate#fabric laminate texture#pvc sunmica sheet#Bendable Laminate#laminate designs#premium laminates#pvc laminate#advance pvc laminate#best laminates in india#buy laminates online#latest laminates design#latest mica design#0.8 mm laminate

0 notes

Text

#decorative laminate sheet#pvc laminate sheet#flexible pvc laminate#90 degree bendable pvc laminates#color core laminate

0 notes

Note

sol theres a massive fucking spider on my living room floor rn what do i do i trapped it under a cup i dont want to kill it but i live in an apartment how am i supposed to get it outside

If you have something like laminated paper (something thin but not too bendable n stuff) slide it between the floor and the cup and try to lift it up. Then take them outside and let the cup open wherever u think is appropriate.

6 notes

·

View notes

Text

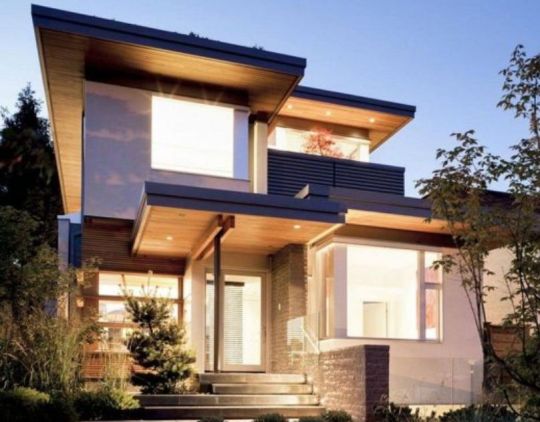

Best HPL Sheets Manufacturer in India

What is HPL Sheets?

HPL Sheets – High Pressure Laminates : For a very long time, traditional wood – with its pristine looks has been used in various ways to suffice for our dwelling needs. Our buildings always used the beauty and usefulness of wood. However, in-spite of its advantages, wood had some serious shortcomings. First, it was not in abundant supply. Second, it had a life limited to a couple of years and its maintenance was not easy. Also, it is here that ReynoArch brought forward AHPL, which is an Aluminum based High Pressure Laminate (HPL Sheets). It is more durable and elegant in looks as compared to wood. It is also highly weather resistant. AHPL has overcome the shortcomings of wood as it is manufactured using aluminium coil with double layered Lumiflon coating that is resistant to dust. To top it all ReynoArch HPL sheets comes in a variety of colors, textures and sizes. ReynoArch also offers customized colors and sizes. All this at a very competitive price coupled with an unmatched quality. AHPL has redefined the concept of high-end facade and exterior. ReynoArch offers professional service as it has a robust marketing network in India and abroad. Whether it is Villas, housing societies, corporate buildings or resorts, AHPL is a perfect foil in place of wood.

FEATURES

Weather Resistant

Anti fading

90 Degree bendable

Chemically resistant

Scratch-resistant

Versatile and easy to manage

Management Simplicity

Floor Wear Tolerance

Soft heat resistance

Looks powerful, rigid, and beautiful

Color Transition Tolerance of Artificial Light

Cigarette Burn Tolerance

Why should you choose REYNOARCH HPL SHEETS?

ReynoArch Best HPL Sheets are noted for their colorful designs and real wooden feel, so it comes as no surprise that they make the surroundings lively and beautiful to look at. It is a vibrant and trendy graphic that will immediately raise the spirits. Our HPL sheets can reside in your home for a longer period of time without losing their color and beauty effectiveness. It is clean of minor or larger bruises or marks created by the children or injuries due to its lumiflon coating. You must be aware of the health effects of HPL sheets because they are used nearly everywhere. Finally HPL sheets are fully risk-free because they do not contain any toxic substances, are hygienic, and safe for your child and family.

HPL Sheets Related FAQ

What is HPL Sheet? Where is HPL Sheets used?

HPL cladding, or high-pressure laminate cladding for short, is primarily used for exterior and interior surfacing in commercial and residential properties. Multiple layers of kraft paper saturated with thermosetting mastics with incomparable bonding strength are heated to create this cladding.

Is HPL a water-resistant material?

Yes, ReynoArch HPL is water-resistant making it a perfect application for home exteriors.

What is HPL wall cladding, and how does it work?

HPL sheets are used for wall cladding in both exterior and interior architectural architecture because of their rigidity and resilience. It is the finest modern-day building material for cladding because it can withstand extreme weather, and its extended life span is exceptional for use. High-Pressure Laminate is a lightweight metal that is easy to install, so custodians widely use it.

Source URL:- https://reynoarch8.wordpress.com/2023/02/28/hpl-sheets-manufacturer-in-india/

#HPL Sheets#HPL Sheet#Best HPL Sheets Manufacturer in India#HPL Sheets Manufacturer in India#HPL Sheets Manufacturer Near Me#architecture#interiordecor#interiors#HPL sheet price#High Pressure Laminates#High Pressure Laminates Sheet

2 notes

·

View notes

Text

Exploring Rigid-Flex PCBs: A Comprehensive Guide

As electronic devices become more advanced and compact, the need for versatile and space-efficient circuit solutions grows. Rigid-flex printed circuit boards (PCBs) have emerged as an innovative answer to this demand. Combining the best of both rigid and flexible PCBs, rigid-flex PCBs provide increased reliability, flexibility in design, and enhanced performance, making them ideal for various high-tech industries. In this blog, we’ll dive into what rigid-flex PCBs are, their advantages, applications, and why they’re becoming increasingly popular in modern electronics.

What is a Rigid-Flex PCB?

A rigid-flex PCB is a hybrid circuit board that combines elements of both rigid PCBs (the traditional solid boards) and flexible PCBs (bendable, adaptable circuits). Typically, these boards consist of multiple layers, including rigid layers that provide structural support and flexible layers that can be bent or twisted without breaking.

In a rigid-flex PCB, the rigid sections provide the stability and mechanical strength needed for mounting components, while the flexible sections allow the board to fit into spaces where conventional rigid boards wouldn't. The combination enables more complex designs, improved connectivity, and space-saving opportunities.

How Rigid-Flex PCBs Are Manufactured

Manufacturing rigid-flex PCBs is a more complex process compared to traditional PCBs. It requires a combination of both rigid and flexible layers, which are laminated together into a unified structure. This process must be done with precision to ensure that the flexible portions can bend as required without delamination or cracking.

Materials typically used include polyimide for the flexible sections due to its excellent thermal stability and reliability, while FR4 or similar materials are used for the rigid sections. High-quality adhesives and specialized plating are also applied to ensure electrical integrity and durability over time.

Advantages of Rigid-Flex PCBs

Space-Saving Design: One of the primary advantages of rigid-flex PCBs is their ability to reduce space within a device. By combining rigid and flexible components, these boards can be folded or shaped to fit into compact areas, allowing for sleeker, more compact product designs.

Reduced Component Count: Since rigid-flex PCBs can replace multiple individual PCBs with one hybrid solution, they often lead to a reduction in connectors, cables, and other interconnects, simplifying the design and improving overall reliability.

Durability and Reliability: Rigid-flex PCBs are known for their durability, especially in environments that experience vibrations, shocks, or movement. Their design eliminates weak points, such as connectors that can break under stress, making them ideal for dynamic applications.

Improved Signal Integrity: By eliminating the need for multiple connectors and cables, rigid-flex PCBs reduce potential signal interference. The direct, continuous pathways in these boards ensure consistent electrical performance, even in complex designs.

Weight Reduction: In applications where weight is a concern, such as aerospace and automotive industries, rigid-flex PCBs offer a lightweight solution compared to using multiple separate PCBs connected by cables.

Applications of Rigid-Flex PCBs

Rigid-flex PCBs are used in a variety of industries, especially where space, weight, and durability are critical considerations. Some key applications include:

Aerospace and Defense: Rigid-flex PCBs are widely used in aerospace technology due to their lightweight nature and ability to withstand high-vibration environments. They’re commonly found in navigation systems, control units, and satellites.

Medical Devices: The compact and durable design of rigid-flex PCBs makes them ideal for medical devices such as pacemakers, hearing aids, and imaging systems, where reliability and space are crucial.

Wearable Technology: Smartwatches, fitness trackers, and other wearable electronics benefit from rigid-flex PCBs due to their flexibility, allowing for compact, comfortable, and highly functional designs.

Automotive Electronics: In the automotive industry, rigid-flex PCBs are used in safety systems, engine management, and infotainment systems due to their durability in harsh environments.

Consumer Electronics: Smartphones, laptops, and cameras increasingly rely on rigid-flex PCBs to allow for thinner, more lightweight designs without compromising on performance.

Conclusion

As technology continues to advance, the demand for space-efficient, reliable, and durable circuit boards will only grow. Rigid-flex PCBs offer a unique solution that combines the best aspects of both rigid and flexible boards, making them indispensable for industries that require high-performance electronics in compact and demanding environments. For more details visit our website www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

0 notes

Text

Breathe Easy with Flexibility: Exploring the Power of Flexible Ducts (Ducting Supplies Epping)

At Advanced Duct Systems, your trusted supplier of ducting supplies in Epping, we understand the importance of efficient airflow in your home or business. While rigid ducting remains a popular choice, flexible ducts, also known as flex ducts, offer a unique set of advantages, particularly when dealing with tight spaces or intricate layouts. Let's delve into the world of flexible ducting and explore how it can benefit your ventilation project.

Beyond the Straight and Narrow: Unveiling the Advantages of Flexible Ducts

While rigid ducting offers a robust and reliable solution, its inflexibility can pose challenges in certain scenarios. Here's where flexible ducting shines:

Conquering Tight Spaces: Flexible ducts, as the name suggests, can bend and maneuver around obstacles, making them ideal for navigating cramped crawl spaces, attics, or areas with existing plumbing or electrical lines.

Simplified Installation: The bendable nature of flex ducts allows for easier installation, especially in retrofit projects where modifying existing structures might not be feasible.

Reduced Labor Costs: The ease of installation often translates to faster completion times, potentially leading to lower labor costs for your ventilation project.

Noise Reduction: Certain types of flexible ducts can dampen sound transmission, contributing to a quieter ventilation system.

Ducting Supplies Epping: Unpacking the World of Flexible Ducts

Not all flexible ducts are created equal. At Advanced Duct Systems, we offer a variety of flex duct options to suit your specific needs:

Insulated vs. Non-Insulated: Insulated flex ducts minimize heat gain or loss during air transmission, improving energy efficiency. Non-insulated ducts are suitable for short runs or applications where temperature control isn't a major concern.

Material Options: We offer flexible ducts constructed from different materials, each with its own advantages. Common choices include aluminum foil, laminated foil/metalized polyester, and PVC-coated polyester.

Diameter and Length: Flexible ducts come in various diameters and lengths to accommodate diverse ventilation requirements. Our team can help you determine the right size for your project.

Advanced Duct Systems Epping: Your Partner in Flexible Solutions

Looking for the best ducting supplies in Epping, including flexible ducts? Here's why Advanced Duct Systems is your ideal partner:

Extensive Product Range: We offer a comprehensive selection of flexible ducts, along with all the necessary accessories for a successful installation.

Expert Guidance: Our knowledgeable staff is here to answer your questions, recommend the most suitable flex duct option for your project, and guide you through the selection process.

Competitive Prices: We provide high-quality ducting supplies at competitive prices, ensuring you get the best value for your investment.

Commitment to Customer Satisfaction: We prioritize your satisfaction and are here to support you throughout your ventilation project.

Imagine Efficient Ventilation Made Easy

Imagine a seamless ventilation system installation, navigating tight spaces with ease thanks to the flexibility of flex ducts. Picture reduced labor costs and a quieter ventilation system contributing to a more comfortable environment. That's the power of flexible ducts!

Beyond Flexible Ducts: A Comprehensive Ducting Solution

While flexible ducts offer unique advantages, Advanced Duct Systems Epping is your one-stop shop for all your ducting needs:

Rigid Ducts: We offer a variety of rigid duct options, perfect for situations requiring a more robust solution.

Ducting Accessories: From connectors and clamps to dampers and grilles, we have all the necessary accessories for a complete ventilation system.

Ventilation System Design: Our team can assist with designing an efficient and effective ventilation system for your home or business.

Contact Advanced Duct Systems Epping Today!

Ready to explore the world of flexible ducts and find the perfect solution for your ventilation project? Contact Advanced Duct Systems Epping today! Browse our extensive selection of ducting supplies, discuss your project requirements with our knowledgeable staff, and get expert advice to achieve optimal airflow in your home or business.

Contact Web - https://ductsystems.com.au/duct-felxible-stainless-steel-suppliers-epping/ Mail - [email protected] Ph - 1300 382848 Address - 3/11 Cooper St Campbellfield VIC 3061 AU

0 notes

Text

Flexy ply is a brand name for a type of flexible plywood that is designed to be more applicable and bendable than traditional plywood. It is made by laminating thin layers of wood veneer together with a flexible adhesive, resulting in a panel that can bend and flex without breaking or splintering. Flexy ply is commonly used in the construction of curved surfaces and shapes, such as those found in boat building, cabinet making, and furniture manufacturing. VPK is renowned for its broad selection of premium building goods, which includes flexible plywood, as well as for offering the best customer service. VPK can be a good option to take into consideration if you’re looking for a supplier of Flexy Ply.

0 notes

Photo

Researchers make world's thinnest Christmas tree

A Christmas tree with a thickness of one atom has been made at DTU. It shows how terahertz measurements can be used to ensure the quality of graphene.

The Christmas tree in the pictures above is 14 centimeters long. Since it is made of graphene, it consists of carbon atoms in only one layer and is only a third of a nanometer thick. It is cut out of a 10-meter long roll of graphene, transferred in one piece using a rebuilt laminating machine and then scanned with terahertz radiation.

The experiment shows that continuous quality control can be done during the production of graphene, which is expected to play a significant role in future high-speed electronics, i.e. medical instruments and sensors.

Graphene is a so-called two-dimensional material, i.e. it consists of atoms in one cohesive layer that is only one atom thin. It is more robust, stiffer and better at conducting electricity and heat than any other material we know of. Therefore, graphene is an obvious candidate for electronic circuits that take up less space, weigh less, are bendable and are more efficient than the electronics we know today.

Read more.

27 notes

·

View notes

Text

How to Choose the Best Laminates for Your Home Renovation ?

Discover the best laminates for your home renovation with Amulya Mica. Explore a wide range of laminate designs, including the latest mica designs, and find the best laminates in India. Buy laminates online with ease and style your home to perfection.

#door laminate design#plywood boards#laminate designs#amulya mica#latest mica design#Best Laminates in India#Buy Laminates Online#decorative laminate texture#0.8 mm laminate catalogue#0.8 mm laminate#1 mm laminate#advance pvc laminate#premium laminates#pvc laminate sheet#pvc laminate#pvc laminates catalogue#pvc sunmica sheet#pvc board#synchronized laminates#acrylic laminates catalogue#latest laminates design#high gloss laminates catalogue#marble texture laminate#hpl laminate sheet#fabric laminate texture#leather finish laminate#Bendable Laminate#Imperial Premium Laminate

0 notes

Text

Moon Boat 4 Sets Bloody Garland Banner - Halloween Zombie Vampire Party Decorations Supplies

Moon Boat 4 Sets Bloody Garland Banner – Halloween Zombie Vampire Party Decorations Supplies

Price: (as of – Details) To calculate the overall star rating and percentage breakdown by star, we don’t use a simple average. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. It also analyzed reviews to verify trustworthiness. Made of a Thin & Bendable laminated sheet of plastic that is made to look shiny like metal. They are not…

View On WordPress

0 notes

Text

Moon Boat 4 Sets Bloody Garland Banner - Halloween Zombie Vampire Party Decorations Supplies

Moon Boat 4 Sets Bloody Garland Banner – Halloween Zombie Vampire Party Decorations Supplies

Price: (as of – Details) To calculate the overall star rating and percentage breakdown by star, we don’t use a simple average. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. It also analyzed reviews to verify trustworthiness. Made of a Thin & Bendable laminated sheet of plastic that is made to look shiny like metal. They are not…

View On WordPress

0 notes

Link

0 notes

Link

0 notes

Text

Introduction Of OLED And Structural Issues

https://www.weiyedisplay.com/What exactly is OLED? How is it different from the LCD screens that are currently in vogue?

The original word for OLED is OrganicLightEmittingDiode, which means organic light emitting diode in Chinese. The principle is to sandwich the organic light-emitting layer between two electrodes, when the positive and negative electrons meet in this organic material will light up, its component structure is simpler than the current popular TFTLCD. OLED also has many advantages, such as its own light-emitting characteristics, the current LCD are required backlight module (in the liquid crystal behind the addition of a lamp), but OLED will be powered on their own light, you can save the weight of the lamp volume The OLED's response time (less than 10ms) and colour are both better than TFTLCD, and the bendable nature of the product makes it extremely versatile. Font clarity is quite high. What's more, the transparent flexible OLED display still shows clearly under sunlight, unlike normal colour screens, such as the current colour screen mobile phones, which are dulled by sunlight.

Transparent flexible OLED display to reach the level of efficiency in the application of fluorescent lamps, its power efficiency must reach at least 70lm / W, although about 100lm / W Oled lighting devices have been reported, but this is in very extreme cases manufactured, usually manufactured OLED lighting device efficiency is only 30 ~ 50lm / W, obviously this is far from Obviously this is far from meeting the requirements.

From the point of view of materials, to achieve such high efficiency, it is necessary to use luminous efficiency of up to 100% of the phosphorescent materials, green and red phosphorescent materials have no problem, the urgent solution is to play an important role in the blue phosphorescent materials. Now there is a great lack of high-efficiency, high-stability blue phosphor light-emitting materials, but also the main technical difficulties that currently hinder the efficiency of transparent flexible OLED display devices, so the development of practical high-efficiency, high-stability light-emitting materials for mass production technology has become the main direction of attack in this field.

From the device structure point of view, effective device structure design is also the key to improve the efficiency of the device, the current good device structure including multi-luminous layer structure, single-luminous layer structure, stacked layer structure and top emission structure. Multi-emitting layer structure is currently the most prepared white OLED devices, the process is more mature, device performance is also the best, but the complex process may affect it in the future transparent flexible OLED display yield and production cost issues, and this structure devices sometimes also have the disadvantage of spectral and chromaticity coordinates change with the driving voltage. However, due to the good device performance of the multi-layer structure, and the spectral and chromaticity coordinate variation with the drive voltage can be completely solved by the design of the device structure, so if the yield can be controlled and improved, the structure is still a mass production technology, Philips, UDC, Novaled companies are currently using this structure.

Although the single-light structure can avoid the variation of colour purity with driving voltage to a certain extent and may simplify the process during production, the unsatisfactory efficiency and stability problems also prevent this structure from being used in practice.

The laminated structure has the characteristics of a single light-emitting layer and multiple light-emitting layer structure, it is through the charge generation layer will be a number of light-emitting units in series of a device structure, laminated devices have very good spectral stability, and high luminous efficiency, high luminous brightness and good stability and other characteristics make the laminated structure devices in the practical application is very competitive, if the complex process in the laminated structure can be If further improvements can be made in the complex process of laminated structures, laminated structure devices are expected to become the main technology for the production of white OLEDs for lighting. Top-emitting structures may also become an important technology development direction for white OLEDs for lighting due to their advantages in terms of effective light-emitting area and efficiency, and the combination of other structures and top-emitting structures could lead to higher performance white OLEDs.

The combination of other structures and top emitting structures could lead to the development of higher performance white OLEDs.

As a manufacturer of transparent flexible OLED displays, Weiye has professional equipment and technical personnel, and we believe our products will satisfy you.

0 notes

Text

India’s Best-in-Class Premium Range of PVC Laminates

Ogaan Laminates has introduced the world to fresh waterproof, termite-proof, and 100% lead-free PVC laminates that are bound to make their way in homes and offices of people with a stylish bent of mind. PVC laminate cost is quite affordable and it has a modern minimalist design plan for the house is an utmost delight and almost heaven for people who are obsessed with the perfect ambience. To incorporate the modern outlook in your interiors is perhaps one of the most satisfying experiences. The colour tone in PVC Mica is subdued which gives every space a clean and crisp yet absolutely attractive look. A sagacious way in which you can integrate the minimalist look for your home and offices is by using PVC laminate sheets which are budget-friendly.

Some important features of modern interiors are clean and very basic detailing with the focus on forms and functionality which are again, simplistic in nature. Choosing 90 Degree bendable laminates helps you get a smooth and seamless edge of your furniture, give your furniture a brand new finish with a single sheet look and feel. PVC laminate features a solid colour throughout the material that makes it ideal for use as counters, reception desks, house furniture, etc. With a greater creative breadth in colour and texture, it offers an assortment of inspiring and vibrant colours that matches all the way through avoiding ant dark edges.

Beginning from the ’80s when laminates first gained popularity, they have come a long way from looking cheap and unrealistic to being a popular choice for floorings and walls. They have evolved into being modern-day realistic caricatures of expensive hardwood overlays. Easy to maintain and affordable to all, PVC laminates are going to be an intrinsic part of indoor and outdoor decors for a long time keeping in mind everyone’s likings.

0 notes

Text

Application of willow glass

At this stage, many customers are looking for us to consult a glass polarimeter for testing willow glass which refers to glass with a thickness less than or equal to 0.1mm, and belongs to the category of ultra-thin glass, usually soda lime glass, high-alumina glass or low-alkali glass. It is a bendable, very flexible material with a layer of laminated plastic outside, so people can easily bend the glass. Since willow glass is still in the preliminary stage of development, without this layer of laminated plastic, it would not be so easy to bend. Good flexibility is the biggest feature of willow glass. It can be highly bent and very flexible. In addition to its flexibility, willow glass is the same as ordinary glass in many properties. In addition, it has the advantages of high hardness, high temperature resistance, good flatness and good air tightness.

The emergence of folding screen mobile phones reminds everyone of willow glass, and flexible screen refers to flexible OLED. The successful mass production of flexible screens is not only a major benefit to the manufacturing of a new generation of high-end smart phones, but also has a profound impact on the application of wearable devices due to its low power consumption and flexibility. In the future, flexible screens will follow the development of personal intelligence, and the continuous penetration of the terminal is widely used. A flexible screen mobile phone refers to a mobile phone with a bendable and flexible screen. Because it looks like a awning roll, it is also called a awning phone.

OLEDs are very thin and can be mounted on flexible materials such as plastic or metal foil. Using plastic instead of glass will make the display more durable and lighter. The flexible OLED panel is concave from top to bottom, with a bending radius of up to 700 mm.

OLED uses a plastic substrate instead of a common glass substrate. It uses thin-film packaging technology and pastes a protective film on the back of the panel to make the panel bendable and not easy to break. Flexible screens can be rolled, but cannot be folded. Future products should be foldable, and their appearance will change more. The display is cut from the panel. The bendable display screen, also known as the flexible screen, is regarded as a product of the initial stage of the display revolution. The ultimate goal is to transform mobile and wearable electronic devices.

Compared with traditional screens, flexible screens have obvious advantages. They are not only lighter and thinner in size, but also lower in power consumption than original devices. This helps to improve the endurance of the device. At the same time, based on its bendable and flexible characteristics, its The durability is also much higher than that of previous screens, reducing the probability of accidental damage to the equipment.

https://www.ptc-stress.com/application-of-willow-glass/

0 notes