#Belt conveyor system

Explore tagged Tumblr posts

Text

Belt Conveyor System: A Comprehensive Guide to Its Uses and Benefits

Belt conveyor systems are ubiquitous in modern manufacturing and transportation industries. These systems are designed to transport materials from one location to another, typically over long distances and across various terrains. Belt conveyor systems are used in a wide range of applications, including mining, agriculture, food processing, and packaging. The basic design of a belt conveyor…

View On WordPress

#agriculture and food processing#airport baggage handling#Belt conveyor system#belt materials#conveyor structure#manufacturing and packaging#mining and quarrying#pulley#roller#tensioning mechanisms

0 notes

Text

#Belt Conveyor System#conveyor belt system for sale#conveyor belt types#flat belt conveyor system#conveyor belt manufacturer#conveyor belt monitoring system#Belt Conveyor System manufacturer India

0 notes

Photo

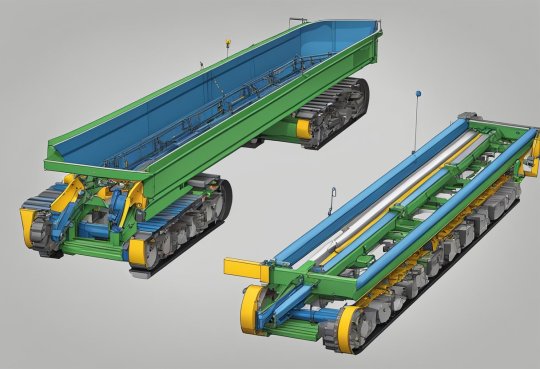

Belt Conveyor System

Belt conveyor system is an efficient and cost-effective way to move goods, materials, and products around a facility or between different locations. From small parts to large items, belt conveyors can be used to move them efficiently and safely. With their simple design and wide range of uses, they are an essential part of any industry or business.

The conveyor belt is the part of the system that actually moves the goods from one location to another. It is usually made from a flexible material such as rubber or plastic and is designed to move over pulleys or rollers. The pulleys are the metal wheels that the belt runs over and help to move the belt along. The drive is the motor or other power source that powers the pulley, which in turn moves the belt.

Belt conveyor system advantages: 1- The conveyor is used in many different industries and businesses. It is often used in manufacturing and assembly lines, warehouses, distribution centers, and other industrial facilities. It can also be used in food and beverage production, pharmaceutical processing, and mining operations. The conveyor can even be used to move materials and products in the agricultural industry. 2- The conveyor can be used to move goods in many different ways. It can be used for long-distance transportation, short-distance transportation, or even for sorting and separating materials. It can also be used to move items between different levels of a facility or between different buildings or locations. 3- The conveyor is relatively easy to install and maintain. It requires minimal maintenance, and its component is relatively easy to repair or replace. It is also low-cost and efficient, making them a popular choice for many businesses and industries.

#Belt Conveyor System#Conveyor Belt#Conveyor Belt System#Conveyor Belt Wire Mesh#Transport Belt#Wire Belt#Wire Conveyor Belt

0 notes

Text

Big Mouth Mini Compactors

The Big Mouth Mini Compactors by The Mark Costello Co. offer the ultimate waste management solution for businesses of all sizes. These innovative compactors are designed to save space, reduce waste volume, and improve efficiency. Perfect for handling a variety of waste materials, they are a cost-effective choice for managing waste in tight spaces. Explore the power of Big Mouth Mini Compactors to streamline your waste processes and enhance operational productivity with The Mark Costello Co. today!

#Big Mouth Mini Compactors#industrial recyclers#stainless steel conveyor belts#conveyor system#medical waste disposal#consolidated sterilizer systems#stationary compactor#waste management#balers for cardboard#waste handling equipment#waste cart

0 notes

Text

Innovative Features in Rolling Conveyor Systems: What to Look For

In the fast-evolving world of industrial automation, rolling conveyor systems play a crucial role in streamlining operations. Whether you're in manufacturing, warehousing, or e-commerce, choosing a conveyor system with innovative features can significantly impact efficiency, safety, and scalability. This blog highlights some of the latest advancements in rolling conveyor systems and what you should look for when investing in one.

1. Smart Automation and IoT Integration

Modern rolling conveyor systems are increasingly integrated with smart technology. Features like real-time tracking, automated sorting, and predictive maintenance powered by the Internet of Things (IoT) make these systems more intelligent and efficient.

What to look for:

Sensors for real-time monitoring.

Automated error detection and alerts.

Integration with warehouse management systems (WMS).

2. Modular and Scalable Designs

Businesses grow, and so do their material handling needs. Modular conveyor systems allow for easy expansion or reconfiguration without significant downtime or cost.

What to look for:

Easy-to-add modular components.

Flexibility in system design for future scalability.

Quick assembly and disassembly mechanisms.

3. Energy Efficiency

Energy-efficient systems reduce operational costs and align with sustainable business practices. Innovative rolling conveyor systems come with features like variable speed drives and energy-saving modes.

What to look for:

Energy-efficient motors.

Low-friction rollers to minimize power consumption.

Options for solar-powered or hybrid energy solutions.

4. Advanced Safety Features

Employee safety is paramount, and conveyor systems equipped with advanced safety features minimize the risk of accidents.

What to look for:

Emergency stop mechanisms.

Guardrails and anti-slip coatings.

Sensors to detect and halt operations if an obstruction occurs.

5. Customization for Industry-Specific Needs

Different industries have unique requirements, and modern rolling conveyor systems cater to this with customizable options.

What to look for:

Food-grade materials for the food and beverage industry.

Anti-static rollers for electronics handling.

Heavy-duty construction for industrial manufacturing.

6. High-Speed Capabilities

For industries with high throughput demands, conveyor systems with high-speed capabilities ensure fast and efficient movement of goods without compromising safety.

What to look for:

Rollers designed for minimal vibration at high speeds.

Smooth transitions between conveyor sections.

Precision controls to maintain consistent speed.

7. Enhanced Durability and Low Maintenance

Innovative materials and engineering make modern rolling conveyor systems more durable, reducing maintenance costs and downtime.

What to look for:

Corrosion-resistant and wear-resistant rollers.

Self-lubricating components.

Maintenance-free drive systems.

8. Integration with Robotics

As automation advances, conveyor systems that integrate seamlessly with robotic systems are becoming a game-changer in industries like e-commerce and manufacturing.

What to look for:

Compatibility with robotic arms and automated guided vehicles (AGVs).

Software for synchronized operations.

Vision systems for product identification and sorting.

Conclusion

The right rolling conveyor system can transform your operations by improving efficiency, reducing costs, and enhancing safety. When exploring your options, prioritize systems with innovative features like IoT integration, energy efficiency, and customization capabilities. Investing in cutting-edge technology ensures that your conveyor system remains an asset for years to come, adapting to the evolving demands of your business.

Looking for the perfect rolling conveyor system? Partner with a trusted UK manufacturer to explore options tailored to your industry needs.

0 notes

Text

The Importance of Dust Filtration in Industrial Settings

In today’s industrial landscape, effective dust filtration is more crucial than ever. Dust not only poses health risks to workers but can also damage equipment and reduce productivity. This is where advanced dust filtration systems come into play, offering a solution to maintain a safe and efficient working environment.

Understanding Dust Filtration

Dust filtration refers to the process of capturing airborne particles to improve air quality and maintain cleanliness in various settings, from manufacturing facilities to warehouses. Effective dust collection systems, like those offered by Scrapetec Trading, are designed to handle various types of dust generated during industrial processes.

Health and Safety Benefits

One of the primary reasons for implementing a robust dust filtration system is to protect the health of employees. Inhalation of dust can lead to respiratory problems, allergic reactions, and long-term health issues. By installing high-quality dust collection systems, businesses can significantly reduce these risks, fostering a healthier workplace and ensuring compliance with health regulations.

Enhancing Operational Efficiency

Dust accumulation can interfere with machinery, leading to costly downtime and maintenance. By utilizing efficient dust filtration solutions, companies can keep their equipment running smoothly. Clean environments not only prolong the lifespan of machinery but also improve overall productivity, as workers can focus on their tasks without the distractions and hazards associated with dust.

Types of Dust Filtration Systems

There are various dust filtration systems available, each suited for different industrial needs. From cartridge filters to baghouse systems, selecting the right type depends on the specific application and the nature of the dust produced. Scrapetec Trading provides tailored solutions that cater to diverse industries, ensuring optimal performance and compliance with safety standards.

Environmental Considerations

Dust filtration also plays a vital role in environmental sustainability. By effectively capturing and reducing emissions, businesses can minimize their ecological footprint. Investing in dust collection technology not only benefits the workplace but also contributes to a cleaner environment, aligning with corporate responsibility goals.

Conclusion

In conclusion, dust filtration is an essential aspect of modern industrial operations. With the right systems in place, businesses can safeguard their employees' health, enhance operational efficiency, and promote environmental sustainability. Companies like Scrapetec Trading offer innovative dust filtration solutions that address the unique challenges of various industries, helping organizations maintain a clean and productive working environment. Prioritizing dust filtration is not just a regulatory necessity; it's a commitment to health, safety, and efficiency.

#airscape conveyor belting#belt monitoring solutions#belt tracking#Dust Dirt Scraper#the dustbox#dust removal system#dust filtration

0 notes

Text

RCN Grading Machine: automatic kaju processing machine

Introduction

The cashew processing industry has witnessed remarkable technological advancements, aimed at enhancing efficiency, productivity, and product quality. Among these advancements, the RCN Grading Machine is a pivotal solution for effective cashew grading. This machine streamlines the sorting process, ensuring that cashew nuts are categorized according to size and quality, which is crucial for meeting market demands. In this comprehensive article, we will delve into the features and benefits of the RCN Grading Machine, explore its components, and discuss its significance in the context of modern cashew processing.

Understanding Cashew Grading

Cashew grading refers to the process of sorting cashew nuts based on various parameters, including size, shape, and quality. This grading process is essential for several reasons:

Quality Control: Proper grading ensures that only the best quality cashew nuts reach consumers, enhancing customer satisfaction and loyalty.

Market Value: Graded cashew nuts fetch higher prices in the market. Different grades can command different price points, so processors can optimize their profits by accurately grading their products.

Operational Efficiency: An efficient grading process allows for faster production cycles, reducing the time and labor required for sorting.

Packaging and Distribution: Grading facilitates better packaging, ensuring that nuts of similar sizes are packed together, which helps in maintaining quality during transportation.

The RCN Grading Machine is specifically designed to address these needs, making it an indispensable asset in the cashew processing industry.

Features of the RCN Grading Machine

1. Grading Conveyor System

At the heart of the RCN Grading Machine is its advanced grading conveyor system. This system plays a crucial role in the sorting process by ensuring smooth and efficient movement of cashew nuts during grading. The grading conveyor allows for the continuous flow of nuts, reducing bottlenecks and improving overall processing speed.

2. Belted Conveyor

The inclusion of a belted conveyor enhances the machine’s functionality. The belt transports cashews with minimal damage, maintaining their quality throughout the grading process. This is particularly important as cashew nuts can be delicate, and improper handling can lead to breakage or blemishes that reduce their market value.

3. Adjustable Conveyor

One of the standout features of the RCN Grading Machine is its adjustable conveyor. This feature allows operators to customize the machine settings based on the specific requirements of the cashew nuts being processed. Whether the nuts are large or small, the adjustable conveyor can be fine-tuned to optimize the grading process, ensuring accuracy and efficiency.

4. Versatility in Conveyor Systems

The RCN Grading Machine is part of a comprehensive suite of conveyor systems that can be integrated into any cashew processing setup. These conveyor systems are designed to work harmoniously with other machines in the processing line, such as automatic cashew peeling machines and automatic cashew cutting machines. This integration creates a seamless workflow, reducing downtime and maximizing productivity.

5. Durability and Low Maintenance

Constructed from high-quality materials, the RCN Grading Machine is built to withstand the rigors of continuous operation. Its robust design minimizes wear and tear, reducing maintenance needs and ensuring longevity. This durability makes it a cost-effective investment for cashew processors looking to enhance their operational capabilities.

6. User-Friendly Interface

The machine features a user-friendly interface that simplifies operation. Operators can easily adjust settings, monitor the grading process, and troubleshoot any issues that may arise. This ease of use reduces training time and enhances overall operational efficiency.

The Importance of Efficient Cashew Grading

As the demand for cashew nuts continues to rise globally, efficient cashew grading becomes increasingly important. The RCN Grading Machine addresses this need by providing processors with a reliable solution for sorting their products accurately and efficiently. Here are some of the key benefits of using this machine:

1. Increased Productivity

With its advanced grading conveyor system and seamless operation, the RCN Grading Machine significantly increases productivity. The continuous flow of cashews through the grading process allows processors to handle larger volumes in less time, meeting market demands more effectively.

2. Improved Quality Control

By accurately sorting cashews based on size and quality, the RCN Grading Machine enhances quality control measures. This leads to higher-quality products, which are essential for maintaining a competitive edge in the market. Consumers are increasingly discerning about the quality of the food products they purchase, and processors must respond accordingly.

3. Cost Efficiency

Investing in the RCN Grading Machine can lead to significant cost savings in the long run. By optimizing the grading process, processors can reduce labor costs, minimize product loss, and improve their overall operational efficiency. Additionally, better quality products can command higher prices, further enhancing profitability.

4. Scalability

As a processor’s business grows, the RCN Grading Machine can easily adapt to increased production demands. Its adjustable conveyor and integration with other automatic processing machines make it a versatile solution for businesses of all sizes.

The Role of RCN Grading Machine in Automatic Cashew Processing

The RCN Grading Machine plays a vital role in the broader context of automatic cashew processing. To fully appreciate its significance, it’s essential to explore how it fits into the overall production line.

1. Integration with Automatic Cashew Processing Machines

The RCN Grading Machine can be seamlessly integrated with various automatic cashew processing machines, such as:

Automatic Cashew Peeling Machine: This machine efficiently removes the outer shell of cashews, preparing them for the grading process. The RCN Grading Machine ensures that only the best-peeled nuts are sorted and packaged.

Automatic Cashew Cutting Machine: After grading, the RCN Grading Machine can direct cashews to the cutting machine for further processing. This integration creates a streamlined workflow that reduces manual handling and enhances efficiency.

Automatic Kaju Processing Machine: The RCN Grading Machine is part of a complete processing solution that includes automatic machines designed specifically for kaju processing, ensuring high quality at every stage.

2. Ensuring Consistency in Quality

The integration of the RCN Grading Machine with other automatic machines ensures that quality control measures are maintained throughout the entire processing line. Consistent grading leads to uniformity in size and quality, which is crucial for packaging and distribution.

3. Minimizing Manual Labor

By automating the grading process, the RCN Grading Machine significantly reduces the need for manual labor. This not only decreases labor costs but also minimizes the risk of human error, leading to more accurate grading results.

Choosing the Best Automatic Cashew Processing Machine Supplier in India

When considering the investment in the RCN Grading Machine, it’s essential to select a reputable supplier. As the best automatic cashew processing machine supplier in India, we are committed to providing high-quality machinery that meets the specific needs of cashew processors. Here’s what to look for in a supplier:

1. Industry Experience

Choose a supplier with extensive experience in the cashew processing industry. A knowledgeable supplier will understand the unique challenges faced by processors and can offer tailored solutions.

2. Range of Products

The best suppliers offer a comprehensive range of machines, including the RCN Grading Machine, automatic cashew peeling machines, automatic cashew cutting machines, and more. This range ensures that processors can find all the equipment they need from a single source.

3. Quality Assurance

Look for a supplier that prioritizes quality assurance. High-quality machines are essential for ensuring consistent processing results and minimizing downtime due to maintenance issues.

4. After-Sales Support

Reliable after-sales support is crucial for maintaining the performance of processing machines. Choose a supplier that offers training, maintenance services, and readily available replacement parts.

5. Competitive Pricing

While cost should not be the sole factor in your decision, it is essential to find a supplier that offers competitive pricing without compromising on quality. Evaluate the overall value offered by the supplier in terms of machine features, performance, and support.

Conclusion

In conclusion, the RCN Grading Machine is a game-changer in the cashew processing industry. With its advanced features, including the grading conveyor, belted conveyor, and adjustable conveyor, it provides an efficient solution for cashew grading. The machine’s integration with other automatic processing machines ensures a streamlined workflow, enhancing overall productivity and product quality.

As the top cashew processing equipment supplier in India, we are committed to delivering the best automatic cashew processing machines to our customers. Our dedication to quality, innovation, and customer satisfaction sets us apart in the industry. By investing in the RCN Grading Machine and other automatic processing machines, cashew processors can optimize their operations, reduce costs, and meet the growing demands of the market.

Choose us as your partner in cashew processing and experience the difference that advanced technology can make. Elevate your production capabilities and ensure the highest quality products for your customers with our state-of-the-art machinery. Partner with us today to take your cashew processing operations to the next level!

#grading conveyor#conveyor#cashew grading#belted conveyor#adjustable conveyor#conveyor systems#"Cashew Processing Equipments#Automatic Cashew Processing Machine#Cashew Processing Machine#automatic cashew peeling machine supplier in india#Cashew Processing Equipments#Automatic Kaju Processing Machine#Fully Automatic Cashew Processing Machine#kaju processing machine#cashew nut peeling machine#cashew processing#kaju cutting machine#cashew manufacturers in maharashtra#automatic cashew nut cutting machine#cashew machine manufacturer#cashew processing machinery#cashew nut cutting machine

0 notes

Text

Enhancing Workplace Safety with Material Handling Equipment

Material handling equipment refers to tools and machinery designed to efficiently move, store, and manage materials and products within various industrial settings. This equipment includes items such as forklifts, conveyor belts, pallet jacks, and cranes, which streamline the movement of goods, reduce manual labor, and enhance productivity. By automating and optimizing processes, material handling equipment helps minimize operational costs and improve safety. These systems are crucial in warehouses, manufacturing plants, and distribution centers, ensuring smooth and effective material flow from one stage to the next. Properly chosen and maintained equipment can significantly impact overall operational efficiency and performance. Discover a wide range of top-quality material handling equipment at https://www.headsupb2b.com/material-handling-equipment . Find the perfect solutions for your business needs today!

#Conveyor Belts#Forklifts#Pallet Jacks#Handling Systems#Manufacturing Equipment#Industrial Machinery#Warehouse Equipment

1 note

·

View note

Text

#Industrial Conveyor manufacturers in Bangalore india#Belt conveyor manufacturers in india#Conveyor belt suppliers and manufacturers in bangalore#Over head conveyor manufacturers#Conveyor System manufacturers in bangalore#Roller conveyor manufacturers in india#Conveyor oven manufacturers in india#Gravity roller Conveyor manufacturers in bangalore#Conveyor rollers manufacturers in bangalore

0 notes

Text

Conveline Rollers is a leading manufacturer specializing in airport rollers, crucial components used extensively in airport baggage handling systems worldwide. Renowned for their durability and precision engineering, Conveline's airport rollers ensure efficient and reliable movement of luggage throughout airport terminals. For More Info Visit our website : https://www.convelinerollers.com/rollers-uses-in-airport

#airport rollers manufacturers#airport conveyor Roller systems#airport conveyor belt manufacturers#airport roller conveyor manufacturers

0 notes

Text

0 notes

Text

#wire conveyor belt#conveyor system#mesh#airflow#drainage#sifting#separation#lightweight#mesh type#wire gauge#material#belt width#belt length#edge options#surface treatments#product characteristics#conveyor incline/decline#operating environment#maintenance requirements#manufacturer#supplier#India#customization#Wire Mesh#Rubber Conveyor Belt#Conveyor Belt#Vibrating Screen#Wedge Wire Screen#Wedge Wire Panel#Barbed Wire

0 notes

Text

Lifting Plough Assembly: Calculations for Conveyor System Loads and Forces

Lifting plough assemblies are a crucial component of conveyor systems that aid in the efficient transfer of bulk materials. These assemblies are used to divert materials from the conveyor belt to various discharge points, ensuring that the materials are delivered to their intended location. The design and calculation of lifting plough assemblies require a thorough understanding of the forces…

View On WordPress

#acceleration load#belt conveyor#conveyor motor#conveyor speed#conveyors#dead load#flat belt conveyor system#friction load#impact load#lifting plough assembly#live load

0 notes

Text

Waste Management Equipment Solutions

Discover top-quality waste management equipment solutions at The Mark Costello Co. We offer innovative products designed to make waste disposal more efficient and environmentally friendly. Our solutions help businesses streamline waste handling, reduce costs, and improve sustainability. With years of expertise and a commitment to innovation, we provide reliable equipment tailored to your needs. Explore our advanced waste management equipment solutions today and take the first step toward a cleaner, more efficient future.

#Waste Management Equipment Solutions#Medical Waste Disposal Service In Los Angeles#Industrial Waste Compactor In San Diego#industrial recyclers#consolidated sterilizer systems#balers for cardboard#stainless steel conveyor belts#medical waste disposal#conveyor system#waste cart#waste management#stationary compactor#waste handling equipment

0 notes

Text

.

#the idol system is such a fascinating and scary thing to me#like hearing shit over the years it's like how does anyone survive it?#(i'm staying away from all the anti-blackness of kpop & their fandoms rn so just the system)#((that was more for me bc my brain wants to go in that direction bc hooooooo. it's the main reason i cannot vibe w more than a few songs#over the last almost 15 years cause like knowing.... anyway))#like i just got groundfloored w a group rn via jbrekkie shoutout michelle like literally their debut is 24 hrs from now i've rabbitholed#since i heard their snippet on her vid and like the way ppl talk about it already like... as an outsider it's like alriiiight here we goo#they're (mgmt) pipelining another group of ppl let's be sure to support it! streamstreamvote!! oo it looks like their taking the toy/doll#route w these girls super aesthetic let's goo. & like......????? and ppl are already rabid about it. it's wild. and like this is the system#this is it. they make groups and then tease and the people who follow the conglomerate see it and are waiting to#be fed another x amount of folks doing formations and looking cute/hot open wide and consume#(like ik some (or a lot) of those accnts are bots/plants to pad the release and gain traction against algos but like also real folks too)#like not to discredit their vocal work (&dancing though some (alot) of these grps are not nearly as lit w 'dancing' as folks hype em up to#be Frfr. good movers/formations/camera motion & body rolls do not a dancer/good choreo make) but it's really secondary for a lot of#folks atp it's so strange & fascinating. and like i dug the song that's why i'm here so no knock against that but just the factory of it al#it's so damn WILD to me. but at the same time let's be real here. same dish different kitchen for a lot of western pop#they're just more transparent about it and have streamlined finding their popstars & having the public be great w it#it's just... i think it would be less strange if stan culture wasn't a thing or at least more mild than it is now#if it wasn't blown up to this unfathomably massive ever-churning industry by people in literal droves#idk idk i have a lot of thoughts on kpop it's truly a very interesting thing and to have been aware of it and into it to#an extent a while before the sonic boom in the west is an incredibly wild thing to look back on#like i wanna follow this (mostly cause i wanna hear the whole song) but also v curious but also like man the system is bad for many#reasons & here's another batch on the conveyor belt. idk :/#like as long as the participants are happy and healthy and being actually taken care of and not advantage of then great but#yk. the music industry at large is horrible (and esp to women) so like. god ide wanna think about the disparities btwn girl & boy groups#(like to start are they not referred to as 'male groups' on the reg but 'girl groups' more often than 'female'? always w the infantalizing#like given girl group has way more ring than female group but the words still conjure up different things it's just how language works#but boy group idk if i've ever really heard someone use that? and there's been a long time battle w the reclamation of 'boy band'#like it's still dirty for a lot of folks but anyway v western context but there's a large fanbase here so many fans speak as such#this is what we call our own pop groups etc. and it's just interesting and sad idk anyway it's just... huuuhhh a lot.) ok gn lol

0 notes

Text

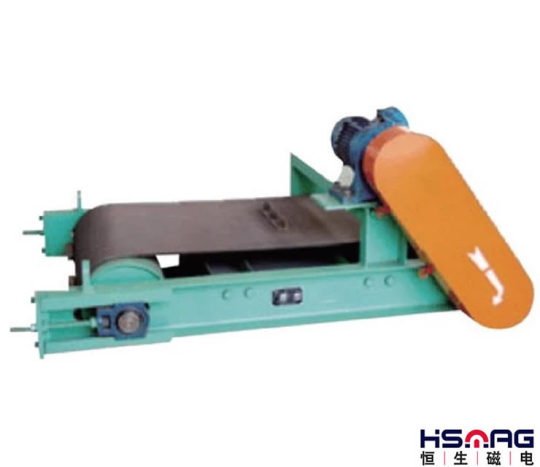

Magnetic Separator Conveyor Belts Types

Magnetic Separator Conveyor Belts Types Mgnetic separator conveyor belts move things from one place to another in factories. Some conveyor belts have magnets. The magnets take away pieces of metal that shouldn’t be there. This makes the product cleaner. It also stops metal from breaking machines further down the line. There are a few types of these magnetic separator conveyor belts. Each one…

View On WordPress

#Belt Drum Separator#Drum separators#hump magnets#In-line Magnets#industrial application#Industrial Magnetic Assemblies#industrial magnetic equipment#Magnet Design#magnetic attraction#Magnetic belts#Magnetic Circuits#magnetic components#Magnetic device#Magnetic drum separators#MAGNETIC field#magnetic field attraction#Magnetic Filters#Magnetic Filtration#magnetic filtration system#Magnetic Liquid traps#magnetic permeable sheets#Magnetic pulley separator#Magnetic Pulleys#Magnetic Separation#magnetic separation assemblies#magnetic separation equipment#magnetic separation systems#Magnetic Separator#Magnetic Separator Conveyors#Permanent magnet types

1 note

·

View note