#BRAIDED COPPER CONNECTOR

Explore tagged Tumblr posts

Text

Braided Connectors | Bajeria Industries

We Bajeria manufacture braided copper connector, round standard copper cables, earthing tapes & ropes. These highly flexible connectors are manufactured by using copper wire of any diameter as per requirement. For more information please kindly visit our website https://www.bajeria.com/copper-braided-flexible-connectors.html

#BRAIDED CONNECTORS#BUSBAR FLEXIBLE CONNECTORS#]COPPER BRAIDED FLEXIBLE CONNECTOR#COPPER BRAIDED FLEXIBLE#COPPER BRAIDED FLEXIBLE SHUNT#COPPER STRANDED FLEXIBLE SHUNT#COPPER BRAIDED FLEXIBLE CONNECTOR#COPPER FLEXIBLE BRAID#BRAIDED COPPER FLEXIBLE#BRAIDED COPPER CONNECTOR

0 notes

Text

PVC-covered aluminum circular condenser

Terowell is leading manufacturer ,supplier and exporter Pvc Coverded Aluminium Circular Conductor. Aluminum is often used in the manufacture of electrical conductors, due to it being ductile and relatively resistant to corrosion, as well as its low resistance and excellent conductivity, being part of the Furs range of conductors.

#PVC Covered Copper Tape#Tinned copper flexible Braided Connectors Manufacturer#Earth Bar with twin disconnecting link manufacturer#solid copper earth rod manufacturer#Copper Bonded Earth Rod manufacturers in mumbai

0 notes

Text

#Hydraulic Hoses#PTFE Hoses#PTFE Tubes#Convoluted PTFE Hose Manufacturers#Convoluted Hoses#High Pressure PTFE Hose#Threaded Pipe Connector#Threaded Connector#SS Wire Braided Convoluted Hoses#PTFE Hoses Aerospace#PTFE Plain Hoses#Two Axis Pipe Connector#Fixed Flange Connector#Copper Ended Connector#Dash 2 PTFE Hoses

1 note

·

View note

Text

The Science Behind Improved Signal Transmission and Durability in IEM Cables

In-ear monitors (IEMs) have become indispensable tools for musicians, audiophiles, and audio professionals. While IEMs themselves play a crucial role in delivering high-quality sound, the cables that connect them to audio sources are often overlooked. However, the choice of cable material can significantly impact both signal transmission and overall durability. In this article, we delve into the…

View On WordPress

#Audio Fidelity#Audio Fidelity Enhancement#Audio Performance#Audio Professionals#Audio Signal Loss#Audiophile Cables#Braided Cables#Braided Copper Science#Cable Breakage#Cable Connectors#Cable Design#Cable Durability#Cable Flexibility#Cable Impedance#Cable Longevity#Cable Maintenance#Cable Materials#Cable Quality#Cable Science#Cable Technology#Cable Upgrade#Conductive Materials#Copper Cables#Durability#Electrical Conductivity#Electrical Properties#EMI Shielding#Flexibility#High-Quality Cables#IEM Cables

1 note

·

View note

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description Multi-functional 3 in 1 charging cable with built-in all three cables like Type C, and Micro USB connectors and compatible for iphone, allowing compatibility with every phones. Charge multiple devices simultaneously with just one cable. This durable charging cable 3 in 1 fast charging is crafted from high quality nylon material, providing resistance to fraying and wear-related damage. Its flexibility and durability make it ideal for long-term use. Multi charger cable fast charging boasts special features like a touch and sleek design, premium nylon braided material, and high durability. 3in 1 charging cable with Robustic Design, the super purity copper conductor ensures high quality and safe charging. Resist high pressure with excellent design For Charging multiple devices, these 3 in 1 fast charging cable is recommended to use a USB power adapter with a minimum output of 2A. [ad_2]

0 notes

Text

Engineered for audiophiles and music lovers, the J&D RCA Cable features:

🔌 18AWG single crystal silver-plated 6N OCC copper core

💎 24K gold-plated PURE copper connectors

🎧 Superior shielding for zero signal loss

🧵 Durable nylon braided jacket + flexible PVC for max lifespan

Whether you're connecting a turntable, amp, HDTV, or studio gear—this cable delivers high-fidelity audio without compromise. Perfect for home theater and professional setups alike.

👉 https://www.amazon.com/dp/B0DL8QGFSZ?maas=maas_adg_B0692708E08FFFA0638DA1573E287E00_afap_abs&ref_=aa_maas&tag=maas

0 notes

Text

NexTik is a top supplier and manufacturer of data cables in Noida, India. Excellent, Strong, and Quick-Charging Cables

Manufacturers of high-quality data cables in Noida, India | Suppliers of data cables in Noida, India

Noida has quickly become a significant center for connectivity and electronics. One of the major players among Data cable suppliers in Noida, India is NexTik, a top producer and provider of data cables in Noida. NexTik has established itself as a respected name in the data cable manufacturing sector, thanks to its state-of-the-art technology, exceptional quality standards, and dedication to innovation. As a leading supplier, NexTik continues to meet the growing demands of businesses and consumers for high-performance data cables.

NexTik: A Leader in Data Cable Manufacturing

NexTik is committed to providing high-end data connections that guarantee dependable communication, quick charging, and longevity. As one of the leading Data cable suppliers in Noida, India, the company has built a solid reputation over the years for delivering high-performance cables that cater to the needs of both individual customers and commercial applications. With extensive experience in the industry, NexTik ensures that every cable meets the highest standards of quality, reliability, and durability, making it a trusted choice for businesses and consumers alike

Reasons why NexTik stands out

High-Quality Materials – NexTik uses high-grade copper conductors and premium insulation materials to enhance data transfer speed and durability.

Cutting-Edge Technology – The company employs advanced manufacturing techniques, ensuring compliance with global safety and performance standards.

Wide Product Range – NexTik offers a variety of data cables designed to meet the diverse needs of customers.

Reliable and Durable – NexTik cables undergo rigorous testing procedures to ensure long-lasting performance and resistance to wear and tear.

Eco-Friendly Manufacturing – Sustainability is a key priority, and NexTik follows environmentally friendly production processes.

NexTik Offers a Wide Selection of Data Cables

NexTik produces a wide range of data and mobile cables that are made to fit various gadgets and applications.

1. USB Type-C Cables

Presently, USB Type-C connectors are the industry standard for high-speed data transfer and quick charging. Power Delivery (PD) technology is supported by NexTik's Type-C cables, guaranteeing quick charging and effective data syncing.

2. Micro USB Cables

NexTik's Micro USB cables offer reliable and effective connectivity for older Android handsets and other electronic equipment. These wires provide seamless data transfer and charging operations.

3. Lightning Cables

NexTik’s Apple MFi-certified Lightning cables guarantee compatibility with iPhones, iPads, and other Apple devices, ensuring fast, safe, and efficient charging.

4. Braided Fast-Charging Cables

For enhanced durability, NexTik offers braided cables with reinforced insulation. These cables are tangle-free, wear-resistant, and built for long-term use.

NexTik's Commitment to Creativity and Quality

Quality is the foundation of success at NexTik. To provide the greatest data cables available, the company closely complies with international safety and performance regulations.

Advanced Manufacturing Standards

NexTik runs a state-of-the-art production facility with the newest technology to guarantee quality and uniformity in each product. Every cable is put through several rounds of quality testing to ensure:

Fast and reliable data transfer

Safe and efficient power delivery

Resistance to bending, wear, and environmental factors

Research & Development

NexTik's primary goal is innovation. To provide next-generation data cables that satisfy the changing technological needs of the market, the company consistently invests in research and development. NexTik continues to lead the way in innovation, from high-speed gaming cables to smart cables driven by AI.

Industries & Applications

NexTik caters to a wide range of industries and consumer needs, including:

Smartphones & Tablets – High-speed charging and data transfer for personal and professional use.

Laptops & PCs – Seamless connectivity for work, gaming, and multimedia.

Automotive Sector – High-durability cables for in-car charging and infotainment systems.

Telecom & Networking – Efficient data cables for smooth network connectivity.

Why is NexTik the Best Data Cable Manufacturer and supplier in Noida?

Extensive Industry Experience – Years of expertise in designing and producing high-performance data cables.

Customer-Centric Approach – Dedicated to understanding customer needs and delivering tailored solutions.

Competitive Pricing – Offering high-quality products at affordable rates.

Fast & Secure Delivery – Efficient supply chain management to ensure timely product availability.

Exceptional Customer Support – Reliable service before and after purchase.

Conclusion

NexTik is the best option if you're searching for reliable Data cable suppliers and manufacturers in Noida, India. With a continuous dedication to quality, innovation, and client satisfaction, NexTik has consistently set industry standards in data cable manufacturing. Whether you need high-speed charging cables, robust data cables, or customizable connectivity solutions, NexTik is a trusted name that guarantees performance, durability, and cutting-edge technology. Their commitment to excellence makes them the go-to supplier for all your data cable needs in Noida, India.

0 notes

Text

Thanh Nối Đồng Bện Mềm - Kết Nối Điện mềm cho MBA

Tên gọi: Thanh nối đồng bện mềm, thanh nối đồng mềm, khớp nối mềm, khớp nối đồng bện, Dây đồng bện nối Máy biến áp, Dây đồng bện MBA, Flexiable busbar, Flexible connector , Flexible link Copper foil connector, copper braid connector Liên hệ: 085.555.5356 – 085.555.5259 (Zalo, Telegram) – Email: [email protected] 1. Thanh Nối Đồng Bện Mềm Là Gì? Thanh nối đồng bện mềm (còn gọi là dây đồng…

0 notes

Text

A002 BLACK Cable Connectors

ATI Pro Audio is a distinguished name in the audio industry, renowned for its extensive selection of speakers and sound systems. As a premier supplier, wholesaler, and importer of A002 (5M) BLACK cable is a versatile solution for audio, video, data, power, CCTV, and networking applications. It features an attractive design, 24k gold plating, high-density insulation, and 100% oxygen-free copper braiding. Its high-purity solid plated copper ensures optimal conductivity and durability.

0 notes

Text

Braid Copper | Bajeria Industries

We Bajeria is specialized in manufacturing, Tinned Copper Braided Flexible Jumpers. We offer complete customized solutions to our customers depending upon their exact requirements. For more information please kindly visit our website https://www.bajeria.com/copper-braided-flexible-jumpers.html

#BRAID COPPER#COPPER BRAIDED FLEXIBLE JUMPER#COPPER BRAIDED FLEXIBLE#COPPER BRAIDED FLEXIBLE SHUNT#COPPER STRANDED FLEXIBLE SHUNT#COPPER BRAIDED FLEXIBLE CONNECTOR#COPPER FLEXIBLE BRAID#BRAIDED COPPER FLEXIBLE#BRAIDED COPPER CONNECTOR

0 notes

Text

Choosing the Right RF Cable Assemblies for Your Communication Needs

Radio Frequency (RF) cable assemblies are an essential component of modern communication systems, providing the paths required to transfer high-frequency signals between various devices and systems. Whether you're creating a wireless communication network, a satellite system, or a radar system, choosing the correct RF cable assembly is critical to achieving peak performance, dependability, and efficiency.

In this blog, we'll look at the important aspects to consider when selecting RF cable assemblies for your communication needs, such as cable types, connectors, performance characteristics, and environmental considerations. Understanding these components will allow you to make an informed decision that meets your project's individual requirements.

What are RF Cable Assemblies? An RF cable assembly is a set of coaxial cables and connectors used to carry high-frequency electrical signals in applications such as telecommunications, television, radar, and wireless networks. These assemblies typically include a cable with a central conductor, insulating material, shielding, and an outer jacket, as well as a connector to enable a secure connection between devices and systems.

RF cable assemblies are intended to convey signals at radio frequencies (usually ranging from 3 kHz to 300 GHz), and their performance is directly determined by the cable's materials, construction, and connectors.

Key Factors to Consider When Selecting RF Cable Assembly

1. Frequency range and performance requirements.

When choosing an RF wire assembly, the frequency range required for your application should be the most significant consideration. RF cables are intended to transmit signals across specific frequency bands, and each cable performs better at a different frequency. Choosing the appropriate cable assembly for the intended frequency results in low signal loss and high-quality transmission.

Low-frequency applications (e.g., up to 1 GHz) are commonly served by ordinary coaxial cables.

High-frequency applications (e.g., 10 GHz and above) necessitate cables made of particular materials and structure to reduce loss and distortion, as higher frequencies tend to encounter more attenuation.

RF cable assemblies frequently have a specified frequency range, such as DC to 18 GHz, DC to 40 GHz, or greater, depending on the application. Make sure the assembly you choose can handle your system's frequency spectrum while retaining signal integrity.

2. Cable Construction and Materials

The design of an RF cable assembly affects its performance in terms of signal attenuation, longevity, and dependability. When selecting a cable assembly, it is critical to understand the following components.

The center conductor transmits the signal and is typically constructed of copper, silver, or gold. The material used influences the signal's conductivity, with copper being the most popular due to its superior conductivity and cost-effectiveness. For high-performance applications, silver or gold plating may be used to reduce signal loss.

Dielectric Insulation: The dielectric material surrounds the center conductor and serves to maintain the cable's required impedance. Polyethylene, Teflon, and foam are examples of dielectric materials, each with its own set of performance properties. Teflon, for example, is extremely resistant to both heat and electrical deterioration, making it perfect for high-frequency applications.

Shielding: Shielding reduces electromagnetic interference (EMI) and keeps extraneous signals from interfering with the transmitted signal. It can be built using braided copper, aluminum foil, or a combination of the two. A single braid may be sufficient in low-EMI situations, but in high-EMI conditions, additional or double shielding may be required.

Outer Jacket: The outer jacket protects the cable and its components from environmental hazards such as moisture, UV radiation, and physical damage. PVC, rubber, and fluoropolymers are among the most used jacket materials.

3. Impedance Matching.

To avoid signal reflection, power loss, and interference in RF systems, the cable, connections, and devices must be precisely impedance matched. The most typical impedance values for RF cables are 50 ohms and 75 ohms, which serve distinct applications:

50-Ohm cables are widely utilized in communication systems, including wireless, cellular, and network applications. They achieve a balance between power handling and signal integrity.

75-Ohm cables are commonly employed in broadcast and television applications, where signal attenuation is more important than power handling.

Make sure you select a cable assembly with the correct impedance for the devices you're connecting. An impedance mismatch can cause reflection, signal degradation, and decreased system performance.

4. Connector types

The connectors on the RF cable assembly are equally important as the cable itself. There are several types of connections available, each suitable to a distinct application. Commonly used RF connections include:

BNC (Bayonet Neill-Concelman): These connectors are commonly used in applications that require a quick-connect mechanism, such as test equipment and video surveillance systems.

SMA (SubMiniature version A) connectors are widely used in wireless communication, GPS systems, and other high-frequency applications due to their small size and dependable operation at frequencies of up to 18GHz.

N-Type connectors are designed for high-power applications such as cellular, broadcast, and industrial. N-type connectors are suited for frequencies of up to 11 GHz.

TNC (Threaded Neill-Concelman) connectors are similar to BNC but feature a threaded construction for greater durability and performance at higher frequencies.

F-Type connectors, which are widely used in cable television and satellite applications, are designed for 75-ohm cables and provide a dependable connection with low signal loss.

Each connector type has a unique application and frequency range. When choosing an RF cable assembly, make sure the connectors are compatible with your equipment and can withstand the required frequency and power levels.

5. Environmental Factors

RF cable assemblies must be chosen in accordance with the environmental conditions under which they will be used. Temperature, humidity, chemical exposure, and mechanical stress all have an impact on cable performance and longevity.

Temperature Range: The tolerance to temperature extremes varies depending on the cable material and insulation type. For example, Teflon-insulated wires can withstand higher temperatures than PVC-insulated cables.

Outdoor Use: If your application takes place outside or in hostile settings, consider using cables with UV-resistant jackets or additional weatherproofing. Cables used in outdoor applications should be resistant to dampness and harsh weather.

Flexibility: In applications where the wire will be regularly moved or bent, flexible cables with a low bend radius should be utilized. These cables are designed to resist frequent movement while maintaining signal quality.

6. Length & Attenuation

Signal loss, also known as attenuation, rises with cable length. The longer the cable, the weaker the signal becomes as it passes through the conductor. If your system requires extensive cable runs, select a cable with low attenuation to reduce signal degradation. Consider the use of amplifiers or repeaters if larger distances are required.

Check that the length of the RF cable assembly fits your installation requirements while retaining an acceptable signal loss over distance.

Final Considerations

When choosing RF cable assemblies, you should consider your individual communication requirements in terms of frequency range, power management, environmental conditions, and signal integrity. Understanding the various cable construction materials, impedance matching, and connector types will allow you to make the optimal decision for your application.

Work with reputable vendors who can deliver high-quality, long-lasting, and customizable RF cable assemblies that fit your individual requirements. Whether you're working on a 5G network, satellite communication, radar systems, or another RF application, the appropriate RF cable assembly can help you achieve peak system performance, reduce signal loss, and increase network reliability and efficiency.

Finally, selecting the correct RF cable assembly is critical for ensuring that your communication systems operate at peak efficiency. To attain the greatest results, consider your objectives and choose a cable assembly that satisfies your frequency, power, and environmental criteria.

0 notes

Text

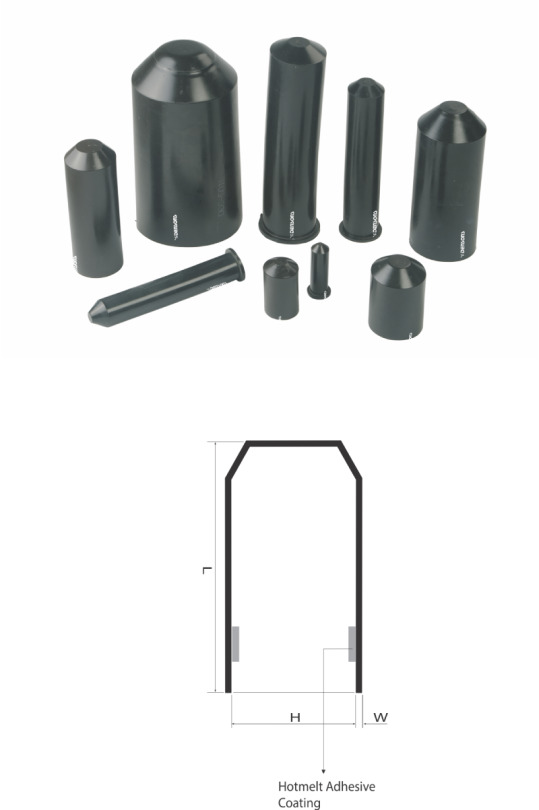

Protect Your Equipment with Yamuna Denson's Heat Shrinkable End Caps

Yamuna Denson Heat Shrinkable End Caps provide optimum waterproofing and environmental protection for underwater, underground, and outdoor applications. Our heat-shrink end caps are highly resistant to moisture, fungus, and weathering. We also offer electrical end caps with pre-coat sealants. The heat-shrink end caps are available in several sizes to accommodate varying cable diameters due to their large range-taking ability.

Contact Us Today.

#connector front & rear#cold shrink cable joints & terminations#conductor cover#heat shrinkable end caps#medium voltage cable jointing kit#low voltage cable jointing kit#bus bar connector#cable repair sleeve#shrinkable anti tracking#copper braid

0 notes

Text

What Materials are Used in Auto Wiring Harnesses

The automotive industry has undergone significant changes over the past few decades, and with each advancement, the complexity of automotive wiring harnesses has increased. These harnesses are essential for transmitting power and signals throughout the vehicle to ensure optimal operation of electrical and electronic components. As a professional automotive wiring harness manufacturer, we understand the importance of using high-quality materials to ensure safety, reliability, and durability. In this article, we will discuss the materials commonly used in automotive wiring harness manufacturing.

Conductive Materials: Copper and Aluminum

At the heart of any wiring harness is the conductive material that carries the current. Copper is the most commonly used conductive material in automotive wiring harnesses because of its excellent conductivity, flexibility, and tensile strength. It can carry high current loads without significant voltage drop, which is critical in automotive applications where performance and safety are critical.

Insulation Materials: PVC, XLPE, and TPE

Insulation materials are critical in automotive wiring harnesses because they protect wires from environmental factors and prevent electrical leakage. Polyvinyl chloride(PVC)is a common insulation material favoured for its flexibility, durability, and resistance to abrasion, chemicals, and temperature changes. It is suitable for both low- and high-voltage applications and can be easily colour-coded for wire identification.

Cross-linked polyethene (XLPE)is another popular insulation material used in automotive wiring harnesses. It has superior thermal, chemical, and physical properties to PVC and has enhanced abrasion resistance, making it ideal for harsh automotive environments.

Thermoplastic elastomers(TPE)are a blend of plastic and rubber, so they have the properties of both materials.TPEs are used in applications that require flexibility and durability, such as areas that experience frequent movement or vibration.

Protective Coverings: Corrugated Tubing, Braided Sleeving, and Foil Tape

To further protect wires from environmental hazards such as moisture, heat, abrasion, and chemical leaks, additional protective coverings are required. Corrugated tubing made from nylon or polypropylene offers an excellent balance between flexibility and strength and is commonly used to wrap automotive wiring harnesses.

Braided tubing made from materials such as polyester or nylon provides physical protection while maintaining flexibility. They can also reduce noise by minimizing vibration and rattle of cables within the harness.

Foil tape is made from aluminium or copper and can be wrapped around the harness to shield electromagnetic interference(EMI), which can disrupt the operation of sensitive electronic components in modern vehicles.

Connectors and Terminals: Brass, Copper, and Plastics

Connectors and terminals play a key role in connecting wires and ensuring reliable electrical connections. Brass and copper are widely used to manufacture terminals due to their excellent conductivity and corrosion resistance. Terminals can also be plated with materials such as tin or gold to further improve performance and lifespan.

Committed to Quality and Innovation

As a professional automotive wiring harness manufacturer, we are constantly exploring and adopting new materials and technologies to ensure that our products meet the highest standards of quality and reliability. Our commitment to innovation is matched by our dedication to sustainability, which compels us to seek environmentally friendly materials and manufacturing processes.

In summary, there are a variety of materials used in automotive wiring harnesses, which are selected for their ability to withstand the harsh conditions in which automobiles operate. Copper and aluminium remain the conductors of choice, while insulation and protective jacketing materials such as PVC, XLPE, and TPE ensure the integrity of the wiring harness. Connectors and terminals made of brass, copper, and durable plastics ensure a solid electrical connection. As a manufacturer, we are committed to providing the automotive industry with wiring harnesses that are superior in performance, safety, and quality.

0 notes

Text

How MILCOM’s Coaxial Cable Course Assist You for a Great Career in Cabling?

Every successful cable technician in Australia knows the value of an excellent coaxial cable course. And they would always recommend MILCOM Coaxial Cable Course, which is perfect for anyone who wants to start a cabling career or advance their skills to the next professional level. The current article covers everything you need to know about coaxial cables, the NBN Coaxial cable standard, and how MILCOM’s coaxial cable course meets that standard.

Introduction about coaxial cable

Coaxial cables typically transmit signals between devices like TVs, radios, and computers. They consist of an inner conductor, an insulating layer, a conductive shield, and an outer insulating layer. The inner conductor is usually copper, while the conductive shield is braided copper or aluminum foil. The insulating layer keeps the conductive shield from touching the inner conductor, and the outer insulating layer protects the cable from environmental factors, such as moisture and temperature changes.

Different types of coax cable

There are many types of coaxial cable, each designed for specific applications. For example, the most common type of coaxial cable is RG-6, which is used for cable TV and satellite installations. RG-11 is a thicker, more durable cable often used for longer cable runs. Other types of coaxial cable include RG-59, RG-213, and RG-214.

Coaxial cabling application in the telecom sector in Australia

Coaxial cabling plays a crucial role in the telecom sector in Australia. It is used for everything from cable TV and satellite installations to broadband internet and phone services. As technology evolves, the demand for skilled cabling technicians who can install, maintain, and repair coaxial cabling systems will continue to grow.

NBN coaxial cable standard

The National Broadband Network (NBN) is a government-owned company responsible for rolling out high-speed broadband across Australia. As part of this rollout, the NBN has established a set of cabling standards that must be followed by all cabling technicians who work on NBN installations. One of these standards is the NBN coax cabling course, which specifies the type of coaxial cable used for NBN installations. NBN also prefers having a skilled coaxial cabling technician to work on NBN projects. NBN recognizes a few institutions in Australia, including MILCOM, that offer coaxial cabling course to the aspirant cable technicians.

How MILCOM’s coaxial cabling training course meets NBN standard

MILCOM’s Coaxial Cable Course is designed to teach aspiring cabling technicians everything they need to know about coaxial cabling, including how to meet the NBN Coaxial cable standard. The course covers cable types, connectors, installation techniques, safety procedures, and industry best practices.

MILCOM’s cable course is recognized by NBN and offers excellent career opportunities to cabling technicians

Not only does MILCOM’s course meet the NBN Coaxial cable standard, but it’s also recognized by the NBN as an approved training provider. Anyone who completes MILCOM’s course will have the skills and knowledge necessary to work on NBN installations. Additionally, MILCOM’s course offers a great career opportunity for cabling technicians as the demand for skilled professionals grows.

Admission rules and formalities in MILCOM’s coaxial cable course

Admission to MILCOM’s Coaxial Cable Course is open to anyone interested in a career in cabling. To enroll, visit the MILCOM website and complete the online application form. Once you have been accepted and admitted into the program, you will receive all the necessary course materials and instructions on how to get started.

MILCOM’s Coaxial Cable Course is the perfect way for aspiring cabling technicians to begin a great career in coaxial cabling.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] The USB Type C to USB 3.0 OTG Cable offers seamless connectivity between compatible devices such as smartphones, laptops, and tablets. With its braided cable and matte finish, this connector enables fast data transfer of up to 5 Gbps through its USB 3.0 compatibility. Supporting all Type-C enabled mobile smartphones and devices, this OTG cable allows for quick and efficient file transfer to and from external storage devices, such as USB flash drives, making it easy to connect your phone to other devices and transfer files with ease. Its simplicity and efficiency make it a convenient accessory for anyone looking to expand their device's connectivity options. This Type C Adapter Cable is designed for durable usage, featuring an aluminum alloy connector that is anti-deform and corrosion-resistant, along with tinned copper conductors and multiple-layer shielding, ensuring stable transmission and a longer lifespan. With the USB C to USB 3.0 adapter, you can enjoy full USB 3.0 super speed data transfer of up to 5Gbps, which is 10 times faster than USB 2.0, allowing you to quickly transfer files, HD movies, and songs to your USB-C devices in seconds with high efficiency. This USB On The Go adapter cable enables you to connect computer peripherals like flash drives, keyboards, hubs, mice, and more to your USB-C devices, allowing for seamless syncing, charging, and data transfer, making your USB-C devices more versatile and functional. This Type-C OTG cable is widely compatible with a range of devices, including OnePlus 9/9Pro/8T/8/8 Pro/7 Pro/7T/7/6T/6/5T/5/3T/3, iPad Pro 2020/2018, MacBook Pro, Samsung Galaxy S20 FE/S20 Ultra/S10 Plus/S10e/S10/S9 Plus/A10e/A20/A70/A51/A50, Samsung Note 20 Ultra/Note 10 Plus/Note 9/Note 8, LG Stylo 4/Stylo 5/G5/G6/G7 ThinQ, Moto Z2 Force, Sony Xperia XA2, HTC 10, and many more, making it a versatile and convenient accessory for various devices. Pacakge Included :- 1 x Type C To USB 3.0 OTG Adapter. [ad_2]

0 notes

Text

Upgrade your sound setup with J&D XLR Microphone Cables! 🔊

✅ Multi-Color Cables: 5 vibrant cables for easy identification & organization.

✅ HI-FI Sound Quality: Oxygen-free copper & copper braided shielding for crystal-clear audio and noise reduction.

✅ Gold-Plated 3 Pins: Stable signal transmission with durable connectors.

✅ Wide Compatibility: Perfect for mixers, amplifiers, cameras, sound systems, and more.

🎧 Get yours and experience top-tier sound!

0 notes