#Automotive Mold Manufacturers

Explore tagged Tumblr posts

Text

Leading Plastic Molding Manufacturer for Custom Solutions

Partner with a trusted Plastic Molding Manufacturer for high-quality, custom plastic parts. Our advanced molding technologies and experienced team ensure precision and consistency in every project. Serving various industries, we provide tailored solutions that meet your exact specifications, from concept to production. Rely on us for durable, efficient, and cost-effective plastic molding services.

#plastic injection molding supplier#electronics manufacturing services#automotive mold manufacturers#aluminium die casting

0 notes

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Text

How to use MoldFlow to reduce hidden costs in injection molding industry

Classification of mass production costs of plastic products Relationship between design and cost Although design cost only accounts for 20% of the total cost, it determines 80% of product manufacturing cost. And of 80% of product manufacturing cost, only less than 40% is determined by manufacturing itself! How to effectively reduce hidden costs in development The most effective tool to reduce…

View On WordPress

#automotive parts#Casting system design#injection mold#injection molding#injection molding process#injection molds#injection simulation analysis#mold design#Mold exhaust structure#mold flow analysis#mold manufacturing#mold structure design#molded plastic parts#molding process#plastic part#Plastic part process analysis#plastic part structure#Thin-walled inner wheel cover molding process

0 notes

Text

Fastener Expo Shanghai 2025 https://expopeak.com/event/fastener-expo-shanghai-2025/

Fasten Your Future at the Fastener Expo Shanghai 2025

Explore the cutting edge of fastener technology and innovation at Fastener Expo Shanghai 2025. Get all the details on ExpoPeak.

Click here to access our article on Fastener Expo Shanghai 2025 and explore how this event is revolutionizing the way we connect!

#Automotive#Industry#Dies#Engineering#Sector#Fastener#Fixing#Services#fastener#manufacturing#equipment#materials#Fasteners#Industrial#lathe#parts#Logistics#Manufacture#Manufacturing#Mold#Molds#nonstandard#fasteners#Packaging#Equipment#Stamping#Standard#Testing#Tools

0 notes

Text

Experience the best in class with Chemteach.com, your trusted chemical manufacturing company in India.

#Die Cast#Foundry Solutions#Composites#Polyurethane#Rubber Molding#Tire Manufacturing#Rotational Molding#Thermoplastics#Advanced Composites#Automotive Solutions#Industrial Manufacturing#Casting Release#Composite Molding#Process Aids#Surface Coatings#Manufacturing Efficiency#Performance Materials

1 note

·

View note

Text

Automotive rubber parts – Driving the automotive industry

The auto sector cannot do without rubber parts. The automotive industry is undergoing a tremendous change, the biggest challenge lies in the supply of value-added products. Here are some new trends in automotive rubber parts. https://alfarubber.home.blog/2023/11/03/automotive-rubber-parts-driving-the-automotive-industry/

#Automotive rubber parts#Gaskets and Seals#Rubber Injection Molding#Seal manufacturer#Bush manufacturer

0 notes

Text

The Growing Role of Automotive Plastics in Vehicle Design and Manufacturing

Automotive plastics are materials used for the construction of parts and components in automobiles, including the body, interior, and powertrain. These plastics are designed to be lightweight, durable, and cost-effective. Common types of automotive plastics include polypropylene, polyurethane, ABS, and polycarbonate. Automotive plastics are used in many areas of the vehicle, including interior…

View On WordPress

#automotive bioplastic market#automotive injection#automotive injection molding#automotive injection molding companies#automotive plastic additives market#automotive plastic injection molding companies#automotive plastic manufacturers#Automotive Plastics#Automotive Plastics Industry#automotive Plastics industry for Passenger Cars#Automotive Plastics Market#Automotive Plastics Market for Passenger Cars#automotive plastics market industry share#automotive plastics market industry size#automotive plastics suppliers#COVID 19 impact on Automotive Plastics Market#global automotive plastics market#injection molding in automotive industry#plastic car#plastic car part#plastics for electric vehicle market#polypropylene in cars#use of plastic in automobile

0 notes

Text

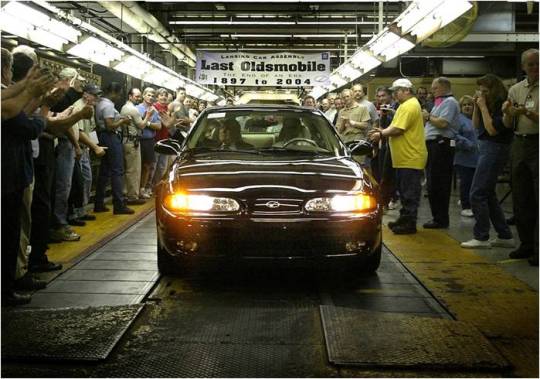

Oldsmobile

April 29'th 2004. The last Oldsmobile rolls off the line. You may be surprised to learn, that for a long time Oldsmobile meant innovation. Here are just a few of the Automotive technologies Olds pioneered in it's 100+ years in business:

1898: Olds Motor Vehicle Company exports the first American car, a steam-powered automobile, to Mumbai, India.

1901: The first speedometer offered on a production car was on an Oldsmobile Curved Dash.

1901: Oldsmobile was the first to procure parts from third-party suppliers.

1901: Olds produces 635 cars, becoming the first high-volume gasoline automobile producer.

1901: Oldsmobile becomes the first manufacturer to publicly promote their vehicles.

1902: The Oldsmobile Curved Dash is the first mass-produced vehicle in America.

1903: Oldsmobile builds the first purpose-built mail truck.

1908: Oldsmobile rebadges the Buick Model B as the Oldsmobile Model 20, possibly creating the first badge-engineered car.

1915: First standard windshield introduced by Oldsmobile.

1926: Oldsmobile is the first to use chrome plating on trim.

1929: Oldsmobile creates the first Monobloc V8 engine in its Viking Sister brand.

1932: Oldsmobile introduces the first automatic choke.

1935: Oldsmobile offers the first all-steel roof on an automobile.

1940: Oldsmobile introduces the Hydra-Matic, the first fully automatic transmission.

1948: Oldsmobile offers one-piece curved windshields, along with Buick and Cadillac.

1949: Oldsmobile introduces the Rocket, the first high-compression OHV V8 engine.

1952: Oldsmobile introduces the "Autronic Eye," the first automatic headlight dimming system.

1953: Oldsmobile switches its lineup to the 12v charging system.

1962: Oldsmobile creates the first production turbocharged car, the F-85 Jetfire.

1962: Oldsmobile also creates the first production car with water injection, the F-85 Jetfire.

1966: The Oldsmobile Toronado is the first mass-produced front-wheel-drive American car.

1969: First use of chromed ABS plastic exterior trim on the 1969 Oldsmobile Toronado.

1969: First electric grid window defogger on an American car, the 1969 Oldsmobile Toronado.

1971: The Oldsmobile Toronado is one of the first cars to feature a high-mounted brake light.

1974: The Toronado is the first American car to offer a driver-side airbag.

1977: The Toronado is the first American car with a microprocessor to run engine controls.

1982: First use of high-impact molded plastic body components on the 1982 Oldsmobile Omega.

1986: Oldsmobile introduces the Delco VIC touchscreen interface on the Toronado, shared with Buick Riviera.

1988: The first production heads-up display system is introduced on the 1988 Oldsmobile Cutlass Supreme Indy Pace Car.

1988: Oldsmobile breaks a world speed record with the Oldsmobile Aerotech at 267 mph, driven by A.J. Foyt.

1990: Oldsmobile updates the color touchscreen interface with a built-in cellular phone on the 1990 Toronado Trofeo.

1995: Oldsmobile introduces Guidestar, the first onboard navigation system on a U.S. production car.

1997: Oldsmobile becomes the first American car company to turn 100 years old.

2001: The redesigned 2002 Oldsmobile Bravada becomes the first truck to pace the Indianapolis 500.

93 notes

·

View notes

Text

Ford: Coffee husk to build car parts

In an innovative collaboration, Ford and McDonald’s are using coffee chaff—the husk of the coffee bean—to manufacture car parts. This initiative, involving Canadian-based Competitive Green Technologies, repurposes coffee chaff from McDonald’s suppliers into a composite material for automotive components like headlamp parts, interior elements and under-hood components.

The process involves exposing the coffee chaff to high temperatures in low-oxygen environments and combining it with resin, plastic and additives to create pellets that can be molded into different shapes. This pioneering use of coffee chaff in car part production renders Ford products approximately 20% lighter and achieves up to 25% energy savings during the molding process.

source

8 notes

·

View notes

Text

Exploring the top-notch DB6 and H13 Steels Supplier's in MIDC Thane? Look no further—Virat Special Steels delivers excellence!

Whether it’s tool steel, die steel, mold steel, or any other steel requirement, Virat Special Steels stands out as a trusted supplier in #Maharashtra!

Thane's industrial sector boasts a robust tool and die steel industry. These industries are the unsung heroes behind the manufacturing processes of various sectors, providing the essential tools, dies, molds, and components required for production. They serve a wide array of industries, including automotive, aerospace, and medical, which are pivotal to the country's growth.

VIRAT SPECIAL STEELS PVT. LIMITED, your go-to partner for superior quality and reliability. Headquartered in Gurgaon, Virat Special Steels act as a leading supplier of tool and die steels in India offers a wide range of high-quality steels with technical support and customized solutions, ensuring that clients receive materials that perfectly match their manufacturing requirements.

Special offer for Thane MIDC Industrial Area's Available Grades:

Die Steel (HH 370 – 410 BHN): DB6, DIN-1.2714, and AISI L6.

Hot Work Steels: DIN 2343, 2344, AISI H11, and H13.

Plastic Mould Steels: Varieties like DIN 2738, 2311, and AISI P20.

High-Speed Steels: Featuring DIN 3243, 3343, AISI M2, and M35.

Cold Work Steels (HCHCr): DIN 2379, 2080, AISI D2, and D3.

Alloy Steels, EN-Series, and More.

With a state-of-the-art plant in #Gurugram and #Ludhiana, they ensure quality and reliability. Their strong distribution network across India makes them accessible to customers nationwide.

You can explore their offering: https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-thane/

Any further queries feel free to contact us: 🌐https://www.viratsteels.com 📨 [email protected] 📞 +91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#toolsteel#DieSteels#SteelTrades#SpecialSteel#MetalIndustry#DB6#H13#tool steel

3 notes

·

View notes

Text

Automotive Injection Molding - Precision Manufacturing for High-Quality Auto Parts

Automotive Injection Molding by Keiteq offers advanced solutions for producing precise and durable automotive components. This process ensures high efficiency and consistency, making it ideal for creating complex parts like dashboards, bumpers, and interior panels.

#electronics manufacturing services#automotive mold manufacturers#electronic manufacturing services#aluminium die casting#automotive molding#plastic injection molding supplier#plastic injection molding company

0 notes

Text

PREPRATION OF A BUEATY SOAP || A2Z SKILLS Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products, from everyday essentials to specialized components. Take wires, for instance: these are typically manufactured through drawing processes, where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformity and strength, crucial for applications in electronics, construction, and industrial settings. On the other hand, the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a molten state and then inflates it into a mold cavity to create a hollow shape, used extensively for beverage containers and packaging. Injection molding, meanwhile, injects molten plastic into a mold under high pressure, ideal for producing intricate shapes with precision, like medical vials or automotive parts. Both wire and bottle manufacturing rely heavily on materials science, engineering precision, and quality control measures to meet stringent specifications. Advances in automation, robotics, and sustainability practices are transforming these industries, reducing waste, improving efficiency, and expanding design possibilities. Overall, manufacturing processes like these exemplify the intersection of innovation, engineering, and practical application in meeting global OUR LINKS:

TIKTOK: https://www.tiktok.com/@a2zskills YOUTUBE: https://www.youtube.com/@A2ZSKILLS-123 FACEBOOK: https://www.facebook.com/profile.php?id=61562585190878&sk=about INSTAGRAM: https://www.instagram.com/a2zskills123/ VIMEO: https://vimeo.com/?signup=true TUMBIR: https://www.tumblr.com/dashboard HASAHTAGS : #satisfying #manufacturing #molding #shorts #A2Zskills #thermacolplates #thermacol #clay #tips #tipsandtricks #tutorials #prank #youtubeshorts #youtube #manufacture #manufacturer #ytshorts #material #materials #science #sciencefacts #technology #equipments #wires #work #design #efficiency #hacks #reducingwaste #electronic #automobiles

3 notes

·

View notes

Text

Research on injection mold for thin-walled inner wheel cover of automobile

1 Plastic part process analysis 1.1 Thin-walled inner wheel cover molding process Large thin-walled inner wheel cover has an outer dimension of 1407mm*390 mm*656 mm and a wall thickness of 1.3 mm. It is a typical large-size thin-walled automobile part. Quality is required to be reduced by more than 25%, which is in line with current trend of automobile lightweighting. Plastic part material is…

View On WordPress

#automotive parts#Casting system design#injection mold#injection molding#injection molding process#injection molds#injection simulation analysis#mold design#Mold exhaust structure#mold flow analysis#mold manufacturing#mold structure design#molded plastic parts#molding process#plastic part#Plastic part process analysis#plastic part structure#Thin-walled inner wheel cover molding process

0 notes

Text

Fastener Expo Shanghai 2025

Fasten Your Future at the Fastener Expo Shanghai 2025

Explore the cutting edge of fastener technology and innovation at Fastener Expo Shanghai 2025. Get all the details on ExpoPeak.

Click here to access our article on Fastener Expo Shanghai 2025 and explore how this event is revolutionizing the way we connect!

#Automotive#Industry#Dies#Engineering#Sector#Fastener#Fixing#Services#fastener#manufacturing#equipment#materials#Fasteners#Industrial#lathe#parts#Logistics#Manufacture#Manufacturing#Mold#Molds#nonstandard#fasteners#Packaging#Equipment#Stamping#Standard#Testing#Tools

0 notes

Text

What Industries Is Injection Molding(Moulding) Applicable To?

Injection moulding is a common manufacturing process by injecting molten plastic material into a mould so that it can be formed into the desired product shape upon cooling.

Injection moulding process has the advantages of low cost, high production efficiency and stable product quality to make it widely used in various industries. In this vast injection moulding market, there are three industries are particularly eye-catching, which are extensively used for production and manufacturing due to their specific needs and product characteristics.

1.Household Appliance Manufacturing Industry

As an indispensable part of people's daily life, the market demand for household appliances is stable and continuously growing. The injection moulding process plays a pivotal role in the manufacturing of household appliances, from the outer shell to the internal components, injection moulding technology provides key support. Most of the exterior and structural components of home appliances, such as TV remote controls, refrigerators, TV sets, air-conditioning panels, and washing machine shells, are manufactured by injection molding process.

2.Automotive Components Industry & Transportation Sector

With the booming development of the automotive industry, the auto components and parts market has ushered in unprecedented development opportunities. Components and parts such as automotive dashboards, door interior panels, bumpers, and lamp housings as well as a wide range of pipework and connections are made through the injection moulding process. These parts require not only high precision and good mechanical properties, but also need to meet the strict appearance requirements, which injection moulding process is precisely by virtue of its unique advantages, in this field to occupy a place. In addition, with the rise of new energy vehicles, injection moulded parts play an important role in the manufacturing of key components such as battery packs and motor housings.

3.Medical Device Industry

With the increasing emphasis on health, the market demand for medical devices continues to grow. In medical device manufacturing, the injection moulding process is used to produce disposable medical devices such as syringes, infusion tubes and surgical instruments. These products require strict quality control and hygiene standards, and injection moulding process ensures product safety and effectiveness.

In addition, the injection moulding process is also widely used in the electrical and electronic industry, consumer electronics, packaging industry, toy manufacturing, construction materials, industrial parts, furniture and household furnishings and agriculture, among many others.

4.Electrical & Electronic Industry

In the manufacturing process of electronic products, many components such as housings, cases, sockets, connectors, cables, switches and holders for electronic circuit boards need to be manufactured by injection moulding process. Injection moulding process can achieve precise control of product appearance, size and structure, to meet the requirements of electronic products for appearance quality, functionality and reliability.

5.Consumer Electronics Industry

In the electronics industry, injection moulded parts are equally widely used. From mobile phone housings, computer components including keyboards and mice to remote controls and battery cases, the injection moulding process offers a wide variety of appearance and structure options for electronic products. These components not only need to have good mechanical properties and appearance, but also need to have excellent electrical insulation properties to ensure the stable operation of electronic products. Injection moulding technology occupies an important position in the manufacture of electronic products due to its advantages of high precision and low cost.

6.Construction Sector

In the construction field, injection moulded parts also have a wide range of applications, the drainage systems, door and window frames, pvc pipes, valves, wire troughs, insulation materials and other construction materials and accessories are mostly manufactured by injection moulding process. These components are not only high-strength and corrosion-resistant, but also weather-resistant and easy to install, meeting the construction industry's requirements for material performance and ease of use and improve construction efficiency and aesthetics. The application of injection moulding technology in the construction field not only improves the performance and quality of construction materials, but also promotes the sustainable development of the construction industry.

7.Packaging Industry

The packaging and container industry is also one of the key application areas for injection moulding processes. Plastic bottles, food boxes, cosmetic bottles, plastic bags and other packaging containers are mostly manufactured by injection moulding process to meet food safety and aesthetic requirements. These containers need to be well-sealed, drop-resistant, retain freshness and recyclable to ensure that the products are safe and environmentally friendly. Injection moulding processes can offer flexible design and manufacturing options to adapt to different packaging needs and provide strong support for the development of the packaging industry.

These areas above are just a few examples of the application areas of the injection moulding process. In the toy industry, injection moulded parts are used to manufacture a variety of plastic toys; In the textile and clothing industry, injection moulded parts are used to manufacture accessories such as zips and buttons; In the agricultural sector, injection moulded parts are used to manufacture agricultural tools and equipment such as sprayers and watering cans; Even in the aerospace sector, injection moulded parts are also used to manufacture parts for aircraft and spacecraft. It can be said that injection moulded parts have penetrated into almost every corner of our life.

In summary, injection moulded parts play an important role in several industries by virtue of their high precision, low cost and wide applicability. The application of injection moulding process in these areas not only improves production efficiency, but also meets the needs of product diversification and individualisation. With the continuous progress of science and technology and the continuous improvement of people's requirements on product quality, injection moulding technology will continue to be widely used and developed in various fields.

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#injection molding#plastic injection molding#injection moulding machine#injection moulding#plastic injection#injection molded#injection molding parts#injection molded parts

2 notes

·

View notes