#Arc Weldy

Explore tagged Tumblr posts

Text

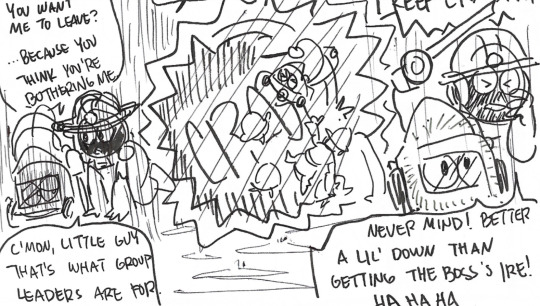

Sakugarne and Quint talk to each other but the way it goes, while Sakugarne is very expressive, they don't actually ever talk--Quint just intuitively picks what they mean in a mostly one-sided conversation. Basically the same rules I usually use for a lot of Pokemon/MM fanfics.

No one asked but the Pickmen in that story (and Pumpy K whenever I use him) are sort of middlemen between the lower robots and robot masters. Like a robotic chain of command.

But while I was thinking about this AU, I made the connection between the normal Pokemon universe and the PMD one where the pokemon talk and quite literally yesterday, I thought, "wait then why doesn't Sakugarne talk?" So they talk now. A lot. And...wow, okay this autocomplete or whatever will automatically suggest Sakugarne after I wrote it in this post but will STILL refuse to put the special e in Cafe Woman no matter how many times I put iin it. Fuck off!

#Saku also goes by Arc Weldy rules where in universe pronouns used to refer to them is “it” but#I use them because personal rules of narrative humanity of characters.#For the same reason The Great is such a headache to right lol.#Sakugarne doesn't get gendered in anything right so#Yes quite literally an object but treat them the same as PMD characters in this AU at least

3 notes

·

View notes

Text

Mastering Welding Fabrication: A Breakdown of Essential Techniques

Welding fabrication is a vital process in manufacturing, construction, and repair industries. It involves the joining of metals through various welding techniques to create durable, robust, and high-quality structures or components. Whether it’s constructing buildings, bridges, or machinery, welding plays an essential role in almost every sector. There are numerous welding methods, each suited for different applications and materials. Understanding the types of welding fabrication helps in choosing the appropriate method for specific projects, ensuring quality, safety, and cost-effectiveness.

In this article, we’ll explore some of the most common types of welding fabrication, their applications, and their advantages and disadvantages.

1. Arc Welding

Arc welding is one of the most widely used welding processes in the industry. It works by using an electric arc to create heat, which melts the metal at the joint between two workpieces. Once cooled, the metals are fused together, forming a strong bond.

Types of Arc Welding:

Shielded Metal Arc Welding (SMAW): Also known as stick welding, this method uses a consumable electrode coated in flux. When the electrode melts, it creates a weld, and the flux coating burns off, creating a protective gas shield to prevent contamination. SMAW is versatile and can be used on various metals like steel, iron, and aluminum, making it suitable for heavy-duty tasks like building construction and shipbuilding.

Gas Metal Arc Welding (GMAW): Commonly known as MIG welding, this method uses a continuous wire feed as an electrode. The welding area is shielded from contamination by an external gas, such as argon or carbon dioxide. MIG welding is favored for its speed and ease of use and is typically employed in automotive and manufacturing industries.

Gas Tungsten Arc Welding (GTAW): Also called TIG welding, this method uses a non-consumable tungsten electrode and a shielding gas, typically argon, to protect the weld from contamination. TIG welding is known for producing high-quality, precise welds and is often used for welding thin materials like stainless steel and aluminum.

Flux-Cored Arc Welding (FCAW): Similar to MIG welding, FCAW uses a continuous wire feed, but the wire is flux-cored, eliminating the need for external shielding gas in some applications. It’s commonly used for outdoor or heavy-duty work, such as construction and shipbuilding.

2. Oxy-Fuel Welding

Oxy-fuel welding, also known as gas welding, is one of the oldest forms of welding. It uses a combination of oxygen and a fuel gas, typically acetylene, to produce a flame that melts the metal at the joint. This method is suitable for welding ferrous and non-ferrous metals and is widely used in small-scale fabrication and repair work.

Advantages:

Portable and inexpensive equipment.

Versatile, can also be used for cutting metals.

Disadvantages:

Slow welding process.

Limited to thin materials, not suitable for heavy-duty tasks.

3. Resistance Welding

Resistance welding is a process where heat is generated through the resistance of the materials being joined to the flow of electric current. The pressure is applied to fuse the materials together, making it a fast and efficient method for mass production.

Types of Resistance Welding:

Spot Welding: One of the most common types of resistance welding, spot welding is typically used to join two metal sheets by applying pressure and heat to localized areas (or “spots”). It’s widely used in the automotive industry to fabricate car bodies and other sheet metal products.

Seam Welding: Seam welding is similar to spot welding but involves a continuous weld along a seam, making it ideal for applications that require leak-tight seals, such as fuel tanks and pipes.

4. Plasma Arc Welding

Plasma arc welding (PAW) is a precision welding process that uses a high-velocity jet of ionized gas (plasma) to melt and fuse metals. It is similar to TIG welding but provides more control and higher precision, making it ideal for applications that require intricate and detailed welds, such as aerospace and medical device manufacturing.

Advantages:

High level of precision and control.

Suitable for thin materials and complex shapes.

Disadvantages:

Requires specialized equipment and highly skilled operators.

Slower process compared to other welding methods.

5. Electron Beam Welding

Electron beam welding (EBW) is a high-energy welding process that uses a focused beam of electrons to melt and join materials. It’s performed in a vacuum to prevent electron scattering, resulting in extremely precise and high-quality welds. EBW is used in industries like aerospace, automotive, and electronics, where precision is critical.

Advantages:

Produces clean, high-quality welds with minimal distortion.

Suitable for thick materials and deep welds.

Disadvantages:

Expensive equipment and setup.

Limited to applications that can be performed in a vacuum.

6. Laser Beam Welding

Laser beam welding (LBW) uses a concentrated laser beam to melt and join materials. This method is highly accurate and fast, making it ideal for automated welding processes in industries like automotive and electronics manufacturing. It can weld thin materials with minimal heat input, reducing distortion.

Advantages:

High welding speed and precision.

Minimal heat-affected zone.

Disadvantages:

High initial equipment cost.

Limited to thin materials.

7. Ultrasonic Welding

Ultrasonic welding is a solid-state welding process that uses high-frequency ultrasonic vibrations to create frictional heat between the materials being joined. This method is commonly used for plastics but can also be used for metals. It’s widely applied in the electronics, automotive, and medical industries for welding components without using external heat or adhesives.

Advantages:

Fast, clean, and precise.

Ideal for materials sensitive to heat.

Disadvantages:

Limited to small, thin components.

Requires specialized equipment.

8. Orbital Welding

Orbital welding is a specialized form of automated welding, typically used for joining pipes or tubes. The process involves a welding head that rotates around the stationary pipe, allowing for a continuous and precise weld. Orbital welding is primarily used in industries where high-quality, repeatable welds are essential, such as aerospace, pharmaceuticals, nuclear, and semiconductor manufacturing.

Advantages:

Produces highly consistent and precise welds.

Ideal for clean environments and industries with stringent standards, like pharmaceuticals and semiconductors.

Disadvantages:

Requires specialized, expensive equipment.

Setup can be complex and time-consuming.

Conclusion

Welding fabrication is a diverse and essential process in various industries, each method offering unique advantages suited to specific applications. Whether it’s the simplicity and versatility of arc welding, the precision of TIG or laser welding, or the speed of resistance welding, the right technique depends on factors like material type, joint design, and project scale.

Understanding these different types of welding fabrication through expert training courses allows manufacturers, engineers, and fabricators to choose the most appropriate method, ensuring that their projects are efficient, durable, and cost-effective.

#orbital welding training#orbital welding technology#welding technology#welding types#orbital welding courses

0 notes

Text

Welding Machine Specialists: Alphaweld’s Top-Performing Models

When it comes to high-quality welding machines, Alphaweld stands out as a trusted supplier. With a focus on performance, reliability, and innovation, Alphaweld offers a diverse selection of top-performing models from some of the leading brands in the industry. Whether you're a professional welder or a DIY enthusiast, Alphaweld has the right welding machine to suit your needs.

Why Choose Alphaweld for Your Welding Machines?

Alphaweld is renowned for its expertise in welding equipment, providing customers with access to high-performance welding machines that deliver consistent results. Here’s why you should consider Alphaweld for your welding needs:

Expert Knowledge: The team at Alphaweld comprises welding specialists who understand the intricacies of various machines. They can help guide you to the best model for your specific applications.

Quality Brands: Alphaweld exclusively stocks products from reputable brands known for their reliability and advanced technology.

Wide Selection: With a comprehensive range of welding machines, customers can find everything from entry-level models to advanced industrial machines.

Top-Performing Welding Machine Models at Alphaweld

Alphaweld features a variety of high-performance welding machines from trusted brands. Here’s a look at some of the top models you can find at Alphaweld:

1. Lincoln Electric Power MIG 210 MP

The Lincoln Electric Power MIG 210 MP is a versatile welding machine that combines multiple processes into one compact unit. Here are some of its standout features:

Multi-Process Capability: This machine can perform MIG, TIG, and stick welding, making it suitable for a wide range of applications.

Portability: Weighing just under 40 pounds, it's easy to transport, perfect for both shop and fieldwork.

User-Friendly Interface: The intuitive display and easy-to-use settings allow beginners and experienced welders alike to achieve excellent results.

2. Unimig Viper 140

The Unimig Viper 140 is a fantastic choice for those looking for an affordable yet high-performing welding machine. Its key features include:

Lightweight and Compact Design: Weighing only 13.5 kg, it’s easy to carry, making it ideal for mobile welding applications.

MIG Capabilities: Perfect for light fabrication and home projects, it provides solid welds on various materials.

Adjustable Settings: Users can easily adjust the voltage and wire speed to suit different welding tasks.

3. Miller Multimatic 215

The Miller Multimatic 215 is a top-of-the-line welding machine that offers unmatched versatility. It’s perfect for welders who work on diverse projects. Key features include:

All-in-One Functionality: Capable of MIG, TIG, and stick welding, making it a great option for varied applications.

Auto-Set Technology: This feature simplifies setup, automatically adjusting settings based on material type and thickness.

Compact and Portable: Weighing just 50 pounds, it’s designed for easy transport without sacrificing performance.

4. ESAB Rebel EMP 215ic

The ESAB Rebel EMP 215ic is an advanced welding machine known for its powerful performance and portability. Its features include:

Multi-Process Welding: Capable of MIG, TIG, and stick welding, it handles any job with ease.

Intuitive User Interface: The color display and clear menus make it user-friendly for all skill levels.

Durability: Built to withstand tough working conditions, it’s a reliable choice for both professionals and hobbyists.

5. Fronius TransPocket 150

For those needing high-precision stick welding, the Fronius TransPocket 150 is an excellent option. Here’s what sets it apart:

Compact and Lightweight: Its portable design makes it easy to transport to job sites.

Superior Arc Stability: The innovative technology provides a stable arc for clean and consistent welds.

Versatile Applications: Perfect for various materials and thicknesses, making it ideal for many industrial tasks.

How to Choose the Right Welding Machine for Your Needs

Selecting the right welding machine can seem daunting, but focusing on a few key factors can help:

Welding Process: Determine which type of welding (MIG, TIG, or stick) you will primarily be doing.

Material Types: Consider the materials you’ll be working with, as some machines are better suited for specific materials or thicknesses.

Portability: If you plan to work in different locations, choose a lightweight and portable model.

Expert Support and Service at Alphaweld

Alphaweld prides itself on providing exceptional customer service and support. Their team of welding specialists is always available to answer questions, provide recommendations, and assist with any issues related to your welding machine. Furthermore, Alphaweld offers comprehensive after-sales support to ensure your welding machine remains in top condition throughout its lifespan.

Conclusion

Alphaweld is your go-to source for high-performance welding machines that deliver reliability and efficiency. Featuring top-performing models from Lincoln Electric, Unimig, Miller, ESAB, and Fronius, you can trust that you’re making a smart investment in your welding capabilities. Visit Alphaweld today to explore their extensive range of welding machines and find the perfect model to elevate your welding projects!

1 note

·

View note

Text

What Makes a TIG Welder the Best Option for Welding Aluminum?

When it comes to welding aluminum, choosing the right welding method is crucial for achieving high-quality results. Aluminum is a popular material in various industries due to its lightweight nature and resistance to corrosion. However, welding aluminum can be challenging because of its unique properties. This is where a TIG welder, or Tungsten Inert Gas welder, comes into play. A TIG welder machine offers precise control, making it the preferred choice for welding aluminum. In this article, we will discuss why a TIG welder is considered the best option for welding aluminum, covering important aspects that make it stand out.

Why is Precision Important in Welding Aluminum?

Aluminum is a highly conductive material, which means it heats up quickly and can also cool down fast. This rapid change in temperature can lead to warping and distortion if not handled correctly. A TIG welder provides precise control over the welding process, allowing you to manage heat input effectively. This precision helps in minimizing the chances of warping and ensures a clean and strong weld. The best TIG welder machines come with adjustable amperage settings that let you fine-tune the heat according to the thickness of the aluminum being welded, ensuring optimal results.

How Does a TIG Welder Provide Better Control Over the Weld?

One of the main reasons a TIG welder for sale is preferred for welding aluminum is the level of control it offers. With a TIG welder machine, you can control the heat, speed, and amount of filler material used during the welding process. This control is essential for creating high-quality welds, especially when working with thin sheets of aluminum. The foot pedal on many TIG welders allows you to adjust the heat output in real time, providing more control compared to other welding methods. This feature is particularly useful for avoiding burn-through or overheating, which can damage the aluminum.

What Role Does the Inert Gas Play in TIG Welding Aluminum?

TIG welding uses an inert gas, typically argon, to shield the weld area from atmospheric contamination. This shielding gas is crucial when welding aluminum because it prevents oxidation and contamination, which can lead to weak welds and defects. A TIG welder machine provides a constant flow of argon gas over the welding area, creating a clean and controlled environment. This shielding gas ensures that the weld pool remains uncontaminated, resulting in a stronger and more durable weld. When looking for a TIG welder for sale, it’s important to choose one that supports proper gas flow and coverage for aluminum welding.

Why is the TIG Welding Method Ideal for Thin Aluminum Sheets?

Welding thin sheets of aluminum requires a method that offers both precision and control to avoid overheating and burn-through. A TIG welder is ideal for this purpose because it allows for a lower heat input compared to other welding methods, such as MIG or stick welding. The ability to use a filler rod in TIG welding also provides additional control over the weld pool. This makes TIG welding suitable for delicate work and ensures that even thin aluminum sheets can be welded without damaging the material. The best TIG welder machines offer features like pulse welding, which further enhances control and precision when working with thin aluminum.

How Does the Clean Start Feature Benefit Aluminum Welding?

A clean start is essential for high-quality aluminum welding. TIG welders often come with a high-frequency start feature, which allows for a smooth arc start without touching the electrode to the metal. This clean start reduces the risk of contamination and helps maintain the quality of the weld. A TIG welder machine with a high-frequency start ensures that the arc ignites cleanly and consistently, which is particularly important when welding aluminum. This feature contributes to the overall quality and appearance of the weld, making TIG welding the preferred choice for professional and precise aluminum welding tasks.

What Should You Consider When Buying a TIG Welder for Aluminum Welding?

When looking for the best TIG welder for aluminum, there are several factors to consider:

AC/DC Capability: Aluminum welding typically requires alternating current (AC) to clean the oxide layer on the aluminum surface. A TIG welder that offers both AC and DC capabilities is ideal for versatile welding options.

Amperage Range: Choose a TIG welder machine with an appropriate amperage range that suits the thickness of aluminum you plan to weld. Having a wide range allows you to work on various projects without switching machines.

Cooling System: A good cooling system is important to prevent overheating during extended welding sessions. Look for a TIG welder with a built-in or compatible water cooler for longer-lasting performance.

Ease of Use: Features like a user-friendly interface, clear controls, and a foot pedal for amperage adjustment make the welding process more manageable, especially for beginners.

How Does the TIG Welding Technique Improve Aluminum Weld Quality?

The TIG welding technique is known for producing high-quality welds that are both strong and aesthetically pleasing. This technique offers a clean and precise weld bead with minimal spatter, making it ideal for projects where appearance matters. Using a TIG welder machine, you can create welds that are smooth and free of defects, which is important for both structural integrity and visual appeal. When looking for a TIG welder for sale, opting for a machine that offers advanced features like pulse control can further enhance the quality of aluminum welds.

Conclusion: Why TIG Welding is the Best Option for Aluminum

TIG welding is the preferred method for welding aluminum due to its precision, control, and ability to produce high-quality welds. The use of an inert gas shield, combined with the fine control over heat and filler material, makes TIG welding ideal for both thin and thick aluminum applications. Whether you are a beginner or an experienced welder, using the best TIG welder machine ensures that you can achieve clean, strong, and visually appealing aluminum welds. By understanding the unique benefits of TIG welding, you can make an informed decision when selecting a TIG welder for your aluminum welding needs.

0 notes

Text

Robotic Welding Market: Breakthrough & Forecast

Welding robots can perform complicated tasks and provide superior output quicker than human workers. They are developed by combining welding, robotics, artificial intelligence, control systems, and sensor technology. These robots’ operational excellence, along with increased productivity, contribute to their demand.

Industry 4.0 Implementation bolsters Welding Robot Deployment

Industry 4.0 has revolutionized the manufacturing sector by equipping it with advanced technology, thus leading to enhanced productivity, flexibility, quality, and speed. Manufacturers are now shifting towards the adoption of intelligent and networked Industry 4.0-compatible robots incorporated with wireless connectivity, sensors, and a centralized control system.

Additionally, players in the robotic welding market are also focusing on introducing such solutions to the market. For instance, in March 2020, Roboteco Italargon developed a robotic welding cell for its client Steel Tech, to increase production and ensure interconnection within all stages of the manufacturing process. The cell is comprised of a TIG arc welding solution and an Industry 4.0 kit to enable easy data exchange for efficient interconnection.

Automotive & Transportation Sector Leads the Way

The automotive & transportation sector is the leading industry vertical in the robotic welding market, which accounted for the highest revenue share of $4172.27 million in the segment in 2021.

The rising demand for vehicles and efficient infrastructure has compelled the automotive & transportation sector to enhance production and construction activities. Being at the forefront of embracing technological innovations, it has largely adopted robotic welding arms to boost the accuracy and speed of the vehicle-building process. In fact, from 2018 to 2023, the use of welding robots in this sector increased with a CAGR of 8.91%.

What makes the Asia-Pacific a leader in the Global Market?

The Asia-Pacific robotic welding market is the leading region globally. It accounted for $8767.11 million in 2021 and is estimated to gain $7985.35 million by 2028.

According to the International Federation of Robotics (IFR) , Asia accounted for 71% of all newly deployed industrial robots in 2020, with 168,400 units installed in China itself. Moreover, India, China, Japan, and South Korea are among the leading automobile manufacturers in the world. The presence of a robust automotive industry has enhanced the adoption of welding robots in the Asia-Pacific.

Besides, Japan is home to several leading market players, including Yaskawa Electric Corp, Hyundai Motor, Nachi-Fujikoshi Corp, Kawasaki Heavy Industries Ltd, and others, which are focused on devising growth-driven strategies. For instance, in March 2022, Nachi-Fujikoshi Corp launched its MZ F series comprising high-speed and high-precision robots, driven by the need to tackle labor shortage.

Further, in July 2022, Daihen Corporation developed a new welding arc called Plasma Jet TIG, which is optimal for joining main components such as stator coils of motors used in electric vehicles. Also, in August 2022, Yaskawa Electric Corp launched its new lineup of Motoman-HC30PL welding robots, with a 30 kg payload capacity for palletizing applications.

Along with these factors, the implementation of major manufacturing initiatives such as ‘Made in China 2025’ and ‘Make in India’ is expected to aid the adoption of robotic welding systems, thus positioning the region’s market on a growth path.

Capitalizing Future Tech

Currently, operators are required to program welding robots before deploying them for a process. However, with advancements in technology, they may only need to think about the desired task to be performed by the robot. In February 2019, researchers at the University of Illinois Urbana-Champaign developed an EEG-based cap that converts brain waves into operational instructions for robotic welding arms.

If used for industrial applications, this breakthrough development could eliminate the need for computer programming and also reduce the time taken for training the personnel. Though the complete development and adoption of such mind-controlled robots may still take several years, it creates positive prospects for the future of the global robotic welding market.

FAQs:

Q 1) Which region is expected to show the fastest growth in the global market?

North America is expected to grow the fastest in the global market, with a CAGR of 8.99% during the forecast period.

Q 2) Which are the different types of welding covered in the market report?

The global robotic welding market by welding type includes spot, plasma, arc (TIG, MIG), laser, and other welding types.

Q 3) What is a key challenge in the path of market growth?

The high costs for installing and maintaining welding robots are a key market challenge hindering their adoption.

0 notes

Text

A Study of Leading MIG Welding Machine Manufacturers in India

The Indian industry is booming and welding technology is playing a vital role in its growth. Among the various welding techniques, MIG (Metal Inert Gas) welding stands out for its efficiency and versatility. In this article, we explore the top mig welding machine manufacturers in India, explore the benefits of MIG welding and highlight how these manufacturers are shaping the industry. Additionally, we cover TIG welding equipment manufacturers and the wider landscape of welding product manufacturers in India.

Understanding MIG Welding

MIG welding, also known as Gas Metal Arc Welding (GMAW), uses a continuous wire electrode that is passed through a welding gun, creating an arc that melts the wire and joins the metals. The process is protected by an inert gas, usually argon or a mixture of argon and carbon dioxide, which protects the weld from impurities. This technology is popular due to its high productivity, ease of use and compatibility with different materials such as stainless steel, aluminium and carbon steel.

Best MIG Welding Equipment Manufacturers in India

1. weldarc India

Weldarc India is a leading welding products manufacturer in India, known for its advanced MIG welding equipment. Their products are designed to meet the diverse needs of industries from automotive to construction. Weldarc India MIG welding machines are known for their precision, durability and user-friendly features, making them the best choice for professionals.

2. Ador Welding Ltd.

Ador Welding Ltd. has been a major player in the Indian welding market for decades. Their MIG welding machines are known for their robust design and consistent performance. Ador Welding's commitment to innovation and quality has earned it a loyal customer base in various industries.

3. ESAB India

A subsidiary of global welding giant ESAB, ESAB India offers a wide range of MIG welding equipment. Known for cutting-edge technology and reliability, ESAB MIG welding equipment is preferred by industries that require high-quality welding solutions. Their machines are designed to produce excellent welds with minimal spatter and excellent arc stability.

4. Kemppi India

As part of Finnish welding equipment manufacturer Kemppi, Kemppi India supplies state-of-the-art MIG welders. Kemppi's focus on advanced technology and user-oriented design ensures that their MIG welding machines are efficient and easy to use. Their products are widely used in heavy engineering, shipbuilding and manufacturing.

5. Panasonic Welding Systems India

Panasonic Welding Systems India offers a wide range of MIG welding equipment known for its reliability and efficiency. Panasonic's commitment to research and development has led to the creation of innovative welding solutions that meet the changing needs of the industry. Their machines are popular for their energy efficiency and precision.

Advantages of MIG Welding

MIG welding has several advantages that make it the preferred choice in many industries:

Speed and Efficiency: MIG welding is faster than traditional welding methods, which increases productivity .

Versatility: Suitable for welding a variety of materials, including thin and thick metals.

Ease of Use: MIG welding is relatively easy to learn, making it accessible to novices.

Clean welds: Creates cleaner welds with minimal spatter, reducing post-welding.

TIG welding equipment manufacturers in the spotlight

While MIG welding is popular, TIG (Tungsten Inert Gas) welding also has an important position in the industry. TIG welding is known for its precision and quality welds, making it ideal for critical applications.

Top TIG welding machines in India:

Weldarc India: weldarc India not only excels in MIG welding machines but also offers state of the art TIG welders. Their TIG welding machines are designed for precision welding and to serve industries that require high-quality welds, such as aerospace and electronics.

Rilon Welding: Rilon Welding is known for its advanced TIG welding machines that combine technology and durability. Their machines are used in a variety of applications from light manufacturing to heavy industrial welding.

Hi Tech Welding: Hitech Welding offers a variety of TIG welding equipment known for its efficiency and reliability. Their products are designed to produce precise welds, making them a favourite among professionals.

Manufacturers of welding products in India

The Indian welding industry is supported by a strong network of welding manufacturers. These companies provide the consumables and accessories needed to ensure smooth welding.

Famous manufacturers of welding products:

Ador Welding Ltd.: In addition to welding machines, Ador Welding Ltd. manufactures a wide range of welding accessories including electrodes, wires and flux.

DandH Sécheron: DandH Sécheron is a leading manufacturer of welding accessories in India and offers a variety of products suitable for various welding processes.

Diffusion Engineers: Diffusion Engineers specialise in the supply of welding accessories and wear-resistant products, ensuring the longevity and efficiency of welding operations.

Conclusion

The Indian welding industry is growing and leading manufacturers such as weldarc India, Ador Welding Ltd., ESAB India, Kemppi India and Panasonic Welding Systems India are driving innovation and quality. MIG welding remains the cornerstone of this industry, offering many advantages for a variety of applications. Additionally, the presence of well-known TIG welding machine and welding product manufacturers provides the industry with the support and resources it needs to succeed.

By choosing the right MIG welding machine, the industry can improve its productivity and achieve quality welds. Committed to excellence and innovation, weldarc India continues to be a trusted partner to companies across the country. Be it MIG or TIG welding or a wide range of welding products, Indian manufacturers are well equipped to meet the demands of a dynamic and evolving industry.

#MIG welding machine manufacturers#TIG welding machine manufacturers#welding products manufacturer in India#MIG welding benefits#top welding machine manufacturers in India#Weldarc India#Ador Welding Ltd.#ESAB India#Kemppi India#Panasonic Welding Systems India#welding industry in India#MIG vs TIG welding#welding technology

0 notes

Note

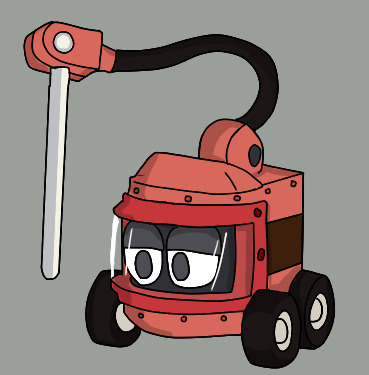

You'd be sad too if you were built for fixing and building and some egomaniac reprogramed you for destroying.

His heart just ain't in it.

Also, apparently their official name is Arc Weldy.

Do the welderbots in Megaman 11 always look rather sad to you?

They do kinda have eyelids tilted that way to look a bit sad, yeah.

3 notes

·

View notes

Photo

https://www.deviantart.com/beekirby/art/mega-friends-857511534

mega man enemies...good

#mega man#mega man classic#shotman#adhering suzy#octopus battery#bunby heli#mambu#telly#ring ring#peterchy#crazy razy#nombrellan#arc weldy#pointan#droppy#mizzile#mettaur#metool#metall#mega man 1#mega man 2#mega man 3#mega man 4#mega man 5#mega man 9#mega man 10#mega man 11#i'm going to tag all of them. they all deserve to be tagged#shoutout to crazy razy fans#fanart

306 notes

·

View notes

Text

2019 Megaman Valentine’s Day (Humor) Contest Results!

Apologize for the delay on this once again. Didn’t expect to be posting these results nearly a month after Valentine’s Day, but the extended deadline did help make sure we got a healthy competition this year. Thank you to all for your patience!

I’m going to start out this year’s results thread with a totally appropriate callout 4-Koma that is not technically an official humor entry from SubzeroIceSkater, even though it fit the rules. But it’s worth posting, to publicly humiliate myself anyways:

I'll take my token Akane-in-an-entry bribery any way I can get it, since nobody felt inclined to draw Mrs. Stelar’s fresh, piping hot, iced cinnabuns for their talent entry this year...Did I just type that? I mean, um...

Play me off, Johnny!

I kid, I kid! After all, these contests aren’t about me, it’s about the characters you love and want to draw. And that’s what makes everyone’s entries unique and helps motivate you to create time after time. And I am grateful for it, whether you are a long-time participant, or the yearly new contestant.

I’ll be doing things a little different this year, because the post would be way too long if I kept everything in one. So this first post will just contain the Humor category, and I will have a second, separate post for the Talent category. Raffle prize winners will be contained in both posts, so keep an eye out after my commentary on your art, for some possible winners here. The rest will follow soon. I’ll be contacting all winners soon enough, so sit tight!

Here are your humor winners and full gallery of entries, after the break!

Category 2 (Humor) - Princess Sigmia Returns

A much smaller group of entries for this category, but the zany mergers were great, all the same. I thank you all for getting as creative as you could with this concept, as it was a little more than just a mere gender swap you had to consider, when designing your combined character. Whether you won or not, know I truly enjoyed seeing all of these pics.

I know imgbox gallery gave people some issues before, so as always, let me know if images or links appear broken. Crossing my fingers this works smoothly this year! XD

After each entrant’s name, there will be a link in the character description to the entry, too, just in case the inserted external images don’t load for you.

[Full humor gallery]

1.) SubzeroIceSkater - Arc Weldy Falls In Love (featuring Tundroll.EXE the Arc Weldy, plus ‘Master Albert’)

[Page 1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] [21]

Comics with length and substance always seem to steal the show, and this year was no different. Joining the ranks of fenril-huayra, wintesm and so many others in recent years, I believe SubzeroIceSkater’s wonderful tale will stick with many of you, as much as it did me. As a humor piece, sure there are great sight gags and comedic lines all around, but it also has a lot of heart. You feel really bad for Arc Weldy to start out, but also feel so many emotions of compassion, friendship and love throughout. Wonderful work, and thank you for all the effort you put into this massive entry!

Also, are 21 pages not enough for you all? Well, SubzeroIceSkater also had ANOTHER 15 pages worth of ideas, alternates, and outtakes to go with this comic. And, while I won’t upload each link or image here, because this one entry is long enough, you can see them in THIS GALLERY LINK. They are also really great.

*For coming in 1st, SubzeroIceSkater has won $100 via Paypal, or a prize of their choice up to that value.*

2.) @drewblossom - Geminette

Nearly equally deserving in length, Drew’s comic more closely followed the Bowsette-style transformation gimmick to give Snake Man his comeuppance. The classic bait-and-switch kiss, turned on it’s head with a ‘lil Search Snake rather than a gross Toad Man, was a funny end.

Design-wise, I really liked what you did to create Geminette’s look. Splitting his helmet crystals to the side as like dual hair broaches, and keeping the motif with the choker, armband, garter straps and chestplate, worked out nice. I can see why Snake was so easily charmed.

*For coming in 2nd, Drew has won $50 via Paypal, or a prize of their choice up to that value.*

3.) @wimzik - Rollbble.EXE

If dominatrix Devil Roll wasn’t enough of a pain in Rockman’s side, I shudder to think how bad a Bubble Roll would be, puku! Or, would her devotion to him be as great (or clingy) as Bubs was with Shademan-sama?

Taking Bubbleman’s yellow flipper feet motif, and turning it into a fish fin design, both on her feet, legs, and hair ribbon, turned out pretty neat. If anything, I’m sure this transformation gives her very kissable lips, though! XD I have to wonder what her plan is with that Roll Navi Data chip, now that the chocolate is all gone, and what it will do to Rockman?

*For coming in 3rd, wimzik has won $25 via Paypal, or a prize of their choice up to that value.*

And the remaining wonderful entries, in alphabetical order by alias:

@3-oclock-blues - Dr. Willis

What you talkin’ ‘bout, Wil-lis? Or Dr. WHY?!-ris, if you prefer. With that absolutely awesome wide-eyed grin, she’s hellbent on living together with Zero in a world where only Reploids exist. Being that they both have spent time piloting flying machine bodies, and have sorta possessed some form of an evil energy, it’s a rather fitting combo. Unless you are Zero, and it’s your dad and girlfriend merged into one being. Awk~waaaarrrd.

The skull motif and spikes are subtle on Iris’ design, but fit in really well. Her bangs are just wild enough on both sides now, that it gives that Wily hair vibe, without having to give her a horrible, bushy mustache. XD

*3-OClock-Blues is the winner of Raffle Prize #2 - The X OCW artbook and Zero keychain*

@bracedshark - Mettayer

This might be a terrible concept, but I’m going to type it. When a Met pops out from under it’s helmet, especially in sprite form, usually all you can see is the whites of it’s dark, beady eyes under that helmet, on it’s dark grey/black blobby round body form. With Layer, you don’t get to see her eyes under her bangs, hardly ever. So staring at Mettayer’s underboob for too long, due to her chest armor mimicking a Met helmet, all I see is a Met’s pair of closed bottom eyelids, and I’m seriously waiting for those eyes to open up and start staring back at me. Would that not be the most wrong way for Mettayer’s eyes to work?! But I can’t unsee it! Her belly button even feels like a snoring, sleeping Met’s mouth. I’ll spare everyone of me editing this art to make my point. But it’s in your head now, isn’t it?

OK, despite that awful paragraph, this is one hot Metall Mommy. Sorry, I’m starting this paragraph off pretty badly, too, I guess. ^^; Despite my interpretation of the combination, the design elements do stand out in a unique way. The fiery reddish-pink hair seems like a different choice considering the characters merged, but it plays off the red of a Met’s mouth and earpiece, and, well, fitting for Valentine’s, too! And instead, you get the Layer color scheme in the pickaxe, so it still connects visually.

@drewblossom’s 2nd entry - Roll n’ Rock

This bonus entry from Drew flips the genders of both DLN-001 and 002. I liked Roll’s hair bow converting into more of a bow tie, and Rock getting her version of Roll’s hoodie, in a Blue Bomber color scheme. The V-Day card concept, complete with crayon-ish name writing, made for a cute entry. Hearts all around!

@supernovabee - Bayer

No, there won’t be any paragraph about underboob eyes for this version of a Layer transformation, as supernovabee has merged her with Bass. Bayer loves belting out her hard and heavy siren song to woo prospective love interests during karaoke night.

Keeping Layer’s purple hair here actually kinda still keeps a Treble Boost feel, that the color scheme fits seamlessly, to go along with the more obvious Layer armor design pieces.

#Rockman#Megaman#Mega Man#Rock Miyabi's 2019 Megaman Valentine's Day Contest#Fanart Contest#Too many tags to list

7 notes

·

View notes

Photo

Arc Weldy is an absolute pure good boy. I love him so much in Mega Man 11.

13 notes

·

View notes

Text

Culture bottle automatic welding leak tester-cell culture bottle product features

The culture bottle automatic welding leak tester can be used for automatic feeding, automatic discharge, automatic closing, automatic welding, automatic leak detection and automatic unloading of the culture bottle.

According to different surface treatment processes, there are hydrophilic cell culture flasks (for adherent cells) and hydrophobic cell culture flasks (for suspension cells). Under the same environment, the colony formation rate and growth generation of cells cultured in Fudao cell culture flasks have reached the index of similar international products.

Product features of cell culture bottle:

1. High-quality transparent polystyrene (PS) raw material, in line with USP Ⅵ medical grade.

2. The TC-treated culture bottle is treated with ultra-vacuum plasma surface. After 48 hours of Vero cell culture, the number of cell growth has reached the level of similar products in the world.

3. The whole process of production is in a C-level purification workshop, managed in accordance with the ISO13485 quality system and produced with automated equipment, without direct contact with personnel, with good product consistency and small batch-to-batch differences.

4. Sterile, DNase-free and RNase-free. Endotoxin content ≤0.03EU/m.

5. According to different cultivation needs, there are air-permeable cover and airtight cover for option.

6. Upgrade the angle of the bottle mouth and the arc design of the bottom of the bottle to easily obtain a complete growth surface and make subsequent operations easier.

0 notes

Link

0 notes

Link

Regardless of your expertise degree, or in case you're a producer or licensed engineer, you in all probability weld commonly when performing metalwork. For people who find themselves unfamiliar with this phrase, 'welding' is the becoming a member of of metallic parts collectively, using heat created from an electrical arc. Although this is a widespread process, it's pretty complex. There is a broad vary of materials, techniques and gear that could be used. In the following textual content, we will focus on every thing to do with stud welding, together with the stud welding products, provides and tools we offer.

0 notes

Text

Miller Max 200 Welder (Pageland, SC) $2500

For sale or equivalent trade is this Miller Max 200 welder that can weld arc, mig or TIG. This unit was used less then 3 months and was tested out on 06/29/16. This unit alone sales new for just over $3000. It comes with a cart, manual and 25' weldi [...] from Craigslist http://charlotte.craigslist.org/for/6031159957.html Fraud Bloggs made possible by: http://circuitgenie.wix.com/techsupport

0 notes

Text

I know hits don't necessarily mean someone read them but it's a nice thought that someone did. Mostly I'm wondering, if they're a new reader, what made them check "Arc Weldy" out but not "Passionate Moments."

1 note

·

View note

Text

10 Fanworks Fanart in 10 minutes done in a 1000 x 1000 canvas in 1 layer and to 1 song!

Henceforth shortened to TUNDRA 11 outta 10!

Arc Weldy Falls in Love

I love the way you make me fly One shot, this is the moment We've all been waiting for, ooh

I wanted something done for International Fanworks Day and while I couldn't make it on time for the day itself (same old story :/), I still want to join somehow and hey some events run the whole weekend. I thought of a bunch ideas based on the ten (10) theme and decided on this mini prompt drawble. Dunno what exactly a "drawble" is supposed to be and searching online was no help but if a drabble is supposed to be exactly 100 words then I deca-cided to limit myself to multiples of ten as well. I always wanted to draw something short and romantic for Valenines, like a countdown of couples or ships up to the day pr maybe throughout February but...Yeah, anyway, once again, I decided on my Tundra (obviously) (forever) story ideas as a theme but my story fanart contest entries and maybe a couple of what could've beens. Onward!

2 notes

·

View notes