#Apply for plastic waste authorization

Explore tagged Tumblr posts

Text

Plastic Waste Authorization is essential for legal compliance with India’s Plastic Waste Management Rules. It ensures eco-friendly recycling, prevents fines, and promotes sustainable practices. Showcase your commitment to environmental responsibility and contribute to a cleaner planet!

#plastic waste authorization#Online plastic waste authorization#Apply for plastic waste authorization#plastic waste disposal

2 notes

·

View notes

Text

Our planet is choking on plastics. Some of the worst offenders, which can take decades to degrade in landfills, are polypropylene—which is used for things such as food packaging and bumpers—and polyethylene, found in plastic bags, bottles, toys, and even mulch.

Polypropylene and polyethylene can be recycled, but the process can be difficult and often produces large quantities of the greenhouse gas methane. They are both polyolefins, which are the products of polymerizing ethylene and propylene, raw materials that are mainly derived from fossil fuels. The bonds of polyolefins are also notoriously hard to break.

Now, researchers at UC Berkeley have come up with a method of recycling these polymers that uses catalysts that easily break their bonds, converting them into propylene and isobutylene, which are gases at room temperature. Those gases can then be recycled into new plastics.

“Because polypropylene and polyethylene are among the most difficult and expensive plastics to separate from each other in a mixed waste stream, it is crucial that [a recycling] process apply to both polyolefins,” the research team said in a study recently published in Science.

Breaking It Down

The recycling process the team used is known as isomerizing ethenolysis, which relies on a catalyst to break down olefin polymer chains into their small molecules. Polyethylene and polypropylene bonds are highly resistant to chemical reactions, because both of these polyolefins have long chains of single carbon-carbon bonds. Most polymers have at least one carbon-carbon double bond, which is much easier to break.

While isomerizing ethenolysis had been tried by the same researchers before, the previous catalysts were expensive metals that did not remain pure long enough to convert all of the plastic into gas. Using sodium on alumina followed by tungsten oxide on silica proved much more economical and effective, even though the high temperatures required for the reaction added a bit to the cost.

In both plastics, exposure to sodium on alumina broke each polymer chain into shorter polymer chains and created breakable carbon-carbon double bonds at the ends. The chains continued to break over and over. Both then underwent a second process known as olefin metathesis. They were exposed to a stream of ethylene gas flowing into a reaction chamber while being introduced to tungsten oxide on silica, which resulted in the breakage of the carbon-carbon bonds.

The reaction breaks all the carbon-carbon bonds in polyethylene and polypropylene, with the carbon atoms released during the breaking of these bonds ending up attached to molecules of ethylene. “The ethylene is critical to this reaction, as it is a coreactant,” researcher R.J. Conk, one of the authors of the study, told Ars Technica. “The broken links then react with ethylene, which removes the links from the chain. Without ethylene, the reaction cannot occur.”

The entire chain is catalyzed until polyethylene is fully converted to propylene, and polypropylene is converted to a mixture of propylene and isobutylene.

This method has high selectivity—meaning it produces a large amount of the desired product: propylene derived from polyethylene, and both propylene and isobutylene derived from polypropylene. Both of these chemicals are in high demand; propylene is an important raw material for the chemical industry, while isobutylene is a frequently used monomer in many different polymers, including synthetic rubber and a gasoline additive.

Mixing It Up

Because plastics are often mixed at recycling centers, the researchers wanted to see what would happen if polypropylene and polyethylene underwent isomerizing ethenolysis together. The reaction was successful, converting the mixture into propylene and isobutylene, with slightly more propylene than isobutylene.

Mixtures also typically include contaminants in the form of additional plastics. So the team also wanted to see whether the reaction would still work if there were contaminants. They experimented with plastic objects that would otherwise be thrown away, including a centrifuge and a bread bag, both of which contained traces of other polymers besides polypropylene and polyethylene. The reaction yielded only slightly less propylene and isobutylene than it did with unadulterated versions of the polyolefins.

Another test involved introducing different plastics, such as PET and PVC, to polypropylene and polyethylene to see if that would make a difference. These did lower the yield significantly. If this approach is going to be successful, then all but the slightest traces of contaminants will have to be removed from polypropylene and polyethylene products before they are recycled.

While this recycling method sounds like it could prevent tons upon tons of waste, it will need to be scaled up enormously for this to happen. When the research team increased the scale of the experiment, it produced the same yield, which looks promising for the future. Still, we’ll need to build considerable infrastructure before this could make a dent in our plastic waste.

“We hope that the work described … will lead to practical methods for … [producing] new polymers,” the researchers said in the same study. “By doing so, the demand for production of these essential commodity chemicals starting from fossil carbon sources and the associated greenhouse gas emissions could be greatly reduced.”

40 notes

·

View notes

Text

The hair that drops in clumps on the floors of some salons in Kiel, a port city in northern Germany, is swept up to be turned into fabrics that filter oil from water. Parents who want to buy their children cloth nappies instead of disposable ones can apply for grants of up to €200 from the local authorities. At the city’s biggest festival last year, the organisers got rid of single-use cutlery and replaced it with a deposit system.

Germany is famed as a world leader in recycling – and Kiel, as I found out during a visit this summer, has some of the most weird and workable plans in the country to deal with its trash. It is the first German city to be declared “zero waste” by the environmental campaign group Zero Waste Europe. The certificate does not mean it has already stopped throwing things away – far from it – but rather that it has a concrete plan for how to do better.

“It’s one step in the right direction,” says Bettina Aust – a Green party politician who was elected president of Kiel city council in June – over a glass of juice made from apples that had been saved from landing in a supermarket bin. “You have to keep thinking further … You cannot stay still.”

Germany has a complicated relationship with waste. Despite its status as a world leader in recycling, Europe’s biggest economy is also one of its dirtiest. In 2021, the average German generated 646kg of waste, while the average EU citizen generated 530kg. Only in four EU countries – Austria, Luxembourg, Denmark and Belgium – did people throw away more.

Dino Klösen, a manager at Kiel’s waste management company ABK, says trends in the country’s consumption can be seen in its bins. Paper recycling bins that would have once been full of newspapers are now bursting with cardboard from delivery packages. “The weight of paper waste has dropped but the volume keeps rising from online shopping,” he says.

Awash with waste, cities like Kiel are exploring ways to throw away less and recycle more of what it does chuck. The city council has announced projects ranging from a ban on single-use items in public institutions, to installing more public drinking fountains, to teaching schoolchildren about waste. It is also encouraging people to make simple changes to their behaviour such as using solid bars of soap instead of buying plastic bottles of the stuff.

Other proposals are more systemic. The city is trialling a “pay as you throw” system where people are charged only for the rubbish they throw in the mixed waste bin. A report from the European Environment Agency last year found only about 30% of Germany is covered by such a scheme, even though areas that were covered saw an average drop in mixed waste of 25%.

“General waste is the most expensive form of rubbish there is,” says Klösen. “We are trying to motivate citizens to throw less waste in the bin by making them pay less for doing so.”

Even though waste-cutting efforts like Kiel’s are fairly novel in Germany, recycling is firmly rooted in the culture. In 2021, Germans collected more than two-thirds of their municipal solid waste to be repurposed – more than any other country in Europe. They burned most of the rest for energy, and dumped just 1% in landfills (the EU average is 16%).

24 notes

·

View notes

Text

A machine learning-based approach to discover nanocomposite films for biodegradable plastic alternatives

The accumulation of plastic waste in natural environments is of utmost concern, as it is contributing to the destruction of ecosystems and is causing harm to aquatic life. In recent years, material scientists have thus been trying to identify all-natural alternatives to plastic that could be used to package or manufacture products. Researchers at University of Maryland, College Park, recently devised a new approach to discover promising biodegradable plastic alternatives. Their proposed method, outlined in a paper published in Nature Nanotechnology, combines state-of-the-art machine learning techniques with molecular science. "My inspiration for this research was sparked by a 2019 visit to Palau in the Western Pacific," Prof. Po-Yen Chen, co-author of the paper, told Tech Xplore. "The impact of plastic pollution on marine life there—floating plastic films deceiving fish and sea turtles mistaking plastic waste for food—was deeply disturbing. This motivated me to apply my expertise to this environmental issue and led to my focus on finding a solution when setting up my research lab at UMD."

Read more.

#Materials Science#Science#Machine learning#Composites#Nanotechnology#Biodegradable#Computational materials science

8 notes

·

View notes

Text

Who Is The Best Sewage Treatment Plant Manufacturer In Faridabad ?

Situated in the Southern district of Haryana, India, Faridabad is a significant industrial metropolis. Pulp & paper mills, chemical plants, & textile mills are some of the major heavy industries present here, in addition to various medium & small-sized businesses that produce plastic goods, soaps, & other items.

The natural drains & waterways surrounding Faridabad have been severely contaminated for decades by the untreatedeffluent water & sewage wastesdischarge from these companies & houses. According to research, the water in these bodies of water is unfit for human use due to dangerously high levels of contaminants such color, total dissolved solids, chlorides, sulfur compounds, & bio-chemical oxygen demand. Faridabad must therefore quickly create the most novel & expanding wastewater treatment systems.

STP Plants Need to be Built in Faridabad

Based on current estimations, the STP treatment sets' or set-up capacity & efficacy are insufficient to meet or satisfy the regulatory discharge limits for treating large quantities of complicated Sewage or effluent wastewater.

Less than 60-65% of residences in the town are linked to the sewer lines, indicating a poor level of sewage network connectivity. When the leftover raw sewage is disposed of in landfills & nearby bodies of water, groundwater becomes contaminated.

Putting into practice scientifically planned STP Plants is the most important action authorities at Faridabad can take right now to reduce its excessive water pollution & maintain both industrial & residential expansion in the years to come.

The responsibility or role of Netsol Water & COmmercial RO Plant in STP Plant functioning

Netsol Water & Commercial RO Plant are among the most rapidly emerging firm in Central India that manufactures bespoke Sewage Treatment Plants, has the potential to significantly contribute to the provision of practical & effective wastewater treatment solutions to Faridabad's municipality & industry sectors.

With the exercise of revolutionary & progressive trending technology, Netsol Water & Commercial RO Plant specializes in developing decentralized, compact STP Plants that can overcome the constraints imposed by limited acreage, inadequate drainage infrastructure, & fluctuations in incoming sewage waste quality & related flow rates.

Plans for Implementation in the Faridabad Area

With the utilization of population & industrial growth estimates, the following Sewage Treatment Plant Manufacturer in Faridabad may integrate diverse plans to developed STP Plants especially for this region:

Common STP based on cluster habitats: On the outskirts of Faridabad, related small & medium-sized enterprises such as textile, dying, & plastic products manufacture can establish industrial parks or group clusters.

With a collecting tank & an underground sewage network, Netsol Water & Commercial RO Plant may set up Centralized Common Sewage Treatment Plants with several capacities. These plants would transport wastewater from each factory to the STP for treatment prior to ultimate discharge following pollution board regulations. Individual units save money on infrastructure as a result.

Consecutive Wastewater or Sewage Treatment: Larger chemical, pulp & paper factories must implement the idea of sequential sewage treatment, which divides the plant's sewage waste streams into ports with high & low COD-BOD levels.

Primary & secondary biological treatments are applied to the high COD-BOD fraction to eliminate organics & recycle treated water for any utilization in subsequent processes. Before being discharged following all regulations, the extra Low COD-BOD sewage waste is treated by means of a tertiary process such as RO or ultra-filtration to get rid of solids, salts, & trace amounts of harmful contaminants.

Upgrading Existing Sewage treatment Plants: A considerable number of Faridabad's older, underperforming industrial STPs may be either fully reconstructed with a bigger treatment capacity by Netsol Water & Commercial RO Plant 's technical team to match the increasing sewage liquid waste flow rates & characteristics, or retrofitted with new equipment.

When ZLDP(Zero Liquid Discharge Plants) modules with Multiple Effect Evaporators & Agitated Thin Film Dryers are added, it becomes possible to recover dry soluble salts & high-quality distilled water from sewagewater that are challenging to handle.

Decentralized STP Plants for residential apartments & colonies are necessary due to Faridabad's growing urban population. These plants need to be placed in close proximity to the sewage generation source. Netsol Water & Commercial RO Plant provides small, skid base mounted STP systems powered by SBR & MBBR technologies.

Rather of relying on extensive sewer networks to treat sewage, these ready-to-install STPs may be installed close to big residential flats, housing societies, & urban villages.

Tertiary Treatment for Reuse: To produce permeate quality that satisfies recycled water quality standards for utilizations like horticulture, agriculture, construction, etc., the secondary treated sewage from STPs can be further polished using tertiary membrane filters like Ultrafiltration.

O&M(Operation & Maintenance): Netsol Water & Commercial RO Plant provides full operation & maintenance responsibility for the STP Plants they installed in Faridabad. This includes providing process chemicals, yearly maintenance contracts, equipment health checks, periodic plant audits, laboratory testing, & operator training.

This makes it possible for unattended & unassisted treatment systems to function, allowing commercial businesses & community organizations to focus on their main areas of expertize.

Conclusion

Faridabad needs an integrated strategy that combines public involvement, sustainable engineering solutions, & legislative interventions to handle the environmental disaster brought on by its unchecked development.

Netsol Water & Commercial RO Plant, a privately owned, modern facilities for wastewater treatment system manufacturer in Central India, provides complete, turnkey solutions for setting up specialized sewage treatment plant manufacturer in Faridabad region in accordance with site-specific requirements & legal requirements.

#sewage treatment plant#sewage treatment plant manufacturer in faridabad#water is life#water treatment plant#save water save life

0 notes

Text

What is Food-Grade rPET and Why Is It Important?

Definition and Uses

Food-grade rPET (recycled polyethylene terephthalate) refers to recycled PET that meets rigorous safety standards for contact with food products. It is produced from post-consumer plastic waste, recovering and repurposing bottles and containers, and offers a sustainable alternative for manufacturers and packaging companies. Typically, food-grade rPET is utilized in a wide range of applications including food and beverage packaging, containers, and various other forms of consumer products.

Importance in Reducing Environmental Impact

The use of food-grade rPET sheets significantly contributes to the reduction of environmental impact. By recycling PET, fewer raw materials, such as virgin plastic, are required, leading to decreased energy consumption and minimized waste. Furthermore, implementing rPET into the production cycle helps in reducing carbon footprints, fostering a circular economy that promotes sustainability. As companies shift toward eco-friendly packaging solutions, rPET serves as a pivotal aspect of their transition towards greener alternatives.

How Does Decontamination Work in the Production of rPET Sheets?

Vacuum Decontamination Methods

Decontamination is crucial in ensuring that food-grade rPET sheets are free from contaminants. One effective approach involves vacuum decontamination methods, which remove impurities through a series of temperature and pressure adjustments. By applying heat under vacuum conditions, volatile organic compounds and other contaminants are effectively vaporized, ensuring the integrity of the recycled material. This not only enhances the quality but also ensures compliance with food safety regulations.

Solid-State Polycondensation (SSP) Procedures

In addition to vacuum methods, solid-state polycondensation (SSP) is utilized to further purify rPET. This process involves heating the recycled flakes under specific conditions that promote the removal of remaining contaminants, ultimately increasing the intrinsic viscosity of the material. The result is a higher-quality food-grade rPET that meets or exceeds regulations set forth by food safety authorities. Incorporating both vacuum decontamination and SSP in the production process significantly enhances the purity of the final product.

The Role of Extrusion in Ensuring Purity

Single-Screw Extruder Functions

Extrusion plays an essential role in transforming decontaminated rPET flakes into usable sheets. Single-screw extruders effectively mix and melt the material, allowing for a thorough integration of additives that further enhance the performance of food-grade rPET sheets. This process ensures a homogenous product devoid of any impurities, achieving the necessary specs for food-contact applications.

Melting and Conveying Process at High Temperatures

During the melting and conveying stages, temperatures must be optimized to facilitate the removal of any residual contaminants. This high-temperature processing not only ensures that any remaining impurities are eradicated but also assists in achieving the desired viscosity and flow characteristics for the food-grade rPET sheets. The high temperatures combined with efficient conveying infrastructure lead to the production of a clean and reliable end product.

Advanced Filtration Techniques for Food-Grade rPET

Types of Filtration Used

To achieve the desired purity of food-grade rPET sheets, advanced filtration techniques are employed throughout the production process. Various filtration technologies such as melt filters, screen changers, and fine filtration systems are utilized. These systems are critical in removing micro-contaminants, additives, and other particulate matter from the rPET melt.

Effectiveness in Removing Micro-Contaminants and Additives

The effectiveness of these filtration techniques ensures that the final food-grade rPET sheets maintain high standards of cleanliness. As contaminants are removed at multiple stages in the production cycle, the material's quality is significantly improved. This rigorous approach to filtration supports compliance with health and safety standards necessary for food contact materials, reinforcing the overall value of using food-grade rPET sheets in packaging applications.

For those seeking a reliable partner in food-grade packaging solutions, Intco Plastic offers exceptional products, including their Food-grade R-PET Sheet, which has been certified by the appropriate food safety authorities.

As the market moves towards sustainability and environmental awareness, utilizing food-grade rPET not only serves a functional purpose but also aligns with your commitment to reducing plastic waste. The solution offered by Intco Plastic may streamline your packaging operations while ensuring adherence to all safety regulations.

Washing and Pre-Treatment Processes: Ensuring a Clean Start

Initial Washing Steps

The initial washing steps are pivotal in removing significant surface contaminants from post-consumer PET materials. This phase typically involves several mechanical processes such as rinsing, soaking, and agitating the shredded PET flakes in water to dislodge foreign materials. Labels, lids, and rings can often cling to the surface and must be removed thoroughly to ensure high-quality end products. By executing these washing procedures effectively, the foundation for producing clean food-grade rPET sheets is established, thus paving the way for subsequent treatments.

Removing Labels, Lids, and Rings

Label and lid removal occurs during the washing step and is critical for quality. The adhesives used in labels can pose a risk of contamination, while lids and rings can impede the recycling process. Therefore, specialized equipment such as label removers and centrifugal washing systems are utilized. These machines employ mechanical agitation to ensure that all recyclable components are stripped away, leaving a clean substrate suitable for further processing.

Chemical Treatments for Additional Safety

Once the physical contaminants have been eliminated, chemical treatments are employed to enhance the safety and reliability of the recycled material. Various detergents and cleaning agents are applied to dissolve any remaining contaminants that mechanical washing may not have addressed. This chemical washing process is crucial in ensuring that any residues, odors, or chemical traces are removed. Such treatments are especially important for food-grade applications, as even minute contaminants could compromise product safety and quality.

Addressing Challenges in Producing High-Quality Food-Grade rPET

Quality of Postconsumer Scrap Materials

The quality of postconsumer scrap materials significantly impacts the production of high-quality food-grade rPET sheets. Variability in the source of recycled materials can introduce impurities that affect the final product's properties. By carefully sorting and categorizing the incoming materials, manufacturers can minimize risks associated with inferior-quality inputs. It’s essential to implement a stringent quality control process during the collection and segregation phases to ensure that only suitable materials proceed through the production pipeline.

Steps to Improve Material Performance and Consistency

To enhance the performance and consistency of food-grade rPET sheets, manufacturers often go through various upgrading procedures. Integrating advanced sorting technologies and purification methods can lead to uniform quality in the raw materials. Additionally, investing in training and operational best practices can help staff effectively manage the sorting and cleaning processes. Recognizing the importance of these steps will not only elevate the end user's experience but also foster trust in the sustainability claims associated with these products.

Integrated Solution for High-Quality Food-Grade Recycled PET Sheets

For manufacturers aiming to achieve a quality guarantee in their food-grade rPET efforts, integrating advanced processing technologies can provide a powerful advantage. Adopting a comprehensive approach that includes not only washing and chemical treatments but also state-of-the-art filtration techniques ensures all contaminants are addressed thoroughly. This solution can drive efficiency and reduce variability in the end product. As outlined by Intco Plastic, their integrated solutions are designed specifically to meet the rigorous standards required for food-grade applications.

Choosing the Right Manufacturer for Your rPET Needs

Selecting a reliable manufacturer for food-grade rPET sheets is essential to ensuring your products meet high safety and quality standards. Engaging with companies that prioritize compliance with FDA and EFSA regulations will provide you peace of mind. It's advisable to assess manufacturers' certifications and their commitment to sustainable practices. Companies like Intco Plastic not only deliver high-quality Food Grade Recycled PET Sheet solutions but also emphasize on sustainable materials made from recycled inputs. This commitment reflects their understanding of both environmental responsibility and the priorities of today’s packaging landscape.

Conclusion

When it comes to the production process of food-grade rPET sheets, eliminating all contaminants is crucial. From the initial washing and chemical treatments to addressing challenges with postconsumer scrap material quality, the steps taken will ultimately influence the integrity of the final product. By partnering with manufacturers that provide integrated solutions and uphold stringent compliance standards, you can achieve a high-quality, sustainable product fit for food contact applications. Embracing these methods not only enhances your operational efficiency but also solidifies your dedication to environmental sustainability.

0 notes

Text

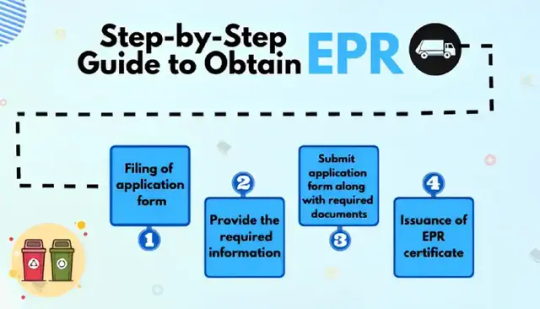

EPR Registration in India: A Comprehensive Guide

As environmental concerns grow worldwide, the concept of Extended Producer Responsibility (EPR) has gained significant traction in India. EPR is a policy approach that holds producers responsible for the entire lifecycle of their products, including waste management. This article will explore the importance of EPR registration in India, the registration process, and how businesses can comply with these regulations to promote sustainability.

Understanding EPR and Its Significance

Extended Producer Responsibility is designed to encourage manufacturers to take responsibility for their products beyond the point of sale. The primary objectives of EPR include:

Reducing Waste: EPR helps minimize waste generated from products by encouraging manufacturers to design for recycling and reuse.

Promoting Sustainability: By implementing sustainable practices, producers can reduce their environmental impact.

Encouraging Recycling: EPR facilitates the establishment of recycling programs, ensuring that waste is managed efficiently.

In India, the implementation of EPR is crucial, especially in sectors like plastic, electronics, and packaging, where waste generation is high.

The Need for EPR Registration in India

EPR registration is essential for producers and importers to comply with regulations set by the government. Here are a few reasons why EPR registration in India is necessary:

Legal Compliance: EPR registration ensures that businesses adhere to the rules laid down by the Ministry of Environment, Forest, and Climate Change (MoEFCC) in India.

Access to Markets: Companies that comply with EPR requirements are more likely to gain trust and access to various markets.

Corporate Social Responsibility: EPR aligns with CSR initiatives, demonstrating a company's commitment to environmental sustainability and responsible business practices.

The EPR Registration Process in India

The process of obtaining EPR registration in India involves several steps. Here’s a detailed look at the process:

Step 1: Assess Eligibility

Before applying for EPR registration, producers must determine their eligibility. Manufacturers, importers, and brand owners engaged in the production and sale of goods covered under EPR regulations need to register.

Step 2: Prepare Required Documents

The following documents are typically required for EPR registration in India:

Proof of identity (Aadhar card, passport, etc.)

Business registration documents

Details of the products being manufactured or imported

A waste management plan outlining how the waste will be handled

Step 3: Submit Application

Once the necessary documents are gathered, businesses must submit their application to the Central Pollution Control Board (CPCB) or the relevant State Pollution Control Board (SPCB). The application must include all required information, such as:

The type of waste generated

The amount of waste the company commits to managing

Details of the waste management systems in place

Step 4: Pay Fees

After submitting the application, the next step is to pay the required registration fees. The fee structure may vary based on the type of product and the scale of operations.

Step 5: Await Approval

Upon submission, the concerned authorities will review the application. If all criteria are met, the applicant will receive EPR registration, which must be renewed periodically as per government regulations.

Challenges in EPR Registration

While EPR registration is essential, companies may face several challenges during the process:

Lack of Awareness: Many businesses are unaware of the EPR requirements and the registration process.

Complex Regulations: The regulatory framework can be complex, making it difficult for companies to navigate the requirements.

Resource Allocation: Companies may struggle to allocate resources for waste management and compliance efforts.

How Bhoomi Environmental Services Can Help

Navigating the EPR registration in India process can be daunting for many businesses. That's where Bhoomi Environmental Services comes in. With extensive experience in environmental consulting, we provide the following services:

Consultation: Our experts will guide you through the EPR registration process, ensuring you understand all requirements and steps involved.

Documentation Support: We assist in preparing and reviewing all necessary documents, reducing the chances of delays or rejections.

Compliance Monitoring: Bhoomi Environmental Services offers ongoing support to help you remain compliant with EPR regulations and updates.

Conclusion

There fore, EPR registration in India is a crucial step for businesses looking to contribute to environmental sustainability and comply with legal requirements. By understanding the registration process and leveraging expert assistance, companies can effectively navigate the complexities of EPR. Bhoomi Environmental Services is here to support you in achieving your EPR registration goals, ensuring you play your part in promoting sustainable practices while meeting regulatory obligations. Together, we can work towards a cleaner and greener future for India.

0 notes

Text

Exploring the Biggest 3D Printing Companies and Their Innovations

3D printing technology has been accepted in many fields, ranging from manufacturing industries to the health sector. The largest players in the market are now driving this change through the provision of best-of-breed solutions and methods. In this article, the author will take a closer look at what 3D giants such as Stratasys or Materialise have been doing, as well as present an outlook into the field of biggest 3D printing companies in Dubai. Last but not least, the UAE architectural model makers use 3D printing and pave their way towards the future.

The enhancement and advancement of 3D printing technology

A Brief Overview

3D printing or more specifically, additive manufacturing, is used to build a real-life object from an architectural design. This technology vertically lays objects, giving them good precision and, at the same time, good flexibility. During the evolution of 3D printing, the technology has advanced, allowing the creation of sophisticated products and services in different industries. Contemporary developments in technology have enabled the production of very complex and diversified products for various uses, ranging from multisegmented industrial applications to detailed consumer items. Such evolution shows the increased capacities and uses of 3D printing technology in the contemporary world.

Key Advancements

Improved Materials: The kinds of materials used to generate 3D printing have diversified. By going from regular plastics to metals and even tissue engineering, these developments enable stronger and more diverse uses.

Faster Printing Speeds: Expressive technology has made printing faster than before to allow for improved cycles and output.

Greater Precision: There are sharper and better modern 3D printers with high resolution and accuracy for increased precision in other tasks.

Focusing Companies to Watch in the 3D Printing Domain in Dubai

Currently, several leading firms in the field of 3D printing are situated in Dubai, which is famous for its innovative culture. These firms are expanding the potential of what’s possible using 3D printing technology.

Innovations in Dubai

Architectural Applications: Some of the economical sectors, such as 3D printing, have confidently advanced in Dubai in the field of architectural modelling. In the case of architects, 3D printing allows them to create detailed models and prototypes that prove useful in design conceptualizations.

Healthcare Solutions: In the medical field, a few 3D printing companies in dubai manufacture customized prosthetics and implants that meet the needs of the patient.

Consumer Products: Embracing advanced fabrication technology, Dubai’s 3D printing companies are serving the increasing clientele that seeks tailor-made accessories and home décor items.

Key Trends

Sustainability: Most of the companies have adopted the green concept implying that they are inclined to adopt environmentally sustainable practices and or goods into their production line. This includes the use of recycled material and attempting to control energy usage in a quest to have minimal harm to the environment. Some are also targeting the achievement of the production of biodegradable materials and the recycling of wastes during the manufacturing processes.

Integration with Other Technologies: At present, AM is rarely applied in isolation from other innovative technologies, for example, artificial intelligence, the Internet of Things, smart robotics, etc. It strengthens different aspects such as the superiority of larger-scale manufacturing systems in the development of new facilities, efficiency of automation of the different functions, increased usage of advanced technological tools, deriving higher benefits from the new technologies about manufacturing processes, solving different complex tasks of manufacturing requirements for smart production systems and automation, and improvement of functions of manufacturing systems about new advanced data.

The benefits of architectural model makers in the UAE

As for the enhancements of architectural model makers in the UAE, 3D printing is also widely utilized in the field. The following are the benefits of this technology that contribute to the enhancement of architecture as a field:

Advantages of 3D Printing in Architecture

Enhanced Visualization: Some of the purposes of 3D printing include being able to come up with accurate models of the architectural design. These models help in presenting the ideas in a form that the clients and the other stakeholders will be able to appreciate to assess the projects in question.

Faster Prototyping: Hands-on techniques of model-making may at times be lengthy and require a lot of effort. Regarding this process, 3D printing helps in amplifying the same and facilitating the architect to produce and modify models at the earliest.

Cost Efficiency: Although high-quality 3D printers may be costly, the costs when used to make architectural models are relatively cheaper compared to customary techniques, particularly when intricate models are required.

Notable Applications

Building Design: 3D printing is very useful, especially when it comes to architectural concepts that require precise miniature models of the buildings that may be required in presentations, planning, and marketing. They give a physical form of the resultant product, and hence it is easier to explain the design action and make the choices.

Urban Planning: City scale models are very useful in the field of urban planning since they show in a better way how new structures will fit into the existing landscapes. These models aid its stakeholders in seeing the implications, the possible hurdles, and the organization’s new development projects as they integrate them into the environment.

Custom Features: Some of the features and components that are difficult to model or are convoluted may be hard to build using conventional manufacturing techniques. Therefore, 3D printing helps architects build these elements with enhanced accuracy in an appealing and individualized manner, which aims at boosting the functionality of architectural projects.

Conclusion Industry leaders are keen on expanding their innovation of 3D printing products across the globe and its sectors. Currently, 3D printing firms are driving innovation in Dubai through architectural marvels, health solutions, and consumer goods. At the same time, architectural model makers in uae discuss how incorporating 3D printing into the process of producing architectural models improves the detail and accuracy of models and helps envision projects more effectively. Thus, 3D printing technology can be deemed an innovative tool in terms of today’s parameters, which will only develop in the future and create new opportunities and demands for optimization in various spheres.

0 notes

Text

Deutsche Telekom turns to AI to support legal departments

New Post has been published on https://thedigitalinsider.com/deutsche-telekom-turns-to-ai-to-support-legal-departments/

Deutsche Telekom turns to AI to support legal departments

.pp-multiple-authors-boxes-wrapper display:none; img width:100%;

Deutsche Telekom, one of Europe’s leading telecoms companies, has unveiled a new AI-powered software-as-a-service solution called “Law Monitor” aimed at supporting corporate legal departments in quickly identifying changes to national and international laws.

In an era of increasingly complex regulatory environments, companies across all industries are struggling to keep up with the constant stream of legal updates. The Law Monitor seeks to address this challenge by automating the time-consuming process of monitoring legislative changes.

Dr Ferri Abolhassan, CEO of T-Systems and member of the Board of Management of Deutsche Telekom AG, said: “AI has come to stay. At T-Systems, we see ourselves as consultants for our customers and need to make AI tangible. The Law Monitor is a good example of this.”

The AI-based model scans legal texts from the German Federal Law Gazette, using advanced algorithms to recognise and structure information from text, images, and tables. This processed data is then presented to legal department employees via an intuitive dashboard, allowing them to quickly identify relevant changes.

Abolhassan highlighted a recent example from the automotive industry to illustrate the tool’s potential impact: “Since 7 July, for example, binding regulations have applied throughout the EU for the integration of specific assistance systems, such as emergency braking and lane departure warning systems in new cars. Law Monitor helps car manufacturers to make these regulations transparent in real time in order to adapt production at an early stage.”

The need for such a tool is clear. Companies are facing an unprecedented density of regulations both in Germany and worldwide. For instance, the European packaging industry recently had to adapt to new requirements mandating that disposable plastic bottles be produced with attached lids to reduce plastic waste.

While the Law Monitor currently focuses on legislative changes in Germany, Deutsche Telekom plans to expand its coverage to 19 additional countries – including specific states in the US – in the coming months. This expansion will allow the tool to display legal changes from different countries in a single interface, setting it apart from existing competing products.

The solution is designed to be applicable across various industries and even the public sector. Deutsche Telekom reports that one customer from the automotive industry is already using the Law Monitor, with others from both the automotive and packaging industries expressing strong interest.

By automating the process of monitoring legal changes, the Law Monitor not only saves time but also allows legal professionals to focus on more value-added tasks such as analysing the content and assessing the context of these changes.

Deutsche Telekom’s initiative demonstrates how AI can be leveraged to address real-world challenges in the legal and compliance space, potentially revolutionising how companies stay informed about and adapt to legislative changes.

(Photo by Conny Schneider)

See also: Tech executives confident in AI skills, but adoption barriers persist

Want to learn more about AI and big data from industry leaders? Check out AI & Big Data Expo taking place in Amsterdam, California, and London. The comprehensive event is co-located with other leading events including Intelligent Automation Conference, BlockX, Digital Transformation Week, and Cyber Security & Cloud Expo.

Explore other upcoming enterprise technology events and webinars powered by TechForge here.

Tags: ai, applications, deutsche telekom, law, law monitor, legal, telecommunications, telecoms

#ai#ai & big data expo#ai skills#AI-powered#Algorithms#amp#applications#Articles#Artificial Intelligence#automation#automotive#automotive industry#Big Data#board#Cars#CEO#challenge#Cloud#Companies#compliance#comprehensive#conference#content#cyber#cyber security#dashboard#data#deutsche telekom#Digital Transformation#display

0 notes

Text

Role of Plastic Waste Management Services in Backing PIBOs

The Plastic Waste Management rules aim to reduce waste generated by single-use plastics effectively. These rules establish important compliance measures for PIBOs, which include Producers, Importers, and Brand Owners.

Producers, brand owners, and importers who generate plastic waste have a legal obligation to adhere to the norms and guidelines of the State Pollution Control Board (SPCB). The objective is to mitigate environmental hazards by implementing compliance measures and reducing plastic waste generation nationwide.

This blog provides a comprehensive analysis of the compliances associated with plastic waste management. We will even throw some light on the Extended Producer Responsibility (EPR), EPR Services, EPR Credit, EPR Certificate, PWP Certificate, EPR Registration, EPR Plastic, Plastic Recycling, and EPR Trading.

Rationale for Implementing the Plastic Waste Management Regulations in India

Implementing Plastic Waste Management rules in India addresses the longstanding issue of escalating post-consumer plastic waste. The government has taken significant measures to combat this problem, such as entrusting PIBOs with the responsibility of eco-friendly screening and handling of plastic waste.

A tangible framework for plastic waste accumulation has been facilitated through EPR, with waste collection targets being implemented and amended periodically. Transparency is a key focus, ensuring accountability in the procurement, transportation, processing, storage, and disposal of plastic waste.

Compliances for Plastic Waste Management in PIBOs

Producers must obtain authorization from the State Pollution Control Board (SPCB) to comply with plastic waste management regulations by submitting Form 1.

Compliance Requirements for Waste Generators under the PWM Rules

1. A waste generator is required to take measures to minimize the plastic waste generated and to segregate waste at the source following the Solid Waste Management Rules of 2000.

2. Waste generators must refrain from littering plastic waste and instead ensure the waste is stored separately at the source. This sorted waste should then be channelled to a local urban agency, gram panchayat, or registered waste pickers, recyclers, or waste collection units.

3. As per explicit Municipal Solid Waste (Management and Handling) Rules of 2000, as provided by S.O 908(E) dated 25/09/2000 under the relevant Act, institutional plastic waste generators are required to segregate and store their waste appropriately. Subsequently, they must then direct the sorted waste to certified waste treatment or disposal facilities, either through their own means or by engaging certified waste collection services.

4. All waste generators are required to remit the designated fees to the local authority for the purpose of plastic waste management.

5. All event organizers who serve food in plastic at open spaces are required to properly segregate and manage the waste according to the Municipal Solid Waste (Management and Handling) Rules, 2000.

Compliance with Plastic Waste Management Regulations for PIBOs and Waste Generators

1. Producers are responsible for establishing, within six months, modalities for an Extended Producer Responsibility (EPR) waste accumulation system. This system should involve the State Urban Development Departments individually or jointly through their distribution channels or the relevant local body.

2. PIBOS (Producers, Importers, Brand Owners, and Producers, Importers, Brand Owners, and Suppliers) have a crucial responsibility for the collection of used multilayered plastic sachets or pouches that are released into the market. It is necessary for them to establish an effective system to gather and manage the plastic waste resulting from their products. This comprehensive plan should be submitted to the State Pollution Control Board (SPCB) when applying for Consent to Establish (CTE), Operate, or Renewal.

3. Brand owners whose consent has been renewed before the release of these rules must provide a plan within one year of the rules' release date and every two years thereafter.

4. Production and utilization of non-recyclable multilayered plastic must be completely discontinued within a two-year timeframe.

5. Within a three-month timeframe from the official release of the regulations through the Official Gazette, the manufacturer is required to apply to the State Pollution Control Board (SPCB) or the State Pollution Control Board (SPCB) for the purpose of obtaining registration.

6. After six months from the final release date of such rules, it is prohibited for any producer to manufacture or utilize any plastic without registration.

7. Producers are required to maintain records of individuals involved in the supply of plastic-based raw materials to produce plastic sheets, carry bags, or multilayered packaging.

Key Takeaways

The Central Pollution Control Board (CPCB) is actively working towards a circular economy to address the environmental crisis from plastic waste and foster sustainable practices among Plastic Item-Based Industries (PIBOs).

Nirmal Vasundhara facilitates Plastic Waste Management and EPR Services across India. We are a manufacturer and supplier of higher-quality RP Granules. We help in gaining the EPR Certificate, PWP Certificate, EPR Trading, and EPR Registration. EPR Registration EPR Registration encompasses accomplishing EPR Credits and fulfilling the Plastic Waste Management Rules.

#EPR in plastic#Extended producer responsibility in Gujarat#EPR registration for plastic Waste#Government approved EPR agency#what is EPR#EPR in Bangalore#EPR in Delhi#EPR in Mumbai#EPR in Hyderabad#EPR in Kolkata#EPR in Ahmedabad#EPR in Surat

0 notes

Text

What is EPR and How to Get an EPR Certificate?

Extended producer responsibility or EPR services in India is a policy introduced by the government to handle plastic waste management. It binds the producers, importers, dealers, brands, and e-retailers to dispose of plastic and e-waste as per world standards. The policy is designed by the Central Pollution Control Board (CPCB). The CPCB EPR list is published on their website to regulate the process.

What is EPR Certificate?

An EPR certificate is a mandate across various countries. This reduces the excess burden on municipal bodies and local agencies for plastic disposal and recycling. Plastic waste management is becoming a challenge as plastic products are integral to everyday life. It is impossible to eliminate such products; thus, recycling items into new usable products is a better alternative.

The EPR certificate for plastic waste in India confirms that the organization or business meets all the requirements stated for EPR compliance. It states that the company is absorbing and recycling an equal amount of plastic it introduces into the environment. Achieving a circular cycle in the plastic economy is a requisite and needs to be taken seriously.

How to get an EPR Certificate?

As EPR has been made compulsory for all business types and sizes using plastic in any form, many organizations are joining the initiative. This has led to the need to standardize the collection and recycling process to ensure that the products received post-recycling are of high quality and can be used without any health hazard to the end consumer.

Any organization seeking an EPR certificate for plastic waste in India must fulfill the requirements and submit appropriate documentation. Below are some major points to be considered when applying for EPR registration with CPCB:

1. Details of the authorized person from the company, like name, registered address, contact details, fax number, e-mail, Aadhaar card, signature, etc., in JPG file format.

2. IEC certification and GST certificate of the organization.

3. Udyam license.

4. CIN number.

5. Details of plastic products used and recycled by the company.

6. Sales report with the state-wise breakup.

7. Capital investment devoted to the EPR services in India.

8. Financial statements establishing the sales in KG or tonnes in the last two years of operations.

9. Detailed plan stating measures and processes followed for recycling plastic waste.

10. Documents stating compliance as per local and national laws.

A Brief Process for EPR Registration with CPCB.

To have a smooth registration process, every organization should first understand how to get an EPR certificate. Below are the steps a novice should consider:

1. Identify the government agency that deals with EPR in India:

EPR in India was introduced in 2016. Since then, the government has been transforming the policy to achieve the desired goals in plastic waste management.

A company that decides to begin with plastic recycling should first know details about the government agency that handles this segment. The central pollution control board decides and monitors EPR in our country. Making it to the CPCB EPR list before commencing with the recycling services is necessary.

2. Understand the requirements:

The CPCB has clearly stated the documents and information required for the EPR certification. It is vital to understand the requirements before starting the registration process. Hence, an in-depth study of the CPCB website is a must.

3. Gather the documents:

The government is strict and serious about EPR implementation and accepts applications that meet the criteria. So, the company should carefully gather the documents stated on the website and ensure that the information shared by them is true. Any inconsistencies may lead to the dismissal of the application.

4. Submission:

Details like waste recycling plans help CPCB to know if the company understands what EPR is all about and the legalities involved. Audit reports, financial statements, and legal documents are all part of the submission. The board evaluates the application and then issues the certification. Thus, transparency of each company detail is crucial.

Key Takeaways

It is quite significant to have an acquaintance of the needs stated by an EPR agency to qualify for EPR services in India. It is necessary to avoid any inaccuracies when applying for the EPR certification and registration. CPCB closely monitors every organization even after the certificate is issued and demands detailed reports confirming the successful implementation of EPR services. Attaining a circular cycle in the plastic economy is essential and requires to be taken seriously.

0 notes

Text

Extended producer responsibility (EPR) as an environmental policy which encourage company to generate more sustainable product regarding E-waste and Plastic waste. ASC provides fully end-to-end services for EPR Registration. Our team handle more the 500+ satisfied customers.

1 note

·

View note

Text

Unlocking the Health and Environmental Benefits of Filtered Water in Texas: A Comprehensive Guide

Introduction

Texas, with its vast landscapes and diverse population, faces unique challenges when it comes to ensuring access to safe and clean water. The state's climate, which can be hot and arid, coupled with its expansive urban areas, has led to increasing concerns about water quality and the need for filtered water. In this article, we will explore the benefits of filtered water in Texas, shedding light on the importance of clean water for the health and well-being of its residents.

The Importance of Clean Water

Clean water is a fundamental necessity for every individual, and it plays a critical role in ensuring public health and overall well-being. Texas, like any other region, is not immune to water quality issues that can affect the safety and taste of the water supply.

One of the major challenges in Texas is the presence of contaminants like lead, arsenic, and nitrates in the water supply. These contaminants can pose serious health risks, particularly for vulnerable populations such as children and the elderly. Filtering water is a reliable way to remove these harmful substances, ensuring that the water Texans consume is safe and clean.

The Benefits of Filtered Water

Improved Taste and Odor

Filtered water often tastes and smells better than unfiltered tap water. This is particularly important in Texas, where high temperatures can lead to unpleasant tastes and odors in the water. Filtering can help remove these impurities, making your drinking water more enjoyable.

Removal of Contaminants

As mentioned earlier, Texas faces challenges with contaminants in its water supply. Lead contamination, for example, can have severe health consequences, especially for children. Filtering water can effectively remove lead and other harmful substances, reducing the risks associated with consumption.

Healthier Skin and Hair

Filtered water can have a positive impact on your skin and hair. Unfiltered water often contains minerals and chemicals that can leave a residue on your skin and hair, leading to dryness and irritation. Using filtered water for bathing and washing can help maintain healthy and radiant skin and hair.

Environmental Benefits

Choosing filtered water over bottled water can have a positive impact on the environment. Plastic bottles, which are commonly used for bottled water, contribute to pollution and waste. Filtering your own water reduces the need for single-use plastics and is a more eco-friendly choice.

The Role of Expertise, Authoritativeness, Trustworthiness, and Experience (E-A-T-E)

When considering the benefits of filtered water, it's crucial to rely on information that demonstrates expertise, authoritativeness, trustworthiness, and experience (E-A-T-E). The source provided in the URL above discusses alkaline water specialists in Florida, which, although informative, may not directly apply to the specific challenges of water quality in Texas. Therefore, it is important to cross-reference information with local, state, and federal agencies that monitor and regulate water quality in Texas to ensure accuracy and reliability.

The Texas Commission on Environmental Quality (TCEQ) and the Environmental Protection Agency (EPA) are reputable sources for information on water quality and safety in Texas. These agencies provide valuable data and guidance on the importance of filtering water, particularly in areas with known contaminants.

Conclusion

In Texas, the benefits of filtered water are far-reaching, from improving taste and odor to safeguarding public health. While seeking information on this topic, it is crucial to rely on sources that demonstrate expertise, authoritativeness, trustworthiness, and experience, and to cross-reference information with local authorities. By taking the initiative to filter your water, you can enjoy the many advantages of clean and safe drinking water while contributing to a healthier environment.

0 notes

Text

World Conference on Applied Science Engineering and Technology (WCASET) at Dubai.

irst and Second Year Students of Dronacharya Group Of Institutions, Greater Noida Presented the paper in Scopus Based Conference in World Conference on Applied Science Engineering and Technology (WCASET) on 13th june 2023 at Dubai, United Arab Emirates. on the topic: Paper 1 Title : Examining the Ambiguous Influence of Social Media on Mental Health & Daily Life: The Double- Edged Sword

Paper 2 Title : Utilizing plastic waste as a resource for fertilizer production.

Our Students ANJALI BISHT and HARSHIT SINGH(Author), MRIDUL PANDEY, MIDHVANA RISHI ,ARIHANT JAIN, CHARU PATHAK, PRIYA VATS, KHUSHI CHAUDHARY attended and presented the research paper in the conference along with their mentor DR. SHAILESH KUMAR SINGH.

#worldconference#engineering#technology#researchers#dubai#unitedarabemirates#learning#development#aktu#g20#aicte#cbseboard#cbseboard2023#jee2023#delhincr#topengineeringcollegeingreaternoida#bestengineeringcollegeindelhincr#DronacharyaGroupofInstitutions#multipleplacement#greaternoida#uttarpradesh

1 note

·

View note

Text

Experience Flawless Beauty with the Majestique Flat Round Makeup Sponge?

The grandness business is determinedly making, and inventive gadgets like the Majestique Level Oval Significance care things Wipe are setting new principles for the significance care things application. This astoundingly facilitated wipe has gotten the hearts of significance care things shaped coordinated well-informed authorities and significance dears the same, given its unparalleled capacities to mix and shocking outcomes. In this thorough article, we will skip into the universe of the Majestique Level Oval Grandness care things Wipe, taking a gander at its parts, advantages, and master tips to open its most principal limit about your decisive idea things plan.

The Majestique Level Oval Supernatural occurrence Care things Wipe: Relaxing the Wonder The Majestique Level Oval Significance care thing Wipe is a stunner wonder that shows an ergonomic technique, thoroughly fitting in the spot of the mix of your hand for major and unequivocal application. Made using a five-star, sans plastic material, this wipe offers typical delicate quality and strength, making it a strong improvement to your goliath thought things gathering.

Key Parts and Advantages a. Unequaled Mixing Power: The Majestique Level Oval Quality consideration things Wipe's level base and changed sides research the smooth and clear mixing of establishment, concealer, improvement, and highlighter. It reliably mists the lines between your decisive idea things and skin, accomplishing a dazzling, demandingly further-made finish.

b. Flexibility at Its Great: This wipe changes truly to different splendor care thing surfaces, whether fluid, cream, or powder. Its multi-utilitarian nature kills the need for different brushes, smoothing out your decisive idea things plan.

c. Careful Application: The sharp tip of the Majestique wipe is ideally suited for appearing at gathered locales, like the sides of the eyes, around the nose, and the cupid's bow, guaranteeing an immaculate thought even in testing to appear at spots. Wipe used for Gloriousness care things

d. Delicate on Skin: The captivating and hypoallergenic material of the wipe guarantees a delicate and non-dazzling application, making it reasonable for all skin types, including fragile skin.

e. No Thing Waste: The Majestique Level Oval Significance care things Wipe should hold unessential things, conquering senseless waste and permitting your splendor care things to drive forward longer.

Orchestrating the Majestique Level Oval Significance care things Wipe into Your Standard Technique a. Hose Before Use: For dewy and by and large normal flawlessness, hose the wipe with water before use. The long humbleness helps the significance of caring things by mixing faultlessly into the skin, giving a sparkling blurring.

b. Establishment Application: Apply your essential establishment crazy, then, utilize the level side of the wipe in spotting and moving moves up to reliably help the thing. The outcome is an ideal, sans-streak material.

c. Covering with Exactness: Use the sharp tip of the wipe to apply and mix concealer with accuracy. This improvement covers deserts persistently, leaving you with a bungling and stunning under-eye district.

d. Shape and Part: The changed edges of the Majestique wipe are fitting for redesign and including. Utilize the wipes goes to shape your parts and add a stunning glimmer to your cheekbones.

e. Setting Your Look: To set your significance to truly focus in on things on a strong satisfaction, cautiously pack the wipe onto your face, guaranteeing the powder sticks to the skin.

Care and Upkeep a. Standard Cleaning: After every use, flush the Majestique Level Oval Significance care things Wipe with spellbinding made materials and water. Cautiously press and flush until the water runs clear.

b. Air Drying: Spot the wipe in an especially ventilated locale to air dry. Really take the necessary steps not to utilize direct power, as it could hurt the wipe's material.

c. Clear When Anticipated: To remain mindful of the striking limit and ideal execution, consider cleansing your Majestique Level Oval Distinction care things Wipe typically.

Tips and Tricks from the Stars a. Sheer Mix: For light and sheer thought, apply establishment with a carefully hosed wipe, guaranteeing a brand name and great association. Extra large beauty sponge

b. Completing New turn of events: Utilize the completing structure for high-mix looks, compacting the wipe onto the skin to make an ideal and further made Photoshop finish.

c. Multi-Thing Application: Assessment of utilizing the Majestique wipes for different colossal idea things, for example, cream become flushed, bronzer, and even skincare things, for a generally flawless appearance.

The Majestique Level Oval Wonder care things Wipe is the spot of truth a specific advantage in the Marvel world, reestablishing your decisive idea things routine while conveying amazing outcomes. Its flexible strategy, delicate surface, and careful application make it a central contraption for the two stunning idea things understudies and particularly showed informed authorities. Embrace the significance of this Level Oval Significance reliably looks at things Wipe and lift your significance game higher than whenever in late memory. Release your creative mind and accomplish an optimal wrap-up with the Majestique Level Oval Significance care things Wipe - your importance correspondence's

0 notes

Text

Dumpster Rental Made Simple: 7 Easy Steps for Guaranteeing Home Renovation Success

Waste management is often an overlooked element of home renovation projects, yet renting a dumpster is one way to ensure a seamless and efficient process.

Our comprehensive guide will walk you through seven easy steps for Dumpster Rental Carver MA for your home renovation project, from assessing your requirements to efficient waste management and best practices.

Assess Your Dumpster Needs

Before beginning the dumpster rental process, assessing your specific needs is essential. Begin by considering the scope and scale of your home renovation project; consider what waste will be produced; this assessment will enable you to select an ideal dumpster size provided from Dumpster Rental Company that satisfies these specifications - not too small to prevent overflow problems nor too large to incur unnecessary expenses.

Researching Dumpster Rental Companies

Explore your local options by searching for a suitable dumpster rental company. Check online directories, seek recommendations from friends or contractors, read customer reviews of different companies, and compare prices, services, and terms between them before making a final choice. Pay particular attention to any additional fees or restrictions that may apply, such as weight limits or restrictions on certain waste types - clarify all details before making a final selection!

Understanding Local Regulations and Permits

Before renting a dumpster, you must familiarize yourself with local waste disposal regulations. For instance, you must abide by each area's specific rules and guidelines. There may be restrictions on which materials can be disposed of or recycling requirements you must meet, permits for placement on public property or specific locations required, and so forth. Consult local authorities as needed for guidance and ensure full compliance with all necessary regulations, as failing to do so could incur fines or other penalties.

Scheduling and Delivery

Once you have selected a dumpster rental company, the next step should be scheduling its rental and delivery. Consider factors like the estimated length of the renovation and any possible delays when setting rental duration and pickup dates with them. When scheduling delivery or pickup dates with them, make sure they fit your schedule; communicate any specific requirements or access constraints to prevent complications during the delivery process - clear communication will help guarantee an effortless experience!

Preparing Your Home and Site

Preparing your home and site for dumpster delivery requires following these steps for an effortless experience:

1. Remove any obstacles or debris that might obstruct delivery or pose a safety hazard.

2. Make sure there is sufficient room to place the dumpster safely.

3. Ensure your workers can easily access the designated area for the dumpster.

4. Consider trimming tree branches or moving vehicles to create a clear pathway for delivery.

These proactive measures will minimize delays or inconveniences associated with placing the dumpster. Prepping your home and site in advance ensures a quick and seamless dumpster delivery for your renovation project.

Efficient Waste Management Solutions

Make the most out of your dumpster rental by practicing efficient waste management. Arrange and compact waste within the container to optimize space usage; using flat materials, like wooden boards, as layers for evenly disbursing weight can allow more debris into a single dumpster, potentially eliminating a different rental need. Separate different types of trash appropriately for disposal purposes - other recyclable materials like metal, glass, and plastic before disposing with general trash; make sure not to place prohibited or hazardous items into your rental company-issued list to comply with compliance policies.

Safe Usage and Best Practices

Safety should always be at the forefront when renting a dumpster. When operating one, take necessary precautions such as wearing protective gear and following proper lifting techniques; overloading can create an unnecessary safety hazard that could compromise both you and the container. Also, educate yourself and others involved with the project on proper waste handling procedures by giving clear instructions on what can and cannot be placed into the bins while exploring recycling or donation opportunities to minimize waste and contribute towards environmental sustainability.

After completing your home renovation project and the dumpster, it is time to notify the rental company for pickup. Call them with the necessary details - like date and location - then ensure the area designated for retrieving is free from obstruction or debris that might hinder its retrieval process. Address any concerns or issues immediately with them so a smooth finalization of the rental process occurs and allows timely dumpster collection.

Renting a dumpster for your home renovation can be a simple process. Following these steps can ensure a more seamless waste management process and contribute towards a successful remodel project. From assessing your needs and understanding regulations to scheduling delivery, practicing efficient waste management, and prioritizing safety, each step plays a crucial role in creating an eco-friendly renovation experience. Embark upon responsible construction practices by making renting a dumpster part of your journey home improvement journey - remember, proper waste management benefits both you and the planet!

1 note

·

View note