#Aluminum Wire (Copper Cladded) News

Explore tagged Tumblr posts

Text

Aluminium Wire(Copper Cladded) Prices Trend | Pricing | News | Database | Chart

North America

In Q3 2024, Aluminium Wire (Copper Cladded) pricing in North America exhibited a downward trend, influenced by several key factors. Market prices declined compared to the same quarter in 2023, reflecting challenges in supply and demand dynamics. Oversupply emerged as a significant driver of this decline, exacerbated by global economic uncertainties and regulatory changes affecting trade flows. Mexico experienced the most substantial price changes in the region, with market volatility driven by newly imposed tariffs and disruptions in supply chains. Seasonal factors further contributed to price fluctuations. The correlation in price changes between the first and second halves of the quarter indicates a sustained downward trajectory. Demand remained notably low, primarily due to challenges in the automotive sector, a major consumer of Aluminium Wire (Copper Cladded) products. The quarter-ending price highlighted the persistent negative pricing environment, underscoring a period marked by uncertainties and market instability.

Get Real time Prices for Aluminium Wire (Copper Cladded): https://www.chemanalyst.com/Pricing-data/aluminum-wire-copper-cladded-1549

APAC

In Q3 2024, the Aluminium Wire (Copper Cladded) market in the APAC region experienced a significant price increase, driven by various factors. Production challenges, including supply chain disruptions and rising demand, played a pivotal role in driving prices upward. Global shipping challenges and reduced container vessel supply also impacted timely deliveries, further accentuating price hikes. Despite stable supply supported by Chinese efforts in copper scrap recycling and increased aluminium production, the growing demand led to price escalation. China witnessed the most significant price changes in the region, with consistent increases throughout the quarter. The interplay of rising demand and limited supply fueled this surge. Seasonal factors and supply chain inefficiencies further amplified the upward price trend. The quarter ended with Aluminium Wire (Copper Cladded) priced at USD 6,468/MT FOB Shanghai, reflecting a positive and upward pricing environment.

Europe

In Q3 2024, Aluminium Wire (Copper Cladded) prices in Europe followed a notable uptrend, with Germany exhibiting the most significant price changes. Several factors influenced this increase. A surge in demand from the aviation sector, driven by large orders from major airlines, significantly boosted prices. Additionally, supply constraints in global alumina and bauxite resources heightened production costs, supporting the price surge. In Germany, the market benefitted from a balanced supply situation due to the commissioning of a new aluminium billet casting line in a neighboring country, which improved regional supply capabilities. Despite challenges in the manufacturing sector, the overall trend in Europe indicated a positive outlook for Aluminium Wire (Copper Cladded) prices. The quarter recorded a 3% price increase compared to the previous quarter, with a notable rise between the first and second halves of the quarter. Ultimately, Q3 2024 ended with Aluminium Wire (Copper Cladded) prices in Germany reflecting a bullish pricing environment.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Aluminum Wire (Copper Cladded)#Aluminum Wire (Copper Cladded) Prices#Aluminum Wire (Copper Cladded) News

0 notes

Text

Long Island Residential Electrical Wiring: An In-Depth to Learning the Basics

Long Island Residential Electrical Wiring: An In-Depth to Learning the Basics

Outline

Greetings from the best source for Long Island residential electrical wiring! For both safety and functionality, it is essential to comprehend the complexities of electrical wiring, whether you are building a new home or remodeling an old one. We'll cover all you need to know to become an expert in Long Island residential electrical wiring in this book.

Knowing How to Wire Residential Properties Electrically

Set off on an adventure to learn the principles of Long Island household electrical wiring. We can help you with everything from fundamental ideas to sophisticated methods.

The Importance of Safe Electrical Wiring

Learn why residential homes require adequate electrical wiring. Investing in high-quality electrical wiring is essential for a number of reasons, including ensuring efficiency, safety, and regulatory compliance.

Major Residential Electrical System Components Explore the key elements that comprise domestic electrical systems. Comprehending various components, such as outlets, switches, and circuit breakers, is essential for efficient wiring. Long Island Electrical Wiring Codes and Regulations Keep up with the most recent Long Island electrical codes and regulations. Adherence to these guidelines is crucial in order to guarantee safety and prevent possible legal complications.

Wiring Types Appropriate for Residential Properties Examine the many kinds of wiring that are frequently utilized in residential buildings. Consider the advantages and disadvantages of various options, such as copper-clad aluminum and aluminum and copper wire, in order to make well-informed choices.

How to Plan and Design an Electrical System Discover the significance of careful planning and design for electrical wiring. A safe and effective electrical system is largely dependent on variables including load calculations, circuit structure, and outlet and fixture location. Safety Measures to Take While Installing Electrical Wiring Throughout the installation of the electrical wiring, put safety first. Precautions can help avoid mishaps and injuries by employing the right instruments and equipment and adhering to safety procedures.

Typical Errors in Electrical Wiring to Avoid Steer clear of typical hazards that could jeopardize your electrical system's functionality and safety. To guarantee a seamless and error-free wiring process, take note of these faults.

FAQs About Electrical Wiring for Residential Properties in Long Island

FAQs

Is it necessary to hire a professional electrician for residential wiring projects?

While DIY electrical work may seem tempting, hiring a licensed electrician is highly recommended to ensure safety and compliance with regulations.

What factors should I consider when choosing electrical wiring materials?

Factors such as durability, cost, and compatibility with your home's electrical system should be taken into account when selecting wiring materials.

How often should residential electrical systems be inspected?

It's advisable to schedule regular inspections by a qualified electrician to detect any potential issues and ensure the continued safety and performance of your electrical system.

Can I upgrade my home's electrical system to meet increased power demands?

Yes, upgrading your electrical system may be necessary if you're adding new appliances or experiencing frequent power disruptions. Consult with a licensed electrician to assess your needs and make appropriate upgrades.

What are the signs of electrical problems in residential properties?

Signs such as flickering lights, tripped circuit breakers, and burning odors indicate potential electrical issues that should be addressed promptly by a professional electrician.

Are there any government incentives or rebates available for upgrading residential electrical systems?

Depending on your location and specific circumstances, there may be government incentives or rebates available for energy-efficient upgrades to your home's electrical system. Consult with local authorities or utility companies for more information.

To sum up

Well done on taking the initial step toward becoming an expert in Long Island residential electrical wiring! With the right information and by adhering to best practices, you can guarantee the dependability, efficiency, and safety of the electrical system in your house. Always put safety first, and seek the advice of a licensed electrician before beginning any complicated wiring projects.

LONG ISLAND OFFICE:

262 Orinoco Drive Brightwaters, NY 11718

(800) 924-9297

· (631) 666-0477

· Fax #:(631) 666-0479

E-mail Us

https://allwayselectriccorp.com/

#Electrical Wiring Residential Long Island#Electric Repair Service Long Island#Emergency Electrician Long Island

2 notes

·

View notes

Text

Additive Manufacturing Market, Industry Forecast, 2024–2030.

Additive Manufacturing Market Overview:

Sample Report :

Additionally, Increasing focus on metal additive manufacturing technologies. Researchers and companies have been actively working on expanding the range of metals and alloys available for AM. This includes not only traditional metals like titanium, aluminum, and stainless steel but also high-performance alloys for specialized applications. The development of new metal powders suitable for various AM processes has been a focus area. The integration of Additive Manufacturing with traditional manufacturing processes in companies were exploring hybrid manufacturing approaches that combine the strengths of additive and subtractive methods. This integration aimed to leverage the design flexibility of Additive Manufacturing and the efficiency of traditional methods to optimize production workflows. These factors impact the growth in Additive Manufacturing Market.

Market Snapshot:

Additive Manufacturing Market — Report Coverage:

The “Additive Manufacturing Market Report — Forecast (2024–2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Additive Manufacturing Market.

AttributeSegment

By Type

● Materials

● Systems

● Services & Parts

By Material

● Plastics

○ Acrylonitrile Butadiene Styrene (ABS)

○ Polylactic Acid (PLA)

○ Polyethylene (PE)

▪ High-Density Polyethylene (HDPE)

▪ Low-Density Polyethylene (LDPE)

▪ Linear Low-Density Polyethylene (LLDPE)

▪ Others

○ Polycarbonate (PC)

○ Polypropylene (PP)

○ Polyethylene Terephthalate (PETE)

○ Nylon

○ Others

● Metals

○ Iron

○ Steel

○ Silver

○ Aluminum

○ Copper

○ Titanium

○ Gold

○ Zinc

○ Others

● Ceramics

○ Glass

○ Silica

○ Quartz

○ Others

● Others

By Technology

● Powder Bed Fusion

○ Direct Metal Laser Sintering (DMLS)

○ Selective Laser Sintering (SLS)

○ Selective Laser Melting (SLM)

○ Electron Beam Melting (EBM)

○ Others

● Binder Jetting

● Directed Energy Deposition

○ Laser Deposition Technology (LDT) excluding LCT

○ Laser Additive Manufacturing (LAM)

○ Laser Metal Deposition (LMD)

○ Laser Engineering Net Shape (LENS)

○ Laser Cladding Technology (LCT)

○ Electron Beam Additive Manufacturing (EBAM)

○ Wire Arc Additive Manufacturing (WAAM)

○ Laser Deposition Welding (LDW)

○ Others

● Material Extrusion

● Material Jetting

○ Drop On Demand (DOD)

○ Polyjet by Object

○ Others

● Vat Polymerization

○ Stereolithography (SLA)

○ Digital Light Processing (DLP)

○ Continuous Liquid Interface Production (CLIP)

○ Others

● Others

By End-Use Industry

● Industrial

● Aerospace

○ Commercial

○ Military

○ Others

● Consumer Goods

○ Furniture

○ Watches and Jewelry

○ Shoes and Soles

○ Others

● Oil & Gas

● Automotive

○ Passenger Cars

○ Light Commercial Vehicles (LCV)

○ Heavy Commercial Vehicles (HCV)

○ Others

● Medical & Healthcare

● Electrical & Electronics

○ Conductors

○ Resistors

○ Sensors

○ Semiconductors

○ Others

● Building and Construction

○ Residential

○ Commercial

○ Industrial

○ Infrastructure

The COVID-19 pandemic had a mixed impact on the Additive Manufacturing (AM) market. While disruptions in global supply chains initially posed challenges for material sourcing, the flexibility of AM processes proved beneficial in addressing urgent needs for medical equipment and components. The demand for 3D printing surged during the pandemic, with AM technologies being utilized for the rapid production of ventilator parts, face shields, and other critical supplies. The crisis highlighted the agility of AM in responding to unforeseen challenges and increased awareness of its potential across various industries.

Inquiry Before Buying :

The situation in Ukraine had indirect effects on the Additive Manufacturing (AM) market, primarily through broader geopolitical and economic repercussions. Disruptions in supply chains, especially for metals and other raw materials used in AM processes, were potential concerns. Additionally, uncertainties in global markets may have influenced investment decisions and R&D activities in the AM sector. However, the impact varied depending on the resilience of individual companies and their exposure to the geopolitical developments.

Key Takeaways:

North America Dominated the Market

Geographically, in the Additive Manufacturing market share, the North America region has held a dominant market share of 41% in 2023, Rising government investments and projects in the United States for additive manufacturing have also raised the growth of the market. For instance, to address the challenges in single laser melting (SLM), America Makes awarded GE Global $2.6 million to build an open-source, multi-laser production machine and AM platform. Additionally, in Canada, the rising partnership between research universities in the field of additive manufacturing is also influencing the growth of the market. U.S. is anticipated to lead the global additive manufacturing market with the largest installed base for 3d printer in the world. With such a dominant presence of the 3d printers in the country U.S. is likely to contribute more than one third in the revenue generated by additive manufacturing worldwide.

Metal is the Fastest Growing Segment

In the Additive Manufacturing Market forecast, the Metal segment is estimated to grow with a CAGR of 23.5% during the forecast period. Metals are a better option for 3D printing compared to plastics, as they have more industrial usage. Often the 3D metal printing shows itself to be unique as the new technologies can readily surpass what was offered by traditional processes. In AM of metals a powder feedstock or more rarely a wire is fully melted by the energy input of a laser or electron beam and transformed layer by layer into a solid part of nearly any geometry. The most popular processes for AM of metals are Laser Beam Melting (LBM), Electron Beam Melting (EBM) and Laser Metal. In a survey conducted across the globe, about 23% of the 3D printing materials used are metals. The 3D printing metals segment is also poised to grow as it has a competitive edge over other plastic materials used in 3D Printing. Metal 3D printing is too expensive, furthermore other companies, like Desktop Metal and Markforged, are developing approaches to manufacture affordable metal 3D printers.

Schedule A Call :

Aerospace to Hold Largest Market Share

According to the Additive Manufacturing Market analysis, the Aerospace segment is estimated to hold the largest market share of 34% in 2023, the aerospace and defense industry is a perfect example of how to use additive manufacturing (AM) (commonly referred to as 3D Printing) to produce components that are heavier and lighter than parts manufactured using conventional manufacturing methods. Additive manufacturing or 3D printing has applications in the aerospace industry such as engine compartments, cabin accessories, air ducts among others. NASA researchers are looking into how electroplated SLA parts perform in space. Engineers at NASA’s Goddard Space Flight Center designed brackets that were 3D printed on printers, electroplated, and sent to space aboard a summer 2022 SpaceX commercial resupply services (CRS-25) mission to the International Space Station (ISS). The results could inform how NASA and possibly other aerospace manufacturers may incorporate electroplating and additive manufacturing into potential future product plans.

Ease of Manufacturing Complex Design

he basic physical difference in how objects are made with the additive manufacturing process produces some major functional differences when compared with other traditional manufacturing processes. The most significant of these functional differences is the ability of additive manufacturing to produce complex geometries that would be difficult or impossible to achieve using conventional manufacturing methods. These intricate geometries are also stronger and lighter than their conventional counterparts. Additive manufacturing eliminates the additional costs normally associated with creating more complex objects. A highly complex component usually costs much more using conventional methods. This is primarily because conventional fabrication methods rely on the conversion of three-dimensional illustrations into two-dimensional drawings for fabrication, as well as the labor cost of assembling such components. However, regardless of the complexity of a component, the method in additive manufacturing is the same. Thus, no additional cost is incurred for manufacturing complex designs using additive manufacturing.

Buy Now :

Relatively Lower Production Cost for Rapid Manufacturing

The manufacturing companies experience various benefits while using additive manufacturing methods to produce objects. Since the complexity of the component has little or no impact on the manufacturing time and costs, additive manufacturing is ideal for low-cost production as well as small and (very) large series. Design changes can be implemented quickly at a low cost. Metal structures are made up of atom by atoms in additive manufacturing, as opposed to subtractive approaches like chemical etching. As a consequence, almost every piece of metal is utilized during the production process, with almost no waste of material and reducing material wastage. When using additive manufacturing, all of the extra features that are needed for the assembly, such as fasteners, brazing, or welding, can be omitted. Thus, additive manufacturing also reduces assembly costs.

Difficulty in Producing Large Single Parts

Even if additive manufacturing were to dramatically increase production speed and volume performance, it would still be unable to manufacture large single parts. This is yet another major challenge confronting additive manufacturing researchers as they pursue new applications for 3D printing technology. Arc-based wire feed metal AM was chosen as the best process to produce large metal parts. While metal powder bed printers are available commercially, they are not currently capable of producing large-scale metal parts. Therefore, arc-based wire feed technology provided the most cost-effective solution. The building envelope for current additive manufacturing technologies is limited, meaning even larger components that can be printed must still be assembled by mechanical joining or welding.

For More Details on This Report — Request for SampleKey Market Players:

duct/Service launches, approvals, patents and events, acquisitions, partnerships and collaborations are key strategies adopted by players in the Additive Manufacturing Market. The top 10 companies in this industry are listed below:

Proto Labs, Ltd.

3D Systems, Inc

Stratasys Ltd.

Desktop Metal

Autodesk, Inc.

Materialise NV

Markforged

Optomec, Inc.

Dassault Systemes

Titomic Limited

Geographies Covered

North America (U.S., Canada and Mexico), Europe (Germany, France, UK, Italy, Spain, Netherlands and Rest of Europe), Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand and Rest of Asia-Pacific), South America (Brazil, Argentina, Colombia and Rest of South America), Rest of the World (Middle East and Africa).

Key Market Players

For more Automation and Instrumentation Market reports, please click here

0 notes

Text

Bottle Filling, Capping & Labeling Line

Bottle Filling, Capping & Labeling Line, also known as the liquid filling line, is made up of machinery for cleaning, filling, capping, inspecting, and labeling bottles as they are packaged. Every machine was oriented to function as a single, cohesive system. Its other name, Automatic Bottle Packaging Line, comes from the conveyors of each machine being connected to one other for completely automatic operations. It is used to fill syrups, oral liquids, and oral suspensions in the pharmaceutical sector. The food, chemical, pharmaceutical, cosmetic, and agricultural industries also use production lines.

The bottle filling line is made up of the equipment listed below:

Bottle Washing Machine

The pharmaceutical industries use bottle washing machines, also known as linear bottle washers, extensively. These machines are best suited for round vials. Vials can be manually pushed off the feed table or loaded onto an SS wire mesh conveyor using the feed conveyor’s automatic loading setup. Because vials are automatically fed into pockets, this saves labor. The automated unloading process involves emptying the vial and moving on to the turn table (Optional).

youtube

Bottle Filling Machine

The most popular type of filling machine for filling liquid in various container types is the bottle filler, often known as the bottle liquid filling machine. Aqueous solutions, foamy liquids, and semi-viscous solutions can all be filled with our selection of filling machines. PET, plastic, glass, aluminum, stainless steel, copper, and other containers can all be filled using bottle liquid filler. Adinath bottle filling machines can be used to fill bottles, jars, containers, and other solid packing types. The foundation structure, piston pump, filling needles, and a conveyor belt with stainless steel slats make up the basic unit.

youtube

Bottle Capping Machine

The bottle capper, also known as the bottle capping machine, has been uniquely designed with a stainless steel finish, incorporating an M.S. frame structure with stainless steel enclosures and cladding. The orientation type cap feeder on the ROPP bottle cap sealing machine allows for continuous cap feeding for online operation on any liquid or powder filling line. With the use of interchangeable pieces, this machine can accommodate bottles of different sizes as well as ROPP caps. The ROPP Capping Machine has fewer production requirements and can be used in the pharmaceutical, food, beverage, chemical, pesticide, and liquor sectors, among other packaging industries. It operates automatically online.

youtube

Bottle Inspection Machine

Vials and bottles of liquid are inspected using an online bottle inspection machine. Online Vial & Bottle Inspection Machines are used in the biotech, veterinary, and pharmaceutical industries. This apparatus consists of a three-track conveyor with a hood, an alternate black and white visual inspection background, and illumination configuration. The inspection table is made of stainless steel and has a moving chain of stainless steel slats. Structure supported by adjustable bolts and constructed from square stainless steel pipe. The machine meets GMP requirements.

youtube

Bottle Sticker Labeling Machine

A straightforward mechanism linear design machine, the bottle sticker labeling machine, also known as the bottle self-adhesive sticker labeling machine, is used to mark bottles, jars, cans, tins, and other containers. PET, glass, plastic, aluminum, metal, and tin containers can all be labeled with a bottle labeler. This apparatus has a cutting-edge Micro Processor Control label dispensing mechanism with a product and label detection system. Using an optional unique label sensing system, a specially built electronic and mechanical system applies transparent (No Look) labels to bottles at a very high speed. It’s interesting to note that no new format or change parts are needed to convert a bottle from one size to another.

youtube

#liquid filling line#Automatic Bottle Packaging Line#bottle filling line#Bottle Washing Machine#Bottle Filling Machine#Bottle Capping Machine#Bottle Inspection Machine#Bottle Sticker Labeling Machine#Youtube

0 notes

Text

Aluminium Wire(Copper Cladded)Prices Trend, Monitor, News & Forecast | ChemAnalyst

Aluminum wire (copper-clad) prices have witnessed fluctuations influenced by various factors, including global market dynamics, industrial demand, and raw material costs. Understanding these price movements requires a comprehensive analysis of supply and demand dynamics, technological advancements, and macroeconomic indicators.

One of the primary drivers affecting aluminum wire (copper-clad) prices is the balance between supply and demand within the wire and cable industry. Aluminum wire with a copper cladding is commonly used in electrical applications due to its conductivity and corrosion resistance. Disruptions in the supply chain, such as fluctuations in aluminum and copper prices or availability of key raw materials, can impact the cost of producing aluminum wire (copper-clad) and subsequently affect its market price.

Industrial demand plays a crucial role in determining aluminum wire (copper-clad) prices. The electrical industry is a major consumer of aluminum wire (copper-clad), using it in applications such as power transmission, telecommunications, and automotive wiring. Fluctuations in demand from these sectors, influenced by factors such as infrastructure projects, technological advancements, and regulatory changes, can lead to price volatility for aluminum wire (copper-clad).

Raw material costs significantly influence aluminum wire (copper-clad) prices. The price of aluminum and copper, the primary raw materials for producing aluminum wire (copper-clad), can fluctuate due to changes in global supply and demand dynamics, geopolitical tensions, and currency fluctuations. Any substantial increase in raw material costs is likely to be passed on to consumers in the form of higher aluminum wire (copper-clad) prices.

Get Real Time Aluminium Wire(Copper Cladded) Prices: https://www.chemanalyst.com/Pricing-data/aluminum-wire-copper-cladded-1549

Macroeconomic indicators, such as GDP growth, inflation rates, and currency exchange rates, can indirectly impact aluminum wire (copper-clad) prices by affecting overall industrial activity and consumer demand. Economic downturns or currency devaluations in major aluminum wire (copper-clad)-consuming regions may lead to decreased demand and downward pressure on prices. Conversely, robust economic growth and stable currencies can support higher aluminum wire (copper-clad) prices by stimulating industrial production and infrastructure investments.

Technological advancements and innovation influence aluminum wire (copper-clad) prices by enhancing manufacturing efficiency and product quality. Advanced wire drawing and cladding technologies can lead to cost savings in the production process, potentially mitigating price increases resulting from higher raw material costs or external factors.

Looking ahead, several factors are expected to continue shaping aluminum wire (copper-clad) prices. Continued urbanization, infrastructure development, and technological advancements in emerging economies are likely to drive sustained demand for aluminum wire (copper-clad). Moreover, advancements in materials science and engineering could lead to the development of new applications for aluminum wire (copper-clad), further influencing demand and price levels.

In conclusion, aluminum wire (copper-clad) prices are subject to a complex interplay of factors including supply and demand dynamics, industrial trends, raw material costs, macroeconomic indicators, and technological advancements. Stakeholders in the wire and cable industry must closely monitor these factors to anticipate price movements and make informed decisions. As the global economy evolves and technologies advance, navigating the dynamic landscape of aluminum wire (copper-clad) pricing will remain a key challenge for industry participants.

Get Real Time Aluminium Wire(Copper Cladded) Prices: https://www.chemanalyst.com/Pricing-data/aluminum-wire-copper-cladded-1549

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Remote Robot Lawn Mower Wire Green Safety Cable 3.8mm 3.4mm 2.7mm Signal Cable for Field Lawn Mower

Boundary Wire used for Auto Lawn Mower

The conductor has aluminum core and is coated with copper and tin.

As this cable corresponds to the cable that comes with many new robotic mower it is considered by the

manufacturers of the robot mowers to be adequate for handling the mowers loop signal. An alternative to this cable is our Premium cable of tin-plated copper. To secure the cable in the ground use Grimsholm signal cable holder. Conductor material: Tinned copper clad aluminium Conductor area:1.423 mm2 insulation material: PE Diameter incl insulation: 3.4 mm

0 notes

Text

Copper Clad Steel Wire Market Estimated to Witness High Growth Owing to Rising Demand in Construction Industry

Copper clad steel wire is a type of composite material consisting of a steel core coated with a layer of copper. It possesses properties of both steel such as high strength and copper such as excellent conductivity. Copper clad steel wire is majorly used in transformers, motors, generators and other electrical equipment for its ability to efficiently conduct electricity while providing mechanical strength. It helps in reducing energy losses and enhancing the performance of equipment. The growing construction industry has augmented the demand for power infrastructure and electric vehicles which is propelling the copper clad steel wire market.

The global copper clad steel wire market is estimated to be valued at US$ 0.99 Bn in 2023 and is expected to exhibit a CAGR of 47% over the forecast period 2023 to 2030. Market Dynamics: One of the key drivers for the copper clad steel wire market size is the rising demand from the construction industry. Rapid urbanization and growing investments in infrastructure development projects across both developed and developing economies are fueling the demand for electricity. This is subsequently propelling the need for efficient conductors like copper clad steel wire in transformers and other equipment being installed at construction sites as well as in power grids. Moreover, increasing investments towards upgrading the existing power infrastructure to integrate renewable energy will further support the market growth over the coming years. However, volatile copper prices continue to pose challenges for market players. Copper Clad Steel Wire Market SWOT Analysis Strength: Copper clad steel wire has high tensile strength and flexibility. Its conducts electricity well while resisting corrosion making it ideal for electrical and telecom applications. It can withstand higher operating temperatures compared to aluminium and copper wires. Weakness: Raw material prices especially of copper and steel are volatile which increases production costs. Copper clad steel wire requires more complex manufacturing processes than plain copper or aluminium wires raising costs. Opportunity: Growing power transmission and distribution networks in developing regions drives demand. Rising investments in telecommunication infrastructure expansion opens new avenues. Rapid urbanization and industrialization boosts construction activities employing copper clad steel wires. Threats: Developing energy efficient alternatives and technologies pose substitution threat. Slowdown in major end-use sectors impacts demand adversely. Trade wars and geo-political issues disrupts supply chains. Key Takeaways The global copper clad steel wire market is expected to witness high growth. The global copper clad steel wire market is estimated to be valued at US$ 0.99 Bn in 2023 and is expected to exhibit a CAGR of 47% over the forecast period 2023 to 2030.

Regional analysis comprises Asia Pacific dominates currently due to massive infrastructure development and industrialization in China and India. It is expected to maintain its leading position throughout the forecast period backed by continuing investments. Key players operating in the copper clad steel wire market are Ballard Power Systems, Toyota Motor Corporation, Hyundai Motor Company, New Flyer Industries, Van Hool, Wrightbus. Copper clad steel wire finds wide usage in electrical distribution, power generation and transmission, telecommunications, and construction industries. It exhibits superior conductivity and ability to withstand high operating temperatures compared to copper and aluminum.

Get more insights on this topic: https://www.newswirestats.com/copper-clad-steel-wire-market-size-and-outlook/ Explore more information, Please visit:https://www.urdughr.com/2023/12/ecoelegance-cellulose-plastics-the-green-alternative-to-traditional-petroleum-based-plastics.html

#Copper Clad Steel Wire#Copper Clad Steel Wire Market#Copper Clad Steel Wire Market size#Copper Clad Steel Wire Market share#Coherent Market Insights

0 notes

Text

Copper Clad Copper Wire (CCC Wire)

Copper-clad copper (copper-plated copper) is a new generation of products based on copper-clad steel and copper-clad aluminum technology. It uses high-quality alloy copper wire as the base material and covers its surface with a layer of pure copper (red copper) through advanced copper plating technology. It is the preferred material for audio and video wires, electronic wires, and communication cables.

Advantages:

1) Compared with copper-clad aluminum, copper-clad copper has good oxidation resistance and tensile strength;

2) Compared with copper-clad steel, copper-clad steel has better conductivity and oxidation resistance.

Our company can provide the environmental RoHS report tested by SGS.

0 notes

Text

Transoceanic Fiber Optics: The Cable That Runs the Tech World

by Scott Mortenson

A few years ago, an underwater cable broke, plunging a nation into Internet darkness. While some may say not having Facebook for a few hours is a positive thing, this was more than that, called “an absolute disaster . . . a national crisis.” It cut off not just social media, but email, cell phone service, financial transactions, business, and government communications.

It's still not clear what caused the breakage, but it was fixed about two weeks later.

And then, in 2022, it happened again. Only this time, it was worse.

You may recall seeing news on the Tonga volcano eruption and tsunami that left at least 6 dead, 19 injured, and others reported missing, with $90.4 million in damages. Besides bearing a devastating natural disaster, the people in Tonga lost their main connection to the outside world.

We can certainly understand why a volcanic eruption hundreds of times more powerful than the atomic bomb would take out a transpacific fiber optic cable, but it also underscores the fragility of our digital lives.

A Brief History

In a way, the whole idea of laying a cable on the bottom of the ocean floor almost sounds like science fiction. How does a cable thousands of miles long even get made? How do they get it on the boat? How do they lay it on the ocean floor?

Cable breakages on land are bad enough, with everything from construction equipment, fires, even vandalism disrupting the fiber optics. But land “interruptions” are relatively easy to fix. How do they get repaired 25,000 feet (about 7.62 kilometers) underwater?

Communication cables laid on the ocean floor were not created when the Internet came along. The first “submarine cable” was dropped into the water in 1858, but only lasted about three weeks. It was attempted again in 1866, and worked, sending telegraph signals across the Atlantic. Telephone communications (i.e., AT&T) used underwater cables beginning in 1956 and the Internet started utilizing them in 1988.

Today, some estimates say there are 550,000 miles (about 885,000 kilometers) of transoceanic fiber optic cables, while others claim 750,000. That’s like stringing a line from the moon and back twice. Whatever the actual number, it is a lot, which means “The Cloud” is not really in the sky, but 5 miles underwater.

The cable itself is just a little bit more complex than its land-locked cousin. A “standard” fiber optic cable has a core, a cladding layer, and is usually coated with acrylate polymer or polyamide. There could be more layers of protection, depending on the application. Inside all of that is the optical fiber which carries the light. A submarine cable resting on the bottom of the ocean has more layers to protect it than a land-based one, like a scuba diver wears more than just a swimming suit.

A cross section of the shore-end of a modern submarine communications cable.

1) Polyethylene, 2) Mylar tape, 3) stranded steel wires, 4) aluminum water barrier, 5) polycarbonate, 6) copper or aluminum tube, 7) petroleum jelly, 8) optical fibers

Drawing by Oona Räisänen

—

Despite all this protection, an underwater cable can be damaged not just by volcanoes and tsunamis, but earthquakes, storm currents, ship anchors, and fishing trawlers. Even sharks looking for a snack.

Politics get involved as well, with both transoceanic cables and pipelines being sabotaged or blown up over governmental agendas and spats.

How The Cables Are Made

As for the manufacturing process of undersea cables . . . yes, it is a big process. The cables are fed into a high-speed mill the size of a jet engine, put in a copper casing that may have plastic, steel or aluminum and even tar added to protect it from the elements.

You may think the end-product is fat and big, but it’s about as big as a larger-size garden hose. And the cable is designed to last 25 years if not subjected to volcanoes, earthquakes, or fishing trawlers.

The planning of where the cable is laid in the ocean takes at least a year so they can arrange its course miles underwater, where the seabed has been charted but a little unpredictable. After all, there are both trenches and mountains down there.

Implementing The Fiber Optic Cable

Alcatel Submarine Networks (a part of Nokia) has more than 700,000 kilometers (435,000 miles) of optical submarine systems deployed worldwide (enough to circumnavigate the globe 16 times). One of the ships used to deploy the cable is about 450 feet long and can have as many as 80 crew members, with teams working in two 12-hour shifts. Although they have plenty of food for their long journey (two months or more), alcohol is not allowed. That’s for the better since the seas can be rough, sometimes so bad the captain may order operations to stop, cut the cable and find safe waters. Before cutting the cable, they tie a buoy to it so they can find it when they return.

Of course, the ship does not carry enough cable to span the whole ocean, so it is done in segments. The ship can carry up to 4,000 miles (about 6437.38 km) and it can take a month for the gigantic tanks (where the cable is stored) to be fully loaded.

A special subsea plow is used to trough and bury submarine cables along the seabed closer to shorelines where things like anchoring and fishing are most prevalent and could damage submarine cables.

Out at sea, the cable is unspooled into the water, attached to several buoys temporarily so it doesn’t sink to the bottom too soon. Once out far enough, the buoys are removed and the cable sinks to the ocean floor. This is repeated over and over.

Those of you who are thinking “Wait a minute! The light in fiber optics can only go so far before it loses strength — how can a cable traveling thousands and thousands of miles keep the signal alive?”

Repeaters placed every 60-70 kilometers — about 40 miles.

The Technology of Submarine Cable

Power to the repeater is fed from power feeding equipment, which is located in Submarine Cable Station. In traditional submarine cables, every fiber pair will have their own repeaters, and four fiber pairs will have a repeater with a four-amplifier chassis. One amplifier chassis has dual laser 980nm pump units. This is called 2x2 Pump redundancy, the type of redundancy scheme used in the past.

Now they use 4x2 redundancies, improving reliability by using additional 2 pump lasers compared to the 2x2 pump redundancies. Two EDFA’s share the power from four pump lasers, which can tolerate three-pump laser failure at most in each fiber pair.

The submarine cables use DWDM (Dense Wavelength Division Multiplexing) so the data capacity is maximized at hundreds of Gbps (gigabits per second). The cables also employ optical amplifiers (a.k.a. repeaters) that boost the signals across each cable section.

So, yes, laying a cable from, say, Oregon to Japan is quite complicated and time-consuming to say the least.

From Land to Sea to Land

Once the cable (or more accurately, series of cables) reaches its land-based destination, it is connected to submarine line terminal (SLTE) and power feed equipment (PFE) installed at a cable landing station. The PFE can be installed at a cable landing station, while at another inland location — such as a data center or central office — the SLTE is set in place.

There is, like everything in the tech world, much more to the technology, but that is a basic look at how your laptop gets connected to a webpage in Japan or Spain.

0 notes

Text

Application fields and precautions of copper-clad aluminium wire

Copper-clad aluminum enameled wire is a new type of electromagnetic wire using copper-clad aluminum material as the inner conductor.

advantage:

Its characteristics are between copper and aluminum, combining the excellent electrical conductivity of copper with the advantages of aluminum's light weight.

Features:

1. DC resistivity: The DC resistivity of copper-clad aluminum wire is about 1.45 times that of pure copper wire; when the resistance is the same, the weight of copper-clad aluminum wire is about 1/2 of that of pure copper wire.

2. Good solderability: Because the copper-clad aluminum wire is concentrically covered with a layer of pure copper, it has the same solderability as pure copper wire without the need for special treatment like aluminum wire; meanwhile, copper The aluminum-clad wire has a thicker copper layer to ensure that the solder performance of the product will not be affected when scraping paint;

3. Light weight: Copper-clad aluminum wire density is 1 / 2.5 of pure copper wire with the same diameter, which is very effective in reducing the weight of the coil; using Shenzhou copper-clad aluminum wire instead of copper wire can save at least 30% of cost.

Application areas:

1. High-frequency transformers and ordinary transformers;

2. Inductance, electromagnetic coil;

3. Motors, including household motors, various micro-motors, and compressors, which have higher environmental requirements;

4. Special electromagnetic wires for audio coils and optical drives;

5. Magnet wire for display deflection coil;

6. Electromagnetic wire for degaussing coil;

Precautions:

1. Copper-clad aluminum enameled wire can be used for signal transmission, but now it is used for power transmission, it is easy to cause problems, and the life of its products will be greatly reduced. In fact, in the use of copper-clad aluminum enameled wire, pay attention to the oxidation protection of the lower side of the enameled wire to ensure the effective combination of copper and aluminum, which can be used for a long time.

2. Copper-clad aluminum wire and copper-clad aluminum enamelled are actually unavailable in many areas, but the fact that many companies use transformers is very worrying. There are two concerns about the use of copper-clad aluminum wire. The specific resistance itself is higher than that of copper of equal section and the problem of temperature rise; the easy oxidation of aluminum wire will further increase the resistance of the wire and prevent oxidation.

3. What is worrying is the combination of copper and aluminum in the copper-clad aluminum wire. The metallurgical combination often said in the industry is truly reliable in the long-term use process, and whether the copper-aluminum bonding ability can Withstand the test, there is no real argument in the industry.

1 note

·

View note

Text

Aluminum Wire (Copper Cladded) Prices | Pricing | Trend | News | Database

Aluminum wire, particularly copper-clad aluminum wire, has garnered significant attention in various industries due to its unique properties and cost-effectiveness. As markets evolve, understanding the pricing dynamics of copper-clad aluminum wire becomes essential for businesses and consumers alike. The prices of aluminum wire can fluctuate based on several factors, including raw material costs, market demand, and advancements in technology.

Copper-clad aluminum wire combines the lightweight characteristics of aluminum with the excellent conductivity of copper. This duality offers a compelling alternative to traditional copper wire, particularly in applications where weight is a critical factor, such as in aerospace and automotive industries. The manufacturing process involves coating aluminum wire with a thin layer of copper, which significantly enhances its electrical performance while maintaining a lower overall weight compared to solid copper wire.

Get Real Time Prices for Aluminum Wire (Copper Cladded): https://www.chemanalyst.com/Pricing-data/aluminum-wire-copper-cladded-1549The market for aluminum wire, especially copper-clad variants, has seen a steady increase in demand. Factors driving this demand include the growing emphasis on energy efficiency and the rising costs of raw copper. As industries strive to reduce costs without compromising performance, copper-clad aluminum wire presents an attractive solution. Moreover, its resistance to corrosion and lightweight nature make it an ideal choice for many applications, further boosting its market presence.

Price trends for aluminum wire can be influenced by several external variables. For instance, fluctuations in the price of raw materials such as copper and aluminum significantly impact the cost of production. As global supply chains adapt to geopolitical changes, the prices of these metals can vary, directly affecting the pricing of copper-clad aluminum wire. Market analysts often monitor these trends to provide insights into future pricing, allowing businesses to make informed purchasing decisions.

Additionally, the demand-supply dynamics play a crucial role in determining the prices of aluminum wire. When demand surges, particularly in construction, automotive, and electrical sectors, the prices may see a corresponding increase. Conversely, in periods of oversupply or decreased demand, prices may stabilize or even drop. This volatility necessitates that buyers stay updated on market trends and forecasts to navigate pricing effectively.

Technological advancements in manufacturing processes also contribute to pricing dynamics. Innovations that enhance the efficiency of producing copper-clad aluminum wire can lead to reduced production costs, which may translate into more competitive pricing in the market. Companies that invest in research and development often find themselves with a pricing advantage, allowing them to offer high-quality products at lower prices, thus attracting more customers.

The geographical location of suppliers can also influence pricing. In regions where aluminum and copper resources are abundant, the production costs may be lower, leading to more competitive pricing structures. Conversely, in areas where these materials must be imported, the added transportation costs can inflate prices. This geographic pricing variability emphasizes the importance of sourcing strategies for businesses looking to procure aluminum wire.

Another important aspect is the impact of regulatory policies on pricing. Environmental regulations, for instance, can influence production costs, especially if manufacturers are required to implement greener technologies or comply with strict waste management practices. Compliance with such regulations may add to the overall costs, which can be reflected in the final pricing of copper-clad aluminum wire.

As industries increasingly focus on sustainability, the demand for recyclable materials has risen. Aluminum wire is known for its recyclability, making it an attractive option for environmentally-conscious consumers and businesses. This growing trend towards sustainable materials may affect pricing, as companies that emphasize recycling may command a premium for their products, reflecting their commitment to environmental stewardship.

In addition, the global economic climate can have profound effects on aluminum wire pricing. Economic growth in emerging markets often leads to increased infrastructure development and a surge in demand for electrical wiring. As countries invest in modernizing their power grids and expanding transportation networks, the demand for copper-clad aluminum wire may rise, leading to potential price increases. Conversely, economic downturns can dampen demand, resulting in more competitive pricing as suppliers seek to maintain sales volumes.

For businesses involved in the electrical and construction industries, staying informed about the pricing trends of aluminum wire, particularly copper-clad variants, is essential for strategic planning. Understanding the factors that influence these prices allows companies to better manage their budgets and forecast future expenses. Engaging with suppliers who provide transparent pricing and updates on market trends can further enhance procurement strategies, ensuring that businesses secure the best possible deals.

In conclusion, the pricing of aluminum wire, especially copper-clad aluminum, is shaped by a multitude of factors ranging from raw material costs and market dynamics to technological advancements and regulatory influences. As demand continues to grow and industries evolve, understanding these elements is vital for anyone involved in the purchasing or selling of aluminum wire. By staying informed about market conditions and trends, stakeholders can navigate the complexities of pricing more effectively, ensuring they make informed decisions that benefit their operations and bottom line.

Get Real Time Prices for Aluminum Wire (Copper Cladded): https://www.chemanalyst.com/Pricing-data/aluminum-wire-copper-cladded-1549

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Aluminum Wire (Copper Cladded)#Aluminum Wire (Copper Cladded) Prices#Aluminum Wire (Copper Cladded) News

0 notes

Text

Long Island Residential Electrical Wiring: An In-Depth to Learning the Basics

Long Island Residential Electrical Wiring: An In-Depth to Learning the Basics

Outline

Knowing How to Wire Residential Properties Electrically

Set off on an adventure to learn the principles of Long Island residential electrical wiring. We can help you with everything from fundamental ideas to sophisticated methods.

The Importance of Safe Electrical Wiring

Learn why residential homes require adequate electrical wiring. Investing in high-quality electrical wiring is essential for a number of reasons, including ensuring efficiency, safety, and regulatory compliance.

Major Residential Electrical System Components Explore the key elements that comprise domestic electrical systems. Comprehending various components, such as outlets, switches, and circuit breakers, is essential for efficient wiring. Long Island Electrical Wiring Codes and Regulations Keep up with the most recent Long Island electrical codes and regulations. Adherence to these guidelines is crucial in order to guarantee safety and prevent possible legal complications.

Wiring Types Appropriate for Residential Properties Examine the many kinds of wiring that are frequently utilized in residential buildings. Consider the advantages and disadvantages of various options, such as copper-clad aluminum and aluminum and copper wire, in order to make well-informed choices.

How to Plan and Design an Electrical System Discover the significance of careful planning and design for electrical wiring. A safe and effective electrical system is largely dependent on variables including load calculations, circuit structure, and outlet and fixture location. Safety Measures to Take While Installing Electrical Wiring Throughout the installation of the electrical wiring, put safety first. Precautions can help avoid mishaps and injuries by employing the right instruments and equipment and adhering to safety procedures.

FAQs About Electrical Wiring for Residential Properties in Long Island

FAQs

Is it necessary to hire a professional electrician for residential wiring projects?

While DIY electrical work may seem tempting, hiring a licensed electrician is highly recommended to ensure safety and compliance with regulations.

What factors should I consider when choosing electrical wiring materials?

Factors such as durability, cost, and compatibility with your home's electrical system should be taken into account when selecting wiring materials.

How often should residential electrical systems be inspected?

It's advisable to schedule regular inspections by a qualified electrician to detect any potential issues and ensure the continued safety and performance of your electrical system.

Can I upgrade my home's electrical system to meet increased power demands?

Yes, upgrading your electrical system may be necessary if you're adding new appliances or experiencing frequent power disruptions. Consult with a licensed electrician to assess your needs and make appropriate upgrades.

What are the signs of electrical problems in residential properties?

Signs such as flickering lights, tripped circuit breakers, and burning odors indicate potential electrical issues that should be addressed promptly by a professional electrician.

Are there any government incentives or rebates available for upgrading residential electrical systems?

Depending on your location and specific circumstances, there may be government incentives or rebates available for energy-efficient upgrades to your home's electrical system. Consult with local authorities or utility companies for more information.

To sum up

Well done on taking the initial step toward becoming an expert in Long Island residential electrical wiring! With the right information and by adhering to best practices, you can guarantee the dependability, efficiency, and safety of the electrical system in your house. Always put safety first, and seek the advice of a licensed electrician before beginning any complicated wiring projects.

#Electrical Wiring Residential Long Island#Electric Repair Service Long Island#24 hour Electrician Long Island

1 note

·

View note

Photo

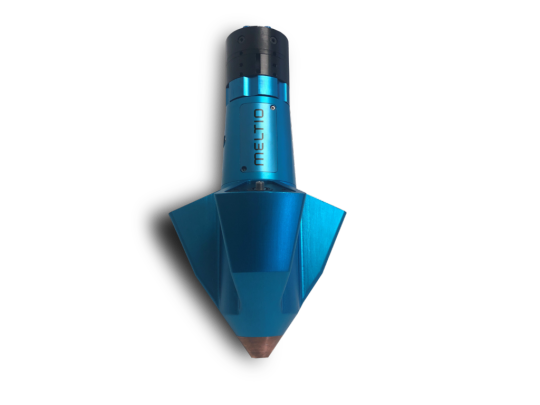

Meltio’s 3E Metal Deposition Technology: Easy, Efficient and Expandable Meltio has entered the 3D printing market to meet the needs of industries that have been waiting years for a reliable, accessible, and hassle-free solution to implement direct metal 3D printing into the production process. Thanks to an exclusive development, Meltio’s unique patented technology brings many advantages compared to existing technologies in the industry. It’s what the company has called 3E Metal Deposition Technology: Easy, Efficient and Expandable. Meltio defines its technology as easy because it avoids the inconveniences of existing metal 3D printers. The outer dimensions of the hardware are significantly compact (550x600x1400 mm), without the typical hassle of common and bulky industrial hardware, which usually needs special facilities and infrastructure. The multi-laser printhead, which is in fact the core of this technology, is able to manufacture with metal wire, which makes the operation clean and safe and with 100% material utilization. Apart from this, the printers are able to fabricate parts with metallic wire, powder, or by combining both materials in the same part and without changing the nozzle, which is an industry first. The result is 100% dense metal parts made of any material commonly used in welding: titanium, steel, copper, aluminum, Inconel, etc. The new development will also allow many companies to integrate metal 3D printing in their workflows, by lowering traditional access barriers in terms of pricing. The acquisition cost of hardware is about 50% to 75% lower than current market prices and material cost is up to 10 times lower, which is a significant step towards massive adoption of direct metal 3D printing. Moreover, the possibilities of Meltio’s 3D printing are easily expandable thanks to the integration of 3D printing modules (Meltio Engine) with CNC, robotic, or gantry systems. This way manufacturing possibilities range from small parts to parts of several meters in size, turning traditional systems into hybrid ones with metal deposition capabilities. This makes the technology easily adaptable to multiple applications across various industries including aerospace, automotive, and large scale manufacturing. How it works 3E Metal Deposition technology works with a multi-laser printhead with a high-power capacity (0.6 to 6 kw). The highly compact deposition head (150mm width/depth x 265mm height) features three independent diode lasers (although more lasers can be added as an upgrade for more power). The printing takes place within an argon chamber that only requires a small amount of gas or in an open atmosphere with just nozzle argon shield gas coverage. Furthermore, changing materials is automatic and accomplished in seconds without the risk of contamination, unlike powder bed fusion technology where it is necessary to perform time-consuming decontamination between material changes. The system features active process control, which automatically sets the nozzle to part distance for each layer and also manages process parameters throughout the print based on sensor feedback. Meltio’sunique laser technology allows the production of metallic alloys which are usually difficult to weld. In addition, more applications can be used besides 3D printing: repairing of existing parts through additive manufacturing, cladding, welding (autogenous and with filler), curing, texturing and polishing. This technology has a significant endorsement through ArcelorMittal, the world leading steel manufacturing company, which has participated in the company since its formation. Meltio is a new joint venture with the participation of Additec, an American company based in Las Vegas, Nevada, and Sicnova, a Spanish company with a vast history in the 3D field. its inception has been an international company with a clear global vision and offices in United States and Spain. The main headquarters and factory are located in Linares, Jaen (Spain), with R&D centers in both, the US and Europe. Meltio’s new metal 3D printer, the Meltio M450, and the Engine deposition modules for hybrid manufacturing and robotic applications, will be showcased at Formnext November 19th-22nd (Hall 12.1, booth C111). The stand will also feature other additive manufacturing and 3D digitalization solutions from Meltio’s portfolio. The post Meltio’s 3E Metal Deposition Technology: Easy, Efficient and Expandable appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. https://buff.ly/2NCpSlI

1 note

·

View note

Text

Electrical power Wire Done Affordably

There are several kinds of electrical wire. Each different kind of electrical wire is good for a different job. The wires have even kinds of insulation and protection; itrrrs this that makes every one great for another application. There is THHN and TFFN wires that happen to be similar. You can also find the NM-B and Romex wires and even the MC Conduit cable. Many of these wires are ideal for electrical work indoors and some ones could also be used outside, as well as in conduit. TFFN and THHN Both these wire names are abbreviations. TFFN is short for thermoplastic insulation, flexible, fixture, and nylon coating. Even though the THHN stands for thermoplastic insulation, heat resistant, high heat resistant, and nylon coating. Then throw in that many of the THHN wires come during a water, coal and oil resistant form, so you get THWN wire. These are all single conductor copper wires that can be used both indoors, outdoors along with conduit.

NM-B and Romex Romex may be the Southwire model of an NM-B cable. Currently the NM is short for non-metallic. Because of this instead of the wire being incased in the metal jacket. The NM-B cable has a PVC jacket across the multiple conductors it holds. Now this form of electrical wire are only able to supply indoors. The wire doesn't have enough protection about it for use outside. The most typical use because of this sort of wire is within insulated homes and buildings, running power from electrical boxes to outlets, appliance and lighting. MC Conduit Cable This type of electrical cable is incredibly different from the NM-B cable. That is because the MC Conduit cable is metal clad. This type of electrical cable comes with a aluminum interlocked armor jacket rather than typical PVC. The aluminum jacket round the wires conductors is supposed to become a conduit there will not the need for one if it's being installed. This design is additionally designed to speed up the installation process, consequently saving electricians and contractors both time and cash. These electrical wires can be used indoors as building wire. Most can also be used outdoors in conduit also. Now even though most of these wires are somewhat similar, they may be still different, which means the variation in applications. Make sure to have a look at your entire choices to find the appropriate wire for your job or project! To learn more about ong thep luon day dien SMARTUBE visit our new web portal.

1 note

·

View note

Text

Seven in-ear headphones

First, VSONIC GR07 in-ear headphones

product description:

VSONIC GR07 adopts the 11mm drive, which adopts the official design of “100-layer composite diaphragm material”, CCAW copper-clad aluminum voice coil design, and the wire is the 82-core silver wire that VSONIC likes.

Second, Rhapsodio Solar in-ear headphones

product description:

The new ten-balanced armature single earphone Solar is very different from the previous slightly crowded performance. The previous version is prone to the problem of sound field disorder. Although the instrument and the human voice are not without separation, they are easy to get together. The new Solar has improved a lot. However, the low frequency still has a general multi-balanced armature. The earphones are not natural enough for the point-like dive. However, compared with the balanced armature headphones, the style of the near-field monitoring is more important. The presentation of the sound field is still more spacious.

Third, Sennheiser IE80 professional monitor earplugs

Word of mouth commentary:

The new IE80 in-ear earphone features high-fidelity stereo enhancement and high-noise passive attenuation with excellent bass response and effective noise isolation. Designed for high-intensity use, the IE80 is a rugged earphone case and headphone cord for a sleek, ergonomic look. The safety cover and cleaning tools take care of your earbuds. Different sizes of ear adapters are available for different sizes of ear canals until your comfort is met.

Fourth, Noble Audio Savant headphones

product description:

The Noble Audio Savant is different from the previous Classic series. Its structure and shape are modeled on the Kaiser 10, but it is superior in terms of sound, especially the low-frequency texture.

Fifth, Ultimate Ears In-Ear Reference Monitors In-Ear Headphones

product description:

Tone balance is the avatar of this headset. It is difficult for me to find a word to describe the sound of UERM. UERM provides a smooth response curve. Compared with the response curve of the general headphones, you can always be simple. It was found that UERM provides a softer sound line and a more natural tone balance. Of course, I mentioned that he has a slightly rolled off at the very high frequency, which makes him lack the airiness that some flag earmuffs can provide, but it also Brings a warmer tone, making it easier to listen for longer.

Six, HiFiMAN RE-400 in-ear headphones

Word of mouth commentary:

The RE-400 looks a bit dazzling and the cavity is designed to be smaller. The material is no different from the previous RE-0 and is still made of metal. The silver look of the RE-400 looks very beautiful, and it shines brightly and beautifully under the illumination of the light. A change to the traditional black design may have the opposite effect, but for HiFiMAN it is not the case, the appearance of the RE-400 will make people shine.

Seven, Sony MDR EX1000 headphones

Word of mouth commentary:

The application of liquid crystal polymer technology to the unit diaphragm, with a variety of earplugs of different sizes and functions, can be seen in the SONY's intentions for the MDR-EX1000. The MDR-EX1000 is light and elegant in terms of sound and has strong rendering power in the middle and high frequency. It is very pleasing to the user's ear in the vocal interpretation. The low-frequency dive is good, the sense of volume and speed are quite good, and the level of detail is clear.

1 note

·

View note

Text

Boundary Wire Installation Kits

Boundary Wire used for Auto Lawn Mower

The conductor has aluminum core and is coated with copper and tin.

As this cable corresponds to the cable that comes with many new robotic mower it is considered by the manufacturers of the robot mowers to be adequate for handling the mowers loop signal. An alternative to this cable is our Premium cable of tin-plated copper. To secure the cable in the ground use Grimsholm signal cable holder. Conductor material: Tinned copper clad aluminium Conductor area:1.423 mm2 insulation material: PE Diameter incl insulation: 2.7 mm; Metal Mesh; Diameter incl jacket: 4.2 mm

0 notes