#Copper Clad Steel Wire Market

Explore tagged Tumblr posts

Text

Copper Clad Steel Wire Market Estimated to Witness High Growth Owing to Rising Demand in Construction Industry

Copper clad steel wire is a type of composite material consisting of a steel core coated with a layer of copper. It possesses properties of both steel such as high strength and copper such as excellent conductivity. Copper clad steel wire is majorly used in transformers, motors, generators and other electrical equipment for its ability to efficiently conduct electricity while providing mechanical strength. It helps in reducing energy losses and enhancing the performance of equipment. The growing construction industry has augmented the demand for power infrastructure and electric vehicles which is propelling the copper clad steel wire market.

The global copper clad steel wire market is estimated to be valued at US$ 0.99 Bn in 2023 and is expected to exhibit a CAGR of 47% over the forecast period 2023 to 2030. Market Dynamics: One of the key drivers for the copper clad steel wire market size is the rising demand from the construction industry. Rapid urbanization and growing investments in infrastructure development projects across both developed and developing economies are fueling the demand for electricity. This is subsequently propelling the need for efficient conductors like copper clad steel wire in transformers and other equipment being installed at construction sites as well as in power grids. Moreover, increasing investments towards upgrading the existing power infrastructure to integrate renewable energy will further support the market growth over the coming years. However, volatile copper prices continue to pose challenges for market players. Copper Clad Steel Wire Market SWOT Analysis Strength: Copper clad steel wire has high tensile strength and flexibility. Its conducts electricity well while resisting corrosion making it ideal for electrical and telecom applications. It can withstand higher operating temperatures compared to aluminium and copper wires. Weakness: Raw material prices especially of copper and steel are volatile which increases production costs. Copper clad steel wire requires more complex manufacturing processes than plain copper or aluminium wires raising costs. Opportunity: Growing power transmission and distribution networks in developing regions drives demand. Rising investments in telecommunication infrastructure expansion opens new avenues. Rapid urbanization and industrialization boosts construction activities employing copper clad steel wires. Threats: Developing energy efficient alternatives and technologies pose substitution threat. Slowdown in major end-use sectors impacts demand adversely. Trade wars and geo-political issues disrupts supply chains. Key Takeaways The global copper clad steel wire market is expected to witness high growth. The global copper clad steel wire market is estimated to be valued at US$ 0.99 Bn in 2023 and is expected to exhibit a CAGR of 47% over the forecast period 2023 to 2030.

Regional analysis comprises Asia Pacific dominates currently due to massive infrastructure development and industrialization in China and India. It is expected to maintain its leading position throughout the forecast period backed by continuing investments. Key players operating in the copper clad steel wire market are Ballard Power Systems, Toyota Motor Corporation, Hyundai Motor Company, New Flyer Industries, Van Hool, Wrightbus. Copper clad steel wire finds wide usage in electrical distribution, power generation and transmission, telecommunications, and construction industries. It exhibits superior conductivity and ability to withstand high operating temperatures compared to copper and aluminum.

Get more insights on this topic: https://www.newswirestats.com/copper-clad-steel-wire-market-size-and-outlook/ Explore more information, Please visit:https://www.urdughr.com/2023/12/ecoelegance-cellulose-plastics-the-green-alternative-to-traditional-petroleum-based-plastics.html

#Copper Clad Steel Wire#Copper Clad Steel Wire Market#Copper Clad Steel Wire Market size#Copper Clad Steel Wire Market share#Coherent Market Insights

0 notes

Text

Global Copper Clad Steel Wire Market Is Estimated To Witness High Growth Owing To Increasing Demand

The global Copper Clad Steel Wire Market is estimated to be valued at US$12,366.13 million in 2020 and is expected to exhibit a CAGR of 6.84% over the forecast period of 2021 to 2028, as highlighted in a new report published by Coherent Market Insights. A) Market Overview: Copper clad steel wire is a composite conductor consisting of a copper coating that is metallurgically bonded to a steel wire core. It combines the conductivity of copper with the strength and durability of steel, making it an ideal choice for various applications. The market for copper clad steel wire is witnessing high growth due to the increasing demand for high-quality conductive materials in industries such as telecommunications, electronics, power distribution, infrastructure, and automotive. Copper clad steel wire offers superior electrical conductivity while maintaining mechanical strength, making it suitable for high-performance applications. B) Market Key Trends: One key trend in the global copper clad steel wire market is the growing demand for lightweight and energy-efficient vehicles. The automotive industry is increasingly adopting copper clad steel wire for wiring harnesses and connectors due to its lightweight nature and excellent electrical conductivity. This helps in reducing the overall weight of vehicles, improving fuel efficiency, and reducing carbon emissions. For instance, automakers are incorporating copper clad steel wire in electric vehicles (EVs) to enhance their performance and range. C) PEST Analysis: Political: The political stability of countries and their trade policies can impact the import and export of copper clad steel wire. Changes in government regulations and tariffs can influence the market dynamics. Economic: Economic factors such as GDP growth, disposable income of consumers, and infrastructure development play a significant role in the demand for copper clad steel wire. Social: The increasing adoption of advanced technologies in industries such as telecommunications and electronics is driving the demand for copper clad steel wire. Technological: Technological advancements in the manufacturing processes of copper clad steel wire, such as improved bonding techniques and coating methods, are enhancing the product quality and driving market growth. D) Key Takeaways: 1. The global Copper Clad Steel Wire Market Growth is expected to witness high growth, exhibiting a CAGR of 6.84% over the forecast period. The increasing demand for high-quality conductive materials in various industries is one of the key factors driving market growth. 2. In terms of regional analysis, Asia-Pacific is expected to be the fastest-growing and dominating region in the copper clad steel wire market. The region's rapid industrialization, infrastructural development, and increasing automotive production are propelling market growth. 3. Key players operating in the global copper clad steel wire market include Elecref Industries Inc., Copperhead Industries LLC, Fisk Alloy Inc., LEONI Wire Inc., AFL, MWS Wire Industries Inc., Kris-Tech Wire, Nehring Electrical Works Company, and American Wire Group Inc. These companies are focusing on product innovation, strategic collaborations, and mergers and acquisitions to expand their market presence. The global copper clad steel wire market is witnessing high growth due to the increasing demand for high-quality conductive materials. The market is driven by the adoption of copper clad steel wire in industries such as telecommunications, electronics, power distribution, infrastructure, and automotive. The growing trend of lightweight and energy-efficient vehicles is also contributing to market growth. Asia-Pacific is expected to be the fastest-growing region, while key players are focusing on product innovation and strategic partnerships to gain a competitive edge in the market.

0 notes

Text

Copper Clad Steel Wire Market Analysis: Exploring the Future Scope and Opportunities in the Global Copper Clad Steel Wire Industry

Copper clad steel wire is a composite material consisting of a steel core that is encased in a layer of copper. This wire combines the strength and durability of steel with the excellent electrical conductivity of copper. It is commonly used in applications such as electrical cables, telecommunications, electronics, and the automotive industry. Copper clad steel wire offers a cost-effective alternative to solid copper wire, providing similar electrical conductivity while being more affordable due to the reduced use of copper. Its corrosion resistance, high tensile strength, and suitability for various environmental conditions make it a popular choice in different industries.

The copper clad steel wire market is a segment of the global wire and cable industry. Copper clad steel wire is a composite material consisting of a steel core covered with a layer of copper. This combination provides the advantages of both materials, with the strength and durability of steel and the excellent conductivity of copper.

Applications of Copper Clad Steel Wire:

Electrical Cables: Copper clad steel wire is commonly used in electrical cables and wiring due to its high electrical conductivity. It is used in power transmission and distribution systems, as well as in various electrical appliances and equipment.

Telecommunications: CCS wire is widely used in the telecommunications industry for applications such as coaxial cables, antenna wires, and grounding systems. Its electrical conductivity and mechanical strength make it suitable for transmitting signals over long distances.

Electronics: Copper clad steel wire is utilized in various electronic devices and components. It is commonly found in connectors, circuit boards, and electromagnetic shielding due to its conductivity and magnetic properties.

Automotive Industry: CCS wire is employed in the automotive sector for applications like battery cables, wiring harnesses, and grounding systems. Its strength and corrosion resistance make it suitable for demanding automotive environments.

Market Dynamics: The copper clad steel wire market is influenced by several factors, including:

Growing Demand for Electricity: The increasing demand for electricity, driven by industrialization, urbanization, and infrastructure development, is boosting the demand for copper clad steel wire in power transmission and distribution systems.

Telecommunication Infrastructure Expansion: With the rise in data consumption and the deployment of 5G networks, there is a significant demand for high-quality cables and wires, including copper clad steel wire, to support the expanding telecommunication infrastructure.

Cost-Effectiveness: Copper clad steel wire offers a cost-effective alternative to solid copper wire. It provides similar electrical conductivity while being more affordable due to the reduced use of copper.

Corrosion Resistance: The steel core of copper clad steel wire provides enhanced corrosion resistance compared to pure copper wire. This makes it suitable for outdoor and underground applications, where exposure to moisture and other environmental factors is a concern.

Competition from Aluminum: Copper clad steel wire faces competition from aluminum wire, which is often preferred for its lower cost. However, CCS wire offers better electrical conductivity and strength compared to aluminum wire, making it a preferred choice for certain applications.

Key Market Players: Major players operating in the global copper clad steel wire market include Elecref Industries Inc., Copperhead Industries, LLC, Fisk Alloy Inc., LEONI Wire Inc., AFL, MWS Wire Industries, Inc., MWS Wire Industries, Inc. Kris-Tech Wire, Nehring Electrical Works Company, and American Wire Group, Inc.

These companies manufacture and supply copper clad steel wire for various industrial applications worldwide.

#Copper Clad Steel Wire Market#Copper Clad Steel Wire Market Growth#Copper Clad Steel Wire Market Trends

0 notes

Text

0 notes

Text

Additive Manufacturing Market, Industry Forecast, 2024–2030.

Additive Manufacturing Market Overview:

Sample Report :

Additionally, Increasing focus on metal additive manufacturing technologies. Researchers and companies have been actively working on expanding the range of metals and alloys available for AM. This includes not only traditional metals like titanium, aluminum, and stainless steel but also high-performance alloys for specialized applications. The development of new metal powders suitable for various AM processes has been a focus area. The integration of Additive Manufacturing with traditional manufacturing processes in companies were exploring hybrid manufacturing approaches that combine the strengths of additive and subtractive methods. This integration aimed to leverage the design flexibility of Additive Manufacturing and the efficiency of traditional methods to optimize production workflows. These factors impact the growth in Additive Manufacturing Market.

Market Snapshot:

Additive Manufacturing Market — Report Coverage:

The “Additive Manufacturing Market Report — Forecast (2024–2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Additive Manufacturing Market.

AttributeSegment

By Type

● Materials

● Systems

● Services & Parts

By Material

● Plastics

○ Acrylonitrile Butadiene Styrene (ABS)

○ Polylactic Acid (PLA)

○ Polyethylene (PE)

▪ High-Density Polyethylene (HDPE)

▪ Low-Density Polyethylene (LDPE)

▪ Linear Low-Density Polyethylene (LLDPE)

▪ Others

○ Polycarbonate (PC)

○ Polypropylene (PP)

○ Polyethylene Terephthalate (PETE)

○ Nylon

○ Others

● Metals

○ Iron

○ Steel

○ Silver

○ Aluminum

○ Copper

○ Titanium

○ Gold

○ Zinc

○ Others

● Ceramics

○ Glass

○ Silica

○ Quartz

○ Others

● Others

By Technology

● Powder Bed Fusion

○ Direct Metal Laser Sintering (DMLS)

○ Selective Laser Sintering (SLS)

○ Selective Laser Melting (SLM)

○ Electron Beam Melting (EBM)

○ Others

● Binder Jetting

● Directed Energy Deposition

○ Laser Deposition Technology (LDT) excluding LCT

○ Laser Additive Manufacturing (LAM)

○ Laser Metal Deposition (LMD)

○ Laser Engineering Net Shape (LENS)

○ Laser Cladding Technology (LCT)

○ Electron Beam Additive Manufacturing (EBAM)

○ Wire Arc Additive Manufacturing (WAAM)

○ Laser Deposition Welding (LDW)

○ Others

● Material Extrusion

● Material Jetting

○ Drop On Demand (DOD)

○ Polyjet by Object

○ Others

● Vat Polymerization

○ Stereolithography (SLA)

○ Digital Light Processing (DLP)

○ Continuous Liquid Interface Production (CLIP)

○ Others

● Others

By End-Use Industry

● Industrial

● Aerospace

○ Commercial

○ Military

○ Others

● Consumer Goods

○ Furniture

○ Watches and Jewelry

○ Shoes and Soles

○ Others

● Oil & Gas

● Automotive

○ Passenger Cars

○ Light Commercial Vehicles (LCV)

○ Heavy Commercial Vehicles (HCV)

○ Others

● Medical & Healthcare

● Electrical & Electronics

○ Conductors

○ Resistors

○ Sensors

○ Semiconductors

○ Others

● Building and Construction

○ Residential

○ Commercial

○ Industrial

○ Infrastructure

The COVID-19 pandemic had a mixed impact on the Additive Manufacturing (AM) market. While disruptions in global supply chains initially posed challenges for material sourcing, the flexibility of AM processes proved beneficial in addressing urgent needs for medical equipment and components. The demand for 3D printing surged during the pandemic, with AM technologies being utilized for the rapid production of ventilator parts, face shields, and other critical supplies. The crisis highlighted the agility of AM in responding to unforeseen challenges and increased awareness of its potential across various industries.

Inquiry Before Buying :

The situation in Ukraine had indirect effects on the Additive Manufacturing (AM) market, primarily through broader geopolitical and economic repercussions. Disruptions in supply chains, especially for metals and other raw materials used in AM processes, were potential concerns. Additionally, uncertainties in global markets may have influenced investment decisions and R&D activities in the AM sector. However, the impact varied depending on the resilience of individual companies and their exposure to the geopolitical developments.

Key Takeaways:

North America Dominated the Market

Geographically, in the Additive Manufacturing market share, the North America region has held a dominant market share of 41% in 2023, Rising government investments and projects in the United States for additive manufacturing have also raised the growth of the market. For instance, to address the challenges in single laser melting (SLM), America Makes awarded GE Global $2.6 million to build an open-source, multi-laser production machine and AM platform. Additionally, in Canada, the rising partnership between research universities in the field of additive manufacturing is also influencing the growth of the market. U.S. is anticipated to lead the global additive manufacturing market with the largest installed base for 3d printer in the world. With such a dominant presence of the 3d printers in the country U.S. is likely to contribute more than one third in the revenue generated by additive manufacturing worldwide.

Metal is the Fastest Growing Segment

In the Additive Manufacturing Market forecast, the Metal segment is estimated to grow with a CAGR of 23.5% during the forecast period. Metals are a better option for 3D printing compared to plastics, as they have more industrial usage. Often the 3D metal printing shows itself to be unique as the new technologies can readily surpass what was offered by traditional processes. In AM of metals a powder feedstock or more rarely a wire is fully melted by the energy input of a laser or electron beam and transformed layer by layer into a solid part of nearly any geometry. The most popular processes for AM of metals are Laser Beam Melting (LBM), Electron Beam Melting (EBM) and Laser Metal. In a survey conducted across the globe, about 23% of the 3D printing materials used are metals. The 3D printing metals segment is also poised to grow as it has a competitive edge over other plastic materials used in 3D Printing. Metal 3D printing is too expensive, furthermore other companies, like Desktop Metal and Markforged, are developing approaches to manufacture affordable metal 3D printers.

Schedule A Call :

Aerospace to Hold Largest Market Share

According to the Additive Manufacturing Market analysis, the Aerospace segment is estimated to hold the largest market share of 34% in 2023, the aerospace and defense industry is a perfect example of how to use additive manufacturing (AM) (commonly referred to as 3D Printing) to produce components that are heavier and lighter than parts manufactured using conventional manufacturing methods. Additive manufacturing or 3D printing has applications in the aerospace industry such as engine compartments, cabin accessories, air ducts among others. NASA researchers are looking into how electroplated SLA parts perform in space. Engineers at NASA’s Goddard Space Flight Center designed brackets that were 3D printed on printers, electroplated, and sent to space aboard a summer 2022 SpaceX commercial resupply services (CRS-25) mission to the International Space Station (ISS). The results could inform how NASA and possibly other aerospace manufacturers may incorporate electroplating and additive manufacturing into potential future product plans.

Ease of Manufacturing Complex Design

he basic physical difference in how objects are made with the additive manufacturing process produces some major functional differences when compared with other traditional manufacturing processes. The most significant of these functional differences is the ability of additive manufacturing to produce complex geometries that would be difficult or impossible to achieve using conventional manufacturing methods. These intricate geometries are also stronger and lighter than their conventional counterparts. Additive manufacturing eliminates the additional costs normally associated with creating more complex objects. A highly complex component usually costs much more using conventional methods. This is primarily because conventional fabrication methods rely on the conversion of three-dimensional illustrations into two-dimensional drawings for fabrication, as well as the labor cost of assembling such components. However, regardless of the complexity of a component, the method in additive manufacturing is the same. Thus, no additional cost is incurred for manufacturing complex designs using additive manufacturing.

Buy Now :

Relatively Lower Production Cost for Rapid Manufacturing

The manufacturing companies experience various benefits while using additive manufacturing methods to produce objects. Since the complexity of the component has little or no impact on the manufacturing time and costs, additive manufacturing is ideal for low-cost production as well as small and (very) large series. Design changes can be implemented quickly at a low cost. Metal structures are made up of atom by atoms in additive manufacturing, as opposed to subtractive approaches like chemical etching. As a consequence, almost every piece of metal is utilized during the production process, with almost no waste of material and reducing material wastage. When using additive manufacturing, all of the extra features that are needed for the assembly, such as fasteners, brazing, or welding, can be omitted. Thus, additive manufacturing also reduces assembly costs.

Difficulty in Producing Large Single Parts

Even if additive manufacturing were to dramatically increase production speed and volume performance, it would still be unable to manufacture large single parts. This is yet another major challenge confronting additive manufacturing researchers as they pursue new applications for 3D printing technology. Arc-based wire feed metal AM was chosen as the best process to produce large metal parts. While metal powder bed printers are available commercially, they are not currently capable of producing large-scale metal parts. Therefore, arc-based wire feed technology provided the most cost-effective solution. The building envelope for current additive manufacturing technologies is limited, meaning even larger components that can be printed must still be assembled by mechanical joining or welding.

For More Details on This Report — Request for SampleKey Market Players:

duct/Service launches, approvals, patents and events, acquisitions, partnerships and collaborations are key strategies adopted by players in the Additive Manufacturing Market. The top 10 companies in this industry are listed below:

Proto Labs, Ltd.

3D Systems, Inc

Stratasys Ltd.

Desktop Metal

Autodesk, Inc.

Materialise NV

Markforged

Optomec, Inc.

Dassault Systemes

Titomic Limited

Geographies Covered

North America (U.S., Canada and Mexico), Europe (Germany, France, UK, Italy, Spain, Netherlands and Rest of Europe), Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand and Rest of Asia-Pacific), South America (Brazil, Argentina, Colombia and Rest of South America), Rest of the World (Middle East and Africa).

Key Market Players

For more Automation and Instrumentation Market reports, please click here

0 notes

Text

Copper Clad Steel Wire Market Analysis Trends: 2023, Segmentation, Signify Explosive Growth Factors and Dynamics by 2030

The copper clad steel wire market refers to the industry involved in the production, distribution, and use of copper clad steel (CCS) wire. Copper clad steel wire is a composite wire that consists of a central steel core surrounded by a layer of copper. It combines the conductivity of copper with the strength and durability of steel, making it suitable for various applications.

Market Overview:

The copper clad steel wire market has witnessed significant growth in recent years. The increasing demand for efficient and cost-effective electrical conductors, particularly in power transmission and distribution applications, has been a key driver for market growth. The unique properties of copper clad steel wire, such as high conductivity, corrosion resistance, and mechanical strength, have contributed to its popularity in various industries.

Applications:

• Power Transmission and Distribution: Copper clad steel wire is extensively used in overhead power transmission and distribution lines. Its high tensile strength and corrosion resistance make it suitable for long-distance power transmission, minimizing power loss and ensuring efficient electricity delivery.

• Telecommunications: Copper clad steel wire is also widely used in telecommunications applications, such as telephone cables, coaxial cables, and data transmission cables. Its combination of electrical conductivity and strength makes it suitable for carrying signals over long distances without significant signal degradation.

• Automotive Industry: Copper clad steel wire is utilized in the automotive industry for applications like vehicle grounding systems, battery cables, and electrical connections. Its mechanical strength and resistance to vibration and corrosion make it an ideal choice for these applications.

• Electronics and Consumer Goods: Copper clad steel wire finds use in the manufacturing of electronics components, such as printed circuit boards (PCBs) and connectors. It is also employed in consumer goods like appliances, electrical tools, and home entertainment systems.

• Others: Copper clad steel wire is also used in other applications, including welding wires, magnet wires, and grounding systems for buildings and infrastructure.

Market Dynamics:

Several factors contribute to the growth of the copper clad steel wire market:

• Increasing Demand for Electricity: The growing demand for electricity, driven by urbanization, industrialization, and the expansion of the renewable energy sector, has fueled the need for efficient power transmission and distribution systems, boosting the demand for copper clad steel wire.

• Cost-Effectiveness: Copper clad steel wire offers a cost-effective alternative to pure copper wire while maintaining high electrical conductivity. This has led to its increased adoption in various industries, especially where cost considerations are crucial.

• Superior Properties: The combination of copper and steel imparts advantageous properties to copper clad steel wire, such as high strength, corrosion resistance, and thermal stability. These properties make it suitable for demanding environments and contribute to its market demand.

• Technological Advancements: Continuous research and development efforts have led to improvements in the manufacturing process, resulting in higher-quality copper clad steel wire with enhanced performance characteristics.

• Government Initiatives: Government initiatives aimed at upgrading power infrastructure and promoting the use of renewable energy sources have stimulated the demand for copper clad steel wire in power transmission and renewable energy projects.

Key Players:

The copper clad steel wire market is highly competitive and comprises several key players, including:

Sumitomo Electric Industries, Ltd. Furukawa Electric Co., Ltd. LS Cable & System Ltd. ZTT Group Shanghai Shenghua Cable Group Co., Ltd. Jiangsu Huaxin Cable Co., Ltd. Tongda Cable Co., Ltd. TBEA Co., Ltd. NKT A/S Zhongtian Technology Co., Ltd.

These companies engage in product development, strategic collaborations, and mergers and acquisitions to strengthen their market position and expand their product portfolios.

Regional Outlook:

The copper clad steel wire market is geographically segmented into North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Asia Pacific dominates the market due to the presence of a large manufacturing base, rapid industrialization, and increasing infrastructure investments. North America and Europe also contribute significantly to the market, driven by the demand for advanced power transmission and telecommunications systems.

Conclusion:

The copper clad steel wire market is experiencing steady growth due to the increasing demand for efficient electrical conductors in various industries. The unique properties of copper clad steel wire, combined with its cost-effectiveness, make it a preferred choice for applications in power transmission, telecommunications, automotive, electronics, and more. With ongoing technological advancements and government initiatives, the market is expected to continue its upward trajectory in the coming years.

0 notes

Text

Aluminum Market: Top 7 Uses of Aluminum | Specialty Materials

As the most abundant metallic element naturally found on the Earth’s crust and the most extensively used nonferrous metal, aluminum and its alloys are extensively utilized across various sectors. These include building materials, aircraft construction, consumer durables, chemical and food-processing equipment, and electrical conductors.

According to Inkwood Research, the global aluminum market is predicted to grow with a CAGR of 4.97% during the forecast years of 2022 to 2030.

On account of the metal’s unique properties, including corrosion resistance as well as high tensile strength and heat capacity, aluminum is used in a diverse range of commercial products, as well. Moreover, since it is also 100% and infinitely recyclable, the metal constitutes a distinguished part of the global foundational infrastructure.

Read on for a comprehensive compilation of the top 7 uses of aluminum spanning different industries –

Consumer Products – Smartphones, laptops, flat-screen televisions, tablets, computer monitors, and other consumer products widely use aluminum, primarily due to its potential to dissipate and absorb heat. Also, since the material is lighter than steel and stronger and more reliable compared to plastic, leading market manufacturers are increasingly making use of aluminum in their production processes.

Automotive & Transportation – With the automotive industry’s rising focus on fuel efficiency and minimizing carbon-dioxide emissions, aluminum has become a preferred material in the production of vehicles. The use of aluminum in the automotive & transportation sector not only helps enhance the vehicle’s durability and safety but also serves as a more cost-effective solution for manufacturers. Accordingly, as per Inkwood Research, the automotive & transportation segment under the end-user category held the highest market share of 03% in 2021.

Electrical – The low density of aluminum makes it an excellent choice for long-distance power lines. Since it is anti-corrosive, ductile, and lighter than copper, aluminum can be formed into wires for electrical purposes with ease. As a result, copper wiring is increasingly being replaced by aluminum in transformers, in addition to the majority of all updated wiring systems. Aluminum is also being used in satellite dishes, fuse boxes, and sound systems, among other electrical devices.

Building & Construction – The applications of aluminum in the building & construction sector include foil insulation, roofing, windows, doors, cladding, shopfronts, architectural hardware, balustrading, as well as guttering. Furthermore, aluminum is used for treadplates and industrial flooring, as well. Inkwood Research’s estimates suggest that building & construction is expected to be the fastest-growing end-user, progressing with a CAGR of 5.18% during the forecast period, 2022 to 2030.

Foil & Packaging – Owing to its non-toxic property, aluminum is ideal for packaging food. As a result, high amounts of aluminum are utilized for the packaging of medication, food, and beverages, without causing any impact on their respective tastes. Aluminum also plays a vital role in repelling water, in addition to extending the shelf life of food items, as well.

Household Appliances – Aluminum is highly energy-efficient and is, therefore, a suitable material for household appliances that use heating and cooling processes, such as air conditioners and refrigerators. The metal is also ideal for holding certain temperature levels, a key factor that helps create the efficient cooling that modern refrigerators require.

Aerospace – The aerospace industry utilizes aluminum to build navigation instruments as well as aircraft parts. Moreover, the consumption of aluminum for manufacturing aircraft, especially in the United States and Europe, is likely to witness significant growth over the upcoming years. While the metal’s high resistance to corrosion helps to ensure the safety of aircraft and its passengers, aluminum is also used by NASA for its properties, such as lightweight and strength under tremendous pressure.

Aluminum Market: Trending Usage Combined with Tech Developments

Various technological developments associated with the use of aluminum and its alloys are emerging across the globe. For example, in the field of 3D printing technology, aluminum powder is utilized to print separate as well as fully functional parts that are intricate, strong, and capable of handling details as small as 0.25 mm. As a result, the growing popularity of 3D printing technology is a notable factor expected to fuel the demand for aluminum over the upcoming years.

Additionally, in the current market scenario, metal additive manufacturing (AM) processes, like selective laser melting (SLM), enable arbitrary 3D structures’ fabrication. Aluminum alloys comprise the material systems in this regard, and are also being favored in several high-value applications. In addition to achieving the objectives of lightweighting, part reduction, and increased functionality, AM techniques also deliver the advantages of potential savings on raw materials and minimal waste since it only utilizes the material required to fabricate the part of interest. Hence, such technological developments are anticipated to create lucrative opportunities for the global aluminum market growth during the forecast period.

Sustainability Factor | What Does the Future Hold for the ‘Green’ Metal?

Over the last decade, the world has witnessed a paradigm shift in terms of global consciousness. Besides, with the global economy rapidly transitioning towards a greener, cleaner, and more sustainable régime, the demand for energy-efficient, durable, and environmentally safe mechanisms and infrastructures are on the rise. In this regard, the 100% recyclability of aluminum, especially without any losses to the material’s property, makes it an ideal choice compared to other non-recyclable substitutes.

Accordingly, secondary or recycled aluminum holds tremendous market value since the scrap acquired from machinery, equipment, and automotive can be effectively reprocessed and used owing to its cost efficiency. As the reprocessing of secondary metal consumes only a fraction of the energy needed to produce new metal from the ore, this factor causes substantially less harm to the environment. Furthermore, given the fact that the mining of bauxite (aluminum ore) is highly eco-friendly, the surging adoption of the ‘green metal’ is set to be a major step towards a more sustainable world. Hence, these factors are expected to further augment the use of aluminum across various applications, thereby propelling the global aluminum market growth during the forecasted years.

By Shruti Vanjare

FAQs:

What are some of the key properties of aluminum?

Aluminum is non-toxic, non-magnetic, lightweight, and non-sparking, with excellent corrosion resistance and high thermal conductivity. Moreover, the metal has a low density and can be easily machined, cast, and formed.

Which are the leading players operating in the global aluminum market? Hindalco Industries Ltd, Rio Tinto, Aluminum Corporation of China Ltd (CHALCO), and others are among the leading players operating in the global aluminum market.

0 notes

Text

0 notes

Text

For Pennies

Warm-up mini fic. Consider this a doodle.

....

The Fentons were selling their house for pennies.

The “For Sale” sign out front was easily missed against the ostentatious display of the op center, and the “FENTON” sign, and the Fenton RV. Or perhaps, all that made it more noticeable. It bolstered the weird and unsettling mundanity of a standard-issue For Sale sign dictating the fate of a house so indescribably odd.

It took only a few curious gossips to find the listing, and to spread the news further when the listing asked for hardly a fifth of standard asking price. Real estate agents weighed in on town facebook pages that, yes, this was abysmally low. Others rationalized it. “It’s only natural. Those house modifications have killed the resale value. The basement is uninhabitable according to the listing. They’re selling an extreme fixer-upper.”

And when the house did not sell in the first week, the price dipped again. And when rumors spread that the house owners were responsible for the town’s ghost blight, the price dipped once again. Then nearly overnight, the op-center vanished, and the FENTON sign disappeared from sight. The Fentons were, if nothing else, impressive engineers, capable of undoing a lifetime’s work in a weekend. Soon after, the listing sold.

The buyer, Peter, was looking for fixer-uppers to flip and rent. He knew about the Amity Park rumors, but if the renting market proved stale for the fear of ghosts, he knew the airbnb market would thrive with curious tourists, so the property was a safe bet regardless.

He met the family once, in the house, when he came to inspect it and sign paperwork if he was satisfied. The husband was perhaps the biggest man Peter had ever seen, portly yet rock solid, clad head to toe in neon orange. The wife matched him in jumpsuits, a powder blue one. Their daughter seemed normal, though she and Peter only exchanged a handful of words.

“Where are you folks headed once this place is sold?” Peter asked, cordially, eyes flitting between the contract before him and the couple seated across the table.

“Westward, a bit. Um, Maddie’s got a sister out there. We’re trying to be closer to family.”

Peter nodded. “Always good to have family around.” He glanced in the daughter’s direction. “Are you excited to be moving closer to your aunt?”

The daughter met his gaze, level. “I’m not going with them, actually.”

“Oh?” Peter asked. “Headed to college? That would make sense.”

“I’m a rising senior,” the girl answered.

“Jazz is—” the mother, Maddie, cut in. “It’s well, it’s about to be her senior year of high school. Hard time to switch schools, you know? She’s going to be renting a place nearby so she can finish school here.”

“Oh? First time living all on your own?” Peter asked, initialing a page of the contract.

“I’m 17. It’s not that weird.”

“Never said it was. I remember my first place pretty fondly. It’s an exciting milestone, don’t waste it!”

Peter initialed another page. He spun the document back to the Fentons to sign as well.

“Well, I really like the place, is what I’ve got to say. The newly redone flooring on this floor was a perk I wasn’t expecting, can’t have been cheap. You still managed to keep the price amazing though. Don’t worry about the dings and scratches – I’ve got the art of fixing up places down to a science. I’ll take a crack at the basement too.”

“We’d rather you didn’t,” Maddie answered.

Peter waved her off. “I know it was some kind of lab, yeah? You won’t be liable if I say, spill acid on myself or dunk myself in radiation or, whatever you had going on down there. We can go over that clause of the contract again if you want. Ghosts, right?”

“It’s dangerous—”

“If I can’t hack it, I’ll seal up the basement for good. But I won’t know until I try. Seriously, don’t worry.”

The Fentons signed the final page, and flipped the contract back around to Peter. He pulled an envelope from his coat – a check made out with the full amount. No loan needed. No mortgage. Their asking price was practically pocket change.

The daughter excused herself from the room.

…

The Fenton basement had fewer wonders than Peter was expecting.

He swung a flashlight around, as the bulb hanging overhead had been cut from the main power supply. Most everything had been cleared out, leaving a room hollowed out. His feet clicked across the metal floor. Walls of bolted steel rose high on all four sides. On the opposite wall, the scars of heavy bolting remained, along with the smoky stain of something huge, and geometric, no longer bolted to the wall.

He swung his beam wide, across every which wall beveling with bloated shadows, until he pinned the electrical panel.

“There you are.”

It took some tampering, and some patience, because something had physically demolished the box before him. Peter knew his way around basic house wiring, so it took only a few experimental adjustments until he threw the breaker, and the industrial light overhead clunked to life.

Peter turned, surveying the mouse cage of pure, uninterrupted steel sheeting, bolted together wall to wall, across the floor, across the ceiling. It was an impressive expanse of space, and under the proper flood lighting Peter could make out the deeper shadowy stains of where industrial cabinets used to be affixed to the floors, the walls. He was staring into the burnt out afterimage of what, he could only conjecture, had once been an impressive scientific facility.

It wasn’t above being carpeted and turned into a rec room.

Peter paused, his eyes training to the back corner near the octagonal imprint left in the wall. Something seemed amiss, something with color, popping bright against a display of pure ash and silver.

Peter stepped forward, flashlight still pointed though it served little use now. The space took shape – a rectangular impression on the floor, about as large as a twin bed, formed a negative image. The rectangle was spotlessly clean, silver and shiny, as though recently cleaned and polished and recleaned and repolished.

It was the edges of the rectangle, the spatters of space stretching beyond it, that held Peter’s attention.

Green, verging toward a rusty brown, splattered the floor. He stepped closer, and knelt, and stared at the pattern. Like a dropped vial of green chemicals that shattered and spattered the floors, the neighboring wall. Like radioactive spill left to eat into the floor. Peter thought back to his radioactive quip, and wondered if he should perhaps back away.

He set a nail to one of the stains and scratched at it. It would not lift. It would not budge. He swung the flashlight beam, and he found the stains glittered, and then dulled where they edged closer to rust.

And it was the rust that confused Peter the most. That copper color, like pennies, that morphed away from the green. It wasn’t uniform. It did not eat away symmetrically at the edges of the stains. Instead it spattered, and dragged, and molded from droplets to long streaks dragging across the floor like chalk dust on a blackboard.

Peter followed them. The streaking ended. Beyond that, he caught a single droplet speckled into the floor a foot away. Another, when he swung his beam. And another. He followed them, one by one, tracing them back to the basement stairs, up, up, up, up.

At the top of the stairs, the trail vanished. The brand new hardwood flooring that stretched through the whole first floor was immaculate.

1K notes

·

View notes

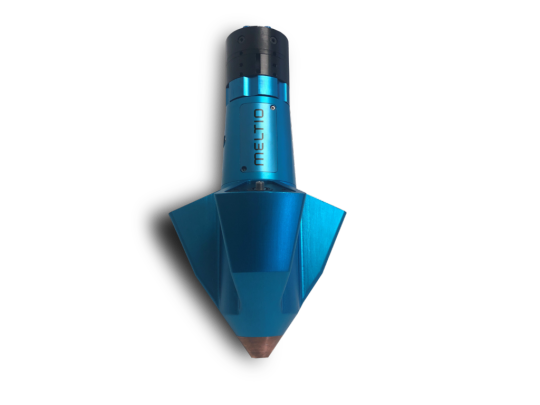

Photo

Meltio’s 3E Metal Deposition Technology: Easy, Efficient and Expandable Meltio has entered the 3D printing market to meet the needs of industries that have been waiting years for a reliable, accessible, and hassle-free solution to implement direct metal 3D printing into the production process. Thanks to an exclusive development, Meltio’s unique patented technology brings many advantages compared to existing technologies in the industry. It’s what the company has called 3E Metal Deposition Technology: Easy, Efficient and Expandable. Meltio defines its technology as easy because it avoids the inconveniences of existing metal 3D printers. The outer dimensions of the hardware are significantly compact (550x600x1400 mm), without the typical hassle of common and bulky industrial hardware, which usually needs special facilities and infrastructure. The multi-laser printhead, which is in fact the core of this technology, is able to manufacture with metal wire, which makes the operation clean and safe and with 100% material utilization. Apart from this, the printers are able to fabricate parts with metallic wire, powder, or by combining both materials in the same part and without changing the nozzle, which is an industry first. The result is 100% dense metal parts made of any material commonly used in welding: titanium, steel, copper, aluminum, Inconel, etc. The new development will also allow many companies to integrate metal 3D printing in their workflows, by lowering traditional access barriers in terms of pricing. The acquisition cost of hardware is about 50% to 75% lower than current market prices and material cost is up to 10 times lower, which is a significant step towards massive adoption of direct metal 3D printing. Moreover, the possibilities of Meltio’s 3D printing are easily expandable thanks to the integration of 3D printing modules (Meltio Engine) with CNC, robotic, or gantry systems. This way manufacturing possibilities range from small parts to parts of several meters in size, turning traditional systems into hybrid ones with metal deposition capabilities. This makes the technology easily adaptable to multiple applications across various industries including aerospace, automotive, and large scale manufacturing. How it works 3E Metal Deposition technology works with a multi-laser printhead with a high-power capacity (0.6 to 6 kw). The highly compact deposition head (150mm width/depth x 265mm height) features three independent diode lasers (although more lasers can be added as an upgrade for more power). The printing takes place within an argon chamber that only requires a small amount of gas or in an open atmosphere with just nozzle argon shield gas coverage. Furthermore, changing materials is automatic and accomplished in seconds without the risk of contamination, unlike powder bed fusion technology where it is necessary to perform time-consuming decontamination between material changes. The system features active process control, which automatically sets the nozzle to part distance for each layer and also manages process parameters throughout the print based on sensor feedback. Meltio’sunique laser technology allows the production of metallic alloys which are usually difficult to weld. In addition, more applications can be used besides 3D printing: repairing of existing parts through additive manufacturing, cladding, welding (autogenous and with filler), curing, texturing and polishing. This technology has a significant endorsement through ArcelorMittal, the world leading steel manufacturing company, which has participated in the company since its formation. Meltio is a new joint venture with the participation of Additec, an American company based in Las Vegas, Nevada, and Sicnova, a Spanish company with a vast history in the 3D field. its inception has been an international company with a clear global vision and offices in United States and Spain. The main headquarters and factory are located in Linares, Jaen (Spain), with R&D centers in both, the US and Europe. Meltio’s new metal 3D printer, the Meltio M450, and the Engine deposition modules for hybrid manufacturing and robotic applications, will be showcased at Formnext November 19th-22nd (Hall 12.1, booth C111). The stand will also feature other additive manufacturing and 3D digitalization solutions from Meltio’s portfolio. The post Meltio’s 3E Metal Deposition Technology: Easy, Efficient and Expandable appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. https://buff.ly/2NCpSlI

1 note

·

View note

Text

Industry analysis provides a company with an understanding of its position relative to other companies in the industry. This can help them identify opportunities and potential threats, so they can prepare for the present and future. MRI Research helps organizations to figure out whats happening in a given industry, including demand and supply statistics, degree of competition, state of competition with other emerging industries, future prospects considering technological changes, and external factors on the industry.

0 notes

Text

Not easily burned fan motor-YISENBAO

A friend's exhaust fan, which was just renovated and bought last year, suddenly found that it would not work one day, and there was no problem with checking the circuit. I was surprised that the motor was not durable. I disassembled the motor and found that there was a problem with the coil. After scraping off the surface, it was found that it was made of aluminum, which is a copper-clad aluminum coil. Consumers spend money, but it is not worth it. It is no wonder that they buy high-quality imitation goods, because many of us simply cannot judge whether the materials used inside the products are adulterated.

Why do some manufacturers use aluminum instead of copper? In addition to the lower cost, the price war in the market is a big factor. Recently, copper prices have risen rapidly, and too much inventory is not conducive to the return of funds. Every day expenses in various aspects make enterprises bear heavy pressure. Reducing costs is the current strategy to deal with market changes.

The Single-phase fan motor produced by YISENBAO is specially designed for high temperature resistance, Not Easily to Burne, Cheap price, after-sale guarantee, meets the needs of many consumers.

The phenomenon of using aluminum to replace copper is not to say that it is only now, but it is becoming more and more obvious now. While the Internet age brings convenience to people, product prices are becoming more and more transparent, and middlemen are removed to earn the difference. The competition among manufacturers is intensifying, the product profits are reduced, and the quality will not be able to keep up.

The stator of YISENBAO motor is made of silicon steel sheet, which can effectively protect the internal structure of the motor, the electromagnetic power is stable, the operation is more stable and durable; the cast aluminum rotor is used, which has stable performance and good consistency. . The shell is made of iron, which is resistant to high temperature, not easy to deform, and can better protect the bearing; the inner coil of the motor is made of high-quality enameled wire, which has good conductivity, high temperature resistance and low energy consumption;

YISENBAO has always been committed to selecting a variety of high-quality materials to provide you with better products.

0 notes

Text

Commonly used small-size cable knowledge

How much do you know about commonly used small-size cables? The pneumatic stripping machine can cut and strip various cables according to the length and stripping method you need. Let's see what wire is usually used for?

RVVP: Copper core PVC insulated PVC sheathed flexible cable, voltage 300V/300V 2-24 core. Main quality indicators: wire diameter (including core wire and braided wire, the thicker the better, the thicker the impurity copper should meet the resistance standard), the purity of the copper core, the braiding density, and the lay length.

Purpose: installation of instruments, meters, intercom, monitoring, and control.

RG: Physically foamed polyethylene insulated access network cable is used to transmit data and analog signals in the coaxial optical fiber hybrid network (HFC). This is an American standard, which is approximately equivalent to the national standard SYWV series. Main quality indicators: copper core wire diameter, insulation thickness, braiding material (mostly braided with aluminum-magnesium wire in the market, tinned copper should be used for good quality), braiding density.

UTP: LAN cable Purpose: transmission of telephone, computer data, fire protection, anti-theft security system, intelligent building information network. Commonly used UTP CAT 5, UTP CAT 5E shielded model is STP

KVVP: PVC sheathed braided shielded cable Uses: signal transmission, control, and measurement of electrical appliances, meters, and power distribution devices

SYWV (Y), SYKV cable TV, broadband network dedicated cable structure: (coaxial cable) single oxygen-free round copper wire + physical foamed polyethylene (insulation) + (tinned wire + aluminum) + polyvinyl chloride (poly Ethylene), (equivalent to American standard RG-6, RG-59). Nowadays, aluminum-magnesium wire is used for braiding (not welded, easy to oxidize), and the core wire is made of copper-clad aluminum and copper-clad steel. Many people think that SYWV wire is cheaper than SYV wire, but in fact it is not the case.

RVV (227IEC52/53) PVC insulated flexible cable (cross-sectional area: 0.5-6.0 cores 1-24) Uses: power cords, signal lines, household appliances, small electric tools, instruments and power lighting, etc. As long as the price of this specification line meets the national standard, the price is not much different, but there is no lack of useful impurity copper in the market, insufficient wire diameter, short meters, and straight (core wire copper wire is not twisted or core wire is not twisted, so the tensile strength is greatly reduced. The resistance increases) to charge the number. Derivative model: RVVS: The stranded pitch encryption of this model is generally used in broadcast systems.

AVVR PVC sheathed flexible cable for installation (cross-sectional area: 0.12-0.5 core number 1-24) Purpose: signal, control. Such as access control signal, control, pan/tilt control, etc.

HYV, HYA data communication cable (indoor and outdoor) (core wire diameter 0.5mm, core wire number 2, 4, 8, etc.) namely telephone line, used for telephone communication and radio equipment connection and telephone wiring network distribution box Wiring and so on. Generally, the core wire diameter in the market is 0.4 mm, but steel wire or copper-aluminum alloy is almost always used. In addition, the number of meters in telephone lines is generally insufficient.

RV, RVP PVC insulated cables, PVC shielded cables, mainly used in equipment.

RVS, RVB are suitable for connecting cables for household appliances, small electric tools, instruments, meters and power lighting. RVS can also be used for broadcasting lines or instead of RVV lines. RVB can replace gold and silver wires when the requirements are not high.

BV, BVR polyvinyl chloride insulated cables Uses: suitable for fixed wiring of electrical appliances, instrumentation and power lighting, with low resistance and affordable price. It can be considered in many situations where the power supply is connected.

RIB speaker cable (fever cable, gold and silver cable) Some audio cable models are often marked with the words "6N" and "7N", and their meaning is to indicate the purity of the fever cable made of metal materials. For example, "99.9999%" can be represented by "6N", which means that its purity is 6 9s. The larger the number in front of N, the higher the purity of the audio line. Whether home theater audio equipment needs to use high-quality audio cables, the key is to master the principle of seeking truth from facts and doing what we can. For general audio equipment (less than 10,000 yuan), there is no need to deliberately pursue the high quality of the wire, as long as the copper core signal wire with a larger cross-section is used. For better home theater audio equipment, consider using high-quality audio cables.

Weijion is a professional wire processing equipment manufacturer, producing all kinds of wire stripping machines, terminal crimping machine equipment, if you are purchasing pneumatic wire stripping machines, welcome to contact us, I believe weijion will be your best choice.

Recommended reading:

Application of wire stripping machine

Features of wire stripping machine products

What should I do if the automatic terminal machine overheats?

0 notes

Text

Copper Clad Steel Wire Market - Increasing Demand, Growth Analysis and Future Outlook by 2030

Copper clad steel wire is a type of electrical wire that consists of a steel wire core that is coated with a layer of copper. The steel core provides the wire with strength and durability, while the copper coating provides excellent conductivity for electrical current.

Copper clad steel wire is commonly used in applications where high conductivity is required, but where the wire must also be able to withstand harsh environments or high mechanical stress. For example, it is often used in the telecommunications industry for transmission lines, grounding wires, and other applications where electrical conductivity and durability are both important.

In addition to its electrical properties, copper clad steel wire also has some unique mechanical properties. Because the copper coating is typically thinner than the steel core, the wire can be made to have a higher tensile strength than copper wire of the same size. This makes it useful in applications where the wire must be able to withstand high tension or bending forces.

The copper clad steel wire market has been experiencing steady growth in recent years due to the increasing demand for high-quality, durable, and cost-effective wires in various industries such as telecommunications, power transmission, and construction.

One of the major factors driving the market growth is the expanding telecommunication industry, where copper clad steel wire is commonly used for transmission lines and grounding wires. With the increasing demand for high-speed internet and data transmission, the demand for copper clad steel wire is expected to rise in the coming years.

The power transmission sector is another significant application area for copper clad steel wire, as it is used in overhead transmission lines, substation grounding, and other applications. The construction industry is also a major consumer of copper clad steel wire for applications such as reinforcing concrete structures and underground power distribution systems.

Geographically, Asia-Pacific is the largest market for copper clad steel wire, driven by the rapid industrialization and urbanization in countries such as China and India. The North American and European markets are also significant, driven by the growing demand for advanced technologies and infrastructure.

Major players operating in the global copper clad steel wire market include Elecref Industries Inc., Copperhead Industries, LLC, Fisk Alloy Inc., LEONI Wire Inc., AFL, MWS Wire Industries, Inc., MWS Wire Industries, Inc. Kris-Tech Wire, Nehring Electrical Works Company, and American Wire Group, Inc.

The demand for copper clad steel wire is expected to increase in the coming years due to its numerous advantages over other types of wires.

Copper clad steel wire offers high electrical conductivity, durability, and resistance to corrosion, making it ideal for use in industries such as telecommunications, power transmission, and construction.

With the rapid expansion of the telecommunication industry and the increasing demand for high-speed data transmission, the demand for copper clad steel wire is expected to rise. Additionally, the construction industry is also a significant consumer of copper clad steel wire, which is used in applications such as reinforced concrete structures and underground power distribution systems.

Furthermore, the use of copper clad steel wire is expected to increase in the automotive industry due to its strength and durability, which make it suitable for use in vehicle wiring and harnesses.

Copper-clad steel wire is a type of composite wire made by coating a steel wire core with a layer of copper. The resulting wire combines the strength and durability of steel with the conductivity and corrosion resistance of copper, making it ideal for a range of applications. Here are some common applications of copper-clad steel wire:

Electrical Wiring: Copper-clad steel wire is widely used for electrical wiring in homes, buildings, and industrial facilities. It is an affordable alternative to pure copper wire, which can be expensive, while still providing good electrical conductivity.

Telecommunications: Copper-clad steel wire is used in the telecommunications industry to transmit data and voice signals over long distances. Its high strength and durability make it ideal for outdoor applications, where it can withstand harsh weather conditions.

Automotive: Copper-clad steel wire is used in automotive applications, such as for grounding wires and battery cables. It is resistant to corrosion and can withstand high temperatures, making it suitable for use in engine compartments.

Construction: Copper-clad steel wire is used in construction applications, such as for reinforcing concrete structures. Its high strength and durability make it ideal for use in applications where strength is critical.

Military and Defense: Copper-clad steel wire is used in military and defense applications, such as for communications and electronic equipment. Its high strength and durability make it ideal for use in harsh environments, such as in combat zones.

The Copper Clad Steel (CCS) Wire market offers a range of benefits for various industries and applications, including:

Cost-effective: CCS wire is an affordable alternative to pure copper wire, as it combines the strength of steel with the conductivity of copper, providing significant cost savings without compromising on performance.

High Strength: The steel core of the CCS wire provides strength and durability, making it suitable for high-tension applications.

High Conductivity: The copper layer on the outside of the steel core provides excellent electrical conductivity, allowing for efficient transmission of signals.

Corrosion-resistant: The copper layer also provides corrosion resistance, making CCS wire ideal for use in harsh environments.

Lightweight: CCS wire is lighter than pure copper wire, making it easier to handle and install.

Wide range of applications: CCS wire is used in a variety of applications, including telecommunications, power transmission, electronic circuits, and automotive wiring, among others.

Long-lasting: CCS wire is highly durable and long-lasting, making it a reliable choice for applications that require a high level of performance.

In summary, the Copper Clad Steel Wire market provides a cost-effective, high-strength, highly conductive, corrosion-resistant, lightweight, and long-lasting alternative to pure copper wire, making it an excellent choice for various industries and applications.

0 notes

Text

Don't Use The Data Cable Indiscriminately!

With the development of smart phones for so many years, I believe you have changed several waves of mobile phones, followed by a lot of data cables piled up at home, including free mobile phones and self purchased ones. Sometimes when the self-contained data cable cannot be found, it will be mixed with other data cables. This must be very common.

You may notice that when we charge the mobile phone with different data cables, even if the charging head is the same, the charging speed seems to be different. Therefore, you may wonder, will the data cable also affect the charging speed of the mobile phone?

Today, let's talk about the impact of data cable on mobile phone charging speed.

What's in the data cable?

Before talking about how the data cable affects the charging speed, let's take a look at what's in the data cable.

After removing the external wire, you will first see a layer of metal braid, which is called shielding net, which can prevent the electromagnetic fields inside and outside the data cable from interfering with each other.

There is also an aluminum foil shielding layer under the metal braid, which is used to prevent the magnetic field generated when the current passes through the cable from affecting other components.

Further down are various wires. Of course, we don't need to know what different wires are used for. We just need to know that normally, red and black belong to the power cable (red positive pole and black grounding), and green and white are used to transmit data.

Inside them, there are many very thin cores. At present, the core of mobile phone data cable in the market mainly includes 24 shares, 32 shares, 40 shares, etc. the number of shares may have an impact on the charging speed. Generally, the more shares, the thicker the wire, the higher the charging speed. But this is not absolute.

The charging speed is affected by the material and cross section of the core, and the conductivity is affected by the resistivity and cross section.

Materials of data cable

At present, the materials of data cable core mainly include tinned copper, aluminum magnesium wire, enamelled wire, bare copper, silver copper, iron core copper, iron core zinc plating, iron core and so on.

In terms of conductivity, you can refer to the ranking of metal conductivity, silver > copper > Aluminum > iron > zinc > tin.

In terms of comprehensive conductivity, service life and other conditions, generally better data cables will use tinned copper and bare copper, of which tinned copper is more common. The conductivity is slightly lower than bare copper, but it is more durable. More high-end data cables may use silver plated copper.

Aluminum magnesium wire, enamelled wire, copper foil wire, etc. are usually used for common data cables.

Worse data cables may use iron core copper, iron core zinc plating, iron core, steel clad steel, steel clad iron, etc.

Usually, when we buy the data cable, the merchant will list the material of the inner core of the data cable on the product introduction page. You can pay attention to it when you buy.

Cross section of wire

As for the cross section, generally speaking, the larger the cross section of the wire, the higher the conductivity of the data cable.

So what about the cross section? Among the technical parameters of the data cable, there is a parameter called AWG, which can reflect the size of the cross section of the wire.

AWG, fully known as American wire gauge, is an American wire gauge and the most widely used industrial standard at present. Usually, AWG is preceded by a number, which is the wire number, and is used to represent the diameter of the wire (in inches), such as 24AWG and 26AWG.

The larger the number in front of AWG, the thinner the internal wire of the data cable, and the worse the corresponding conductivity; The smaller the number, the thicker the wire, and the better the conductivity.

At present, not all data cable manufacturers will indicate the AWG value of data cable on the package. You can consult customer service or inquire oncable when purchasing.

Principle of data cable affecting charging rate

Before further explanation, we will list three formulas:

Power = voltage × electric current

Voltage = resistance × electric current

Resistance = resistivity × (length / sectional area)

When it comes to charging speed, we first think of looking at the charging power on the charger. Yes, the charging power is the key to determining the charging speed.

But there is also a data cable between the charger and the mobile phone. Will the existence of the data cable affect the power output? The answer is yes. As mentioned earlier, there are wires inside the data cable. All wires have resistance. If there is resistance, it will cause power loss.

This loss is mainly reflected in the voltage, so we call it the "voltage drop" of the data cable.

For example, a 5V / 4A charger has a power of 20W. If a data cable with a voltage drop of 0.3V is connected to charge the mobile phone, the output voltage to the mobile phone will be 4.7V and the power will become 18.8W.

It can be seen that in order to make the input power close to the rated power of the charger when charging the mobile phone, the voltage drop of the data cable must be reduced as much as possible to reduce this loss.

The voltage drop of the data cable is essentially a voltage, so it can be expressed by formula 2. In formula 2, the current remains unchanged, so it is directly related to the resistance.

According to the expression of resistance in Formula 3, the resistance of data cable is directly proportional to resistivity, directly proportional to conductor length and inversely proportional to cross-sectional area.

This formula accurately expresses the factors affecting the charging speed of the data cable: material (resistivity), length and thickness (cross section).

We talked about the material and thickness, and what about the length?

Theoretically, if the length of the data cable is too long, the resistance will increase, which will slow down the charging speed. However, considering that the probability of using a 2m or even 3m data cable to charge the mobile phone is small, the impact of length may be small. Even for data cables up to 3m, some well-known third-party brands can offset the resistance by using thicker wires.

Therefore, the impact of the length on the charging capacity of the data cable is not large in daily life, but we should remember that if you want to buy an ultra long data cable, you must choose a relatively well-known brand, not a cheap ultra long data cable of miscellaneous brands, otherwise the mobile phone charging may be extremely slow or even unable to charge.

This also shows that in today's environment where fast charging is everywhere, it's best not to mix the standard data cables of mobile phones. If you want to use a third-party data cable, you should also know more about its parameters before buying, whether it can adapt to your mobile phone's fast charging scheme, and don't be confused by the publicity of unscrupulous and unscrupulous businessmen. It's useless to spend money on data cables.

Summary

When using and purchasing data cables, we must not ignore the product description and think that they are all data cables, as long as the interface is the same. When looking at the product description, you can focus on the following points:

Check whether the data cable has both shielding network and shielding layer. If both are available, it means that the quality of the data cable will not be too poor at least.

Look at the materials of the internal wire core. Generally, copper core, tinned copper and silver plated copper core are better. Carefully select the iron core, aluminum magnesium core, etc.

Look at the AWG value. Generally, 20AWG and 22AWG are better. If it reaches 26AWG, be careful.

If there are no special requirements, you can choose a data cable with a shorter length.

Compare the fast charging scheme used by your mobile phone to see if the maximum current that the data cable can carry can match the fast charging scheme on the charger.

If you are looking for an OEM Bendable Charging Data Cable, we look forward to being your first choice and provide you with high quality products, plz feel free to contact us.

0 notes