#Aluminum Veneer Sheets

Text

Buy Premium Quality Metallic Veneer Online at Low Prices In India | Frikly

Cost of Metallic Veneer - Shop Metallic Veneer Sheet Online at Best Prices | Frikly.com – Add a touch of glamour to any interior with our stunning metallic veneer collection lends itself to a multitude of applications. Free Delivery, COD.

https://frikly.com/category/veneer/mettalic

#Metallic Veneer#Metallic Veneer Price#Metallic Veneer Sheets#Cost of Veneer#Metal Veneer#Aluminum Veneer Sheets

0 notes

Text

Metallic Veneer - Buy Premium Quality Metallic Veneer Online at Low Prices In India | Frikly

Cost of Metallic Veneer - Shop Metallic Veneer Sheet Online at Best Prices | Frikly.com – Add a touch of glamour to any interior with our stunning metallic veneer collection lends itself to a multitude of applications. Free Delivery, COD.

https://frikly.com/category/veneer/mettalic

#Metallic Veneer#Metallic Veneer Price#Metallic Veneer Sheets#Cost of Veneer#Metal Veneer#Aluminum Veneer Sheets

0 notes

Text

Innovative Materials in Exterior Wall Cladding: Trends and Technologies

The materials used for exterior wall cladding have experienced tremendous improvements in the construction and architectural industries in recent years. The necessity for long-lasting, visually beautiful, and sustainable solutions that satisfy contemporary construction codes is what motivates this development. Here, we examine the newest developments in exterior wall cladding material trends and technology.

1. Aluminum Composite Panels (ACP)

It is often known that aluminum composite panels are strong, flexible, and have a modern appearance. These panels are composed of a non-aluminum core, usually composed of polyethylene or a substance resistant to fire, surrounded by two thin layers of aluminum.

Key Benefits:

Durability: A long lifespan is ensured by resistance to weathering, corrosion, and UV radiation.

Aesthetics: A range of hues, textures, and finishes are available, inspiring imaginative design ideas.

Lightweight: Handled and installed more easily than with solid aluminum sheets.

Fire Resistance: Building safety is increased by ACPs that are fire-rated.

2. High-Pressure Laminates (HPL)

For external cladding, high-pressure laminates are still another well-liked option. HPL sheets are renowned for their durability and visual attractiveness. They are created by pressing layers of kraft paper that have been coated with phenolic resin at high pressure and temperature.

Key Benefits:

Durability: Extremely resilient to UV radiation, moisture, and impact.

Flexibility in Design: Available in an extensive array of hues, patterns, and textures.

Low Maintenance: Over time, it becomes more cost-effective because it requires less maintenance.

Environmental friendliness: Materials sourced responsibly are used in the production of many HPL products.

3. Fiber Cement Panels

Cement, cellulose fibers, and sand make up fiber cement panels. These panels are praised for their remarkable robustness and ability to withstand challenging climatic conditions.

Key Benefits:

Fire Resistance: Non-combustible properties enhance building safety.

Durability: Withstands extreme weather conditions, including heavy rain and high winds.

Aesthetic Versatility: Mimics the appearance of wood, stone, or stucco while offering superior durability.

Low Maintenance: Resistant to pests and rot, reducing long-term maintenance costs.

4. Terracotta Cladding

Natural clay is used to make terracotta cladding, which is then baked in a kiln to produce a robust material. This cladding has a distinctive, rustic look that is both modern and classic.

Key Benefits:

Aesthetic Appeal: Offers a cozy, organic appearance that complements a variety of architectural designs.

Sustainability: Composed of recyclable, natural materials.

Thermal Performance: Superior thermal mass characteristics contribute to temperature control in buildings.

Durability: Able to withstand corrosion, cold, and UV radiation, guaranteeing long-term performance

.

5. Natural Stone Veneers

When compared to full-thickness stone, natural stone veneers have the same timeless beauty but also less weight and simpler installation.

Key Benefits:

Aesthetic Authenticity: Offers a lighter, more workable version of stone with the timeless appearance.

Durability: Extremely resilient to physical harm and corrosion.

Low Maintenance: Natural stone looks good for a long period with little maintenance needed.

Versatility: Comes in a range of stone kinds, hues, and textures.

6. Composite Wood Cladding

Wood fibers and plastic polymers are combined to form composite wood cladding, a material that has the natural appearance of wood but is more durable and weather resistant..

Key Benefits:

Aesthetic Appeal: Offers more durability while simulating the look of natural wood.

Low Maintenance: Unaffected by UV rays, decay, and insects.

Sustainability: This refers to the use of recycled resources, which helps maintain the environment.

Installation Ease: Lightweight and simple to use, which cuts down on installation expenses and time.

.

7. Glass Fiber Reinforced Concrete (GFRC)

Cement, fine aggregate, water, acrylic polymer, and glass fiber combine to form GFRC, a composite material. It provides a special blend of robustness and adaptability in design.

Key Benefits:

Strength: Excellent resistance to impact and tensile strength.

Lightweight: Being lighter than conventional concrete makes handling and installation simpler.

Design Flexibility: Adaptable to a range of finishes and forms.

Durability: Capable of withstanding corrosion, fire, and weathering.

8. Metal Cladding

Steel, aluminum, and zinc are among the common metals utilized for cladding because of their strong performance qualities and contemporary look.

Key Benefits:

Durability: Outstanding defense against impact, corrosion, and weather.

Aesthetic Flexibility: Comes in a range of colors, profiles, and finishes.

Recyclability: Metal cladding is completely recyclable and frequently composed of recycled materials.

Low Maintenance: Takes little care to maintain and holds its beauty over time.

9. Green Walls

Growing plants on a building's façade creates a live, breathing cladding system known as "green walls," sometimes referred to as "living walls" or "vertical gardens."

Key Benefits:

Aesthetic Appeal: Gives building facades a distinctive, organic touch.

Environmental Benefits: Provides insulation, lowers the impact of the urban heat island, and improves air quality.

Biodiversity: By giving insects and birds a place to live, urban biodiversity is supported.

Thermal Performance: Lowers energy expenses by assisting in temperature regulation in buildings.

10. 3D Printed Cladding

A cutting-edge technique for producing personalized external cladding panels with elaborate patterns and decorations is 3D printing technology.

Key Benefits:

Design innovation makes it possible to create intricate, custom designs that were previously unachievable.

Sustainability: Minimizes material waste by using exacting production techniques.

Production Speed: Shortens lead times by speeding up the process.

Customization: Provides specialized solutions to fulfill particular architectural specifications.

To know more visit our website:https://timexbond.com/hpl-projects

0 notes

Text

Sliding Table Saw Machine : 45°, 90° Wood Cutting Machine

Sliding Table Saw Uses and characteristics

Panel saw machine is a type of woodworking equipment designed for cutting large panels and sheets of wood, plastic, and other similar materials with precision and efficiency. Panel saws are commonly used in woodworking shops, furniture manufacturing, cabinet making, and other industries where accurate and straight cuts in large sheets of material are required.

This machine tool can provide vertical and horizontal sawing of square lumber and panels, and is suitable for processing various panels such as construction, furniture, vehicle and ship manufacturing.

Features: This machine can saw wood, veneer particleboard, various man-made boards, plastic boards, and aluminum alloy boards. There are two saw blades at the front and back. The front is the pre-cutting saw and the back is the main saw. The two saw blades work at the same time, no planing process after sawing, good smoothness, high accuracy, and no burrs.

The body has a sliding table and a fixed table. Therefore, the machine can be used for sawing and cutting the sheet size without laying a foundation.

Panel Saw Application

The sliding table saw or panel saw is mainly used to cut wooden boards in the woodworking industry.It can cut various types of wood materials, like hardwood, softwood, MDF, particle boards, melamine boards, plywood, etc. Besides cutting, it can also make straight and inclined slots on the wooden boards by adjusting the angle of the saw blade.

Cabinet Making: Panel saws are commonly used in cabinet shops to cut sheets of plywood or MDF for cabinet components.

Furniture Manufacturing: Furniture manufacturers use panel saws to cut large panels for tables, dressers, and other furniture pieces.

Architectural Millwork: For producing architectural elements like doors, windows, and moldings.

Sign Making: In sign-making shops to cut large panels for signs and displays.

Construction: In construction projects for cutting sheathing, siding, and other building materials.

Sliding Table Saw Machine Technical Parameter

Maximum cutting length2800/3000/3200mmMaximum cutting width1250mmMain saw blade diameter250-300mmVice saw blade diameter120mmMain saw blade speed4500-6000rpmVice saw blade speed8000rpmMain saw motor power4kwVice saw motor power0.75kwMachine size3050*3150*900mmWeight800kg

Types of Panel Saws:

Vertical Panel Saw: This type of panel saw is designed to make vertical cuts in large panels. It typically has a vertical cutting blade mounted on a carriage that moves along vertical tracks. Vertical panel saws are well-suited for cutting large sheets of plywood, MDF, and other materials into smaller pieces.

Horizontal Panel Saw: Horizontal panel saws are used for making horizontal cuts in large panels. They have a horizontal cutting blade that moves along a horizontal axis. These machines are often used for cutting sheets into strips or for trimming the edges of panels.

Working principle:

After the adjustment of the machine tool is completed, according to the required plate size, align the backing plate according to the standard size on the worktable. The backing plate can be adjusted horizontally and diagonally. Adjust the main saw blade to an appropriate height (the pre-cutting saw lifting is controlled by the star handle) and then put the plate on the worktable and press the button to realize the cutting.

Maintenance and repair of machine tools

The cutting and sawdust at the bottom of the machine must be cleaned regularly, especially the track and drive pulley should be kept clean.

The commonly used adjustment, locking, bolts should be washed and cleaned with resin frequently, and coated with lubricating oil.

In order to ensure that the sawing does not stick to the guide rail of the double roller carriage, it should be blown with compressed air before leaving get off work every day.

When the telescopic part of the revolving arm is accumulated with oil, it should be removed and wiped or cleaned with compressed air without dismantling it.

The bearing of the saw blade shaft is fully enclosed, and it will be replaced after 4000 hours of construction use.

If any abnormality is found in the use of the machine tool, repair it in time, and pay attention to the location of the original parts and the transmission interval during maintenance.

If the spindle rotates abnormally or the shaft seat is heated, remove the bearing for inspection. If there is no damage, clean it and inject new oil.

Panel Saw Machine

The horizontal panel saw machine is mainly for cutting various wooden panels and sheets. It takes more space but easier to use than vertical ones. The panel sizing machine mainly includes the computer beam saw (computer CNC panel saw) and the sliding table saw.

Our computer beam saw, also know as panel dividing saw or panel sizing saw, can cut wooden panels with a thickness up to 100mm and the length up to 3700mm with high speed and excellent accuracy. The computer beam saw is the most effective method of precise panel cutting with modern software that allows the saw to gain maximum yields from the materials. Sliding table saw makes cutting tasks easier and safer. It can cut panels at certain angles (22.5°, 45°, 90°) and can also make right-angle and inclined grooves.

If you are looking for sliding table saws, computer controlled horizontal wood saws, panel saws, beam saws, panel sizing centers or an alternatives of vertical panel saws, please read on our site or come to us for latest prices and more details, suggestions.

Features of a sliding table saw

Humanized design. The panel saw machine adopts a humanized design, and its sliding table adopts a widened design. This makes the wood sawing operation quite easy and labor-saving. It ensures a quick, accurate, and smooth cutting process.

Pure copper motor. The panel table saw adopts a high-quality panel saw kit. For example, the pure copper motor is powerful and can effectively increase the sawing speed.

Stable machine bed structure. The machine bed structure of the panel saw machine is made of fine steel. It has the characteristics of high precision, wear resistance, and corrosion resistance, making the fuselage relatively firm.

Intelligent processing function. From the overall point of view, the sliding panel saw machine adopts a retractable design, and the body can be retracted according to actual production needs. It can be enlarged or reduced at will to adapt to the processed workpieces.

High processing precision. The panel saw machine adopts an imported round bar guide rail and other high-accuracy and best panel saw kit. All these can effectively improve the sawing accuracy of the equipment.

Wide range of applications. sliding table panel saw has wide applications in lumber mills, furniture factories, board factories, and other occasions.

0 notes

Text

Door Skin A Comprehensive Overview for Homeowners

As a homeowner, selecting the right door materials is crucial for enhancing the aesthetic appeal, functionality, and durability of your home's interiors. Door skin, also known as door facing or door veneer, is a popular choice due to its versatility, cost-effectiveness, and aesthetic options. In this comprehensive overview, we'll delve into the features, benefits, types, installation, maintenance, and design possibilities of door skin for homeowners.

Features of Door Skin:

Material Composition: Door skin is typically made from thin sheets of materials such as wood veneer, PVC (Polyvinyl Chloride), HDF (High-Density Fiberboard), MDF (Medium-Density Fiberboard), or metal. These materials offer varying degrees of durability, finish options, and customization possibilities.

Durability: High-quality door skins are durable, scratch-resistant, moisture-resistant, and easy to clean, making them suitable for both interior and exterior doors.

Design Options: Door skins come in a wide range of designs, colors, textures, and finishes to suit different interior styles, from classic and traditional to modern and contemporary.

Cost-Effective: Compared to solid wood or metal doors, door skins are more affordable while offering similar aesthetic appeal and functionality.

Benefits of Door Skin for Homeowners:

Aesthetic Appeal: Door skins enhance the visual appeal of doors with their decorative patterns, wood grain finishes, textured surfaces, and vibrant colors, adding a touch of elegance to your home.

Versatility: Door skins can be used for various types of doors, including interior doors, exterior doors, wardrobe doors, cabinet doors, and more, providing design consistency throughout your home.

Customization: Homeowners can customize door skins by choosing specific designs, colors, textures, and finishes that complement their interior décor and personal preferences.

Easy Installation: Installing door skins is relatively straightforward and can be done by professionals or DIY enthusiasts using adhesives, screws, or nails to secure the skin onto the door frame.

Low Maintenance: Door skins require minimal maintenance, occasional cleaning with a damp cloth or mild detergent, and routine inspection for any damages or wear and tear.

Types of Door Skin:

Wood Veneer Door Skin: Made from thin slices of natural wood, wood veneer door skins offer a classic and authentic wood grain appearance, available in various wood species such as oak, walnut, maple, cherry, and more.

PVC Door Skin: PVC door skins are durable, moisture-resistant, and come in a wide range of colors, patterns, and textures, including matte, glossy, embossed, and printed designs.

HDF/MDF Door Skin: High-Density Fiberboard (HDF) and Medium-Density Fiberboard (MDF) door skins are engineered wood products that offer versatility, durability, and a smooth surface for painting, laminating, or veneering.

Metal Door Skin: Metal door skins, such as stainless steel or aluminum, provide a sleek and modern appearance, ideal for contemporary interiors or commercial applications.

Installation Process:

Prepare the Door: Ensure that the existing door frame is clean, dry, and free from any defects or damage. Remove old paint, varnish, or adhesive residues as needed.

Cut the Door Skin: Measure the dimensions of the door frame and cut the door skin to fit using a sharp utility knife, saw, or scissors, leaving allowances for edges and corners.

Apply Adhesive: Apply a suitable adhesive (recommended by the manufacturer) evenly on the backside of the door skin, covering the entire surface area but avoiding excessive application to prevent seepage.

Attach the Door Skin: Carefully position the door skin onto the door frame, starting from one edge and smoothing out any air bubbles or wrinkles as you go along. Use a roller or flat tool to press the door skin firmly onto the surface.

Trim and Finish: Trim any excess door skin material using a sharp blade or router, and finish the edges with edge banding, trim pieces, or molding for a clean and seamless appearance.

Allow for Drying and Curing: Allow the adhesive to dry and cure as per the manufacturer's instructions before using the door. Avoid excessive moisture exposure during this period to ensure proper bonding.

Maintenance Tips for Door Skin:

Regular Cleaning: Wipe the door skin surface regularly with a soft cloth or sponge dampened with mild detergent and water to remove dust, dirt, or stains.

Avoid Harsh Chemicals: Avoid using abrasive cleaners, solvents, bleach, or harsh chemicals on the door skin as they may damage the finish or surface texture.

Protective Measures: Use door mats, rugs, or protective pads near doors to prevent scratches, dents, or impact damage from heavy objects or footwear.

Inspect for Damage: Periodically inspect the door skin for any signs of damage, peeling, or delamination, and address any issues promptly to prevent further deterioration.

Design Possibilities with Door Skin:

Wood-Look Finishes: Achieve the warmth and elegance of natural wood with wood veneer door skins, available in various wood species and finishes like oak, walnut, cherry, mahogany, and more.

Contemporary Patterns: Explore modern and contemporary designs with PVC door skins featuring geometric patterns, abstract motifs, floral prints, metallic finishes, or minimalist textures.

Textured Surfaces: Add depth and tactile appeal to your doors with textured door skins, including embossed patterns, brushed textures, leather-like surfaces, or stone-inspired finishes.

Customized Graphics: Personalize your doors with custom graphics, artwork, logos, or branding elements printed on PVC or metal door skins for a unique and distinctive look.

Color Options: Choose from a spectrum of colors and shades to match your interior color scheme, create contrasts, or make a bold statement with vibrant hues or subtle neutrals.

Conclusion:

Door skin offers homeowners a cost-effective, versatile, and stylish solution for enhancing the appearance of doors throughout their homes. With a wide range of materials, designs, textures, finishes, and customization options available, door skins allow homeowners to achieve luxurious aesthetics, durability, and functionality while staying within budget constraints. Whether you prefer the classic charm of wood veneer, the contemporary appeal of PVC patterns, the durability of metal surfaces, or customized graphics, door skin provides endless design possibilities to elevate your home's interior décor.

0 notes

Text

Walking Altar

(October 2023, activated the 26th)

Walking as worship. Surrendering to the perpetual advance and it's impression on form. An approximate document of nomadic intimacy.

Wood tray, untreated pine scraps, oak veneer, aluminum sheet, aluminum screen mesh, foil tape, cotton ribbon, discarded bike break

0 notes

Text

Variety Siding Service

The Ultimate Guide to Siding: Enhance Your Home's Aesthetics and Protection

When it comes to the exterior of your home, few elements have as significant an impact as siding. Not only does it play a vital role in protecting your home from the elements, but it also contributes to its overall aesthetic appeal. Choosing the right siding material and understanding the installation process are essential factors in achieving a beautiful and durable home exterior. In this comprehensive guide, we will explore the various types of siding, their benefits, and important considerations to help you make an informed decision. Click here to discover how ZdoubleB can help your business reach the next level: https://zdoubleb.com/

The Importance of Siding

Protecting Your Home: The primary function of siding is to shield your home from the elements, including rain, snow, wind, and UV rays. It acts as a barrier, preventing moisture from seeping into your walls and causing structural damage.

Enhancing Energy Efficiency: Quality siding, properly installed, can help insulate your home, reducing energy consumption and lowering utility bills. It acts as an additional layer of insulation, keeping your home cooler in the summer and warmer in the winter.

Aesthetic Appeal: Siding is an essential part of your home's curb appeal. The right choice of material and color can enhance its beauty, complement the architectural style, and increase its value.

Types of Siding Materials

Vinyl Siding: Vinyl is a popular and cost-effective option. It comes in a wide range of colors and styles, requires minimal maintenance, and offers excellent durability.

Fiber Cement Siding: Fiber cement siding combines the look of wood with the durability of cement. It is resistant to rot, insects, and fire, making it a long-lasting and low-maintenance choice.

Wood Siding: Wood siding provides a timeless, natural look and can be customized with various finishes and stains. However, it requires regular maintenance to prevent rot, insect infestation, and warping.

Metal Siding: Metal siding, such as aluminum or steel, offers exceptional durability and fire resistance. It is available in a range of styles, including vertical panels, shingles, and corrugated sheets.

Brick and Stone Veneer: Brick and stone veneers add a touch of elegance and sophistication to any home. They are durable, require little maintenance, and offer excellent protection against the elements.

Factors to Consider When Choosing Siding

Climate Considerations: Different climates require specific siding materials. Some materials are better suited for extreme temperatures, heavy rainfall, or high humidity. Consider the climate in your region when selecting siding.

Maintenance Requirements: Evaluate the level of maintenance you are willing to commit to. Some materials, like vinyl or metal, require minimal upkeep, while others, like wood, need regular painting, staining, and sealing.

Cost and Budget: Determine your budget for siding installation, including material and labor costs. Keep in mind that while some materials may have a higher upfront cost, they can provide long-term savings due to their durability and energy efficiency.

Architectural Compatibility: Consider the architectural style of your home and choose siding that complements its design. Different materials and styles work better with certain architectural styles, ensuring a cohesive and visually pleasing result.

Siding Installation Process

Hiring Professionals: Siding installation is a complex process that requires expertise. It is recommended to hire professional contractors who have experience in siding installation to ensure proper installation and minimize potential issues.

Preparing Your Home: Before installation, the existing siding needs to be removed, and any necessary repairs or modifications should be made to the underlying structure. This includes addressing any water damage, replacing rotten wood, and ensuring a level surface.

Installation Techniques: The installation technique varies depending on the siding material chosen. It typically involves measuring, cutting, and fitting the siding panels or shingles, followed by securing them to the wall using appropriate fasteners.

Finishing Touches: Once the siding is installed, the finishing touches, such as caulking, sealing, and painting, are applied to provide a polished and weatherproofed final result.

Choosing the right siding for your home is a crucial decision that combines functionality, aesthetics, and long-term value. By understanding the various types of siding materials, considering important factors like climate and maintenance requirements, and following a proper installation process, you can ensure your home's exterior is not only visually appealing but also well-protected from the elements. Invest in quality siding today and enjoy the benefits of a beautiful, durable, and energy-efficient home for years to come.

Click here

1 note

·

View note

Text

Different Types Of Shutters For Kitchen And Wardrobes Design For Your Home By Shutter Shop

Shutters for kitchen and wardrobes, which are individually manufactured in a factory and assembled on-site, make a modular kitchen truly unique. A central structure surrounds an inner box and a shutter on the outside of each kitchen cabinet. Choosing the right shutters for your cabinets is an important part of creating the ideal modular kitchen. Shutter Shop Kitchen shutters come in a wide variety of colours, materials, finishes, mechanisms, and styles from which to choose. You'll definitely run out of options. A quick guide to the various kinds of modular kitchen designs in Bangalore is provided below:

Laminate Shutters: Laminate shutters are a popular choice because they are long-lasting and come in a variety of designs. An MDF (Medium Density Fiberboard) or HDF (High-Density Fiberboard) core is bonded to a laminate sheet in these products. Laminate shutters come in a wide range of colours, patterns, and textures, allowing you to create a variety of looks for your kitchen.

Acrylic Shutters: High-gloss acrylic shutters are renowned for their sleek appearance. Acrylic sheets are heat-pressed onto an MDF or HDF base to create them. Acrylic shutters provide a reflective surface that enhances the overall aesthetics of your kitchen and are available in a wide range of vibrant colours says Shutter Shop modular kitchen shutter manufacturers in Bangalore.

Veneer Shutters: Your modular kitchen will look more natural and sophisticated with shutters made of veneer. They are made of thin wood slices that are bonded to a base made of MDF or plywood. You can add a touch of warmth and sophistication to your kitchen with the help of veneer shutters, which are available in a variety of woods and finishes, including oak, teak, walnut, and cherry.

Glass Shutters: Glass shutters give your kitchen cabinets a modern and chic appearance. They come in a variety of styles, including tinted glass, clear glass, frosted glass, textured glass, and so on. A distinctive and visually appealing kitchen design can be created by combining glass shutters with other materials like aluminium frames or wooden frames.

PVC Shutters: For modular kitchens, PVC shutters are a cost-effective option. They are known for their resistance to moisture, termite infestation, and ease of maintenance. They are made of polyvinyl chloride (PVC). PVC shutters come in a variety of colours and finishes, including metallic, glossy, and matte, so you can pick the one that best complements your kitchen's design.

Aluminum Shutters: Aluminum shutters are corrosion-resistant, lightweight, and long-lasting. They come in a variety of colours and finishes, some of which can be powder-coated. With glass inserts or frosted glass, you can create a modern and minimalist kitchen look with aluminium shutters.

Consider your kitchen's style, maintenance requirements, durability, and budget when selecting a floor to ceiling wardrobe in Bangalore and modular kitchen shutters. Shutter Shop a professional kitchen designer or kitchen shutter manufacturers Bangalore can offer you expert guidance that is tailored to your specific requirements and preferences.

For more information:

Website: https://www.shuttershop.co.in/

Address: A24, 3rd Floor, Geetha Towers

Near Skoda Showroom, above Sri Udupi Sannidhi, Kamadhenu Nagar, B Narayanapura, Mahadevapura,

Bengaluru, Karnataka - 560 016

Contact: +91 74065 56660

Email: [email protected]

#shuttersforkitchenandwardrobes#modularkitchenshuttermanufacturersinbangalore#modularkitchendesignsinbangalore#kitchenshuttermanufacturersbangalore#floortoceilingwardrobehardwareinbangalore

0 notes

Text

Frikly offers premium quality Metallic Veneer at low prices in India.

Get the highest quality Metallic Veneer at affordable prices. We offer a wide range of colours and finishes, so you can create the perfect look for your project. Shop online for Free Delivery, COD, fast delivery and excellent customer service.

#Metallic Veneer#Metallic Veneer Price#Metallic Veneer Sheets#Cost of Veneer#Metal Veneer#Aluminum Veneer Sheets#Thick Metallic Veneer

1 note

·

View note

Text

Natural Stone Laminates: The Perfect Blend of Elegance and Durability

Natural stone has always been a symbol of elegance and luxury. From ancient times to the present, it has been used to decorate homes, palaces, and public buildings.

However, natural stone can be expensive, heavy, and difficult to install. That's where natural stone laminates come in. They offer the beauty of natural stone in a more affordable, lightweight, and easy-to-install form.

In this article, we will explore the world of natural stone laminates and why they are an excellent choice for your next renovation or construction project.

Visit Uro Veneer World Today!!!

Buy the Best and High Quality Natural Stone Laminates Now and Make your Home Decor Elegant and Beautiful.

Contact Us Now!!!

What are Natural Stone Laminates?

Natural stone laminates are thin sheets of natural stone that are adhered to a backing material, such as fiberglass, aluminum, or polyethylene. This backing material provides support, stability, and flexibility to the stone. The result is a lightweight and durable product that can be used for walls, floors, countertops, and other surfaces.

Natural stone laminates are an increasingly popular option for homeowners who want the look and feel of natural stone without the high cost and maintenance requirements. These laminates consist of a thin layer of real natural stone, such as granite or marble, bonded to a backing material, such as MDF or plywood. This creates a product that looks and feels like solid stone, but is much lighter and easier to install.

One of the key benefits of natural stone laminates is their versatility. They are available in a wide range of colors and patterns, which makes it easy to find a style that fits your home and your personal taste. Some popular options include granite, marble, travertine, and limestone, each of which has its own unique look and feel.

When choosing a natural stone laminate, it is important to consider the thickness of the stone layer. Thicker layers will offer more durability and resistance to damage, but they will also be more expensive. Thinner layers may be more affordable, but they may not hold up as well over time.

Another factor to consider when choosing a natural stone laminate is the type of backing material. MDF and plywood are two common options, each of which has its own advantages and disadvantages. MDF is a more stable and durable material, but it is also heavier and more difficult to work with. Plywood is lighter and easier to work with, but it may not be as stable over time.

Installation of natural stone laminates is relatively straightforward, but it does require some basic carpentry skills. The first step is to measure and cut the backing material to the desired size and shape. The natural stone layer is then glued to the backing material using a high-quality adhesive.

Once the stone layer is in place, the edges and corners can be finished using a router or other cutting tool. The laminate can then be sanded and polished to create a smooth, even surface.

When installing natural stone laminates, it is important to follow the manufacturer's instructions carefully. This will help to ensure that the laminate is installed properly and that it will last for many years to come.

In addition to their use in countertops and vanities, natural stone laminates can also be used for flooring, backsplashes, and other applications. This versatility makes them a great choice for a wide range of home improvement projects.

Overall, natural stone laminates offer a cost-effective and versatile alternative to solid stone surfaces. With their durability, low maintenance requirements, and wide range of styles and colors, they are a great choice for any home renovation project.

Whether you are looking to update your kitchen or add a touch of luxury to your bathroom, natural stone laminates are a great choice.

Visit Uro Veneer World Now and Buy your Favorite Natural Stone Laminates @ Uro Veneer World.

Get in touch with us Today!!!

Largest Collection of Laminates Ever.

South India’s Largest Supplier of Laminate Sheets.

Buy the Best and Largest Collections of Natural Stone Laminates from Uro Veneer World.

There are several types of natural stone laminates available in the market. The most popular ones are : -

Marble Laminates: Marble is a classic and timeless natural stone that exudes elegance and luxury. Marble laminates come in various shades of white, gray, beige, and black, and are perfect for creating a sophisticated and chic look.

Granite Laminates: Granite is a strong and durable natural stone that is ideal for high-traffic areas. Granite laminates come in a range of colors, from light to dark, and offer a unique and natural look.

Onyx Laminates: Onyx is a translucent natural stone that is known for its stunning patterns and colors. Onyx laminates are perfect for creating a dramatic and eye-catching effect.

Travertine Laminates: Travertine is a versatile natural stone that is characterized by its unique texture and color variations. Travertine laminates are available in shades of cream, beige, and tan, and are ideal for creating a warm and inviting ambiance.

Visit Us for more info!!!

Contact Us for more info!!!

Buy Now!!!

Advantages of Natural Stone Laminates -

Beauty and Elegance: Natural stone laminates offer the beauty and elegance of natural stone at a fraction of the cost. They come in a range of colors, patterns, and textures, and can be customized to fit any design style.

Lightweight and Flexible: Natural stone laminates are lightweight and flexible, making them easy to install and handle. They can be cut, shaped, and bent to fit any surface, and can be installed on walls, floors, and ceilings.

Durable and Long-Lasting: Natural stone laminates are durable and long-lasting, thanks to the backing material that provides support and stability to the stone. They are resistant to scratches, stains, and heat, and require minimal maintenance.

Cost-Effective: Natural stone laminates are more affordable than natural stone, making them a cost-effective option for those who want to achieve the look of natural stone without breaking the bank.

Easy to Install: Natural stone laminates are easy to install, and can be installed by a professional or a DIY enthusiast. They can be cut to size using a saw, and can be adhered to any surface using a special adhesive.

Get Quotes and View Prices

Applications of Natural Stone Laminates -

Natural stone laminates are composite materials that consist of a thin layer of natural stone (such as granite or marble) bonded to a backing material. These laminates offer the beauty and durability of natural stone at a lower cost and weight.

Some common applications of natural stone laminates include : -

Walls: Natural stone laminates are ideal for creating accent walls, feature walls, and backsplashes. They can be used in living rooms, bedrooms, kitchens, and bathrooms to add a touch of elegance and sophistication.

Floors: Natural stone laminates are suitable for high-traffic areas, such as hallways, foyers, and commercial spaces. They are durable, slip-resistant, and easy to maintain, making them an excellent choice for flooring.

Countertops: Natural stone laminates are popular for kitchen and bathroom countertops. They are available in a range of colors and patterns, and are resistant to scratches, stains, and heat.

Flooring: Natural stone laminates can be used for flooring in homes and commercial spaces. They offer the look of natural stone without the high cost and maintenance requirements.

Wall cladding: Natural stone laminates can be used to cover walls in interior and exterior spaces. They are durable and can withstand exposure to weather and moisture.

Furniture: Natural stone laminates can be used to create furniture pieces such as tables, desks, and shelves. They add a unique and sophisticated touch to any space.

Decorative accents: Natural stone laminates can be used to create decorative accents such as fireplace surrounds, mantels, and backsplashes. They add visual interest and texture to a space.

Overall, natural stone laminates are a versatile material that can be used in a variety of applications. They offer the beauty and durability of natural stone at a lower cost and weight, making them an attractive option for many projects.

#uro veneer world#laminates#best laminate brand in india#decorative laminates#laminate flooring#best laminates in india#laminate countertops#laminate sheets#laminates for kitchen cabinets#high pressure laminates#designer laminates#luxury laminates#premium laminates#best quality#best laminate shop in bangalore#digital laminates#decor#decoration#home decorating#home decor#interior decorating#home interior#home#home improvement#home decorators#home office#living room#kitchen#kitchen laminate design#natural stone laminates

0 notes

Text

Tips To Lower Your Modular Kitchen Budget

Modular kitchen is the cherished dream of every family when it comes to kitchen remodeling Austin. There are tons of modular kitchen ideas to explore and a galaxy of solutions to try, making the options in front of you overwhelming. However, here are a few modular kitchen ideas you can try on a manageable budget.

Understand the concept well

A modular kitchen means pre-made cabinet parts. These parts are fixed together to create a functional kitchen. The various modules are made of different materials in order to accommodate the different accessories while making the space management effective. Floor cabinets, wall cabinets, shutters for cabinets, kitchen countertop, and functional hardware like hinges and knobs make up the different components of a modular kitchen in addition to the different appliances you may install.

Consider your typical needs

The cooking space needs of every family are unique. Therefore, a tailor-made design is what you will need for suitable results. The layout will decide the installation style. This can depend on your budget and expectations. You must also think about your cooking style. If you need extra counter space or if you will need to fit in a larger fridge, you will have to address these issues in your kitchen design.

Cabinet materials and finishes

The major part of the kitchen expenses are consumed by kitchen cabinets. It is best to choose durable as well as pocket friendly kitchen materials. Laminates are most economical options and they come in different colors. They are also easy to maintain. The other options in the line of more expensive options are wood veneers and PVC sheets. The latter come with faux wooden grains and moulding. For more durable option, you may opt for steel or aluminum.

Countertop ideas

There is a long list of options available when it comes to kitchen countertops. A few cost effective solutions you can try are marble and granite. However, a marble countertop can be stained easily.

Backsplash ideas

To bring in a fresh color, backsplash is another area to focus on. You can think of adding some texture and pattern in your cooking space. Patterned porcelain or ceramic tiles are better than plain tiles. Traditional patterns including white pattern, graphic checkered black and Turkish tile patterns can also be good options. The other options to check out are metallic finishes like copper, aluminum or brass in addition to steel and glass tiles.

0 notes

Text

Aluminum curtain wall introduction

Aluminum veneer curtain wall is a cladding system commonly used on the exterior of commercial and institutional buildings. The curtain wall consists of a series of panels that hang from the building structure and support their own weight. Aluminum veneer is a popular curtain wall material because of its light weight and good corrosion resistance. The aluminum veneer is made of high-quality high-strength aluminum alloy sheet, which makes it a solid whole, strengthens the strength and rigidity of the aluminum veneer curtain wall, and ensures the flatness in terms of long-term use, wind resistance and earthquake resistance. If sound insulation is required, efficient sound insulation and heat insulation materials can be installed inside the aluminum veneer.

Curtain walls usually consist of aluminum honeycomb panels sandwiched between two aluminum veneers. The honeycomb core provides rigidity to the panels, while the aluminum veneer provides the weather resistant barrier. Curtain wall systems can be structural or nonstructural. Structural systems connect to the building structure and help support the weight of the panels, while non-structural systems rely on the weight of the panels to hold them in place.

0 notes

Text

CNC Router Machines for Furniture Making

CNC Furniture

Smart furniture CNC machine relies on a sophisticated array of machines and automation processes to create cutting-edge, functional, and user-friendly products. These machines work seamlessly together to transform raw materials into smart furniture pieces that enhance modern living spaces. CNC router machines are commonly used in the furniture-making industry for their precision, versatility, and efficiency. They can automate various woodworking processes, allowing for the production of high-quality furniture components.

Panel furniture production refers to the manufacturing process of furniture using panels or sheets of material, such as plywood, MDF (medium-density fiberboard), particleboard, or melamine-faced boards. Panel furniture is popular due to its cost-effectiveness, design flexibility, and ease of mass production.

Here are some key aspects of CNC furniture making

CNC Nesting Router Machine

A CNC nesting router machine is an industrial automatic wood cutting machine with computer numerical controller, which has the ability of feeding, cutting and unloading in furniture customization. The layout file is designed by CAD/CAM software, and the G-code command is generated by the computer, which is transmitted to the user friendly computer numerical control system, so as to control the machine to perform various operations. The CNC nesting machine drives the gantry to move through the stepper motor, cuts the panel through the tool in the high speed spindle. It is divided into single-process, double-process, three-process, and four-process based on the number of spindles, and is classified into single-table, double-table, and moving-table based on the different table structures. In addition, it can be customized and designed to meet the commercial woodworking plans.

It is mainly used to cut various wooden boards. In terms of processing functions, the cutting machine mainly includes cutting, punching, slotting and other processes. The CNC nesting machine is widely used in the furniture industry, such as cabinet doors, wardrobe doors, solid wood doors, paintless doors, solid wood composite doors, and suite doors.

Polishing machine:

Edge banding machine

Introduction: The edge banding machine is widely applied to panel furniture, customized furniture, cabinets, office furniture, wood furniture, tables & chairs, windows & doors, wood products and decorations. It is able to process a variety of panel materials, such as density fiberboard, ecological boards, composite boards, particle boards, plane wood boards, aluminum honeycomb panels etc.

Precision saw

Introduction: Precision saw is used for the longitudinal sectioning and cross-cutting work of various board materials, such as density fiberboard, particle boards, artificial boards, ABS boards, PVC boards, PMMA, solid wood panels and other panels with similar hardness.

Vacuum press machine

Introduction: The vacuum press machine can paste various PVC films on furniture, cabinets, speakers, paint-free doors and other materials in three dimensions, and can be used for thermal printing film and single-sided solid wood veneer after the addition of silicone plate.

Side drilling machine

Introduction: The side drilling machine is designed for panel furniture and cabinets, such as wardrobes, closets. It is capable for the side drilling work of three-in-one side holes/wood pinholes/blind holes/fixed groove/straight slot/four invisible parts.

Introduction: The polishing machine is used for rough and fine sanding, buffing and polishing the side surface, anisotropic surface, plane and curve surface of straight, L-shaped wood boards and door panels of various materials, such as solid wood, density fiberboard, tinplate etc. It is the ideal equipment for anisotropic polishing processing for doors, windows, cabinets and other furniture.

If you need to upgrade your panel furniture production line with a new nesting CNC machine to make cabinets, closets, wardrobes, home doors, home decorations, and other personalized panel furniture, we suggest starting your buying process sooner rather than later, as it can fully automate your panel furniture manufacturing process, which not only saves labor and production costs, but also improves production efficiency. Buy early and benefit early. CNC technology excels in custom furniture production. It allows for easy customization and personalization of furniture pieces to meet specific client requirements. CNC machines can quickly adapt to design changes, enabling furniture makers to create bespoke furniture items efficiently.

0 notes

Text

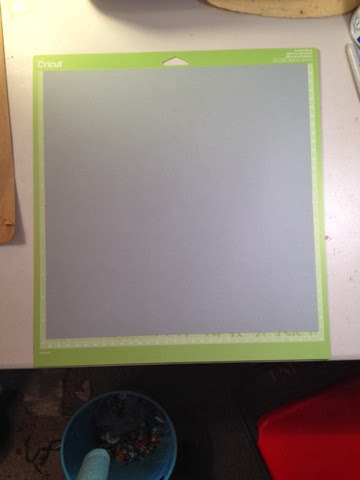

Can I Use A Cricut Mat With My Silhouette Cameo?

We are well aware these days that crafting supplies are not as cheap as they were earlier. In fact, the ones that are repetitively used by us get a bit torn with the passage of time. One such important yet very useful crafting supply is a cutting mat. I am sure you are here because you already have a Cricut cutting mat and want to know about the multiple ways you can put it to use.

We all know that both Cricut and Silhouette Cameo companies are primarily in the business of manufacturing cutting machines. And often times they require certain additional accessories. Since both the cutting machines are basically solving the same purpose, so are their additional accessories. In case you have been wondering - can I use a Cricut mat with my Silhouette Cameo - then the straightforward answer is yes, you can. So, wait no more and keep reading to find out everything I did to use a Cricut mat with my Silhouette Cameo. This insightful blog will actually be a perfect guide for when you start putting your Cricut mat to use with your Silhouette Cameo cutting machine.

How Many Types Of Cricut Mats Are There?

A Cricut machine mat holds material firmly in its place as the cutting machine cuts, writes, or embellishes on it. These mats are primarily compatible with Cricut Explore and Cricut Maker series cutting machines. But they work perfectly well with cutting machines from other brands as well. There are four varieties of Cricut cutting mats available in the market, and each has a different color, namely, Blue, Green, Purple, and Pink. The blue one is also known as the light grip mat, which is used for lightweight materials like printer paper, pearl paper, Vellum, wrapping paper, etc.

The green-colored Cricut mat is known as the Standard Grip mat, which is used for medium-weight materials like Iron-on, Vinyl, Acetate, Matboard, Truebrush paper, glitter cardstock, embossed cardstock, etc. The purple-colored cutting mat is called the Strong Grip mat that is used for Heavyweight materials that include Wood veneer, Basswood, Felt, Aluminum sheets, Chipboard, Corrugated paper, and Leather. And lastly, the pink-colored Cricut cutting mat is known as the FabricGrip cutting mat, which is used for all kinds of fabrics and crepe paper.

Can I Use A Cricut Mat With My Silhouette Cameo?

Yes, you can use a Cricut mat with your Silhouette Cameo cutting machine. See either one you have at present; both are interchangeable. But without a doubt, the mats are slightly different. This difference can be a bit tricky while performing precision cuts like cutting vinyl scraps. It can be hard to print and cut those materials where the Silhouette Cameo needs to read the registration marks. When I purchased the Cricut mat and compared it with my Silhouette mat, that was torn. I found out that the Cricut mat is slightly smaller than my old and worn-out Silhouette mat. The only reason why I had to buy a Cricut mat even though I had a Silhouette Cameo cutting machine was that first thing; I wanted to rule out all the possibilities. And secondly, I did not have enough time to wait for the shipping and delivery, which was quite a long process.

The black line where the top of the paper that we use for our creative endeavors would usually go on the Silhouette mat a little higher than on the Cricut cutting mat. The white-lined grids on the Cricut mats are surrounded by a small shaded border. So, like I did, you can also line up the paper along the top of the shading, leaving the shading on the side exposed. Then, I loaded the Cricut mat along with the paper material into the Silhouette Cameo. By doing so, the edge of the Cricut mat lined up with the edge of the roller in my Cameo machine. The best part was that I thought that I might need to adjust the blade settings since the Cricut mats are usually a little thicker, but luckily, I didn’t have to.

How To Use A Cricut Mat With My Silhouette Cameo?

We can use the Cricut mat with a Silhouette Cameo using the template method. You will need certain crafting supplies before we get started:

Cricut cutting mat

Masking Tape

Razor Knife

Straight Edge Metal Ruler

Marker

A clear sheet (same size as that of your Cricut mat)

Silhouette Cameo Cutting Machine

First, lay your Cricut cutting mat on a cutting-safe work surface. Then place the clear sheet on your Cricut mat and cover it completely by lining up all the corners.

Next, tape the clear sheet as well as the Cricut cutting mat on your work surface.

Mark the corners using the marker after you secured them well.

This is a basic template you can use to cut using a Cricut mat, and that is pretty much it.

Source:-Silhouette Cameo 4 Pro , Silhouette Cameo 4 Pro

1 note

·

View note

Text

Things We Love About the New Thelio Mira

Today, we introduce you to the newest addition to our Thelio desktop line: Thelio Mira. Our in-house engineers have been hard at work creating this pro solution for you, so without further ado, let’s get into the things we love about our new desktop:

A Chimera of Size and Performance

One day, we wondered, “What if we expanded Thelio to support more memory and more powerful GPUs?” Our in-house science team quickly got to work, splicing the compact genes of Thelio and the performant genes of Thelio Major. Then they removed the extra limbs, and presto! Thelio Mira was born. This happy little test tube baby is configurable with 4th Gen AMD Ryzen CPUs, PCIe 4.0 NVMe storage, and up to 128GB of RAM.

A Tale of Two GPUs

Thelio Mira can house two of the largest, most powerful GPUs on the market, like the NVIDIA Quadro RTX 8000. Legend has it that when these two components are brought together, humanity will accelerate past its archaic technology towards an enlightened future. Double your multitasking capabilities, rendering resources, and CUDA cores to provide the might your project deserves. It also deserves a large cookie. We don’t sell those, though.

A Terraformed Interior Climate

Thelio Mira is thermally engineered to prevent throttling and allow your pro-grade components to perform to their maximum potential. To account for the accumulating heat generated by these components, we’ve taken advantage of the jet streams to draw cool air through the bottom of the chassis and expunge hot air out through a CPU duct. Meanwhile, liquid in copper pipes absorbs heat from the CPU and carries it into the heat sink as a gas, where it’s cooled back into a liquid. Our in-house meteorologists predict sunny days and strong winds, resulting in a perfect temperate day for your system.

A Gentle Whisper

What’s it saying? If you listen closely, you’ll hear your system pledge to keep things quiet while the fans are running. More importantly, you’ll hear yourself on video calls, as well as your cat’s many pleas for a gourmet salmon dinner. Maybe tomorrow, Coriander.

A Humble Origin

Thelio Mira is born from a single sheet of aluminum that’s then cut, bent, powder-coated, and dipped in a soothing acid, all at our manufacturing facility in Denver. The chassis is then etched with elegant design and topped off with a veneer of real wood, adding character to your office. Legally, we may or may not be required to say that this character absolutely 100% will not be Mickey Mouse.

Handcrafting computers in-house also means better support for YOU, noble citizen. Our team of real humans is here to ensure you enjoy the best product experience possible. Unlike those other guys, who rely on a team of real desk-birds-who-dip-faces-in-water to peck at the problem to no avail.

And that’s the list! Head to our website to learn more about all the things to love about Thelio Mira. Our team would love to hear about what you’ll be using it for!

#linux#thelio#system76#Pop!_OS#desktop#machine learning#ai#developers#developer pc#gaming pc#gaming rig#wood#NVIDIA#AMD#Ubuntu#Tensorflow#manufacturing#made in denver#Thelio Mira#thermals#thermal engineering#engineering pc#science#computer science#nvme#CUDA#design#illustration#editing pc#editing suite

8 notes

·

View notes

Photo

"Aluminum City" Housing, New Kensington, Pennsylvania, 1941-1942: Brick veneer wall sections and details (1 1/2" and 6" = 1'-0"), Walter Gropius, 1941-1942, Harvard Art Museums: Prints

Harvard Art Museums/Busch-Reisinger Museum, Gift of Walter Gropius

Size: sheet: 89.1 x 106.2 cm (35 1/16 x 41 13/16 in.)

https://www.harvardartmuseums.org/collections/object/166042

4 notes

·

View notes