#Alloy Forged Threaded Fittings

Explore tagged Tumblr posts

Text

UNS N08020 Alloy Forged Threaded Fittings Explained

What are UNS N08020 Alloy Forged Threaded Fittings?

UNS N08020 is one of the most widely used alloys in the manufacturing of industrial and chemical processing equipment. It is a highly resistant, low-carbon nickel-iron-chromium-molybdenum alloy, also known as Carpenter 20, which exhibits excellent corrosion resistance against different chemicals and solvents, including acids, organic compounds, and saltwater. UNS N08020 Alloy Forged Threaded Fittings have unique mechanical and physical properties, which make them ideal for numerous industrial applications.

The alloy is heated to the ideal forging temperature and then hammered into a specific shape using a forging press or hammer. The forged fittings are further processed by machining or grinding to achieve the required dimensions, tolerances, and surface finish. The fittings are heat-treated to optimize their mechanical and physical properties. The finished fittings undergo rigorous testing to ensure their quality and compliance with various standards and specifications.

Benefits of UNS N08020 Alloy Forged Threaded Fittings

Exceptional Corrosion Resistance: UNS N08020 alloys feature an extraordinary combination of mechanical strength and superior corrosion resistance, making them ideal for use in harsh industrial or marine environments.

High Tensile Strength: The alloy's mechanical strength allows it to withstand high pressures, making it ideal for use in critical applications where failure could be disastrous.

Outstanding Weldability: Welding UNS N08020 Alloy Forged Threaded Fittings is straightforward and produces strong and durable joints that are resistant to cracking and other forms of damage.

High Temperature Resistance: The alloy can withstand high temperatures, making it ideal for use in applications where heat is a primary concern. It also exhibits excellent resistance to thermal shock.

Applications of UNS N08020 Alloy Forged Threaded Fittings

Chemical Processing: UNS N08020 Alloy Forged Threaded Fittings are commonly used in chemical processing industries, which require equipment to handle highly corrosive acids, organic compounds, and hydrogen sulfide.

Petrochemical Processing: The alloy's excellent resistance to seawater and other aggressive environments makes it ideal for the production and handling of petrochemicals.

Marine Industry: UNS N08020 Alloy Forged Threaded Fittings are used extensively in the marine industry for manufacturing pipelines and equipment, due to their superior seawater corrosion resistance properties.

Power Generation: The alloy's high-temperature resistance and corrosion resistance make it ideal for use in steam generation plants, where pipes and fittings are exposed to high temperatures, pressure, and corrosive environments.

Specifications of UNS N08020 Alloy Forged Threaded Fittings

UNS N08020 Alloy Forged Threaded Fittings come in different sizes, shapes, and specifications. Some of the specifications include:

Shapes: Alloy Forged Threaded Fittings come in different shapes, including elbows, tees, couplings, reducers, and unions.

Pressure Class: The fittings are designed and manufactured to specific pressure classes for safety and efficiency, with the most common being class 150, 300, 600, and 900.

Sizes: UNS N08020 Alloy Forged Threaded Fittings are available in various sizes, from 1/8” to 4”.

End Connections: They are available in different end connections, including NPT, BSPT, and BSPP.

#UNS N08020 Alloy Forged Threaded Fittings#Alloy Forged Threaded Fittings#Forged Threaded Fittings#UNS N08020 Forged Fittings

0 notes

Text

Monel K500 vs. Monel 400: Which Forged Fittings are Right for You?

Manilaxmi Industrial

Introduction: Monel alloys, including Monel K500 and Monel 400, are known for their excellent resistance to corrosion and mechanical properties. However, choosing between Monel K500 and Monel 400 forged fittings depends on the specific needs of your application.

Key Differences:

Strength: Monel K500 offers higher tensile and yield strength due to the addition of aluminum and titanium, making it better suited for high-pressure applications.

Cost: Monel K500 is more expensive than Monel 400, but its enhanced mechanical properties and longer service life can justify the higher cost.

Applications: Monel 400 is used for general corrosion resistance, while Monel K500 is preferred in more demanding applications, such as offshore oil platforms and chemical plants.

Conclusion: Monel K500 forged fittings provide higher strength and better performance in extreme environments, while Monel 400 offers a cost-effective solution for less demanding applications.

#Monel Alloy ASTM B564 K500 Forged Fittings#Alloy K500 Forged Socket Weld Equal Tee#Monel K500 Threaded Fittings#Alloy K500 Socket Weld Fittings#K500 Monel Forged Threaded 90° Elbow#Monel Alloy K500 Forged Fittings in India

3 notes

·

View notes

Text

Starlight Chapter 7 Sneek Peek! 😏

Summary: What if Osha and Qimir never left The Jedi Order

Osha knows she is dreaming.

She can feel the tether slithering around her limbs, gently pulling her from a dreamless slumber to the waiting arms of darkness.

When she opens her eyes, she finds herself in a darkened throne room.

Upon an oval podium sits two thrones. They are illuminated by moonlight pouring in through the mosaic window behind them, the stages of an eclipse captured within the glass. Straining her eyes, Osha can make out crimson banners cascading down the walls on either side of the vast room, the crest of The Sith proudly embroidered upon them in black thread.

What is this place? Osha wonders, an uneasy feeling trickling down her spine.

"It's a possibility," That cold, metallic voice calls out. Osha sees The Stranger then, standing between the thrones as he steps into the moonlight. "Or an inevitability, depending on who you ask." He tilts his head, his voice turning appreciative. "You look beautiful in that dress. It suits you."

Osha glances down.

The gown she wears is as dark as a sunless ocean, the edges detailed with silver embroidery. It has an off-shoulder neckline, dramatic bell sleeves, and a trailing skirt that flares as she moves. Upon her waist is an alloy belt, forged in the shape of a willow tree's branches, the leaves detailed by tiny emeralds. It is there that her lightsaber is secured, attached by a magnetic clip at her hip. Her hair feels longer too, her locs resting over one shoulder, adorned by silver flowers and stars. There is a diadem upon her head, hidden below her fringe.

It is an outfit fit for a Queen, more luxurious than anything Osha has ever worn.

"No," The Stranger corrects the thought, taking a step forward. His hand caresses the arm of the left throne. "It's a gown fit for an Empress."

Second snippet

"Have you told him about us?"

"There is no us," Osha grits out. "Not now. Not ever."

"Would you consider it?" The Stranger asks, his voice deadly soft. "If I were a Jedi like him?"

Osha ignites her lightsaber.

45 notes

·

View notes

Text

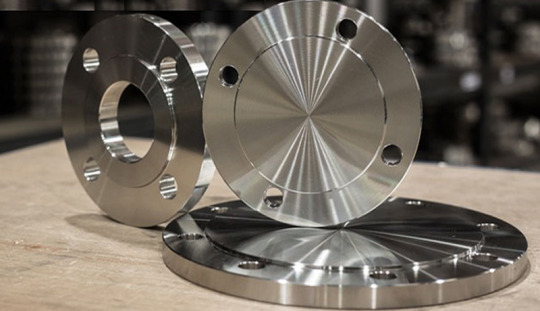

Types Of Flange & Flange Manufacturer in India

WHAT ARE FLANGES AND HOW DO THEY WORK?

Dalmine Flanges is a well-known Flange Manufacturer in India. A Flange is a forged or cast ring used to join sections of a pipe or any other machinery that requires a connection point in the middle. Stainless Steel Flange, Alloy Steel Flange, Carbon Steel Flange, and Nickel Alloy Flange are some of the most common types of flanges that are in high demand.

We are one of the largest Flange Suppliers in India. Flange comes in a variety of shapes, diameters, and thicknesses. Dalmine Flanges manufactures all products following international standards. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide.

Size, Standards, and Specifications for Flanges

A Flange is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Flanges are available in different sizes and standards, each with its specifications. We will explore flanges' size, bars, and specifications.

Flanges Type

Dalmine Flanges is a well-known Flanges supplier in India. They offer a wide range of flanges, including stainless steel flanges, carbon steel flanges, and alloy steel flanges. Their products are made to the highest quality standards and are backed by a 100% satisfaction guarantee.

Slip On Flanges

A Slip On Flanges is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Slip On Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Blind Flanges

It is used to bring the end of a piping system to a close. The Blind Flange is essentially a flange without a hub or a drilled centre. Blind Flanges have the face thickness of a flange, a matching face type, and a bolting pattern that is identical to that of a flange. Blind Flanges can also be employed to seal a pressure vessel's nozzle opening.

Lap Joint Flanges

These Flanges can swivel flexibly around the pipe. This makes it easier to align opposing Flange bolt holes. Because Lap Joint Flanges Manufacturer are not in contact with the fluid inside the pipe, they are more durable. The Lap Joint Flanges in corroding or eroding pipe systems can be saved for re-use.

Threaded Flanges

Threaded Flanges are extremely robust and are made to accommodate a variety of pipe sizes. They are used as connectors in piping systems to link pipes to other pipes, tees, reducers, elbows, valves, and other piping equipment. We have cutting-edge facilities with the highest standards of technology, quality, and productivity at Dalmine Flanges.

We are one of the largest Flange Manufacturer in India These Gate Valves can be altered to meet the unique needs of our customers and are available in a variety of sizes, forms, and dimensions.

For more details

Website :dalmineflanges.com/

Source : Flange Manufacturer in India

9 notes

·

View notes

Text

Core Features Of Copper Tube And Stainless Steel Swage Nipple

Swage nipples in piping and plumbing are applied for connecting different pipes with varying diameter and change directions. Among all the swage nipple materials, copper tube and stainless steel are widely utilized because of their natural properties.

In this sense, an application-attached piping connector, Stainless Steel Swage Nipple connects pipes of all diameters together. In addition to corrosion resistance, it is realized due to a high quality of stainless steel with notable strength and durability. It could practically be used in nearly any area-from industries, oil and gas, through food processing.

1. Material Properties

Corrosion Resistance: Because copper is a self-protection material, meaning it will not corrode easily unless the influence of a third material encourages a chemical reaction, copper has been utilized for many years in the distribution of water and gas as well as other applications.

Thermal Conductivity: Copper has a high coefficient of heat; hence, it is suited to all applications in which extensive transfer of heat is needed.

Ductility: The ability of copper to easily be forged into workable forms reduces the chances of the works leaking or corroding.

Strength and Toughness: The tensile strength of stainless steel is high, thus its use in high-pressure operations.

Resistance to Corrosion: Alloying chromium into the stainless steel allows the material to have resistance to corrosion, thus the material can easily be implemented in extreme conditions.

Resistance to High and Low Temperatures: The strength of the stainless steel withstands not only extreme operations but also extremely high temperature operations and low-temperature operations.

2. Design and Flexibility

Variety of Sizes: Stainless steel swage nipples may be available in a broad range of sizes. This does make them somewhat flexible, which makes it easier to use a good assortment of piping applications. It also helps quite easily fit into various systems.

Types of Connections: Swage nipples can be designed for any type of connection, that may be threaded or socket weld or butt weld. With this kind of versatility they easily fit the piping system.

Compact Design: The compact nature of swage nipples provides space-efficient installation capacity that is perfectly suited for compact spaces or when the pipe routing is constrained.

3. Areas of Application

Copper Tube

Residential Plumbing: They are used in residential plumbing systems for functions like water supply lines as well as heating systems.

HVAC Systems: Due to the reasons of thermal conductivity, they are applied in heating, ventilation, and air conditioners.

Stainless Steel Swage Nipples

Industrial Use: It is highly used in oil and gas, chemical processing, and pharmaceutical plants industries where strength and resistance to corrosion at a high degree is required

Food and Beverages: Because of its non-reactive nature, it is vastly used in food processing and beverage preparation.

4. Installation Easy

Easy Installation: There is lesser man-hours by reason of easy installation. Swage nipples have been designed to be mounted quickly and with minimum bother; hence, site labor hours and site labor costs are also saved.

Less maintenance is another similarity of copper and stainless steel nipples as their least maintenance keeps the overall running costs low and extends its service life.

Copper Tube Manufacturer in India applied finishes for all types of plumbing, heating, ventilation, air conditioning, refrigeration, and electrical systems. Manufacturers would always opt for the better manufacturing technique and process with rigid quality control so that they meet the international standards.

Conclusion

Characteristics-wise, copper tube, and stainless steel swage nipples differ perfectly to be applied for ideal purposes. Copper benefits from high thermal conductivities and has an excellent strength against corrosion; therefore, it is used as the material mostly in plumbing and HVAC systems. The other material, stainless steel, is strong and tolerant to harsh conditions. Nevertheless, the best swage nipples for your projects must take into consideration the aspect of properties of materials, the necessities of application, and the budget of ensuring optimal performances and durability.

0 notes

Text

Why Purchase Forged Fittings In India?

Today, it is one of the major players in the global manufacturing scenario with respect to forgings, specifically forged fittings. As the growth of industries involved in oil and gas, construction, and automobiles grows exponentially, their demand has surged for quality forged steel fittings. Piping systems depend on these pieces that exhibit high strength and resistance to ensure full integrity and safety of these systems. The article deals with the landscape of Indian forgings manufacturers, capabilities, challenges they face in threaded fittings, and their contribution to the global market.

Know About Steek Forging

Forged fittings are made through localized compressive forces. This method makes stronger and more resilient components than those produced through traditional casting. The most extensively applied forged fitting applications are in piping, such as making a connection, diversion, or regulation of fluid flow. Some of the most common types being fabricated include elbows, tees, reducers, and flanges. Materials used are carbon steel, stainless steel, and alloy steel.

Indian Manufacturing Edge

Forged Fittings Manufacturers In India is well diversified with its product range and advanced manufacturing techniques. Good infrastructure, including human resource and easy availability of raw material, gives India a chance to produce good-quality fittings as per international standards. Many manufacturers are ISO certified and have strict control over quality measures, which makes their fittings reliable and strong.

Additional integration of modern technologies such as CNC machining and automated forging processes have enhanced efficiency in the production process. These advancements enable the manufacturer to produce designs that may be complex or in any orientation with considerable accuracy, thus fulfilling the demands of their clients and remaining competitive within various industries.

Key Players

Several vendors have come out to lead the Indian forged fittings business. Bhavani Industries, K. K. Industries, and S. A. Engineering are some of the vendors that have a strong portfolio and adhere to high quality. These companies export about 50 percent of the production made. They sell to markets that include North America, Europe, and the Middle East. The standards they achieved contributed to their success in the global market and the customized solutions they could offer.

Challenges Facing the Producers

The sector does offer scope for expansion; however, there are several challenges the Indian forgings fittings manufacturing industry faces. One of the major issues that face them is volatility in the prices of raw material products, which at times can increase the cost of production and also decrease profitability. The competition a domestic player faces at his doorstep is mainly from international manufacturers whose labour costs are on the lower side.

Another challenge is continuous innovation and constant adjustment towards changing industry standards. Over time, the industries keep updating their requirements; thus, the manufacturers need to invest more in research and development in order to meet the new requirements, especially in sectors like renewable energy and water management.

Conclusion

With this in mind, here is the conclusion of forgings made by manufacturers in India: they play a crucial role in supplying high-value products meeting all kinds of industrial needs around the world. Solving challenges and embracing innovation will help these manufacturers flourish and ensure economic development in the country. As industries change, Indian manufacturers will have to be committed to quality and efficiency to remain competitive in the global market.

0 notes

Text

Closed-die drop forging at KB:

In this video: a 4000-ton press.

Every nut, bolt, and screw - Forgings for harsh environments.

KB Schmiedetechnik GmbH expertly manages all processes in-house, including CAD design, engineering, material flow and forging simulation, CAM tool manufacturing, forging, heat treatment and quenching, destructive testing and surface crack detection in own laboratory, CNC machining, and dimensional inspection.

Key Applications Across Critical Areas

Valve bodies and yokes for cryogenic, nuclear, and hydrogen applications; pipe fittings and specialty flanges for shipbuilding and boiler fabrication; pinion and gear blanks; forged supports, chain links and hooks; as well as applications in the agricultural, maritime, and defense applications.

Development of a forged valve body.

As a leader in the small-batch production of high-quality forgings in Germany, KB Schmiedetechnik GmbH serves a broad range of industries.

Closed-Die Forgings for Extreme Conditions

The company works with a variety of materials, including virtually all steel grades—carbon steels, high- and low-alloy steels, including AISI 316 and duplex stainless steels, as well as nickel-based superalloys such as Monel®, Incoloy®, Inconel®, and Hastelloy®, along with titanium.

Securing the drop-forge.com domain supports the company’s strategic vision to expand its global reach and underscores its dedication to quality and innovation.

For environmental aspects, please click on "ALT" in the image:

Eyebolts, Eyelets, Eye Nuts - For Your Trust!

Examples

Example: a socket for a tram wagon

Examples: forged hydraulic component, support and a forged eyelet.

Examples (l.t.r.): forged chain links, a forged support, and a forged hydraulic component.

Example: some forged pinion blanks (machined)

Example: threaded support hooks (forged)

YouTube channel with a few videos (mostly in German):

#DropForging#ClosedDie#ValveBodies#nuclear#hydrogen#boilers#Monel#Inconel#Incoloy#Hastelloy#AISI316#DuplexSteel

0 notes

Text

Sankalp Alloys Overseas is one of the renowned ISO 9001:2000 manufacturers, suppliers, stockists, and exporters of Incoloy 800 Flanges, available in various sizes, shapes, thicknesses, and dimensions as per the requirements of customers. Slip-on flanges, weld neck flanges, blind flanges, socket weld flanges, threaded flanges, and long weld neck flanges are part of the forged flanges that fit into domestic and global markets.

#Incoloy 800 Flanges Manufacturers#Incoloy 800 Flanges Manufacturers in India#Incoloy 800 Flanges Exporters#Incoloy 800 Flanges Exporters in India#mumbai#india#maharashtra#suppliers#business#manufacturers#Sankalpalloys

0 notes

Text

Types of Plates Flanges Supplier

Types includes slip-on, threaded, lap joint, socket-welding, weld neck, blind, and long weld neck plates. Depending on each specific need and kind of connection certain sources advantages will be applied in different extent.

ASME/ANSI B16.5 plate flanges (SLIP-ON) MANUFACTURER IN INDIA MANUFACTURER/EXPORTER OF plate flanges & HIGH QUALITY PLATE SLIP-ON FLANGES CARBON, ALLOY, STAINLESS STEEL plate flanges.

Platinex Piping Solutions LLP is a specialised manufacturer of high quality ASME/ANSI/DIN standard plate flanges in India. We offer immediate delivery programs for standard size of carbon steel plate flanges and stainless steel plate flanges. Plate flanges can be manufactured as per custom size requirements of our customers.

Stainless steel plate flanges are manufactured from plated produced in accordance to the ASTM A240 and ASME SA240 standards. Plate flanges are widely accepted as an alternative to cast or forged flanges in low pressure applications because of the benefits listed below.

Advantages of Plate Flanges

Free of any defects

Superior grain structure compared to forged or cast products

Extended service life

Reduction of the normal maintenance costs

Plate flanges are most widely used in fuel and water pipelines, where two flange plates are bolted together with a gasket in between them. The flange plate will have bolt holes all around the perimeter and will be used to create junctions, tees and joints.

0 notes

Text

Carbon Steel A182 Flanges Manufacturers In India

Carbon Steel A182 Flanges Manufacturers In India,Supplier In India ,Stocklist In India ,Exporter in India

Introduction:- Carbon Steel A182 Flanges Manufacturers In India

Carbon steel A182 flanges are crucial components used to connect pipes, valves, and other equipment in high-temperature and high-pressure systems. They are known for their robustness and ability to handle extreme conditions, making them indispensable in sectors requiring reliable performance.

India is a significant player in the global manufacturing sector for carbon steel flanges, particularly those conforming to the ASTM A182 standard. The country's manufacturing industry is well-equipped with advanced technologies and practices, enabling it to produce high-quality flanges for various industrial applications. These flanges are essential in industries such as oil and gas, power generation, chemical processing, and more.

Product Overview:-

India is a significant hub for the production of carbon steel A182 flanges, offering a diverse range of high-quality products tailored to various industrial applications. Indian manufacturers leverage advanced technology and strict quality controls to deliver flanges that meet international standards.

Indian manufacturers provide a wide variety of carbon steel A182 flanges to cater to different needs and specifications

Manufacturers offer various grades of carbon steel A182 flanges to meet different performance requirements:

ASTM A182 F1: Low carbon steel suitable for moderate temperatures.

ASTM A182 F5: Alloyed with chromium and molybdenum, providing good strength and oxidation resistance at higher temperatures.

ASTM A182 F11: Medium carbon steel with chromium and molybdenum, offering better strength and heat resistance.

ASTM A182 F22: High-carbon steel with enhanced chromium and molybdenum content for superior high-temperature performance.

Specification List of Carbon Steel ASTM A 182 Flanges

ASME/ANSI B 16.5

A182 F92 Welding Neck Flange, A182 F92 Slip on Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, A182 F92 Lap Joint Flange, Threaded Flange, A182 F92 Ring Type Joint Flange

PRESSURE CLASS

150, 300, 400, 600, 900, 1500, 2500

ASME/ANSI B 16.47

A182 F92 Welding Neck Flange, A182 F92 Blind Flange [Series A & B]

PRESSURE CLASS

75, 150, 300, 400, 600, 900

ASME/ANSI B 16.36

A182 F92 Welding Neck Flange, A182 F92 Slip on Flange, A182 F92 Threaded Flange

PRESSURE CLASS

300, 400, 600, 900, 1500, 2500

BS 4504 SEC 3.1

A182 F92 Welding Neck Flange, A182 F92 Hubbed Slip on Flange, A182 F92 Hubbed Threaded Flange, Lapped Pipe End Flange, A182 F92 Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange

PRESSURE CLASS

PN 2.5 TO PN 40

BS 4504[PART 1]

A182 F92 Welding Neck Flange, A182 F92 Hubbed Slip-On Hubbed Threaded, Plate Flange, A182 F92 Loose Plate With Weld On Plate Collar, Blank Flange

PRESSURE CLASS

PN 2.5 TO PN 400

BS 1560 BOSS

A182 F92 Welding Neck Flange, Socket Welding Flange, A182 F92 Slip-On Flange, A182 F92 Blind Flange, A182 F92 Screwed Boss Flange, A182 F92 Lapped Flange

PRESSURE CLASS

150, 300, 400, 600, 900, 1500, 2500

BS10

A182 F92 Welding Neck Flange, A182 F92 Plate Slip-On Flange, A182 F92 Screwed Boss Flange, Slip-On Boss Flange, A182 F92 Blind Flange

TABLE

D, E, F, H

DIN FLANGES

DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673

PRESSURE CLASS

PN 6 TO PN 100

Benefits:-

A182 Carbon Steel ASTM flanges are manufactured with ideal chemical experiments and connections and will not wear out quickly.

This grade of Carbon Steel ASTM flanges is used for stainless steel pipe flanges, rolled alloys, forged pipes, valves, forged fittings, and other high temperature applications. A182 Carbon Steel ASTM flange is one of the results of the best chemical experiments and good connections. These flanges don't wear out as quickly. Widely used in petroleum industry, chemical industry, paper industry and many other industries. Due to its properties, this type of flange is one of the most reliable products that can be used for a long time and does not require repairs immediately after installation. You can trust blindly the durability of this product if you buy it from the right place.

Conclusions:-

Carbon Steel A182 flanges are highly versatile components used in a wide range of industrial applications. They are well-suited for high-temperature and high-pressure environments, making them a reliable choice for sectors such as oil and gas, power generation, and chemical processing. Their ability to handle severe conditions underscores their importance in critical infrastructure.

Carbon Steel A182 Flanges are a critical component in many industrial systems, providing strength, durability, and reliability in challenging conditions. Their versatility, coupled with cost-effectiveness, makes them a preferred choice for a wide range of applications. However, consideration of their limitations regarding corrosion resistance and temperature constraints is essential for optimal performance.

Email Id :- [email protected] Contact No:- 88879709191

0 notes

Text

Ananka

1: Introduction to Hex Coupling Nut Fasteners Manufacturing

Introduction

Hex coupling nut fasteners are crucial components in many industrial applications, used to connect two threaded rods or bolts. This series of s will walk you through the comprehensive process of manufacturing hex coupling nut fasteners, from selecting the right materials to quality control. Understanding these steps provides insight into the precision and expertise required to produce reliable fasteners.

Overview of the Manufacturing Process

The manufacturing of hex coupling nuts involves several critical steps:

1. Material Selection

2. Forging and Shaping

3. Threading

4. Heat Treatment

5. Surface Finishing

6. Quality Control and Packaging

Each step in the process is designed to ensure the hex coupling nuts meet the high standards required for their intended use.

Conclusion

Manufacturing hex coupling nut fasteners is a meticulous process that ensures these components are strong, durable, and reliable. In the next , we’ll start by exploring the importance of selecting the right materials.

Hex Coupling Nut Fasteners Manufacturer

2: Material Selection for Hex Coupling Nut Fasteners

Introduction

The foundation of a high-quality hex coupling nut lies in selecting the right material. The choice of material affects the fastener's strength, corrosion resistance, and durability. This discusses the materials commonly used in manufacturing hex coupling nut fasteners and why they are chosen.

Material Properties

Hex coupling nuts need to withstand significant stress and exposure to various environmental factors. Therefore, the materials used must have specific properties:

- Carbon Steel: Widely used due to its strength and cost-effectiveness. It's suitable for general-purpose coupling nuts.

- Stainless Steel: Offers superior corrosion resistance, making it ideal for applications in moist or chemical environments.

- Alloy Steel: Combines high strength with corrosion resistance, used in heavy-duty or high-stress applications.

Why Material Selection Matters

Choosing the right material is critical because it determines the fastener's performance and longevity. The material must be compatible with the environmental conditions and the mechanical requirements of the application to ensure the coupling nut functions effectively.

Conclusion

Material selection is a crucial step in the manufacturing process, setting the foundation for the performance and durability of the hex coupling nut fasteners. The next will discuss the forging and shaping processes that transform raw materials into the desired form.

Hex Coupling Nut Fasteners Manufacturer in India

3: Forging and Shaping Hex Coupling Nut Fasteners

Introduction

Forging and shaping are the steps where raw materials are transformed into the hexagonal shape that defines coupling nuts. This covers the methods used to form and shape hex coupling nut fasteners, ensuring they meet precise dimensional standards.

Forging Techniques

Forging is the process of shaping metal using localized compressive forces. The common forging techniques include:

- Cold Forging: Performed at or near room temperature, this method increases the strength of the material through work hardening. Cold forging is ideal for producing coupling nuts with high precision and minimal waste.

- Hot Forging: Involves heating the material to make it more malleable before shaping it. This technique is used for larger or more complex shapes, allowing for better control over the material's grain structure.

Shaping Processes

Once the basic shape is formed through forging, the hex coupling nut undergoes additional shaping processes:

- Hexagonal Shaping: The nut is shaped into a hexagon using precision dies, ensuring that it fits standard wrenches and provides the necessary torque for installation.

- Threading Preparation: The inner surface is prepared for threading, which is essential for the nut’s ability to connect rods or bolts securely.

Conclusion

Forging and shaping are vital processes in manufacturing hex coupling nuts, determining their strength and precise dimensions. In the next , we’ll delve into the threading process, which is crucial for the functional integrity of the coupling nut.

Hex Coupling Nut Fasteners stockist

4: Threading Hex Coupling Nut Fasteners

Introduction

Threading is one of the most critical steps in manufacturing hex coupling nuts, as it enables the nut to securely join two threaded components. This explores the threading process and the techniques used to ensure precision and strength in the threads.

Threading Techniques

Creating threads inside the coupling nut involves several methods, each with its advantages:

- Thread Rolling: This process displaces the material rather than cutting it, resulting in stronger threads. The rolled threads are more resistant to wear and fatigue, making this method ideal for high-stress applications.

- Cut Threading: In this method, threads are cut into the nut using a threading machine. While this process can be used for smaller production runs, it may not provide the same strength as thread rolling.

Importance of Precision in Threading

Accurate threading is essential for the proper function of hex coupling nuts. The threads must be precisely aligned and evenly spaced to ensure a tight and secure fit when the nut is used to connect rods or bolts. Any imperfections in the threading process can compromise the fastener's performance.

Conclusion

Threading is a crucial step that requires precision and expertise to ensure that hex coupling nut fasteners perform reliably in their intended applications. The next will discuss heat treatment processes that enhance the mechanical properties of these fasteners.

Hex Coupling Nut Fasteners exporter

5: Heat Treatment for Hex Coupling Nut Fasteners

Introduction

Heat treatment is a process that significantly enhances the mechanical properties of hex coupling nut fasteners, such as strength, toughness, and wear resistance. This will discuss the heat treatment processes used in manufacturing these fasteners and their importance.

Purpose of Heat Treatment

Heat treatment alters the microstructure of the metal, improving its mechanical properties. The goals include:

- Increasing Strength: By refining the grain structure, heat treatment can enhance the overall strength of the coupling nut.

- Improving Toughness: Heat treatment can make the coupling nut more resistant to impact and mechanical stress.

- Reducing Brittleness: Proper heat treatment reduces the brittleness of the metal, preventing fractures under load.

Key Heat Treatment Processes

Several heat treatment processes are commonly used in manufacturing hex coupling nut fasteners:

- Annealing: Softens the metal, making it easier to machine and reducing internal stresses.

- Quenching and Tempering: This process hardens the metal by heating it and then rapidly cooling it (quenching). Tempering follows to reduce brittleness while maintaining hardness.

Conclusion

Heat treatment is essential in manufacturing hex coupling nut fasteners, ensuring they possess the necessary mechanical properties to perform under various conditions. The next will cover surface finishing techniques that further protect and enhance these fasteners.

Hex Coupling Nut Fasteners

6: Surface Finishing and Quality Control for Hex Coupling Nut Fasteners

Introduction

Surface finishing is the final step in the manufacturing process, providing additional protection and improving the appearance of hex coupling nut fasteners. Quality control ensures that every fastener meets the required standards before it leaves the factory. This covers these crucial final steps.

Surface Finishing Techniques

Surface finishing provides a protective barrier against corrosion, wear, and environmental factors. Common techniques include:

- Electroplating: A thin layer of metal, such as zinc or nickel, is applied to the surface to enhance corrosion resistance and appearance.

- Passivation: This process, used mainly for stainless steel, removes surface contaminants and promotes the formation of a protective oxide layer.

- Powder Coating: Provides a durable and aesthetically pleasing finish, often used in environments where the nuts are exposed to harsh conditions.

Quality Control

Before hex coupling nuts are packaged and shipped, they undergo rigorous quality control checks:

- Dimensional Inspection: Ensures the nuts meet precise size and shape specifications.

- Thread Verification: Confirms that the threads are correctly formed and will function as intended.

- Mechanical Testing: Assesses properties like hardness, tensile strength, and fatigue resistance.

Conclusion

Surface finishing and quality control are the final steps that ensure hex coupling nut fasteners are ready for use in demanding applications. These processes not only enhance the durability and appearance of the fasteners but also guarantee that they meet the highest standards of quality. This

series has provided a detailed look at the meticulous process behind manufacturing these essential components.

Hex Coupling Nut Fasteners Manufacturer in Mumbai

0 notes

Text

The Suppliers of Monel 400 Forged Fittings - Manilaxmi Industrial

Manilaxmi Industrial is briliant manufacturers of various monel products like Pipe Fittings, Flanges, Round Bars and best example is Monel 400 & Monel K500.

#Alloy 400 Forged Socket Weld Equal Tee#Monel Alloy ASTM B564 400 Forged Fittings#Monel 400 Threaded Fittings#Alloy 400 Socket Weld Fittings#400 Monel Forged Threaded 90° Elbow#Monel Alloy 400 Forged Fittings in India#Alloy 400 Hex Bushing#ASTM B564 Alloy 400 Threaded Union#400 Monel Socketweld 45 Deg Elbow#Alloy 400 Forged Coupling#Monel 400 High Pressure Forged Pipe Fittings#Monel 400 Plug#Monel Alloy 400 Forged Fittings Manufacturers in India#UNS N04400 Forged Fittings#Monel® Alloy 400 Forged Fittings#Alloy 400 High Pressure Forged Fittings#Monel Alloy 400 Socket weld Fittings#Monel 400 Socket weld Fittings#2.4360 Forged Fittings#400 Monel Forged Fittings#Alloy 400 Threaded Fittings#Monel 400 Threaded Fittings Manufacturer in Mumbai#India

1 note

·

View note

Text

The Best SS Flanges Manufacturers in India: A Comprehensive Guide

Stainless Steel (SS) flanges are critical components in various industries, from construction to oil and gas. India's manufacturing sector is renowned for producing high-quality SS flanges that meet international standards. This guide will explore the best SS flange manufacturers in India, delving into their offerings, quality standards, and what makes them stand out in the market.

What Are SS Flanges?

SS flanges are used to connect pipes, valves, pumps, and other equipment to form a piping system. Made from stainless steel, these flanges are known for their durability, resistance to corrosion, and ability to withstand high pressure and temperature. They come in various types, including weld neck, slip-on, socket weld, and blind flanges, each serving a specific purpose in different applications.

8 Types Of Stainless Steel Flanges:

Slip-On Flange: A slip-on flange is essentially a ring that is placed over the pipe end, with the flange face extending far enough from the end of the pipe to allow for a weld bead to be applied on the inside diameter.

Weld Neck Flanges: The flange is made up of a drilled flanged blade with a machined face on one side and a female socket into which the pipe is inserted on the other. These flanges, like the weld neck, are typically made of forged steel.

Blind Flanges: Stainless Steel Blind Flanges are machined with solid forgings. We are also known as one of the Largest Suppliers of high-quality Alloy Steel Blind Plate Flanges, Carbon Steel Blind Flange, and many more. Stainless Steel Blind Flanges are defined as one of the essential parts of the Pipe Fitting Industry. We are also known as one of the Largest Suppliers of Screwed/Threaded Flanges.

Screwed/Threaded Flanges: Screwed/Threaded Flanges are machined with solid forgings. We are also known as one of the Largest Suppliers of high-quality Stainless Steel Threaded Flanges, Alloy Steel Screwed Flanges, Nickel Alloy Screwed Flanges, Duplex Steel Threaded Flanges, and many more. Screwed/Threaded Flanges are defined as one of the essential parts of the Pipe Fitting Industry. We are also known as one of the Largest Suppliers of Long Weld Neck Flanges.

Socket Weld Neck Flanges: Stainless Steel Socket Weld Neck Flanges are machined with solid forgings. We are also known as one of the Largest Suppliers of high-quality Carbon steel Socket Weld Neck Flanges, Alloy steel Socket Weld Neck Flanges, and many more. Stainless Steel Socket Weld Neck Flanges are defined as one of the essential parts of the Pipe Fitting Industry. We are also known as one of the Largest Suppliers of Slip On Flange.

Quality Standards and Certifications

When choosing an SS flange manufacturer, it's crucial to consider their quality standards and certifications. Top manufacturers in India adhere to international standards such as ASTM, ASME, and ANSI. These certifications ensure that the flanges are manufactured to meet stringent quality requirements, providing reliability and safety in their applications.

Benefits of Using SS Flanges from Indian Manufacturers

Cost-Effectiveness: Indian manufacturers offer high-quality SS flanges at competitive prices, making them a cost-effective choice for global buyers.

Quality Assurance: Adherence to international standards ensures that the flanges are of superior quality and reliability.

Customization: Many Indian manufacturers provide customized solutions to meet specific client requirements, offering flexibility in design and specifications.

Innovation: The use of advanced technology and continuous innovation in manufacturing processes ensures that Indian SS flanges are at par with global standards.

Superior Quality SS Flanges Manufacturers in India

Riddhi Siddhi Metal Impex is one of the leading Stainless Steel Flanges Manufacturers In India. The SS flanges have been meticulously crafted in compliance with national and international industrial standards, utilising premium raw materials and state-of-the-art technology.

Our high-grade stainless steel flanges and other commodities are submitted to rigorous quality inspections prior to shipment. We keep a ready supply of stainless steel flanges in various sizes and forms to satisfy our clients' needs.

SS Flanges are machined with solid forgings. Performance and Dependability have made Riddhi Siddhi Metal Impex the leading Stockholder, Manufacturer, Supplier, Importer, and Exporter in India.

The goal of our business has been to provide our customers with high-quality stainless steel flanges and pipe fittings, rather than EIL Approved Pipe Fittings Manufacturer in India & IBR Approved Pipe Fittings Manufacturer in India.

For More Detail

Website: riddhisiddhimetal.com

Product: Stainless Steel Flanges Suppliers in India

Other Product: EIL Approved Pipe Fittings Suppliers in India & IBR Approved Pipe Fittings Suppliers in India.

#Stainless Steel Flanges Manufacturer in India#EIL Approved Flanges Manufacturers#Stainless Steel Flanges Manufacturer#Stainless Steel Flanges

0 notes

Text

Carbon Steel A182 Flanges Manufacturers

Carbon Steel A182 Flanges ,Exporters,Stocklist,Suppliers,Manfacture

Introduction:- Carbon Steel A182 Flanges

Carbon Steel A182 flanges are a critical component in piping systems used in various industries. They are made from carbon steel and adhere to the ASTM A182 specification, which sets standards for high-temperature and high-pressure service applications. These flanges are particularly valued for their strength, durability, and resistance to high temperatures.

ASTM A182 is a standard specification for forged or rolled alloy and stainless steel pipe flanges, forged fittings, and valves. The specification is particularly relevant for high-temperature applications and includes several grades of materials. Carbon steel grades within ASTM A182 are designed to withstand high-pressure and high-temperature condition

Product Overview:-

A182 Carbon Steel ASTM flanges are used in high temperature applications such as: B. For stainless steel pipe flanges, valves, forged fittings and rolled alloys. Also suitable for low corrosion applications.

ASTM A182 steel is the standard specification for forged or rolled alloys, stainless steel pipe flanges, and all types of parts and valves for high temperature service.

A182 Carbon Steel ASTM flanges are manufactured with ideal chemical experiments and connections and will not wear out quickly.

This grade of Carbon Steel ASTM flanges is used for stainless steel pipe flanges, rolled alloys, forged pipes, valves, forged fittings, and other high temperature applications. A182 Carbon Steel ASTM flange is one of the results of the best chemical experiments and good connections. These flanges don't wear out as quickly. Widely used in petroleum industry, chemical industry, paper industry and many other industries. Due to its properties, this type of flange is one of the most reliable products that can be used for a long time and does not require repairs immediately after installation

Specifications:-

Specification List of Carbon Steel ASTM A 182 Flanges

ASME/ANSI B 16.5

A182 F92 Welding Neck Flange, A182 F92 Slip on Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, A182 F92 Lap Joint Flange, Threaded Flange, A182 F92 Ring Type Joint Flange

PRESSURE CLASS

150, 300, 400, 600, 900, 1500, 2500

ASME/ANSI B 16.47

A182 F92 Welding Neck Flange, A182 F92 Blind Flange [Series A & B]

PRESSURE CLASS

75, 150, 300, 400, 600, 900

ASME/ANSI B 16.36

A182 F92 Welding Neck Flange, A182 F92 Slip on Flange, A182 F92 Threaded Flange

PRESSURE CLASS

300, 400, 600, 900, 1500, 2500

BS 4504 SEC 3.1

A182 F92 Welding Neck Flange, A182 F92 Hubbed Slip on Flange, A182 F92 Hubbed Threaded Flange, Lapped Pipe End Flange, A182 F92 Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange

PRESSURE CLASS

PN 2.5 TO PN 40

BS 4504[PART 1]

A182 F92 Welding Neck Flange, A182 F92 Hubbed Slip-On Hubbed Threaded, Plate Flange, A182 F92 Loose Plate With Weld On Plate Collar, Blank Flange

PRESSURE CLASS

PN 2.5 TO PN 400

BS 1560 BOSS

A182 F92 Welding Neck Flange, Socket Welding Flange, A182 F92 Slip-On Flange, A182 F92 Blind Flange, A182 F92 Screwed Boss Flange, A182 F92 Lapped Flange

PRESSURE CLASS

150, 300, 400, 600, 900, 1500, 2500

BS10

A182 F92 Welding Neck Flange, A182 F92 Plate Slip-On Flange, A182 F92 Screwed Boss Flange, Slip-On Boss Flange, A182 F92 Blind Flange

TABLE

D, E, F, H

DIN FLANGES

DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673

PRESSURE CLASS

PN 6 TO PN 100

Benefits:-

Carbon Steel A182 flanges offer numerous advantages that make them suitable for a wide range of industrial applications. Here’s a detailed look at the benefits:

Carbon Steel A182 flanges offer a combination of high-temperature strength, pressure resistance, and cost-effectiveness, making them a valuable component in a wide range of industrial applications. Their adherence to ASTM standards ensures quality and reliability, while their versatility in types and grades allows for customization to meet specific operational needs. These benefits make Carbon Steel A182 flanges a preferred choice for demanding environments where performance and durability are crucial.

Conclusions:-

Carbon Steel A182 flanges are essential components in high-temperature and high-pressure piping systems. Their design and material properties ensure reliability and performance in challenging environments. By adhering to ASTM A182 specifications, these flanges offer strength, durability, and versatility for various industrial applications, from oil and gas to power generation and chemical processing.

Contact:-88797–09191

Email Id:[email protected]

0 notes

Text

Difference Between Carbon Steel Flanges And Duplex Flanges

Flanges are versatile parts of piping where pipes, valves, and equipment are joined. While carbon steel flanges and duplex stainless steel flanges are quite popular in industries ranging from oil and gas through chemical processing to water treatment, international standards, grades, types, and testing methods applied to carbon steel and duplex flanges.

Carbon Steel Flanges Manufacturers In India produce products of superior quality and up to international standards, including ASME, ANSI, and ISO. A variety of grades like A105, A350 LF2, A182 F11 accommodate the products to specific pressure and temperature requirements. Indian manufacturers are preferred for reliability, durability, and cost-effectiveness using advanced manufacturing techniques combined with rigorous processes for quality control, making them the first choice among the discerning global clients who seek robust piping solutions.

Duplex Flanges Manufacturers In India are superior strength and corrosion resistance. DUPLEX FLANGES India manufactures in various grades, such as UNS S31803 and UNS S32750, under international standards of ASTM, ASME, and ISO. Indian duplex flanges are designed for critical applications in oil and gas, petrochemicals, and marine engineering through state-of-the-art manufacturing processes and rigid quality control procedure

International Standards for Flanges

International Standards about flanges are followed so that the flanges are of certain quality, safety, and interoperability. The most recognized standards are as follows:

ASME

ASME B16.5 : It comprises pipe flanges and flanged fittings for NPS 1/2 to NPS 24.

ASME B16.47: For larger flanges, from NPS 26 to NPS 60.

ASME B31.3: This standard deals with process piping and therefore requires a description of flanged connections.

ANSI (American National Standards Institute)

ANSI/ASME standards often overlap when assuring the flanges are designed in specific pressure classes.

API (American Petroleum Institute)

ISO 7005 Deals with general requirements for pipe flanges and flanged fittings, looking at various materials

EN 1092-1 Deals with specification for metallic flanges, dimensions and pressure ratings

Grades of Carbon Steel and Duplex Flanges

Carbon Steel Flanges

Carbon steel flanges are categorized based on their chemical composition and mechanical properties. There are, for example, several grades of carbon steel as follows:

A105: General-purpose carbon steel for forged flanges, used at ambient and at higher temperature.

A350 LF2: Carbon steel flanges for low-temperature applications when low-temperature conditions arise.

A182 F11/F22: Alloy steel for high-temperature and also high-pressure applications.

Duplex Stainless Steel Flanges

Duplex stainless steel flanges, high-strength corrosion-resistant, mostly come under:

UNS S31803: The most widely available duplex grade: providing a perfect balance of strength and corrosion resistance.

UNS S32205: The superior variant of S31803: superior pitting resistance compared to S31803

UNS S32750 (Super Duplex): Higher strength and corrosion resistance with higher strength compared to S31803; in excellent performance in the presence of chlorides

Flange Types

Flanges differ in various types. Some common are as follows:

Weld Neck Flanges: They can be used in high pressure applications and bear a long neck which takes care of welding to the pipe.

Slip-On Flanges: They are easier in alignment and installation; merely slide onto the pipe to be welded on the place.

Blind Flanges: It is used for closing a piping system. It does not contain any bore.

Socket Weld Flanges: It is used with small-sized pipes, where the pipe is inserted into the flange, which is then welded.

Threaded Flanges: These flanges have the internal threads, and hence screw onto the pipes suitable for low-pressure applications.

Testing Methods for Flanges

Quality assurance is an important element during the production of flanges. Among some common testing methods for them are:

Dimensional inspection of the dimensions of flanges with respect to these standards.

Pressure Test: Pressure test on flanges is tested under a predetermined pressure for tests to ensure the flanges have been designed to withstand operational conditions.

Chemical Analysis: The material composition is checked to meet the required standards.

Understanding the international grades types of testing applicable for carbon steel and duplex flange is important, which could allow it to achieve a piping system with reliability and safety.

#Carbon Steel Flanges Manufacturers In India#Duplex Flanges Manufacturers In India#Rishabh steel industries#Ramesh group

0 notes

Text

Stainless Steel 316 Flanges Exporters in India

Introduction

Stainless Steel 316 Flanges, renowned for their exceptional resistance to corrosion and high temperatures, are a cornerstone in various industrial applications. These flanges are particularly favored in environments where superior resistance to chlorides and acids is required, making them indispensable in industries such as chemical processing, petrochemical, and marine engineering. At Universe Metal & Alloys, we pride ourselves on being leading Manufacturers, Suppliers, Stockists, and Exporters of top-quality Stainless Steel 316L Flanges, ensuring that our clients receive only the best in durability and performance.

Description

Universe Metal & Alloys specializes in manufacturing stainless steel 316 flanges, designed to meet the rigorous demands of industries such as petrochemical, oil and gas, power generation, and more. Stainless steel 316 is a highly sought-after material due to its superior corrosion resistance, strength, and durability. These flanges are produced using state-of-the-art technology and adhere to stringent international standards to ensure optimal performance and reliability.

The flanges are available in various types, including slip-on, weld neck, blind, socket weld, and threaded, catering to the diverse needs of different applications. Each flange is meticulously crafted to ensure a perfect fit and seal, providing long-lasting and leak-free connections in piping systems.

Benefits

Choosing stainless steel 316 flanges from Universe Metal & Alloys comes with a multitude of benefits:

Excellent Corrosion Resistance: Stainless steel 316 flanges offer superior resistance to corrosion, especially in harsh environments and chemical exposure, ensuring longevity and reliability.

High Strength and Durability: The mechanical properties of stainless steel 316 make these flanges exceptionally strong and durable, capable of withstanding high pressure and temperature conditions.

Versatility: Available in various types and sizes, these flanges can be used in a wide range of applications, from industrial piping systems to specialized equipment.

Hygiene and Cleanliness: The smooth surface finish of stainless steel 316 ensures easy cleaning and maintenance, making these flanges ideal for applications in the food and pharmaceutical industries.

Compliance with Standards: Universe Metal & Alloys ensures that all its products meet international standards and certifications, providing customers with confidence in the quality and safety of their products.

Specification

Stainless Steel 316L Flanges Specification:

Stainless Steel 316 Flange Specification

ASTM A182 / ASME SA182

Stainless Steel 316 Flange Manufacturing Process

Hot Forging / Rolling / Machining

Stainless Steel 316 Flange Other Grades

202 / 304 / 304L / 304H / 309S / 310S / 316 / 316L / 316Ti / 317L / 321 / 321H / 347 / 347H / 904L etc. UNS No. - UNS S30400, UNS S30403, UNS S31008, UNS S31620, UNS S31603, UNS S31603, UNS S31635, UNS S31703, UNS S32100, UNS S34700, UNS S34709, UNS S8904 EN No. - 1.4301, 1.4307, 1.4845, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4550, 1.4551, 1.4539

Stainless Steel 316 Flange and Flanges Pipe Fittings Outer Diameter

1/2" NB TO 64" NB

Stainless Steel 316 Flange Pressure Class

Class 150#, Class 300#, Class 400#, Class 600#, Class 900#, Class 1500#, Class 2500# or As Per Custom Requirement PN 6, PN 10, PN 16, PN 25 and PN 40 etc

Stainless Steel 316 Flange Schedule

Sch 10s TO Sch XXS or As Per Custom Requirement

Stainless Steel 316 Flange Facing

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Stainless Steel 316 Flange Dimension

ASME B16.5, ASME B16.47 SERIES A, ASME B16.47 SERIES B, ASME B16.36, BS10, EN1092-1:2013, MSS SP44, ASA, API-605, ISO 7005, ISO 15590-3, DIN 2631--2638, DIN 2573-2576, DIN 2527, DIn 2641-2642, DIN 2565-2566, DIN2502, AWWA, AS2129 TABLE C, D, E, F, J etc..

Stainless Steel 316 Flange Other Testing

NACE MR0175, Ultrasoung TEST, IGC TEST, Intergranular Corrrosion Test as per ASTM A262 Practice E, Charpy Impact Test, Macro, Grain Size, Hardness, HIC, SSC, Sour Service etc.

Stainless Steel 316 Flange Value Added Services

Rolling, Drill, Punch, CNC Machining, Sand Blasting, Shot Blasting, Heat Treatment, Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized

Stainless Steel 316 Flange Packaging

Loose / Carrate / Wooden Pallet / Wooden Box / Plastic Cloth Wraps

Stainless Steel 316 Flange Shipment & Transportation

By Road - Truck / Train Partial Load, Full Load, By Sea - Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air - Freighter Civil Passenger and Cargo Planes

Stainless Steel 316 Flange Material Test Certificate

Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS, Bureau of Indian Standards BIS Approved ETC

Conclusion

Universe Metal & Alloys has established itself as a leading manufacturer of stainless steel 316 flanges in India, thanks to its unwavering commitment to quality, innovation, and customer satisfaction. Their products are trusted by industries worldwide for their superior performance, durability, and compliance with stringent standards.

For more information or to place an order, contact Universe Metal & Alloys at [email protected] or call +91-22-66363360 / 66393788. Experience the excellence of working with a premier manufacturer of stainless steel 316 flanges.

0 notes