#Alloy 20 Flanges Stockists In India

Text

Alloy 20 Flanges Stockists In India

Introduction: In the intricate tapestry of industrial infrastructure, Alloy 20 Flanges stand out as essential components, revered for their exceptional corrosion resistance, durability, and versatility. Within India's dynamic manufacturing landscape, numerous stockists specialize in providing high-quality Alloy 20 Flanges, catering to the diverse needs of industries worldwide. With an unwavering commitment to quality assurance, reliability, and customer satisfaction, these stockists fortify India's reputation as a premier exporter of alloy steel products.

Benefits of Alloy 20 Flanges: Alloy 20 Flanges offer a myriad of benefits that make them indispensable in various industrial applications. Renowned for their exceptional resistance to corrosion, particularly in acidic and corrosive environments, these flanges ensure longevity and reliability in critical operations. Their superior mechanical properties, including high tensile strength and impact resistance, make them suitable for demanding conditions such as chemical processing, pharmaceuticals, and petrochemicals. Additionally, Alloy 20 Flanges exhibit excellent weldability and formability, facilitating easy fabrication and installation. Their compatibility with a wide range of fluids and chemicals further enhances their versatility and suitability for diverse industrial settings.

Countries Importing Alloy 20 Flanges from India: India's expertise in manufacturing Alloy 20 Flanges has positioned it as a preferred supplier for countries worldwide. Importers from nations including the United States, United Kingdom, Germany, United Arab Emirates, and Singapore recognize the superior quality and reliability offered by Indian stockists. These countries rely on India's robust manufacturing infrastructure, stringent quality control measures, and competitive pricing to fulfill their industrial requirements. With India's unwavering commitment to continuous improvement and customer satisfaction, Alloy 20 Flanges stockists contribute significantly to global supply chains, fostering mutually beneficial trade relationships and driving industrial growth.

Conclusion: In conclusion, Alloy 20 Flanges stockists in India play a pivotal role in supplying top-quality components to industries worldwide. With a focus on excellence, reliability, and customer-centric solutions, these stockists uphold India's reputation as a dependable exporter of alloy steel products. As industries continue to prioritize corrosion resistance, durability, and versatility in their infrastructure projects, Alloy 20 Flanges stockists remain poised to meet their needs with steadfast dedication and expertise.

For more details

Email: [email protected]

Contact: 8779038854

If any enquiries please contact us our support team will connect you as soon as possible.

#Alloy 20 Flanges Manufacturers#Alloy 20 Flanges Suppliers#Alloy 20 Flanges Stockists#Alloy 20 Flanges Exporters#Alloy 20 Flanges Manufacturers In India#Alloy 20 Flanges Suppliers In India#Alloy 20 Flanges Stockists In India#Alloy 20 Flanges Exporters In India

0 notes

Text

Orifice Flanges Exporters in India

Introduction

Universe Metal & Alloys has extensive experience in manufacturing and supplying all types of pipe fittings. The entire manufacturing process is supported by trained professionals who have extensive experience in handling different types of pipe fittings and other products.

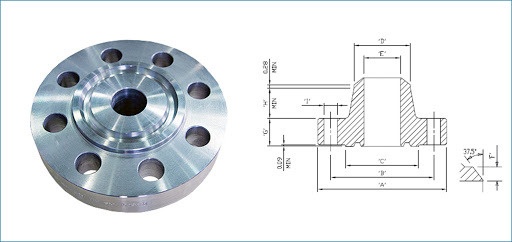

Description

Universe Metal & Alloy stands tall as one of the leading Manufacturers, Suppliers, Stockists, and Exporters of Orifice Flanges in India. With a rich legacy and a commitment to quality, we have carved a niche for ourselves in the competitive metal market. Our dedication to Suppliers to international and national quality standards sets us apart, making us a trusted name in the industry.

At Universe Metal & Alloy, we take pride in our Stainless Steel Orifice Flanges, which are meticulously designed and developed to meet the diverse needs of various industries. Crafted with precision and excellence, our ASTM A182 Stainless Steel Orifice Flanges are renowned for their durability and reliability, making them ideal for a wide range of piping applications across sectors such as Chemical, Petrochemical, Building, Construction, and more.

Benefits:

Accuracy and Reliability: Orifice flanges provide precise flow measurement, which is essential for process control and optimization.

Versatility: Suitable for a wide range of applications, including water, oil, gas, and steam.

Cost-Effective: They offer an economical solution for flow measurement, especially in large-scale industrial applications.

Durability: Made from robust materials, these flanges can withstand harsh operating conditions, ensuring long-term performance.

Ease of Installation and Maintenance: Orifice flanges are designed for easy integration into existing piping systems and require minimal maintenance.

Specification:

ASME B16.5 Orifice Flange Size Chart1/2" (15 NB) to 48" (1200NB) DN10~DN5000grooved Orifice flange StandardsANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092Spectacle Flange Pressure Rating ANSIClass 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Spectacle FlangeSpectacle Flange Pressure Calculation in DIN6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 Spectacle FlangeJIS5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K Spectacle FlangeUNI6Bar 10Bar 16Bar 25Bar 40Bar grooved Orifice flangeEN6Bar 10Bar 16Bar 25Bar 40Bar Forged grooved Orifice flangeCoatingOil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized ASME B16.5 Orifice FlangeMost common types of Orifice FlangeForged / Threaded / Screwed / PlateTest CertificatesEN 10204/3.1B

Raw Materials Certificate

100% Radiography Test Report

Third Party Inspection Report, etcProduction technique

Forged, Heat treated and machined

Connect Type/ Flange Face TypeRaised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, GrooveSpecial designAs per your drawing

AS, ANSI, BS, DIN and JIS

15 NB (1/2″) to 200 NB (8″)

Equal and Reducing ConfigurationsTestDirect-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detectorEquipmentPress machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etcOriginIndian / West Europe / Japan / USA / KoreanManufacturer of

ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

Spectacle Flange: -BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange

B.S: BS4504 , BS3293, BS1560, BS10

AS 2129: Table D; Table E; Table H

ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

ANSI : ANSI B16.5, ANSI B16.47(API605), MSS SP44, ANSI B16.36, ANSI B16.48

ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

American standard (ANSI)

German (DIN)

British standard (BS)

DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638 Forged grooved Orifice flange

The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276

grooved Orifice flange Uses & application

Bitumen upgraders.

Heavy oil refineries.

Nuclear power (mostly seamless).

Petrochemicals and acids.

Export toIreland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc

Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175

Product Overview:

At Universe Metal & Alloys, our orifice flanges are designed and manufactured to the highest standards. Each product undergoes rigorous quality control to ensure it meets the specific requirements of our clients. Our orifice flanges are suitable for a variety of applications, including chemical processing, petroleum refining, power generation, and water treatment. With a commitment to excellence, we provide detailed product information, technical support, and competitive pricing to meet the needs of our customers.

Conclusion:

Orifice flanges are an indispensable component for accurate flow measurement in industrial piping systems. Universe Metal & Alloys is dedicated to delivering high-quality orifice flanges that meet the exacting standards of various industries.

For more information or to place an order, please contact us at [email protected] or call us at +91-22-66363360 / 66393788.

0 notes

Text

Flanges Stockist in Oman

A350 LF2 flanges are designed for low-temperature applications. These flanges are made from carbon steel or low alloy steels. There are A350 LF2 Class 1 and Class 2 flange types. Both types require a notch toughness test to ensure they meet the necessary quality standards. The ASTM A350 LF2 flanges come in various shapes, sizes, dimensions, and grades. We are a manufacturer and supplier of all these different types. Our company has been in operation for many years, producing various types of flanges in different material grades.

The ASTM A350 LF2 manufactured flanges are stronger because they are made from a single piece of metal, making them suitable for applications requiring high strength. Purchase directly from ASTM A350 LF2 Class 1 flange manufacturers in Dubai. These flanges can also be easily welded with piping systems. For applications requiring durability and hardenability, the ASME A350 LF2 flanges are suitable. In certain conditions, killed carbon products are preferred. For such applications, we supply A350 LF2 killed carbon steel flanges to meet the requirements. Different dimensions and scales are also available. Please feel free to contact us to learn more or to inquire about our products. All forgings provided by the SA 350 Gr LF2 Cl1 flange manufacturer are typically ultrasonically tested.

Specification Chart of ASTM A350 LF2 Flanges

Size Chart:

1/2″ to 48″ (15 NB to 1200 NB)

Pressure Rating Chart:

ANSI: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS

DIN Pressure Calculation: PN6, PN10, PN16, PN25, PN40, PN64 (6 Bar, 10 Bar, 16 Bar, 25 Bar, 40 Bar, 64 Bar)

JIS: 5 K, 10 K, 16 K, 20 K, 30 K, 40 K, 63 K

Manufacturer Standards:

UNI, BS, AS2129, ANSI, DIN, GOST, JIS, SABS, NFE, AWWA, EN, etc.

Testing Methods:

X-ray detector

Ultrasonic flaw detector

Direct-reading spectrograph

Magnetic particle detector

Hydrostatic testing machine

Coating Options:

Zinc plated

Yellow transparent

Cold and hot dip galvanized

Anti-rust paint

Oil black paint

Common Types:

Threaded / Screwed

Forged

Plate

Equipment Used:

Press machine

Bending machine

Sand-blasting machine

Pushing machine

Electric bevelling machine, etc.

UNI / EN Pressure Ratings:

6 Bar, 10 Bar, 16 Bar, 25 Bar, 40 Bar

Connection / Flange Face Types:

RF (Raised Face)

Small Tongue

RTJ (Ring Type Joint)

FF (Flat Face)

LJF (Lap Joint Flange)

Large Tongue & Groove

Origin:

West Europe, Japan, India, USA, Korea

Standards:

API7S-43, API605, ISO70051, JISB2220, API7S-15, ANSI/ASME B16.5, BS4504, BS 10, EN-1092, DIN, B16.47 Series A & B, MSS S44, BS1560-3.1, B16.48, EN1092

#ASTM A350 LF2 Flanges Manufacturers in UAE#ASTM A350 LF2 Flanges Suppliers in UAE#ASTM A350 LF2 Flanges Stcokists in UAE#ASTM A350 LF2 Flanges Exporters in UAE#CS Flanges in UAE

0 notes

Text

High Hub Socket Weld Flanges Stockists in India

High Center point Flanges is an especially round plate with no middle hold bordering with the most magnificent shock openings. It is utilized to shut wraps down of redirecting plans. It is open in different sizes and materials and is utilized to give positive closer on the perceive of Pipes & Tubes, valves or hardware spouts.

High Center point Blind Flanges manufacturers in India. We are offering ASME B16.5 High Center point Blind Flanges, Carbon Steel High Center point Blind Flanges, High Center point Blind steel pipe flanges and Alloy 20 Huge High Center point Blind Flanges at Processing plant cost considering sensible expert hours in India and top wellspring of undeniable EN 1092-2 PN16 High Center Visually impaired Flanges, most very smart arrangement, cost open in Mumbai, India. Check Value design of 150# Raised Face High Center Flanges and High center point stagger Flanges examinations.

Nutech Overseas is speediest making manufacturers of Stainless Steel High Center point Blind Flanges guaranteed by Saudi Aramco. We are most crucial examiner of ANSI b16 5 High Center Flanges. Nutech Overseas is most obvious exporter of Nutech Overseas steel High Center point flanges, Nickel Alloy High Center point Blind Flanges in different sizes.

High Hub Socket Weld Flanges Manufacturers, High Hub Socket Weld Flanges Suppliers, High Hub Socket Weld Flanges Stockists, High Hub Socket Weld Flanges Exporters

Purchase from our arranged stock Class 150 High Center point Blind Flanges, most very smart arrangement, cost in India, notice our cost of ASME B16.5 High Center point Blind Flanges including Hastelloy C22 High Center Visually impaired Flanges, Nickel Alloy 200 High Center point Blind Flanges and Copper Nickel Enormous High Center point Blind Flanges. ASTM A105 carbon steel high Center point Blind Flanges to Germany, Canada, Singapore, Russia, Malaysia, Oman, Turkey, Sweden, Kuwait, Italy, Qatar, UK, Indonesia, Egypt, UAE, Australia, Israel, Iran, Thailand, Bahrain, France, USA, Sri Lanka and Saudi Arabia.

We are driving exporter and suppliers of AWWA C207 Nutech Overseas 20 High Center point Blind Flanges and Stainless Steel High Center Visually impaired Flanges, most very smart arrangement, cost as we are one of the most unfathomable suppliers and vendor of MSS SP-44 High Center point Blind Flanges in India. We have our stocking wholesalers in Delhi, Bangalore, Surat, (Gujarat), Hyderabad, Pune (Maharashtra) and Chennai in Tamil Nadu. Check once our ASTM A182 SS High Center Visually impaired Flanges and Stainless Steel Furrow and Tongue Flanges cost going preceding purchasing High Center Visually impaired Flanges from India or China. moreover mail for our live deftly of A350 Gr LF2 Tapped Center point Blind Flanges to check types and sizes with our set up stock we can give you best cost of Carbon steel High Center Flanges.

We can likewise give free event of High Center Visually impaired steel pipe Flanges, Nutech Overseas is having our Vendor and Merchant in Khopoli, Punjab, Gurgaon, Kolkata, Kolhapur, Rajkot, Ahmedabad, Delhi, Karnataka, Rajasthan, Karnataka, Pune, Jaipur, Madhya Pradesh, Tamil Nadu, Bangalore, Faridabad, Chhattisgarh, Vadodara, Gujarat, Aurangabad, Uttar Pradesh, Maharashtra, West-Bengal, Indore, Ghaziabad, Bhosari, Nagpur, Haryana, Chennai (Madras), Ludhiana, Raipur. So on the off chance that you are searching for best cost of Hastelloy High Center point Blind Flanges or Carbon Steel High Center Visually impaired Flanges, ANSI b16 5 High Center point flanges close to you with briefest time transport or free event of Commotion 86029 PN10 High spot obviously deterred Flanges.

0 notes

Text

The Role of Monel Fasteners in Petrochemical Refineries

Monel fasteners have emerged as one of the most sought-after choices in petrochemical refineries due to their safety, reliability, and efficiency. Jay Steel Corporation, serving as the premier Monel Fasteners Manufacturer, Supplier, Stockist, and Exporter in India, takes immense pride in presenting a comprehensive range of top-notch Monel fasteners, which includes the highly sought-after Monel 400 Fasteners and Monel K500 Fasteners. Our offerings encompass an array of essential components such as Bolts, Nuts, Washers, Screws, Stub Bolts, and Anchor Bolts. With a commitment to empowering our esteemed customers, we tailor our solutions perfectly to meet the unique requirements of their projects. Trust in Jay Steel Corporation for top-quality Monel 400 Fasteners from reliable Suppliers of Monel 400 Fasteners.

In this blog post, we will delve deep into the realm of Monel fasteners and explore how they play a pivotal role in the operations of petrochemical refineries.

What are Monel Fasteners?

Monel is a group of nickel-copper alloys known for their exceptional corrosion resistance, high strength, and excellent mechanical properties. These alloys are primarily composed of approximately 65-70% nickel and 20-29% copper, with small amounts of iron, manganese, carbon, and silicon. Monel fasteners exhibit unique properties that set them apart from traditional materials. The primary components of Monel are nickel and copper, with small amounts of other elements such as iron, manganese, and silicon.

Significance of Monel Fasteners in Petrochemical Refineries

Petrochemical refineries play a pivotal role in transforming raw materials into a wide range of essential products. However, their operations involve handling hazardous chemicals, extreme temperatures, and high pressures. The failure of a single fastener in critical equipment can have severe consequences. Here's why Monel fasteners are indispensable in petrochemical refineries:

Corrosion Resistance for Safety:

Safety is of paramount importance in any industrial setting, especially in petrochemical refineries. The ability of Monel fasteners to resist corrosion ensures that essential equipment, such as pipelines and reactors, remains intact and leak-free. This significantly reduces the risk of accidents, environmental contamination, and potential harm to personnel.

Enhanced Reliability:

Monel fasteners provide long-term reliability in demanding refinery environments. They maintain their integrity and performance over extended periods, reducing the need for frequent replacements and maintenance, ultimately leading to cost savings.

Preventing Downtime:

Unexpected equipment failures can lead to significant downtime and production losses. Monel fasteners' robustness and resistance to corrosion help prevent sudden breakdowns, ensuring continuous and uninterrupted refinery operations.

High Tensile Strength:

Monel fasteners possess excellent mechanical properties, including high tensile strength. This makes them capable of withstanding heavy loads and stresses encountered in refinery equipment, maintaining their integrity even under challenging conditions.

Temperature Resistance:

In the world of petrochemicals, temperature variations are common, and fasteners must be able to perform consistently across a wide range of temperatures. Monel fasteners boast excellent thermal stability, allowing them to retain their mechanical properties even in extremely hot or cold environments. This capability ensures smooth operations and minimizes downtime due to temperature-related issues.

Types of Monel Fasteners Used in Petrochemical Refineries

The diverse range of Monel fasteners offers solutions for various applications within petrochemical refineries. Understanding the specific functions of each type helps in making informed decisions for equipment assembly and maintenance.

Bolts: Monel bolts are extensively used in connecting heavy machinery, flanges, and pipelines in petrochemical refineries. Their high tensile strength and corrosion resistance make them reliable for critical joints.

Nuts: Monel nuts complement the use of bolts, providing secure and sturdy connections in refinery equipment. Their resistance to corrosion ensures that connections remain intact even under aggressive conditions.

Washers: Monel washers act as spacers and distribute loads evenly, reducing stress on fastener connections. They protect the equipment surface from damage and enhance the longevity of the fastened joints.

Screws: Monel screws are used for assembling components and fixing parts in petrochemical refinery equipment. Their corrosion resistance is crucial, especially in outdoor or corrosive environments.

Stub Bolts: Stub bolts, also known as stud bolts, are threaded rods used to secure flanges and other connections in refinery pipelines. Monel stub bolts withstand high pressures and temperatures, ensuring leak-free joints.

Anchor Bolts: Monel anchor bolts provide essential support for heavy equipment and structures in petrochemical refineries. Their robustness is vital for anchoring critical equipment in concrete foundations.

Why Choose Monel Fasteners over Alternatives?

With so many types of fasteners available in the market, why should petrochemical refineries specifically opt for Monel fasteners? The answer lies in their unmatched combination of properties that directly address the unique challenges faced by this industry.

Longevity and Reduced Maintenance

Due to their exceptional corrosion resistance and durability, Monel fasteners offer an extended service life compared to traditional alternatives. This longevity translates to reduced maintenance costs and minimizes the risk of sudden failures, providing peace of mind to refinery operators.

Improved Safety Standards

Safety is of utmost importance in the petrochemical industry. Monel fasteners' ability to withstand harsh conditions and temperature variations ensures the structural integrity of vital components, enhancing overall safety standards in the refinery.

Enhanced Efficiency

By utilizing Monel fasteners, petrochemical refineries can experience improved operational efficiency. The reduced need for frequent replacements and repairs allows the facility to focus on core processes, leading to enhanced productivity.

Applications in Petrochemical Refineries

Monel fasteners find a plethora of applications within petrochemical refineries, contributing significantly to the overall efficiency and safety of the facility. Some of the primary applications include:

Piping Systems

Heat Exchangers

Reactors and Pressure Vessels

Flange Connections

Distillation Columns

Storage Tanks

Reactor Internals

Instrumentation and Control Systems

Catalyst Regeneration Systems

Pump and Compressor Assemblies

Furnaces and Boilers

Ancillary Equipment and Many More

Best Practices for Choosing Monel Fasteners

Selecting the appropriate Monel fasteners for petrochemical refinery applications requires careful consideration of several factors. By following these best practices, refinery professionals can ensure optimal performance and safety:

Assessing Environmental Conditions: Understand the specific environmental conditions in which the fasteners will operate. Consider factors such as exposure to corrosive chemicals, temperature variations, and humidity levels.

Identifying Material Requirements: Determine the suitable Monel grade based on the severity of corrosion expected and the mechanical properties required for the application.

Adhering to Industry Standards: Ensure that the chosen Monel fasteners comply with relevant industry standards and specifications. This guarantees their suitability and performance in petrochemical refinery settings.

Collaborating with Manufacturers: Consult with reputable manufacturers like Jay Steel Corporation, who have expertise in supplying Monel fasteners for petrochemical applications. Being Monel Fasteners Manufacturers, they can offer valuable insights and guidance in selecting the right fasteners.

Installation and Maintenance of Monel Fasteners

Proper installation and regular maintenance play vital roles in maximizing the performance and longevity of Monel fasteners in petrochemical refineries:

Installation Techniques: Follow the recommended installation guidelines provided by the fastener manufacturer. Improper installation can lead to reduced fastener life and compromised equipment integrity.

Regular Inspections: Implement a comprehensive inspection program to identify signs of corrosion, wear, or damage in Monel fasteners. Timely detection allows for prompt replacements, preventing potential failures.

Preventive Maintenance: Periodically lubricate Monel fasteners and take preventive measures to protect them from harsh environmental conditions. Routine maintenance ensures the fasteners' reliability and extends their service life.

Final Thoughts!..

Monel fasteners are now essential elements in the petrochemical sector, effectively maintaining the safety, dependability, and productivity of refinery activities. Their remarkable ability to resist corrosion and possess high tensile strength significantly contributes to accident prevention, reduced downtime, and the protection of both personnel and the environment. As the leading Monel Fasteners Manufacturer, Supplier, Stuckist, and Exporter in India, Jay Steel Corporation takes pride in supplying high-quality Monel fasteners that meet industry standards and cater to diverse project requirements. Petrochemical refineries must prioritize the selection of reliable fasteners to enhance operational performance and secure their critical assets. Our Monel Flanges have earned a stellar reputation in India and have gained significant demand worldwide, including in countries such as Singapore, Malaysia, Nigeria, Tunisia, the USA, France, Saudi Arabia, Kuwait, Qatar, and more. Through strategic partnerships with trusted manufacturers and adherence to best practices, the petrochemical industry can forge ahead towards safer, more efficient, and sustainable operations, with Monel fasteners serving as indispensable allies.

#MONEL FASTENERS MANUFACTURER#MONEL K500 FASTENERS STOCKIST#MONEL 400 FASTENERS SUPPLIER#MONEL 400 FASTENERS SUPPLIER IN INDIA.#.

0 notes

Text

How are flanges manufactured?

Flanges, those unassuming yet indispensable components in piping systems, play a crucial role in connecting pipes, valves, and other equipment. As a leading Flanges Manufacturer, Supplier, Stockist, and Exporter in India, Bullion Pipes & Tubes LLP takes pride in offering a diverse range of flanges to cater to various industrial needs.

In this blog post, we delve into the fascinating world of flange manufacturing, shedding light on the intricate processes that give rise to these versatile components.

Understanding Flanges!

Flanges are common components in industrial piping systems that provide a strong, leak-proof connection between pipes or equipment. Essentially, a flange is a disc-shaped fitting with evenly spaced holes for bolts and is designed to be attached to the end of a pipe or any other object that requires a joint. Flanges can be made of various materials such as Stainless Steel, Hastelloy, Carbon Steel, Nickel, Duplex Steel, Alloy Steel, Super Duplex Steel, Titanium, Aluminium, Tantalum, Monel, Alloy 20 Steel, SMO 254, Inconel, and Incoloy Flanges. One of the primary functions of a flange is to facilitate the ease of maintenance, repair, or replacement of the equipment that is connected to the piping system. Flanges also help in minimizing leakage, as they create a tight seal between two pipes or equipment.

The Step of how flanges are Manufactured!

Selecting the Right Raw Materials

The durability and reliability of flanges hinge on meticulous material selection. We recognize the significant impact that material choice has on the performance and longevity of the final product. Our extensive range of flanges is forged from an array of materials, each boasting distinct properties that determine compatibility with specific applications and environmental conditions.

Forging: A Cornerstone of Flange Manufacturing

The forging process takes center stage in the production of flanges. This method involves shaping the flange by heating a metal billet and applying controlled pressure to deform it. The sequential steps include billet heating, shaping using a die, and controlled cooling. Forged flanges exhibit exceptional strength and durability, making them ideal for demanding applications. However, it's important to note that forging is a time-intensive process that demands skilled labor.

Casting: An Alternate Path to Flange Creation

Casting stands as another prevalent method for manufacturing flanges. In this process, a mold is created with the desired flange shape, and molten metal is poured into the mold. As the metal cools and solidifies, the mold is removed, leaving behind the cast flange. Casting allows for intricate shapes and is particularly cost-effective for large quantities. However, it's important to consider that cast flanges may possess slightly lower strength compared to their forged counterparts, necessitating additional quality control measures.

Machining for Precision and Customization

Machining involves removing material from a pre-formed flange blank to achieve the desired shape. This method is frequently employed for specialized or customized flanges. Machined flanges offer precise dimensions and tight tolerances, achieved through cutting, drilling, and shaping processes. While machining ensures flexibility and accuracy, it might not be the most cost-effective solution for high-volume production.

Drilling and Threading for Secure Connections

Flanges require strategically placed holes and threads to accommodate bolts and gaskets. Specialized machines execute the drilling and threading process with precision, ensuring accurate alignment for a secure and leak-free connection.

Enhancing Properties Through Heat Treatment

To elevate the mechanical properties of flanges, they undergo various heat treatment processes such as annealing, quenching, or tempering. Heat treatment imparts increased strength, hardness, and resistance to wear and tear, enhancing the overall performance of the flanges.

Surface Finishing for Protection and Appeal

Flanges receive surface finishing treatments to enhance their aesthetic appeal and safeguard against corrosion. Processes such as pickling, passivation, electroplating, or coating are applied based on the material and specific customer requirements.

Rigorous Quality Inspection

Our unwavering commitment to quality control permeates every manufacturing stage. Our flanges undergo meticulous inspections to validate dimensions, surface quality, and material integrity, ensuring that our customers receive products of the utmost quality.

Concluding the Manufacturing Journey

Following the completion of manufacturing and rigorous quality control processes, the flanges undergo a final inspection to ensure they conform to all specifications. Subsequently, they are meticulously packaged and readied for shipping to their intended destinations.

Types of Flanges we do offer!

We offer a wide range of flanges to cater to diverse industrial needs. Here are some commonly used types:

Slip-on Flanges: These flanges slide over the pipe and are then welded in place. They are easy to install and provide excellent alignment.

Blind Flanges: Used to close the end of a pipe, blind flanges are solid discs without a bore. They are ideal for testing and inspection purposes.

Weld Neck Flanges: These flanges have a long, tapered hub that provides reinforcement and reduces stress concentration. They are widely used in high-pressure and high-temperature applications.

Threaded Flanges: Threaded flanges have internal threads that allow them to be connected to pipes with external threads. They are suitable for low-pressure applications.

Socket Weld Flanges: These flanges have a socket-like end that fits over the pipe, followed by fillet welding. They are commonly used for small-diameter, high-pressure piping.

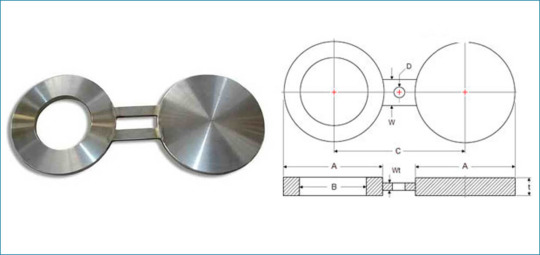

Spectacle Flanges: Spectacle flanges consist of two discs attached to each other by a small section of metal. They are primarily used in applications where frequent inspection or cleaning is required.

Lap-Joint Flanges: Lap-joint flanges are used in combination with stub ends when dismantling is necessary. They allow easy alignment and disassembly of the piping system.

Orifice Flanges: Designed for orifice metering applications, these flanges feature a smaller bore and come with additional tapping holes and bolts.

Groove Flanges: Groove flanges have a groove machined into their face, which accommodates an O-ring or gasket. They are commonly used in industries requiring a tight seal.

Long Neck Flange: These flanges have an extended neck that provides reinforcement and reduces heat transfer to the flange. They are suitable for applications involving thermal expansion.

Flat Face Flange and Raised Face Flanges: These flanges have different face configurations. Flat face flanges are used in applications requiring low friction, while raised face flanges provide better sealing capabilities.

Materials & Grades We Offer - Flanges

Stainless Steel

304/304L/304H, 316,316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347H, 446 & 904L

Titanium

Titanium Alloy Gr 2

Titanium Alloy Gr. 5

Titanium Alloy Gr. 7

Monel

Monel K500

Monel 400

Carbon Steel

Tantalum

Inconel

Inconel 718

Inconel 600

Inconel 601

Inconel 625

Alloy Steel

Alloy Steel P5

Alloy Steel P9

Alloy Steel P11

Alloy Steel P12

Alloy Steel P22

Alloy Steel P91

Aluminium

Nickel

Nickel Alloy 200/201

SMO 254

Duplex Steel

Duplex UNS S32205

Duplex UNS S31803

Hastelloy

Hastelloy C22, B2

Hastelloy C276

Super Duplex Steel

Super Duplex Steel UNS S32750

Super Duplex Steel UNS S32760

Incoloy

Incoloy 825

Incoloy 800/800H/800HT

Alloy 20

Flanges Offered by Bullion Pipes & Tubes LLP: Your Trusted Partner

As India's foremost flanges manufacturer, Bullion Pipes & Tubes LLP takes immense pride in delivering a diverse array of top-notch flanges. Our unwavering commitment to excellence, extensive industry expertise, and rigorous quality control processes set us apart in the market.

We comprehend the unique needs of our clientele and offer flanges in a multitude of sizes, standards, grades, and materials. Whether your requirements span stainless steel, Hastelloy, carbon steel, or any other type of flange, we stand ready to fulfill them. Our flanges find applications across industries such as oil and gas, petrochemicals, power generation, water treatment, and many more.

Moreover, as reputable flanges exporters, we extend our services to clients across the globe, including Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, Russia, and beyond. Our global outreach, coupled with exceptional customer service, guarantees a seamless experience for international clients.

Applications of Flanges

Flanges are widely used in various industries for a range of applications due to their versatility and functionality. Here are some common applications of flanges:

Pipe Connections

Plumbing Systems

Oil and Gas Industry

Power Generation

Chemical Processing

Shipbuilding and Maritime Industry

HVAC System (Heating, ventilation, and air conditioning systems)

Food and Beverage Industry

Pharmaceutical Industry

Automotive Industry and many more.

Final Thoughts!..

The manufacturing of flanges is a complex and intricate process that demands expertise, precision, and a commitment to quality. Bullion Pipes & Tubes LLP, as a leading Flanges Manufacturer, Supplier, Stockist, and Exporter in India, takes pride in offering a diverse range of flanges that cater to a wide spectrum of industrial needs.

With an unwavering focus on raw material selection, manufacturing methods, and quality assurance, we provide flanges that stand the test of time, ensuring seamless and efficient piping systems for our valued clients worldwide.

0 notes

Text

Types of Buttweld Fittings Explained

Buttweld fittings play a critical role in piping and plumbing systems. These fittings play a vital role in ensuring the seamless flow and structural integrity of your projects. As a frontrunner in the industry, Metal Forge India takes pride in being the premier Buttweld Fittings Manufacturer, Supplier, Stockist, and Exporter in India. Our diverse range of buttweld fittings, encompassing elbow 45, 90, & 180-Degree, Cross, Caps, Tee, Concentric, Eccentric Reducer, and Stub End, empowers our customers to cherry-pick fittings that impeccably align with their project prerequisites.

In this comprehensive guide, we'll delve into the various types of buttweld fittings available, each designed to suit different project requirements.

Understanding Buttweld Fittings

Before we dive into the specifics, let's understand the basics. Buttweld fittings are essential components that facilitate the connection of pipes, allowing for fluid flow and structural continuity. These fittings are meticulously designed to withstand varying pressures, temperatures, and corrosive environments. Their primary goal is to ensure a secure, leak-free, and efficient flow of liquids and gases within industrial setups.

Common Types of Buttweld Fittings

Elbows: Directing Flow with Precision:

Elbows are the workhorses of piping systems, responsible for changing the direction of flow at crucial junctures. Available in angles of 90°, 45°, and 180°, these fittings find applications in diverse industries, from oil and gas to chemical processing. A 90° elbow, for instance, efficiently redirects flow around tight corners, while a 45° elbow offers a gentler turn, ideal for nuanced applications.

Tees: Branching Out for Versatility:

When branching connections are needed, tees step in. Equal tees create three-way connections while reducing tees allows for different-sized pipes to merge seamlessly. Industries dealing with distribution and diversion, such as water treatment and pharmaceuticals, benefit greatly from the functionality of tees.

Reducers and Expanders: Adapting to Change:

Pipelines often need to transition between different diameters. Reducers and expanders are the solutions to this challenge. Concentric reducers maintain center alignment, ensuring a smooth transition, while eccentric reducers are perfect for applications where precise alignment isn't crucial, like drain lines.

Caps and Stub End: Sealing and Connecting:

Caps serve as protective covers for pipe ends, preventing debris and contaminants from entering. Stub ends, on the other hand, provide an alternative to welding when connecting pipes to flanges, offering versatility and ease of maintenance.

Crosses and Laterals: Navigating Complex Pathways:

For intricate systems involving intersecting or branching pipelines, crosses and laterals prove invaluable. Cross fittings create four-way connections, while laterals are perfect for splitting flow in multiple directions, making them essential in industries with intricate distribution needs.

Couplings and Olets: Ensuring Structural Integrity:

Couplings provide a straightforward way to connect pipes of the same diameter, often used in repairs or retrofitting. Olets, including weldolets and sockolets, offer a reliable means of creating branch connections without compromising the overall integrity of the system.

Standards & Specifications of Buttweld Pipe Fittings

Size

1/8” NB – 48” NB

Standards

ASME/ANSI and DIN

Schedules

5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS with NACE Certifications

Types

45 Degree elbow, 90 Degree elbow & 180 Degree elbow, Cross, Caps, Tee, Concentric Reducers, Eccentric and Stub End

Materials

Stainless Steel & Alloy 20 Steel, Monel, Inconel, Hastelloy, Duplex Steel, Super Duplex Steel, and 254 SMO Fittings

Forms

Seamless, Welded & Fabricated

Grades

Stainless Steel 304, 316, 304L, 316L, 317, Alloy 20 Buttweld Fittings, SMO 254 Buttweld Fittings, UNS N06600 Buttweld Fittings, Hastelloy C276 Buttweld Fittings, Stainless Steel 904L Buttweld Fittings, and Inconel 600 Buttweld Fittings

Applications of Buttweld Fittings

Buttweld Fittings are commonly used to connect pipes and tubing sections, providing a secure and leak-free connection. Here are some of the key applications of buttweld fittings:

Oil and Gas Industry

Chemical Processing

Power Generation

Water Treatment

Food and Beverage

Pharmaceuticals

Pulp and Paper Industry

Mining Industries

Construction and Infrastructure

Marine and Shipbuilding

Agriculture Industry

Automotive and Transportation

Aerospace:

Renewable Energy

Medical and Healthcare

Other Applications

Final Words!..

Selecting the ideal butt weld fittings is a pivotal stage in ensuring the accomplishment and dependability of your industrial piping system. At the forefront of the industry, Metal Forge India emerges as a reliable source for a diverse range of butt weld fittings. As a distinguished Buttweld fittings Supplier, Manufacturer, Stockist, and Exporter in India, we offer an extensive assortment including Alloy 20 Buttweld Fittings, SMO 254 Buttweld Fittings, UNS N06600 Buttweld Fittings, Hastelloy C276 Buttweld Fittings, Stainless Steel 904L Buttweld Fittings, and Inconel 600 Buttweld Fittings. Our product lineup encompasses elbow fittings, crosses, caps, tees, reducers, and stub ends, catering comprehensively to an array of project prerequisites. This guarantees peak performance, longevity, and meticulousness in every application. By opting for Metal Forge India, you're not simply acquiring a product; you're initiating a partnership with excellence in the realm of butt weld fittings.

0 notes

Text

Hig Hub Flange

What is a high Hub blind flange?

high hub flange is a kind of round plate with no center hold but with all the proper bolt holes. It is used to close ends of piping systems. It is available in various sizes and materials and is used to provide positive closer on the ends of pipes, valves or equipment nozzles.

Material & Grades of High Hub Flanges :

Stainless Steel High Hub Flanges : ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L High Hub Flanges

Duplex & Super Duplex Steel High Hub Flanges : ASTM A182 / ASME SA182 F44, F 45, F51, F 53, F 55, F 60, F 61 High Hub Flanges

Carbon Steel High Hub Flanges : ASTM A105 / ASME SA105 ASTM / ASME A 350 , ASTM A181 LF2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706 High Hub Flanges

Low Temperature Carbon Steel High Hub Flange: ASTM A350, LF2, LF3 High Hub Flanges

Alloy Steel High Hub Flanges : ASTM A182 / ASME SA182 & A387 F1, F5, F9, F11, F12, F22, F91 High Hub Flanges

Copper Alloy Steel High Hub Flanges : ASTM SB 61 , SB62 , SB151 , SB152 UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200

Nickel Alloy High Hub Flanges : ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020) High Hub Flanges

Application of High Hub Flange

ANSI B16.5 Class 150 High Hub Flanges uses in Industrial Boilers Industry

ASTM A182 Stainless Steel High Hub Flanges uses in Power Plants Industry

ASME B16.47 Series A and B High Hub Flanges uses in Nuclear Plants Industry

Stainless Steel High Hub Flanges uses in Oil & Gas Industry

Super Duplex Steel High Hub Flanges uses in Refineries Industry

Industrial High Hub Flanges uses in Ship Building Industry

Super Duplex Steel High Hub Flange Forged Flanges uses in Heat Exchanger Industry

Carbon Steel Industrial High Hub Flanges uses in Condensers Industry

Alloy Steel Industrial High Hub Flanges uses in Paper & Pulp Industry

Duplex Steel Industrial High Hub Flanges uses in Marine Applications

Stainless Steel Industrial High Hub Flanges uses in Nuclear Power Industry

Industrial High Hub Flange / Fittings System uses in Fossil Fuel Power Plants Industry

About Flanges And Nuts

Flanges nuts Is An ISO 9001:2015 licensed enterprise And Has A song file Of providing A wide variety Of Piping solution At Very competitive prices. In a totally brief time period, we've gained An tremendous national And international popularity.

Headed through Mr. Ronak Bhansali (Director) And Supported by way of Our committed, expert team, we are able to fulfill The needs Of Our customers In A timely And Systematic manner. The Profound know-how And wealthy experience Of our crew within the Respective arena Of metal merchandise Has Assisted The business enterprise To gather outstanding role Amidst The reliable chrome steel, Pipe fitting In India.

we're Counted most of the nice manufacturer, Exporter Stockist & provider. We Export 60% Of Our range Of Flanges, shops, Pipe Fittings And solid Fittings To many nations Like u.s.a., united kingdom, Italy, Malaysia, Gulf and so on. we'd admire To Get Your Esteemed Enquires And look ahead to The delight Receiving Your precious response. we're often supplying these objects To Many main industrial gadgets inclusive of : ship constructing, Petrochemical flora, metallic flowers, Refineries, chemical substances, Fertilizers, electricity Plant, Pharmaceutical, Ports, Oil & gas, Railway, Mining, Cement vegetation, Paper mills, Sugar generators, Fabrication units and so on.

TO KNOW MORE ABOUT OUR PRODUCTS YOU CAN VISIT OUR WESITE

www.flangesnuts.com

Used in different industries by

Refineries Gas Processing Off-Shore Oil Drilling Companies Petrochemicals Hydro-Carbon Fertilizers Paper & Pulp Companies Power Generation Specialty Chemicals Pharmaceuticals Drugs Steel Cement Water Pipe Line Pesticides General Piping Construction Engineering Nuclear Food Processing & Dairy boiler & heatexchangers

0 notes

Text

Spectacle Blind Flanges Manufacturers

Show Blind Flanges is used to unquestionably guarantee that a thing of stuff is fittingly and securely blanked off with no shot at any stream or spillage through a valve during upkeep. Created scored circumstance deaden spine is used to stream can be diverted to various things of contraption yet not just sidestepped around the reasonable as this would deal the succeeding farthest reaches of the show flounder. Show puzzle rib PN16 of the clearly hindered will have an opening to permit stream through the line during progress and the farthest edge is solid to baffle stream during help. Set steel show floor spine are everything thought of as prominent as a ceaseless contraption with take out measure redirecting systems. We are Spectacle Blind Flange Manufacturers in India.

Set Steel Spectacle Blind Flange to Singapore, Philippines, Thailand, UK, Bahrain, India, Malaysia, Indonesia, Kuwait, Vietnam, Oman, Qatar, South Africa, Saudi Arabia (KSA), United Arab Emirates (UAE). We are driving Spectacle Blind Flange Manufacturers in India. Call us for stockist of Class 150 superstar deaden spine in india. A105 Carbon Steel Spectacle Blind Flange, most ideal condition, cost as we are extraordinary diverged from other supplier and transporter of Carbon Steel Spectacle Blind Flange in India. Supplier of DIN 86029 PN10 Blind Spectacle Flange in india. Aiming to purchase Class 150 show debilitate rib, most ideal situation, cost in India, request respect list from Forged scored show surprise rib including Carbon steel show incapacitate rib, Flat Face Spectacle Blind Flange and Alloy 20 Spectacle Blind Flange.

https://omaaflange.com/spectacle-blind-flanges-manufacturers-exporters-suppliers-stockists.html

0 notes

Link

Indias' leading manufacturer and supplier of Flanges in materials like Stainelss Steel, Nickel, Super Duplex Steel, Duplex Steel, Monel, Hastelloy, INconel/Incoloy, Titanium and Aluminium materials all availble in various grades, dimensions, specification as per national standard. WE are committed to provide the clients with uncompromising quality products. We work in close coordination and with discipline. Our manufacturing plant is located at Mumbai, India. We have robust infrastructure with modern machinery and highly skilled workforce which enable us to produce ferrous and nonferrous metal products in bulk quantity. We have years of experience in manufacturing metal products like Pipes & Tubes, Sheets & Plates, Bars & Rods, Pipe Fittings, Flanges, Fasteners, Piping Spools, etc.

0 notes

Text

Spool Flange Manufacturer

SPECIALIZED SPOOL FLANGE MANUFACTURER, PIPE SPOOL FLANGE DIMENSIONS, SPOOL ADAPTER FLANGE.

Marcel Piping Projects Supply PVT LTD is prominent Manufacturers, Stockists, Suppliers, and Exporters of Spool Flange in India. The prefabricated components of a piping system are called pipe spools. They include the pipes, flanges and fittings, and they are mounted during the fabrication before they are delivered to the construction are. They are delivered pre-mounted so to make them easier to assemble using hoists, gauges, and other tools for assembly. Pipe spools connect long pipes with flanges at the tips so that they can be bolted to another pipe with matching flange.

Pipe spools are the components that can be welded or fitted to each other and constitute a whole pipe system. a pipe spool is a complex shaped tube that consists of different segments. In modern engineering applications, pipe spools are used near everywhere for the transportation of desired matters. The spool components can be divided into the sized straight pipes and the fittings. Moreover, fittings can also be classified as flanges, tees, and elbows. These different components are used extensively for miscellaneous demands.

We are most trusted exporters of Flange Spool Pipe Fitting, Drilling Spool Adapter Flange, ASA Spool Flange, Ductile Iron Spool Flange, Turbo Spool Flange, 3 Flanged Spool, 4 Flanged Spool, 6 Flanged Spool Piece in USA, UK, Qatar, Mexico, Nigeria, Saudi Arabia, Kuwait, Iran, Kazakhstan, Bahrain, Vietnam, Indonesia, Norway, Ghana, Colombia, Azerbaijan, Libya at market leading prices.

We are ISO Certified Manufacturer and Stockist of Spool Flange in Stainless Steel, Carbon Steel, Mild Steel, Alloy Steel, Duplex Steel, Super Duplex Steel, Hastelloy, Monel, Copper Nickel, Inconel, Incoloy, Nickel Alloy, Alloy 20, 254 Smo, Titaniun, Bronze, Aluminium, Brass at Reasonable Price.

We are Leading Exporter and Supplier of ASA Spool Flange, Flange Spool Pipe Fitting, Spool Adapter Flange, Ductile Iron Spool Flange, Turbo Spool Flange, 3 Flanged Spool, 4 Flanged Spool, 6 Flanged Spool Piece in a variety of Sizes and Lengths.

0 notes

Photo

Technolloy is As one of the pioneers among Manufacturers, Stockist, and Exporters of Backing Flange (Back up Flange), ASME B16.5/ANSI B16.47 Backing Flange, We are offering genuine expenses in India on Galvanized Backing Flange.

We keep adequate stockpile of SS Backing Flange, Alloy Steel Backing Flange, Nickel Alloy 200 Backing Flange, Carbon Steel Backing Flange, Inconel Backing Flange, Hastelloy Backing Flange, Copper Nickel Backing Flange, Duplex & Super Duplex Backing Flange, Alloy 20 Backing Flange, Aluminum Backing Flange in all Dimensions to satisfy nearly nothing and colossal sum orders from our significant customers.

0 notes

Text

Threaded Bull Plug

Dipti Metal Industries is Manufacturer, Stockists and Supplier of premium quality scope of ASME B16.11/BS3799 Threaded Bull Plug, Stainless Steel Flanges and Other Stainless Steel Pipe fittings that are produced under the master direction of our tireless workforce. we are exceedingly experienced organization in ASME B16.11/BS3799 Threaded Bull Plug and other pipe fittings. our ASME B16.11/BS3799 Threaded Bull Plug and Other Fitting items are made utilizing quality material and experience a thorough quality check at all phases of creation to guarantee quality. Planned in consistence with universal quality gauges, these ASME B16.11/BS3799 Threaded Bull Plug are consumption protection, durable and solid. we additionally supply ASME B16.11/BS3799 Threaded Bull Plug and other pipe fittings Flanges in redid measure. Our Product Supply Division offers an expansive arrangement of Steel Flanges and ASME B16.11/BS3799 Threaded Bull Plug. When you submit a request with Dipti Metal Industries, you will get the items that will stand up in benefit from individuals that will remain behind their item.

ASME B16.11 / BS3799 THREADED BULL PLUG

· NICKEL ALLOY BULL PLUG

ASTM / ASME SB 336 UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

· COPPER ALLOY STEEL BULL PLUG

ASTM / ASME SB 111 UNS NO.C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 , C 71500 ASTM / ASME SB 466 UNS NO.C 70600 ( CU -NI- 90/10) , C 71500 ( CU -NI- 70/30)

· STAINLESS STEEL BULL PLUG

ASTM / ASME SA 403 GR WP "S" / "W" / " WX" 304 , 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H

Threaded Bull Plug, Threaded Bull Plug Manufacturers, Threaded Bull Plug Exporters, Threaded Bull Plug Suppliers.

Threaded Bull Plug Manufacturers in India, Threaded Bull Plug Exporters in India, Threaded Bull Plug Suppliers in India.

Threaded Bull Plug Manufacturers in Mumbai, Threaded Bull Plug Exporters in Mumbai, Threaded Bull Plug Suppliers in Mumbai.

0 notes

Photo

Technolloy is As one of the pioneers among Manufacturers, Stockist, and Exporters of Backing Flange (Back up Flange), ASME B16.5/ANSI B16.47 Backing Flange, We are offering genuine expenses in India on Galvanized Backing Flange.

We keep adequate stockpile of SS Backing Flange, Alloy Steel Backing Flange, Nickel Alloy 200 Backing Flange, Carbon Steel Backing Flange, Inconel Backing Flange, Hastelloy Backing Flange, Copper Nickel Backing Flange, Duplex & Super Duplex Backing Flange, Alloy 20 Backing Flange, Aluminum Backing Flange in all Dimensions to satisfy nearly nothing and colossal sum orders from our significant customers.

Steel Backing Flange, Steel Backing Flange manufacturers, Steel Backing Flange suppliers, Steel Backing Flange stockiest, Steel Backing Flange exporter.

Steel Backing Flange in Mumbai, Steel Backing Flange in india

0 notes

Text

Ring Type Joint Flanges Stockists in India

Nutech Overseas Flanges Aspects are reasonable for high-weight and high-temperature applications. ASME B16.5 RTJ Flanges are relentlessly applied to brilliant, going with Alloy Steel Ring Type Joint Plate flanges. Which accordingly guarantees thrilling, with the right assurance of profiles and material in the ASME B16.47 Series An and B RTJ Flanges.

ASME B16.5 RTJ Flanges manufacturers and exporter in India. We are exporing Ring Type Joint flanges, Level Confronted Ring Type Joint Flanges, Ring Type Joint Weld Flanges and Ring Type Joint Raised Face flanges at dumbfounding expense because of sensible expert hours in India and complete wellspring of astounding ANSI B16.5 Class 150 Ring Type Joint flanges, most very smart arrangement, cost open in Mumbai, India. You ought to check ASME B16.5 Ring Type Joint Flanges Aspects, RTJ Flanges weight structure and RTJ Flanges groove assessments. We have organized stock in various assessments like rtj Flanges examinations 1500 and rtj Flanges assessments 900.

Ring Type Joint Flanges Manufacturers, Ring Type Joint Flanges Suppliers, Ring Type Joint Flanges Stockists, Ring Type Joint Flanges Exporters

We are financial expert of Duplex Steel RTJ flanges, most very smart arrangement, cost as we are one of the most exceptional suppliers and vendor of Hastelloy C22 Ring Type Joint Flanges in India. We have our stocking traders in Delhi, Bangalore, Surat, (Gujarat), Hyderabad, Pune (Maharashtra) and Chennai in Tamil Nadu. Check once our ANSI B16.5 RTJ flanges cost going before purchasing Class 300 Ring Type Joint Flanges from India or China. other than mail for our live deftly of Inconel Ring Type Joint Flanges to check types and sizes with our set up stock we can give you best cost of DIN86029 PN10 Ring Type Joint Flanges.

We can correspondingly give free event of Alloy 20 Ring Type Joint Flanges, Nutech Overseas is having our Seller and Wholesaler in Chhattisgarh, Karnataka, Faridabad, Gujarat, Karnataka, Gurgaon, Bhosari, Rajkot, Ghaziabad, Delhi, Chennai (Madras), Ahmedabad, West-Bengal, Haryana, Kolkata, Pune, Raipur, Uttar Pradesh, Nagpur, Madhya Pradesh, Khopoli, Ludhiana, Aurangabad, Jaipur, Bangalore, Punjab, Maharashtra, Tamil Nadu, Rajasthan, Kolhapur, Indore, Vadodara. So on the off chance that you are searching for best cost of MSS SP-44 RTJ Flanges or ASME B16.5 Ring Type Joint Flanges, RTJ Flanges Class 1500 close to you with most limited time transport or free illustration of Stainless Steel RTJ Flanges.

#Ring Type Joint Flanges Manufacturers in India#Ring Type Joint Flanges Suppliers in India#Ring Type Joint Flanges Stockists in India#Ring Type Joint Flanges Exporters in India

0 notes

Text

Monel Flanges vs. Other Flange Materials: A Comparative Analysis

Monel Flanges vs. Other Flange Materials: A Comparative Analysis

When it comes to industrial piping systems, the choice of flange material plays a pivotal role in ensuring peak performance and long-lasting functionality. Among the myriad materials available, Monel stands out as one of the most popular and reliable options. As the leading Monel Flanges Manufacturer, Supplier, Stockist, and Exporter in India, we take pride in offering a wide range of options to cater to diverse project requirements. Our Monel Flanges come in various sizes, specifications, standards, and grades, including the popular Monel 400 Flanges and Monel K500 Flanges.

Moreover, we offer different types of flanges, such as Slip On Flanges, Weld Neck Flanges, Socket Weld Flanges, Blind Flanges, Orifice Flanges, Reducing Flanges, Ring Type Joint Flange, Spectacle Blind Flanges, and Lap Joint Flanges, ensuring that you find the perfect fit for your projects. With our expertise and dedication as suppliers of Monel 400 Flanges and other products, we strive to meet the highest industry standards and be your preferred partner for all your Monel Flange needs in India and beyond.

In this blog post, we will explore the unique advantages of Monel Flanges over other flange materials, demonstrating why they are the preferred choice for critical applications across various industries.

Understanding Flanges and Their Role in Industrial Piping

Before we dive into the comparison, let's briefly understand what flanges are and why they are vital in industrial piping systems. Flanges are flat, circular discs with evenly spaced bolt holes used to connect pipes, valves, and other equipment in a piping network. Their primary functions include providing support, facilitating alignment, and allowing for easy assembly and disassembly of components.

Exploring Monel Flanges

Monel Flanges are a class of nickel-copper alloy flanges renowned for their exceptional properties. The composition primarily consists of nickel and copper, with additions of small amounts of iron, manganese, and other elements. This alloy's chemical composition results in a combination of impressive characteristics, including excellent corrosion resistance, high tensile strength, and exceptional temperature stability.

The corrosion resistance of Monel Flanges is particularly noteworthy, making them suitable for use in harsh and corrosive environments. They perform exceptionally well in marine applications, offshore drilling, and chemical processing industries where exposure to seawater, acids, and alkalis is common. The resistance to localized corrosion, such as pitting and crevice corrosion, adds to their popularity.

Comparing Monel Flanges with Other Flange Materials

To make an informed decision, it is essential to compare Monel Flanges with other commonly used flange materials, such as stainless steel, carbon steel, Inconel, and Alloy 20.

Stainless Steel Flanges

Stainless steel flanges are widely used due to their general corrosion resistance and cost-effectiveness. However, when compared to Monel Flanges, they may fall short in highly corrosive environments. Monel Flanges, with their higher nickel content, exhibit superior resistance to chloride-induced stress corrosion cracking, a common concern in stainless steel.

Carbon Steel Flanges

Carbon steel flanges are widely used in various industries due to their affordability and mechanical properties. However, they lack the corrosion resistance required for aggressive environments. Monel Flanges outshine carbon steel in corrosive atmospheres, making them the preferred choice for applications where durability and longevity are crucial.

Inconel Flanges

Inconel is another popular nickel-based alloy known for its high-temperature strength. While Inconel Flanges offer excellent performance in extreme heat, they may not provide the same level of corrosion resistance as Monel Flanges. For applications where both heat and corrosion resistance are essential, they prove to be the optimal choice.

Alloy 20 Flanges

Alloy 20, also known as Carpenter 20, is a nickel-chromium-molybdenum stainless steel alloy that offers excellent resistance to corrosion and pitting. While Alloy 20 is suitable for many corrosive environments, it may not match the overall corrosion resistance and mechanical properties of Monel Flanges.

Advantages of Monel Flanges

The advantages of using Monel Flanges extend far beyond their corrosion resistance. Let's explore the various reasons why they are a preferred choice in different industries and applications.

High Tensile Strength and Temperature Stability

Monel Flanges are known for their high tensile strength, which ensures they can withstand significant mechanical stress without deformation. This property makes them suitable for applications where the flanges are exposed to high-pressure conditions, such as in oil and gas pipelines, chemical reactors, and high-temperature environments.

Durability and Longevity

Monel Flanges exhibit exceptional durability and longevity, even in the most demanding conditions. Their ability to withstand extreme weather conditions, abrasive elements, and frequent exposure to corrosive substances makes them a reliable choice for critical applications with long operational lifespans.

Resistance to Biofouling and Microbial Corrosion

In marine and offshore industries, biofouling and microbial corrosion can pose significant challenges. Monel Flanges possess inherent resistance to these issues, making them ideal for use in seawater desalination plants, offshore platforms, and shipbuilding.

Excellent Weldability and Formability

Monel Flanges are known for their excellent weldability and formability. They can be easily welded, machined, and formed into complex shapes, allowing for greater design flexibility and ease of installation.

Low Risk of Contamination

For industries dealing with sensitive materials such as pharmaceuticals and food processing, Monel Flanges offer a low risk of contamination. Their non-reactive nature ensures that they do not leach any harmful substances into the conveyed fluids or products.

Key Considerations for Choosing Flange Materials

Selecting the appropriate flange material is crucial to ensuring the success and safety of your projects. Here are some key considerations to keep in mind when choosing flange materials:

Operating Conditions

Evaluate the temperature and pressure conditions under which the flanges will operate. Monel Flanges, with their excellent high-temperature and pressure capabilities, are an ideal choice for applications where these factors are critical.

Corrosive Environment

Consider the nature of the fluid being transported and the corrosive environment in which the flanges will operate. Monel Flanges excel in corrosive atmospheres, providing reliable performance and extended service life.

Industry Standards and Certifications

Ensure that the chosen flange materials meet industry standards and certifications. At Jay Steel Corporation, we take pride in adhering to global standards, providing our customers with the assurance of top-quality products.

Cost-Effectiveness

While Monel Flanges may have a higher initial cost compared to some other materials, their long-term durability and low maintenance costs make them a cost-effective choice in the long run.

Expert Guidance

Seek expert guidance from professionals who can analyze your project requirements and recommend the most suitable flange material. At Jay Steel Corporation, our team of experts is always ready to assist you in making the right choice.

Applications of Monel Flanges

Monel flanges are essential components used in various industries due to their unique properties and corrosion-resistant nature. Monel is a group of nickel-copper alloys known for their excellent resistance to seawater, acids, alkalis, and various corrosive environments. Here are some of the common applications:

Marine industry

Oil and Gas industry

Chemical processing

Aerospace industry

Power generation

Seawater desalination

Food processing

Pharmaceutical industry

Water treatment

Nuclear industry

Other Application

Final Thoughts!..

Monel Flanges emerge as the ideal choice for critical applications where corrosion resistance, high strength, and temperature stability are paramount. Their exceptional properties and performance set them apart from other flange materials, making them the preferred option for industries such as marine, offshore, chemical processing, aerospace, and so on.

As India's leading Monel Flanges Manufacturer, Supplier, Stockist, and Exporter in India, Jay Steel Corporation is committed to delivering top-notch products that cater to your specific project requirements. Our Monel Flanges are not only highly regarded in India but are also in demand across the globe, with exports to countries such as Singapore, Malaysia, Nigeria, the USA, France, Saudi Arabia, Kuwait, Tunisia, Qatar, and more. Our products have gained international acceptance due to their unmatched quality, reliability, and adherence to global standards and certifications.

0 notes