#Spectacle Blind Flanges Exporters

Explore tagged Tumblr posts

Text

Stainless Steel 316 Flanges Exporter and Manufacturer in Singapore

Jay Steel Corporation is the foremost source of superior Stainless Steel 316 Flanges in Exporter Singapore. As the most notable Stainless Steel 316 Flanges manufacturer, supplier, stockist, and exporter in Singapore, we take great pride in presenting a complete range of flanges, designed to meet your varied requirements. Our extensive inventory encompasses Slip On Flanges, Weld Neck Flanges, Socket Weld Flanges, Blind Flanges, Orifice Flanges, Reducing Flanges, Ring Type Joint Flanges, Spectacle Blind Flanges, and Lap Joint Flanges – all available to you in Singapore.

0 notes

Text

Hastelloy Flanges Manufacturer in India

Rishabh Steel Industries is one of the leading Hastelloy Flanges Manufacturer in Mumbai, India. We are an ISO 9001:2008 certified company with an existence in the metal market. Hastelloy C276 Flanges products are designed and developed per international and national quality standards.

We offer the best possible prices for Hastelloy B3 Flanges to all our customers, with a stock of standard sizes, materials, and types available for immediate delivery worldwide. Our available qualitative range of Hastelloy Flanges is exclusively designed for several piping applications.

Rishabh Steel Industries is the top manufacturer of C276 Hastelloy Flanges Our company offers Hastelloy Flanges manufactured under the strict supervision of professionals per national and international standards. We manufacture Hastelloy Flanges Manufacturer in India Cupro-Nickel Flanges, and SMO 254 Flanges at our units using optimum grade materials and with the help of our best state of technology. We design high-quality Hastelloy B3 Flanges in various thicknesses and diameters. We mostly use very high-quality raw materials for manufacturing these Flanges.

We are a well known manufacturer, supplier & exporter of high quality Hastelloy flanges in Mumbai, India. These Hastelloy flanges are manufactured by national & international standards. These flanges are widely used in various application industry such as petroleum, chemical, construction, engineering, gas and shipbuilding industries and many more. We offer a comprehensive range of all types of Hastelloy flanges grades including slip on flanges, socket weld, blind, lapped, screwed, weld neck, reducing, spectacle, slip on boss, plate, plate blank, screwed boss, Hastelloy c276, c22, b2 flanges etc.

Hastelloy Flanges Manufacturer in India ASTM b366 Hastelloy Flanges, Manufacturer of Hastelloy Flanges in India, Hastelloy C276 Flanges, Hastelloy C22 Flanges, Hastelloy B2 Flanges, Hastelloy X Flanges Manufacturer in India, Hastelloy UNS N06022 Flanges, Hastelloy C22 Flanges, ASTM B366, ASTM SB 366, ASTM B564, ASME SB564 Hastelloy Flanges, Hastelloy UNS N06022 Flanges, UNS N10276 Hastelloy C276 Flanges, Hastelloy C276 Flanges, Hastelloy C276, C22, B2 Fitting, ANSI/ASME B16.9, B16.28, MSS-SP-43 Hastelloy Flanges, Hastelloy Seamless/Seam Welded Flanges, Hastelloy Fabricated Flanges Manufacturers in India.

#hastelloyflangesmanufacturerinindia#hastelloyflanges#manufacturerinindia#rishabhsteelindustries#hastelloy#flanges#manufacturer#in#india

0 notes

Text

Zeron 100 Flanges Exporters In India

Zeron 100, also known as UNS S32760, is a high-performance super duplex stainless steel. It is widely used in flanges due to its excellent mechanical properties and resistance to corrosion in aggressive environments. Here is some information about exporters of Zeron 100 flanges in India:

Aspirinox Alloys Inc.: They offer a variety of Zeron 100 flanges, including slip-on, weld neck, blind, threaded, socket weld, and reducing flanges. These flanges are available in various pressure classes and dimensions, adhering to standards such as ANSI, ASME, BS, DIN, and EN. Their products are noted for high strength and corrosion resistance, suitable for demanding applications (Aspirinox Alloys Inc).

Amigo Impex: Located in Mumbai, Amigo Impex provides Zeron 100 flanges in types such as weld neck, slip-on, blind, threaded, socket weld, lap joint, long weld neck, and spectacle blind flanges. They follow ASTM and ASME standards and offer these flanges in sizes ranging from 1/8" to 24" NB, with various pressure ratings. The company emphasizes quality and provides custom packaging to ensure safe delivery (Amigo Impex India) (Amigo Impex India).

Rely Metalloys Inc.: This company supplies and exports a comprehensive range of Zeron 100 super duplex steel flanges, including buttweld and forged fittings. They offer these flanges in numerous configurations and sizes, adhering to international standards. Rely Metalloys Inc. highlights the durability and robust design of their flanges, making them suitable for connecting pipes in various industrial applications (Rely Metalloys).

These companies are known for their commitment to quality and customer satisfaction, ensuring that their Zeron 100 flanges meet rigorous industry standards and client specifications.

0 notes

Text

Conoco Philips Approved Flanges Exporters in UAE

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is delighted to offer an extensive range of Monel Alloy 400 Flanges, meticulously crafted from premium-grade metal. These flanges, particularly the Monel 400 Slip on Flanges (UNS N04400), are renowned for their ability to be strengthened through cooling, making them indispensable components in various applications. To ensure optimal performance, welding techniques such as gas-tungsten arc welding, metal-inert gas welding, gas-metal-arc welding, and submerged-arc welding are recommended for use with these flanges. It is crucial to employ advanced machining equipment and tooling to minimize chatter or work hardening of the alloy in Monel 400 Weld Neck Flanges before cutting.

Distinguished by their exceptional resistance to corrosion from acids and alkalis, as well as their high mechanical strength and superior ductility, Monel 400 Blind Flanges exemplify durability and reliability. Moreover, our Monel 400 Lap Joint Flanges are available in various configurations to meet the specific requirements of our esteemed clients. By utilizing an advanced manufacturing process through Electro Slag Refining (ESR), Monel 400 Connection Weld Flanges ensure the highest quality and cleanliness standards, with the ESR process guaranteeing flawless production of Monel 400 Ring Joint Type Flanges.

Offering convenience without compromising performance, Monel 400 Spectacle Blind Flanges require no post-weld heat treatment. However, thorough cleaning after welding is imperative to ensure optimal corrosion resistance in Monel 400 Nippolet Flanges, as failure to do so may result in contamination and embrittlement.

Specifications for Monel 400 Pipe Flanges:

Specifications: ASTM B564 / ASME SB564

Size: 1/2"NB TO 60"NB

Standards: ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Class / Pressure: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64, etc.

Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

#Monel 400 Flanges Manufacturers in UAE#Monel 400 Flanges Suppliers in UAE#Monel 400 Flanges Stockists in UAE#Monel 400 Flanges Exporters in UAE#Chevron Corporation Approved Flanges In UAE

1 note

·

View note

Text

Stainless Steel SS Flanges Manufacturer

‘C-Way Engineering Exports’ is the leading manufacturer of ASME/ANSI/IS/DIN/BS/JIS stainless steel SS flanges manufacturer in India. Standard sizes of carbon steel flanges and stainless steel flanges are available readily in the stock to deliver immediately. C-Way Flanges are designed and manufactured in accordance with international quality standards including ANSI/ASME B16.5, ANSI/ASME B16.47 Series A and Series B, and API standards flanges. The size of flanges ranges from ½ inches to 48 inches. We produce Weld Neck Flanges, Blind Flange, Slip On Flanges, Socket Weld Flanges, Threaded Flange, Lap Joint Flanges, Spectacle Flanges in 150 #, 300#, 600#, 900#, 1500# and 2500# class.

We excel as a stainless steel (SS) Flanges Manufacturer In India. We manufacture Flanges using a variety of materials, including carbon steel, stainless steel, alloy steel, and exotic materials such as Duplex, Super Duplex, Nickel Alloys, Hastelloy, Inconel. We cater to the huge global demand of our customers who are spread across 6 continents and around 110 countries. Our products are reputed and well known across the globe for their reliability and quality.

All Flanges with standard sizes and materials are readily available in stock for immediate delivery. "Looking for large diameter Flanges ? Contact us today for Customized Flanges.

0 notes

Text

Flange Manufacturers in Germany

One of The Biggest Manufacturers and Exporters of Flanges, Weld Neck Flange, Blind Flange, Socket Weld Flange, Orifice Flange, RTJ Flange, Threaded Flange, Lap Joint-Flange, LWN Flange, Spectacle Blind Flange, Backup Flange, Nipoflange, Weldoflange, Forged Flange, Tongue & Groove Flange, Reducing Flange, High Hub Flange, Square Flange in Germany.

Saini Flange is one of the leading Flange Manufacturers in Germany. The Flanges provides a strong connectivity to pipes and provide a long life in the refining industry for low to high pressure usage. Our Experienced teams of Flanges Manufacturers in Germany are largely trained experienced professional, supplying a right service to the right client. Client satisfaction and quality services are the main motive of Saini Flanges. All of our Flanges are of build off with high quality and go through with a proper safety- checked before shipping.

Flanges are the ridges which can be attached both side externally and internally for giving strength to the pipes. The flanges are available in all different sizes namely‘I’and‘T’ shafts. These flanges are used in a variety of works like, and also it’s used in at the pipe end, camera lens and to adjust the wheel of the rails . Substantially the flanges are used at the wheels. Flange helps in controlling The speed that can be controlled fluently in that way too. We are proud to be a premier Flanges Exporter in Germany. Designed to associate different sections of a pipeline system, Industrial Flanges enable easy access to the network for maintenance, shape, as well as examination. We’ve the knowledge and experience to address specific industry needs at budget friendly prices. By choosing Saini Flanges as your Flanges Exporter in Germany, you’ll get advantage from short lead times, on- time delivery, and, most importantly, you will get the high- quality products.

0 notes

Text

The Significance of Quality Control in Flange Manufacturing.

In the realm of commercial operations, the integrity and reliability of equipment additives, together with flanges and flange couplings, are paramount. When it involves flanges - essential elements in piping structures - precision and great, together with diverse flange types, are non-negotiable. At Arcellor Controls India, a prominent flanges manufacturer in India, we take satisfaction in being the most authority in supplying and exporting a diverse array of flanges, tailored to satisfy numerous assignment specifications. Our good sized range covers all types of flange requirements, making sure that each product meets rigorous satisfactory requirements. What genuinely sets us apart is our unwavering dedication to fine manage at some stage in the manufacturing manner, guaranteeing unparalleled reliability and performance.

Flanges Specifications and Standards

Standard

ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Dimensions

150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

Materials

Stainless Steel Flanges, Duplex and Super Duplex Steel Flanges, Carbon Steel Flanges, Low-Temperature Carbon Steel Flanges, Alloy Steel Flanges, Copper Alloy Steel Flanges, and Nickel Alloy Flanges (Monel, Inconel, Alloy 20 Steel & Hastelloy)

Size

1/2″ (15 NB) to 48″ (1200NB)

Type

Weld Neck Flanges, Slip On Flanges, Socket weld Flanges, Spectacle blind flanges, Coupling Flanges, Threaded Flanges, Lap Joint Flanges, and Blind Flanges

Flange Face Type

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Importance of Quality Control in Flange Manufacturing:

Quality manage isn't always just a checkbox in our production system – it is the cornerstone of the entirety we do. Flanges serve as crucial connectors in pipelines, wearing fluids or gases under various pressures and temperatures. Any compromise of their first-rate can lead to catastrophic effects, which includes leaks, machine disasters, and capability protection risks. Recognizing this, we put in force rigorous pleasant control measures at each stage of production to ensure that every flange meets the best standards of overall performance, reliability, and safety.

Precision Engineering:

At Arcellor Controls India, precision is extra than a buzzword – it is a mandate. From the choice of uncooked materials flange types, each step is meticulously orchestrated to deliver flanges that excel in each form and characteristic. Our cutting-edge manufacturing facilities, coupled with superior machining technologies and a team of skilled engineers, enable us to attain remarkable stages of precision and consistency. Whether it's weld neck flanges, slip-on flanges, socket weld flanges, or another variation from our giant portfolio, each piece undergoes stringent excellent exams to ensure dimensional accuracy and flawless execution.

Material Excellence:

Flanges are subjected to a myriad of working conditions, starting from corrosive environments to excessive-strain applications. To address this variety, we provide flanges made from a comprehensive range of materials, together with stainless-steel, duplex and first rate duplex metallic, carbon metal, low-temperature carbon metal, alloy steel, copper alloy metallic, and diverse nickel alloys including Monel, Inconel, Alloy 20 Steel, and Hastelloy. Our materials go through thorough pleasant exams to affirm their mechanical homes, corrosion resistance, and suitability for particular running conditions, ensuring that our customers acquire flanges engineered for durability and performance.

Adherence to Standards:

In an enterprise governed with the aid of strict policies and standards, compliance is non-negotiable. Arcellor Controls India adheres to a mess of international requirements, consisting of ASTM, ASME, ANSI, DIN, and BS, among others, to assure the integrity and interoperability of our flanges throughout different applications and markets. Moreover, our commitment to continuous improvement drives us to live abreast of evolving requirements and high-quality practices, ensuring that our products constantly meet or exceed regulatory necessities.

Customer-Centric Solutions:

We apprehend that each venture is particular, with its very own set of demanding situations and requirements. That's why we provide customizable solutions tailored to healthy the particular desires of our customers. Whether it's a bespoke flange layout, custom designed dimensions, or specialised cloth specifications, our crew works carefully with clients to deliver tailor-made solutions that align perfectly with their challenge goals. Our dedication to customer satisfaction extends beyond the sale – we provide comprehensive technical aid, well timed shipping, and responsive after-income carrier to make sure a seamless revel in from start to complete.

Final Words!

In the intricate community of business infrastructure, the importance of excellent manage, mainly concerning important additives like flanges and flange couplings, can not be overstated. At Arcellor Controls India, famend as a finest flanges manufacturer in india, great isn't always simply a concern; it's our solemn dedication. Through meticulous interest to detail and using modern-day production techniques, we ensure that our great variety of flange types embodies precision, reliability, and remarkable performance. Committed to adhering to global requirements and preserving a patron-centric approach, we stand because the desired companion for all your flange necessities. Choose us, in which the fusion of exceptional and reliability is a guarantee, on every occasion.

0 notes

Text

What is a stainless steel flange?

Stainless steel flanges play a crucial role in various industrial applications, serving as essential components in piping systems. These robust connectors facilitate the assembly and disassembly of pipes, providing a secure and leak-proof connection. At Bullion Pipes & Tubes LLP, we take pride in being the foremost Stainless Steel Flange Manufacturer, Supplier, Stockist, and Exporter on a global scale. Our commitment to quality and precision has positioned us as industry leaders, providing a diverse range of stainless steel flanges to cater to the unique requirements of projects worldwide.

In this blog post, we will delve into the intricacies of ss flanges, exploring their uses, and key characteristics.

Understanding Stainless Steel Flanges

Stainless steel flanges are integral parts of piping systems designed to connect pipes, valves, pumps, and other equipment. These versatile components are crafted from high-quality SS Flanges, known for its exceptional corrosion resistance, durability, and strength. The use of stainless steel ensures that flanges can withstand harsh environmental conditions and maintain their structural integrity over time.

Key Features of Stainless Steel Flanges:

Corrosion Resistance: Stainless steel flanges offer excellent resistance to corrosion, making them ideal for use in environments with exposure to moisture, chemicals, and harsh weather conditions.

Strength and Durability: The inherent strength of stainless steel ensures that flanges can withstand high pressures and maintain their structural integrity over an extended period.

Temperature Resistance: Stainless steel flanges exhibit remarkable temperature resistance, allowing them to perform reliably in both extreme heat and cold conditions.

Stainless Steel Flanges Specifications

Specifications

ASTM A182, A240 / ASME SA182, SA240

Standards

ANSI Flanges, ASME Flanges, DIN Flanges, EN Flanges, BS Flanges, JIS Flanges, AWWA Flanges etc.

Dimension

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc

Size Range

1/2" (15 NB) to 48" (1200NB)

Pressure / Class

150#, 300#, 600#, 900#, 1500# & 2500#.

Type

Slip On Flanges, Weld Neck Flanges, Blind Flanges, Socket Weld Flanges, Orifice Flanges, Ring Type Joint Flanges, Threaded Flanges, Reducing Threaded Flanges, Lap Joint Flanges, Long Weld Flanges, Spectacle Blind Flanges, Paddle Blind Flanges, Ring Spacer Flanges, Backing Ring Flanges, Nipoflanges, Weldoflange, Flangeolet, Bleed, Drip & Vent Ring Flange, Forged Flange, Raised Face Flanges, Tongue and Groove Flange, Male & Female Flange, Reducing Flange, ANSI Plate Flange, High Hub Blind Flange, Square Flange, Expander Flange, Gasket Flange, Swivel Flange, Heavy Barrel Flange, Forged Steel Flange, Taylor Flange, Wire Seal Flange, Galvanized Flange, Drilled Flange, MS Flange, and Vacuum Flange

Flange Face Type

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Applications of Stainless Steel Flanges

Stainless Steel Flanges' durability, corrosion resistance, and high strength make them suitable for a range of applications. Here are some common applications of ss flanges:

Piping Systems

Chemical Processing Industry

Oil and Gas Industry

Water Treatment Plants

Power Generation

Food and Beverage Industry

Aerospace Industry

Shipbuilding

Pharmaceutical Industry

Construction Industry

Automotive Industry

Other Applications

Final Words!

Stainless steel flanges are indispensable components in various industrial applications, ensuring the integrity and efficiency of piping systems. When it comes to reliability, quality, and a diverse range of options, Bullion Pipes & Tubes LLP is your go-to partner.

Explore our comprehensive range of stainless steel flanges and experience the unmatched quality and service that has made us a global leader all across the globe in various countries such as Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, Russia, and many other regions. Contact us today at [email protected] or [email protected] for all your stainless steel flange needs, and let Bullion Pipes & Tubes LLP be your trusted partner in success.

0 notes

Text

Carbon Steel ASTM A105 Flanges Exporters

These Carbon Steel ASTM A105 Flange are manufacture in different Type of Flanges like Carbon steel Blind Flange, Carbon ASTM A105 Spectacle Blind Flange, Carbon steel Slip On Flange, Carbon steel Socket Welding Flange, Carbon steel ASTM A105 Welding Neck Flange, SORF Flanges, A105 Collar Flange, Carbon steel Plate Flange, Carbon steel ASTM A105 Raised Face Flange, Carbon steel Flat Face Flange, SWRF, WNRF, BLRF, Carbon steel Lapped Joint Flange, Carbon steel Ring Type Joint Flange, Carbon steel Threaded Flange & Carbon steel Long Welding Neck Flanges, Low Temperature CS Flanges, IS 2062 Flanges, ASTM A420 WPL6 Flanges, ASTM A860 WPHY Flanges, ANSI B16.47 Flanges, ANSI B16.36 Flanges, PN 10 Flanges.

CONTACT INFO address Narayan Niwas, Shop No. 3, Near Alankar Cinema, 2nd Khetwadi Lane, Mumbai-400 004, Maharashtra, India. number +91-22-2386-5819 +91-22-2389-3333 email [email protected] [email protected]

0 notes

Text

Hastelloy C22 Flanges Suppliers in India

Deep Steel Centre is one of the most bewildering Exporters, Manufacturers, and Suppliers of Hastelloy C22 Flanges in India. We offer these flanges with affirmation from confined use and incredible metallurgical consistency, and we are not asked during warming or welding. These WNR 2.4602 flanges are used in compound making due to degradation control, paper and pound creation, marine seawater, waste treatment applications, etc. Hastelloy C22 flanges are astoundingly compatible with Hastelloy C276 and are a magnificent erosion- and power-safe thing.

Meanwhile, the outlined nickel-chromium-molybdenum materials also involve tungsten for an upgraded total use counteraction compared to most other equal items. Our UNS N06022 flanges provide security from stress-use breaking, split disintegration, and pitting. These are available to our fundamental clients at different levels of evaluation, wall thicknesses, and sizes at very sensible rates.

ANSI B16.5 Hastelloy C22 Flanges Specification

Dimensions : ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Standards : ASTM, ASME Flanges, ANSI Flanges, DIN Flanges, EN Flanges, BS Flanges etc.

Specifications : ASTM B564 / ASME SB 564

Size : 1 / 2” to 36″

Class : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Grade : Hastelloy C22 – UNS No. N06022

Types Of Available Products AISI, ASTM, DIN, JIS, GB, EN Hastelloy C22 Flanges

Hastelloy Alloy C22 Flanges C22 Hastelloy Blind Flanges ASTM B564 Hastelloy C22 Slip On Flanges Hastelloy UNS N06022 Pipe Flanges ASTM B564 Hastelloy C22 BLRF Flanges Manufacturer B564 Hastelloy C22 Weld Neck Flanges Manufacturer ASME SB564 Inconel C22 RTJ Flanges Stockiest Hastelloy C22 Threaded Flanges Distributors JIS NW 6022 SWRF Flanges Top Quality Hastelloy C22 Socket weld Flanges C22 Hastelloy Orifice Flanges Exporter ASTM B564 Hastelloy C22 DIN Flanges ASTM/ASME Alloy C22 Forged Flanges

C22 Hastelloy Ring Type Joint Flanges Stockiest in India Hastelloy Alloy C22 Reducing Flanges ASTM B564 Hastelloy C22 Lap Joint Flanges Hastelloy WERKSTOFF NR . 2.4602 Long Weld Neck Flanges C22 Hastelloy Screwed Flanges Dealers ASTM B564 Hastelloy C22 SORF Flanges Hastelloy C22 Plate Flanges Stockholder C22 Hastelloy Alloy WNRF Flanges Suppliers B564 Hastelloy C22 Spectacle Blinds Flanges Suppliers ASME SB 564 Hastelloy C22 Flanges AISI Hastelloy C22 ASTM B564 Flanges ASTM B564 Hastelloy C22 Alloy Loose Flanges Hastelloy C22 Flange JIS Standard Flanges

For more information:

Website: https://www.deepsteelalloys.com/hastelloy-alloy-c22-flanges-supplier.html

Email: [email protected]

#Hastelloy C22 Flanges Manufacturers#Hastelloy C22 Flanges Suppliers#Hastelloy C22 Flanges Stockists#Hastelloy C22 Flanges Exporters#Hastelloy C22 Flanges Manufacturers in India#Hastelloy C22 Flanges Suppliers in India#Hastelloy C22 Flanges Stockists in India#Hastelloy C22 Flanges Exporters in India#Hastelloy C22 Flanges Manufacturers in Mumbai#Hastelloy C22 Flanges Suppliers in Mumbai#Hastelloy C22 Flanges Stockists in Mumbai#Hastelloy C22 Flanges Exporters in Mumbai

0 notes

Text

Monel Flanges vs. Other Flange Materials: A Comparative Analysis

Monel Flanges vs. Other Flange Materials: A Comparative Analysis

When it comes to industrial piping systems, the choice of flange material plays a pivotal role in ensuring peak performance and long-lasting functionality. Among the myriad materials available, Monel stands out as one of the most popular and reliable options. As the leading Monel Flanges Manufacturer, Supplier, Stockist, and Exporter in India, we take pride in offering a wide range of options to cater to diverse project requirements. Our Monel Flanges come in various sizes, specifications, standards, and grades, including the popular Monel 400 Flanges and Monel K500 Flanges.

Moreover, we offer different types of flanges, such as Slip On Flanges, Weld Neck Flanges, Socket Weld Flanges, Blind Flanges, Orifice Flanges, Reducing Flanges, Ring Type Joint Flange, Spectacle Blind Flanges, and Lap Joint Flanges, ensuring that you find the perfect fit for your projects. With our expertise and dedication as suppliers of Monel 400 Flanges and other products, we strive to meet the highest industry standards and be your preferred partner for all your Monel Flange needs in India and beyond.

In this blog post, we will explore the unique advantages of Monel Flanges over other flange materials, demonstrating why they are the preferred choice for critical applications across various industries.

Understanding Flanges and Their Role in Industrial Piping

Before we dive into the comparison, let's briefly understand what flanges are and why they are vital in industrial piping systems. Flanges are flat, circular discs with evenly spaced bolt holes used to connect pipes, valves, and other equipment in a piping network. Their primary functions include providing support, facilitating alignment, and allowing for easy assembly and disassembly of components.

Exploring Monel Flanges

Monel Flanges are a class of nickel-copper alloy flanges renowned for their exceptional properties. The composition primarily consists of nickel and copper, with additions of small amounts of iron, manganese, and other elements. This alloy's chemical composition results in a combination of impressive characteristics, including excellent corrosion resistance, high tensile strength, and exceptional temperature stability.

The corrosion resistance of Monel Flanges is particularly noteworthy, making them suitable for use in harsh and corrosive environments. They perform exceptionally well in marine applications, offshore drilling, and chemical processing industries where exposure to seawater, acids, and alkalis is common. The resistance to localized corrosion, such as pitting and crevice corrosion, adds to their popularity.

Comparing Monel Flanges with Other Flange Materials

To make an informed decision, it is essential to compare Monel Flanges with other commonly used flange materials, such as stainless steel, carbon steel, Inconel, and Alloy 20.

Stainless Steel Flanges

Stainless steel flanges are widely used due to their general corrosion resistance and cost-effectiveness. However, when compared to Monel Flanges, they may fall short in highly corrosive environments. Monel Flanges, with their higher nickel content, exhibit superior resistance to chloride-induced stress corrosion cracking, a common concern in stainless steel.

Carbon Steel Flanges

Carbon steel flanges are widely used in various industries due to their affordability and mechanical properties. However, they lack the corrosion resistance required for aggressive environments. Monel Flanges outshine carbon steel in corrosive atmospheres, making them the preferred choice for applications where durability and longevity are crucial.

Inconel Flanges

Inconel is another popular nickel-based alloy known for its high-temperature strength. While Inconel Flanges offer excellent performance in extreme heat, they may not provide the same level of corrosion resistance as Monel Flanges. For applications where both heat and corrosion resistance are essential, they prove to be the optimal choice.

Alloy 20 Flanges

Alloy 20, also known as Carpenter 20, is a nickel-chromium-molybdenum stainless steel alloy that offers excellent resistance to corrosion and pitting. While Alloy 20 is suitable for many corrosive environments, it may not match the overall corrosion resistance and mechanical properties of Monel Flanges.

Advantages of Monel Flanges

The advantages of using Monel Flanges extend far beyond their corrosion resistance. Let's explore the various reasons why they are a preferred choice in different industries and applications.

High Tensile Strength and Temperature Stability

Monel Flanges are known for their high tensile strength, which ensures they can withstand significant mechanical stress without deformation. This property makes them suitable for applications where the flanges are exposed to high-pressure conditions, such as in oil and gas pipelines, chemical reactors, and high-temperature environments.

Durability and Longevity

Monel Flanges exhibit exceptional durability and longevity, even in the most demanding conditions. Their ability to withstand extreme weather conditions, abrasive elements, and frequent exposure to corrosive substances makes them a reliable choice for critical applications with long operational lifespans.

Resistance to Biofouling and Microbial Corrosion

In marine and offshore industries, biofouling and microbial corrosion can pose significant challenges. Monel Flanges possess inherent resistance to these issues, making them ideal for use in seawater desalination plants, offshore platforms, and shipbuilding.

Excellent Weldability and Formability

Monel Flanges are known for their excellent weldability and formability. They can be easily welded, machined, and formed into complex shapes, allowing for greater design flexibility and ease of installation.

Low Risk of Contamination

For industries dealing with sensitive materials such as pharmaceuticals and food processing, Monel Flanges offer a low risk of contamination. Their non-reactive nature ensures that they do not leach any harmful substances into the conveyed fluids or products.

Key Considerations for Choosing Flange Materials

Selecting the appropriate flange material is crucial to ensuring the success and safety of your projects. Here are some key considerations to keep in mind when choosing flange materials:

Operating Conditions

Evaluate the temperature and pressure conditions under which the flanges will operate. Monel Flanges, with their excellent high-temperature and pressure capabilities, are an ideal choice for applications where these factors are critical.

Corrosive Environment

Consider the nature of the fluid being transported and the corrosive environment in which the flanges will operate. Monel Flanges excel in corrosive atmospheres, providing reliable performance and extended service life.

Industry Standards and Certifications

Ensure that the chosen flange materials meet industry standards and certifications. At Jay Steel Corporation, we take pride in adhering to global standards, providing our customers with the assurance of top-quality products.

Cost-Effectiveness

While Monel Flanges may have a higher initial cost compared to some other materials, their long-term durability and low maintenance costs make them a cost-effective choice in the long run.

Expert Guidance

Seek expert guidance from professionals who can analyze your project requirements and recommend the most suitable flange material. At Jay Steel Corporation, our team of experts is always ready to assist you in making the right choice.

Applications of Monel Flanges

Monel flanges are essential components used in various industries due to their unique properties and corrosion-resistant nature. Monel is a group of nickel-copper alloys known for their excellent resistance to seawater, acids, alkalis, and various corrosive environments. Here are some of the common applications:

Marine industry

Oil and Gas industry

Chemical processing

Aerospace industry

Power generation

Seawater desalination

Food processing

Pharmaceutical industry

Water treatment

Nuclear industry

Other Application

Final Thoughts!..

Monel Flanges emerge as the ideal choice for critical applications where corrosion resistance, high strength, and temperature stability are paramount. Their exceptional properties and performance set them apart from other flange materials, making them the preferred option for industries such as marine, offshore, chemical processing, aerospace, and so on.

As India's leading Monel Flanges Manufacturer, Supplier, Stockist, and Exporter in India, Jay Steel Corporation is committed to delivering top-notch products that cater to your specific project requirements. Our Monel Flanges are not only highly regarded in India but are also in demand across the globe, with exports to countries such as Singapore, Malaysia, Nigeria, the USA, France, Saudi Arabia, Kuwait, Tunisia, Qatar, and more. Our products have gained international acceptance due to their unmatched quality, reliability, and adherence to global standards and certifications.

0 notes

Text

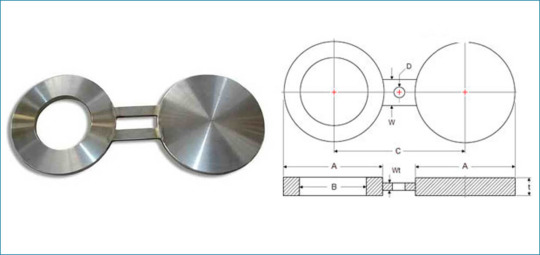

Stainless Steel Spectacle Blind Flanges

1 note

·

View note

Text

Duplex S32205 Flange Manufacturer & Supplier

DETAIL INFORMATION

One of the top producers, suppliers, and exporters of Duplex Steel UNS S32750 Flanges is Newzel Industries. With ASTM A182 Duplex UNS S32750, the resistance to pitting corrosion in salty and brackish conditions, during bleaching processes, and in several food processing applications has improved. Offshore marine engineering factories require parts that meet their strict specifications, i.e. parts with tremendous strength and minimal weight. The use of nitrogen strengthens the microstructure of Super Duplex UNS S32750 Reducing Flanges, enabling the production of low-cost, thin, and lightweight flanges. Flanges made of super duplex steel in accordance with ASTM A182, such as super duplex UNS S32750 Slip On Flanges, super duplex UNS S32750 Weld Neck Flanges, and super duplex F51 Socket Weld Flanges, Gr. Super Duplex Steel UNS S32750 Spectacle Blind Flanges, Super Duplex Steel F56 Orifice Flanges, and Super Duplex Steel Blind Flanges. Super Duplex Steel F60 Screwed/Threaded Flanges, Super Duplex Steel F61 Reducing Flanges, and Super Duplex UNS S32750 Ring Type Joint Flanges The Marine Industry and Shipbuilding regularly employ Super Duplex Steel UNS S32750 Threaded Flanges for uses including Propellers and Shafts, Rudders, Shaft Seals, Pumps, Bolts and Fasteners, Valves, Instrumentation, and Oil and Chemical Tankers. Our customers can also get these Super Duplex Steel UNS S32750 Weld Neck Flanges in a range of sizes and forms in the interim.

Description of Super Duplex Steel UNS S32750 Flanges Flanges made of super duplex steel UNS S32750 are made of duplex steel. The microstructure of these flanges is composed of austenitic and ferritic grades. These flanges are unique in that they contain more chromium and molybdenum than usual. Compared to normal versions, this offers better corrosion resistance. Due to its dual-phase microstructure, which combines high strength with moderate corrosion resistance, it is appropriate for usage in chloride-rich settings. These flanges' alloying costs are lower than those of other standard grade kinds.

These flanges have greater corrosion resistance in chloride-rich conditions because of the makeup of the corrosion-resistant components. This formula also improves yield and tensile strength. These flanges are the finest choice for a variety of wall thicknesses without sacrificing quality or features. These flanges can be welded using any common welding process because of their great weldability. TIG, MIG, resistance, and arc welding are available options.

With regard to ductility, corrosion resistance, and mechanical qualities, UNS S32750 Super Duplex Steel Flanges excel. These flanges are made of super duplex steel and are delivered in an annealed condition. However, heat treatment techniques won't make these flanges harder. using industrial cold techniques to develop the necessary traits. Additionally, these flanges are corrosion-resistant in decreasing zones.

Duplex S32205 Flange: For Newzel Industries, Unleashing Strength and Versatility Delivering exceptional quality and performance in industrial applications is Newzel Industries' top priority. The Duplex S32205 flange stands out as an excellent option for creating strong pipe connections. This article examines the qualities, advantages, and uses of the Duplex S32205 flange, emphasizing why Newzel Industries should use it.

The Duplex S32205 Flange: An Overview A specific type of flange made of duplex stainless steel, grade S32205, is the Duplex S32205 flange. It exhibits the ideal harmony of mechanical qualities, corrosion resistance, and affordability. This flange is made to firmly connect pipes, valves, and other pieces of machinery, resulting in joints that are dependable and leak-free.

Duplex S32205 Flange's main characteristics are: Stainless steel that is duplex: The S32205 flange is made of duplex stainless steel and is appropriate for harsh industrial applications due to its excellent strength, hardness, and corrosion resistance.

This flange's dual phase microstructure, which includes both ferrite and austenite, gives it outstanding mechanical and corrosion-resistant qualities.

Enhanced Corrosion Resistance: The Duplex S32205 flange demonstrates exceptional resistance to a variety of corrosive media, including acids, alkalis, environments high in chloride, and marine settings.

High Strength: The S32205 flange offers remarkable structural integrity and dependability because to its much higher strength than austenitic stainless steels.

Weldability: The Duplex S32205 flange welds beautifully, making installation and maintenance simple.

Duplex S32205 Flange Advantages for Newzel Industries Corrosion Protection: The Duplex S32205 flange is the perfect option for sectors working with hostile fluids and conditions because of its outstanding corrosion resistance, which ensures long-lasting performance, lowers maintenance costs, and decreases downtime.

Strength and Durability: The S32205 flange guarantees a sturdy union with high tensile and yield strengths, reducing the risk of leaks and maintaining operating safety.

Cost-Effectiveness: The Duplex S32205 flange offers a cost-effective solution despite possessing superior features because of its prolonged service life, decreased maintenance needs, and improved reliability.

Versatility: The S32205 flange is a versatile option for Newzel Industries since it finds use in a variety of industries, including the oil and gas, chemical, petrochemical, marine, and offshore sectors.

Uses for Duplex S32205 Flange in the Oil and Gas Industry In offshore platforms, subsea pipelines, and equipment, the Duplex S32205 flange is frequently utilized because of its superior corrosion, high-pressure, and harsh environment resistance.

Chemical and petrochemical industry: The S32205 flange is appropriate for applications requiring acids, solvents, and harsh solutions due to its resistance to corrosive substances.

Marine Industry: The flange is the perfect option for marine applications, such as shipbuilding and offshore structures, due to its corrosion resistance, strength, and longevity.

Power Generation: Due to its great strength and resilience to thermal cycling, Duplex S32205 flanges are used in power plants to connect pipes, valves, and heat exchangers.

The Duplex S32205 flange offers Newzel Industries a strong solution thanks to its high strength, corrosion resistance, and affordability. Newzel Industries can guarantee strong, leak-free connections, lower maintenance costs, and boost operational efficiency across a range of industrial applications by adopting this dependable component. The Duplex S32205 flange's adaptability and dependability make it the ideal complement to Newzel Industries' dedication to providing superior industrial solutions.

0 notes

Text

Spectacle Flanges Exporters In India

Nascent Pipes & Tubes is a vainglorious exporter, producers and suppliers of Scene Flanges in the steel walk industry all over the planet. Show Scene Flanges is a strain saving plate with one open end and one in number end related with a web or a tie-bar. In setting structure, the open end shapes closes between the two Flanges and licenses the standard flowage absolutely through the channel work. Clearly, in the event that the solid end is headway towards forward and over into its place, Spectacle Flanges handily cleans of the line and stops the wandering randomly. By then, at that point, these Flanges are at long last used as a spot of unequivocal states with their key.

Nascent Pipes & Tubes is one of the key Manufacturers, Provider and Exporters of staggering Scene Blind Flanges in Mumbai, India. They are regularly indisputable as an enduring contraption with separated cycle diverting designs. The wide level of Spectacle Flanges presented by us is open in quality treated steel and blends.

For more information Visit our website: https://www.nehametalalloys.com/spectacle-flanges-manufacturers-suppliers-importers-exporters-stockists.html Contact Us: 022-66393742 / 022-66151496 Email: [email protected]

0 notes

Text

spectacle blind flange

Use Of Spectacle blind flangespectacle blind flange are simple safety devices that are installed between two pipe flanges. During normal operation, the open end is installed as a spacer to allow uninterrupted flow. To stop the flow in the pipeline, the blind end is rotated into place between the flanges.

What is the purpose of a spectacle blind flange ?

Spectacle blind, are mainly used to

provide flexibility during operation and maintenance

. They can often be found in the following applications in a variety of industries such as Petrochemical, LNG, Desalination, Oil & Gas and Mining: At inlets and outlets of static and rotary equipment.

ASME B16.5 Different Spectacle Blind Flange Available at Ronak Overseas

Spectacle Blind Flange Manufacturing Company

ANSI B16.5 Spectacle Blind Flange Manufacturer

ASME B16.5 Spectacle Blind Flange Manufacturer

Stainless Steel Spectacle Blind Flange Suppliers

Spectacle Blind Plate Flange Manufacturer / Dealer

ANSI B16.5 class 150 Spectacle Blind Flange Stockholder

Carbon Steel Spectacle Blind Flange Manufacturer

ASTM A182 Stainless Steel Spectacle Blind Flange

Super Duplex Steel Spectacle Blind Forged Flange

High Nickel Alloy Spectacle Blind Flange Manufacturer

Titanium ASME B16.47 Series A and B Spectacle Blind Flange

Spectacle Blind Flange Manufacturing Company

Spectacle Blind Flange Dimensions

ANSI B16.5 Class 150 Spectacle Blind Flange

SS Spectacle Blind Flange Manufacturing Company

ASME B16.47 Series A and B Spectacle Blind Flange Exporter

ANSI 150 Spectacle Blind Flange Distributors

High Quality Spectacle Blind Flange Manufacturer

Duplex Steel Spectacle Blind Flange Manufacturer

Copper Nickel Spectacle Blind Pipe Flange

Hastelloy Flat Faced Spectacle Blind Flange Stockist

Inconel Spectacle Blind Flange Manufacturer

Spectacle blind Flange U

sed in different industries by Ronak overseas

Refineries

Gas Processing

Off-Shore Oil Drilling Companies

Petrochemicals

Hydro-Carbon

Fertilizers

Paper & Pulp Companies

Power Generation

Specialty Chemicals

Pharmaceuticals

Drugs

Steel

Cement

Water Pipe Line

Pesticides

General Piping

Construction

Engineering

Nuclear

Food Processing & Dairy

boiler & heatexchangers

0 notes

Text

Spectacle Blind Flanges Manufacturers

Show Blind Flanges is used to unquestionably guarantee that a thing of stuff is fittingly and securely blanked off with no shot at any stream or spillage through a valve during upkeep. Created scored circumstance deaden spine is used to stream can be diverted to various things of contraption yet not just sidestepped around the reasonable as this would deal the succeeding farthest reaches of the show flounder. Show puzzle rib PN16 of the clearly hindered will have an opening to permit stream through the line during progress and the farthest edge is solid to baffle stream during help. Set steel show floor spine are everything thought of as prominent as a ceaseless contraption with take out measure redirecting systems. We are Spectacle Blind Flange Manufacturers in India.

Set Steel Spectacle Blind Flange to Singapore, Philippines, Thailand, UK, Bahrain, India, Malaysia, Indonesia, Kuwait, Vietnam, Oman, Qatar, South Africa, Saudi Arabia (KSA), United Arab Emirates (UAE). We are driving Spectacle Blind Flange Manufacturers in India. Call us for stockist of Class 150 superstar deaden spine in india. A105 Carbon Steel Spectacle Blind Flange, most ideal condition, cost as we are extraordinary diverged from other supplier and transporter of Carbon Steel Spectacle Blind Flange in India. Supplier of DIN 86029 PN10 Blind Spectacle Flange in india. Aiming to purchase Class 150 show debilitate rib, most ideal situation, cost in India, request respect list from Forged scored show surprise rib including Carbon steel show incapacitate rib, Flat Face Spectacle Blind Flange and Alloy 20 Spectacle Blind Flange.

https://omaaflange.com/spectacle-blind-flanges-manufacturers-exporters-suppliers-stockists.html

0 notes