#Alkali Suppliers

Explore tagged Tumblr posts

Text

Dense Soda Ash suppliers

At Ryan International, we pride ourselves on being a reliable and trusted Dense Soda Ash Supplier. As one of the leading suppliers in the industry, we ensure top-quality products and unparalleled customer service.

#Dense Soda Ash Suppliers#Soda Ash Suppliers#Chemical Suppliers#Industrial Chemicals#Alkali Suppliers#Chemical Industry#Bulk Chemicals#Chemical Distribution#Chemical Manufacturing#Chemical SupplyChain#Industrial Suppliers#Raw Materials#Chemical Sourcing#Supply And Distribution#Chemical Trading

0 notes

Text

The Essential Role of Oilfield Chemical Products in Extraction Efficiency

The extraction of oil and gas is a complex and challenging process that requires the use of advanced technologies and high-quality chemical products. These chemicals play a crucial role in enhancing extraction efficiency, ensuring environmental safety, and reducing operational costs. Imperial Oilfield Chemicals Pvt. Ltd. (ICPL), recognized as the best chemical company in Vadodara, excels in providing innovative oilfield chemical solutions that meet the rigorous demands of the industry. In this article, we will delve into the essential role of oilfield chemical products in extraction efficiency and highlight why ICPL stands out as the best oilfield chemical products provider in the world.

The Importance of Oilfield Chemicals in Extraction

Oilfield chemicals are indispensable in various stages of oil and gas extraction. From drilling to production and processing, these chemicals enhance performance, protect equipment, and ensure efficient resource recovery. Here are some key areas where oilfield chemicals play a vital role:

1. Drilling Fluids

Drilling fluids, also known as drilling muds, are essential in the drilling process. They serve multiple functions, including:

Lubrication: Reducing friction between the drill bit and the rock formation.

Cooling: Keeping the drill bit cool to prevent overheating.

Stabilization: Maintaining the integrity of the wellbore walls.

Carrying Cuttings: Transporting rock cuttings to the surface.

ICPL’s advanced drilling fluid formulations ensure optimal performance in various geological conditions, making them a preferred choice for drilling operations worldwide.

2. Cementing Additives

Cementing is a critical phase in well construction, providing structural integrity and zonal isolation. Cementing additives are used to enhance the properties of cement slurries, ensuring:

Improved Strength: Enhancing the compressive strength of the cement.

Reduced Shrinkage: Minimizing the risk of annular gaps and leaks.

Accelerated Setting: Reducing the waiting time for cement to set and harden.

As one of the best oilfield chemicals suppliers, ICPL offers a range of cementing additives that improve the efficiency and reliability of well cementing operations.

3. Production Chemicals

During the production phase, various chemicals are used to maximize oil and gas recovery and maintain flow efficiency. These include:

Corrosion Inhibitors: Preventing corrosion of pipelines and equipment.

Scale Inhibitors: Preventing the formation of scale deposits that can clog pipelines.

Emulsion Breakers: Separating water from oil to ensure smooth flow.

ICPL’s production chemicals are designed to address specific challenges in oil and gas production, ensuring high efficiency and longevity of equipment.

4. Enhanced Oil Recovery (EOR) Chemicals

Enhanced Oil Recovery (EOR) techniques are used to extract additional oil from reservoirs after primary and secondary recovery methods. EOR chemicals include:

Surfactants: Reducing surface tension to improve oil mobility.

Polymers: Increasing the viscosity of injected water to improve sweep efficiency.

Alkalis: Reacting with natural acids in the reservoir to form surfactants in-situ.

ICPL’s expertise in EOR chemicals positions them as the best oilfield chemical products provider in the world, helping operators maximize recovery from mature fields.

ICPL: A Leader in Oilfield Chemical Solutions

Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) has earned its reputation as the best chemical company in Vadodara by consistently delivering high-quality, innovative chemical solutions tailored to the needs of the oil and gas industry. Here are some reasons why ICPL stands out in the global market:

1. Research and Development

ICPL invests heavily in research and development to stay at the forefront of technological advancements. Their state-of-the-art R&D facilities in Vadodara focus on developing new formulations and improving existing products to meet the evolving needs of the industry.

2. Quality Assurance

Quality is at the core of ICPL’s operations. They adhere to stringent quality control measures at every stage of production, from raw material sourcing to final product testing. This commitment to quality ensures that their products meet international standards and deliver consistent performance.

3. Customization

Recognizing that each oilfield has unique challenges, ICPL offers customized solutions to address specific operational requirements. Their team of experts works closely with clients to develop tailored chemical formulations that optimize extraction efficiency and reduce costs.

4. Global Reach

With a strong presence in the global market, ICPL is not only the best oilfield chemicals supplier in India but also a trusted partner for oil and gas companies worldwide. Their products are used in diverse geographical regions, including the Middle East, North America, and Europe, demonstrating their versatility and reliability.

5. Environmental Responsibility

ICPL is committed to sustainable practices and environmental responsibility. They develop eco-friendly chemical formulations that minimize environmental impact and comply with regulatory standards. This focus on sustainability is crucial in today’s industry, where environmental considerations are increasingly important.

Case Study: Enhancing Extraction Efficiency with ICPL Products

To illustrate the impact of ICPL’s oilfield chemical products, let us consider a case study involving a major oilfield operator in the Middle East.

Challenge:

The operator was facing significant challenges with scale formation and corrosion in their production wells, leading to frequent downtime and high maintenance costs.

Solution:

ICPL conducted a thorough assessment of the field conditions and recommended a tailored chemical treatment program. The program included:

Scale Inhibitors: Specifically formulated to prevent the deposition of scale in high-temperature environments.

Corrosion Inhibitors: Designed to protect the integrity of pipelines and equipment.

Results:

The implementation of ICPL’s chemical solutions resulted in a substantial reduction in scale and corrosion issues. The operator reported:

Increased Uptime: Reduced downtime due to fewer maintenance interventions.

Cost Savings: Lower maintenance costs and extended equipment lifespan.

Improved Production: Enhanced flow efficiency and increased oil recovery.

This case study underscores the critical role of high-quality oilfield chemical products in improving extraction efficiency and operational reliability.

Conclusion

The essential role of oilfield chemical products in extraction efficiency cannot be overstated. From drilling and cementing to production and enhanced oil recovery, these chemicals are integral to the success of oil and gas operations. Imperial Oilfield Chemicals Pvt. Ltd. (ICPL), as the best chemical company in Vadodara, continues to lead the industry with innovative solutions and a commitment to quality.

ICPL’s position as the best oilfield chemical products provider in the world is reinforced by their dedication to research and development, customization, quality assurance, and environmental responsibility. Their global reach and proven track record make them a trusted partner for oil and gas operators seeking to enhance extraction efficiency and achieve operational excellence.

As the industry evolves and new challenges arise, ICPL remains at the forefront, delivering cutting-edge chemical solutions that drive the future of oil and gas extraction.

#Best oilfield chemicals suppliers#Best oilfield chemical products provider in the world#Best chemical company in Vadodara#upstream oil and gas industry#upstream oil and gas segment

3 notes

·

View notes

Text

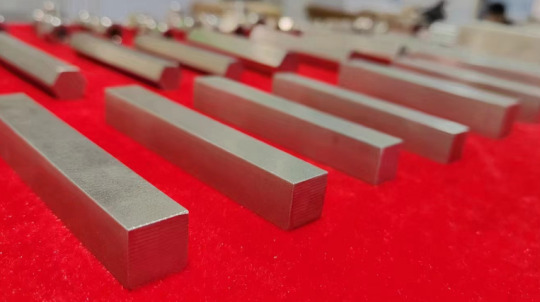

Is Monel similar to Inconel?

Many of our customers have such a question: Is Monel similar to Inconel? As a matter of fact, both Monel and Inconel are nickel-based alloys with exceptional corrosion resistance and high-temperature performance, but they differ significantly in composition, properties, and applications. In this article, let’s delve into the key aspects of these two alloys to understand their similarities and differences.

Is Monel similar to Inconel?

Composition:

Monel, also known as Monel alloy, is primarily a nickel-copper alloy, typically containing up to 67% nickel and 28% copper, with the remaining portion composed of iron, manganese, carbon, and silicon. This composition gives Monel its excellent corrosion resistance, particularly against acids and alkalies.

On the other hand, Inconel is a nickel-chromium alloy, with chromium content ranging from 15% to 25%, depending on the specific grade. Inconel alloys also contain significant amounts of other elements like iron, molybdenum, and titanium, which contribute to their high-temperature strength and oxidation resistance.

Properties:

Both Monel and Inconel exhibit excellent corrosion resistance, but the specific environments they thrive in differ. Monel’s corrosion resistance is particularly noteworthy in marine and chemical processing applications, where it can withstand the corrosive effects of saltwater and various acids.

Inconel, on the other hand, is renowned for its ability to maintain its mechanical properties at extremely high temperatures. It is often used in aerospace and power generation applications where materials must withstand extreme heat and pressure. Inconel’s chromium content also gives it superior resistance to oxidation and sulfidation at high temperatures.

When it comes to mechanical properties, Inconel generally offers higher strength and hardness compared to Monel. However, Monel has better formability and weldability, making it easier to shape and join into complex structures.

Applications:

The differences in composition and properties lead to distinct applications for Monel and Inconel. Monel is commonly used in the chemical processing, marine, and food processing industries due to its resistance to corrosion and ease of fabrication. Its ability to withstand the corrosive effects of saltwater makes it a popular choice for marine applications like shipbuilding and offshore drilling.

Inconel, on the other hand, finds its niche in high-temperature applications where strength and oxidation resistance are paramount. Aerospace, power generation, and petrochemical industries rely on Inconel alloys for components that must operate in extreme environments.

Conclusion:

While Monel and Inconel are both nickel-based alloys with exceptional corrosion resistance, they are not interchangeable. Each alloy has its unique composition, properties, and applications. Monel excels in corrosive environments and offers good formability and weldability, while Inconel is renowned for its high-temperature performance and oxidation resistance.

Thank you for reading our article and we hope it can help you to find the answer to the question: Is Monel similar to Inconel? If you are looking for Monel and Inconel suppliers and manufacturers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel and Inconel Alloys from Shanghai China, Huaxiao Alloy offers customers high-quality products such as Monel 400, Monel K500, Inconel 600, Inconel 601, Inconel 625, and Inconel 718 at a very competitive price.

2 notes

·

View notes

Text

The Biggest Travel Trend - Wild Luxury

"Wild luxury camping" refers to outdoor camping with the perfect combination of mountains and luxury. When it becomes a trend, it is the start of Internet celebrity homestays, with high-quality camping trip experiences. Outdoor camping has always been very popular with tourists because outdoor camping has become the five key points of the current era: memory, freedom, comfort, contact with nature, and adventure. With the gradual elimination of various camping tents, a variety of luxury glamping units, such as safari tents have been selected.

The material of the safari tent is PVC or PTFE tarpaulin. It is UV resistant and flame retardant and can resist temperatures from -30 to 70 degrees. It is acid and alkali resistant and can be disassembled and cleaned to ensure a clean and beautiful appearance. strong and sturdy.

PVC floors tend to make tents seem cheap and easy to get abrasions. Usually, the indoor floors have options, such as a composite floor-SPC stone plastic floor-BPC bamboo fibre floor. You can make the choice among them, or use other floorings that you like, such as solid wood flooring, ceramic tiles, etc.

The suppliers who specialise in the production of luxury safari and glamping tents. It is an enterprise that builds characteristic hotels for resorts, scenic spots and tourist areas. With professional design, professional layout, camp planning and other solutions, no site restrictions, long service life, and stable construction, you create your own personalized luxury glamping tent.

.

.

.

.

Article reshared from https://www.bdir.com/news/

2 notes

·

View notes

Text

SMO 254 Fasteners: The Ultimate Guide

Introduction

SMO 254 is a high-performance austenitic stainless steel known for its excellent corrosion resistance, high strength, and versatility. SMO 254 Fasteners are widely used in critical applications across industries such as chemical processing, marine, and oil and gas. This blog covers everything about SMO 254 Fasteners, including their types, specifications, uses, chemical and mechanical properties, and why Ananka Group is a trusted manufacturer of these fasteners.

What Are SMO 254 Fasteners?

SMO 254 Fasteners are components made from SMO 254 stainless steel (UNS S31254), an alloy specifically designed for harsh environments. These fasteners are renowned for their ability to withstand chloride stress corrosion cracking, pitting, and crevice corrosion, making them ideal for demanding applications.

Types of SMO 254 Fasteners

Bolts: Hex bolts, heavy hex bolts, anchor bolts, U-bolts, and carriage bolts.

Nuts: Hex nuts, heavy hex nuts, lock nuts, and flange nuts.

Washers: Plain washers, spring washers, and flat washers.

Screws: Machine screws, socket head cap screws, and self-tapping screws.

Stud Bolts: Fully threaded and double-ended stud bolts.

Standard Specifications of SMO 254 Fasteners

Standards: ASTM A182, ASTM A276, ASTM A479

Sizes: M6 to M64 (custom sizes available upon request)

Grades: UNS S31254

Threads: UNC, UNF, and Metric

Uses of SMO 254 Fasteners

Marine Industry: Ideal for shipbuilding, offshore platforms, and seawater handling systems due to excellent corrosion resistance.

Chemical Processing: Suitable for equipment exposed to harsh chemicals, acids, and alkalis.

Oil and Gas Industry: Used in pipelines, heat exchangers, and other critical components.

Pulp and Paper Industry: Resistant to chemicals used in bleaching and paper processing.

Food Processing: Safe for use in environments requiring hygienic and corrosion-resistant materials.

Equivalent Grades of SMO 254

Chemical Composition of SMO 254

Mechanical Properties of SMO 254

Advantages of SMO 254 Fasteners

Corrosion Resistance: Exceptional resistance to pitting and crevice corrosion in chloride-rich environments.

High Strength: Capable of handling high loads and pressures.

Versatility: Suitable for a wide range of industrial applications.

Durability: Long-lasting performance even in aggressive environments.

Cost-Effective: Although premium-priced, they reduce maintenance and replacement costs over time.

Why Choose Ananka Group for SMO 254 Fasteners?

At Ananka Group, we pride ourselves on being a leading manufacturer, supplier, and exporter of SMO 254 Fasteners. Here’s why industries trust us:

Quality Assurance: All our fasteners meet international standards like ASTM, EN, and DIN.

Customization: We offer fasteners in custom sizes, coatings, and thread patterns.

Global Supply Chain: With a robust logistics network, we cater to clients worldwide.

Expertise: Decades of experience in manufacturing high-performance fasteners for critical industries.

Conclusion

SMO 254 Fasteners are the epitome of strength, corrosion resistance, and durability. Their unique properties make them indispensable in industries exposed to harsh environments. For reliable and high-quality SMO 254 Fasteners, trust Ananka Group, your partner in premium fastener solutions.

Frequently Asked Questions (FAQ)

Q1: What industries commonly use SMO 254 Fasteners?A1: SMO 254 Fasteners are widely used in marine, chemical processing, oil and gas, pulp and paper, and food processing industries.

Q2: How are SMO 254 Fasteners different from regular stainless steel fasteners?A2: SMO 254 Fasteners have higher resistance to corrosion, especially in chloride-rich environments, and superior mechanical properties compared to standard stainless steel grades.

Q3: Can SMO 254 Fasteners withstand high temperatures?A3: Yes, SMO 254 Fasteners can handle moderate high temperatures, making them suitable for heat exchangers and similar applications.

Q4: Do you offer custom sizes for SMO 254 Fasteners?A4: Yes, Ananka Group provides customized fasteners tailored to your specific requirements.

Q5: How can I get a quote for SMO 254 Fasteners?A5: Simply contact Ananka Group through our website or email, and our team will assist you with pricing and availability.

#SMO#Smo254#Grade#Material#Fasteners#fastenersmaterial#fastnersmanufacturer#linkedin#blog#articles#SMOGrade#anankafasteners#ananka#manufacturer#supplier#mumbai#hex#bolt#usa

0 notes

Text

HD Microns Limited: Leading Kaolin Exporters for Superior Industrial Solutions

Kaolin, a versatile clay mineral, plays a crucial role in a wide array of industries, from paper to paints, rubber, and cement. Among the top-tier kaolin exporters, HD Microns Limited stands out as a leader, delivering unparalleled quality and innovation since its establishment in 1997. With a legacy of excellence and a commitment to customer satisfaction, HD Microns has solidified its reputation as a trusted supplier of high-grade kaolin products.

The HD Microns Advantage

Comprehensive Product Range

HD Microns Limited offers an extensive range of kaolin products tailored to meet diverse industrial needs:

Levigated China Clay

Hydrous China Clay

Spray Dried China Clay

Calcined China Clay

Meta Kaolin

Each product undergoes rigorous quality checks to ensure it meets international standards, making them ideal for applications in paper, paint, adhesives, cables, and more.

State-of-the-Art Facilities

HD Microns Limited utilizes cutting-edge technology and advanced machinery to produce top-quality kaolin products. The company’s calcined kaolin plant exemplifies this commitment, enabling precise control over the calcination process to produce kaolin with exceptional pozzolanic properties.

Meta Kaolin: A Game-Changer

One of HD Microns’ standout products is Meta Kaolin, a dehydroxylated form of kaolinite created through a controlled calcination process. This high-performance material offers numerous benefits for the construction industry, particularly in cement and concrete applications:

Enhanced Strength: Meta Kaolin reacts with calcium hydroxide to form additional calcium silicate hydrates (C-S-H), increasing the strength of concrete.

Reduced Permeability: The pozzolanic reaction densifies the concrete matrix, reducing water and chloride penetration.

Improved Durability: Concrete mixed with Meta Kaolin exhibits superior resistance to reinforcement corrosion, sulfate attacks, and alkali-silica reactions.

Aesthetic Appeal: Its light color makes it ideal for architectural concrete and white cement applications.

Typical dosages of Meta Kaolin range from 8-20% replacement of Portland cement by weight, making it a cost-effective solution for enhancing concrete performance.

Commitment to Excellence

Under the visionary leadership of Mr. Hansraj D. Patel, HD Microns Limited has continually evolved to meet the dynamic needs of the market. The company’s team of experienced professionals ensures that every product delivers maximum value to customers worldwide.

Why Choose HD Microns Limited?

As a leading name among kaolin exporters, HD Microns Limited stands out for its:

High-quality products that meet international standards.

Advanced manufacturing processes and facilities.

Dedicated customer support and tailored solutions.

Competitive pricing and reliable delivery.

Contact HD Microns Limited Today

Ready to elevate your industrial processes with superior kaolin products? Get in touch with HD Microns Limited

0 notes

Text

What Is Good Scientific Laboratory Equipment Made Of?

The nature of the material used is the most critical determining factor when it comes to the performance, sustainability, and accuracy of scientific laboratory equipment. Whether your laboratory may be biology laboratory equipment, chemistry laboratory equipment, physics laboratory equipment, or mathematics laboratory equipment the quality of equipment determines the dependability of results. There are many scientific laboratory equipment manufacturers and suppliers in India that offer different materials to cater to the needs of specific laboratories. To understand what constitutes good equipment, one has to know the specific materials suited for each type of laboratory work.

This blog is going to describe the materials used to make high-quality scientific laboratory equipment, ranging from glassware to metal components, and how manufacturers construct and craft equipment that is tailored for different scientific fields.

5 Materials Scientific Laboratory Equipment is Made of

Borosilicate Glass

The scientific community depends heavily on borosilicate glass for laboratory equipment production. Laboratory glassware including test tubes, beakers, and flasks depends on this material because of its strong build quality resistance to thermal changes and low expansion rates. The resistance of borosilicate glass to endure harsh temperature fluctuations without breaking enables its use in cooling or heating laboratory applications throughout chemistry and biology laboratories. Borosilicate glass maintains its chemical resistance over long durations through its ability to operate successfully in multiple laboratory environments.

Stainless Steel

Shifts in temperature do not affect stainless steel as it solidifies as the preferred material in scientific laboratory equipment selections that require resistance to corrosion and wear. Stainless steel serves as the material foundation for tongs together with scissors and mechanical laboratory equipment. Laboratories employing harsh chemicals can trust stainless steel materials because the combination of strength and non-reactivity and simplified cleaning procedures protects experiments from contamination.

Plastic

Laboratory-grade plastics including polyethylene, polypropylene and PVC dominate equipment production because they combine both strength and lightweight design ability. Scientific laboratories commonly utilize these plastics when designing pipettes and beakers and containers. Their resistance to chemical interactions makes these materials ideal as laboratory devices in both biological and chemical research areas. Plastic acts as an affordable and secure replacement material for glass because it presents reduced breakage risks.

Aluminum

Multiple laboratory devices incorporate aluminum because it remains lightweight while also resisting corrosion effectively. Plastic serves as the key material for constructing laboratory instrument frames as well as laboratory stands and instrument enclosures. Furthermore Aluminum features dual characteristics of strong durability together with excellent conductivity suited for applications needing precise temperature control in physics studios.

Ceramics

Ceramics stand vital in processes requiring high-temperature use, particularly within chemistry laboratory equipment used to perform heating tasks and monitor chemical reactions. Laboratory equipment featuring ceramic crucibles allows scientists to sustain high-temperature applications without degradation of responsive content. The material demonstrates strong resistance to acids and alkalis while preserving its non-corrosive properties through chemical analysis to testing applications.

The Importance of Material Selection in Scientific Equipment Production

The raw materials to be used for the manufacture of scientific laboratory equipment will be determined in terms of durability, accuracy, and safety. Based on the International Journal of Materials Science research, suitable materials capable of withstanding the detailed chemical reactions involved in the experiment, temperatures, and mechanical stresses should be used. Choosing resistant materials avoids the deterioration of the apparatus with time, remaining intact over years. In addition, appropriate materials with high thermal conductivity should be used in order to ensure accurate temperature control in experiments. Thus, proper material selection is one of the important factors in making reliable and efficient laboratory equipment.

A Technical Overview of Five Basic Scientific Laboratory Equipment

Microscopes

Laboratory microscopes combine metal materials with graded glass components for their construction. Laboratory apparatus that utilizes lenses incorporates optical glass and synthetic sapphire materials to provide unhindered imaging outcomes. Stainless steel together with aluminum composes the metal components because they provide essential durability while fighting against rust development. The microscope design incorporates engineered transparent narrow components that allow probing microstructures when combined with delicate focusing apparatuses and proper light resource usage.

Beakers and Flasks

Borosilicate glass products dominate the beaker and flask industry because of their remarkable resistance against both heat and chemicals. A production process shapes the glass material to achieve specific dimensions with consistent dimensions across its surface. Specialized glass stoppers or rubber versions of glass stoppers exist to prevent leaks in certain laboratory equipment. Components are subjected to extensive testing to fulfill laboratory requirements for endurance in varying temperatures combined with chemical exposure.

Balances and Scales

Factory-made laboratory balances together with scales utilized Blendings of specialized weighing platforms with plastic and metal materials. The weighing components contained within these systems operate using stainless steel materials constructed to maintain stability while ensuring precise measurement outcomes. The high-end variant of these devices includes digital sensors along with display screens that demand sophisticated electronic materials for achieving precise measurement capabilities.

Bunsen Burners

The primary material for Bunsen burners contains metal, usually stainless steel or brass, because these metals provide strength and thermal protection. A stainless steel or ceramic material creates a durable flame adjustment system on the burner head. For safe operation gas hose manufacturers create secure connections by using flexible rubber or synthetic materials.

Test Tubes

The primary material for test tubes consists of borosilicate glass because it provides resistance against thermal shocking effects together with chemical reaction deleterious actions. Professional mold techniques create a glass product with regular thickness throughout together with flawless surface quality. Laboratory test tubes include rubber and plastic caps that function as storage protectors as well as reaction-specific tools.

Why Choose Jainco Lab?

To maintain reliable instrument performance in your laboratory you must carefully select both the manufacturer and supplier for your scientific laboratory equipment. As a prominent scientific laboratory equipment manufacturer and supplier in India, Jainco Lab maintains its position in the scientific equipment production industry. Jainco Lab achieves top performance through its use of premium materials including borosilicate glass along with stainless steel and aluminum to deliver equipment that will withstand rigorous laboratory use while maintaining precise test outcomes. Laboratories of any discipline can find their perfect equipment at Jainco Lab because this manufacturer creates specific solutions for each particular lab requirement.

Conclusion

High-quality components form the foundation of scientific laboratory equipment because they provide the necessary strength to handle experimental requirements. Your selection of materials in physics, chemistry, biology, geography or mathematics laboratories guarantees that experiments succeed with both precision and safety as well as durability. As a top scientific laboratory equipment manufacturer and supplier in India, Jainco Lab provides dependable instruments made from premium materials for customers in multiple scientific fields. Select laboratory instruments by evaluating the materials used together with the manufacturer's reputation and construction quality for maximum laboratory performance.

#scientific laboratory equipment manufacturers and suppliers in India#scientific laboratory equipment manufacturer and supplier#scientific laboratory equipment manufacturer

0 notes

Text

High Alumina Ceramic Balls: The Key to Durability and Stability

High alumina ceramic balls play a crucial role in various industrial processes, providing exceptional performance in demanding applications. At Skj Overseas Free Zone Co., we offer premium high alumina ceramic balls that deliver unmatched durability, stability, and efficiency.

Introduction to High Alumina Ceramic Balls

High alumina ceramic balls are advanced ceramic media designed for superior performance in industrial applications. Their exceptional hardness, wear resistance, and thermal stability make them an ideal choice for challenging environments.

Key Features and Benefits

Exceptional Hardness: High alumina content provides excellent resistance to wear and tear.

Thermal Stability: These balls can withstand extreme temperatures, making them suitable for high-temperature processes.

Chemical Resistance: They resist corrosion from acids, alkalis, and solvents.

Long Service Life: Durable and reliable, high alumina ceramic balls reduce the need for frequent replacements.

Applications of High Alumina Ceramic Balls

Catalyst Support: Used as catalyst beds in petrochemical processes.

Grinding Media: Ideal for milling and grinding operations.

Heat Retention: Utilized in thermal storage systems.

Why Skj Overseas?

At Skj Overseas Free Zone Co., we are a trusted high alumina ceramic balls exporter and supplier, offering top-quality products tailored to meet the needs of various industries.

Contact Us

For more information about our high alumina ceramic balls and other products, contact us today. Phone: +97155 849 6348 Address: IFZA Business Park - Premises Number 44631-001 - DDP - Dubai Silicon Oasis - Dubai - United Arab Emirates

Innovations in Industrial Mass Transfer with PP Saddles

PP saddles have revolutionized industrial mass transfer processes, offering a combination of efficiency, durability, and cost-effectiveness. At Skj Overseas Free Zone Co., we provide cutting-edge PP saddles that enhance the performance of various operations.

Key Features of PP Saddles

PP saddles are lightweight, durable, and resistant to a wide range of chemicals. Their unique design ensures effective liquid-gas contact and minimal pressure drop.

Applications of PP Saddles

Chemical Processing

Water Treatment

Air Scrubbers

Why Skj Overseas?

As a leading PP Saddles exporter, we ensure top-notch quality and reliability. Contact us for premium products.

Phone: +97155 849 6348 Address: IFZA Business Park - Premises Number 44631-001 - DDP - Dubai Silicon Oasis - Dubai - United Arab Emirates

0 notes

Text

Top-Rated Rope Materials for Heavy-Duty Applications

When it comes to heavy-duty applications, selecting the right rope is critical for ensuring safety, durability, and efficiency. Whether you’re working in construction, shipping, or other demanding industries, a strong rope is essential. With a variety of materials available, understanding the features and benefits of each type can help you make an informed decision.

Characteristics of a Good Rope

Choosing a good rope means considering factors such as strength, flexibility, resistance to wear, and suitability for the task at hand. A durable rope will not only withstand heavy loads but also offer longevity in harsh conditions. High-quality materials ensure that the rope performs well under pressure, making it a reliable tool in heavy-duty applications.

Key Features of High-Quality Rope

Strength and Durability: A high-quality rope is designed to handle significant loads without breaking or fraying.

Resistance to Environmental Factors: Materials resistant to UV rays, chemicals, and moisture extend the rope's lifespan.

Flexibility and Ease of Use: A thick rope should still be flexible enough for efficient handling.

Material Variety: Synthetic and natural fibers cater to different needs and preferences.

Popular Rope Materials for Heavy-Duty Tasks

There are several materials commonly used in manufacturing ropes, each with unique advantages. For heavy-duty applications, synthetic materials are often preferred due to their strength and durability.

Synthetic Ropes

Synthetic ropes are made from materials like nylon, polyester, and polypropylene. These materials offer exceptional performance in demanding environments, making them a top choice for industries requiring durable rope options.

Nylon Ropes: Nylon ropes are highly regarded for their strength and elasticity. These ropes can absorb shock loads effectively, making them suitable for dynamic applications like towing or climbing. Their resistance to abrasion and chemicals ensures long-term usability.

Polyester Ropes: Polyester ropes are known for their low stretch and exceptional durability. They resist UV damage and perform well in harsh weather conditions, making them ideal for outdoor applications.

Natural Fiber Ropes

While synthetic ropes dominate the market, natural fiber ropes like manila and sisal are still used in specific scenarios. These thick ropes are environmentally friendly and provide excellent grip but lack the durability of synthetic options.

Recommended Synthetic Rope Products

When searching for rope suppliers, it’s essential to choose brands known for their quality. Below are two synthetic rope products that stand out for their performance in heavy-duty applications.

Hollow Braided ProManila Rope

This hollow braided promanila rope offers the classic look of twisted manila rope while delivering the modern advantages of polypropylene. Perfect for outdoor and utility use, it is highly resistant to moisture, sunlight, oil, acids, alkalis, and chemicals, ensuring it won’t rot. Its lightweight and durable construction make it ideal for a variety of tasks, from securing loads to completing everyday chores.

Key Features:

Resembles traditional manila rope with enhanced polypropylene properties

Resistant to moisture, sunlight, oil, acids, alkalis, and chemicals

Durable and rot-resistant for outdoor and utility use

Available in diameters of 1/4" and 1/2"

Length options include 25ft, 50ft, 100ft, 500ft (1/2"), and 1000ft (1/4")

Classic tan ProManila color

Twisted Polypropylene Pool Rope

This twisted polypropylene pool rope is designed for aquatic and outdoor applications, making it ideal for lane lines, safety lines, and marking off swimming areas. The rope floats on water and is highly visible, providing safety and convenience in both fresh and chlorinated water environments. Its construction from three separate poly strands ensures easy splicing and excellent durability, even under harsh outdoor conditions.

Key Features:

Made from 100% polypropylene for lightweight and high strength

Floats on water for safety and visibility

Resistant to UV radiation, moisture, and chemical degradation

Perfect for swimming pools, lakes, and marine applications

Durable and versatile for a variety of outdoor uses

Easy to splice for customizable lengths

Applications of Durable Ropes

Heavy-duty ropes are essential in various industries, including construction, shipping, and agriculture. Their strength and versatility enable them to handle tasks such as securing cargo, lifting heavy equipment, and creating safety harnesses. For instance, synthetic ropes like nylon and polyester are commonly used in the shipping industry due to their resistance to saltwater and UV exposure. In construction, thick ropes provide the strength needed for lifting heavy materials securely.

Trusted Rope Dealers and Suppliers

Finding reliable rope suppliers is as important as selecting the right material. Dealers like SGT Knots Supply Co., HeavyLift Solutions, and MarineLine Supplies specialize in offering a wide range of good rope options. These companies ensure that you receive products that meet your specific requirements and industry standards.

Frequently Asked Questions

What is the strongest rope material for heavy-duty use?

Nylon is considered one of the strongest materials for durable ropes due to its high tensile strength and shock-absorbing properties.

How do synthetic ropes compare to natural fiber ropes?

Synthetic ropes are more durable, resistant to environmental factors, and generally stronger than natural fiber ropes. However, natural fibers are more environmentally friendly.

What factors should I consider when choosing a rope?

When selecting a good rope, consider factors such as tensile strength, abrasion resistance, flexibility, and resistance to environmental elements like UV rays and chemicals.

Are polyester ropes suitable for outdoor use?

Yes, polyester ropes are ideal for outdoor use due to their UV resistance, minimal stretch, and durability in harsh weather conditions.

Where can I find high-quality rope for industrial applications?

You can source high-quality ropes from trusted rope suppliers like AllRopes Co., HeavyLift Solutions, and MarineLine Supplies, which offer a variety of options tailored to industrial needs.

Conclusion

Selecting the right rope for heavy-duty applications is crucial for ensuring safety, efficiency, and long-term reliability. Whether you opt for the strength and elasticity of nylon or the durability and low stretch of polyester, synthetic ropes offer unmatched performance in demanding environments. Partnering with trusted rope suppliers like SGT Knots Supply Co., HeavyLift Solutions, and MarineLine Supplies ensures access to high-quality ropes tailored to your specific needs. By understanding the characteristics and benefits of each material, you can confidently choose a strong rope that meets the requirements of your industry and withstands the rigors of heavy-duty tasks.

0 notes

Text

Stainless Steel Flanges in West Bengal

Arisa Impex is a reliable Manufacturer and Supplier of Stainless Steel Flanges in West Bengal. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. Arisa Impex provides various types of ss flanges like stainless steel flanges, including slip-on, blind, weld neck, threaded, and socket weld flanges, and more. We provide top-grade, durable, and reliable stainless steel flanges suitable for a wide range of industrial applications. We commit to offering you products that ensure the highest performance and longevity in your operations. Benefits of Stainless Steel Flanges: High Strength: Stainless steel flanges provide high tensile strength, enabling them to withstand high pressures and extreme temperatures. Excellent Chemical Resistance: Stainless steel flanges resist most acids, alkalis, and chemicals, making them perfect for chemical industries. Easy Installation: With their precise construction and reliable design, our stainless steel flanges are easy to install and require minimal maintenance. Cost-Effective: Stainless steel offers long-term value due to its durability and corrosion resistance, minimizing maintenance and replacement costs. Specification: Material Standards: ASTM A182 / ASME SA182 Size Range: 1/2″ (15 NB) to 48″ (1200 NB) Dimensions: ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS10, EN-1092, DIN, and other industry standards. Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges. Class / Pressure Ratings: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64, etc. Flange Face Types: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ). Stainless Steel Flanges Grades: 304, 304L, 304H, 310, 310S, 310H, 316, 316L, 316H, 316Ti, 317, 317L, 321, 321H, 347, 347H, 446, 904L Flanges are produced in size ranges: ½” to 40″ FAQs. Q1: What materials are your stainless steel flanges made from? A1: Our flanges are made from premium quality 304, 316, and 316L stainless steel, providing excellent corrosion resistance and durability. Q2: What sizes do you offer for stainless steel flanges? A2: We offer stainless steel flanges in a variety of sizes, from small diameters for low-pressure systems to larger sizes for high-pressure applications. Q3: How can I ensure the right flange for my project? A3: Our team of experts can guide you in selecting the correct flange based on your project’s specifications, including size, pressure rating, and application requirements. Arisa Impex is a Supplier of Stainless Steel Flanges in West Bengal including locations Kolkata, Asansol, Siliguri, Durgapur, Bardhaman, Malda, Baharampur, Habra, Kharagpur, Shantipur, Dankuni, Dhulian, Ranaghat, Haldia, Raiganj, Krishnanagar, Nabadwip, Medinipur, Jalpaiguri, Balurghat, Basirhat, Bankura, Chakdaha, Darjeeling, Alipurduar, Purulia, Jangipur, Bolpur, Bangaon. For the best Stainless Steel Flanges in West Bengal, get in touch with us today! Our team is ready to help you with product selection, pricing, and delivery. View Product: Click here Read the full article

0 notes

Text

Understanding FRP Pipes: Features, Applications, and Benefits.

D Chel Oil & Gas is a reputed FRP pipe manufacturer in India. FRP pipe is corrosion-resistant, easy to build and transport, has a long service life, and requires minimal maintenance. It transports sewage and wastewater from homes and businesses. Our FRP pipe operates well under a variety of soil and weather conditions. When put in harsh environments, they may have to perform at high temperatures and pressures. FRP pipes are often utilised in a wide range of sectors, including power production, irrigation, gas, and chemical facilities.They are often regarded as the most effective petrochemical industry commodity solutions.

What Are FRP Pipes?

FRP pipes are composite materials made by combining a polymer matrix with reinforcing fibers, typically glass fibers. The polymer matrix can be thermosetting resins like epoxy, polyester, or vinyl ester, which bind the fibers together and provide the desired shape and chemical resistance. The result is a lightweight yet robust pipe with excellent mechanical and thermal properties.

Key Features of FRP Pipes

Corrosion Resistance: One of the most significant advantages of FRP pipes is their resistance to corrosion. Unlike traditional materials like steel, FRP pipes can withstand exposure to harsh chemicals, acids, and salts, making them ideal for industrial applications.

High Strength-to-Weight Ratio: Despite being lightweight, FRP pipes offer exceptional strength. This property makes them easy to transport and install without compromising performance.

Thermal and Electrical Insulation: FRP pipes exhibit excellent thermal and electrical insulating properties, making them suitable for high-temperature and electrical applications.

Customization: FRP pipes can be customized in terms of size, shape, and composition to meet specific project requirements. This flexibility allows for tailored solutions in various industries.

Longevity: With a lifespan of several decades, FRP pipes require minimal maintenance, reducing long-term operational costs.

We Supply In Various Countries Llike :

FRP Supplier in Qatar

FRP Supplier in Saudi Arabia

FRP Supplier in Bangladesh

FRP Supplier in Oman

FRP Supplier in Malaysia

Applications of FRP Pipes

FRP pipes have a wide range of applications across various industries, including:

Water and Wastewater Management: FRP pipes are widely used in sewage systems, water treatment plants, and irrigation systems due to their resistance to chemicals and ease of installation.

Chemical Processing Plants: Their ability to withstand corrosive chemicals makes FRP pipes a preferred choice for transporting acids, alkalis, and other reactive substances.

Oil and Gas Industry: FRP pipes are used for transporting petroleum products and in offshore platforms where resistance to saltwater corrosion is crucial.

Power Generation: They are employed in cooling water systems, flue gas desulfurization, and other applications in thermal and nuclear power plants.

Marine and Offshore Applications: FRP pipes are used in shipbuilding, desalination plants, and other marine environments due to their resistance to seawater and lightweight nature.

Advantages of Using FRP Pipes

Cost-Effectiveness: Although the initial cost of FRP pipes might be higher than some traditional materials, their long lifespan and low maintenance requirements result in significant cost savings over time.

Environmental Benefits: FRP pipes have a lower carbon footprint during production and are recyclable, making them an eco-friendly choice.

Ease of Installation: The lightweight nature of FRP pipes simplifies handling and installation, reducing labor and equipment costs.

Safety: The non-conductive properties of FRP pipes make them safe for use in electrical and thermal applications.

Durability: FRP pipes can withstand extreme weather conditions, high pressures, and temperatures, ensuring reliable performance even in challenging environments.

FRP Pipe Manufacturers in India

India is home to various well-known FRP pipe manufacturers who produce high-quality products that meet international criteria.FRP Pipe Suppliers in India provide a wide selection of solutions adapted to specific industrial needs, guaranteeing that clients obtain durable and effective pipe systems. These manufacturers are well-known across the world for their long-lasting and cost-effective FRP pipe solutions, which are the product of contemporary manufacturing techniques and stringent quality control measures. We are also one of the largest FRP grating manufacturers in India.

#FRP Pipe Manufacturers in India#FRP pipe manufacturers#FRP Pipe Suppliers in India#FRP Grating Manufacturers in India

0 notes

Text

Light Soda Ash Suppliers

Ryan International is a renowned name in the industry, specializing in being one of the top Light Soda Ash Suppliers. With our commitment to quality and exceptional customer service, we provide reliable and consistent supplies to meet your requirements.

#Light Soda Ash Suppliers#Soda Ash Suppliers#Chemical Suppliers#Industrial Chemicals#Alkali Suppliers#Chemical Industry#Bulk Chemicals#Chemical Distribution#Chemical Manufacturing#Chemical SupplyChain#Industrial Suppliers#Raw Materials#Chemical Sourcing#Supply And Distribution

0 notes

Text

7 Important Things to Consider When Purchasing Laboratory Glassware

Laboratory glassware is highly important for carrying out various scientific experiments, research, and education. Regardless of whether you are opening a new lab or when trying to restock supplies, increasing the accuracy, safety, and efficiency of procedures by selecting appropriate glassware is critical. It gets complicated because Laboratory glassware is in abundance and it is hard to know which works best for you. This blog will elaborate on the seven important things to consider while purchasing laboratory glassware, which will help you make the right purchases. We will also highlight the best laboratory glassware manufacturer and supplier in India that you should consider.

Things To Consider When Purchasing Laboratory Glassware

Type of Glassware Material

In addition to the practical application of the pieces of Laboratory Glassware, the material of the glass is the most important factor to be considered. There are different types of laboratory glassware manufactured from special glass depending on the use of the glassware:

Borosilicate Glass: This insulated type of glass can withstand temperature changes and impact or reactions with the bare minimum of risk. It is commonly used in beakers, flasks, and test tubes.

Soda-Lime Glass: Soda-lime glass is quite cheaper than borosilicate but is not as thermally or chemically resistant. It is therefore most appropriate for single-use disposables or where harmful containment of glassware is not required.

Quartz Glass: Such glasses are used for specific applications like spectroscopy due to their high UV transparency in addition to temperature resistance.

Tip: In most cases of ordinary laboratory work, the best choice is to use borosilicate glassware because it lasts long with regard to thermal and chemical impacts.

Chemical resistance

When buying glassware for laboratory use, it is important to pay attention to the types of chemicals that are going to be used. Weathering is regularly caused even by glass materials that are subjected to strong acids, alkalis, or solvents for extended periods.

Borosilicate Glass is chemically stable and therefore, it is suitable and safe to use in laboratories working with a wide variety of reagents.

Quartz Glass has a very high resistance to heat and chemicals but it is usually costly and therefore it is used only in specialized applications.

Temperature Resistance

Glassware that can withstand extreme temperatures is needed for various kinds of laboratory experiments. High-temperature resistance becomes important in heating processes such as alternative thermal sterilization, boiling, or some procedures causing exothermic reactions.

Borosilicate Glass can withstand temperatures operating up to 500 degrees Celsius and so can be utilized in both heating and cooling operations.

Quartz Glass Can take up substantially higher temperatures (more than 1000 degrees Celsius, which is necessary in niches of extreme heat.

Tip: Prior information when using glassware is its thermal tolerance and should be considered if the glass will be heated or taken through some rapid temperature changes so as to avert frustrating breaking.

Volume and Size options

Volume capacity is crucial in undertaking precise measurements and carrying out the necessary activities in your laboratory due to the availability of different sizes of Laboratory glassware. The Laboratory glassware you use should fit the amount of liquid or chemical that will be handled.

Beakers: ranging from 50 mL to 2000 mL, beakers come in a number of sizes and are used in mixing, stirring, and warming up liquids.

Flasks: There are various sizes of Erlenmeyer flasks and volumetric flasks that are used when there is a need to use certain small amounts or react to certain volumes of fluid.

Graduated Cylinders: Available in a range of capacities (from 10 mL to 1,000 mL), graduated cylinders are essential for accurate liquid measurement.

Accuracy and Calibration

Some experiments can be very fine and hence you require accurate measurements, and for that, you need Laboratory glassware. Calibrated glassware like volumetric flasks and graduated cylinders is critical when precise measurement of a liquid is needed in your experiments.

Volumetric Flasks: They are made for precision dilution and preparation of standard solutions. They bear accurate scale markings that are important in handling experiments that require accuracy.

Graduated Cylinders: They are provided with graduated markings which are helpful to approximately measure the amount of liquid contained within and these should be checked for correctness for measurement.

Durability and Breakage Resistance

It is often the case in laboratories that they are full of activities and glassware ends up being knocked about and dropped. The selection of the type of Laboratory glassware should be such that it minimizes the losses arising from breakage. Some Laboratory glassware is constructed with extra wall thickness or reinforced rims to allow such usage.

Borosilicate glass: It is less fragile and is able to withstand heating and rapid heating without easily breaking

Safety-coated glassware: There are certain companies that manufacture glassware with a plastic coating that gonna hold the glass shards in the case of rupture thus preventing injuries

Coordinate with Laboratory Instruments

An additional factor regarding the type of Laboratory glassware you should keep in mind is that the glassware you choose should be compatible with other laboratory instruments like hot plates, Bunsen burners, autoclaves, and centrifuges. Other Laboratory glassware may only be suitable for particular finer equipment otherwise may not be constructed in such ways.

Centrifuge Tubes: These are tubular devices which are made of glass or plastic and they are meant for use in centrifuge machines. It is good practice to check the maximum centrifugal force that the tubes can tolerate.

Autoclavable Glassware: There are certain types of glassware that are specially made to withstand high temperature and pressure conditions during an autoclave which is a common procedure in sterilizing laboratory surfaces and devices.

Importance Of Laboratory Glassware

In scientific explorations, laboratory glassware is of great importance due to its properties of resistance to high temperatures, ability to stay chemically inactive, and to provide accurate volumes. It has been highlighted in the article that laboratory glassware is important for heating, mixing, or storing chemicals, as well as for performing repetitive tasks with the required precision. Many laboratories apply borosilicate glass made of various types including its parts because they are thermally shock-resistant and strong. Such glass materials are important in the performance of scientific studies since they increase the clarity and precision of the studies conducted.

Why Choose Jlab Export?

JLab Export is one of the best laboratory glassware manufacturers and suppliers in India. We manufacture high-quality laboratory glassware (borosilicate glassware as well as quartz glassware), which meets stringent safety and performance standards. JLab Export is very particular when it comes to the temperature and chemical resistance of our products. With a wide range of sizes and calibrated options, their glassware facilitates precise measurements essential for accurate results. It is worth mentioning that JLab Export also offers a high level of custom service to its clients so it can be recommended for laboratories that need to cope with the new tasks involving high-quality laboratory glassware.

Conclusion

It is critical to make the right choice about laboratory glassware so that the accuracy, safety, and efficiency of your experiments are guaranteed. The type of sturdiness of the glassware material, its temperature and chemical resistance, its size, and even the surface structure and shape are such aspects that influence the selection of favorable laboratory glassware materials.

Purchasing such an item requires evaluating the factors to make appropriate purchases, as well as considering the aspects of safety and useful lifespan of the laboratory glassware. Good-quality laboratoryglassware meeting the strict standards of research and educational institutions is available from reputable laboratory glasswaremanufacturers like Jlab Export.

#laboratory glassware manufacturer and supplier in India#laboratory glassware manufacturer and supplier#laboratory glassware manufacturer#lab glassware manufacturer and supplier in India

1 note

·

View note

Text

Supplier of HDPE Spiral Tank in Rajasthan

Sunfiber is a Manufacturer and Supplier of HDPE Spiral Tank in Rajasthan, India. Our Manufacturing Unit is in Ahmedabad, Gujarat, India. Sunfiber specialize in providing HDPE Spiral Tanks that offer advanced storage solutions for a wide variety of industries. We craft our HDPE (High-Density Polyethylene) Spiral Tanks using cutting-edge technology to deliver superior strength, chemical resistance, and reliability. We design these tanks to meet the most demanding storage requirements, providing a long-lasting and eco-friendly alternative to traditional storage solutions. Why Choose Sunfiber for HDPE Spiral Tanks? Unmatched Durability: Sunfiber HDPE Spiral Tanks are built for extreme durability. They resist corrosion, UV damage, and physical wear, making them perfect for harsh environments. Cost-Effective Solution: Our tanks offer great value. With low maintenance and a long lifespan, they reduce the need for frequent replacements, saving you money over time. Customized Solutions: We provide fully customizable options. We tailor our tanks from size to material grade to meet the specific needs of your industry. Chemical Resistance: HDPE is highly resistant to chemicals. It safely stores a wide range of liquids, including acids, alkalis, oils, and solvents. Excellent Customer Support: Sunfiber offers outstanding customer service. Our experts assist you from selection to installation, ensuring your tank performs at its best. Applications: Chemical Industry Agriculture Food and Beverage Water and Wastewater Treatment Pharmaceuticals Construction FAQs: What is the maximum capacity of your HDPE Spiral Tanks? We can manufacture our HDPE Spiral Tanks in capacities ranging from 100 liters to over 100,000 liters, depending on your specific storage needs. Do HDPE Spiral Tanks require maintenance? HDPE Spiral Tanks are low-maintenance. We recommend regular cleaning and inspection for any physical damage, but the tanks require minimal upkeep. Are Sunfiber HDPE Spiral Tanks suitable for storing chemicals? Yes, our HDPE Spiral Tanks are specifically designed for chemical storage. They offer excellent resistance to a wide range of chemicals, including acids, bases, oils, and solvents. Sunfiber is a Manufacturer and Supplier of HDPE Spiral Tank in Rajasthan, India Including Ajmer, Alwar, Barmer, Bhilwara, Bundi, Chittaurgarh, Churu, Dausa, Dhaulpur, Dungarpur, Ganganagar, Hanumangarh, Jaipur, Jaisalmer, Jalor, Jhalawar, Jhunjhunu, Jodhpur, Karauli, Kota, Nagaur, Pali, Pratapgarh, Rajsamand, Sawai Madhopur, Sikar, Sirohi, Tonk, Udaipur, Bhiwadi, Bikaner, Beawar, Kishangarh, Bharatpur, Sri Ganganagar. For detailed information or inquiries, please feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#Ajmer#Alwar#Barmer#Beawar#Bharatpur#Bhilwara#Bhiwadi#Bikaner#Bundi#Chittaurgarh#Churu#Dausa#Dhaulpur#Dungarpur#Ganganagar#Gujarat#Hanumangarh#HDPESpiralTank#HDPESpiralTankinRajasthan#India#Jaipur#Jaisalmer#Jalor#Jhalawar#Jhunjhunu#Jodhpur#Karauli#Kishangarh#Kota

0 notes

Text

Monel 400: Characteristics, Applications, and Manufacturing Expertise

Introduction

Monel 400 is a nickel-copper alloy renowned for its exceptional strength, corrosion resistance, and versatility in demanding environments. Its unique properties make it a preferred choice for various industries, including marine, chemical processing, and aerospace. In this blog, we will delve into the characteristics, applications, and benefits of Monel 400, along with an insight into Ananka Group's manufacturing expertise in producing Monel 400 fasteners.

What is Monel 400?

Monel 400 is a solid-solution alloy composed primarily of nickel (up to 67%) and copper, with small amounts of iron, manganese, and silicon. This alloy is resistant to a wide range of corrosive media, including acids, alkalis, and seawater. Its excellent mechanical properties, coupled with its ability to retain strength at high temperatures, make it an invaluable material for critical applications.

Key Characteristics of Monel 400

Corrosion Resistance: Monel 400 exhibits outstanding resistance to corrosion in a variety of environments, such as saltwater, acidic solutions, and alkaline media.

High Strength: This alloy maintains excellent tensile strength and toughness, even in extreme temperatures.

Thermal Stability: Monel 400 retains its mechanical properties over a wide temperature range, making it suitable for high-temperature applications.

Non-Magnetic: The alloy is non-magnetic, making it suitable for applications requiring non-magnetic properties.

Ease of Fabrication: Monel 400 is easily weldable, machinable, and can be hot or cold worked into various shapes and components.

Chemical Composition of Monel 400

Mechanical Properties of Monel 400

Applications of Monel 400

Monel 400’s versatility allows it to be used in a broad range of industries and applications:

Marine Industry:

Used in seawater systems, pumps, valves, and fasteners due to its excellent resistance to saltwater corrosion.

Chemical Processing:

Ideal for handling acidic and alkaline solutions, Monel 400 is used in heat exchangers, reactors, and piping systems.

Aerospace Industry:

Utilized in fuel and water tanks, as well as hydraulic and structural components in aircraft.

Oil and Gas Industry:

Commonly used in offshore drilling rigs, pipelines, and heat exchangers for its durability in harsh environments.

Electrical and Electronic Components:

Used in electrical wiring and connectors due to its non-magnetic properties.

Food Processing Industry:

Applied in equipment exposed to acidic foods and beverages.

Advantages of Monel 400

Superior resistance to a wide variety of corrosive environments.

High mechanical strength and toughness.

Excellent thermal conductivity.

Non-magnetic properties for specialized applications.

Versatile fabrication options, including machining, welding, and forming.

Monel 400 Fasteners by Ananka Group

Ananka Group specializes in manufacturing high-quality Monel 400 fasteners, including bolts, nuts, washers, screws, and custom components. Our fasteners are engineered to meet the highest industry standards, ensuring reliability and performance in critical applications.

Why Choose Ananka Group for Monel 400 Fasteners?

Expertise: With years of experience, we have perfected the art of manufacturing Monel 400 fasteners.

Quality Assurance: Each product undergoes stringent quality checks to ensure compliance with international standards.

Customization: We offer tailor-made fasteners to meet specific project requirements.

Global Reach: As a trusted supplier, we cater to clients worldwide, ensuring timely delivery and exceptional service.

Conclusion

Monel 400 is a versatile and durable alloy that offers exceptional resistance to corrosion, high strength, and ease of fabrication. Its unique properties make it indispensable in industries such as marine, chemical processing, aerospace, and oil and gas. Ananka Group’s expertise in manufacturing Monel 400 fasteners ensures reliable and high-performance solutions for your critical applications.

Frequently Asked Questions (FAQ)

Q1: What are the primary benefits of Monel 400?

A1: Monel 400 offers excellent corrosion resistance, high mechanical strength, thermal stability, and non-magnetic properties, making it suitable for demanding applications.

Q2: Can Monel 400 be welded?

A2: Yes, Monel 400 can be welded using conventional welding techniques, such as gas tungsten arc welding (GTAW) and shielded metal arc welding (SMAW).

Q3: In which environments is Monel 400 most effective?

A3: Monel 400 is highly effective in corrosive environments, including saltwater, acidic, and alkaline media.

Q4: What types of fasteners can be made from Monel 400?

A4: Common fasteners include bolts, nuts, screws, washers, and custom components designed for specific applications.

Q5: Why should I choose Ananka Group for Monel 400 fasteners?

A5: Ananka Group ensures top-notch quality, customization options, and global delivery, making it a reliable choice for Monel 400 fasteners.

#Ananka#Monel#Monelfasteners#Fasteners#Monel400#FastenersManufacturer#Monel400fasteners#Anankafasteners#manufacturer#supplier#mumbai#hex#bolt#usa#uk

0 notes

Text

Your favorite book: Chemical Supplier Chennai

Chennai, a thriving center of industrial interest and innovation it is home to many industries. Including the automotive, construction, pharmaceutical and petroleum industries. These industries rely on specialized chemicals for manufacturing, processing, and reprocessing. Therefore, it is very important to find a reliable Chemical Delivery Controller in Chennai. To ensure efficiency and supportability

Why choose Chennai for chemicals?

Chennai's ideal location with a well-connected port and strong transport infrastructure. Making it the main center for distributing chemicals. The city has a strong retail network serving local institutions and international markets. Whether you are looking for laboratory equipment, commercial chemicals or a pharmacy in Fort Chennai, there are deeper possibilities to cater to your various needs.

Types of chemical suppliers in chennai

Industrial chemicals

Used in manufacturing, construction and heavy industry.

Examples: Acids, alkalis, solvents, and lubricants.

Pharmaceutical chemicals

High purity chemicals for pharmaceutical formulation and medical research

Examples: Active pharmaceutical ingredients (API), excipients and reagents

Special chemicals

Customizing formulas for specific application areas in industries such as automotive and electronics.

Examples: Adhesives, beads, corrosion inhibitors and surfactants

Agricultural chemicals

Important for modern agriculture

Examples: Fertilizers, plant nutrients, and growth stimulants.

Laboratory tests

High quality reagents and solutions for research and testing.

Examples: Analytical grade solvents, acids, and buffers.

Key Features of Reliable Chemicals Suppliers in Chennai

Quality guaranteed

Reliable suppliers provide chemical products that meet farmers' standards and certifications.

Procure ISO certified suppliers to guarantee consistent quality.

A wide variety of products

Main suppliers offer sufficient stock to support various setters.

This saves time and eliminates the need to coordinate with multiple suppliers.

Competitive price

Pricing is key for companies. To effectively manage operating costs

Suppliers in Chennai often offer competitive prices due to the city's efficient supply chain.

Timely delivery

Reliable transportation guarantees chemicals reach the factory on time. Minimizes downtime

Suppliers in Chennai take advantage of excellent city connectivity for fast delivery.

Technical support

Many suppliers provide technical advice on the safe handling and use of chemicals.

This guarantees compliance with safety regulations and increases operational efficiency.

0 notes