#Aircraft Avionics Parts

Explore tagged Tumblr posts

Text

Importance of Aviation Bearings in Aerospace

In the dynamic world of aerospace, where precision and reliability are paramount, aviation bearings play a pivotal role in ensuring the smooth and efficient operation of aircraft. These specialized bearings are critical components that contribute to the overall safety, performance, and longevity of aviation systems. Let's delve into the significance of aviation bearings in aerospace applications and understand how they are essential for the seamless functioning of aircraft.

Aviation Bearings: The Backbone of Aerospace Precision:

Aviation bearings are engineered to withstand the demanding conditions of flight, providing essential support for various moving parts within aircraft. Whether in the propulsion system, landing gear, or control surfaces, bearings in aerospace applications must meet rigorous standards to ensure optimal performance and safety.

Key Functions of Bearings in Aerospace:

Reducing Friction: One of the primary functions of aviation bearings is to minimize friction between moving parts. This reduction in friction enhances the efficiency of mechanical systems, leading to improved fuel efficiency and overall performance.

Supporting Loads: Bearings in aerospace applications bear the weight and loads experienced during flight. This support is crucial for the structural integrity of the aircraft, especially during takeoff, landing, and maneuvers.

Enabling Smooth Movement: Bearings facilitate the smooth rotation or movement of components such as wheels, propellers, and control surfaces. This smooth operation is essential for precise and controlled aircraft maneuvers.

Types of Bearings Used in Aerospace:

Ball Bearings: Commonly used in aircraft engines, ball bearings handle radial and axial loads, providing reliable support for rotating components.

Roller Bearings: Found in landing gear systems and engine components, roller bearings excel at handling heavy loads and providing stability.

Spherical Bearings: These bearings accommodate misalignment and oscillation, making them suitable for applications such as control surfaces.

Importance of Quality Bearings in Aerospace:

The demanding conditions of aerospace require bearings of the highest quality. Substandard or faulty bearings can lead to catastrophic failures and compromise the safety of the aircraft. Quality bearings are designed to withstand extreme temperatures, high speeds, and heavy loads, ensuring the reliability and longevity of aviation systems.

ASAP Axis: Your Source for Reliable Aviation Bearings:

At ASAP Axis, we understand the critical role of aviation bearings in aerospace applications. As a trusted aerospace and aviation aftermarket parts supplier, we offer a comprehensive inventory of genuine bearings sourced from reputable manufacturers. Our commitment to authenticity ensures that you receive bearings that meet or exceed industry standards.

Why Choose ASAP Axis?

Authenticity Assurance: When you choose ASAP Axis, you can trust the authenticity of the aviation bearings you receive. We source our components from reputable manufacturers, ensuring they adhere to the highest industry standards.

Comprehensive Inventory: Explore our extensive inventory that includes a wide range of aviation bearings. From ball bearings to roller bearings, we offer a diverse selection to cater to various aerospace applications.

Efficient Procurement: Our user-friendly platform simplifies the procurement process. Navigate through our inventory, place orders seamlessly, and experience efficient deliveries, minimizing downtime for your aerospace operations.

Conclusion: Elevate Your Aerospace Operations with Quality Bearings

In conclusion, the importance of aviation bearings in aerospace cannot be overstated. These precision components are the backbone of efficient and safe flight, contributing to the overall performance and reliability of aircraft. At ASAP Axis, we invite you to explore our inventory of genuine aviation bearings and experience the seamless procurement process we provide. Elevate your aerospace operations with quality bearings, sourced with confidence from ASAP Axis – your trusted partner in navigating the intricacies of aviation excellence.

ASAP Axis: Your Trusted Partner in Aviation Excellence.

#Aircraft Communication Parts#NSN parts#Aviation Parts Electronic Components#Aircraft Avionics Parts#Aircraft radios & servos parts

0 notes

Text

U.S. Air Force Awards RTX $1 Billion Contract to Upgrade F-22 Sensors

The contract follows the recent news about the tests of new advanced sensors on the F-22 Raptor, which the U.S. Air Force is planning to field quickly as part of the ongoing upgrade program.

Parth Satam

F-22 new sensors contract

An F-22 Raptor takes off from Nellis Air Force Base, Nevada, June 30, 2022. (U.S. Air Force photo by Senior Airman Zachary Rufus)

Amid the acute need for 5th generation fighters in modern combat scenarios against peer adversaries, the U.S. Air Force is looking to upgrade its F-22 Raptor with a series of sensors to make it more survivable and relevant. The service announced on Aug. 29, 2024, the award of a $1 billion contract to RTX‘s Raytheon for new sensors that are categorized as “Group B hardware”, together with spares and support equipment.

“Work will be performed in McKinney, Texas, and is expected to be completed by May 8, 2029,” said the DoD contracts statement. The Aviationist had recently reported that the Air Force was testing new sensors on the F-22 to extend its service life, which would also be applied to the NGAD (Next Generation Air Dominance) family of systems.

That report also quoted Brig. Gen. Jason D. Voorheis, the Program Executive Officer for Fighter and Advanced Aircraft, who said they were hoping to field these sensors faster. The Raptor team had conducted six flight tests to demonstrate the advanced sensors.

“The F-22 team is working really hard on executing a modernization roadmap to field advanced sensors, connectivity, weapons, and other capabilities. We’re executing that successfully, and that will lead to […] a rapid fielding in the near future.” This would be done through a Middle Tier Acquisition (MTA) program.

Some of the sensors included in the contract could be the stealthy pods seen on the F-22. Air and Space Forces earlier quoted officials who confirmed that the pods host IRST (Infrared Search and Track) sensors. The development of a new IRST sensor for the Raptor was also confirmed by the service’s 2025 budget request, which however did not mention the sensor being podded.

This work is part of an F-22 improvement campaign that calls for $7.8 billion in investments before 2030, which includes $3.1 billion for research and development and $4.7 billion in procurement.

An F-22 Raptor with the Air Combat Command F-22 Raptor Demonstration Team performs a flyover and air demonstration at the U.S. Air Force Academy in Colorado Springs, Colo., Aug 13, 2024. (U.S Air Force Photo by Trevor Cokley)

F-22’s future in the U.S. Air Force

The development is also in contrast with previously reported USAF plans to retire the older F-22 airframes, for which it had sought approval from the Congress. These F-22s are 32 Block 20 units from a total fleet of 186. At the same time, the service aims to upgrade the remaining 154 with new cryptography, an expanded open architecture, new weapons and an advanced threat warning receiver, beside the IRST.

However, the service now appears to be reconsidering that plan, after Voorheis was quoted in the ASF report: “From an F-22 sunsetting perspective, I don’t have a date for you.” “What I can tell you is that we are hyper-focused on modernization to sustain that air superiority combat capability for a highly contested environment for as long as necessary,” he added.

IMAGE 3: A U.S. Air Force F-22 Raptor assigned to the 3rd Wing takes off above Joint Base Elmendorf-Richardson, Alaska, Jun. 17, 2024. (Image credit: USAF/Senior Airman Julia Lebens)

The U.S. Air Force describes the Raptor as a combination of stealth, supercruise, maneuverability, and integrated avionics, designed to project air dominance, rapidly and at great distance. Initially introduced as an air-superiority-only asset, the F-22 later started performing both air-to-air and air-to-ground missions.

The F-35 is largely a strike fighter and an airborne sensor-fusion and data-processing capable command post in its tactical orientation. But the Raptor is a pure air dominance interceptor. Although costly to upgrade and maintain, it nevertheless can play an important role in degrading adversary air power through either long-range BVR (Beyond Visual Range) and dogfights.

Moreover, having F-22s also increases the number of LO (Low Observable) aircraft in the inventory, at least until more F-35s are available, especially the TR-3 (Technology Refresh-3) Block 4 upgraded variants.

In 2021 too, then Air Force chief General Charles Q. Brown Jr. revealed his “4+1” fighter plan, suggesting the F-22 to be replaced by the NGAD while retaining the F-35, F-15E and EX, and the F-16. The “plus 1” was the A-10, but in March 2023, Brown said the A-10s were being retired faster than expected and the entire fleet would possibly be divested by 2030.

Meanwhile the NGAD’s future itself is uncertain after U.S.A.F have noted its technical complexity and financial implications. The F-22 thus seems to be back in the running.

On Jul. 10, 2024, Air Combat Command chief Gen. Kenneth Wilsbach said during a Mitchell Institute event that the service has no official plan to retire its F-22 Raptors. “Right now, there’s…frankly isn’t an F-22 replacement and the F-22 is a fantastic aircraft,” said Wilsbach. “I’m in favor of keeping the Block 20s. They give us a lot of training value, and even if we had to in an emergency use the Block 20s in a combat situation, they’re very capable.”

F-22 Indonesia

U.S. Air Force F-22 Raptors assigned to the 27th Expeditionary Fighter Squadron, conduct Dynamic Force Employment operations at I Gusti Ngurah Rai Air Force Base, Indonesia, on Aug. 6, 2024. (U.S. Air Force photo by Senior Airman Mitchell Corley)

Other known F-22 upgrades

Other upgrades mentioned in the 2025 budget request are a Mode 5 Identification Friend or Foe (IFF), Link 16, a Multifunction Information Distribution System Joint Tactical Radio System (MIDS JTRS), a new Operational Fight Program, advanced radar Electronic Protection and an Embedded GPS/Inertial Navigation System (INS) Modernization (EGI-M).

Voorheis also mentioned the GRACE (Government Reference Architecture Compute Environment) software that would allow “non-traditional F-22 software” to be installed on the aircraft and provide “additional processing and pilot interfaces.”

A new helmet is also being tested, as part of the Next Generation Fixed Wing Helmet program to replace the current 40-year-old HGU-55P headgear. The new helmet would also allow the introduction of helmet-mounted devices which provide essential flight and weapon aiming information through line of sight imagery, easing the workload of the pilots.

About Parth Satam

Parth Satam's career spans a decade and a half between two dailies and two defense publications. He believes war, as a human activity, has causes and results that go far beyond which missile and jet flies the fastest. He therefore loves analyzing military affairs at their intersection with foreign policy, economics, technology, society and history. The body of his work spans the entire breadth from defense aerospace, tactics, military doctrine and theory, personnel issues, West Asian, Eurasian affairs, the energy sector and Space.

@Theaviationist.com

15 notes

·

View notes

Text

Airplanes VS Aeroships: A Comparison

Hey folks, and happy Worldbuilding Wednesday! Consider this a follow up this post, made in a response to two questions by @pixelazer :

How big the speed gap between fixed-wing types and airships is in your setting, and what sort of aircraft see use?

So, let's go!

Tagging @nerdexer @athenswrites @theprissythumbelina @hessdalen-globe @caxycreations @thatndginger @lividdreamz

Performance Gaps

The answer I gave in the last post was definitely an oversimplification. The real answer probably changes depending on what period in the setting you'd refer to. The earliest fixed wing aircraft, biplanes and the like, were generally not much faster than an aeroship designed with speed in mind, but could comfortably out pace the largest, most lumbering examples of such craft. The development of more powerful engines, culminating eventually with the invention of jet propulsion, would significantly widen the gap between high performance aircraft and aeroships.

To put it in more obvious terms, you could compare aeroships to our world's helicopters, and the latter's relative performance compared to modern jets. An important factor that has shape aeroship design through the ages is how they manouevre; modern aeroships typically don't use control surfaces, instead relying on impulse thrusters across their hull which allow them to adjust their positions even while simply 'levitating'. While they allow incredibly precise movements, they quickly lose effectiveness at higher speeds. The blocky and bulbous hull forms of aeroships, needed to accommodate their Aerium crystals and associated equipment, are also not kind to high speeds.

All that said, I can't really answer the question with a firm answer. If you really tried, you could probably make an aeroship that goes faster than a given fixed wing. The main reason for this general divide is that characteristics like cost, lifting capacity, and others have nudged craft of either type into specific niches which favour varying degrees of speed; you could probably make an aeroship go supersonic, but if you have a need for something to go supersonic, you're better off going fixed wing.

2. Sorts of Aircraft

If I'm reading this correctly, my usual answer for this sort of question is 'anything that currently exists in real life', mostly because I lack the in depth knowledge in the field needed to list every possible aircraft in existence and the roles they fill. I mean, part of my approach in the 12 Worlds is to show that is in whole a genuinely 'believable' Setting, which means acknowledging the existence of a thousand and one things that would logically exist even if I never pay much attention to it. Crop dusters, medical evacuation aircraft, search and rescue, etc., if it's the sort of thing that 'should' exist it probably does. Which feels like a lazy answer, but it's the truth.

------

Bonus Stuff;

All this comparing of aeroships and fixed wing craft reminds me of a few details I've had in mind for a while, on the backburner. Basically, there have at various times been attempts to incorporate Aerium and its associated technologies in 'fixed wing' platforms, or lifting surfaces on aeroships, in order to get the best of both worlds. Most of these tended to fizzle out, but the development of highly sensitive and precise avionics seems poised to shake things up. Test beds of fixed wing aircraft incorporating miniaturised Aerium crystals across their bodies have successfully shown how the lifting output of each crystal can be altered in real time, allowing for the craft's overall lift to be increased without impeding responsiveness. Where these developments might lead is a question for the future.

#worldbuilding wednesday#my worldbuilding#writeblr stuff#writing#worldbuilding#I'm feeling more than a little foggy as I write this#so sorry for any incoherency

12 notes

·

View notes

Text

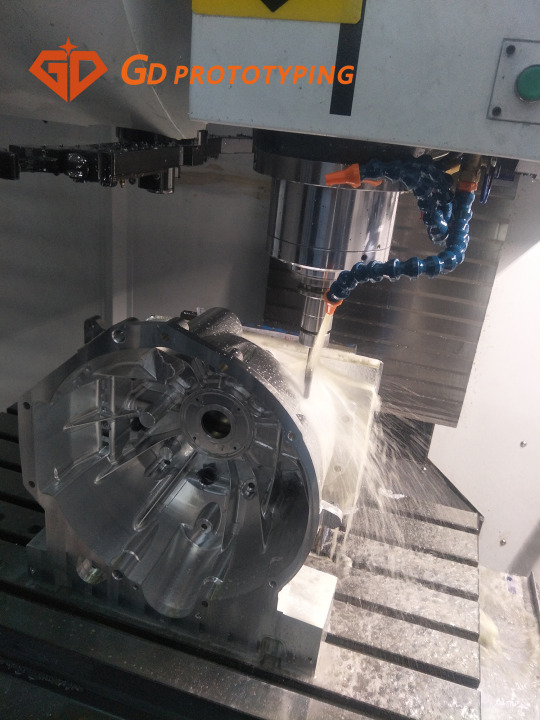

CNC Machining for Aerospace Products

Precision CNC machining of aeronautical parts, as an indispensable part of the modern aeronautical industry, provides strong technical support for the manufacture of aircraft with its high-precision and high-efficiency machining characteristics. With the continuous progress of science and technology and the rapid development of the aviation industry, precision CNC machining technology is also constantly optimised and innovated to meet the more demanding aerospace parts machining needs.

Why is CNC important in the aerospace industry?

There is very high and even demanding requirements in aerospace industry for structural design, functionality, performance, product quality and reliability. A large number of new materials and structures were first applied to aircraft components. National defence needs and market competition require a significant reduction in the development and production cycles of space products. In addition, the average cost of the final product needs to be constantly reduced, thus placing higher demands on the aerospace manufacturing industry and requiring advanced manufacturing technologies. Modern CNC machining is a key part of advanced manufacturing technology and has become a decisive key technology, especially in aerospace manufacturing. The following advantages of CNC machining services make them important in the aerospace industry: ①It is the process of synthesising a variety of advanced technology types, including computer technology, communication technology, modern manufacturing technology, digital control technology and so on. ②During CNC machining, the development of a new product and the machining of another batch can be realised by simply changing the settings and parameters of the CNC machine, greatly increasing automation and flexibility. ③Multiple CNC machining can be done automatically on a single machine or in a single clamping, greatly reducing machining time and production cycle time, as well as increasing efficiency. ④CNC machining technology improves the accuracy and precision of aerospace products, reduces or minimises manufacturing errors and results in CNC aircraft parts of higher quality and durability. ⑤Most materials for aerospace components need to be cut and machined during the manufacturing process.

CNC Aircraft Part Features and Application

What are aerospace products? Aircraft can be classified by structure into fuselage, engines, on-board equipment and components, including wings, large wall and tail frames, casings, valve bodies, hydraulic valves, optical tubes, rotor blades, fasteners, connectors, etc. ①Aircraft engine parts: Aircraft engine is one of the core components of the aircraft, the machining accuracy and performance of its parts directly affect the performance and safety of the entire aircraft. ②Fuselage Structural Components: Structural components are the backbone of the aircraft and are subject to a variety of complex loads. Precision CNC machining technology enables high-precision machining of fuselage structural parts, such as beams, frames, plates and other components, to ensure the stability and reliability of their dimensions and shapes. ③Avionics equipment parts: With the continuous development of avionics technology, avionics are more and more widely used in aircraft. Precision CNC machining technology enables high-precision machining of avionics parts, such as circuit boards, connectors and other components, to ensure their accuracy and reliability.

The main features of CNC machining of aerospace parts are as follows:

①High performance: use of new hard-to-machine materials such as titanium ②High Precision: Aerospace parts require a high degree of precision, and any small error may affect the performance and safety of the entire aircraft. Precision CNC machining technology meets the aerospace industry's need for high precision by machining in the micron level of accuracy, ensuring that the size and shape of the part is exactly as designed. ③High Efficient: Precision CNC machining technology can greatly improve productivity by automating and controlling the machining process. After one programming, the CNC machine can run continuously, reducing manual intervention time and increasing production speed. ④Flexibility: Parts in the aerospace industry are varied and complex in shape. Precision CNC machining technology can be quickly adapted to the machining needs of different parts by changing tools and adjusting the programme, without the need for cumbersome manual adjustments, and is suitable for small batch and multi-species production modes. ⑤Lightweight: Extensive use of thin-walled structures. ⑥Consistency: In mass production, part consistency is critical. Precision CNC machining technology ensures that the machining parameters of each part are exactly the same, avoiding quality fluctuations caused by human factors, thus ensuring product consistency and stability. ⑦Reliability and economy: Increasingly stringent quality and cost controls. ⑧Environmental protection and energy saving: The future of precision CNC machining of aerospace parts will pay more attention to environmental protection and energy saving. Adopting more energy-saving and environmentally friendly materials and processes to reduce resource waste and environmental pollution and realise green manufacturing.

In summary, precision CNC machining of aviation parts, as one of the important technologies in the modern aviation industry, provides strong technical support for the manufacture of aircraft with its high-precision and high-efficiency machining characteristics. With the continuous innovation and progress of technology, the future of precision CNC machining of aviation parts will move towards the direction of intelligence, automation, high-speed and high-precision, multi-axis and environmental protection and energy saving, injecting a new impetus for the development of the aviation industry.

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#cnc precision machining#aerospace parts#cnc precision#machining parts#aerospace#aviation#aircraft

2 notes

·

View notes

Text

Cazas F-16 de la Fuerza Aérea de Rumania en acción por primera vez en los cielos de España

Aviones de combate F-16 están operando estas semanas sobre los cielos de España, varios de la Fuerza Aérea de Turquía y, por primera vez, de la de Rumania están participando en el curso de élite de la OTAN TLP, que tiene sede en la base aérea del Ejército del Aire y del Espacio de Albacete. Tras el verano ha comenzado una nueva edición del curso de vuelo del programa de liderazgo táctico TLP (Tactical Leadership Program), el denominado FC (Flight Course) 2024-3 comenzaba el 16 de septiembre, y concluirá el viernes 4 de octubre, con una duración de 3 semanas. El TLP recibirá unas 650 personas, 34 de ellos se graduarán en este curso, todo un referente en el ámbito de la OTAN, serán 22 pilotos, 6 oficiales de inteligencia y 6 controladores aéreos. Los vuelos, que se realizan de lunes a viernes en periodo de tarde, dieron comienzo el 23 de septiembre, ya que la primera semana se dedica a la actividad académica y a vuelos en simulador. Las naciones participantes en el bando Blue aportarán 18 plataformas, serán España con aviones Eurofighter, Francia con sus aviones de combate Dassault Aviation Mirage 2000D y Mirage 2000-5, Estados Unidos con los espectaculares biplazas F-15E Strike Eagle, y Rumanía y Turquía con F-16. Destaca la presencia por primera vez en España de aviones de combate de la Fuerza Aérea de Rumania, que trasladó a Albacete tres de sus F-16AM MLU (Mid Life Update o Actualización de Media Vida). Esta fuerza aérea de la OTAN adquirió una docena de estos cazas a Portugal de segunda mano en la pasada década, a los que luego sumó otros 5 de la misma procedencia, estando ahora en proceso de recibir otros 32, tras darlos de baja la Real Fuerza Aérea de Noruega. En cuanto a la participación del bando oponente (Red Air), cuentan con un total de 6 aeronaves, siendo las naciones participantes: España con Eurofigher, F-18A y F-18M de sus Alas 11, 46 y 12 respectivamente; y Estados Unidos con los referidos F-15E, de los que en total han llegado a Albacete una docena desde su base de RAF (Royal Air Force)-Lakenheath (centro de Inglaterra), que forma parte de la Fuerza Aérea de los Estados Unidos en Europa o United States Air Force Europe (USAFE). Como apoyo a la realización del curso de vuelo se cuenta, como es ya habitual desde la implantación del TLP en España en 2008, con el concurso de medios de Mando y Control del Ejército del Aire y del Espacio español (EA) durante la ejecución de las misiones. Es de destacar también la participación del avión remotamente tripulado o RPAS (Remotely Piloted Aircraft Systems) MQ-9 Predator B (NR-05) del Ala 23, así como de dos instructores belgas especialistas en misiones de rescate de personal y equipos adicionales de control aéreo táctico americanos y españoles. Como amenaza antiaérea está prevista la participación de sistemas reales de defensa aérea del Ejército del Aire y del Espacio, misiles antiaéreos MBDA Mistral y el de simulación, que realiza la iluminación a las aeronaves con láser o radar Textron Mallina, del que ya hablamos en defensa.com Para simular amenazas también se cuenta con varios sistemas de simulación de la empresa americana Polygon, junto con el sistema del Armée de l´Air et de l´Espace francés ARPEGE que, como los medios españoles, estarán desplegados en distintas zonas del área de operación. Respecto a la intervención de otros medios aéreos, en el ámbito de la búsqueda y rescate en combate o Combat Search and Rescue (CSAR) de las tripulaciones abatidas se espera la participación en misiones específicas de un helicóptero NH 90 del Ejército del Aire y del Espacio en el bando Blue Air, junto con sus respectivos equipos de extracción, y de dos helicópteros Sikorsky MH-60R Seahawk de la Marina de los Estados Unidos en el bando Red. También se contará con la colaboración de un avión de transporte táctico C295 del Ala 35. Finalmente, desde las instalaciones del TLP se continuará utilizando el avanzado simulador de vuelo (MACE), que permite entrenar a los pilotos no solo en el entorno virtual, también interactuar con las aeronaves en misiones reales a través de avanzados protocolos de comunicación. Fuente: Read the full article

2 notes

·

View notes

Text

J-15 "Flying Shark" [飞鲨]

Shenyang Aircraft Corporation wanted to get the PLAN a carrier fighter, and with the fall of the Soviet Union there were very few people willing to sell one. Enter Ukraine, with the prototype Su-33 (Aircraft T-10K-3) still in the country for the unfinished Ulyanovsk Carrier- SAC had a chance. In 2001 they negotiated and managed to secure a deal for it. By 2009, the first J-15 was ready to fly. It used more composites and native home sourced parts than its Soviet (later Russian) ancestor, the Su-33. The AL-31s weren't as powerful as the Chinese had wanted and so they were looking and developing new ones- but for now it was good enough. 2012 marked the first landing quals- and in 2013 full mass production began. Now in 2024 there's likely 60-80 aircraft and several variants. J-15: Single-seat variant J-15S: Two-seat variant J-15T: Designed for CATOBAR (non-sloped deck) rated J-15D: J-15S with EW pods and dedicated EW role J-15B: Improved weapons, sensors and new avionics With a range (combat loaded) of 1270 km, the options for aerial refueling and a pretty heavy weapons load of both A2A and A2G weapons, it is a potent addition to China's Carrier Doctrine and another system which forms both an offensive and defensive bubble.

3 notes

·

View notes

Note

The missile knows where it is at all times. It knows this because it knows where it isn't, by subtracting where it is, from where it isn't, or where it isn't, from where it is, whichever is greater, it obtains a difference, or deviation. The guidance sub-system uses deviations to generate corrective commands to drive the missile from a position where it is, to a position where it isn't, and arriving at a position where it wasn't, it now is. Consequently, the position where it is, is now the position that it wasn't, and it follows that the position where it was, is now the position that it isn't. In the event of the position that it is in is not the position that it wasn't, the system has required a variation. The variation being the difference between where the missile is, and where it wasn't. If variation is considered to be a significant factor, it too, may be corrected by the GEA. However, the missile must also know where it was. The missile guidance computance scenario works as follows: Because a variation has modified some of the information the missile has obtained, it is not sure just where it is, however it is sure where it isn't, within reason, and it knows where it was. It now subracts where it should be, from where it wasn't, or vice versa. By differentiating this from the algebraic sum og where it shouldn't be, and where it was. It is able to obtain a deviation, and a variation, which is called "air"

The 757 is a low-wing cantilever monoplane with a conventional tail unit featuring a single fin and rudder. Each wing features a supercritical cross-section and is equipped with five-panel leading edge slats, single- and double-slotted flaps, an outboard aileron, and six spoilers. The wings are largely identical across all 757 variants, swept at 25 degrees, and optimized for a cruising speed of Mach 0.8 (533 mph or 858 km/h). The reduced wing sweep eliminates the need for inboard ailerons, yet incurs little drag penalty on short and medium length routes, during which most of the flight is spent climbing or descending. The airframe further incorporates carbon-fiber reinforced plastic wing surfaces, Kevlar fairings and access panels, plus improved aluminum alloys, which together reduce overall weight by 2,100 pounds (950 kg). To distribute the aircraft's weight on the ground, the 757 has a retractable tricycle landing gear with four wheels on each main gear and two for the nose gear. The landing gear was purposely designed to be taller than the company's previous narrow-body aircraft to provide ground clearance for stretched models. In 1982, the 757-200 became the first subsonic jetliner to offer longer lasting carbon brakes as a factory option, supplied by Dunlop. The stretched 757-300 features a retractable tailskid on its aft fuselage to prevent damage if the tail section contacts the runway surface during takeoff. Besides common avionics and computer systems, the 757 shares its auxiliary power unit, electric power systems, flight deck, and hydraulic parts with the 767. Through operational commonality, 757 pilots can obtain a common type rating to fly the 767 and share the same seniority roster with pilots of either aircraft. This reduces costs for airlines that operate both twinjets.

3 notes

·

View notes

Note

Question re: the Battle of Hoth. There is an argument waging elsewhere about why, if X-wings can waste AT-ATs like they do in Rogue One, why not use them on Hoth. The argument is X-wings are overkill & too valuable to risk. But they actually used X wing pilots like Luke & Wedge (and Janson, according to the X wing novels) in the speeders. My uncle, years ago, told me pilots are more valuable than planes. Would real military risk pilots in subpar aircraft, to save the more valuable fighter-craft?

Tangentially, would the military refuse to risk expensive assets due to their cost just to save a bunch of infantry? The analogy used was it's not worth risking a B-2 bomber compared to a handful of infantry. Also claiming neither Russia nor Ukraine would be willing to throw away a 6h generation fighter just to cover a few companies worth of infantry. What's the reality of the thinking? I could see a rare strategic asset over troops, but do they make calculations on strictly financial costs?

Your uncle, unfortunately, is looking at a false dichotomy. A pilot without a jet is an overtrained soldier, a jet without a skilled pilot is a glorified paperweight. The pilot and aircraft are a weapons system only when together and must be evaluated as one coherent unit. Moreover, this is driven primarily by industrial capacity and training capability. An industrial nation with many factories but few skilled pilots will have a bottleneck in pilot training, while a country that cannot source components for avionics systems will find themselves constrained in new airframe construction in a way that they may not be with pilot training.

As for dispatching a B-2 to save a bunch of infantry, you have to look at the environment. In an area with dangerous air defense, sending a B-2 to save a bunch of infantry might just end up with a downed B-2 and more dead, wounded, and captured, which is completely counter-productive. As with all things, strategic considerations do consider the long war over the immediate costs. Neither Russia nor Ukraine want to lose a company of skilled troops if they can save them, but something else might be even harder to replace, in which case, that help won't come.

Sadly, that's part of the calculus of war and something that all soldiers (including myself), have to reckon with: you are a political tool, your life is nothing but a hash mark on an asset sheet, and it will be spent to achieve an objective.

Thanks for the question, Anon.

SomethingLikeALawyer, Hand of the King

25 notes

·

View notes

Text

Elevating Excellence: The Significance of Embraer Parts in Aviation

Introduction:

In the realm of aviation, precision engineering and reliability are non-negotiable, and one company that has consistently embodied these principles is Embraer. Renowned for producing innovative and high-performance aircraft, Embraer parts are at the forefront of aviation technology. In this article, we delve into the world of Embraer parts, exploring their significance and the impact they have on the aviation industry.

Embraer parts refer to the components specifically designed and manufactured by Embraer for use in their aircraft models. These parts are meticulously crafted to meet stringent quality standards and are integral to the overall performance, safety, and efficiency of Embraer aircraft.

Importance of Embraer Parts:

Embraer parts play a pivotal role in the performance and safety of Embraer aircraft. Designed with precision and tailored to fit seamlessly within the aircraft's systems, these parts contribute to the overall reliability and longevity of Embraer models. Whether it's engines, avionics, or structural components, each Embraer part undergoes rigorous testing to ensure it meets the company's exacting standards.

The use of genuine Embraer parts is essential for maintaining airworthiness and complying with aviation regulations. Airlines, maintenance facilities, and operators worldwide rely on the quality and reliability of these parts to keep their Embraer aircraft in optimal condition. Choosing Embraer parts ensures compatibility, performance, and adherence to the manufacturer's specifications.

In conclusion, the significance of Embraer parts cannot be overstated in the aviation industry. These parts contribute not only to the individual performance of Embraer aircraft but also to the reputation of the company as a whole. The commitment to excellence and innovation exhibited by Embraer is reflected in the quality of their parts, making them a trusted choice for aviation professionals worldwide.

Conclusion:

Within the intricate web of aviation logistics and supply chain management, the concept of an Integrated NSN adds another layer of efficiency. This system streamlines the identification and procurement of Embraer parts, ensuring a standardized approach to inventory management and supply chain operations. An Integrated NSN simplifies the process of sourcing and acquiring Embraer parts, promoting a seamless flow of components throughout the aviation industry.

#aircraft parts suppliers#aerospace parts distributor#electronic parts supply#IT hardware accessories

2 notes

·

View notes

Text

Rambly Lore Post? Rambly Lore Post.

Ok class today we'll be talking about technological progression and shit woooooooo most of this will be written from the perspective of military aerospace because that's both a good frame of reference for how my brain works (i don't know tank generations very well, for example) and it also is a relatively time-independent frame of reference because there might be some historical events getting switched around, big technological hurdles reached earlier and stuff.

Alright, so let's start with the end of WWII with the last piston and first generation of jet fighters. These were actually fairly close in performance- jets of course were faster, but not by that much just yet. Even if the trend was obvious, engine lifetimes and fuel thirstiness kept jets down for a little while. The second generation of jets fighters would start changing this as we got supersonic entries, and by the third we start seeing relatively long-endurance aircraft with advanced avionics, and the finalization of a shift to missiles. Fourth-gen fighters mark yet further improvements to avionics, sensors, and performance- in some cases also favoring a lower wing loading over third-gen predecessors that often had some pretty dubious low-speed handling. Finally, we reach the currently latest generation fielded, 5. This is a bit of a nebulous generation as a lot of the aerodynamic stuff is essentially just 4 again- if anything, some pure aerodynamics have slipped back, and they've become reliant on sheer thrust to maintain their otherwise superlative kinematic performance. The defining points, however, seem to be Low Observability and advanced computerization that renders their sensors not just more powerful, but also easier to manage- crucial, as the two-seat cockpits older aircraft with similar systems required to distribute the workload are a compromising factor for stealth, and would eat internal space that the internal weapons bays put at a great premium.

Now, the Regular Military has since progressed down this route. Sixth-generation fighter aircraft seem to already have a definition in real life, that being that they're likely to be optimized for drone control. While capable aircraft in their own right, they're projected to be extremely large and expensive compared to their fifth-generation ilk (who already bear a cost spike (if an exaggerated one in some cases)), bomber-like, two-seaters, and likely a true downgrade in pure kinematics. These have been in service for a while in the setting, supplementing 4th and 5th generation aircraft- with 7th generation fighters being prototyped with a number of pre-production "YF-" designated airframes around. G7 aims to streamline the G6 design. It's knocked back down to one pilot in a small, extremely stealthy aircraft, bearing very little of its own equipment and highly kinematic by virtue of just how light it is. Onboard radars are basic, and room for weaponry is lacking- but with computer assistance, these aircraft can command a formation of drones to perform all those jobs. Moving the main radar off of the manned aircraft component of the fleet, for example, is immensely beneficial now that LPI frequency-shifting techniques are starting to get cracked a little bit by this point in time, and beaming an enemy is now somewhat more likely to reveal your position. Of course, it also has the sort of psychological effect that the least threatening part of the fleet being the manned plane means that the manned plane hundreds of miles away is less likely to be shot than the expendable drones actively bombing your position, which itself is likely to vastly increase survivability even in the event of total mission failures.

This is on top of things in between. There've been a lot of intermediate Generation "4.5" or "4+(+?)" aircraft implementing advanced avionics and semi-stealth into G4 planes. On the more fictional side, Freelancers and less-funded militaries have sought upgrades for older aircraft. Sometimes these are relatively reasonable life-extensions and glass cockpits being just barely crammed into G3s. Sometimes they're attempts to turn G2 fighters into light missile trucks with newer engines. Sometimes someone uploads scans of old piston and G1 airframe structures to the internet and Freelancers can have them printed in space-age alloys on the cheap, and manage to cram FLIR, a modern engine, and a rotary cannon into the poor thing. The more scuffed variations of this have been dubbed "KitCarriage" because the main thing they're good for is carrying a kit of modern avionics, countermeasures, and weapon modules- and many are, of course, unmanned. The opposite end of the spectrum is some hair-splitting in G5 aircraft. There's now a recognized "5.5" group of later aircraft that managed to run stealth cheaper than initial 5th gens, with much lower unit price and cost per flight hour. By contrast, many of those early 5th gens were adapted later on into lower-stealth modifications called "5-" (like, Five Minus), which still would bear decent stealth capabilities but save a lot of money.

Of course, the more organized Mercenary cabals had undergone their divergences from this line. Two, to be in fact. The bigger Merc groups were, during the Cold War, split a little bit. MercNet would form from the main group, but many feared that having that much close-knit power could essentially lead to them essentially just becoming a second regular military. These ones split off, but would eventually reconsolidate into a second group. Today known as GhostShip because, uh, well, something happened but they're... Ffff...ine? Now? They're sort of all nebulous personas loosely managing expendable clone armies. Not a terrible gig but boy they should NOT have pissed off that wizard or whatever the fuck that was.

But they naturally had an ideological split happen relatively early, and thus their point of divergence lies between 3rd and 4th gen fighters. GhostShip would have trouble making workload reduction effective, so multi-crewed vehicles were somewhat mandatory if you wanted the radar and stuff to be good. This in turn reflects sort of how their entire thing works out.

GhostShip has options for single-crew vehicles that sorta suck y'know? These "Bantams" are stuck in that lightweight end of 3rd gen, in the aircraft examples- armored vehicles are often light casemate TDs in their analogous class. Emphasis on that they kinda see themselves as expendable, anyone else would make these drones. Then we get to two-seater "Aquilas" that have a gunner/driver or pilot/WSO division and can afford such lavish amenities as radar, or a turret, and it goes up and up from there. Their technology base differs from either MercNet or RegMil. Their material engineering is superlative, but they're held back by low computerization and a (well, at least more blatant) desire to cut costs. A certain crowd of nerds may be glad to know that they're back to the point of viewing guns as the main armament of combat aircraft, in an age where everyone else sees them as weapons of opportunity at best. Ordnance tends to lack measures to increase capacity seen so often in other groups that have minimized munition sizes or just crammed more onto a given pylon via MERs- less so for GhostShip, who tend to plan out their objectives tightly and equip small shot counts of big brute-force weapons specialized for each step. Stealth is a thing, but they sort of converged on it rather than just getting with the program, and trying to work it into the other quirks of their designs can result in some distinctive looks to say the least.

As for MercNet, if that implies they just stuck with RegMil technologically, uh, no. As G6 was underway, MercNet split off and started investing into original models. Directed-Energy weapons were on the horizon and MercNet felt a need to address them directly, managing to create advanced, lightweight ablative armor- this differs from RegMil using drones as a catch-all solution to that, but ADB imagined attrition rates versus a laser-armed peer would be too high even if they were all UAVs (though MUM-T became a shared tactic between them). This led to the "Knighted" aircraft- well, that and the knock-on effects. Ablative armor happens to be marginal kinetic armor, which reduces the effects of blast-frag warheads, which means proximity fusing is off the menu, which means kinetic and shaped-charge penetrator missiles, which mean localized damage, which mean multiple shots to sufficiently damage a plane and also that they could perforate tank armor with some luck and persistence, which meant huge capacities of an omni-purpose short-range missile type were implemented universally to deal with their own ablative armor. Eventually neural interfaces were sought to reduce workload without requiring more manpower, which also lead to insane G-tolerance, single crews, chronic cognitive damage and psychosis, etc.

now i could go on but it'd require talking about space and i'm tired.

6 notes

·

View notes

Text

USAF U-2 Avionics Technician tells why S-300 and S-400 SAMs would not be able to shoot down the SR-71 Blackbird

The SR-71 Blackbird

The SR-71 spy plane, the most advanced member of the Blackbird family that included the A-12 and YF-12, was designed by a team of Lockheed personnel led by Clarence “Kelly” Johnson, then vice president of Lockheed’s Advanced Development Company Projects, commonly known as the “Skunk Works” and now a part of Lockheed Martin. The Blackbird completed its first flight on Dec. 22, 1964.

SR-71 T-Shirts

CLICK HERE to see The Aviation Geek Club contributor Linda Sheffield’s T-shirt designs! Linda has a personal relationship with the SR-71 because her father Butch Sheffield flew the Blackbird from test flight in 1965 until 1973. Butch’s Granddaughter’s Lisa Burroughs and Susan Miller are graphic designers. They designed most of the merchandise that is for sale on Threadless. A percentage of the profits go to Flight Test Museum at Edwards Air Force Base. This nonprofit charity is personal to the Sheffield family because they are raising money to house SR-71, #955. This was the first Blackbird that Butch Sheffield flew on Oct. 4, 1965.

The SR-71 was designed to cruise at “Mach 3+,” just over three times the speed of sound or more than 2,200 miles per hour and at altitudes up to 85,000 feet.

During its 24 years of service, the SR-71 Blackbird gathered intelligence in some of the world’s most hostile environments. The Blackbird evaded all the missiles fired at it and, to this day, remains the only USAF aircraft to never lose a crewmember associated with it; whether in the air or on the ground.

But could the SR-71 be shot down by missile systems such as Russia’s S-300 or S-400?

SR-71 Blackbird Vs S-300 Vs S-400

But could the SR-71 be shot down by missile systems such as Russia’s S-300 or S-400?

‘Looks like I’m going to give the only “no” answer so far,’ Damien Leimbach, former USAF Avionics Technician on U-2 aircraft, says on Quora.

‘The S-200, S-300 and S-400 are amazing platforms, and given their stated performance, the 300 and 400 could probably hit a target at the Sr-71’s speed and altitude. But that is not the same as hitting an SR-71.

‘Now, could those missiles shoot down the version of the SR-71 that existed in the 70’s or 80’s? Sure.

USAF U-2 Avionics Technician tells why S-300 and S-400 SAMs would not be able to shoot down the SR-71 Blackbird

S-400 SAM

‘But the question was could it shoot down the SR-71 if it were still in service, and if it were still in service, it would have received the same jamming and Electronic Warfare upgrades as other planes have.

‘Would these EW jammer upgrades make the plane immune from those missiles? Yes it would.

‘How do I know? Well, because I spent 6 years, recently, working on the sibling of the SR-71, the U-2 and as an electronics specialist I was directly responsible for installing and maintaining the AN-ALQ 221 jammer that made our high flying (but slow moving) plane immune to those missiles as well.

‘The U-2 and the SR-71 don’t just take pictures. They listen to cell phones. They monitor radios. And they also listen to, record and analyze the frequencies, pulse rates, variable modes and power outputs of enemy SAM systems like the S-200, 300 and 400.’

Knowing everything about S-300 and S-400

He continues;

‘We know everything about them. We know how they work, so it’s very easy to design systems to defeat them. The -300 is 1970’s Russian technology, which makes it about as sophisticated from an electronics standpoint as 1950’s American tech. The 400 is just an upgraded version of that. But we’ve had a long time to study them and build electronic countermeasures.

‘When the Berlin wall fell in 1989, and East and West Germany reunified, the very first thing NATO did was go in and scoop up all the Russian military tech it could find. We got T-80’s, We got Fulcrums and we got entire missile battalions worth of S-300 missiles.

SR-71 print

This print is available in multiple sizes from AircraftProfilePrints.com – CLICK HERE TO GET YOURS. SR-71A Blackbird 61-7972 “Skunkworks”

‘When other very poor nations like Belarus and Moldova split away from the USSR, we bought other stuff, like Flankers, Hinds, and more missile systems.

‘Only Russia, China and India operate the -400, but as much as they want access to American markets, I’m more than sure we’ve been allowed to peek at the equipment, and a missile or two may have fallen off a truck somewhere.

S-300 and S-400 could not shoot down the SR-71 Blackbird

‘Maybe its cheating a little, but buying out the competition is the American way. The point is, we know exactly what their missile systems can do and we’ve known for a long time. We build those upgrades into the U-2 and if we still flew the SR-71, we would build them into it as well.’

Leimbach concludes;

‘So, no, if modern weapons can’t even take down the U-2, they could not shoot down the SR-71.’

@Habubrats71 via X

22 notes

·

View notes

Photo

Nous étions hier chez les avions Pierre Robin. Robin Aircraft #constructionaéronautique

https://www.aero-consulting.eu/formations-ateliers-part-145/formation-r%C3%A9glementaire-part-21-g-et-j/

4 notes

·

View notes

Text

How to Keep Your Private Jet in Great Shape

While a private jet symbolizes luxury and convenience, it is also a huge investment requiring diligent care and maintenance. Like high-performance cars, private jets require frequent attention to ensure safety, performance, and longevity.

From routine checks to proper detailing, keeping a private jet in good shape requires aesthetic care and technical precision. Whether you’re a new owner or have experience with this aircraft, keep reading to understand how to keep it in great condition.

1. Perform Routine Inspections and Maintenance

As mandated by aviation authorities, regular inspections are important for keeping your private jet in top condition. These inspection and maintenance efforts allow you to take better care of your aircraft by identifying and dealing with problems before they compromise your safety.

Begin with a solid pre-flight checklist, which includes checking the fluid levels, fuel quality, and tire pressure. Consult your jet’s maintenance manual for recommendations on routine maintenance. Working with licensed technicians can help ensure safety compliance.

2. Change the Oil

Aircraft experts recommend changing your jet’s oil after flying it for 25 hours if its engine does not have a filter. On the other hand, you must change the oil after flying for 50 hours if the engine has a filter.

Depending on the type of engine your jet has and how frequently you fly, you may need to change the oil after two to four months. Whether you’re using your private jet for business or other duties, record your flight times and durations in a log to make tracking easier.

3. Keep the Jet’s Interior Clean

Always clean the interior of your jet before and after a trip. Wipe all the surfaces, vacuum the carpets, and use the appropriate cleaning solutions for leather surfaces. Consider pre-treating vinyl or fabric surfaces to protect them from dirt and spills.

Clean the windows and instrument panel with glass cleaning solutions. Look through the glove compartment and other areas where debris and thrash may gather. Do not forget to look for oil stains to ensure no leaks.

4. Clean and Detail the Plane’s Exterior

Clean the exterior of your jet to remove bugs, dirt, and oxidation. Consider polishing the windows to protect them before ensuring they are adequately sealed. Waxing the outer surface offers protection against ice and snow.

Check the drain holes with a pipe cleaner and dry them properly. Ensure they are always clear because water can cause them to corrode. Finally, observe the plane’s tire pressure to ensure safe takeoff and landing.

5. Change Batteries When Required

Test the jet’s main battery to determine if it’s still performing at its optimal capacity. If it is underperforming, replace it. When the flashlight, carbon monoxide detector, and headset batteries weaken, you must also replace them.

6. Upgrade the Parts and Software

You’ll need to upgrade its parts and software to keep your jet in good condition and improve its efficiency, performance, and safety. As aviation technology evolves, newer systems and components can enhance your aircraft’s capacity.

Consider installing the latest avionics, including navigation systems, weather updates, and communication tools. Replace old mechanical components like brakes, motors, generators, and starters with newer ones from suppliers like DK Turbines.

Endnote

Keeping your private jet in good shape involves performing routine inspections and maintenance, changing the oil, and cleaning its interior. Detailing the plane’s exterior, changing the batteries, and upgrading its parts and software also helps to keep it in top condition.

Original Source: https://wingsair.net/2025/01/14/how-to-keep-your-private-jet-in-great-shape/

0 notes

Text

Aerospace Parts Manufacturing Market Size, Share, Trends Key Drivers & Analysis by 2032

The global Aerospace Parts Manufacturing Market is experiencing significant growth, with a strong annual growth rate expected through 2032. This industry, valued in the billions, demands exceptional skill and advanced technology to produce a wide range of components. These parts include cabin interiors, engines, equipment, aerostructures, and more.

As one of the most tightly regulated sectors globally, aerospace manufacturing operates under strict standards and requirements. Meeting these rigorous demands involves extensive testing and inspections to ensure parts meet industry approval, often requiring multiple trial cycles. This meticulous process highlights the precision and effort needed to manufacture aerospace components.

Informational Source:

https://www.fortunebusinessinsights.com/aerospace-parts-manufacturing-market-102727

Key Companies Covered In Aerospace Parts Manufacturing Market are:

Rolls Royce plc

Intrex Aerospace

GE Aviation

Pratt & Whitney

Honeywell International, Inc

UTC Aerospace Systems

Superior Air Parts, Inc

Safran Group

Jamco Corporation

Eaton Corporation plc

Kellstrom Defense Aerospace, Inc

Others

Technological Innovations

Advancements in materials science are revolutionizing aerospace manufacturing. The development of high-strength, lightweight composites is enabling the production of more efficient and durable aircraft components. Innovative manufacturing techniques, such as automated composite fabrication, are reducing production costs and time, facilitating the broader adoption of these materials across the industry.

Segment:

The aerospace parts manufacturing market is divided into several categories based on the type of components produced. These include engines, aerostructures, cabin interiors, avionics, insulation components, and support systems and equipment.

In terms of the type of aircraft, the market is grouped into three main segments: commercial aircraft, military aircraft, and other types of aircraft.

Geographically, the market is segmented into key regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa.

Sustainability Efforts

Airbus is actively working on a new carbon-fiber "albatross" wing, inspired by the bird's long, slender wings, capable of folding upwards upon landing to fit within standard airport stands. This design aims to enhance fuel efficiency by reducing drag and weight, contributing to the industry's goal of reducing carbon emissions.

Industry Developments in India

India is making significant strides in aerospace manufacturing. In October 2024, Prime Minister Narendra Modi and Spanish Prime Minister Pedro Sanchez inaugurated India's first private military aircraft plant in Vadodara, Gujarat. The Tata Aircraft Complex, in collaboration with Airbus Spain, will produce C-295 transport military aircraft for the Indian Air Force, marking a substantial boost in India's defense manufacturing capabilities.

Challenges and Opportunities

Despite the positive outlook, the industry faces challenges, including supply chain disruptions and workforce turnover. In 2023, member companies of the Aerospace Industries Association experienced a personnel turnover of about 13%, excluding retirements, significantly higher than the U.S. average of 3.8%. Addressing these challenges through digital technologies, workforce development, and supply chain visibility is crucial for sustained growth.

In summary, the aerospace parts manufacturing industry is on an upward trajectory, propelled by market growth, technological innovations, sustainability initiatives, and strategic developments, particularly in emerging markets like India.

0 notes

Text

How Does Aircraft Maintenance Engineering Contribute To Ensuring Aviation Safety?

Aircraft Maintenance Engineering (AME) plays a crucial role in ensuring the safety, reliability, and efficiency of aircraft operations. With the aviation industry witnessing tremendous growth, maintaining high safety standards has become more important than ever. AMEs are the professionals responsible for inspecting, maintaining, repairing, and certifying aircraft to ensure they are airworthy and meet stringent regulatory requirements.

Role of Aircraft Maintenance Engineers

AMEs are tasked with a variety of responsibilities, all of which directly impact aviation safety. Their primary roles include:

Routine Inspections: Regular inspections of aircraft are essential to identify potential issues before they become serious problems. AMEs follow detailed inspection schedules, which include checking the airframe, engine, landing gear, avionics, and other critical components.

Preventive Maintenance: Preventive maintenance involves servicing and replacing components to prevent malfunctions during flight. This proactive approach ensures that aircraft remain in optimal condition and reduces the risk of mechanical failures.

Repairs and Overhauls: In case of damage or wear, AMEs are responsible for repairing or overhauling parts and systems. They ensure that repairs are carried out according to manufacturer guidelines and aviation authority regulations.

Compliance with Safety Standards: Aviation authorities such as the Directorate General of Civil Aviation (DGCA) in India, the Federal Aviation Administration (FAA) in the USA, and the European Union Aviation Safety Agency (EASA) set strict safety standards. AMEs ensure that all maintenance activities comply with these regulations to guarantee the safety of passengers and crew.

Certifying Airworthiness: After performing inspections, maintenance, or repairs, AMEs certify the aircraft as airworthy. This certification is critical for flight clearance and ensures that only safe and reliable aircraft are allowed to operate.

Importance of AME in Aviation Safety

Preventing Accidents: A significant number of aviation accidents are caused by mechanical failures. By performing regular inspections and maintenance, AMEs help prevent such incidents, ensuring the safety of passengers and crew.

Extending Aircraft Lifespan: Proper maintenance not only ensures safety but also extends the lifespan of aircraft. AMEs help airlines save costs by keeping aircraft in good condition and preventing premature wear and tear.

Minimizing Downtime: Aircraft downtime can lead to delays and financial losses for airlines. AMEs work efficiently to keep maintenance time as short as possible without compromising safety. This ensures smooth operations and better service for passengers.

Ensuring Compliance with Regulations: AMEs play a key role in ensuring that airlines meet international safety and maintenance regulations. Non-compliance can result in heavy fines and grounding of aircraft, affecting airline operations.

Improving Passenger Confidence: The aviation industry relies heavily on passenger confidence. Knowing that aircraft are maintained by qualified professionals gives passengers peace of mind and trust in air travel.

Challenges Faced by AMEs

While AMEs play a critical role in aviation safety, they face several challenges, including:

Rapid Technological Advancements: With new technologies being introduced in modern aircraft, AMEs need continuous training to stay updated.

High Responsibility: The safety of hundreds of passengers depends on the work of AMEs, making it a highly responsible and stressful job.

Strict Regulations: AMEs must strictly adhere to guidelines and standards set by aviation authorities, which requires great attention to detail.

Conclusion

Aircraft Maintenance Engineering is vital to the safe operation of aircraft. By ensuring that aircraft are regularly inspected, properly maintained, and repaired according to strict standards, AMEs help prevent accidents, improve reliability, and maintain passenger confidence. As the aviation industry continues to grow, the demand for skilled AMEs will rise, making it a rewarding career path for those interested in aviation safety and technology. With their dedication and expertise, AMEs play a key role in keeping the skies safe for everyone.

0 notes

Text

The Role of Technology in Modern Airline Piloting

The aviation industry has come a long way in terms of technological advancements, and these innovations play a crucial role in modern airline piloting. Today’s airline pilots are no longer solely responsible for manual control of an aircraft; they rely on various high-tech tools to ensure safety, efficiency, and precision.

Transformation of airline piloting in modern technology

1. Advanced Cockpit Systems

Modern cockpits are equipped with state-of-the-art avionics systems, which include digital flight management systems, autopilots, and touchscreen displays. These systems simplify the piloting process, offering real-time data on weather, navigation, and aircraft performance.

2. Enhanced Communication Tools

Airline pilots now communicate with air traffic control (ATC) using advanced communication tools such as satellite communication systems. These systems offer better reliability and coverage, ensuring that pilots remain connected even in remote regions or areas with poor radio reception.

3. Weather Prediction and Monitoring

Technology has revolutionized how pilots handle weather conditions. Real-time weather radar and satellite feeds provide pilots with detailed information about upcoming storms, turbulence, or hazardous weather patterns.

4. Flight Simulators and Training

Flight simulators are now a critical part of pilot training. These systems offer realistic training scenarios, allowing pilots to practice handling various in-flight situations, such as emergency landings or system failures.

5. Automation and Autopilot Systems

While piloting still requires human expertise, automation has greatly reduced the physical and cognitive workload of pilots. Autopilot systems can handle most of the flight once airborne, leaving pilots to focus on monitoring systems and addressing any issues that arise.

6. Safety Improvements

Technology has played a pivotal role in enhancing flight safety. From collision avoidance systems to improved aircraft sensors, modern planes are designed to detect and mitigate potential risks. Pilots receive alerts about potential hazards, allowing them to take proactive measures to prevent accidents.

In conclusion, technology has significantly reshaped modern airline piloting. While pilots remain at the helm, the tools they use today make flying safer, more efficient, and more comfortable.

0 notes