#Agriculture rubber parts manufacturer

Explore tagged Tumblr posts

Text

RUBBER TO METAL BONDED COMPONENTS – CRUCIAL FOR EVERY INDUSTRY

Rubber to metal bonded components are extremely crucial for various industrial applications. Rubber to metal bonded components are made by ways of rubber to metal bonding. This is a process wherein a rubber part is combined with a metal part.

Processes of Rubber to Metal Bonding

Rubber to metal bonding is generally done by two common processes. These are:

· Transfer molding - In this method, the metal parts are inserted into a heated mold and the solid rubber then pushed into the mold. Thereafter, the mold is cured and vulcanized.

· Injection molding - This is similar to the transfer molding process but here, a metal piece is first inserted into the mold and then a liquid elastomer injected into it. Once the mold is cured, the part is removed.

Steps in Rubber to Metal Bonding

Rubber to metal bonding runs through several steps. These steps are:

· Elastomer preparation - The isolation mounts are generally made either with natural rubber or neoprene. For elastomer preparation, rubber latex and neoprene is combined with several kinds of fillers and other ingredients to get the desired properties.

· Surface preparation - In this step, a low carbon steel bonding surface is prepared to offer a good performance in bonding

· Primer and adhesive application - Once the metal components have been prepared, adhesives are applied onto them. Two coat adhesive system is the most common method used here. The primer is applied, thereafter.

· Molding process - In this step, a mold is heated and the metal components loaded onto them.

· Testing - Once the process of manufacturing is completed, the samples of rubber to metal bonded components of each lot are tested for their strength.

Alfa Rubber is one of the leading manufacturers of rubber to metal bonded components. The company makes such components for the automotive, agriculture, electrical, defense and general engineering industries.

For More Details:

ALFA RUBBER & SPRINGS PRIVATE LIMITED

A-13/A, SIPCOT INDUSTRIAL COMPLEX,

GUMMIDIPOONDI. TAMILNADU 601 201, INDIA

PHONE – +91-44-27922057

EMAIL – [email protected]

Website: https://alfarubber.com/

#Rubber to metal bonded components#Rubber cap#Rubber Gasket#Rubber O-Ring#Rubber Washer#Rubber seal#NBR product manufacturer#Automotive rubber parts manufacturer#Electronics rubber parts manufacturer#Manufacturer of rubber molded products#Diaphragm Layer in rubber#Rubber Fuel Seal#rubber collar#Engineering rubber parts manufacturer#Agriculture rubber parts manufacturer#OEM Rubber component supplier#Defense rubber parts manufacturer

0 notes

Text

The Fast Fashion Industry and Its Environmental Costs

With the ever-changing fashion trends circulating on social media and the affordable prices in stores, the fast fashion industry has continued to grow over the past decade with quick online deliveries, rapid clothing production, and overconsumption of clothing items. Many companies within the fashion industry have opted to have their manufacturers overseas for cheap labor to avoid the high minimum wages enforced by developed nations. Although more affordable garments are now accessible to low-income people, it also comes with the cost of ecological destruction and humane indecency.

Forced Labor for profits

Many companies such as Shein, Forever 21, H&M, Urban Outfitters, and Zara use sweatshops, workplaces with socially unacceptable conditions that pay low wages to produce low-cost clothing items. Although these companies can maintain a low price tag on their products, they become part of the unsustainable practices of fast fashion because of underpaid labor, poor working conditions, and a longing contribution to plastic production. By consistently shopping from these brands, many support the unsustainable practices that are the backbone of these companies. Instead, choosing to shop at thrift stores, only buying clothes when necessary, reusing old clothing items, thinking before purchasing, and creating a capsule wardrobe, a set of clothes that can be worn interchangeably, can reduce the need to support the production of these companies.

Materials used

When companies want to profit while manufacturing clothing, they tend to choose low-cost artificial synthetic fibers such as polyester, rubber, and nylon, which take more energy to produce than natural fibers such as wool, cotton, and bamboo. Natural fibers have a lower environmental impact throughout manufacturing because they do not require as many chemicals as synthetic fibers. When choosing what clothing garments to buy, purchasing the ones manufactured with natural fibers is more beneficial to our environment because they can break down quickly in nature.

Polluted waters and excessive water use

The fashion industry is one of the most water-intensive industries because it uses water to spin, dye, and finish the textile. Its use of dye has contributed to the wastewater dumped into our streams, rivers, and oceans, which can spread toxic chemicals to marine ecosystems.

Plastic microfibers

Not only is the pollution of waters happening before the sale of items, but after customers buy clothes, the presence of microfibers that detach when it is in the washer goes into wastewater that will eventually reach our oceans, further polluting them. With filtration as the only laborious and expensive way to remove microplastics, it becomes unsustainable and remains in the ocean. It ends up in the human food chain through agricultural communities and sea life, ultimately causing adverse health effects.

Textile waste

As fashion trends constantly change with the modern age of technology and fast fashion's affordability, many garments are discarded and donated not long after purchase. Although donating might seem like a better, more sustainable way to recycle clothing, it might end up in landfills regardless if not sold. According to the Ellen Macarthur Foundation, "it is estimated that people are buying 60 percent more clothes and wearing them for half as long." This practice has only increased over time, allowing truckloads of textiles to be dumped into landfills or incinerated every second. To better maintain our clothes, one should be more conscious about purchases by deciding if a clothing piece has the potential to be worn multiple years after its purchase, lessening the need to throw away or donate so often.

Carbon emissions

With the production and incineration of clothing items, carbon emissions are released into the air, causing public health dangers to communities around factories. The World Bank says, "The fashion industry is responsible for 10 % of annual global carbon emissions, more than all international flights and maritime shipping combined." With new technologies that try to capture the pollutants, "they remain present and often are turned into a dangerous substance," which will pollute our air regardless.

Solutions

With the overwhelming amount of affordable clothing items that are ecologically damaging, being more conscious is always a way to reduce the effects of consumerism. It is ultimately up to us, consumers, to beware of the adverse impacts of supporting unsustainable brands and find eco-friendly companies that put the planet first. Some sustainable brands to shop from are:

Patagonia

Raven + Lily

The Classic T-Shirt Company

Cou Cou Intimates

My Mum Made It

Avani

Good Guys

Shopsoftlana

L'Envers

Pela

Sources

#climate change#earth#environment#environmentalism#epa#climate justice#fast fashion#carbon emissions#carbon footprint#microplastics

8 notes

·

View notes

Text

Understanding Coated Calcium Carbonate and Its Growing Demand in India

Calcium carbonate is one of the most versatile minerals used across various industries today, and coated calcium carbonate adds an even greater level of utility to its applications. With a rising demand for quality calcium carbonate solutions, Coated Calcium Carbonate Manufacturers in India like Airotech Minerals have emerged as reliable suppliers for industries ranging from plastics and paints to pharmaceuticals and agriculture.

What is Coated Calcium Carbonate?

Coated calcium carbonate is a modified form of regular calcium carbonate, treated with fatty acids, usually stearic acid. This coating process changes its properties and enhances its compatibility with different materials. The coated surface creates better binding, especially in applications like plastics, where smooth texture, improved processing, and reduced moisture sensitivity are needed. This unique quality makes it ideal for use in manufacturing products where durability, water resistance, and flexibility are crucial.

Benefits of Using Coated Calcium Carbonate

The coating on calcium carbonate gives it added benefits that make it highly functional and desirable for industrial applications. Here are some of its key advantages:

Enhanced DispersionCoated calcium carbonate disperses easily within non-polar substances, like plastics and rubbers. This ensures an even mixture, resulting in high-quality finished products. The smooth dispersion minimizes air bubbles, ensuring that the product surface remains smooth and defect-free.

Improved ProcessingThe coated form of calcium carbonate allows better flow and processability in machinery, reducing wear and tear on production equipment. This improves efficiency and lowers the maintenance costs for manufacturers, which is especially beneficial in large-scale production environments.

Increased Water ResistanceCoated calcium carbonate is more hydrophobic than its uncoated counterpart. This property helps prevent moisture absorption, making it an excellent additive in products exposed to water or high humidity. Applications in construction materials and exterior paints benefit greatly from this feature, as it enhances longevity and performance.

Better Impact ResistanceWhen added to plastics, coated calcium carbonate enhances impact resistance, making products more durable. This quality is highly valued in industries producing packaging materials and automotive parts, where the strength and resilience of the product are essential.

Cost-Effective FillerDue to its excellent performance and relatively lower cost, coated calcium carbonate is widely used as a filler in various products, helping to reduce the need for more expensive base materials. This affordability factor makes it an economically smart choice for manufacturers.

Applications of Coated Calcium Carbonate Across Industries

Coated calcium carbonate is valued in a wide range of industries due to its flexibility and unique properties. Here’s a closer look at its applications:

Plastics and PolymersIn the plastics industry, coated calcium carbonate is an essential filler, especially for PVC, polypropylene, and polyethylene products. It adds strength, durability, and resistance to finished products, making it a popular choice for items like pipes, containers, and household goods.

Paints and CoatingsThe paint industry uses coated calcium carbonate to improve paint durability and weather resistance. It enhances coverage and minimizes the amount of binder required in paints, leading to a smoother and more uniform finish. This is particularly beneficial in outdoor paints that need to withstand changing weather conditions.

Rubber and ElastomersCoated calcium carbonate enhances the strength and flexibility of rubber products. Its compatibility with rubber compounds makes it ideal for tires, belts, and other rubber-based goods that require high impact resistance.

Construction MaterialsThe construction industry values coated calcium carbonate for its durability and water resistance. It’s a vital component in materials like cement, plaster, and sealants, where it adds structural integrity and enhances longevity.

Conclusion

The demand for coated calcium carbonate is on the rise, thanks to its diverse applications and unique benefits. Industries ranging from plastics and paints to pharmaceuticals and agriculture are increasingly turning to this modified mineral for its enhanced properties. In India, companies like Airotech Minerals play a crucial role in meeting this demand by producing high-quality, cost-effective coated calcium carbonate that meets global standards. For businesses looking to improve their product quality and cost-efficiency, sourcing from reputable coated calcium carbonate manufacturers in India offers a reliable and effective solution.

0 notes

Text

The Essential Role of China Clay Powder Manufacturers in Various Industries

China clay powder, also known as kaolin, is one of the most versatile raw materials used across a wide range of industries. From ceramics and paints to pharmaceuticals and cosmetics, this naturally occurring material plays a crucial role in enhancing product quality and performance. As a result, the demand for high-quality China clay powder has surged over the years, making China clay powder manufacturers an essential part of many industries.

What Is China Clay Powder?

China clay is a fine, white, soft powder obtained from the mineral kaolinite. It is an alumino-silicate clay mineral that is primarily composed of hydrated aluminum silicate. The powder is highly valued for its natural purity, whiteness, and low abrasive properties, making it ideal for various industrial applications. The raw clay is extracted through mining, processed to remove impurities, and then refined into the fine, powdery substance that is used in different manufacturing processes.

Applications of China Clay Powder

Ceramics Industry: One of the largest consumers of China clay powder is the ceramics industry. China clay is used as a raw material for making porcelain, tiles, pottery, and other ceramic products. Its fine texture, smoothness, and whiteness make it a preferred choice for creating high-quality ceramics that are durable and aesthetically appealing.

Paint Industry: China clay powder is widely used in the paint and coatings industry as a filler and extender. The powder enhances the smoothness, opacity, and consistency of paints. It also improves the durability and brightness of the final paint product. As a result, it is extensively used in both decorative and industrial paints.

Rubber and Plastics: The powder is also used in the rubber and plastics industry, where it acts as a reinforcing agent. It helps in improving the strength and durability of rubber and plastic products. The fine quality of China clay powder ensures the smooth finish of products like tires, gaskets, and electrical insulators.

Pharmaceutical and Cosmetic Products: China clay powder is used in pharmaceutical and cosmetic products due to its soft, absorbent, and non-toxic properties. It is found in products like face masks, talcum powders, soaps, and creams. Its absorbent nature makes it useful for controlling oil and moisture in personal care products.

Paper Industry: The paper industry relies on China clay powder as a coating pigment. It helps in improving the smoothness and brightness of paper. It also enhances the paper’s printability and opacity, making it suitable for high-quality printing jobs.

Agriculture: In agriculture, China clay powder is used in the production of fertilizers and pesticides. Its non-toxic properties make it a safe and effective option for improving soil conditions and supporting plant growth.

Why Choose High-Quality China Clay Powder Manufacturers?

The quality of China clay powder plays a critical role in the performance of products across these industries. That’s why choosing a reliable and experienced China clay powder manufacturer is of utmost importance. High-quality China clay ensures consistency, purity, and desired properties for the end product. A reputable manufacturer will offer a product that is free from impurities, properly processed, and tailored to meet specific industry standards.

Sudarshan Group: A Leading China Clay Powder Manufacturer

When it comes to sourcing high-quality China clay powder, Sudarshan Group is a name that stands out. As one of the leading manufacturers in the industry, Sudarshan Group provides premium-quality China clay that meets the diverse needs of various sectors, including ceramics, paints, pharmaceuticals, and more. With years of expertise in the field, they are known for their commitment to excellence and customer satisfaction.

Their advanced processing techniques ensure that the China clay powder retains its purity, whiteness, and smoothness, making it a preferred choice for businesses looking for top-notch raw materials. Sudarshan Group’s consistent product quality and reliable delivery make them a trusted partner for industries that require China clay powder in bulk quantities.

Conclusion

China clay powder is an essential raw material for a variety of industries, and its demand is expected to continue growing. The versatility of this natural material makes it a vital component in products ranging from ceramics and paints to cosmetics and pharmaceuticals. When selecting a China clay powder manufacturer, it’s crucial to prioritize quality and reliability. Companies like Sudarshan Group are leading the way in providing superior-quality China clay powder that meets the needs of various industries and ensures the best outcomes for their clients.

By working with the right manufacturer, businesses can ensure that they are using the highest-quality materials to produce their products, resulting in greater performance, durability, and overall customer satisfaction.

0 notes

Text

Comprehensive Guide to Rubber Products by Arvico Rubber: Quality and Expertise

Rubber products are essential in various industries, from automotive to construction, offering flexibility, durability, and resistance to wear and tear. Arvico Rubber, a leader in rubber manufacturing, provides a diverse range of high-quality rubber products that cater to these industries' specific needs. Below is an overview of the key products offered by Arvico Rubber, showcasing their functions and applications.

Rubber Diaphragms

Rubber diaphragms are versatile components widely used in industries such as automotive, aerospace, and oil & gas. These products act as flexible barriers that isolate different mediums, allowing for pressure regulation and control in pumps and valves. Arvico Rubber’s diaphragms are designed for high durability, withstanding harsh conditions while maintaining their flexibility and sealing capabilities. These products are particularly known for their resistance to chemicals, heat, and wear, ensuring long-lasting performance.

Rubber Expansion Joints

Rubber expansion joints play a critical role in compensating for expansion, contraction, and vibration in piping systems. They are commonly used in industries like HVAC, power plants, and wastewater treatment. Arvico’s rubber expansion joints offer exceptional flexibility and the ability to absorb movement, protecting pipes from damage due to changes in temperature or pressure. The joints are built with high-quality rubber, ensuring excellent resistance to pressure and environmental factors, making them suitable for demanding applications.

Rubber Stators

Rubber stators are crucial components in progressive cavity pumps, used primarily in the oil and gas, wastewater, and food processing industries. These stators allow for the efficient movement of liquids, ensuring smooth and consistent flow. Arvico’s rubber stators manufacturer with precision, providing high resistance to wear and tear, even when handling abrasive or corrosive materials. Their durability ensures that the pumps maintain optimal performance over extended periods, reducing the need for frequent maintenance.

Bearing Bushes

Bearing bushes, also known as rubber bearing bushes, are essential for reducing vibration, noise, and friction in machinery. Used primarily in the automotive and industrial sectors, these bushes ensure smoother operations by acting as flexible joints in mechanical systems. Arvico’s bearing bushes are designed to withstand heavy loads while minimizing wear on metal parts, enhancing the lifespan of equipment. They are ideal for use in suspension systems, pumps, and engines, where durability and precision are key.

Rubber Gaskets

Rubber gaskets serve as vital sealing solutions in various industries, including plumbing, automotive, and oil & gas. They prevent leakage between two surfaces, ensuring a secure and airtight seal. Arvico offers rubber gaskets made from high-grade elastomers, ensuring resistance to extreme temperatures, chemicals, and pressures. Whether used in pipelines, engines, or industrial machinery, these gaskets provide reliable sealing performance and extend the life of the equipment.

Rubber O-Rings

Rubber O-rings are small but highly effective components used for sealing in hydraulic, pneumatic, and mechanical systems. These rings are known for their ability to withstand high pressure and extreme temperatures, making them suitable for use in automotive engines, industrial machinery, and medical devices. Arvico’s O-rings are available in various sizes and materials, ensuring a perfect fit and long-lasting sealing performance. Their flexibility and durability make them an essential part of any fluid-handling system.

Rubber Sleeves and Seals

Rubber sleeves and seals are used to protect critical components from dust, moisture, and contamination, while also ensuring proper functioning in mechanical systems. These products are widely used in industries such as automotive, agriculture, and aerospace. Arvico’s rubber sleeves and seals are engineered for high resilience and flexibility, offering exceptional protection and durability. Whether you need to cover cables, pipes, or rotating parts, sleeves and seals Manufacturer offer reliable protection in challenging environments.

Extruded Rubber Profiles and Cords

Custom Extruded rubber profiles and cords are highly versatile components used in sealing, insulation, and gasketing applications. Commonly used in the construction, automotive, and marine industries, these products offer excellent resistance to environmental factors, ensuring long-term performance. Arvico’s extruded rubber profiles and cords are available in various shapes and sizes and can be customized to meet specific application requirements. Their flexibility, combined with excellent weather and abrasion resistance, makes them ideal for outdoor and industrial use.

Moulded Rubber Parts

Moulded rubber parts are designed and manufactured to meet the exact specifications of various industries, from automotive to electronics. Arvico’s expertise in moulding allows for the production of precision rubber components that are durable, flexible, and resistant to extreme conditions. These parts can be tailored to suit a wide range of applications, providing solutions for sealing, vibration dampening, and shock absorption. The high-quality moulding process ensures that each part is consistent and meets the stringent standards required by the industry.

PTFE Components

Polytetrafluoroethylene (PTFE) components are known for their exceptional resistance to heat, chemicals, and friction. Arvico offers a range of PTFE components, including gaskets, seals, and diaphragms, used in industries such as chemical processing, pharmaceuticals, and food production. These components provide superior performance in environments where standard rubber materials would degrade. PTFE’s non-stick properties also make it ideal for applications involving the handling of sticky or viscous substances.

Rubber Hoses

Rubber hoses are essential for transferring liquids and gases in a wide variety of industries, including agriculture, automotive, and industrial manufacturing. Arvico manufactures rubber hoses that can withstand high pressure, extreme temperatures, and harsh chemicals. These hoses are designed for flexibility and strength, ensuring smooth and reliable fluid transfer in demanding environments. Whether for fuel, water, or chemicals, Arvico’s rubber hoses provide dependable performance and longevity.

Rubber Sheets

Rubber sheets are used in a range of applications, from insulation and gasketing to flooring and soundproofing. Arvico’s rubber sheets are available in different thicknesses and compounds, offering excellent resistance to abrasion, chemicals, and extreme conditions. These sheets can be cut and customized for various industrial uses, making them an essential material for industries such as construction, automotive, and electronics. Their versatility and durability make Arvico’s rubber sheets a reliable solution for protecting and enhancing surfaces.

Conclusion

youtube

Arvico Rubber offers a wide range of rubber products designed to meet the needs of diverse industries. From rubber diaphragms and gaskets to extruded profiles and PTFE components, every product is crafted with precision and a focus on quality. With over 50 years of expertise, Arvico continues to innovate and provide reliable solutions for industrial applications, ensuring that its products perform consistently, even in the most demanding conditions. Whether you're looking for customized rubber parts or standard solutions, Arvico is committed to delivering excellence.

0 notes

Text

What is the most profitable commercial real estate

Sri Lanka, the pearl of the Indian Ocean, has been experiencing significant growth in its real estate sector over the past decade. As the country continues to develop its infrastructure and attract both local and foreign investments, the commercial property landscape has become increasingly diverse and lucrative. For investors looking to capitalise on this burgeoning market, understanding the most profitable commercial real estate options is crucial. From bustling urban centres to serene coastal areas with "Land For Sale" signs dotting the landscape, Sri Lanka offers a wide array of opportunities for savvy investors.

Urban Office Spaces: The Backbone of Commercial Real Estate

One of the most consistently profitable segments of Sri Lanka's commercial real estate market is urban office spaces, particularly in Colombo, the country's commercial capital. The demand for modern, well-equipped office spaces has been on the rise, driven by:

The growth of the service sector, including IT and BPO industries

Increasing foreign direct investment

The expansion of local businesses

Prime locations such as Colombo 1, 2, and 3 command the highest rents and offer the best returns on investment. These areas are home to major corporations, financial institutions, and government offices, ensuring a steady demand for high-quality office spaces.

Retail Spaces: Capitalising on Consumer Culture

The retail sector in Sri Lanka has been undergoing a transformation, with modern shopping malls and mixed-use developments becoming increasingly popular. Key factors contributing to the profitability of retail spaces include:

Rising disposable incomes and changing consumer habits

Growth of tourism, creating demand for upscale shopping experiences

Expansion of international brands into the Sri Lankan market

Cities like Colombo, Kandy, and Galle are particularly attractive for retail investments, with shopping centres and high-street retail spaces offering strong returns.

Industrial and Logistics Properties: Fuelling Economic Growth

As Sri Lanka positions itself as a key logistics hub in South Asia, industrial and logistics properties have become increasingly profitable. Key drivers include:

Development of major ports and airports

Government initiatives to promote manufacturing and exports

Growth of e-commerce, necessitating modern warehousing facilities

Areas such as Katunayake, Biyagama, and Hambantota, with their proximity to ports and airports, are prime locations for industrial real estate investments.

Hospitality and Tourism-Related Properties

Sri Lanka's tourism industry has been a significant contributor to the country's economy, making hospitality-related properties an attractive investment option. While villas for sale in Sri Lanka often cater to the luxury tourism market, larger commercial properties in this sector include:

Hotels and resorts

Serviced apartments

Mixed-use developments with a tourism focus

Popular tourist destinations such as the southern coast, the cultural triangle, and the hill country offer excellent opportunities for hospitality investments.

Agricultural Land: A Unique Commercial Opportunity

While not traditionally considered commercial real estate, agricultural land in Sri Lanka can be a highly profitable investment, particularly for export-oriented crops. Coconut land for sale in Sri Lanka is a common sight, as coconut plantations are a significant part of the country's agriculture sector. Other profitable agricultural investments include:

Tea estates in the central highlands

Rubber plantations

Spice gardens

These properties can provide steady income through crop sales and potentially through agro-tourism initiatives.

Mixed-Use Developments: The Future of Urban Commercial Real Estate

Mixed-use developments have gained popularity in recent years, offering a blend of residential, commercial, and retail spaces. These projects are particularly profitable due to:

Efficient land use in urban areas

Diverse income streams from various property types

Creation of self-sustained communities, attracting tenants and visitors

Cities like Colombo and Kandy are seeing an increase in mixed-use developments, with projects like Cinnamon Life and One Galle Face leading the way.

Factors Influencing Profitability

When considering commercial property for sale in Sri Lanka, several factors can influence the profitability of an investment:

Location: Properties in prime areas with good infrastructure and connectivity tend to yield higher returns.

Economic Zones: Special economic zones and export processing zones offer tax incentives and other benefits, making properties in these areas potentially more profitable.

Infrastructure Development: Ongoing and planned infrastructure projects, such as highways, railways, and smart city initiatives, can significantly impact property values and rental yields.

Legal and Regulatory Environment: Understanding Sri Lanka's property laws, foreign ownership regulations, and tax implications is crucial for maximising profitability.

Market Trends: Keeping abreast of market trends, such as the shift towards sustainable and green buildings, can help investors make informed decisions.

Challenges and Considerations

While the commercial real estate market in Sri Lanka offers significant profit potential, investors should be aware of certain challenges:

Political and Economic Stability: Sri Lanka has faced periods of political uncertainty and economic challenges, which can impact the real estate market.

Currency Fluctuations: For foreign investors, currency exchange rate fluctuations can affect the overall profitability of investments.

Bureaucracy: Navigating the bureaucratic processes involved in property transactions can be time-consuming and complex.

Market Saturation: Some segments of the market, particularly in urban areas, may be approaching saturation, requiring careful analysis before investment.

Environmental Concerns: Coastal properties and developments in ecologically sensitive areas may face increased scrutiny and regulations.

The commercial real estate market in Sri Lanka offers a diverse range of profitable investment opportunities, from urban office spaces to agricultural lands. The key to success lies in understanding the market dynamics, carefully selecting locations, and aligning investments with the country's economic growth trajectory.

For investors willing to navigate the challenges and capitalise on the opportunities, Sri Lanka's commercial real estate sector presents the potential for significant returns. As the country continues to develop and attract international attention, the demand for high-quality commercial properties is likely to grow, further enhancing the profitability of well-chosen investments.

Whether it is a modern office tower in Colombo, a beachfront resort in the south, or a coconut plantation in the rural interior, Sri Lanka's commercial real estate market has something to offer for every type of investor. By carefully considering the factors influencing profitability and staying informed about market trends, investors can position themselves to benefit from this dynamic and growing sector of the Sri Lankan economy.

0 notes

Text

Understanding Top Exports of Turkey in 2024: Key Insights

Turkey’s export industry plays a significant role in its economy, making it one of the leading countries in global trade. In 2024, Turkey continues to thrive as a vital exporter of goods across diverse sectors, from automotive products to textiles, machinery, and agricultural commodities. As Turkey’s position in international markets strengthens, understanding the top exports of Turkey, its key trade partners, and Turkey export data offers a detailed picture of how its global trade landscape is evolving.

Top Exports of Turkey in 2024

Turkey’s exports are dominated by several key sectors, including automotive, textiles, electronics, and agriculture. The top exports of Turkey include:

Automotive Products: The automotive industry remains Turkey’s largest and most valuable export sector. In 2024, Turkey continues to be a leading producer and exporter of cars, buses, trucks, and automotive parts, primarily to European countries. The automotive sector contributes significantly to the country’s GDP and export revenues, cementing its position as the Turkey biggest export.

Textiles and Apparel: Turkey is globally recognized for its high-quality textiles and garments, which have been central to its export economy. Turkish-made clothing, fabrics, and home textiles are in high demand in European and North American markets. The strong emphasis on innovation and sustainability in textile production has allowed Turkey to remain competitive in this industry.

Machinery and Electronics: Turkey is a significant exporter of machinery and electronic equipment. These include industrial machinery, electrical appliances, and consumer electronics. Turkish machinery, known for its durability and innovation, is widely exported to both developing and developed nations.

Agricultural Products: The agricultural sector remains a cornerstone of Turkey’s economy, contributing significantly to its exports. Turkey exports a wide range of agricultural products, including fruits, vegetables, cereals, and processed foods. Olive oil, nuts, and grains are some of the top agricultural exports that have helped Turkey establish itself as a major player in global agricultural trade.

Chemicals and Petrochemicals: In 2024, the demand for Turkish chemical products, including plastics, rubber, and pharmaceuticals, continues to rise. Turkey’s export of petrochemical products to European and Middle Eastern countries has increased, driven by regional demand for industrial materials.

Turkey’s Biggest Export Categories

The Turkey biggest export categories reflect the country’s industrial strength and strategic capabilities. Here’s a breakdown of the key categories dominating Turkey’s export economy in 2024:

Vehicles and automotive parts: This sector contributes over 20% of Turkey’s total exports.

Machinery and mechanical appliances: This sector, which includes heavy machinery and electrical equipment, is crucial to the country's manufacturing and export capacity.

Textile products: Turkey is among the world’s leading exporters of textiles and garments, particularly in fast fashion.

Iron and steel products: Turkey’s robust steel industry supplies raw materials and processed goods to countries across the globe.

Agriculture and food products: Turkish olive oil, dried fruits, nuts, and cereals remain highly sought after in international markets.

Turkey Export Products in 2024

The variety of Turkey export products highlights the diversity of its economy and its ability to meet global market demands. Turkey’s top exports span various sectors and reflect its industrial strengths:

Automobiles and components: Turkish automakers continue to produce vehicles and components for leading car brands in Europe and beyond.

Apparel and textiles: Turkey's textile industry has evolved, with sustainable and eco-friendly products gaining traction in international markets.

Food and beverages: Turkish agricultural products, such as tea, olives, and nuts, are widely exported to neighboring regions and beyond.

Electronic equipment: Turkey’s production of household appliances and industrial electronics has grown, leading to increased exports of electronic goods.

Furniture and home decor: Turkish furniture and interior decor products are becoming increasingly popular, especially in the Middle East and Europe.

Turkey Export by Country: Key Trade Partners

Turkey’s geographical location between Europe and Asia makes it an essential trade partner for numerous countries. In 2024, the data for Turkey export by country shows strong trading relationships with the following nations:

Germany: Germany remains Turkey’s largest export partner. Turkey’s automotive, textile, and machinery products are in high demand in the German market. This long-standing trade relationship has only strengthened over the years.

United States: The U.S. continues to be a significant market for Turkish products, particularly textiles, electronics, and machinery. Turkey’s exports to the U.S. are projected to grow further as both countries explore deeper trade ties.

United Kingdom: Post-Brexit, Turkey and the UK have maintained a strong trade relationship, especially in sectors like textiles, machinery, and automotive. The two countries benefit from trade agreements that streamline the export process.

Italy and Spain: These two southern European countries are major consumers of Turkish textiles, machinery, and agricultural products. Turkey’s trade with these nations is expected to grow as demand for Turkish goods remains strong.

Iraq and the Middle East: Turkey’s proximity to Middle Eastern countries, particularly Iraq, Iran, and the UAE, makes it a critical trade partner in the region. The agricultural and construction industries dominate Turkey’s exports to these countries.

Russia: Despite political challenges, Russia remains a significant importer of Turkish agricultural products, textiles, and machinery. Trade relations between the two countries are expected to continue despite global uncertainties.

France: Turkey’s trade with France revolves around automotive and textile exports. The demand for Turkish-made vehicles and clothing in the French market has shown consistent growth over the years.

Turkey Export Data for 2024

According to Turkey export data, the country’s export volumes have increased in 2024 despite global economic challenges. Turkey’s total exports in 2024 are projected to exceed the previous year by around 7-9%, supported by increased demand for Turkish goods in Europe, Asia, and North America. The automotive, textile, and electronics sectors are expected to drive the bulk of this growth.

The Turkish government has implemented several policies to support exporters, including financial incentives and digital platforms that simplify trade processes. These measures have helped Turkish businesses access global markets more easily. Additionally, Turkey’s focus on renewable energy and green technologies is opening new opportunities for export growth in the energy sector.

Challenges and Opportunities in 2024

While Turkey’s export economy continues to grow, it faces challenges such as global inflation, rising energy costs, and supply chain disruptions. However, Turkey’s competitive pricing, driven by the devaluation of the Turkish lira, has made its products more attractive to international buyers.

New free trade agreements with African and Asian nations are also set to expand Turkey’s market access. Investments in renewable energy, particularly solar and wind power, are expected to create new export opportunities in the coming years. Furthermore, Turkey’s efforts to reduce carbon emissions in its manufacturing processes will enhance its global competitiveness.

Conclusion

Turkey’s export sector in 2024 is a testament to the country’s resilience and adaptability in the face of global challenges. With strong performances in automotive, textiles, electronics, and agriculture, Turkey has maintained its position as a vital player in the global market. By diversifying its Turkey export products, strengthening trade ties with key countries, and adapting to new global trends, Turkey’s export landscape is set for further growth in the coming years. However if you need import export data connect with ExportImportData.in.

Also Read: The Surge of Mobile Exports from India in 2024

#top exports of turkey#turkey biggest export#Turkey export products#turkey export by country#turkey export data#export#trade data#global market#global trade data#international trade#trade market#import export data#turkey#exports of turkey#major export of Turkey#turkey export products list#turkey trade data

0 notes

Text

Formic Acid Prices | Pricing | Trend | News | Database | Chart | Forecast

Formic acid, a simple carboxylic acid with the chemical formula HCOOH, is increasingly recognized for its versatile applications across various industries, including agriculture, textiles, rubber, and pharmaceuticals. As a critical chemical intermediary, the demand for formic acid continues to rise, directly influencing its market prices. Understanding the factors that affect formic acid prices can provide valuable insights for businesses and investors alike.

One primary driver of formic acid prices is the fluctuating demand from end-user industries. In agriculture, formic acid is used as a preservative and antimicrobial agent in silage, as well as a feed additive to promote livestock growth. The increasing emphasis on sustainable agricultural practices and the demand for high-quality animal feed have boosted the consumption of formic acid in this sector. Similarly, the textile and leather industries utilize formic acid for dyeing and tanning processes, further contributing to its market demand. As these industries expand, the corresponding rise in formic acid consumption inevitably leads to price fluctuations.

Get Real Time Prices for Formic Acid: https://www.chemanalyst.com/Pricing-data/formic-acid-1242Moreover, the global shift toward eco-friendly products is impacting the demand for formic acid. As businesses and consumers become more environmentally conscious, the preference for biodegradable and non-toxic chemicals has surged. Formic acid, being a naturally occurring substance, fits this criterion, making it an attractive alternative to synthetic chemicals. This shift in consumer preferences is likely to sustain or increase demand for formic acid, subsequently influencing its market prices.

Supply chain dynamics also play a crucial role in determining formic acid prices. The production of formic acid is primarily dependent on the availability of raw materials, such as methanol and carbon monoxide. Any disruptions in the supply of these raw materials—due to geopolitical tensions, natural disasters, or economic sanctions—can lead to increased production costs and, consequently, higher formic acid prices. Additionally, the complexity and costs associated with the manufacturing process can further affect pricing. As the production methods for formic acid evolve, including advancements in catalytic processes and green chemistry, manufacturers may experience cost savings that could potentially stabilize or reduce prices.

Another important aspect to consider is the competitive landscape of the formic acid market. Several key players dominate this industry, including BASF, Eastman Chemical Company, and Jiangshan Chemical. The competitive strategies employed by these companies, such as mergers, acquisitions, and product innovation, can influence market pricing. For instance, increased production capacity by leading manufacturers may lead to lower prices, whereas consolidation in the industry could result in reduced competition and higher prices. Market dynamics, therefore, reflect a balance between supply, demand, and competitive forces.

Geographical factors also contribute to the variation in formic acid prices across regions. In regions where agricultural practices are predominant, such as in parts of Asia and Europe, the demand for formic acid may be higher, thereby increasing prices in those markets. Conversely, regions with limited agricultural activity may experience lower demand, resulting in reduced prices. Additionally, transportation costs and tariffs can affect pricing on a regional scale. Export and import regulations further complicate the pricing structure, as tariffs can significantly influence the cost of formic acid in international markets.

Looking ahead, market forecasts indicate that the demand for formic acid is expected to grow steadily over the next few years. This growth can be attributed to increasing applications in various sectors, particularly in renewable energy technologies. Formic acid has garnered attention as a potential hydrogen carrier, offering a clean alternative for energy storage and transportation. As the world transitions towards greener energy sources, the role of formic acid in these applications may become more pronounced, further driving up demand and, consequently, prices.

In conclusion, formic acid prices are influenced by a myriad of factors, including demand from various industries, supply chain dynamics, competition among key players, and regional market conditions. As the global landscape continues to evolve, particularly with the growing emphasis on sustainability and eco-friendly products, the formic acid market is likely to experience significant changes. Businesses and investors should remain vigilant in monitoring these trends, as understanding the interplay of these factors can provide crucial insights into future price movements. By staying informed, stakeholders can make strategic decisions that align with market conditions and capitalize on the opportunities presented by the formic acid market.

Get Real Time Prices for Formic Acid: https://www.chemanalyst.com/Pricing-data/formic-acid-1242

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Formic Acid#Formic Acid Price#Formic Acid Prices#Formic Acid Pricing#Formic Acid News#Formic Acid Price Monitor#Formic Acid Database

0 notes

Text

How Do Organic Chemicals Exported from India Dominate Global Markets?

Introduction

India has become a global powerhouse when it comes to chemical exports. With a vast array of organic chemicals exported from India, the country has established itself as one of the key players in the chemical industry worldwide. Indian organic chemical exporters have tapped into international markets, catering to industries such as pharmaceuticals, agriculture, textiles, and more. In this article, we will explore how India has achieved this dominance, the leading chemical exporters in India, and the diverse list of chemicals exported from India.

What Makes India a Global Leader in Chemical Exports?

India’s rise as a leader in chemical exports can be attributed to several factors. The availability of raw materials, coupled with a highly skilled workforce and advanced manufacturing capabilities, has propelled India’s chemical industry. Moreover, the government has implemented policies that foster growth and innovation, allowing chemical exporters in India to maintain a competitive edge.

A crucial aspect of this growth is the diversity in the list of chemicals exported from India, with organic chemicals being a significant contributor. These chemicals are essential for various global industries, further increasing India’s importance in the chemical supply chain.

Who Are the Key Organic Chemical Exporters in India?

Several major companies drive the organic chemicals exported from India. Industry giants such as Tata Chemicals, UPL, and SRF Limited are renowned for their global reach and high-quality chemical products. These companies have established strong international relationships, positioning themselves as reliable suppliers in competitive markets.

In addition to these large corporations, numerous medium-sized enterprises contribute to the industry’s success. Their ability to meet international standards and adapt to global demands has solidified India's reputation as a leading exporter.

What Are the Top Organic Chemicals Exported from India?

India exports a wide variety of organic chemicals, each serving critical roles across various industries. Some of the top organic chemicals exported from India include:

Acetic Acid: Used in producing vinegar and several industrial chemicals.

Methanol: A versatile chemical that serves as a solvent and is a key ingredient in many products.

Ethyl Acetate: Widely utilized as a solvent in paints, coatings, and adhesives.

Toluene: A chemical used in the production of dyes, detergents, and other industrial products.

Aniline: Important in the manufacturing of polyurethane, rubber chemicals, and dyes.

This wide-ranging list of organic chemicals exported from India highlights the country’s importance in fulfilling global industrial demands.

How Does India Contribute to Global Supply Chains?

The presence of organic chemical exporters from India in global markets ensures that industries around the world have a reliable source of raw materials. These organic chemicals are vital in sectors such as:

Pharmaceuticals: Organic chemicals like methanol and acetic acid are essential in the production of medicines and medical products.

Agriculture: Several organic chemicals serve as key ingredients in fertilizers, herbicides, and pesticides, making them critical to the global food supply.

Textiles: Many chemicals exported from India are used in dyes and finishing agents for textiles.

The ability to supply these chemicals consistently has positioned India as an indispensable part of international supply chains.

What Challenges Do Chemical Exporters in India Face?

Despite the significant success of chemical exports from India, the industry does face certain challenges. These include:

Regulatory Compliance: Exporters must comply with various environmental and safety standards, both domestically and in importing countries.

Global Competition: India faces stiff competition from other countries like China and the United States, which are also major chemical exporters.

Fluctuating Raw Material Costs: Changes in the prices of raw materials can impact production costs, which, in turn, affects the pricing and competitiveness of India’s chemical exports.

Despite these challenges, India’s strong foothold in global markets remains largely intact due to the quality, reliability, and cost-effectiveness of its chemical products.

What Government Initiatives Support Chemical Exports from India?

The Indian government has introduced several initiatives to support and boost the chemical export industry. These include:

Incentives for Exporters: The government provides financial incentives to exporters, which helps them compete on a global scale.

Infrastructure Development: Investment in logistics, transportation, and port facilities has streamlined the process of exporting chemicals, making it more efficient and cost-effective.

Promotion of Green Chemistry: As environmental concerns become more pressing, the Indian government has promoted green chemistry, encouraging manufacturers to adopt sustainable and eco-friendly practices.

These initiatives not only boost the volume of chemical exports but also enhance India's reputation as a sustainable and responsible exporter.

Which Countries Import Organic Chemicals from India?

India exports organic chemicals to a broad range of countries across the globe. Some of the key markets for India’s chemical exports include:

The United States: As a major importer, the U.S. uses Indian organic chemicals in pharmaceuticals, agricultural products, and industrial manufacturing.

China: India’s neighbor imports a significant amount of organic chemicals, particularly for its large-scale manufacturing industries.

Germany: Known for its industrial base, Germany relies on Indian chemicals for use in automotive, pharmaceutical, and chemical manufacturing.

Japan: A vital market for India’s organic chemicals, particularly for its electronics and automotive industries.

These countries are just a few examples of the many international markets that rely on organic chemicals exported from India to support their industries.

What Is the List of Chemicals Exported from India?

India’s chemical export portfolio is extensive, and apart from organic chemicals, it includes a wide variety of industrial and specialty chemicals. The full list of chemicals exported from India also features:

Inorganic chemicals: Such as sulfuric acid, caustic soda, and ammonia.

Fertilizers and pesticides: Crucial for global agricultural productivity.

Pharmaceutical intermediates: Important raw materials for drug manufacturing.

The diversity in this list showcases India’s ability to meet the needs of various industries worldwide.

How Is India’s Chemical Export Industry Evolving?

India’s chemical export industry is continuously evolving to meet the changing demands of global markets. Innovation, research, and development have become central to the growth of the industry. Indian companies are increasingly investing in technology that enhances production efficiency and reduces environmental impact.

Moreover, there is a growing focus on expanding into new markets in Africa, Latin America, and Southeast Asia, where demand for organic chemicals is on the rise. This geographic diversification is essential for maintaining growth in the long term.

What Is the Future Outlook for Organic Chemicals Exported from India?

The future of organic chemicals exported from India looks promising. Global demand for chemicals is expected to increase due to growth in industries such as pharmaceuticals, agriculture, and manufacturing. Indian exporters are well-positioned to capitalize on these trends.

Additionally, the focus on sustainability and green chemistry will likely become a major differentiator for Indian companies. As industries worldwide shift toward more eco-friendly practices, Indian chemical exporters who prioritize sustainability will find themselves in an advantageous position.

Conclusion

India’s dominance in the global chemical market is driven by its vast production capabilities, diverse list of chemicals exported from India, and the expertise of its organic chemical exporters. Despite facing challenges such as global competition and regulatory compliance, the future remains bright for India's chemical export industry. With continued government support, technological advancements, and a commitment to sustainability, the chemical exports from India will continue to thrive and shape global supply chains for years to come.

#organic chemicals exported from India#chemical exports from India#organic chemical exporters#list of chemicals exported from India#list of organic chemicals exported from India#chemical exporters in India

0 notes

Text

Hydraulic Cylinders: What You Need To Know (And Why!)

Hydraulic cylinders form the heart of a wide range of industrial applications, from driving heavy construction machinery to agricultural implements; they take one key role in transforming energy into force and motion. From the tie-rod hydraulic cylinders and welded hydrualic cyinders, to telesoping hydraulics cyliders — knowing what goes into these types of equipment is imperative for maintaining their functionality. The following article outlines how hydraulic cylinders work, detailing the important functions of each section to provide a basic understanding of these strong machines.

Hydraulic cylinders anatomyXSLHydraulics, XSL Hydraulic Cylinders, Custom Hydraulic Cylinder, Custom Hydraulic Cylinders

There are various types of hydraulic cylinders which have different components, and they all do work for making it functional. Knowing these pieces will give you a deeper understanding of the engineering involved in custom hydraulic cylinders, and enable you to choose or maintain those units without ignoring essential components.

Cylinder Barrel

The cylinder barrel is the body of a hydraulic cylinder, thus it is complete product material. This component contains the hydraulic pressure that is created in the cylinder and some internal parts. The durability and the precision machining of a barrel are essential to avoid premature failure in custom hydraulic cylinders via poor operation under high pressure.

Cylinder Base

The barrel of the hydraulic cylinder is closed on one end by a cap called a Cylinder base or Cap; this bounds as well. The base can be mounted on the barrel by welding, threading bolts or tie rods according to design. The base also acts as a mounting place for the hydraulic cylinder, locking it in to its machinery or equipment home. The cylinder base of tie-rod hydraulic cylinders and many others needs to be attached correctly inorder for it to work properly.

Cylinder Head

On the opposite end of that barrel is a cylinder head sealing off the barrel and containing ports for piston rod extension/retraction. The cylinder head is equipped to hold in the pressure of a piston and has seals that don't allow hydraulic fluid escape as it moves through its travel. The design of a cylinder head is one example: in welded hydraulic cylinders which require that the seal hold pressure, quality can be especially critical.

Piston

This piston is a very important member which moves inside the cylinder barrel at hydraulic pressures, to give force or power ot push he rod of the engine. The piston has grooves for seals, and the seals are what keep pressure while preventing fluid from bypassing around the outside of the piston. Using telescopic hydraulic cylinders is reliable and efficient, but the piston must be accurate enough for it to hold up against great or even high forces when working through hundreds of cycles.

Piston Rod

The piston rod is made from hard chrome-plated cold-rolled steel and extends all the way up through to the cylinder head. This is what attaches to the machinery like a plow or dump body that you are going to operate. Movements and the environment are two key factors that make a piston rod useful in its application, therefore a good quality must be expected by any manufacturer. Many times the manufacture of custom hydraulic cylinders focuses on improving the strength, and wear properties in a rod; which will increase overall performance.

The Role of Hydraulic Seals

Any hydraulic cylinder relies on the functionality of a number of hyrasulic seals to retain fluid and maintain smooth force transfer between piston and rod. Hydraulic cylinders are useful only if the seals in them are excellent and compatible with certain types of materials which include rubber-like nitrile, polyurethane based or Teflon®/fluorocarbon.

Primary and Secondary Seals

They are the primary seals against fluid leakage with secondary or buffer seal make up. These seals of course should be selected carefully depending on the cylinder's operating pressure, speed and temperature range. However, you might find that a hydraulic cylinders manufacturer suggests fluorocarbon seals for high-temperature applications or polyurethane seals in filthy environments; alternatives best suited to withstand harsh conditions.

Bearing Elements and Wipers

Bearings elements help to support the alignment of the piston rod and also reduces friction & wear due to different movements during working operation. They keep the rod clean by removing dirt, dust and moisture so that these contaminants cannot get into the cylinder to create harm. Despite what anybody may inform you of the contrary, suitable maintenance to your bearing elements and wipers is essential for extending the lifetime of welded (as well as other) hydraulic cylinders.

Quality Components for Impressive Performance

For the best performance of your hydraulic cylinders, you should use high standard replacement parts and components. That doesn´t encompass just the selection of appropriate seals, rods and other essential elements according to your specific application requirements. At XSLHydraulics.com, we hot sale trade from china hydraulic cylinder manufacturing and carving a wide range of cylinders for use in diverse industries around the globe.

Conclusion

Knowing what you are dealing with in regards to hydraulic cylinders is important if you want them working as efficiently, and reliably, as possible. It does not matter if you deal with tie-rod hydraulic cylinders, welded hydraulic cylinders or telescopic units so tracked or mobile machinery; all of our parts can be inspected and in compliance which helps against breakdowns but also to extend the lifetime.

Hire For the Experts and Be at ease for The One Stop Shop in Hydraulics- XSLHydraulic.com today. We are dedicated to the best products and service for your hydraulic system, so it can run even better.

#XSLHydraulics#XSL Hydraulic Cylinders#Custom Hydraulic Cylinder#Custom Hydraulic Cylinders#Tie-Rod Hydraulic Cylinders#Welded Hydraulic Cylinders#Telescopic Hydraulic Cylinders#Hydraulic Cylinders Manufacturer In China#Hydraulic Cylinders Manufacturer

0 notes

Link

#Electronics rubber parts manufacturer#Automotive rubber parts manufacturer#Manufacturer of rubber molded products#Engineering rubber parts manufacturer#Agriculture rubber parts manufacturer#Defense rubber parts manufacturer

0 notes

Text

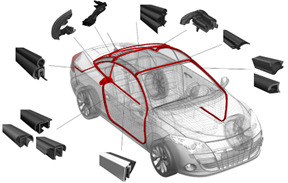

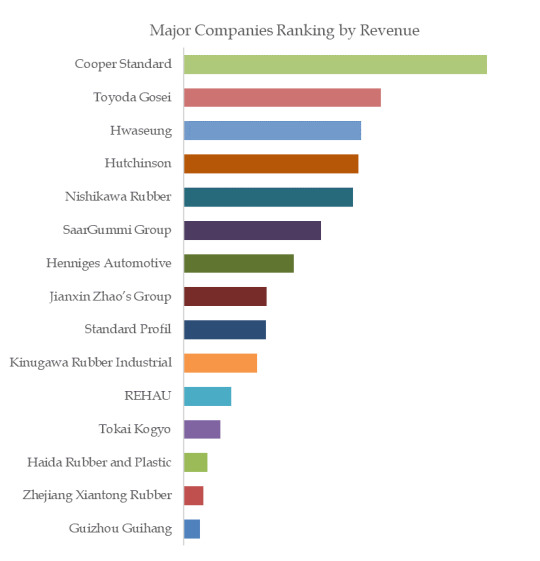

Global Top 15 Companies Accounted for 57% of total Automotive Body Sealing Systems market (QYResearch, 2021)

Body sealing system is commonly made of EPDM rubber and PVC, a thermoplastic elastomer (TPE) mix of plastic and rubber, and a thermoplastic olefin (TPO) polymer/filler blend. The goal of body sealing system is to prevent rain and water from entering entirely or partially and accomplishes this by either returning or rerouting water. A secondary goal of body sealing system is to keep interior air in, thus saving energy on heating and air conditioning.

The automotive body sealing system means the edges of a vehicle's windshield, windows, doors and trunk lid, etc. Automobile Sealing System strip is usually made into a hollow sponge foam tube.

According to the new market research report “Global Automotive Body Sealing Systems Market Report 2023-2029”, published by QYResearch, the global Automotive Body Sealing Systems market size is projected to reach USD 25.95 billion by 2029, at a CAGR of 13.3% during the forecast period.

Figure. Global Automotive Body Sealing Systems Market Size (US$ Million), 2018-2029

Figure. Global Automotive Body Sealing Systems Top 15 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Automotive Body Sealing Systems include Cooper Standard, Toyoda Gosei, Hwaseung, Hutchinson, Nishikawa Rubber, SaarGummi Group, Henniges Automotive, Jianxin Zhao’s Group, Standard Profil, Kinugawa Rubber Industrial, etc. In 2021, the global top five players had a share approximately 57.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

21st July 2024 Discover the industrial and economic hub of Shah Alam, Selangor’s ‘Silicon Valley,’ known for its thriving population, strategic location, and key industries. Learn about Shah Alam’s history, core activities, and unique selling points. Shah Alam, the capital of Selangor, is famous for its oil palm and rubber trade with a thriving population that has grown exponentially from 40,000 to over 600,000 people. What is the history of Shah Alam? Previously known as Sungai Renggam and also referred to as Batu Tiga before Malaysia’s independence, Shah Alam was renowned as the center of the palm oil trade for many years. It successfully replaced Kuala Lumpur as the capital of Selangor in 1978. What are the core activities happening in Shah Alam? Shah Alam houses numerous large industrial factories and warehouses, with more companies and property developers establishing their presence here. The city has a similar urban layout to Petaling Jaya, with housing areas occupying most of the city and commercial centers and industrial properties scattered around its different Sections (Seksyen). Famous sections include Seksyen 15, 16, 22, 23, 31, and 32, with industrial parks such as Mah Sing Integrated Industrial Parks, Hap Seng Industrial Park, and Tiong Nam Industrial Park. Well-known companies with established warehouses here include Nestle, Cadbury, Toyota, Opcom, Cables, UMW Corporation, Bright Steel, Perodua Service Centre, Toyota Service Centre, and Scientex Berhad. What are the economic sectors that Shah Alam supports? Many famous multinational companies located in Shah Alam focus on core clusters emphasized by the Selangor state government. Shah Alam Industrial Park, Glenmarie Industrial Park, and Kota Kemuning are famous for their electronic and electrical clusters. Bukit Raja Selatan Industrial Park and Hicom Industrial Park support the life sciences sector, while Batu Tiga Factory, Persiaran Raja Muda, and Shah Alam Premier Industrial Park focus on food and beverage manufacturing. Bukit Jelutong Industrial Park, Jalan Bicu, and Hicom Glenmarie Industrial Park are known for transport equipment, while Seksyen 16 and Shah Alam Industrial Park specialize in machinery and equipment. Freight Management Holdings plans to invest RM245 million to develop an e-commerce fulfillment center in Shah Alam to qualify for the Investment Tax Allowance (ITA). What is the unique selling point for Shah Alam? Shah Alam’s strategic location in Selangor, surrounded by Kuala Lumpur, Petaling Jaya, and other prominent townships like Klang, Bangi, and Kajang, has contributed to its significant growth, especially after the establishment of Proton’s car manufacturing plant. The city boasts many landmark buildings and tourist spots, such as the Sultan Salahuddin Abdul Aziz Shah building, the Sultan Salahuddin Abdul Aziz Shah Mosque, the Shah Alam Lake Garden, and Bukit Cahaya Seri Alam Agricultural Park. Shah Alam is also home to one of Malaysia’s key institutions of higher learning, Universiti Teknologi MARA (UiTM). How connected is Shah Alam to public access routes? Shah Alam is well-connected with the Federal Highway, New Klang Valley Expressway (NKVE), Kemuning Shah Alam Highway (LKSA), Shah Alam Expressway (KESAS), North-South Central Linkway (ELITE), and Damansara Puchong Highway (LDP). Public transport options include Rapid KL, LRT, and KTM stations. Latest Developments in Shah Alam ? Explore Elmina Business Park, a key component of the City of Elmina in Shah Alam, featuring top-notch infrastructure, strategic location, and sustainable development practices.Elmina Business Park is a crucial part of this visionary plan, featuring 1,300 industrial units and 183 commercial units. With an estimated employment of 35,000 people, it is poised to become a bustling center of industrial and commercial activity. Conclusion Shah Alam’s blend of industrial and commercial growth, strategic location, and robust infrastructure makes it an attractive hub for businesses and residents alike.

If you’re looking for industrial property, factory spaces, or warehouses in Shah Alam, get in touch with us. Let’s discuss how we can assist you in finding the perfect property to meet your needs. For more industrial property insights and opportunities, visit My Industrial Specialist and start your investment journey today!

0 notes

Text

Europe Magnesium Oxide Market Share, Upcoming Trends, Size, Key Segments 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Europe Magnesium Oxide Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the Europe Magnesium Oxide Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Europe Magnesium Oxide Market?

The Europe magnesium oxide market was valued at US$ 1,349.2 Million in 2023 and is expected to register a CAGR of 3.0% over the forecast period and reach US$ 1,752.7 Mn in 2032.

What are Europe Magnesium Oxide?

Magnesium Oxide in Europe encompasses the diverse applications and uses of MgO within the region. This versatile compound is integral to several industries for its thermal stability, electrical insulation properties, and refractory capabilities. It serves as a critical component in construction, ceramics, and agriculture, found in products ranging from refractory bricks to fertilizers. Moreover, magnesium oxide plays a vital role in environmental applications such as wastewater treatment and soil remediation, underscoring its multifaceted significance in both industrial processes and environmental management across Europe.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2353

What are the growth prospects and trends in the Europe Magnesium Oxide industry?

The Europe magnesium oxide market growth is driven by various factors and trends. The European market for magnesium oxide (MgO) is thriving, propelled by its broad applications across various industries. Renowned for its thermal resilience, electrical insulation properties, and refractory capabilities, MgO is indispensable in sectors such as construction, ceramics, agriculture, and environmental remediation. In construction, it is crucial for fire-resistant materials and cement additives, while in agriculture, it enriches soil as a magnesium source in fertilizers. Market expansion is bolstered by advancements in manufacturing technologies and growing demand for sustainable, high-performance materials throughout Europe. Hence, all these factors contribute to Europe magnesium oxide market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Typе

Caustic Calcined Magnesia (CCM)

Dead Burned Magnesia (DBM)/ Sintered Magnesia

Fused MgO

By Form

Pellets

Powder

Sputtering Targets

Tablets

Nanopowder

By Purity

85-95%

99%

By Application

Cements

Refractories

Crucibles

Heating Elements

Thermocouple Tubes

Brake Linings

Plasma Display Screens

Thin Film Semiconductors

Fuel additives

Fertilizers

Waste Water Treatment

Rubber Processing

Cattle Feed Supplement

Adhesive

Others

By End-Usе Industry

Steel

Glass & Cement

Chemical

Electricals & Electronics

Agriculture

Pharmaceutical

Plastics & Rubber

Water Treatment

Environmental

Nuclear

Others

Who are the key players operating in the industry?

The report covers the major market players including:

Linde plc

Air Liquide

Air Products and Chemicals, Inc.

Messer Group GmbH

Yara International ASA

Gasum Oy

SOL Group

RWE AG

SIAD Group

Orlen

View Full Report: https://www.reportsandinsights.com/report/Europe Magnesium Oxide-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Europe Magnesium Oxide Market share#Europe Magnesium Oxide Market size#Europe Magnesium Oxide Market trends

0 notes

Text

Pump Parts Specialties: Essential Components for Optimal Performance

Pumps are vital components in numerous industries, from agriculture and manufacturing to water treatment and oil and gas. Ensuring these pumps operate efficiently and reliably depends largely on the quality and specificity of their parts. Pump parts specialties play a crucial role in maintaining and enhancing the performance of these essential machines.

This blog delves into the importance of specialized pump parts, the different types available, and how they contribute to optimal pump performance.

The Importance of Specialized Pump Parts

Specialized pump parts are designed to meet the unique requirements of various pumping applications. Standard parts may not always provide the durability or efficiency needed for specific tasks, especially in demanding environments. Specialized components are engineered to withstand particular conditions, such as extreme temperatures, high pressures, corrosive fluids, or abrasive materials. Using the right parts ensures that pumps operate at peak performance, reducing the risk of downtime and costly repairs.

Types of Specialized Pump Parts

Impellers

Description: Impellers are critical components in centrifugal pumps, responsible for moving fluid by converting rotational energy into kinetic energy.

Specialties: Specialized impellers are designed for specific flow rates, pressure requirements, and fluid types. For instance, open impellers are suitable for handling slurries and solids, while closed impellers are used for clear liquids to ensure high efficiency.

Seals and Gaskets

Description: Seals and gaskets prevent leaks and ensure that pumps maintain their integrity under various operating conditions.

Specialties: Mechanical seals are used in high-pressure applications, while gland packing might be employed in less demanding environments. Material selection is crucial, with options ranging from rubber and silicone to more durable materials like Teflon or metal composites.

Bearings

Description: Bearings support the rotating shaft of the pump, reducing friction and wear.

Specialties: Different types of bearings are used based on the pump's operating conditions. For example, ceramic bearings are excellent for high-speed applications, while stainless steel bearings offer corrosion resistance for pumps handling aggressive fluids.

O-Rings

Description: O-rings provide a seal between static and dynamic parts to prevent fluid leakage.