#Agriculture Chemical Malaysia

Explore tagged Tumblr posts

Text

Enhancing Crop Productivity with Advanced Agriculture Chemicals

The Agriculture Chemical Market plays a crucial role in modern farming practices by providing essential inputs to enhance crop productivity and protect plants from pests and diseases. In this blog, we'll explore how advanced agriculture chemicals are revolutionizing the agriculture industry and driving improvements in crop yields and overall agricultural efficiency.

Fertilizers for Nutrient Management:

Fertilizers are essential inputs in agriculture, supplying plants with essential nutrients for growth and development. Traditional fertilizers contain nitrogen, phosphorus, and potassium (NPK), but advanced formulations also include micronutrients such as zinc, copper, and boron, tailored to specific crop requirements. These fertilizers help farmers optimize nutrient levels in the soil, leading to healthier plants and higher yields.

Pesticides and Herbicides for Pest Control:

Pesticides and herbicides are vital tools for managing pests, weeds, and diseases that can damage crops and reduce yields. Advanced formulations of pesticides and herbicides are designed to target specific pests while minimizing environmental impact and non-target effects. Integrated pest management (IPM) strategies combine chemical control with cultural, biological, and mechanical methods to reduce reliance on pesticides and promote sustainable pest management practices.

Biologicals and Biopesticides:

Biologicals and biopesticides are gaining popularity as eco-friendly alternatives to traditional chemical pesticides. These products contain naturally occurring microorganisms, such as bacteria, fungi, and viruses, that target pests while minimizing harm to beneficial insects and non-target organisms. Biologicals offer effective pest control with reduced environmental impact and are compatible with organic farming practices.

Soil Conditioners and Amendments:

Soil conditioners and amendments are used to improve soil structure, fertility, and water retention, leading to healthier plants and higher yields. Products such as compost, biochar, and gypsum help restore soil health, enhance nutrient availability, and promote root development. Additionally, soil pH modifiers such as lime and sulfur are used to adjust soil acidity or alkalinity to optimal levels for plant growth.

Plant Growth Regulators:

Plant growth regulators (PGRs) are chemicals that influence plant growth and development, regulating processes such as seed germination, flowering, and fruit set. PGRs can enhance crop yields by promoting root growth, increasing flower and fruit production, and improving stress tolerance. Advanced formulations of PGRs are tailored to specific crops and growth stages, providing precise control over plant physiology.

Precision Application Technologies:

Precision application technologies, such as variable rate application (VRA) systems and GPS-guided sprayers, enable farmers to apply agriculture chemicals with precision, optimizing input use and minimizing waste. These technologies help reduce environmental impact, improve resource efficiency, and maximize the effectiveness of agriculture chemical applications.

Conclusion:

Advanced Agriculture Chemical are revolutionizing modern farming practices by providing farmers with innovative tools to enhance crop productivity, improve soil health, and minimize environmental impact. By leveraging the latest advancements in fertilizers, pesticides, biologicals, and precision application technologies, farmers can optimize agricultural efficiency, increase yields, and ensure sustainable food production for future generations.

#Agriculture Chemical Industry#Global Agrochemical Industry#Agricultural Chemicals Market Research Reports#Agricultural Chemicals Industry Research Reports#Agriculture Chemical Market Analysis#Agriculture Chemical Market Demand#Agriculture Chemical Market Forecast#Agriculture Chemical Market Growth#Agriculture Chemical Market Outlook#Agriculture Chemical Market Revenue#Agriculture Chemical Market Size#Agriculture Chemical Market Trends#Agriculture Chemical Brands in Market#Agricultural Chemicals#Chemicals Used in Agriculture#Agriculture Chemical Companies#Agricultural Chemical Suppliers#Agriculture Chemical Malaysia#Agricultural Chemical Manufacturers

0 notes

Text

After trees were felled in the 1980s, the publicly owned Malua Forest Reserve was dedicated to learning how best to restore tropical forests. A 500-hectare (1,235-acre) study site was divided into 125 experimental plots that, in 2002-03, were either left to recover naturally or planted with a mixture of one, four or 16 native tree species. By 2012, the plots replanted with a mixture of 16 native tree species showed a quicker recovery of canopy area and total tree biomass, compared with areas replanted with four or only a single native species. But even plots replanted with just one tree species recovered more quickly after 10 years than those left to naturally regenerate. Prof Andrew Hector, of the University of Oxford, who set up the experiment more than 20 years ago as part of the South East Asia Rainforest Research Partnership (SEARRP), said: “Our new study demonstrates that replanting logged tropical forests with diverse mixtures of native tree species achieves multiple wins, accelerating the restoration of tree cover, biodiversity, and important ecosystem services such as carbon sequestration.” The researchers, who published their findings in the journal Science Advances, said that the probable reason for the better recovery was that different tree species occupied distinct niches within the forest ecosystem and so diverse mixtures of planted species complemented each other and increased the effective functioning of the whole ecosystem. For instance, some tropical species were more tolerant of drought because they produced more protective chemicals, giving the forest resilience during periods of low rainfall.

[...]

Ryan Veryard, the lead author of the study, said: “Importantly, our results show that logged forest can recover so long as it is not converted to agricultural uses like oil palm plantation. They also emphasise the need to conserve biodiversity within undisturbed forests, so that we can restore it in areas that have already been logged.”

88 notes

·

View notes

Text

Bottling and Packaging Line Solution

Company Overview: Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Bottling and Packaging Line Solution in Ahmedabad, Gujarat, India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. A Bottling and Packaging Line Solution is an integrated system designed to streamline the entire process of filling, capping, labeling, inspecting, and packaging bottles. It is used across industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals, ensuring that liquid and semi-liquid products are efficiently packaged for distribution. These automated systems help businesses reduce production time, minimize human error, and ensure high-quality standards for every product. Similar Name of Bottling and Packaging Line Solution: Automated Bottling and Packaging System, Bottle Filling and Packing Line, Integrated Packaging and Bottling Solution, Liquid Packaging Line System, Complete Bottling Line Setup, Turnkey Packaging and Bottling Solutions, Customizable Bottling and Packaging Equipment, Automated Beverage Bottling Line, Filling and Packaging Machinery Solutions, Industrial Bottling and Packaging System. Why Choose Bottling and Packaging Line Solutions? Increased Efficiency: Automation minimizes manual labor, reducing human error and increasing throughput. Consistency and Quality Control: Advanced systems ensure uniform filling, sealing, and packaging. Scalability: Modular designs allow you to upgrade or expand systems as your business grows. Cost Savings: Streamlined processes reduce waste, energy use, and operational costs. Compliance and Safety: Modern solutions adhere to strict regulatory standards, safeguarding consumer health and brand reputation. Applications of Bottling and Packaging Line Solution: Food and Beverage Pharmaceuticals Cosmetics and Personal Care Chemicals Agricultural Products What is a bottling and packaging line solution? A bottling and packaging line solution encompasses machinery and processes designed to automate the filling, sealing, labeling, and packaging of liquid products. How do I determine the right capacity for my production line? Capacity depends on your current production volume and future growth projections. Consulting with a professional provider can help you determine the optimal configuration. Shiv Shakti Machtech is a Bottling and Packaging Line Solution and an exporter worldwide, including to Algeria, Angola, Antigua, Barbuda, Argentina, Armenia, Australia, Austria, The Bahamas, Bahrain, Bangladesh, Belarus, Belgium, Belize, Benin, Bhutan, Bolivia, Botswana, Brazil, Brunei, Bulgaria, Burkina Faso, Cambodia, Cameroon, Canada, Central African Republic, Chad, Chile, Colombia, Congo, Democratic Republic of the Congo, Costa Rica, Cuba, Cyprus, Denmark, Dominica, Ecuador, Egypt, Guinea, Ethiopia, Fiji, Finland, France, The Gambia, Georgia, Germany, Ghana, Greece, Guyana, Hungary, Iceland, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, South Korea, North Korea, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Libya, Malawi, Malaysia, Maldives, Mali, Mauritania, Mauritius, Mexico, Moldova, Monaco, Mongolia, Morocco, Mozambique, Myanmar (Burma), Namibia, Nepal, Netherlands, New Zealand, Niger, Nigeria, Norway, Oman, Panama, Peru, Philippines, Poland, Portugal, Qatar, Romania, Russia, Rwanda, Saint Lucia, Saudi Arabia, Senegal, Serbia, Singapore, Slovakia, Somalia, South Africa, Spain, Sri Lanka, Sudan, South Sudan, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Togo, Tunisia, Turkey, Uganda, Ukraine, United Arab Emirates (UAE), United Kingdom, United States, Uruguay, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Yemen, Zambia, and Zimbabwe. For further details or inquiries, feel free to reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Algeria#Angola#Antigua#Argentina#Armenia#Australia#Austria#Bahrain#Bangladesh#Barbuda#Belarus#Belgium#Belize#Benin#Bhutan#Bolivia#Botswana#BottlingandPackagingLineSolution#BottlingandPackagingLineSolutioninGujarat#BottlingandPackagingLineSolutioninIndia#Brazil#Brunei#Bulgaria#BurkinaFaso#Cambodia#Cameroon#Canada#CentralAfricanRepublic#Chad

2 notes

·

View notes

Text

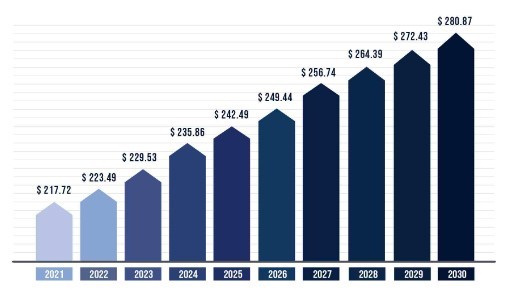

Acetic Acid Market - Forecast(2024 - 2030)

Acetic Acid Market Overview

Acetic Acid Market Size is forecast to reach $14978.6 Million by 2030, at a CAGR of 6.50% during forecast period 2024-2030. Acetic acid, also known as ethanoic acid, is a colorless organic liquid with a pungent odor. The functional group of acetic acid is methyl and it is the second simplest carboxylic acid. It is utilized as a chemical reagent in the production of many chemical compounds. The major use of acetic acid is in the manufacturing of vinyl acetate monomer, acetic anhydride, easter and vinegar. It is a significant industrial chemical and chemical reagent used in the production of photographic film, fabrics and synthetic fibers. According to the Ministry of Industry and Information Technology, from January to September 2021, the combined operating revenue of 12,557 major Chinese garment companies was US$163.9 billion, showing a 9% increase. Thus, the growth of the textile industry is propelling the market growth for Acetic Acid.

Report Coverage

The “Acetic Acid Market Report – Forecast (2024-2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Acetic Acid industry.

By Form: Liquid and Solid.

By Grade: Food grade, Industrial grade, pharmaceutical grade and Others.

By Application: Vinyl Acetate Monomer, Purified Terephthalic Acid, Ethyl Acetate, Acetic Anhydride, Cellulose Acetate, Acetic Esters, Dyes, Vinegar, Photochemical and Others

By End-use Industry: Textile, Medical and Pharmaceutical, Oil and Gas, Food and Beverages, Agriculture, Household Cleaning Products, Plastics, Paints & Coating and Others.

By Geography: North America (the USA, Canada and Mexico), Europe (the UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium and the Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia and the Rest of APAC), South America (Brazil, Argentina, Colombia, Chile and the Rest of South America) and the Rest of the World (the Middle East and Africa).

Request Sample

Key Takeaways

The notable use of Acetic Acid in the food and beverages segment is expected to provide a significant growth opportunity to increase the Acetic Acid Market size in the coming years. As per the US Food and Agriculture Organization, world meat production reached 337 million tonnes in 2019, up by 44% from 2000.

The notable demand for vinyl acetate monomer in a range of industries such as textile finishes, plastics, paints and adhesives is driving the growth of the Acetic Acid Market.

Increase in demand for vinegar in the food industry is expected to provide substantial growth opportunities for the industry players in the near future in the Acetic Acid industry.

Acetic Acid Market Segment Analysis – by Application

The vinyl acetate monomer segment held a massive 44% share of the Acetic Acid Market share in 2021. Acetic acid is an important carboxylic acid and is utilized in the preparation of metal acetates and printing processes, industrially. For industrial purposes, acetic acid is manufactured by air oxidation of acetaldehyde with the oxidation of ethanol, butane and butene. Acetic acid is extensively used to produce vinyl acetate which is further used in formulating polyvinyl acetate. Polyvinyl acetate is employed in the manufacturing of plastics, paints, textile finishes and adhesives. Thus, several benefits associated with the use of vinyl acetate monomer is boosting the growth and is expected to account for a significant share of the Acetic Acid Market.

Inquiry Before Buying

Acetic Acid Market Segment Analysis – by End-use Industry

The food and beverages segment is expected to grow at the fastest CAGR of 7.5% during the forecast period in the Acetic Acid Market. Acetic Acid is also known as ethanoic acid and is most extensively used in the production of vinyl acetate monomer. Vinyl acetate is largely used in the production of cellulose acetate which is further used in several industrial usage such as textiles, photographic films, solvents for resins, paints and organic esters. PET bottles are manufactured using acetic acid and are further utilized as food containers and beverage bottles. In food processing plants, acetic acid is largely used as cleaning and disinfecting products. Acetic acid is extensively used in producing vinegar which is widely used as a food additive in condiments and the pickling of vegetables. According to National Restaurant Association, the foodservice industry is forecasted to reach US$898 billion by 2022. Thus, the advances in the food and beverages industry are boosting the growth of the Acetic Acid Market.

Acetic Acid Market Segment Analysis – by Geography

Asia-Pacific held a massive 41% share of the Acetic Acid Market in 2021. This growth is mainly attributed to the presence of numerous end-use industries such as textile, food and beverages, agriculture, household cleaning products, plastics and paints & coatings. Growth in urbanization and an increase in disposable income in this region have further boosted the industrial growth in this region. Acetic acid is extensively used in the production of metal acetates, vinyl acetate and vinegar which are further utilized in several end-use industries. Also, Asia-Pacific is one of the major regions in the domain of plastic production which provides substantial growth opportunities for the companies in the region. According to Plastic Europe, China accounted for 32% of the world's plastic production. Thus, the significant growth in several end-use industries in this region is also boosting the growth of the Acetic Acid Market.

Acetic Acid Market Drivers

Growth in the textile industry:

Acetic Acid, also known as ethanoic acid, is widely used in the production of metal acetate and vinyl acetate which are further used in the production of chemical reagents in textiles, photographic films, paints and volatile organic esters. In the textile industry, acetic acid is widely used in textile printing and dyes. According to China’s Ministry of Industry and Information Technology, in 2020, textile and garment exports from China increased by 9.6% to US$291.22 billion. Also, according to the U.S. Department of Commerce, from January to September 2021, apparel exports increased by 28.94% to US$4.385 billion, while textile mill products rose by 17.31% to US$12.365 billion. Vinyl acetate monomer is utilized in the textile industry to produce synthetic fibers. Thus, the global growth in demand for textiles is propelling the growth and is expected to account for a significant share of the Acetic Acid Market size.

Schedule a call

Surge in use of vinegar in the food industry:

The rapid surge in population along with the adoption of a healthy and sustainable diet has resulted in an increase in demand for food items, thereby increasing the global production level of food items. As per US Food and Agriculture Organization, in 2019, global fruit production went up to 883 million tonnes, showing an increase of 54% from 2000, while global vegetable production was 1128 million tonnes, showing an increase of 65%. Furthermore, world meat production reached 337 million tonnes in 2019, showing an increase of 44% from 2000. Acetic acid is majorly used in the preparation of vinegar which is further widely utilized as a food ingredient and in personal care products. Vinegar is used in pickling liquids, marinades and salad dressings. It also helps to reduce salmonella contamination in meat and poultry products. Furthermore, acetic acid and its sodium salts are used as a food preservative. Thus, the surge in the use of vinegar in the food industry is boosting the growth of the Acetic Acid Market.

Acetic Acid Market Challenge

Adverse impact of acetic acid on human health:

Acetic Acid is considered a strong irritant to the eye, skin and mucous membrane. Prolong exposure to and inhalation of acetic acid may cause irritation to the nose, eyes and throat and can also damage the lungs. The workers who are exposed to acetic acid for more than two or three years have witnessed upper respiratory tract irritation, conjunctival irritation and hyperkeratotic dermatitis. The Occupational Safety and Health Administration (OSHA) reveals that the standard exposure to airborne acetic acid is eight hours. Furthermore, a common product of acetic acid i.e., vinegar can cause gastrointestinal tract inflammatory conditions such as indigestion on excess consumption. Thus, the adverse impact of Acetic Acid may hamper the market growth.

Buy Now

Acetic Acid Industry Outlook

The top 10 companies in the Acetic Acid Market are:

Celanese Corporation

Eastman Chemical Company

LyondellBasell

British Petroleum

Helm AG

Pentoky Organy

Dow Chemicals

Indian Oil Corporation

Daicel Corporation

Jiangsu Sopo (Group) Co. Ltd.

Recent Developments

In March 2021, Celanese Corporation announced the investment to expand the production facility of vinyl portfolio for the company’s acetyl chain and derivatives in Europe and Asia.

In April 2020, Celanese Corporation delayed the construction of its new acetic acid plant and expansion of its methanol production by 18 months at the Clear Lake site in Texas.

In October 2019, BP and Chian’s Zhejiang Petroleum and Chemical Corporation signed MOU in order to create a joint venture to build a 1 million tonne per annum Acetic Acid plant in eastern China.

Key Market Players:

The Top 5 companies in the Acetic Acid Market are:

Celanese Corporation

Ineos Group Limited

Eastman Chemical Company

LyondellBasell Industries N.V.

Helm AG

For more Chemicals and Materials Market reports, please click here

#Acetic Acid Market#Acetic Acid Market Share#Acetic Acid Market Size#Acetic Acid Market Forecast#Acetic Acid Market Report#Acetic Acid Market Growth

2 notes

·

View notes

Text

IBC Cap Market Size, Share, Trends, Growth and Competitive Analysis

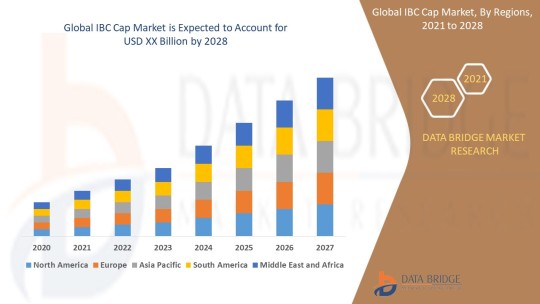

"IBC Cap Market – Industry Trends and Forecast to 2028

Global IBC Cap Market, By Product Type (Flange, Plugs, Vent-in Plug, Vent-out Plug and Screw closure), Type (Plastic IBC, Metal IBC and Composite IBCs), Material Type (Plastics, Metal, Aluminium and Steel), End Use (Chemicals & Fertilizers, Petroleum & Lubricants, Paints, Inks & Dyes, Food & Beverage, Agriculture, Building & Construction, Healthcare & Pharmaceuticals and Mining), Application (Food And Drinks, Chemical Industry, Oil and Agriculture), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

The global IBC cap market is expected to witness significant growth over the forecast period due to the increasing demand for intermediate bulk containers (IBCs) in various industries such as chemicals, food and beverages, pharmaceuticals, and others. The IBC caps play a crucial role in ensuring the safe storage and transportation of liquid products. The market growth is also being driven by technological advancements in IBC cap designs, such as tamper-evident seals and spouts for easy dispensing. Additionally, the growing focus on sustainability and recyclability of packaging materials is further boosting the adoption of IBC caps made from eco-friendly materials.

**Segments**

- Based on material type, the IBC cap market can be segmented into plastic, metal, and others. Plastic caps are widely used due to their lightweight nature and cost-effectiveness. - By cap type, the market can be categorized into screw caps, snap-on caps, and flip-top caps. Screw caps are preferred for their secure sealing properties. - On the basis of end-user industry, the market can be divided into chemicals, food and beverages, pharmaceuticals, and others. The chemicals segment is anticipated to hold a significant market share due to the widespread use of IBCs for storing chemical products.

**Market Players**

- TPS Industrial Srl - Schuetz GmbH & Co. KGaA - Mauser Packaging Solutions - Time Technoplast Ltd - Berry Global Inc. - THIELMANN UCON AG - Precision IBC, Inc. - Peninsula Packaging LLC

These market players are actively involved in strategic initiatives such as product launches, partnerships, and acquisitions to strengthen their market presence and expand their product offerings. The competitive landscape of the IBC cap market is characterized by intense competition, prompting companies to focus on innovation and quality to gain a competitive edge.

The Asia-Pacific region is expected to witness substantial growth in the IBC cap market, driven by the rapid industrialization and the increasing adoption of IBCsThe Asia-Pacific region represents a significant growth opportunity for the global IBC cap market due to several key factors. With rapid industrialization and the expanding manufacturing sector in countries like China, India, and Southeast Asia, there is a growing demand for efficient storage and transportation solutions, including IBCs and their associated caps. The increased focus on chemical production, food processing, and pharmaceutical manufacturing in the region further fuels the need for reliable packaging solutions like IBC caps. As these industries continue to grow, the adoption of IBC caps is expected to rise, driving market expansion in the Asia-Pacific region.

Moreover, the emphasis on enhancing safety standards and ensuring product integrity is a crucial factor contributing to the growth of the IBC cap market in Asia-Pacific. Regulations regarding the safe handling and transportation of hazardous chemicals and pharmaceuticals necessitate the use of high-quality caps that can effectively seal and protect the contents of IBCs. As companies in the region strive to comply with stringent regulatory requirements, the demand for advanced and secure IBC caps is projected to increase significantly.

Additionally, the shift towards sustainability and eco-friendly practices is another trend shaping the IBC cap market in Asia-Pacific. With growing environmental concerns and increasing awareness about plastic pollution, there is a rising preference for IBC caps made from recyclable and biodegradable materials. Market players in the region are focusing on developing sustainable packaging solutions to meet the evolving consumer demands and align with global sustainability goals. This shift towards eco-friendly IBC caps not only addresses environmental concerns but also presents market players with opportunities to differentiate their offerings and attract environmentally conscious customers.

Furthermore, the competitive landscape of the IBC cap market in Asia-Pacific is characterized by the presence of both local manufacturers and international players. Local companies often have a strong understanding of regional market dynamics and customer preferences, giving them a competitive advantage in catering to specific industry needs. On the other hand, multinational companies bring technological expertise and a wide product portfolio, which can appeal to a broader customer base seeking innovative and**Global IBC Cap Market, By Product Type**

- Flange - Plugs - Vent-in Plug - Vent-out Plug - Screw closure

**Type**

- Plastic IBC - Metal IBC - Composite IBCs

**Material Type**

- Plastics - Metal - Aluminium - Steel

**End Use**

- Chemicals & Fertilizers - Petroleum & Lubricants - Paints, Inks & Dyes - Food & Beverage - Agriculture - Building & Construction - Healthcare & Pharmaceuticals - Mining

**Application**

- Food And Drinks - Chemical Industry - Oil and Agriculture

The Global IBC Cap market is experiencing significant growth due to the rising demand for intermediate bulk containers across various industries. Plastic caps are increasingly preferred for their lightweight and cost-effective nature, driving market growth within the material type segment. Screw caps, known for their secure sealing properties, dominate the cap type category. The chemicals segment is anticipated to hold a substantial market share among end-user industries, attributed to the widespread use of IBCs for chemical storage. The market players in the industry are focusing on strategic initiatives like product launches and partnerships to enhance their market presence and offerings. The competitive landscape is intense, spurring companies to innovate and prioritize quality for a competitive advantage.

In Asia-Pacific, the IBC cap market is poised for robust growth fueled by rapid industrialization and the expanding manufacturing sector, particularly in countries like China,

Countries Studied:

North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Key Coverage in the IBC Cap Market Report:

Detailed analysis of IBC Cap Market by a thorough assessment of the technology, product type, application, and other key segments of the report

Qualitative and quantitative analysis of the market along with CAGR calculation for the forecast period

Investigative study of the market dynamics including drivers, opportunities, restraints, and limitations that can influence the market growth

Comprehensive analysis of the regions of the IBC Cap industry and their futuristic growth outlook

Competitive landscape benchmarking with key coverage of company profiles, product portfolio, and business expansion strategies

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Browse Trending Reports:

Calcium Glycinate Market Retinal Biologics Market Facial Fat Transfer Market Angio Suites Diagnostic Imaging Market Adoption Of Benelux Power Tools Market De Quervains Tenosynovitis Treatment Market Biodetectors And Accessories Market Colposcope Market Sports Medicine Market Automotive Adhesives Market Infrared Imaging Market Vapour Deposition Market Professional Diagnostics Market Ct Scanner Market Programmable Application Specific Integrated Circuit Asic Market Hospital Operating Room Or Products And Solutions Market Castor Oil Market Zika Virus Infection Drug Market Toluene Diisocynate Market Antibiotic Resistance Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

2 notes

·

View notes

Link

0 notes

Text

Top 15 Market Players in Global Ethoxylated Sorbitan Esters Market

Top 15 Market Players in Global Ethoxylated Sorbitan Esters Market

The global ethoxylated sorbitan esters market is characterized by the presence of several key players who contribute significantly to its growth and development. These companies are involved in the production and distribution of ethoxylated sorbitan esters, which are widely used as emulsifiers and stabilizers in various industries, including food and beverages, personal care, pharmaceuticals, and agriculture.

BASF SE (Germany): A leading chemical company offering a diverse range of products, including ethoxylated sorbitan esters for various applications.

Kao Chemicals (Japan): Specializes in the production of chemical products, including surfactants like ethoxylated sorbitan esters, catering to multiple industries.

Oxiteno (Brazil): A prominent player in the chemical sector, providing ethoxylated sorbitan esters used in personal care and industrial applications.

Avantor (U.S.): Offers a wide range of high-purity chemicals and materials, including ethoxylated sorbitan esters for pharmaceutical and laboratory use.

Evonik Industries (Germany): Produces specialty chemicals, including ethoxylated sorbitan esters, serving industries such as personal care and pharmaceuticals.

Guangdong Runhua Chemistry (China): Engages in the manufacture of chemical products, including ethoxylated sorbitan esters for various industrial applications.

Nanjing Well Pharmaceutical (China): Focuses on the production of pharmaceutical intermediates and additives, including ethoxylated sorbitan esters.

Lonza (Switzerland): Provides a range of chemical products, including ethoxylated sorbitan esters, for applications in life sciences and personal care.

NOF Corporation (Japan): Specializes in the production of functional chemicals, including ethoxylated sorbitan esters used in various industries.

Clariant AG (Switzerland): Offers specialty chemicals, including ethoxylated sorbitan esters, catering to sectors like personal care and industrial applications.

Croda International Plc (UK): Produces specialty chemicals, including ethoxylated sorbitan esters, for use in personal care and pharmaceutical products.

Emery Oleochemical (Malaysia): Manufactures oleochemical products, including ethoxylated sorbitan esters, serving various industrial sectors.

Addcomp Holland (Netherlands): Provides additive solutions, including ethoxylated sorbitan esters, for applications in plastics and other industries.

Mosselman S.A. (Belgium): Specializes in the production of oleochemicals, including ethoxylated sorbitan esters, for diverse applications.

Stepan Company (U.S.): Produces specialty and intermediate chemicals, including ethoxylated sorbitan esters, for use in various industries.

Request report sample at https://datavagyanik.com/reports/global-ethoxylated-sorbitan-esters-market-size-production-sales-average-product-price-market-share/

Top Winning Strategies in Ethoxylated Sorbitan Esters Market

Leading companies in the ethoxylated sorbitan esters market employ various strategies to maintain and enhance their market positions:

Innovation and Product Development: Continuous investment in research and development to create advanced formulations with improved performance characteristics, catering to specific industry needs.

Strategic Partnerships and Collaborations: Forming alliances with other companies to leverage complementary strengths, expand market reach, and develop innovative solutions.

Sustainability Initiatives: Focusing on sustainable production processes and developing bio-based ethoxylated sorbitan esters to meet the growing demand for environmentally friendly products.

Market Expansion: Exploring new geographical markets and applications to increase market share and capitalize on emerging opportunities.

Customer-Centric Approach: Offering customized solutions and technical support to meet specific customer requirements, thereby building long-term relationships and loyalty.

By implementing these strategies, companies aim to strengthen their competitive edge and drive growth in the dynamic ethoxylated sorbitan esters market.

Request a free sample copy at https://datavagyanik.com/reports/global-ethoxylated-sorbitan-esters-market-size-production-sales-average-product-price-market-share/

#Ethoxylated Sorbitan Esters Market#Ethoxylated Sorbitan Esters Production#market growth#market players#market share#average price#market size#top trends#revenue#competitive pricing strategies

0 notes

Link

0 notes

Link

0 notes

Text

A Deep Dive into the Para Nitrochlorobenzene Market: Insights and Analysis

The global para nitrochlorobenzene market size is projected to reach USD 420.7 million by 2027, according to a new report by Grand View Research, Inc., expanding at a CAGR of 4.1% over the forecast period. Dyes emerged as the most dominant application of para nitrochlorobenzene (PNCB) in 2019 in terms of revenue on account of growing textile market, especially in the developing countries of Asia Pacific.

China and India are the leading producers of PNCB. The growth in benzene production in China and Southeast Asia is, thus, anticipated to generate feedstock availability for the manufacturers of chlorobenzene and its derivatives. One of the planned capacity expansions is the expansion of the Petronas refinery in Malaysia, which is expected to grow by an additional 667,000 mt/year. Moreover, in May 2019, PetroChina’s Huabei refinery announced an expansion plan to reach 200,000 b/d from 100,000 b/d. These expansions are anticipated to increase the annual benzene supply, especially in Asia, thus benefitting the entire benzene value chain in terms of raw material availability, price, and constant supply.

The benzene supply is anticipated to directly have a positive influence on the production of nitrobenzene, chlorobenzene, styrene, and phenol. Para nitrochlorobenzene is on the third stage of the benzene value chain. Its production is anticipated to be positively influenced by the growth in chlorobenzene production.

In spite of the positive outlook of PNCB production, the consumption is anticipated to be hindered by the stringent regulations on the chemical. Nitrofen and parathion are the active ingredients used in pesticides that are manufactured from para nitrochlorobenzene. Both these chemicals are banned in certain countries mainly due to their insolubility in water, which causes harm to the aquatic life and increases the soil salinity. Thus, demand for para nitrochlorobenzene in pesticide manufacturing is anticipated to grow at a slow pace over the forecast period.

Gather more insights about the market drivers, restrains and growth of the Para Nitrochlorobenzene Market

Para Nitrochlorobenzene Market Report Highlights

• By application, pesticides led the market with a share of 29.5% in 2019 in terms of volume

• Para nitrochlorobenzene and active ingredients manufactured from the chemical are under high scrutiny of various regulatory bodies, which is anticipated to result in slow growth of the product in the agriculture industry with a revenue-based CAGR of 3.8% from 2020 to 2027

• Tire is the major application of rubber and its production has significantly increased in the emerging Asia Pacific countries, including China and India. The rubber chemicals application segment is therefore expected to expand at the fastest revenue-based CAGR of 4.8% from 2020 to 2027

• By end use, the pharmaceuticals segment accounted for 25.3% share of the overall revenue in 2019 and is expected to be the fastest growing segment based on revenue as well as volume over the forecast period

Para Nitrochlorobenzene Market Segmentation

Grand View Research has segmented the global para nitrochlorobenzene market on the basis of application, end use, and region:

Para Nitrochlorobenzene Application Outlook (Volume, Kilotons; Revenue, USD Million, 2016 - 2027)

• Dyes

• Pesticides

• Rubber Chemicals

• Others

Para Nitrochlorobenzene End-Use Outlook (Volume, Kilotons; Revenue, USD Million, 2016 - 2027)

• Agriculture

• Pharmaceuticals

• Chemicals

• Others

Para Nitrochlorobenzene Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2016 - 2027)

• North America

o U.S

o Canada

o Mexico

• Europe

o Germany

o U.K.

o Italy

o France

• Asia Pacific

o China

o India

o Japan

o South Korea

• Central & South America

o Brazil

o Argentina

• Middle East & Africa

o Saudi Arabia

o South Africa

Order a free sample PDF of the Para Nitrochlorobenzene Market Intelligence Study, published by Grand View Research.

#Para Nitrochlorobenzene Market#Para Nitrochlorobenzene Market Size#Para Nitrochlorobenzene Market Share#Para Nitrochlorobenzene Market Analysis#Para Nitrochlorobenzene Market Growth

0 notes

Text

The Agricultural Chemicals Market Share, Growth, and Major Players

Introduction

The Agricultural Chemicals Market plays a vital role in modern farming practices, providing essential products for crop protection, soil fertility management, and pest control. This article delves into the dynamics of the agricultural chemicals market, including its demand, growth, outlook, revenue, size, trends, and prominent brands.

Agricultural Chemical Market Demand

The demand for agricultural chemicals remains robust, driven by the need to enhance crop productivity and mitigate yield losses caused by pests, diseases, and environmental stressors. Market research indicates a steady increase in global demand for agricultural chemicals, with the Asia-Pacific region leading consumption due to extensive agricultural activities.

Agricultural Chemical Market Growth

The agricultural chemicals market is experiencing steady growth, with a projected compound annual growth rate (CAGR) of approximately 4.5% over the forecast period. Factors contributing to market growth include population growth, expanding agricultural land, adoption of modern farming techniques, and the emergence of new crop protection solutions.

Agricultural Chemical Market Outlook

The outlook for the agricultural chemicals market is optimistic, driven by technological advancements, regulatory support for agricultural inputs, and increasing adoption of precision farming practices. Market analysts project sustained growth in market value, surpassing USD 300 billion by 2025, with significant contributions from emerging markets in Asia and Latin America.

Agricultural Chemical Market Revenue

In recent years, the revenue generated from the agricultural chemicals market has been on the rise. Global market revenue reached USD 220 billion in 2020, with herbicides accounting for the largest share followed by fertilizers and pesticides. The market revenue is expected to witness further growth, driven by increasing investments in agricultural inputs and crop protection solutions.

Agricultural Chemical Market Size

The agricultural chemicals market is sizable, with diverse product offerings catering to various crop types and farming systems. In 2020, the market size exceeded 250 million metric tons in terms of product volume. Herbicides, fungicides, and insecticides are among the most widely used agricultural chemicals, contributing to the market's substantial size.

Agricultural Chemical Market Trends

Several trends are shaping the landscape of the agricultural chemicals market, including:

Shift Towards Bio-based Solutions: There is a growing preference for bio-based and environmentally friendly agricultural chemicals, driven by concerns over chemical residues, environmental sustainability, and consumer preferences for organic produce.

Digital Agriculture: The integration of digital technologies such as precision agriculture, data analytics, and smart farming tools is transforming agricultural chemical applications. Digital platforms offer farmers real-time insights into crop health, soil conditions, and pest infestations, enabling targeted and efficient use of agricultural inputs.

Sustainable Agriculture Practices: Sustainability initiatives are gaining traction in the agricultural chemicals sector, with companies investing in eco-friendly formulations, biodegradable packaging, and responsible sourcing practices. Sustainable agriculture certifications and labels are becoming increasingly important for market differentiation and consumer trust.

Agriculture Chemical Brands in Market

Prominent brands in the Agricultural Chemicals Market include:

Bayer CropScience

Syngenta

BASF SE

Corteva Agriscience

FMC Corporation

Sumitomo Chemical

Nufarm Limited

UPL Limited

ADAMA Agricultural Solutions

Conclusion

The agricultural chemicals market is poised for continued growth and innovation, driven by technological advancements, sustainability initiatives, and increasing demand for crop protection solutions. As farmers face evolving challenges such as climate change, pest resistance, and regulatory pressures, the role of agricultural chemicals in ensuring food security and sustainable agriculture practices becomes increasingly crucial. Collaboration among stakeholders, investment in research and development, and adherence to sustainable principles will be key to unlocking the full potential of the agricultural chemicals market and addressing the needs of the global farming community.

#Agriculture Chemical Industry#Global Agrochemical Industry#Agricultural Chemicals Market Research Reports#Agricultural Chemicals Industry Research Reports#Agriculture Chemical Market Analysis#Agriculture Chemical Market Demand#Agriculture Chemical Market Forecast#Agriculture Chemical Market Growth#Agriculture Chemical Market Outlook#Agriculture Chemical Market Revenue#Agriculture Chemical Market Size#Agriculture Chemical Market Trends#Agriculture Chemical Brands in Market#Agricultural Chemicals#Chemicals Used in Agriculture#Agriculture Chemical Companies#Agricultural Chemical Suppliers#Agriculture Chemical Malaysia#Agricultural Chemical Manufacturers

0 notes

Link

0 notes

Text

Filling Line - End to End Packaging Solution

Company Overview: Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Filling Line - End to End Packaging Solution in Ahmedabad, Gujarat, India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. Filling lines are advanced, automated systems that optimize packaging efficiency for various industries, such as food and beverages, pharmaceuticals, chemicals, and cosmetics. From product filling to capping, labeling, and sealing, these systems provide a seamless, end-to-end packaging solution. Process of Filling Lines: Filling lines follow a systematic, step-by-step process to ensure efficient product packaging: Product Feeding: The raw material or liquid is fed into the system, often from bulk storage tanks. Filling: The system accurately measures and dispenses the product into containers or bottles. Capping: The system automatically places and tightens caps or lids onto the filled containers. Sealing: The system seals containers using heat or adhesives to ensure product integrity. Labeling: The system applies custom labels to containers for branding and regulatory compliance. Inspection: The system conducts quality checks to ensure that the packaging meets standards. Cartoning & Palletizing: The system groups, boxes, and prepares packaged items for shipping. Applications of Filling Lines: Food & Beverage Industry Pharmaceutical Industry Cosmetics & Personal Care Chemical Industry Agricultural Products What is a filling line? A filling line automates the process of filling containers with liquids, powders, or granules. It can include processes like capping, labeling, and packaging for a complete solution. What industries use filling lines? Industries like food and beverage, pharmaceuticals, cosmetics, and chemical manufacturing commonly use filling lines. Can a filling line handle multiple product types? Yes, our filling lines are versatile and can handle various product types, including liquids, semi-liquids, powders, and viscous materials. Shiv Shakti Machtech is a Filling Line - End to End Packaging Solution and an exporter worldwide, including to Algeria, Angola, Antigua, Barbuda, Argentina, Armenia, Australia, Austria, The Bahamas, Bahrain, Bangladesh, Belarus, Belgium, Belize, Benin, Bhutan, Bolivia, Botswana, Brazil, Brunei, Bulgaria, Burkina Faso, Cambodia, Cameroon, Canada, Central African Republic, Chad, Chile, Colombia, Congo, Democratic Republic of the Congo, Costa Rica, Cuba, Cyprus, Denmark, Dominica, Ecuador, Egypt, Guinea, Ethiopia, Fiji, Finland, France, The Gambia, Georgia, Germany, Ghana, Greece, Guyana, Hungary, Iceland, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, South Korea, North Korea, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Libya, Malawi, Malaysia, Maldives, Mali, Mauritania, Mauritius, Mexico, Moldova, Monaco, Mongolia, Morocco, Mozambique, Myanmar (Burma), Namibia, Nepal, Netherlands, New Zealand, Niger, Nigeria, Norway, Oman, Panama, Peru, Philippines, Poland, Portugal, Qatar, Romania, Russia, Rwanda, Saint Lucia, Saudi Arabia, Senegal, Serbia, Singapore, Slovakia, Somalia, South Africa, Spain, Sri Lanka, Sudan, South Sudan, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Togo, Tunisia, Turkey, Uganda, Ukraine, United Arab Emirates (UAE), United Kingdom, United States, Uruguay, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Yemen, Zambia, Zimbabwe. For further details or inquiries, feel free to reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Algeria#Angola#Antigua#Argentina#Armenia#Australia#Austria#Bahrain#Bangladesh#Barbuda#Belarus#Belgium#Belize#Benin#Bhutan#Bolivia#Botswana#Brazil#Brunei#Bulgaria#BurkinaFaso#Cambodia#Cameroon#Canada#CentralAfricanRepublic#Chad#Chile#Colombia#Congo

2 notes

·

View notes

Text

Sorbitan Monostearate Prices Trend | Pricing | News | Price | Database | Chart

Sorbitan Monostearate a versatile non-ionic surfactant widely used in various industries, has become an essential component in sectors such as food, cosmetics, pharmaceuticals, and industrial applications. Its demand has been steadily increasing due to its multifunctional properties, such as emulsification, stabilizing, and dispersing capabilities. Consequently, the prices of sorbitan monostearate have garnered significant attention from industry stakeholders. Market dynamics, including production costs, raw material availability, regulatory changes, and global trade patterns, play a crucial role in determining the price trends of this compound.

The global market for sorbitan monostearate is influenced by fluctuations in raw material costs, primarily stearic acid and sorbitol. Both of these components are derived from natural sources, such as palm oil and corn, making their prices susceptible to agricultural cycles, geopolitical developments, and environmental regulations. Recent years have seen volatility in palm oil prices due to factors such as adverse weather conditions, labor shortages, and sustainability concerns. These fluctuations directly impact the production costs of sorbitan monostearate, translating into varying market prices. Additionally, the rising demand for sustainable and bio-based products has pushed manufacturers to adopt eco-friendly practices, which can also increase production expenses.

Regional market trends significantly shape the pricing of sorbitan monostearate. In Asia-Pacific, which is a major hub for chemical production, the availability of raw materials and lower labor costs contribute to competitive pricing. However, increasing environmental regulations and stricter sustainability requirements in countries such as Indonesia and Malaysia, key palm oil producers, have started to impact the cost structures for manufacturers. In North America and Europe, where there is a growing preference for natural and organic ingredients, sorbitan monostearate commands higher prices, particularly in the food and cosmetics industries. These regions are also experiencing increased regulatory scrutiny, further driving up costs associated with compliance and quality assurance.

Get Real time Prices for Sorbitan Monostearate: https://www.chemanalyst.com/Pricing-data/sorbitan-monostearate-1538

Technological advancements and innovations in manufacturing processes have also played a role in shaping the market dynamics of sorbitan monostearate. Producers are increasingly leveraging advanced production technologies to enhance efficiency and reduce waste. These innovations help in managing production costs and, consequently, pricing. Moreover, the development of customized grades of sorbitan monostearate tailored for specific applications, such as pharmaceutical excipients or high-performance industrial lubricants, has created a premium pricing segment within the market.

Global trade policies and tariffs also impact the pricing landscape of sorbitan monostearate. Trade disputes and changing import-export regulations can create uncertainties for manufacturers and buyers alike. For instance, tariffs on raw materials or finished goods can lead to increased costs for end-users, while favorable trade agreements can result in price reductions due to enhanced market access. The dynamic geopolitical landscape necessitates continuous monitoring of such factors by market participants.

Sustainability has emerged as a key driver of market trends and pricing for sorbitan monostearate. Consumers and businesses alike are prioritizing environmentally friendly products, compelling manufacturers to adopt sustainable practices in sourcing raw materials and producing the compound. While this shift aligns with global sustainability goals, it often entails higher production costs, which are eventually reflected in market prices. Certifications and eco-labeling also add to the overall cost but provide competitive advantages in markets where green credentials are highly valued.

Demand-supply dynamics also influence the pricing of sorbitan monostearate. Growing demand from burgeoning industries such as plant-based food products, clean-label cosmetics, and biodegradable packaging has put upward pressure on prices. However, overcapacity in certain regions or surplus production due to subdued demand during economic slowdowns can lead to price reductions. Balancing production levels with market demand remains a critical challenge for manufacturers aiming to maintain stable pricing.

The competitive landscape of the sorbitan monostearate market further contributes to its pricing dynamics. Established players with vertically integrated operations enjoy cost advantages, enabling them to offer competitive prices. In contrast, smaller or regional players may face higher production costs due to their reliance on external suppliers for raw materials. Market consolidation and strategic partnerships are becoming common strategies to enhance production efficiency and achieve cost competitiveness.

Looking ahead, the sorbitan monostearate market is expected to witness continued growth, driven by its diverse applications and the global shift towards sustainable products. However, price volatility will likely persist due to factors such as raw material fluctuations, regulatory changes, and evolving consumer preferences. Manufacturers will need to adopt innovative production methods, optimize supply chains, and stay abreast of market trends to maintain competitive pricing while meeting the growing demand. For stakeholders across industries, monitoring these market dynamics will be crucial to navigating the complex pricing landscape of sorbitan monostearate effectively.

Get Real time Prices for Sorbitan Monostearate: https://www.chemanalyst.com/Pricing-data/sorbitan-monostearate-1538

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Sorbitan Monostearate#Sorbitan Monostearate Prices#Sorbitan Monostearate News#Sorbitan Monostearate Pricing#Sorbitan Monostearate Demand#usa#united states#germany#india

1 note

·

View note

Link

0 notes

Link

0 notes