#Aerospace industry clamps

Explore tagged Tumblr posts

Text

Jolly in Space: Clamps That Are Out of This World

Within the fast-paced and rigorous landscape of aerospace industries, adherence to top-tier standards of safety, reliability, and performance is imperative for every component. Among these vital components, Jolly hose clamps serve a pivotal function by firmly securing fluid transfer systems, guaranteeing their integrity even in the face of challenging conditions.

Functionality and Importance:

Hose clamps play a crucial role in aerospace applications by ensuring secure seals between hoses and fittings. By preventing leaks, they mitigate the risk of system failure or jeopardizing the safety of aircraft operations. Whether it’s fuel lines, hydraulic systems, or pneumatic controls, hose clamps offer essential reinforcement, enabling them to endure the high pressures, vibrations, and temperature variations encountered during flight.

Materials and Design:

Due to the crucial role they play in aerospace operations, hose clamps are crafted from materials known for their outstanding strength, resistance to corrosion, and long-lasting durability. Stainless steel and titanium are frequently chosen for their lightweight nature and ability to endure harsh conditions without deteriorating. Additionally, aerospace hose clamps are meticulously designed with precision engineering to achieve the best possible grip and seal, thereby meeting rigorous performance standards.

Maintenance and Inspection:

Routine maintenance and inspection of hose clamps are essential to uphold ongoing reliability and safety in aerospace activities. Scheduled examinations to detect indications of wear, corrosion, or loosening are vital for proactively resolving potential concerns that could undermine system integrity. Moreover, during assembly, adherence to correct installation methods and torque specifications is imperative to ensure peak performance.

The Bottom Line

Our clamps, and clamps in general, play a pivotal role in ensuring peak performance for aerospace applications. These unassuming yet indispensable fixtures secure the integrity of fluid transfer systems that power our skies. Providing a steadfast grip, making system failures near-impossible, and raising the standards for safety while sky-bound, these clamps are power-packed pieces of equipment.

#Stainless steel clamps#Titanium clamps#Hose clamps#Aerospace industry clamps#Clamps for fluid systems

0 notes

Text

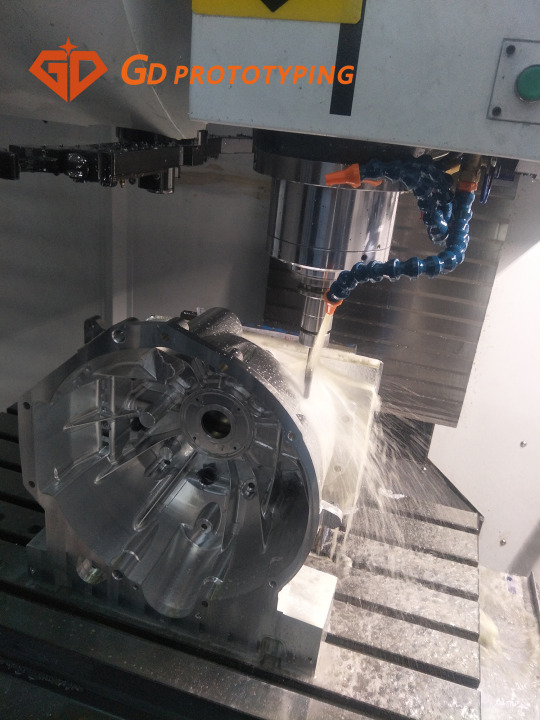

CNC Machining for Aerospace Products

Precision CNC machining of aeronautical parts, as an indispensable part of the modern aeronautical industry, provides strong technical support for the manufacture of aircraft with its high-precision and high-efficiency machining characteristics. With the continuous progress of science and technology and the rapid development of the aviation industry, precision CNC machining technology is also constantly optimised and innovated to meet the more demanding aerospace parts machining needs.

Why is CNC important in the aerospace industry?

There is very high and even demanding requirements in aerospace industry for structural design, functionality, performance, product quality and reliability. A large number of new materials and structures were first applied to aircraft components. National defence needs and market competition require a significant reduction in the development and production cycles of space products. In addition, the average cost of the final product needs to be constantly reduced, thus placing higher demands on the aerospace manufacturing industry and requiring advanced manufacturing technologies. Modern CNC machining is a key part of advanced manufacturing technology and has become a decisive key technology, especially in aerospace manufacturing. The following advantages of CNC machining services make them important in the aerospace industry: ①It is the process of synthesising a variety of advanced technology types, including computer technology, communication technology, modern manufacturing technology, digital control technology and so on. ②During CNC machining, the development of a new product and the machining of another batch can be realised by simply changing the settings and parameters of the CNC machine, greatly increasing automation and flexibility. ③Multiple CNC machining can be done automatically on a single machine or in a single clamping, greatly reducing machining time and production cycle time, as well as increasing efficiency. ④CNC machining technology improves the accuracy and precision of aerospace products, reduces or minimises manufacturing errors and results in CNC aircraft parts of higher quality and durability. ⑤Most materials for aerospace components need to be cut and machined during the manufacturing process.

CNC Aircraft Part Features and Application

What are aerospace products? Aircraft can be classified by structure into fuselage, engines, on-board equipment and components, including wings, large wall and tail frames, casings, valve bodies, hydraulic valves, optical tubes, rotor blades, fasteners, connectors, etc. ①Aircraft engine parts: Aircraft engine is one of the core components of the aircraft, the machining accuracy and performance of its parts directly affect the performance and safety of the entire aircraft. ②Fuselage Structural Components: Structural components are the backbone of the aircraft and are subject to a variety of complex loads. Precision CNC machining technology enables high-precision machining of fuselage structural parts, such as beams, frames, plates and other components, to ensure the stability and reliability of their dimensions and shapes. ③Avionics equipment parts: With the continuous development of avionics technology, avionics are more and more widely used in aircraft. Precision CNC machining technology enables high-precision machining of avionics parts, such as circuit boards, connectors and other components, to ensure their accuracy and reliability.

The main features of CNC machining of aerospace parts are as follows:

①High performance: use of new hard-to-machine materials such as titanium ②High Precision: Aerospace parts require a high degree of precision, and any small error may affect the performance and safety of the entire aircraft. Precision CNC machining technology meets the aerospace industry's need for high precision by machining in the micron level of accuracy, ensuring that the size and shape of the part is exactly as designed. ③High Efficient: Precision CNC machining technology can greatly improve productivity by automating and controlling the machining process. After one programming, the CNC machine can run continuously, reducing manual intervention time and increasing production speed. ④Flexibility: Parts in the aerospace industry are varied and complex in shape. Precision CNC machining technology can be quickly adapted to the machining needs of different parts by changing tools and adjusting the programme, without the need for cumbersome manual adjustments, and is suitable for small batch and multi-species production modes. ⑤Lightweight: Extensive use of thin-walled structures. ⑥Consistency: In mass production, part consistency is critical. Precision CNC machining technology ensures that the machining parameters of each part are exactly the same, avoiding quality fluctuations caused by human factors, thus ensuring product consistency and stability. ⑦Reliability and economy: Increasingly stringent quality and cost controls. ⑧Environmental protection and energy saving: The future of precision CNC machining of aerospace parts will pay more attention to environmental protection and energy saving. Adopting more energy-saving and environmentally friendly materials and processes to reduce resource waste and environmental pollution and realise green manufacturing.

In summary, precision CNC machining of aviation parts, as one of the important technologies in the modern aviation industry, provides strong technical support for the manufacture of aircraft with its high-precision and high-efficiency machining characteristics. With the continuous innovation and progress of technology, the future of precision CNC machining of aviation parts will move towards the direction of intelligence, automation, high-speed and high-precision, multi-axis and environmental protection and energy saving, injecting a new impetus for the development of the aviation industry.

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#cnc precision machining#aerospace parts#cnc precision#machining parts#aerospace#aviation#aircraft

2 notes

·

View notes

Text

The Role of High-Strength Bolt Materials in Secure Fastening

The strength and reliability of any structure depend on the quality of fasteners used. Selecting the right bolt material ensures long-lasting performance, especially in demanding environments.

Stainless Steel: Corrosion-resistant and ideal for outdoor and marine applications.

Carbon Steel: Known for high tensile strength, making it suitable for heavy-duty fastening.

Alloy Steel: A top choice for aerospace and automotive industries due to its superior strength and wear resistance.

Importance of High-Strength Bolts in Construction and Machinery

In construction and industrial applications, fasteners must withstand extreme conditions. Foundation bolts and foundation J bolts are commonly used for securing heavy structures, while anchor bolts manufactures provide stability in concrete foundations. These bolts ensure that buildings, bridges, and machinery remain secure.

For mechanical and piping systems, stud bolts offer excellent holding power, maintaining integrity even under high pressure. Additionally, stainless steel U-bolt manufacturers produce corrosion-resistant U-bolts that are perfect for securing pipes, conduits, and heavy equipment.

Choosing a Reliable Bolt Manufacturer

Working with a trusted U-bolt manufacturer or U-clamp manufacturer ensures precision and durability. High-quality fasteners enhance safety, reduce maintenance costs, and provide long-term reliability.

Whether you're sourcing foundation bolts, stud bolts, or anchor bolts, selecting the right materials and manufacturer is essential for structural integrity. Investing in high-strength bolts guarantees secure and durable fastening solutions across industries.

0 notes

Text

Optimizing Precision Machining With Advanced Equipment

The manufacturing industry constantly evolves to meet the growing demand for precision and efficiency. Advanced machining solutions like the Vertical Turret Lathe, Hydraulic Fixtures For Machining Centers and Deep Hole Drilling Machine have revolutionized metal cutting, ensuring higher productivity and accuracy. These innovations help industries such as automotive, aerospace and heavy engineering streamline their production processes.

Vertical Turret Lathe: Enhancing Large-Scale Machining

A Vertical Turret Lathe (VTL) is a crucial machine tool designed for handling large, heavy workpieces that are difficult to machine using conventional lathes. Unlike horizontal lathes, VTLs hold the workpiece vertically, enabling better stability and precision. These machines are widely used for turning, facing, boring and threading large industrial components.

VTLs offer significant advantages, including high rigidity, superior cutting performance and the ability to handle asymmetrical and large-diameter workpieces. This makes them an essential asset in heavy industries that require meticulous machining processes with minimal errors.

Hydraulic Fixtures For Machining Centers: Improving Workpiece Stability

Precision machining relies heavily on work-holding solutions that ensure stability and accuracy.

play a vital role in securing workpieces during complex machining operations. These fixtures use hydraulic pressure to clamp the workpiece securely, reducing vibrations and enhancing machining accuracy.

play a vital role in securing workpieces during complex machining operations. These fixtures use hydraulic pressure to clamp the workpiece securely, reducing vibrations and enhancing machining accuracy.

Hydraulic fixtures improve operational efficiency by minimizing setup time and enabling consistent production quality. They are particularly useful in high-volume manufacturing environments where repetitive precision is required. Industries such as aerospace, automotive and defence benefit significantly from these fixtures, ensuring seamless component production with reduced manual intervention.

Deep Hole Drilling Machine: Achieving Precision In Bore Machining

When manufacturing components that require deep and precise holes, a Deep Hole Drilling Machine is indispensable. These machines specialize in drilling holes with high depth-to-diameter ratios while maintaining precision and smoothness. They are widely used in applications like oil and gas exploration, mould-making and aerospace manufacturing.

Deep hole drilling technology ensures minimal deflection and excellent surface finish, making it a preferred choice for industries that demand intricate hole drilling. Advanced CNC capabilities further enhance their accuracy, allowing manufacturers to achieve exact specifications with minimal rework.

Why WIDMA Is The Leading Choice For Machining Solutions

When it comes to high-quality machining solutions, WIDMA stands as an industry leader. With decades of expertise in developing precision tools and equipment, WIDMA offers advanced solutions such as Vertical Turret Lathe, Hydraulic Fixtures For Machining Centers and Deep Hole Drilling Machine to enhance industrial manufacturing.

WIDMA’s commitment to innovation and excellence ensures that businesses achieve optimal efficiency, reduced downtime and superior machining accuracy. Their range of specialized CNC machines and work-holding solutions is designed to meet the evolving needs of modern manufacturing. By investing in WIDMA’s cutting-edge technology, industries can maximize their production capabilities and maintain a competitive edge in the market.

With a strong focus on quality, durability and customer satisfaction, WIDMA continues to be a trusted partner for industries seeking reliable machining solutions that drive growth and innovation.

0 notes

Text

How to Choose the Right Rubber Gasket for Your Application?

Rubber gaskets are essential components used to create a secure and leak-proof seal between two surfaces. They play a critical role in various industries, including automotive, food processing, pharmaceuticals, oil and gas, and chemical processing. At Arvico, we offer a wide range of small rubber gaskets manufactured from high-quality materials to meet the most demanding applications.

Our gaskets are known for their durability, flexibility, and resistance to extreme temperatures, chemicals, and pressure. With years of expertise in the industry, we provide reliable and innovative sealing solutions tailored to specific needs.

Importance of Rubber Gaskets

Rubber Gaskets serve as a vital sealing solution, preventing leakage and contamination in various applications. Their flexibility allows them to conform to different surfaces, providing a secure barrier against moisture, gas, and fluids. Properly installed gaskets help reduce maintenance costs, enhance operational efficiency, and improve equipment longevity.

Types of Rubber Gaskets

We offer a diverse range of rubber gaskets, each designed for specific applications and requirements.

1. Flange Gasket

Flange gaskets are used in piping systems to provide a tight seal between two flanges. They prevent leaks of liquids, gases, and other substances, ensuring operational efficiency and safety.

Applications:

Oil and gas pipelines

Water treatment plants

Chemical processing industries

HVAC systems

2. Diecut Gasket

Diecut gaskets are precision-cut to fit specific shapes and sizes. These gaskets offer exceptional sealing capabilities and are widely used in industrial applications.

Applications:

Automotive engines and fuel systems

Electrical enclosures

Industrial machinery

Aerospace equipment

3. Butterfly Valve Gasket

Butterfly valve gaskets are designed to provide an effective seal in butterfly valve applications. They are highly flexible and offer excellent resistance to pressure and temperature variations.

Applications:

HVAC systems

Food and beverage industries

Pharmaceutical processing

Power generation plants

4. TC Gasket

TC gaskets are commonly used in sanitary applications where cleanliness and hygiene are of utmost importance. TC (Tri-Clamp) gaskets ensure a secure seal in food-grade and pharmaceutical pipelines.

Applications:

Dairy and beverage production

Biopharmaceutical manufacturing

Water purification systems

Brewing industry

5. Rubber Washers

Rubber washers provide cushioning and sealing in various mechanical applications. They are highly resistant to wear and tear, making them a reliable choice for many industries.

Applications:

Plumbing and pipe fittings

Automotive assemblies

Industrial machinery

Marine applications

Material Options for Rubber Gaskets

Depending on the application, our rubber gaskets are available in different materials:

EPDM Rubber Gasket – Offers excellent weather, ozone, and heat resistance, making it suitable for outdoor and industrial applications.

Silicone Rubber Gasket – Ideal for high-temperature applications and food-grade uses due to its flexibility and resistance to extreme conditions.

Neoprene Rubber Gasket – Provides good oil and chemical resistance, commonly used in marine and automotive industries.

Nitrile Rubber Gasket – Suitable for applications involving fuel and oil exposure, offering strong sealing in petroleum-related industries.

Viton Rubber Gasket – Ensures high performance in extreme temperatures and aggressive chemical environments, frequently used in aerospace and automotive applications.

How to Choose the Right Rubber Gasket

Selecting the right rubber gasket depends on several factors, including:

Operating Temperature: Ensure the gasket material can withstand the required temperature range.

Chemical Compatibility: Choose a gasket that resists chemical exposure in the application.

Pressure Rating: Verify that the gasket can endure the pressure conditions of the system.

Flexibility & Durability: Opt for a material that provides the necessary elasticity and longevity.

Why Choose Arvico Rubber Gaskets?

At Arvico, we prioritize quality, precision, and customer satisfaction. Our gaskets are manufactured using cutting-edge technology and the highest industry standards. Here’s why we stand out:

Premium Quality: We use only the best raw materials to ensure longevity and performance.

Customization Options: We offer custom rubber gaskets tailored to your specific requirements.

Wide Industry Applications: Our gaskets serve diverse industries, from pharmaceuticals to heavy engineering.

Reliability: With decades of experience, we guarantee durable and dependable sealing solutions.

Technical Expertise: Our team provides expert guidance in selecting the right gasket for your needs.

Conclusion

Rubber gaskets manufacturer play a crucial role in maintaining leak-proof and secure connections across various industries. Arvico offers a comprehensive range of high-quality rubber gaskets, including flange gaskets, diecut gaskets, butterfly valve gaskets, TC gaskets, and rubber washers, among others. Our commitment to quality, innovation, and customer satisfaction ensures that we provide the best sealing solutions tailored to your needs.

Proper gasket selection, maintenance, and installation significantly impact equipment performance and longevity. Partnering with Arvico, a trusted rubber gasket supplier, ensures you receive high-performance rubber gaskets that enhance safety, reliability, and efficiency in your operations.

For more information on our rubber gaskets and to find the perfect solution for your application, contact Arvico today!

youtube

0 notes

Text

Understanding CNC Shearing: Precision Cutting in Modern Manufacturing

CNC (Computer Numerical Control) shearing is a highly efficient and precise cutting process used in metal fabrication industries worldwide. It utilizes automated controls to cut metal sheets with accuracy and speed, making it a preferred method for various industrial applications. Unlike manual shearing, CNC shearing reduces human error, enhances repeatability, and significantly increases production efficiency.

How CNC Shearing Works

The CNC shearing process involves a mechanical or hydraulic shear blade that moves against a fixed blade to cut metal sheets. The machine operates under programmed instructions that dictate cutting dimensions, ensuring precise and consistent results. The process follows a step-by-step approach:

Material Loading: The metal sheet is positioned on the machine’s worktable.

Programming: Operators input the required dimensions and cutting parameters into the CNC system.

Clamping and Shearing: The sheet is held firmly in place, and the upper blade moves downward to make a clean cut.

Inspection and Processing: The cut metal pieces are checked for accuracy before being used in further fabrication processes.

Advantages of CNC Shearing

CNC shearing offers multiple benefits, making it an essential tool in the metal fabrication industry.

1. High Precision and Accuracy

CNC shearing ensures sharp, precise cuts, reducing the need for secondary finishing processes. The automated control system maintains consistency, even in high-volume production.

2. Increased Efficiency

Since the process is automated, it allows for faster production rates, reducing material handling time and improving overall productivity.

3. Versatility in Material Cutting

CNC shearing can handle various metals, including stainless steel, aluminum, copper, and carbon steel, making it suitable for multiple industries.

4. Cost-Effectiveness

By minimizing material waste and reducing labor costs, CNC shearing proves to be a cost-efficient solution for manufacturers.

5. Clean and Smooth Cuts

The precision shearing process results in minimal burr formation, ensuring that the cut edges are smooth and free from deformities.

Applications of CNC Shearing

CNC shearing plays a crucial role in various industries, including:

Automotive Industry: Used for manufacturing car body parts, panels, and structural components.

Aerospace Industry: Essential for cutting lightweight yet strong metals like aluminum and titanium for aircraft structures.

Construction Sector: Used for producing structural metal sheets for buildings, bridges, and roofing materials.

HVAC Manufacturing: Helps in cutting ductwork and ventilation system components.

General Metal Fabrication: Used in the production of appliances, enclosures, and industrial tools.

Choosing the Right CNC Shearing Machine

Selecting an appropriate CNC shearing machine depends on several factors:

Material Type and Thickness: Ensure the machine can handle the required material gauge and composition.

Blade Quality: High-quality blades provide precise cuts and longer durability.

Automation Features: Advanced CNC controls enhance operational efficiency and reduce manual intervention.

Durability and Maintenance Needs: Machines with robust construction and low maintenance requirements ensure long-term usability.

Energy Mission CNC Shearing Machines: A Reliable Choice

Energy Mission is a leading manufacturer of CNC shearing machines, known for their high performance, durability, and precision. Their machines come equipped with advanced automation, high-quality shear blades, and sturdy construction, making them an excellent choice for industrial applications. By investing in Energy Mission CNC shearing machines, businesses can improve productivity, maintain quality standards, and achieve long-term cost savings.

Conclusion

CNC shearing is a fundamental process in modern metal fabrication, offering unmatched precision, efficiency, and reliability. Whether in automotive, aerospace, or general manufacturing, CNC shearing machines streamline production, reduce waste, and ensure high-quality results. With advancements in automation and machine technology, industries can now achieve greater efficiency and accuracy with CNC shearing solutions from trusted manufacturers like Energy Mission.

0 notes

Text

Pneumatic Linear Actuators: How They Work and Why You Need One

Introduction

Pneumatic linear actuators are essential components in various industrial and automation applications. They convert compressed air energy into mechanical motion, providing a reliable and efficient means of achieving linear movement. Whether in manufacturing, robotics, or material handling, these actuators play a crucial role in enhancing productivity and automation.

How Pneumatic Linear Actuators Work

Pneumatic linear actuator operate using compressed air to generate movement. The basic components of a pneumatic actuator include a cylinder, piston, rod, and valves. Here’s a step-by-step breakdown of their operation:

Air Compression – The actuator receives compressed air from a pneumatic system.

Piston Movement – Air pressure forces the piston to move inside the cylinder, pushing or pulling the attached rod.

Directional Control – Control valves regulate airflow, determining whether the actuator extends or retracts.

Exhaust Release – Air exits through an exhaust port when the actuator returns to its original position.

Speed and Force Control – Flow control valves and pressure regulators fine-tune the speed and force output.

Pneumatic actuators can be either single-acting (air pressure moves the piston in one direction, while a spring returns it) or double-acting (air pressure moves the piston in both directions, allowing for more precise control).

Advantages of Pneumatic Linear Actuators

Pneumatic actuators offer numerous benefits over other types of actuators, including hydraulic and electric options. Some key advantages include:

Reliability and Durability – With fewer moving parts, pneumatic actuators have a long service life and require minimal maintenance.

Cost-Effective – They are generally more affordable to install and operate than electric or hydraulic alternatives.

Fast Response Time – Compressed air enables quick movement, making them ideal for high-speed applications.

Safe and Clean – Unlike hydraulic systems, they don’t require oil, reducing the risk of leaks and contamination.

High Power-to-Weight Ratio – Pneumatic actuators provide strong force while remaining lightweight and compact.

Explosion-Proof – Since they don’t generate sparks, they are safe to use in hazardous environments.

Applications of Pneumatic Linear Actuators

Due to their versatility and efficiency, pneumatic actuators are used across various industries, including:

Manufacturing & Automation – Used in assembly lines, conveyor systems, and robotic arms.

Aerospace – Employed in aircraft control systems and landing gear mechanisms.

Medical Equipment – Found in automated surgical tools and laboratory machinery.

Automotive Industry – Used in braking systems, clamping devices, and engine control mechanisms.

Packaging & Material Handling – Assist in sorting, packaging, and moving heavy loads efficiently.

Choosing the Right Pneumatic Linear Actuator

Selecting the right actuator depends on factors such as:

Load Capacity – Ensure the actuator can handle the required force.

Stroke Length – Choose an actuator with the necessary range of motion.

Operating Speed – Different actuators offer varying speeds based on air pressure and cylinder design.

Environmental Conditions – Consider factors such as temperature, moisture, and exposure to chemicals.

Control Requirements – Some applications require precision control, which may necessitate additional components like sensors and regulators.

Maintenance and Troubleshooting

Pneumatic actuators require periodic maintenance to ensure optimal performance. Key maintenance tasks include:

Inspecting for Air Leaks – Regularly check hoses, fittings, and seals.

Cleaning and Lubrication – Keep components clean and well-lubricated to prevent wear and tear.

Checking Pressure Levels – Ensure the air supply pressure is within recommended limits.

Replacing Worn Components – Replace damaged seals, pistons, or rods as needed.

Conclusion

Pneumatic linear actuators are invaluable in industrial automation, offering efficiency, reliability, and cost-effectiveness. Whether you need precision control in manufacturing or robust performance in harsh environments, these actuators provide an optimal solution. By understanding their operation, advantages, and maintenance requirements, you can maximize their efficiency and longevity in your applications.

Contact Us Atiactuators 21225 FM 529 Rd Houston, TX 77433 USA Cypress Area +1-800-924-8037 +1-713-934-0171 [email protected]

0 notes

Text

Hydraulic Torque Wrench Applications: Revolutionizing Industrial Bolting Solutions

In the world of precision bolting, hydraulic torque wrenches have become an indispensable tool, offering accuracy, efficiency, and enhanced safety. With industries demanding higher productivity and reliability, advanced bolting solutions are more crucial than ever. Shingare Industries Pvt Ltd is at the forefront of delivering high-performance hydraulic torque wrenches tailored for various applications.

Key Applications of Hydraulic Torque Wrenches

1. Oil & Gas Industry

Hydraulic torque wrenches play a critical role in the oil and gas sector, ensuring secure and leak-free flange connections in pipelines, refineries, and offshore platforms. Properly torqued bolts prevent costly downtime and enhance operational safety.

2. Power Generation

From wind turbines to nuclear power plants, precise torque application is essential for assembling and maintaining heavy-duty machinery. Hydraulic torque wrenches help prevent mechanical failures, ensuring seamless energy production.

3. Heavy Equipment & Mining

Mining and construction equipment rely on secure bolted connections to withstand extreme loads and vibrations. Hydraulic torque wrenches provide the necessary clamping force for structural integrity and longevity of machinery.

4. Aerospace & Manufacturing

In high-precision industries like aerospace and heavy manufacturing, consistent and accurate torque application is a must. Hydraulic torque wrenches aid in assembling large structures and critical fastening applications, minimizing human error.

5. Shipbuilding & Marine

Shipyards and marine industries utilize hydraulic torque wrenches for hull assembly, engine maintenance, and securing large mechanical components. Proper torque ensures durability and safety in harsh marine environments.

6. Infrastructure & Construction

Bridges, stadiums, and skyscrapers require robust bolted joints. Hydraulic torque wrenches enable precise torque control, ensuring structural stability and longevity of critical infrastructures.

Why Choose Shingare Industries?

At Shingare Industries, we provide industry-leading hydraulic torque wrenches designed for reliability, efficiency, and precision. Our cutting-edge technology ensures that your bolting applications meet the highest standards of safety and performance. Whether it's maintenance, assembly, or heavy-duty bolting, we offer tailored solutions to fit your needs.

Final Thoughts

With industries evolving rapidly, investing in the right bolting solutions can significantly impact productivity and safety. Hydraulic torque wrenches are a game-changer across multiple sectors, and Shingare Industries is committed to providing top-tier solutions for all your industrial needs.

For expert consultation and premium-quality hydraulic torque wrenches, contact Shingare Industries today!

1 note

·

View note

Text

How Turret Punch Presses Work: The Mechanics and Technology Behind Turret Punches

Introduction to Turret Punch Presses

Turret punch presses are an essential part of the metal fabrication industry, providing a fast and efficient method for punching holes, notches, and complex shapes in sheet metal. These machines are widely used in industries requiring precision and repeatability, such as aerospace, automotive, and electrical enclosures. With advancements in Skills, turret punch presses have become more efficient, reducing waste while increasing accuracy.

What is a Turret Punch Press?

A Turret Punches press is a type of CNC (Computer Numerical Control) machine designed to punch various shapes into sheet metal using a rotating turret that holds multiple tools. This machine eliminates manual hole-punching processes, allowing manufacturers to produce intricate designs with high speed and consistency.

Components of a Turret Punch Press

Understanding the mechanics of a turret punch press requires familiarity with its key components:

Turret – A rotating disk that holds multiple punching tools, enabling quick tool changes.

CNC Control Unit – Governs the movement and punching sequence based on programmed designs.

Punching Tools – Various dies and punches for creating holes, slots, and custom shapes.

Sheet Metal Table – Supports the material and ensures precise alignment during punching.

Hydraulic or Servo-Electric System – Provides the punching force required to shape the metal.

How a Turret Punch Press Works

1. Loading the Sheet Metal

The operator or an automated system loads the sheet metal onto the punch press table. The sheet is held in place by clamps that ensure precise positioning.

2. Selecting the Punching Tools

The CNC program determines which tools from the turret will be used based on the design specifications. The turret rotates to bring the required tool into position.

3. Punching Process

The machine applies force using a hydraulic or servo-electric mechanism to drive the punch through the sheet metal, cutting out the desired shape. The punched-out material, known as a slug, falls through the machine for disposal or recycling.

4. Sheet Movement and Repositioning

The CNC system moves the sheet to align with different punching tools, enabling the creation of complex patterns and multiple cutouts without manual adjustments.

5. Finishing and Inspection

Once the punching is complete, the sheet metal undergoes finishing processes such as deburring or forming to achieve smooth edges and the final shape.

Advantages of Using a Turret Punch Press

1. High Speed and Efficiency

Turret punch presses significantly reduce production time by performing multiple punching operations in rapid succession without manual intervention.

2. Precision and Repeatability

With CNC programming, turret punch presses ensure high accuracy and consistency, essential for industries requiring tight tolerances.

3. Versatility

Equipped with multiple punching tools, turret presses can create a variety of shapes, from simple holes to intricate designs.

4. Cost-Effectiveness

Since turret punch presses minimize material waste and reduce labor costs, they offer an economical solution for mass production.

5. Integration with Other Metal Fabrication Techniques

Turret punch presses can be combined with bending, forming, and laser cutting processes to create complex components efficiently.

Conclusion

Turret punch presses play a vital role in modern metal fabrication, providing unmatched speed, precision, and versatility. With advancements in CNC technology and Skills, these machines continue to evolve, offering greater efficiency and cost savings. Whether you're in the aerospace, automotive, or electronics industry, investing in a turret punch press can significantly enhance production capabilities and streamline manufacturing processes.

#metal skills#metal fabrication#metal design#hardware insertion#metal programming#steel fabrication#Turret Punches

0 notes

Text

Welding Equipment Supplier: Your One-Stop Destination for Quality Welding Tools

Introduction

Welding is a fundamental process in manufacturing, construction, and various industries. It requires precision, skill, and, most importantly, high-quality equipment. Whether you are a professional welder, a workshop owner, or a DIY enthusiast, sourcing reliable welding tools and accessories is crucial for efficiency and safety. This is where a welding equipment supplier comes into play, providing a wide range of welding products to meet diverse needs.

What Does a Welding Equipment Supplier Offer?

A welding equipment supplier provides everything necessary for welding operations, including:

Welding Machines - MIG, TIG, Stick, and multi-process welders suitable for various applications.

Consumables - Electrodes, filler metals, and shielding gases required for different welding processes.

Protective Gear - Helmets, gloves, jackets, and respiratory protection for welder safety.

Cutting and Grinding Tools - Plasma cutters, oxy-fuel torches, grinders, and accessories.

Welding Accessories - Clamps, wire feeders, welding tables, and fume extraction systems.

Automation Solutions - Robotic welding systems for industrial-scale applications.

These suppliers cater to industries like automotive, aerospace, construction, shipbuilding, and metal fabrication, ensuring professionals have access to the latest and most efficient welding technology.

Choosing the Right Welding Equipment Supplier

When selecting a welding equipment supplier, it is important to consider several factors to ensure quality, reliability, and affordability.

Product Range and QualityA good supplier should offer a wide range of welding tools and accessories from reputable brands. High-quality equipment ensures durability, efficiency, and precision in welding tasks.

Industry Experience and ReputationSuppliers with years of experience in the industry tend to have in-depth knowledge and can offer expert advice on choosing the right equipment for specific applications.

Customer Support and ServicesLook for a supplier that provides technical support, after-sales service, and repair options. This is especially important for businesses that rely on welding operations for production.

Competitive Pricing and Payment OptionsWhile price should not be the only deciding factor, a supplier with competitive pricing and flexible payment options can be beneficial for businesses looking to manage costs effectively.

Availability and DeliveryA reliable supplier should have readily available stock and efficient shipping or delivery services to ensure minimal downtime for businesses.

Benefits of Partnering with a Welding Equipment Supplier

Partnering with a trusted welding equipment supplier comes with several advantages:

Access to the Latest Technology: Established suppliers keep up with technological advancements and provide state-of-the-art welding solutions.

Bulk Purchasing Options: Businesses can benefit from discounts and better pricing when buying in bulk.

Customized Solutions: Suppliers often provide tailored solutions for specific welding needs, including custom-built machinery.

Expert Consultation: Professional suppliers offer guidance on selecting the best welding equipment based on project requirements.

Compliance and Safety Assurance: Quality suppliers ensure that their products meet safety and industry standards, reducing the risk of workplace hazards.

Top Trends in the Welding Equipment Industry

The welding industry is continuously evolving, with new trends shaping the way professionals and businesses operate. Some of the latest trends include:

Automation and Robotics: Many industries are adopting robotic welding systems to enhance productivity and precision.

Eco-Friendly Welding Solutions: The demand for environmentally friendly welding equipment and techniques is growing.

Smart Welding Machines: Advanced welders with digital interfaces and IoT capabilities are gaining popularity.

Enhanced Safety Gear: Suppliers are now offering improved protective equipment with better ventilation and ergonomic designs.

How to Find a Reliable Welding Equipment Supplier

Finding the right welding equipment supplier requires research and consideration. Here are some steps to help you identify a trustworthy supplier:

Check Online Reviews and Testimonials: Customer feedback and online ratings can provide insights into a supplier’s reputation.

Compare Product Offerings: Assess the range of products available and compare them with competitors.

Evaluate Customer Service: Good customer support can make a significant difference, especially when dealing with technical equipment.

Request Quotes and Samples: If possible, request product samples or quotes to compare pricing and quality.

Verify Certifications and Industry Standards: Ensure the supplier follows industry regulations and provides certified products.

Conclusion

A reliable welding equipment supplier is essential for ensuring high-quality welding operations, whether for industrial applications or small-scale projects. By selecting the right supplier, businesses and professionals can benefit from top-notch products, expert guidance, and cost-effective solutions. Investing in premium welding equipment not only enhances efficiency and safety but also contributes to long-term success in the welding industry.

0 notes

Text

What is a CNC Turning Machine and How Does It Work?

A CNC Turning Machine is a type of computer-controlled equipment used to shape materials, typically metals or plastics, into precise, cylindrical parts. These machines are a subset of CNC (Computer Numerical Control) technology, which uses programmed instructions to automate and control the machining process.

Key Components of a CNC Turning Machine

Lathe Bed: The main framework of the machine where other components are mounted.

Spindle: Rotates the workpiece at various speeds.

Chuck: Holds and secures the workpiece in place during machining.

Tool Turret: Holds multiple cutting tools and can rotate to bring a specific tool into position.

Control Panel: The interface where the operator inputs and manages the CNC program.

Tailstock (optional): Provides additional support for longer workpieces.

Coolant System: Keeps the tools and workpiece cool to reduce heat and wear during machining.

How Does a CNC Turning Machine Work?

1. Programming

The process begins with a CNC program, typically written in G-code, which contains detailed instructions for the machine:

Cutting paths

Tool selection

Spindle speeds

Feed rates

The program is created using CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software.

2. Workpiece Setup

The raw material, usually a cylindrical rod, is securely clamped in the chuck attached to the spindle.

The machine operator ensures that the material is aligned correctly for precise machining.

3. Rotation of the Workpiece

The spindle rotates the workpiece at high speeds.

The rotation speed is determined by the program and depends on the material and required precision.

4. Cutting Process

The cutting tool, mounted on the tool turret, moves along the workpiece to remove material.

The tool follows the programmed path, cutting the material into the desired shape. Movements typically occur in two axes:

X-axis: Controls the diameter of the workpiece.

Z-axis: Controls the length of the workpiece.

5. Finishing

The CNC turning machine can perform additional operations such as threading, boring, and grooving to achieve the final part design.

Coolant is used to prevent overheating and to achieve a smooth surface finish.

6. Inspection

Once the machining is complete, the workpiece is inspected for accuracy, either manually or using automated quality control systems like coordinate measuring machines (CMMs).

Applications of CNC Turning Machines

CNC turning machines are used in industries where precision and repeatability are essential. Common applications include:

Aerospace: Engine components, fasteners, and bushings.

Automotive: Shafts, gears, and brake components.

Medical: Surgical instruments and implants.

Oil and Gas: Fittings, valves, and pipeline components.

Consumer Products: Fasteners, electrical connectors, and custom parts.

Advantages of CNC Turning Machines

High Precision: Ensures parts are machined to exact specifications.

Automation: Reduces the need for manual intervention, increasing efficiency.

Versatility: Capable of handling a wide variety of materials and designs.

Consistency: Delivers uniform quality across multiple parts.

Cost-Effective: Reduces waste and speeds up production in high-volume manufacturing.

Conclusion

A CNC turning machine is an essential tool in modern manufacturing, offering precision, efficiency, and versatility. By automating the turning process, these machines help industries produce high-quality cylindrical parts for a wide range of applications. Whether used for small-scale prototypes or large production runs, CNC turning machines are a cornerstone of advanced machining technology.

0 notes

Text

Top 10 Benefits of Using Stainless Steel Clamps in Industrial Applications

Ladhani Metal Corporation is one of the leading Stainless Steel Clamps Manufacturer in India.In industrial settings, the choice of components can significantly impact the efficiency and durability of operations. Among these components, stainless steel clamps are highly sought after for their strength, versatility, and reliability. For businesses relying on these essential tools, partnering with a trusted stainless steel clamps manufacturer in India ensures superior quality and cost-effectiveness. Here, we explore the top 10 benefits of using stainless steel clamps in industrial applications.

1. Exceptional Durability

Stainless steel clamps is renowned for its strength and resistance to wear and tear. Clamps made from this material can withstand high pressures and stresses, making them ideal for heavy-duty industrial tasks. The durability ensures a longer lifespan, reducing the frequency of replacements.

2. Corrosion Resistance

Industries such as marine, chemical, and construction often operate in environments prone to moisture and harsh chemicals. Ss clamps resist rust and corrosion, maintaining their integrity and functionality even in the most challenging conditions.

3. High Tensile Strength

Stainless steel clamps offer excellent tensile strength, ensuring they hold components securely in place. This property is vital in industries where stability and safety are paramount, such as aerospace and automotive sectors.

4. Versatility

Whether for securing pipes, cables, or other equipment, stainless steel clamps come in various designs and sizes to suit diverse applications. A reliable stainless steel clamps supplier in India can provide customized solutions to meet specific industrial needs.

5. Temperature Resistance

Stainless steel can endure extreme temperatures without losing its structural integrity. This makes stainless steel clamps suitable for industries that deal with high heat, such as power plants and manufacturing facilities.

6. Hygienic Properties

For industries like food processing, pharmaceuticals, and healthcare, hygiene is crucial. Stainless steel clamps are easy to clean and do not harbor bacteria, making them ideal for maintaining sanitary conditions.

7. Aesthetic Appeal

The sleek and polished look of stainless steel clamps adds a professional and modern touch to installations. This aesthetic benefit is particularly valuable in applications where the appearance of equipment matters, such as in architectural projects.

8. Low Maintenance

Stainless steel clamps require minimal maintenance due to their resistance to rust, corrosion, and staining. This translates to cost savings over time, as maintenance and replacement needs are significantly reduced.

9. Environmental Sustainability

Stainless steel is 100% recyclable, making it an environmentally friendly choice. Many stainless steel clamps manufacturers in India emphasize sustainable production practices, contributing to a greener future.

10. Cost-Effectiveness

Although stainless steel clamps might have a higher initial cost compared to alternatives, their longevity, low maintenance, and superior performance make them a cost-effective investment in the long run.

Conclusion

Stainless steel clamps are indispensable in industrial applications, offering unparalleled durability, versatility, and performance. By choosing high-quality products from a trusted stainless steel clamps manufacturer in India, businesses can enhance their operational efficiency and ensure long-term reliability. Whether for heavy-duty tasks or specialized applications, stainless steel clamps remain the preferred choice for industries worldwide.

For more details Website: ladhanimetals.com Product: Stainless Steel Clamp Other Product: Titanium Fittings Manufacturer in India

#StainlessSteelClampManufacturerInIndia#StainlessSteelClampManufacturer#Stainless SteelSupplierInIndia.

0 notes

Text

Aluminium Welding and Fabrication: The Essential Guide

Aluminium welding is commonly used in many industries including auto manufacturing aerospace industries construction marine industries etc. This material is highly versatile because of its lightweight, high durability, and immunity to corrosion; it is a darling of manufacturers and engineers. In this article, we will analyze the possibility of welding and fabrication of aluminum materials, its advantages and disadvantages, anthe d necessary equipment and methods.

Key Characteristics of Aluminium:

Lightweight: Aluminium is about 1/3 of the density of steel.

Corrosion Resistance: To be more specific, it develops an oxide film to prevent the process of rusting.

High Thermal Conductivity: Aluminium conducts heat and hence it is not very suitable for welding procedures.

Oxide Layer: The surface oxide has a higher melting point than the base metal so exacting methods are necessary.

Common Aluminium Welding Methods:

TIG Welding (Gas Tungsten Arc Welding): Recommended for thin sections due to the accuracy and smoothness of the finish.

MIG Welding (Gas Metal Arc Welding): More appropriate for thicker materials to offer a faster rate of production.

Spot Welding: Primarily used in car manufacturing for fastening thin metals such as sheet metal.

Aluminium Fabrication Explained

Fabrication means the shaping of aluminum by processes such as cutting, bending as well as joining to produce particular parts or systems.

Fabrication Processes:

Cutting: Possible to utilize laser cutting, water jet cutting, or CNC machining if accuracy is necessary.

Bending: Aluminium sheets are bent through the use of press brakes/rollers.

Joining: This may be welding, riveting,g, or bonding together of the parts, that is, the use of adhesives to join the parts.

Finishing: Polishing anodizing, or powder coating of the outside view to improve its look and performance.

Industries Using Aluminium Fabrication:

Aerospace: Things like wings and segments of the fuselage as used in the construction of a plane.

Automotive: Fuel-efficient components for lighter cars.

Construction: Windows, doors, and roofing.

Marine: Items such as hulls of ships and structures of decks.

Benefits of Aluminium Welding and Fabrication

Aluminium is a versatile metal, which cannot be substituted in a multitude of industries and applications. Here are the key advantages:

Lightweight Yet Strong: Offers a high strength-to-weight ratio, reducing structural load.

Corrosion Resistance: Excellent for outdoor and marine applications.

Eco-Friendly: Aluminium is 100% recyclable, reducing environmental impact.

Cost-Effective: Despite higher initial costs, its durability and low maintenance make it economical in the long run.

Future Trends in Aluminium Welding and Fabrication

The industry is evolving with advancements in technology and sustainability efforts:

Automation: Robotic welding and CNC machining increase the accuracy and speed of steel production.

3D Printing: Modern manufacturing techniques such as AM are applied to highly complicated aluminum parts.

Sustainable Practices: Focus on reuse and usage of energy-saving practices and policies.

Advanced Alloys: Higher performance non-heat treatable aluminum alloy-based specific applications.

Essential Tools and Techniques

Aluminum welding and fabrication are as important as any other type of welding, but there is a stark difference in the way it has to be done.

Welding Machines: TIG and MIG welders with a pulse to enable control of the heat intensity.

Filler Materials: Base metal compatible aluminum alloy filler rods or wires.

Protective Equipment: Welding helmets gloves and clothing for safety.

Preparation Tools: Wires for brushing the oxide layer away and chemical products for washing the oxide layer off.

Clamping Systems: To keep the component in a fixed position and minimize its movement during the fabrication.

Challenges in Aluminium Welding and Fabrication

Nonetheless, aluminum holds some advantages, yet it needs expertise and tools to work because of its peculiar characteristics.

Warping and Distortion: A high ability to conduct heat can lead to parts distorting as welds are being made.

Porosity: Aluminium reacts with hydrogen and, therefore, porosity is often observed in welds.

Oxide Removal: The oxide layer has to be removed for better adhesion and this can be done through pre-weld cleaning.

Skill Requirements: Welding of aluminum requires skilled professionals and specific parameters to accomplish excellent work.

Final Thoughts

Aluminum welding and fabrication are integral to modern engineering and manufacturing. From selecting the right welding method to leveraging advanced fabrication techniques, working with aluminum requires expertise and precision. As industries push towards lighter, stronger, and more sustainable solutions, aaluminumcontinues to lead the way.For expert aaluminumwelding and fabrication services, trust DARMIS, a name synonymous with quality and innovation in the field. Visit their website to learn more about their offerings and how they can bring your projects to life.

0 notes

Text

Understanding the Importance of Tensile Strength Tester in Material Performance Evaluation

In many industries, ensuring the strength and reliability of materials is crucial for the safety and success of products. Tensile strength testers are essential instruments used to evaluate how materials behave under stress. By measuring the forces a material can withstand before it breaks, manufacturers can better understand its durability and suitability for specific applications. In this article, we will explore the significance of tensile strength, the working principles of tensile strength testers, and why these devices are indispensable in material testing and quality control.

What is Tensile Strength?

Tensile strength refers to the maximum amount of stress or force that a material can handle before it fails or breaks when stretched or pulled. This key property is important for determining how well a material will perform in real-world applications, where it may face varying amounts of tension. Whether used in construction materials, automotive parts, or consumer products, understanding a material's tensile strength helps manufacturers select materials that meet the necessary performance, safety, and reliability standards.

How Do Tensile Strength Testers Operate?

Tensile strength tester measure a material’s ability to withstand pulling or stretching forces. During testing, a sample of the material is placed between two grips or clamps, and a controlled force is applied. As the force increases, the tester records how much the material stretches and at what point it begins to deform or break. The machine precisely captures data such as maximum load, elongation, and yield point — the point at which the material starts to change shape permanently.

The tester gives valuable insight into the material's resistance to deformation, flexibility, and breaking point, all critical factors when choosing a material for a specific task or product.

Features of Advanced Tensile Strength Testers

Today’s tensile strength testers are equipped with a range of innovative features that enhance their precision and ease of use:

Versatile Load Capacity: Whether testing soft films or tough steel, tensile strength testers are capable of handling a wide range of materials, offering flexibility across different sectors.

Adjustable Speed Controls: Operators can adjust the testing speed to match the specific requirements of the material, ensuring more accurate and tailored results.

Real-Time Digital Feedback: Most testers now feature intuitive digital displays that provide immediate readouts of key data points, streamlining the testing and analysis process.

Data Logging and Reporting: Many modern tensile testers integrate advanced software that automatically captures, analyzes, and stores test results. This allows manufacturers to generate detailed reports and track material performance over time.

Standard Compliance: Tensile strength testers are designed to meet the specifications of various international testing standards, such as ASTM, ISO, and JIS, ensuring consistency and reliability in results.

Industries Benefiting from Tensile Strength Testing

Tensile strength testing serves a wide range of industries by helping engineers and manufacturers ensure that materials can withstand the forces they will face during their service life. Here are some industries that rely on these testers:

Manufacturing: In manufacturing, tensile testing helps ensure that raw materials and finished products meet strength and performance requirements. Whether it’s for machinery components or consumer goods, tensile testing guarantees reliability.

Construction: In construction, the tensile strength of materials such as steel reinforcements, cables, and concrete is tested to verify they can handle the forces and stresses they will face in building structures, ensuring long-term stability.

Aerospace and Automotive: Materials used in aircraft and automotive parts must undergo tensile strength testing to ensure they can endure extreme forces and provide safety for passengers. Tensile testing is critical for components like engine parts, body panels, and safety mechanisms.

Textiles and Plastics: Whether for clothing, upholstery, or packaging, tensile testing helps verify that textiles and plastics will hold up to stresses such as pulling, tearing, or stretching.

Why is Tensile Strength Testing Crucial?

Ensures Material Integrity: By confirming a material's tensile strength, manufacturers can be sure that it won’t fail under pressure, reducing the risk of product defects, accidents, or catastrophic failures.

Maintains Consistent Quality: Regular tensile testing during production ensures that materials consistently meet quality and performance standards, maintaining uniformity across different production batches.

Guides Engineering Decisions: Data from tensile tests helps engineers select materials that meet the strength requirements for their designs, ensuring optimized performance and material efficiency.

Regulatory and Safety Compliance: Industries such as construction, automotive, and healthcare require materials to meet specific standards. Tensile strength testing ensures that products comply with regulatory requirements for safety and reliability.

Conclusion

Tensile strength testing is an indispensable part of material performance evaluation. It allows manufacturers, engineers, and researchers to assess the durability and integrity of materials before they are put to use. Whether in construction, product development, or industrial applications, knowing how a material reacts to tension is critical for ensuring it will function safely under expected loads.

If you are looking for high-quality tensile strength testing equipment, explore Labzenix.com. Our reliable and precise tensile strength testers offer the tools needed for accurate testing and efficient quality control in a variety of industries. Make sure your materials are up to the task with our cutting-edge solutions today.

0 notes

Text

Friction Stir Welding: A Revolutionary Joining Technique

Friction Stir Welding (FSW) is a solid-state joining process that has revolutionized the manufacturing industry. Unlike traditional welding methods that involve melting the base materials, FSW utilizes mechanical energy to create a joint. This innovative approach offers numerous advantages, making it a preferred choice for joining a wide range of materials, particularly those that are difficult to weld using conventional techniques.

How Does Friction Stir Welding Work?

FSW employs a rotating tool, typically a cylindrical pin with a shoulder, that is plunged into the interface of the materials to be joined. The tool is then traversed along the joint line, generating intense frictional heat. This heat softens the material around the tool, while the tool's rotation and shoulder pressure plasticize the material and force it to flow around the pin, creating a solid-state weld.

Key Components of a Friction Stir Welding Machine:

1. Spindle: The heart of the FSW machine, the spindle houses the rotating tool and provides the necessary torque and rotational speed.

2. Tooling: The tool itself is a crucial component. It is typically made of high-strength materials like tungsten carbide or ceramics to withstand the high temperatures and pressures generated during the welding process.

3. Drive System: The drive system provides the power to rotate the spindle and traverse the tool along the joint line. This can include servo motors, gearboxes, and other mechanical components.

4. Control System: A sophisticated control system is essential to regulate the spindle speed, feed rate, and other process parameters accurately. This ensures consistent and high-quality welds.

5. Clamping System: A robust clamping system is necessary to hold the workpieces securely in place during the welding process. This prevents any movement or distortion of the materials, ensuring a strong and reliable joint.

Advantages of Friction Stir Welding:

Solid-State Welding: FSW is a solid-state process, meaning there is no melting of the base materials. This eliminates the concerns associated with melting, such as material degradation, porosity, and the formation of harmful fumes or spatter.

Versatility: FSW can be used to join a wide range of materials, including aluminum, copper, magnesium, titanium, and even dissimilar metals.

High Strength and Integrity: FSW produces high-strength joints with excellent metallurgical properties and minimal distortion.

Reduced Environmental Impact: As there is no melting, FSW generates fewer fumes and emissions, making it a more environmentally friendly welding process.

Improved Fatigue Resistance: FSW joints often exhibit superior fatigue resistance compared to those produced by conventional welding methods.

Reduced Residual Stresses: FSW generates lower residual stresses in the weld zone, minimizing the risk of cracking and improving the overall structural integrity of the component.

Applications of Friction Stir Welding:

Aerospace Industry: FSW is widely used in the aerospace industry for joining critical components like aircraft fuselage panels, wing structures, and landing gear.

Automotive Industry: FSW is increasingly being adopted in the automotive industry for manufacturing lightweight and fuel-efficient vehicles. It is used to join aluminum components such as engine blocks, transmission housings, and suspension parts.

Marine Industry: FSW is utilized in the marine industry for constructing lightweight and corrosion-resistant vessels. It is used to join aluminum and other high-strength alloys for shipbuilding applications.

Railroad Industry: FSW is employed in the railroad industry for manufacturing lightweight and durable rail cars. It is used to join aluminum and other high-strength alloys for various rail car components.

Other Industries: FSW is also finding applications in various other industries, including shipbuilding, offshore oil and gas, and renewable energy.

Types of Friction Stir Welding:

Planar FSW: This is the most common type of FSW, where the tool is traversed along a planar surface.

Rotary FSW: In rotary FSW, the tool is rotated around a central axis while simultaneously traversing along the joint line. This technique is particularly useful for joining cylindrical components.

Transient FSW: In transient FSW, the tool is rapidly plunged into and withdrawn from the workpiece, generating a localized heat source. This technique is suitable for joining thin sheets and complex geometries.

Challenges and Limitations:

Tool Wear: Tool wear is a significant challenge in FSW, as the tool is subjected to high temperatures, pressures, and abrasive forces.

Process Control: Precise control of process parameters such as spindle speed, feed rate, and tool geometry is critical to ensure consistent and high-quality welds.

Tooling Development: Developing suitable tooling for specific applications can be challenging and time-consuming.

Cost: FSW equipment and tooling can be expensive, which can increase the overall cost of production.

Future Trends:

Advanced Tooling: The development of advanced tooling materials and geometries will further enhance the performance and efficiency of FSW.

Automation and Robotics: Increased automation and robotics will improve the accuracy, consistency, and productivity of FSW processes.

Hybrid Processes: Hybrid processes that combine FSW with other joining techniques, such as laser welding or adhesive bonding, will offer new possibilities for manufacturing complex components.

In-Situ Monitoring and Control: Real-time monitoring and control of process parameters using sensors and AI will enable more precise and adaptive FSW processes.

Conclusion:

Friction Stir Welding is a transformative technology that offers numerous advantages over traditional welding methods. Its versatility, high-strength joints, and environmental friendliness make it a preferred choice for a wide range of applications. As research and development continue, FSW is poised to play an even more significant role in the manufacturing industry, enabling the production of lighter, stronger, and more sustainable products. Disclaimer: This blog post is for informational purposes only and should not be considered professional engineering advice. The information provided in this blog post is based on general knowledge and may not be applicable to all situations. It is essential to consult with qualified engineers and follow appropriate safety guidelines when performing any welding operations.

1 note

·

View note

Text

Understanding the 5C Collet Chuck: Precision in Workholding

In the precision machining world, workholding tools are very important for achieving accurate and efficient results. Among the workholding tools, the 5C collet chuck is one of the most versatile and reliable tools. This article will discuss the importance of this chuck and its relevance in India, with PG Collets being a name that is trusted in manufacturing high-quality collets.

What is a 5C Collet Chuck?

It is a mechanical device used to hold cylindrical workpieces firmly in place during machining operations. It is a compactly designed tool with an accurate gripping mechanism, making it very useful in the automotive, aerospace, and manufacturing industries. The 5c collet chuck works by compressing a collet around the workpiece, ensuring a firm grip without causing damage to the material.

Key Features of the Chuck

High Accuracy: This chuck can hold workpieces with the highest degree of accuracy, minimizing runout.

Easy to use: The simple mechanism of the chuck allows for easy installation and removal, increasing productivity on the shop floor.

Versatile: It can accommodate a wide range of collet sizes and is thus very versatile in accommodating workpieces of various diameters.

Durable: Made from strong materials, these chucks are designed to withstand tough machining conditions.

Applications of the Chuck

It has wide usage in industries like:

Operations involving turning: widely used for holding work pieces while turning in lathe machines.

Milling and drilling: Provides stability and accurate machining operations both on vertical and horizontal locations.

Grinding: offers secure clamping for fine surface finishes.

Why Use PG Collets?

It is a leading manufacturer and supplier of reliable and high-quality collets and chucks in India. It has earned a reputation for delivering products that meet international standards with a commitment to precision engineering and customer satisfaction. Their range of 5C collet chucks exemplifies the perfect blend of innovation and durability, catering to diverse industrial needs.

Advantages of Using a 5C Collet Chuck

Faster productivity: With this quick clamping mechanism, less time is wasted on setup to allow more cycles of machining.

Better Surface Quality: Stable gripping minimizes the vibrations hence making surface quality very great.

It saves money: This is due to its longevity and adaptability which makes it worthwhile for businesses operating in the machineries sectors.

Tips to Maintain Proper Working

Ensure proper working of your 5C collet chuck and its durability with the following practices:

Regular Cleaning: Prevent dirt and coolant drips to create wear.

Lubrication: The right lubricant for the moving parts for friction-free working.

Periodical checking and replacement of worn out and damaged components, and other requirements based on the criticality level.

Conclusion

The 5C collet chuck is a backbone in precision workholding for the machining industry. Versatility, easy operation, and reliability are the characteristics that make it an indispensable tool to achieve exceptional results. For businesses in India looking for quality and dependability, PG Collets is that reliable partner to produce products characterized by the excellence of engineering. Whether it's turning, milling, or grinding, investments in a 5C collet chuck guarantee higher productivity and precision levels for your operations.

0 notes