#TensileStrengthTester

Explore tagged Tumblr posts

Text

The Science of Tensile Strength Tester A Comprehensive Guide

Understanding Material Strength Analysis

At Labzenix, we've pioneered advanced tensile testing solutions that transform how industries evaluate material performance. Our cutting-edge testers provide precise measurements of a material's resistance to stretching forces, delivering critical data for:

Product development optimization

Quality assurance protocols

Regulatory compliance verification

Failure analysis investigations

Core Principles of Tensile Evaluation

Modern tensile testing examines three fundamental material properties:

Ultimate Tensile Strength

Maximum stress before fracture

Measured in MPa or psi units

Yield Point Determination

Onset of permanent deformation

Critical for structural applications

Elongation Characteristics

Ductility measurement

Important for forming processes

Labzenix Testing Technology

Our innovative tensile testers feature:

✔ Precision Engineered Load Frames

Single/Dual column configurations

Capacities from 5kN to 600kN

✔ Advanced Measurement Systems

Class 0.5 load cells (±0.25% accuracy)

High-resolution extensometry

✔ Intelligent Control Software

Real-time data visualization

Automated report generation

Industry-Specific Applications

Automotive Sector

Component durability validation

Lightweight material evaluation

Fastener performance testing

Aerospace Industry

Composite material characterization

Alloy performance verification

Structural integrity assessment

Medical Technology

Implant material analysis

Packaging strength testing

Device reliability studies

Construction Materials

Rebar certification testing

Geosynthetic evaluation

Structural component validation

Selecting Your Testing Solution

Key decision factors:

Force Requirements

Match to material strength range

Options from 5kN to 600kN

Precision Needs

Measurement accuracy levels

Strain resolution requirements

Environmental Conditions

Standard lab testing

Temperature-controlled chambers

Data Management

Basic reporting

Advanced statistical analysis

The Labzenix Advantage

35+ Years of materials testing expertise

Custom-Engineered Solutions for unique needs

Global Technical Support network

Competitive Value without quality compromise

Conclusion

Tensile strength testing remains essential for material characterization across industries. Labzenix delivers reliable, precise testing solutions supported by unmatched technical expertise.

Ready to enhance your testing capabilities? 🌐 Explore solutions at Labzenix.com

0 notes

Text

How does a Tensile Tester work?

Tensile Testers are one of the most frequently used testing equipment's in the field of material testing. They play a crucial role in determining the mechanical properties of materials, such as pulling strength, elasticity, and flexibility. Understanding how a tensile tester works is essential for producing precise and trustworthy results, be it in the industrial sector or while performing research in a lab.

In this blog, we will delve deep into the working of the tensile strength tester and will also be covering the key benefits that performing a tensile test using a tensile machine offers.

Starting with the step wise process of how a tensile tester typically works:

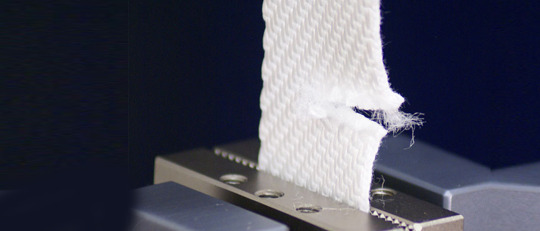

1. Preparation of the Specimen - A small sample of the textile material is cut into a specific size and shape suitable for the tensile strength tester.

2. Mounting the Specimen - The sample is then mounted between the two jaws or grips of the tensile tester. The jaws are specifically designed to prevent any damage or slippage to the specimen (sample) during the test.

3. Testing the Specimen - A controlled force is applied at a steady rate to the specimen until the material breaks. The tensile tester then measures the amount of force applied and resulting elongation of the specimen.

4. Data Compilation - The data that is collected during the test, including the elongation at break, modulus of elasticity, and the tensile strength can then be used to assess the mechanical properties of the textile material.

5. Examination: The results of the test help to assess the performance and quality of textile material which can be used to make decisions regarding the quality control, material selection, and product design.

Understanding the systematic process of a tensile strength tester’s working can make sure that accurate and reliable measurements are undertaken every time a test is performed.

Benefits of performing a Tensile Test using a Tensile Strength Tester :

Identifying Weaknesses at the Initial Stage: Tensile strength testing can help to identify any flaws or weaknesses in a fabric, such as areas that might be prone to breaking or tearing. By using this information, the production process can be adjusted as needed to increase the fabric's quality.

Improving Quality Control: Tensile strength testers are frequently used for quality control assessments in the textile industry. Testing the tensile strength of a fabric can help manufacturers ensure that the final product meets the required standards of durability and strength, thus increasing customer satisfaction and trust.

Cost Efficiency: Performing the tensile test can help to detect the materials that may be prone to breaking or are less durable, which can in turn lead to cost savings by eliminating the use of such damaged materials in the production process.

Assuring Safety Standards: One of the main reasons for performing the tensile test is to also ensure that the safety of fabrics and garments is ensured for end use. Using the tensile strength equipment, manufacturers can make sure that the fabrics/garments meet the required safety standards and are not prone to breaking or tearing during use.

Developing Suitability for Specific Applications: Testing the tensile strength of fabrics can also help to determine its suitability for specific end use applications like outdoor gear or heavy-duty workwear. Thus, by testing the strength of the fabric, manufacturers can make sure that it holds up under the intended use conditions.

We may assert that assessing the tensile strength of materials is important to assure their durability, quality and safety is up to the mark and is fully perfected for its end-use application.

#paramountinstruments#qualitycontrol#testingequipments#qualityassurance#performancetesting#tensilestrengthtester#tensiletesting#tensilestrength#tensilestructure

0 notes

Text

Copper Purity Test Apparatus: Your Ultimate Solution for Precision Testing

When it comes to testing the purity of copper or evaluating the strength and durability of materials like plastics, precision matters. That’s where advanced testing equipment like the Universal Tensile Machine for Plastics comes in.

This state-of-the-art apparatus is designed to meet industry standards, offering unparalleled accuracy for various testing needs, including tensile strength, elongation, and material behavior. And guess what? It’s versatile enough to be used in labs performing copper purity tests too!

Universal tensile test machine are largely used as cable and plastic test equipment. The tester can complete one test with a simple five-step operation: select the existing test method, input the sample size, install the sample, start the test, and print the report. There two models with different variants of force as per the requirements of customers.

Single column UTM invariants from 0.5KN to 10KN.

Dual column UTM invariants from 1KN to 15KN.

Curious to know more about how this equipment can elevate your testing capabilities? Check out the full details here: 👉 Universal Tensile Machine for Plastics

Whether you’re working in a lab or a manufacturing facility, having the right tools makes all the difference. Explore how this machine can help you achieve better results!

0 notes

Text

How to Calculate Tensile Strength of Fabric

How to Calculate Tensile Strength of Fabric #tensilestrength #tensilestrengthtest #fabrictensiletest #TensileStrengthofFabric

Different Methods of Fabric Tensile Strength Test Md. Rubel Miah Department of Textile Engineering World University of Bangladesh Email: [email protected] Fabric Tensile Strength Test Fabric tensile strength can be tested using universal tensile strength testing equipment with suitable sample mounting jaws. There are different methods of tensile testing of fabric, which are as follows: Strip…

View On WordPress

0 notes

Text

Tensile Strength Tester (Manually and Elec):

We at industrialshoppingmall offering Tensile Strength Tester@105000/- Rs. For more details visit:https://industrialshoppingmall.com/product/tensile-strength-tester-(manually-and-elec)/141 mail:[email protected], Mobile:9030000071

Tensile Strength Tester (Manually and Elec):

Tensile Strength Tester (Manually and Elec) Specification: A loading Machine, double lever type, with steel scale marked from 0-500 Newtons in 10 Newton division. Maximum loading capacity 5 kN. Automatic Loading system using Lead Shot. Lead shot 15 kg supplied with the machine. Set of weights for weighing lead shot comprising one each for weighing upto 0.5 kN, 1 kN, 1.5 kN & 2.0 kN. One standard Briquette Mould with Base Plate also Supplied.

0 notes

Text

Understanding the Importance of Tensile Strength Tester in Material Performance Evaluation

In many industries, ensuring the strength and reliability of materials is crucial for the safety and success of products. Tensile strength testers are essential instruments used to evaluate how materials behave under stress. By measuring the forces a material can withstand before it breaks, manufacturers can better understand its durability and suitability for specific applications. In this article, we will explore the significance of tensile strength, the working principles of tensile strength testers, and why these devices are indispensable in material testing and quality control.

What is Tensile Strength?

Tensile strength refers to the maximum amount of stress or force that a material can handle before it fails or breaks when stretched or pulled. This key property is important for determining how well a material will perform in real-world applications, where it may face varying amounts of tension. Whether used in construction materials, automotive parts, or consumer products, understanding a material's tensile strength helps manufacturers select materials that meet the necessary performance, safety, and reliability standards.

How Do Tensile Strength Testers Operate?

Tensile strength tester measure a material’s ability to withstand pulling or stretching forces. During testing, a sample of the material is placed between two grips or clamps, and a controlled force is applied. As the force increases, the tester records how much the material stretches and at what point it begins to deform or break. The machine precisely captures data such as maximum load, elongation, and yield point — the point at which the material starts to change shape permanently.

The tester gives valuable insight into the material's resistance to deformation, flexibility, and breaking point, all critical factors when choosing a material for a specific task or product.

Features of Advanced Tensile Strength Testers

Today’s tensile strength testers are equipped with a range of innovative features that enhance their precision and ease of use:

Versatile Load Capacity: Whether testing soft films or tough steel, tensile strength testers are capable of handling a wide range of materials, offering flexibility across different sectors.

Adjustable Speed Controls: Operators can adjust the testing speed to match the specific requirements of the material, ensuring more accurate and tailored results.

Real-Time Digital Feedback: Most testers now feature intuitive digital displays that provide immediate readouts of key data points, streamlining the testing and analysis process.

Data Logging and Reporting: Many modern tensile testers integrate advanced software that automatically captures, analyzes, and stores test results. This allows manufacturers to generate detailed reports and track material performance over time.

Standard Compliance: Tensile strength testers are designed to meet the specifications of various international testing standards, such as ASTM, ISO, and JIS, ensuring consistency and reliability in results.

Industries Benefiting from Tensile Strength Testing

Tensile strength testing serves a wide range of industries by helping engineers and manufacturers ensure that materials can withstand the forces they will face during their service life. Here are some industries that rely on these testers:

Manufacturing: In manufacturing, tensile testing helps ensure that raw materials and finished products meet strength and performance requirements. Whether it’s for machinery components or consumer goods, tensile testing guarantees reliability.

Construction: In construction, the tensile strength of materials such as steel reinforcements, cables, and concrete is tested to verify they can handle the forces and stresses they will face in building structures, ensuring long-term stability.

Aerospace and Automotive: Materials used in aircraft and automotive parts must undergo tensile strength testing to ensure they can endure extreme forces and provide safety for passengers. Tensile testing is critical for components like engine parts, body panels, and safety mechanisms.

Textiles and Plastics: Whether for clothing, upholstery, or packaging, tensile testing helps verify that textiles and plastics will hold up to stresses such as pulling, tearing, or stretching.

Why is Tensile Strength Testing Crucial?

Ensures Material Integrity: By confirming a material's tensile strength, manufacturers can be sure that it won’t fail under pressure, reducing the risk of product defects, accidents, or catastrophic failures.

Maintains Consistent Quality: Regular tensile testing during production ensures that materials consistently meet quality and performance standards, maintaining uniformity across different production batches.

Guides Engineering Decisions: Data from tensile tests helps engineers select materials that meet the strength requirements for their designs, ensuring optimized performance and material efficiency.

Regulatory and Safety Compliance: Industries such as construction, automotive, and healthcare require materials to meet specific standards. Tensile strength testing ensures that products comply with regulatory requirements for safety and reliability.

Conclusion

Tensile strength testing is an indispensable part of material performance evaluation. It allows manufacturers, engineers, and researchers to assess the durability and integrity of materials before they are put to use. Whether in construction, product development, or industrial applications, knowing how a material reacts to tension is critical for ensuring it will function safely under expected loads.

If you are looking for high-quality tensile strength testing equipment, explore Labzenix.com. Our reliable and precise tensile strength testers offer the tools needed for accurate testing and efficient quality control in a variety of industries. Make sure your materials are up to the task with our cutting-edge solutions today.

0 notes

Text

Understanding Tensile Strength Tester A Key Tool in Material Testing

In the realm of material testing, ensuring that a product meets the required strength standards is vital for its reliability and longevity. One of the most commonly used tests to determine the integrity of materials is the tensile strength test. This test measures the force a material can withstand before breaking, giving engineers and manufacturers crucial data about the material's durability, elasticity, and overall performance. The Tensile Strength Tester, a vital tool in material testing, provides manufacturers with valuable insights to ensure quality control in product design and production.

What is a Tensile Strength Tester?

A tensile strength tester is a laboratory instrument used to test the mechanical properties of materials under tension. It is designed to apply a pulling force (tensile force) to a material, whether it’s plastic, metal, rubber, or composites, to determine how much stress the material can tolerate before it fractures or deforms.

The tester is typically composed of a crosshead, which moves in response to an applied force, pulling the material in a controlled manner. The force is continuously increased until the material reaches its breaking point. The results of the test—such as the ultimate tensile strength, elongation, and yield strength—are essential in evaluating how the material will perform in real-world applications.

Importance of Tensile Strength Testing

Tensile Strength Tester Digital is an essential component in many industries, including manufacturing, automotive, construction, aerospace, and polymers. Understanding the tensile properties of a material is crucial in ensuring product safety, performance, and quality. Here are a few reasons why tensile strength testing is vital:

1. Material Quality Control:

Regular tensile testing ensures that materials used in the manufacturing process conform to strict standards. By identifying materials that fall below required strength specifications, manufacturers can discard substandard materials, preventing the production of defective goods.

2. Design and Engineering:

Tensile testing gives engineers accurate data, allowing them to make informed decisions during product development. Whether designing a new automotive component or a structural part for a building, knowledge of the material’s tensile properties ensures its suitability for the intended application.

3. Predicting Performance:

When materials undergo tensile strength testing, engineers can predict how the materials will behave in different conditions such as pressure, tension, or stretching. This helps in the development of products that can endure environmental stressors, minimizing failure during their useful lifespan.

4. Compliance and Standards:

In most industries, particularly those in aerospace or automotive sectors, certain regulatory standards must be met to ensure that products are safe for consumers. Tensile strength testing helps meet these certifications, ensuring products' overall integrity and durability.

The Testing Process

The tensile strength testing process involves several stages to accurately determine the material’s response to stress. Below is a breakdown of the basic steps involved:

1. Sample Preparation:

A sample specimen of the material to be tested is carefully prepared. The shape and size of the sample are critical because they need to fit into the tensile tester’s grips. For standardized testing, specific sample shapes (such as dog-bone or cylindrical shapes) are used.

2. Gripping the Sample:

The sample is then placed in the grips of the tensile testing machine. These grips secure the specimen while it is subjected to tension. The machine gradually stretches the sample by pulling both ends apart at a constant rate.

3. Force Application:

The tensile tester applies increasing force to the sample, recording the load at various points during the stretch. Sensors in the machine measure the elongation and force, which is transferred to the computer system for data recording.

4. Breaking Point Identification:

The tester will continue applying force until the material either fractures or reaches its breaking point. Once the material breaks, the machine stops the force application and calculates the final results, including maximum tensile strength, elongation, and any deformation characteristics.

5. Data Analysis:

Results from the tensile test include data points such as ultimate tensile strength (UTS), yield strength, and elongation at break. These results are carefully analyzed to determine the material’s ability to withstand stress under different conditions. Engineers use this data to predict material behavior under various loads or extreme conditions.

Key Parameters Measured by Tensile Strength Testers

Several critical parameters are measured during Tensile Strength Tester Price that provides valuable insights into the material's performance characteristics:

Ultimate Tensile Strength (UTS): This is the maximum stress that the material can endure without failing. A higher UTS typically indicates a stronger material.

Yield Strength: This refers to the stress level at which a material begins to deform permanently. It is an important characteristic to ensure that a material won’t bend or stretch excessively in real-world applications.

Elongation: Elongation measures how much the material stretches before it breaks, indicating its ductility. Materials with high elongation are often more flexible and less likely to break under tension.

Modulus of Elasticity: This is a measure of the material's ability to resist deformation under stress. A higher modulus indicates a stiffer material that does not stretch easily.

Breaking Point: This is the point at which the material fails or breaks under stress. It helps engineers identify the limits of material endurance.

Types of Tensile Strength Testers

Tensile strength testers come in various configurations, depending on the specific needs of the user. Some popular types include:

Universal Testing Machines (UTM): These testers are versatile machines capable of performing not only tensile strength tests but also compression and bending tests.

Micro and Nano Tensile Testers: These specialized testers measure the tensile properties of very small or thin materials at microscopic and nanoscopic scales, commonly used in research and development.

Hydraulic Testers: These are typically used for larger samples and offer enhanced control over force application, making them ideal for heavy-duty testing applications.

Conclusion

In summary, a tensile strength tester is a critical tool for evaluating the durability, flexibility, and overall mechanical properties of materials. Whether for quality control, design, or safety testing, understanding a material’s tensile properties is key in a variety of industries. For manufacturers, testing materials for tensile strength ensures that the products are safe, reliable, and fit for use under intended conditions.

0 notes

Text

Tensile Strength Tester

A Tensile Strength Tester is a machine used to determine the tensile strength of materials. It is also known as a universal testing machine, because it can test a wide range of materials including metals, plastics, rubber, textiles, paper, and many more.

The tensile strength testing machine works by clamping a sample of the material at both ends and then applying a tensile force to the sample until it breaks. The force required to break the sample is then measured and recorded, providing an indication of the material's tensile strength.

#TensileStrengthTester #TensileTestingMachine #TensileTester #Tensile

0 notes