#Aerosol Paint Industry

Explore tagged Tumblr posts

Text

Global Aerosol Paint Market Overview : Size, Share, and Future Trends Forecast

Aerosol Paint Market Strategies: Taking Advantage of Trends to Drive Growth in 2032

The Aerosol Paint Market Report provides essential insights for business strategists, offering a comprehensive overview of industry trends and growth projections. It includes detailed historical and future data on costs, revenues, supply, and demand, where applicable. The report features an in-depth analysis of the value chain and distributor networks.

Employing various analytical techniques such as SWOT analysis, Porter’s Five Forces analysis, and feasibility studies, the report offers a thorough understanding of competitive dynamics, the risk of substitutes and new entrants, and identifies strengths, challenges, and business opportunities. This detailed assessment covers current patterns, driving factors, limitations, emerging developments, and high-growth areas, aiding stakeholders in making informed strategic decisions based on both current and future market trends. Additionally, the report includes an examination of the Automatic Rising Arm Barriers sector and its key opportunities.

According to Straits Research, the global Aerosol Paint Market market size was valued at USD XX Billion in 2023. It is projected to reach from USD XX Billion in 2024 to USD XX Billion by 2032, growing at a CAGR of 5.2% during the forecast period (2024–2032).

Get Free Request Sample Report @ https://straitsresearch.com/report/aerosol-paint-market/request-sample

TOP Key Industry Players of the Aerosol Paint Market

Aeroaids Corporation

DUPLI-COLOR

Krylon Products Group

Markal, Masterchem Industries LLC

Montana Colors

Nippon Paint (India) Company Limited.

Plutonium Paint

PPG Industries

Rust-Oleum

Global Aerosol Paint Market: Segmentation

As a result of the Aerosol Paint market segmentation, the market is divided into sub-segments based on product type, application, as well as regional and country-level forecasts.

By Product

Water-based

Solvent-based

By Application

Construction

Automotive

Furniture

Others

Browse Full Report and TOC @ https://straitsresearch.com/report/aerosol-paint-market/request-sample

Reasons for Buying This Report:

Provides an analysis of the evolving competitive landscape of the Automatic Rising Arm Barriers market.

Offers analytical insights and strategic planning guidance to support informed business decisions.

Highlights key market dynamics, including drivers, restraints, emerging trends, developments, and opportunities.

Includes market estimates by region and profiles of various industry stakeholders.

Aids in understanding critical market segments.

Delivers extensive data on trends that could impact market growth.

Research Methodology:

Utilizes a robust methodology involving data triangulation with top-down and bottom-up approaches.

Validates market estimates through primary research with key stakeholders.

Estimates market size and forecasts for different segments at global, regional, and country levels using reliable published sources and stakeholder interviews.

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Aerosol Paint Market#Aerosol Paint Market Share#Aerosol Paint Market Size#Aerosol Paint Market Research#Aerosol Paint Industry#What is Aerosol Paint?

0 notes

Text

Ozone Hole Continues Healing in 2024

A hole that opens annually in the ozone layer over Earth’s southern pole was relatively small in 2024 compared to other years. Scientists with NASA and the National Oceanic and Atmospheric Administration (NOAA) project the ozone layer could fully recover by 2066.

During the peak of ozone depletion season from September 7 through October 13, the 2024 area of the ozone hole ranked the seventh smallest since recovery began in 1992, when the Montreal Protocol, a landmark international agreement to phase out ozone-depleting chemicals, began to take effect.

At almost 20 million square kilometers (8 million square miles), the monthly average ozone-depleted region in the Antarctic this year was nearly three times the size of the contiguous U.S. The hole reached its greatest one-day extent for the year on September 28 at 22.4 million square kilometers (8.5 million square miles).

The map above shows the size and shape of the ozone hole over the South Pole on the day of its 2024 maximum extent. Moderate ozone losses (orange) are visible amid areas of more potent ozone losses (red). Scientists describe the ozone “hole” as the area in which ozone concentrations drop below the historical threshold of 220 Dobson units.

The improvement is due to a combination of continuing declines in harmful chlorofluorocarbon (CFC) chemicals, along with an unexpected infusion of ozone carried by air currents from north of the Antarctic, scientists said.

youtube

In previous years, NASA and NOAA have reported the ozone hole ranking using a time frame dating back to 1979, when scientists began tracking Antarctic ozone levels with satellite data. Using that longer record, this year’s hole ranked 20th smallest in area across the 45 years of observations.

“The 2024 Antarctic hole is smaller than ozone holes seen in the early 2000s,” said Paul Newman, leader of NASA’s ozone research team and chief scientist for Earth sciences at NASA’s Goddard Space Flight Center. “The gradual improvement we’ve seen in the past two decades shows that international efforts that curbed ozone-destroying chemicals are working.”

The ozone-rich layer high in the atmosphere acts as a planetary sunscreen that helps shield us from harmful ultraviolet (UV) radiation from the Sun. Areas with depleted ozone allow more UV radiation to reach Earth's surface, resulting in increased cases of skin cancer and cataracts. Excessive exposure to UV light can also reduce agricultural yields as well as damage aquatic plants and animals in vital ecosystems.

Scientists were alarmed in the 1970s at the prospect that CFCs could eat away at atmospheric ozone. By the mid-1980s, the ozone layer had been depleted so much that a broad swath of the Antarctic stratosphere was essentially devoid of ozone by early October each year. Sources of damaging CFCs included coolants in refrigerators and air conditioners, as well as aerosols in hairspray, antiperspirant, and spray paint. Harmful chemicals were also released in the manufacture of insulating foams and as components of industrial fire suppression systems.

The Montreal Protocol was signed in 1987 to phase out CFC-based products and processes. Countries worldwide agreed to replace the chemicals with more environmentally friendly alternatives by 2010. The release of CFC compounds has dramatically decreased following the Montreal Protocol. But CFCs already in the air will take many decades to break down. As existing CFC levels gradually decline, ozone in the upper atmosphere will rebound globally, and ozone holes will shrink.

youtube

“For 2024, we can see that the ozone hole’s severity is below average compared to other years in the past three decades, but the ozone layer is still far from being fully healed,” said Stephen Montzka, senior scientist of the NOAA Global Monitoring Laboratory.

Researchers rely on a combination of systems to monitor the ozone layer. They include instruments on NASA’s Aura satellite, the NOAA-20 and NOAA-21 satellites, and the Suomi NPP satellite, jointly operated by NASA and NOAA.

NOAA scientists also release instrumented weather balloons from the South Pole Baseline Atmospheric Observatory to observe ozone concentrations directly overhead. The 2024 concentration reached its lowest value of 109 Dobson units on October 5. The lowest value ever recorded over the South Pole was 92 Dobson units in October 2006.

NASA and NOAA satellite observations of ozone concentrations cover the entire ozone hole, which can produce a slightly smaller value for the lowest Dobson unit measurement.

“That is well below the 225 Dobson units that was typical of the ozone cover above the Antarctic in 1979,” said NOAA research chemist Bryan Johnson. “So, there’s still a long way to go before atmospheric ozone is back to the levels before the advent of widespread CFC pollution.”

View the latest status of the ozone layer over the Antarctic with NASA’s Ozone Watch.

NASA Earth Observatory image by Lauren Dauphin, using data courtesy of NASA Ozone Watch and GEOS-5 data from the Global Modeling and Assimilation Office at NASA GSFC. Story by James Riordon, NASA’s Earth Science News Team.

7 notes

·

View notes

Text

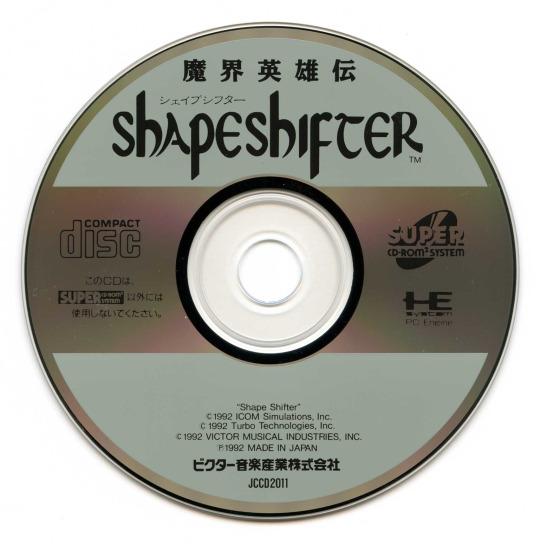

PC Engine - Shape Shifter: Makai Eiyuuden

Title: Shape Shifter: Makai Eiyuuden / シェイプシフター 魔界英雄伝

Developer: ICOM Simulations Inc.

Publisher: Turbo Technologies Inc. / Victor Musical Industries

Release date: 29 September 1992

Catalogue No.: JCCD2011

Genre: Action / Adventure

Format: Super CD-ROM2

This is the first time I have actually seen a Japanese PC Engine release actually credit "Turbo Technologies Inc.", or TTI as they called it. In case you don't know, TTI was a spin-off joint venture set up by NEC Technologies (basically the North American arm of NEC Home Electronics) and Hudson Soft to handle the sales, distribution, marketing, and support of the TurboGrafx-16 line of consoles in North America. After the TurboGrafx-16's lukewarm initial reception in the territory, the joint entity was established in 1992 as Hudson Soft was still confident in the platform's long-term prospects and thought NEC wasn't doing an optimal job as their North American partner. The aim of the new arrangement was to give Hudson Soft more control over the North American operations, while still allowing NEC input and a share of the profits.

The graphics are clean and detailed, the music is catchy and each main character's voice acted quite well (no Last Alert-level bad voice acting shenanigans here), though admittedly I own the Japanese version so, we get JP voice acting here. Adding to this is some wonderful parallax scrolling that many of the system’s side-scrollers lacked. The ICOM team (the same team behind the Consulting Detective Sherlock Holmes games) even wrote the ending song, “Slipping into Nowhere.” Pretty cool to have a game with its own song back then.

It isn’t a perfect title, though - I’m not partial to the Americanized artwork in the cut scenes. There are some blocky transparency issues, and the microphones were too hot when the voices were recorded - or could it be that the voices are actually stored in the PC Engine's system card memory? The music, while catchy sounds like it was recorded using a department store synthesizer made out of that thin silver aerosol paint you can get from Halfords, and also, while the voices were acted well, the main character’s voice is tenor when someone with a more masculine bass should have been used.

youtube

3 notes

·

View notes

Text

Tek's Respirator FAQ for faceups & modding Ball Jointed Dolls

Copied from DenofAngels original posted date: Sep 21, 2010 Last edited by a moderator: Oct 10, 2016

Are you qualified to talk about this?

Yes. I [Tekenduis] am a Certified Respiratory Protection Tester/Trainer with extensive training in respiratory protection. I work at a company where my staff are exposed on a daily basis to some of the most harmful chemicals in industry. They can and will be exposed to things like silica, isocyanates and cyanide gas. Their short and long-term health is in my hands and I take that very seriously. Deadly seriously, in fact.

What is respiratory protection?

Respiratory protection is a part of your Personal Protective Equipment (PPE) designed to filter or block harmful substances from reaching your respiratory system. The hobbyists primary form of respiratory protection is the respirator. There are a great number of types of respirators, some useful only for certain applications (see more on this below). The two most common respirators for hobbyists are the disposable respirator and the half-face respirator.

The half-face respirator is a mask that covers your nose and mouth, and has cartridges that clip on, screw on, or otherwise attach to ports on the mask.

The disposable respirator looks like a dust mask or surgeon's mask. It is, as the name implies, made to be disposed of after a short period of time.

Why do I need it?

Many of the items that we work with as doll customizers are toxic and many of them are cumulatively toxic. You may feel ill for a while and then get better, but the sorts of diseases that can be caused by sanding processes and spraying processes can come back to haunt you many years down the road. These products can cause Cancer and Pneumoconiosis. Cancer may be treatable if caught early enough. Pneumoconiosis, which is respiratory diseases like asbestosis, silicosis and coalworker's "black lung" disease, is NOT TREATABLE. Your doctors will work hard to make you comfortable while you die. That is the most they will be able to do for you. If you get Pneumoconiosis you will DIE.

☠️ Are you scared? You should be. This is life and death. Do not play Russian Roulette with your health. ☠️

What do I need?

That depends on the application that you are going to be using your respiratory protection for.

Sanding

For sanding applications (including sanding of resin, apoxie and other sculpting materials, and wood), you need a respirator that provides at least N95 level protection. It should say N95 somewhere on the mask itself. If it doesn't say, it is not good enough. There is a scale to protection levels and anything above N95 is also acceptable (of course).

The levels are: N95 P95 N100 P100

What does this mean?

The prefix ahead of the number will tell you if the mask is Oil Proof or Not. The number will tell you the percentage effectiveness of the filter against particles of less than 0.3 Microns. An N100 or P100 filter may also be known as a HEPA filter. On the bright side, having a small supply of these types of respirators will mean that you are following CDC and WHO recommendations for infectious disease outbreaks, which may or may not include the Inevitable Zombie Apocalypse.

P100 filters are also effective in welding applications. N95 and above filters are most commonly found in the disposable variety and may also be referred to as "dust masks" or "surgical masks". Remember, if it doesn't say N95 (or one of the other codes listed above) it is not good enough!**

Spray

This includes all types of spray applications, whether you are spraying sealant (like MSC or Testors) or airbrushing or spraying paints. The process of spraying releases aerosols (and this is true whether or not you are using an aerosol spray can product. Airbrushing paint creates aerosols too!) for which an N95 filter is not effective.

At this point, you will need to move into a mask that protects you against Organic Vapors AND has an N95 filter. This will mean moving into a half-face respirator.

Your respirator is no longer disposable and can be used again and again without ill effect; the only thing that will need replacing is your filter and (if applicable) your prefilter. Some respirator brands have an N95 filter built right into the Organic Vapour cartridge, but I recommend looking for one that does not, for ease of replacement. Cartridges and filters have different life spans and it is more economical to replace only the part that requires replacing (more on this below!).

Okay! I've got my mask, I'm totally safe now right?

No. There are three things that can negatively impact the safety of your mask; poor fit, improper maintenance and environmental levels.

Poor Fit

A respirator (of any type) is completely and utterly useless if it is the wrong size for you and is not fitted properly. Please ensure you've read the section on fitting your mask to ensure that your mask is correctly fit.

How do I know if it fits?

According to my local Occupational Health and Safety Code, a respirator cannot legally be used in a workplace environment if it has not been correctly Fit Tested. Keep in mind that half-face respirators come in various sizes. Most women and men wear a medium but if you have a particularly slender or wide face, you may need a small or large. If you have a crooked nose, or sinus problems, look for a mask made of silicon; you will find it more comfortable than plastic or rubber.

Improper Maintenance

Your respirator is equally useless if you are not properly maintaining and caring for it. This includes care of the mask between uses and replacement. Please see the section on maintaining your mask for more information.

Environmental Levels

Environmental levels are important to take into account, as your mask can only protect you against the things it was designed to protect you against up to a certain concentration. since I'm sure none of us have the money or inclination to commit to environmental testing of our workspaces, the best way to ensure this is to make sure that the area in which you are working is properly ventilated before you start your project, and until well after you are finished. Open your windows, PREFERABLY PLEASE work outside so that there is fresh air circulating in the area you're working in. If the air is particularly still (no breeze) while you're working, it is worth investing in a simple fan. Set it up in your window, with the fan blowing out the window (ie: the front of the fan where the air blows from facing towards the window). This will help pull the toxins out of your room. Alternately, if you are working outdoors, set the fan up on your table to help promote air movement.

Fit Testing

Fit testing uses a noxious but harmless substance (usually either irritant smoke or Bitrex; an additive used to create bitterness in household cleaners to prevent children from tasting them) to ensure that the seal between the mask and the face is tight and proper. Qualitative fit testing is the most common type, and requires the user of the mask to confirm the presence of the noxious substance. In some cases (depending on chemicals in the environment or failure of the Qualitative test) Quantitative fit testing may be required; this type of fit testing uses scientific sensors to record levels inside the mask. If you have access to fit testing, especially with a half-face respirator, I encourage you to take advantage of it! Fit testing needs to be redone every two years, in the case of weight loss or gain of more than 15 lbs or in the case of surgery (including dental) involving the face.

And if I don't have access?

I have done hundreds of fit tests for staff at my place of employment and I can usually tell how well a mask is likely to fit prior to the fit test being done. This is done with a simple self test. In order to be effective this test must be done every single time you use the respirator (even if you pull it down to talk to someone and put it right back on!).

For Disposable

Step 1: Put your respirator on. Step 2: Cup your hands tightly over your mouth and nose, over top of the respirator. Step 3: Suck in a long breath. You will get air, but it should all be coming in through the small cracks between your fingers. You should not feel any air coming in from around the nose piece or under your chin. If you do, refit the mask and try again. If you cannot complete this successfully, you will need either a larger or smaller mask. Step 4: With your hands still over your mouth and nose, blow out. Again, you should feel the air moving past your fingers, and never around the bridge of your nose or under your chin.

For Half-Face

Step 1: Put on your mask and make sure the straps are tight. Step 2: Cover the cartridge, as much as possible, with the palm of your hands and suck in. The mask will likely deflate slightly. You should feel some air coming in through the cartridge but no air coming in from the sides, under your chin, or around your nose. If you do, adjust the mask and try again. If you cannot complete this step successfully, you will need either a smaller or larger mask. Step 3: Cover the exhalation valve of your respirator with the palm of your hand and blow out. You should feel the mask inflate slightly and again, you should feel no air escaping from the side of your mask, under your chin or around your nose.

😷 How do I maintain my mask?

Respirator maintenance is exceptionally simple, takes very little time, and ensures that you are not exposing yourself to toxins. Take the extra few minutes to ensure that your respirator is working right!

Before you put it on

For Disposable

Do a quick visual check of the respirator. Is it dirty? A little discolouration from the dust is fine, but too much might mean that your respirator is clogged. I'll discuss this a bit further down. Check that your straps are still in good condition. Check that the foam piece at the nose is intact (if applicable) and that the metal part that bends across your nose is not bent out of shape. If your mask is clogged or not in good condition, replace it.

For Half-Face

Do a quick visual check of the inside and outside of your mask. Make sure that the valves (the little rubbery seals on the inhalation and exhalation points) are present and in good condition. Make sure there are no cracks or tears in your mask. Ensure that your filters are firmly attached. Correct any of these issues before proceeding with your work.

After you take it off

For disposable

Do another quick visual check of your mask. If everything is still in order, seal your mask inside a baggie and put it somewhere safe.

For Half-Face

Wipe all surfaces of the mask that touch your face with a respirator cleaning wipe. If you don't have any, use the following: For masks made of natural rubber, use a non-alcohol based antimicrobial wipe. For masks made of silicone or plastic, wipe with isopropanol (isopropyl alcohol, or rubbing alcohol). This step is less about the effectiveness of your mask and more about preventing build up of oils from the skin which can degrade the mask over time, necessitating replacement, as well as causing skin breakouts!

Seal your mask inside of a baggie or well-sealed (and clean!) coffee can and put it somewhere safe.

🧼 Once a month you should remove the cartridges and clean your mask with soap and water, and hang it up to dry. This keeps the inside of your mask smelling pleasant. Sweat and condensation from your breathing can build up in there over time and cause the mask to smell unpleasant.

🤔 How often do I need to replace my respirator, or cartridges?

Filters will only last so long! Keep in mind that whether or not you are actively breathing through your respirator (IE: wearing it) it is still filtering the air around you. The average Organic Vapour filter, which is what you should be wearing at the least for spraying, lasts approximately 24–48 hours. That's it! Not very long, right?

The good news is that you can extend the life of your filters dramatically by placing them into a sealed container, like a baggie or coffee can, as discussed in the section above. My staff generally see a lifetime of 1–2 weeks from their filters, and most staff are using their filters at least once a day.

💁 How do I know it's time to replace them?

For Disposable, N95 and above Your respirator is a simple filter made up of layer of material that filter out small particulates from the air. Eventually your respirator will become clogged and need to be replaced. This is not a matter of time, it is a matter of volume of filtering, something not easily tracked.

As a general rule of thumb, when your filter is ready to be replaced, you will know it because it will get harder to suck a good deep breath in. As soon as you start to feel this, replace your respirator. For Half-Face

Organic Vapour Cartridge – Because this is filtering vapours (or aerosols), you will know it is time to replace it the moment you smell or taste anything through the filters; even the tiniest bit. Throw them out and get new ones.

N95 Prefilter

Please see the explaination for disposables above, your prefilter works the same way. If your prefilter is built into your organic vapour cartridge, it is a matter of volume of filtering, something not easily tracked.

I've got this bandana/old respirator of my uncles/some other thing…

❌ Cloth is not an effective filter against either particulate or vapours. ❌

Your respirator needs to be yours. Quite aside from the obvious sanitation issues, if the respirator belongs to someone else, it may not fit correctly and is therefore ineffective.

You're just trying to scare us. No one actually gets sick from this. ☠️ ☠️

There are several people here on the [DenofAngels] forums that have stepped up to talk about the health problems that they have suffered as a result of exposure to chemicals in either this hobby or others.

NON ORIGINAL POST NOTE: Before you dismiss the risks involved please realize that even my friend, a professional artist has experienced the direct effects of long term exposure to harsh chemicals and resins for both film and personal BJD casting even when frequently taking proper protection.

🛍️ 🛒 Where do I get these things?

Disposable respirators are readily available in home improvement stores and pharmacies; just make sure you get one that says N95, or above, as discussed earlier. You can also refer to post #3 below for a Shopping Guide.

Half-face respirators are sometimes available in home improvement stores, but are also readily available from safety suppliers (many of which are open to the general public) and online.

🤢 I worked without my mask and now I'm not feeling well. Am I going to be okay?

This question is best discussed with your Doctor. My speciality is prevention, not treatment. I can tell you what results you may incur, but I cannot and will not attempt to diagnose your health, especially not over the internet.

Masks & Respirator Purchase links:

⚠️⚠️⚠️ THIS LIST IS FROM 2010⚠️⚠️⚠️ I AM ONLY INCLUDING PRODUCTS THAT STILL EXIST:

Disposable Respirators ("Dust Masks")

3M 8210 Lowes & Home Depot

3M 8210 Plus As above, but with a fabric elastic strap, so they last longer, but tend to be a bit more expensive.

3M 8511 Similar to the 8210 series, but these have an exhalation valve, which can prove more comfortable in hot or humid environments.

Half-Face Respirators (Rubber)

3M 6000 Series Half-Face Respirator Amazon (Small) Amazon (Med.)

3M 6001 Organic Vapour Cartridges & 3M 5N11 N95 Prefilters Cartridges Amazon Resupply Kit (OV Cartridges and Prefilters)

Starter Kits Amazon

Half-Face Respirators (Silicon)

3M 7500 Series Half-Face Respirator Amazon (Small) Amazon (Medium) Amazon (Large)

Starter Kits Amazon (Small) Amazon (Medium) Amazon (Large)

This is not my original post, I am simply sharing this information as not everyone can access the DenofAngels forums! Stay safe and creative guys!

13 notes

·

View notes

Text

A Comprehensive Guide to PAINT SPRAY GUN

About Paint Spray Gun

A spray gun is a device that uses air pressure to evenly distribute paint or varnish onto a surface. It can be used on a wide range of materials, including metal, wood, stone, ceramic, porcelain, plastic, glass, and textiles.

Working principle

Types

The three main types of spray guns are : airless, pneumatic, and HVLP (high-volume, low-pressure).

Airless paint sprayers

Paint sprayers are popular tools among both DIY enthusiasts and professionals in the home improvement industry due to their efficiency and ability to cover large areas quickly. Free paint sprayers, which utilize a suction tube to draw paint from a pot, are particularly effective for larger projects where speed and coverage are essential.

Pneumatic paint sprayers

Air pressure pistols, commonly referred to as spray guns, utilize compressed air from an air compressor to atomize paint into a fine mist or aerosol. This method allows for an even and controlled application of paint, making it ideal for various projects, including interior painting and finishing work. The ability to create a fog-like spray enables users to cover large areas quickly and achieve a smooth, professional finish.

HVLP Spray gun

HVLP sprayers are indeed gaining popularity due to their ability to produce a finer spray pattern while operating at lower pressure. This characteristic makes them particularly suitable for detailed work and applications on intricate surfaces, such as furniture, cabinetry, and crafts.

Airless paint sprayers are perfect for large-scale projects like painting interior and exterior walls.

HVLP sprayers excel at detailed work, making them ideal for cabinets, furniture, and precision tasks. However, their slower speed and need for frequent cup refills make them less suitable for larger jobs.

Compressed air systems are highly effective for painting metals, particularly in the automotive industry.

Primer?

Primers are essential in the painting process as they enhance the adhesion of paint to various surfaces, ensuring a smoother finish and improving the longevity of the paint job. Additionally, primers can help seal porous surfaces, prevent stains from bleeding through, and provide a uniform base for the topcoat.

Base coat?

A base coat serves several important functions in the painting process. It not only provides a smooth surface for the topcoat but also improves adhesion, ensuring that the finish coat adheres properly and lasts longer. Additionally, base coats can help to block stains and prevent them from bleeding through the topcoat, which is particularly useful when painting over surfaces with existing discoloration. The choice of base coat can significantly impact the final appearance and durability of the paint job.

Clear coat?

A clear coat serves as a protective layer over the color coat and primer in automotive and other painting applications. Its primary function is to shield the underlying layers from various environmental factors, including UV rays, oxidation, acid rain, road salt, and pollutants like bird droppings.

Solution for Paint Spray Gun

ATS ELGI offers SPRAY GUN for Primer painting, Base coat and Clear coat.

Primer Gravity Gun – 1.8mm GTI PROLite Gravity Gun – 1.3mm GTI PROLite Gravity Gun – 1.4mm

0 notes

Text

Aerosol Paints Market Growth

Global Aerosol Paints Market Insights In 2024, the global aerosol paints market was valued at USD 272.82M, with projections to hit USD 434.24M by 2033 at a 4.88% CAGR. Advancements like low-VOC formulations & rising DIY trends are fueling growth.

0 notes

Text

Dialogue with Reality and Illusion

SENSOR MAGNITIC CHARACTERS

A painting is always a window into parallel worlds reflected through the prism of contemporary reality. In his work “SENSOR MAGNITIC CHARACTERS” the artist Antonio Lebedef demonstrates the synthesis of many artistic directions with which he experimented: expressionism, cubism, abstractionism and, of course, surrealism - the main source of his inspiration.

At first glance, the painting may appear to be just an image of the famous character Iron Man from the Marvel universe, surrounded by a colorful background. However, there is much more to this visual metaphor than meets the eye.

Recently, visiting Antonio's studio, I was able not only to see the painting live, but also to talk to the author himself, who told me about his concept. He asked me an unexpected question, “What made Iron Man create his suit and become what he became?” The answer turned out to be deeper than just a physical threat. As the artist explained, it was society and extreme events that forced the character to adapt and hide behind the armor when Stark Industries faced challenges and technology created for good turned against its creator.

Antonio draws a parallel to today's society where people, like Iron Man, hide behind their gadget screens, creating virtual alter egos on social media. They strive to seem rather than be - to demonstrate an idealized picture of life, far from reality. However, unlike the hero of comic books, in real life behind the digital armor are often not billionaires and geniuses, but people seeking to escape reality.

The artistic techniques used in the work reinforce this perception. Abstract compositions of acrylic and aerosol paints applied in a chaotic rhythm symbolize the noise of information overload and everyday hustle and bustle. They literally burst into the viewer's space, creating a sense of layering and dynamics.

The landscape element in the right corner of the painting attracts special attention. Antonio notes that it is a call to natural peace, to a conscious pause amidst the chaos of modern life. It is a kind of counterpoint, calling the viewer to stop and reflect. It is in this contrasting pause that the true meaning of the work lies: rethinking, moving away from digital noise to inner harmony.

Thus, the painting “SENSOR MAGNITIC CHARACTERS” is not just a visual image, but a deep philosophical dialog with the viewer. It is an invitation to reflect on where reality ends and illusion begins, and how to find a balance between the two worlds.

#marvel #iron_man #lebedef #glitchsurrealism #art #surrealism

0 notes

Text

Can Forming Machines: Revolutionizing Can Production with CarnaudMetalBox Engineering

The canning industry plays a crucial role in packaging and preserving food, beverages, and other products. At the heart of this industry is the technology behind can forming machines, which are responsible for shaping the raw materials into the iconic cans we use daily. As manufacturers seek efficiency, precision, and innovation, CarnaudMetalBox Engineering stands at the forefront, offering cutting-edge solutions that transform the can production process.

What Are Can Forming Machines?

Can forming machines are specialized equipment used to create the shape of cans from metal sheets. These machines transform flat sheets of metal (typically aluminum or steel) into cylindrical shapes, which are then used to contain products ranging from soft drinks and canned vegetables to aerosols and paints. The process involves several key stages:

Sheet Feeding: Raw metal sheets are fed into the machine.

Blanking: The sheets are cut into circular blanks.

Forming: The blanks are then shaped into a can body through various forming processes.

Seaming: The top and bottom of the can are attached, completing the can's structure.

Why Choose CarnaudMetalBox Engineering for Can Forming Machines?

When it comes to can forming machines, precision, reliability, and innovation are paramount. CarnaudMetalBox Engineering has a long-standing reputation for providing high-performance can manufacturing solutions. Their machines are designed to meet the growing demands of the packaging industry, offering robust performance and reduced downtime.

Here’s why CarnaudMetalBox Engineering stands out in the field of can forming:

1. State-of-the-Art Technology

CarnaudMetalBox Engineering uses the latest advancements in technology to ensure that their can forming machines deliver consistent, high-quality results. With cutting-edge automation systems and enhanced control features, these machines are designed to optimize every aspect of the production process. This not only improves efficiency but also reduces the likelihood of errors, leading to less waste and higher profitability.

2. Customization for Diverse Needs

One of the key benefits of CarnaudMetalBox Engineering’s can forming machines is their ability to be customized for a wide range of can sizes and designs. Whether you're manufacturing small beverage cans, large food cans, or specialty aerosol cans, CarnaudMetalBox Engineering offers solutions that can be tailored to your specific production requirements. Their machines can handle various materials, including aluminum and steel, with ease.

3. Increased Production Efficiency

CarnaudMetalBox Engineering’s machines are engineered to minimize downtime and enhance throughput. With automated feeding, forming, and seaming processes, these machines enable high-speed production while maintaining exceptional accuracy. This efficiency ensures that manufacturers can meet tight production schedules and keep up with market demand.

4. Sustainability and Cost-Effectiveness

Sustainability is a core principle of CarnaudMetalBox Engineering’s design philosophy. Their can forming machines are energy-efficient, reducing power consumption during production. Additionally, their machines are built for durability, meaning fewer breakdowns and maintenance costs over time. This makes them a cost-effective choice for long-term production, helping manufacturers save money and reduce environmental impact.

0 notes

Text

How Peelable Car Paint Offers Customization Without Commitment

Car enthusiasts are always looking for new and creative methods to customize their cars without committing permanent changes in constantly changing field of car customization. Presenting peelable car paint, revolutionary option which offers freedom to customize your car's look without years of commitment required for traditional paint treatments.

What Is Peelable Car Paint?

Detachable layer of paint put over car's original paint is called peelable car paint. Peelable paint may be quickly removed when desired, exposing original finish below in contrast to traditional paint which needs to be polished and may result in permanent alteration. Because of this car owners may try out several finishes and colors without worrying about devaluing their car or sticking with just one style.

Advantages of Peelable Car Paint

Temporary Customization

Peelable paint offers short term fix which can be peeled off when you feel that you're ready for change, whether you're interested in changing color of your car for specific occasion or period of time.

Protection

Above appearance, peelable paint preserves original paint finish by providing shield against small scratches, UV radiation and pollutants from environment.

Cost-Effective

Standard paint jobs may be costly and time taking. In general, peelable paint is less expensive and can be frequently applied without assistance of professional, which lowers labor expenses.

Easy Removal

Peelable paint is an effortless alternative for people who want to change look of their car often since it can be removed when you're ready to change without causing damage to underneath surface.

Application Process

To assure shiny and durable finish, peelable car paint must be applied via several steps:

Preparation

Wash car properly to get rid of trash, oil and grime. Cover off parts like windows, lights and trim that should not be painted.

Application

Apply peelable paint in several thin layers via spray tool or aerosol containers, giving each layer enough time to dry. This accumulates enough thickness for strength and removal simplicity.

Curing

It may take few hours to several days for paint to completely dry, depending on kind of paint and surrounding circumstances.

Removal

When time comes, start with an edge and carefully take off paint. Original surface should remain intact when paint peels off in big sheets.

Popular Brands and Products

Market for peelable car paint has seen rise of several brands:

Plasti Dip

Plasti Dip one of industry leaders, comes in variety of colors and textures such as metallic, gloss and matte.

Autoflex

Autoflex is well known for its superior finishes that resemble conventional paint and offer glossy long lasting look.

Halo EFX

Halo EFX is commended for its flawless finish and ease of application and it comes in range of vivid hues.

Considerations Before Use

Peelable car paint has several advantages, however it's important to take look at following:

Surface Compatibility

Make sure product works with paint and coatings that are already on your car.

Environmental Factors

Extreme weather and temperature might have impact on peelable paint's lifespan and durability.

Application Skill

Practice may be necessary to get professional finish. Consider getting expert help if you're unsure about your application abilities.

Conclusion

For car owners who want to personalize their vehicles without long lasting nature of conventional paint jobs, peelable car paint provides flexible and affordable option. It is understandable why peelable paint has grown in popularity among car enthusiasts given its capacity to preserve original paint job and its flexibility in terms of color changes. Whether you want minor modification or striking new design, peelable car paint gives you customisation you want without requiring you to commit.

0 notes

Text

Global Metal Packaging Market: Trends, Growth, and Future Outlook

The global metal packaging market has experienced significant growth in recent years, driven by increasing demand for sustainable and durable packaging solutions across various industries. According to a report by Report Prime, the market is projected to expand from USD 147.70 billion in 2023 to USD 193.05 billion by 2030, at a compound annual growth rate (CAGR) of 3.90% during the forecast period.

Market Overview

Metal packaging involves the use of materials such as aluminum and steel to create containers for products in sectors like food and beverages, personal care, and industrial goods. The inherent properties of metals—such as strength, recyclability, and barrier protection—make them a preferred choice for packaging applications that require durability and preservation.

Get Sample PDF

Key Drivers of Market Growth

Sustainability Concerns: With a growing emphasis on environmental sustainability, both consumers and manufacturers are gravitating towards packaging solutions that are eco-friendly. Metals are highly recyclable, and the recycling process consumes less energy compared to the production of new materials, reducing the carbon footprint.

Consumer Preferences: The food and beverage industry has seen a surge in demand for canned products, which offer longer shelf life and convenience. This trend has positively impacted the metal packaging market, as cans are predominantly made from aluminum and steel.

Regulatory Support: Government regulations promoting the use of sustainable materials and imposing restrictions on single-use plastics have further propelled the adoption of metal packaging solutions.

Market Segmentation

The metal packaging market can be segmented based on material type, application, and region.

By Material Type:

Aluminum Packaging: Known for its lightweight and corrosion-resistant properties, aluminum is extensively used in beverage cans and aerosol containers.

Steel Packaging: Steel offers superior strength and is commonly used for food cans, industrial containers, and closures.

By Application:

Food Packaging: Includes canned vegetables, fruits, meats, and ready-to-eat meals.

Beverage Packaging: Encompasses cans for soft drinks, alcoholic beverages, and energy drinks.

Personal Care Packaging: Involves containers for products like deodorants, hairsprays, and creams.

Industrial Packaging: Covers drums and barrels used for chemicals, paints, and oils.

Regional Analysis

North America: This region holds a significant share of the metal packaging market, driven by high consumption of canned beverages and a strong emphasis on recycling initiatives.

Europe: Stringent environmental regulations and a well-established recycling infrastructure contribute to the robust demand for metal packaging in this region.

Asia-Pacific: Rapid urbanization, increasing disposable incomes, and changing consumer lifestyles are propelling market growth in countries like China and India.

Recent Developments

In 2024, Ball Corporation introduced a new line of lightweight aluminum cans designed specifically for the energy drink sector. These cans offer a 5% reduction in material use while maintaining durability, supporting the market's shift toward sustainable, lightweight packaging solutions.

Challenges and Opportunities

While the metal packaging market is on a growth trajectory, it faces certain challenges:

Fluctuating Raw Material Prices: The volatility in prices of aluminum and steel can impact production costs and profit margins for manufacturers.

Competition from Alternative Materials: The rise of biodegradable plastics and other sustainable materials presents competition to metal packaging solutions.

However, these challenges also open up avenues for innovation:

Technological Advancements: Developing advanced manufacturing processes can lead to the production of thinner, stronger, and more cost-effective metal packaging.

Customization and Branding: Offering customizable designs and high-quality printing can help brands differentiate their products and attract consumers.

Future Outlook

The metal packaging market is poised for steady growth, with increasing demand for sustainable and durable packaging solutions across various industries. Manufacturers are likely to invest in research and development to innovate and meet the evolving needs of consumers and regulatory bodies.

Conclusion

The global metal packaging market is set to experience significant growth in the coming years, driven by sustainability concerns, consumer preferences, and regulatory support. By leveraging technological advancements and focusing on innovation, industry players can capitalize on emerging opportunities and navigate the challenges in this dynamic market landscape.

0 notes

Text

Aerosol paint machines have revolutionized the way we tackle various painting and marking tasks, delivering precision, efficiency, and versatility. These machines are widely used across industries for projects like field marking, line striping, and touch-up jobs. Whether you’re painting athletic fields, warehouses, or outdoor spaces, an aerosol paint machine can provide a convenient solution to deliver high-quality results. Learn more - https://fivexfinance.com/exploring-various-aerosol-paint-machines-and-their-practical-applications/

0 notes

Text

Achieve a Superior Finish with SuperonTechnik Stainless Steel Spray Paint

SuperonTechnik proudly presents its top-tier Stainless Steel Spray Paint, designed to offer a sleek and durable finish for various applications. Whether for industrial use, home improvement, or artistic projects, our stainless steel spray paint ensures excellent adhesion, corrosion resistance, and a professional-grade finish. High-quality stainless steel spray paint Transform your projects with the quality and reliability that SuperonTechnik provides. Discover the benefits of our stainless steel spray paint and elevate the look and longevity of your surfaces.

Why Choose SuperonTechnik Stainless Steel Spray Paint?

1. Exceptional Quality

SuperonTechnik’s stainless steel spray paint is formulated with high-quality ingredients to deliver superior coverage and a flawless finish. Our product undergoes rigorous testing to ensure it meets the highest industry standards, providing you with a paint that excels in performance and durability.

2. Easy Application

Our spray paint is designed for ease of use, making it suitable for both professionals and DIY enthusiasts. The aerosol can is engineered to deliver a smooth and even coat with minimal effort. The quick-drying formula reduces downtime, allowing you to complete your projects efficiently.

3. Corrosion Resistance

One of the standout features of SuperonTechnik’s stainless steel spray paint is its excellent corrosion resistance. Ideal for surfaces exposed to harsh environments, moisture, and chemicals, our spray paint provides a protective barrier that prevents rust and prolongs the lifespan of your materials.

4. Versatile Use

SuperonTechnik’s stainless steel spray paint is incredibly versatile and can be used on a wide range of surfaces, including metal, wood, plastic, and more. Whether you are refurbishing industrial equipment, enhancing the appearance of home appliances, or adding a touch of elegance to furniture, our spray paint delivers consistent, high-quality results.

5. Aesthetic Appeal

Our stainless steel spray paint offers a sleek, metallic finish that enhances the visual appeal of any project. The lustrous coating not only looks great but also adds a layer of protection to the underlying surface. With its modern and sophisticated appearance, our spray paint is perfect for decorative applications and restoration projects.

Benefits of Choosing SuperonTechnik Stainless Steel Spray Paint

Superior Coverage: Achieve a uniform and consistent finish with excellent coverage and minimal overspray.

Long-Lasting Protection: Benefit from enhanced durability and resistance to wear, corrosion, and environmental factors.

Easy Application: Enjoy a user-friendly application process with a quick-drying formula for efficient project completion.

Multi-Surface Compatibility: Use on various surfaces, including metal, wood, plastic, and more, for versatile applications.

Professional Finish: Obtain a high-quality, metallic finish that adds value and appeal to your projects.

How to Get Started with SuperonTechnik

Visit Our Website: Explore our range of stainless steel spray paint and learn more about its features and benefits.

Contact Us: Reach out to our team for personalized recommendations and technical support.

Place Your Order: Order your stainless steel spray paint through our secure online platform.

Prepare Your Surface: Ensure the surface is clean, dry, and free of contaminants before application.

Apply the Spray Paint: Follow the application instructions for a smooth and even finish.

Get Started with SuperonTechnik

Ready to elevate your projects with premium stainless steel spray paint? Visit SuperonTechnik today and discover our high-quality spray paint solutions. Our commitment to excellence ensures you receive the best products and support for your needs. Contact us now to learn more about our stainless steel spray paint and how it can benefit your projects.

0 notes

Text

NASA, NOAA rank the 2024 Ozone Hole as 7th-smallest since recovery began

Healing continues in the atmosphere over the Antarctic: a hole that opens annually in the ozone layer over Earth's southern pole was relatively small in 2024 compared to other years. Scientists with NASA and the National Oceanic and Atmospheric Administration (NOAA) project the ozone layer could fully recover by 2066.

During the peak of ozone depletion season from Sept. 7 through Oct. 13, the 2024 area of the ozone hole ranked the seventh smallest since recovery began in 1992, when the Montreal Protocol, a landmark international agreement to phase out ozone-depleting chemicals, began to take effect.

At almost 8 million square miles (20 million square kilometers), the monthly average ozone-depleted region in the Antarctic this year was nearly three times the size of the contiguous U.S. The hole reached its greatest one-day extent for the year on Sept. 28 at 8.5 million square miles (22.4 million square kilometers).

The improvement is due to a combination of continuing declines in harmful chlorofluorocarbon (CFC) chemicals, along with an unexpected infusion of ozone carried by air currents from north of the Antarctic, scientists said.

In previous years, NASA and NOAA have reported the ozone hole ranking using a time frame dating back to 1979, when scientists began tracking Antarctic ozone levels with satellite data. Using that longer record, this year's hole ranked 20th smallest in area across the 45 years of observations.

"The 2024 Antarctic hole is smaller than ozone holes seen in the early 2000s," said Paul Newman, leader of NASA's ozone research team and chief scientist for Earth sciences at NASA's Goddard Space Flight Center in Greenbelt, Maryland. "The gradual improvement we've seen in the past two decades shows that international efforts that curbed ozone-destroying chemicals are working."

The ozone-rich layer high in the atmosphere acts as a planetary sunscreen that helps shield us from harmful ultraviolet (UV) radiation from the Sun. Areas with depleted ozone allow more UV radiation, resulting in increased cases of skin cancer and cataracts. Excessive exposure to UV light can also reduce agricultural yields as well as damage aquatic plants and animals in vital ecosystems.

Scientists were alarmed in the 1970s at the prospect that CFCs could eat away at atmospheric ozone. By the mid-1980s, the ozone layer had been depleted so much that a broad swath of the Antarctic stratosphere was essentially devoid of ozone by early October each year. Sources of damaging CFCs included coolants in refrigerators and air conditioners, as well as aerosols in hairspray, antiperspirant, and spray paint. Harmful chemicals were also released in the manufacture of insulating foams and as components of industrial fire suppression systems.

The Montreal Protocol was signed in 1987 to phase out CFC-based products and processes. Countries worldwide agreed to replace the chemicals with more environmentally friendly alternatives by 2010. The release of CFC compounds has dramatically decreased following the Montreal Protocol. But CFCs already in the air will take many decades to break down. As existing CFC levels gradually decline, ozone in the upper atmosphere will rebound globally, and ozone holes will shrink.

"For 2024, we can see that the ozone hole's severity is below average compared to other years in the past three decades, but the ozone layer is still far from being fully healed," said Stephen Montzka, senior scientist of the NOAA Global Monitoring Laboratory.

Researchers rely on a combination of systems to monitor the ozone layer. They include instruments on NASA's Aura satellite, the NOAA-20 and NOAA-21 satellites, and the Suomi National Polar-orbiting Partnership satellite, jointly operated by NASA and NOAA.

NOAA scientists also release instrumented weather balloons from the South Pole Baseline Atmospheric Observatory to observe ozone concentrations directly overhead in a measurement called Dobson Units. The 2024 concentration reached its lowest value of 109 Dobson Units on October 5. The lowest value ever recorded over the South Pole was 92 Dobson Units in October 2006.

NASA and NOAA satellite observations of ozone concentrations cover the entire ozone hole, which can produce a slightly smaller value for the lowest Dobson Unit measurement.

"That is well below the 225 Dobson Units that was typical of the ozone cover above the Antarctic in 1979," said NOAA research chemist Bryan Johnson. "So, there's still a long way to go before atmospheric ozone is back to the levels before the advent of widespread CFC pollution."

3 notes

·

View notes

Text

Dimethyl Ether: A Versatile Fuel for a Sustainable Future

Dimethyl ether (DME) is emerging as a key player in the pursuit of sustainable energy solutions, offering versatile applications across various industries. This clean-burning compound holds promise as an alternative fuel and a critical component in transitioning away from conventional fossil fuels. In this article, we delve into the properties, production methods, applications, and environmental benefits of Dimethyl ether, exploring its potential to reshape the global energy landscape.

What is Dimethyl Ether?

Dimethyl ether, with the chemical formula CH3OCH3CH_3OCH_3CH3OCH3, is a colorless, odorless gas at standard temperature and pressure. Its molecular structure consists of two methyl groups connected by an oxygen atom, giving it a unique combination of chemical stability and reactivity. DME is highly flammable, liquefies under modest pressure, and possesses physical properties similar to liquefied petroleum gas (LPG).

Production of Dimethyl Ether

DME is synthesized primarily through two pathways: direct and indirect synthesis.

Direct Synthesis: This process involves reacting synthesis gas (syngas), a mixture of carbon monoxide and hydrogen, in the presence of a bifunctional catalyst. The reaction simultaneously forms methanol, which is then dehydrated to produce DME.

Indirect Synthesis: This involves a two-step process where methanol is first produced from syngas and subsequently dehydrated to form DME. This method is widely adopted due to its simplicity and existing infrastructure for methanol production.

Innovative technologies are now focusing on producing DME from renewable sources such as biomass and municipal waste, enhancing its sustainability profile.

Applications of Dimethyl Ether

DME's unique properties make it suitable for a range of applications:

Fuel Alternative:

Transportation: DME serves as a clean alternative to diesel fuel, offering high cetane numbers and eliminating soot emissions during combustion. Vehicles designed or retrofitted for DME are gaining traction in regions focusing on decarbonization.

Cooking and Heating: DME can replace LPG for domestic cooking and heating purposes, reducing greenhouse gas emissions.

Aerosol Propellant:As a non-toxic and ozone-friendly alternative to traditional propellants, DME is widely used in personal care products, paints, and pharmaceuticals.

Chemical Feedstock:DME acts as an intermediate in the production of valuable chemicals like olefins and dimethyl sulfate, contributing to the industrial sector.

Power Generation:In power plants, DME can serve as a substitute for natural gas or coal, reducing harmful emissions and supporting cleaner energy production.

Environmental and Economic Advantages

One of DME's standout features is its environmental friendliness. When burned, it produces minimal particulate matter and significantly lower levels of nitrogen oxides (NOx) compared to conventional fuels. Moreover, its sulfur-free nature ensures no formation of sulfur oxides (SOx), a major contributor to acid rain.

Economically, DME offers cost-effective benefits, especially when derived from abundant or waste-based feedstocks. Its adaptability to existing fuel infrastructure, such as LPG storage and distribution networks, further reduces implementation costs.

Challenges and Future Prospects

Despite its potential, widespread adoption of DME faces hurdles such as production scalability, storage, and transportation challenges. Investments in renewable DME production and government incentives for green energy adoption could accelerate its market penetration.

Conclusion

Dimethyl ether stands at the crossroads of innovation and sustainability, offering a cleaner, efficient, and versatile energy solution. As technological advancements refine its production and applications, DME has the potential to significantly reduce humanity’s carbon footprint, paving the way for a greener future. By embracing this promising compound, we can move closer to achieving global energy sustainability goals.

#Dimethyl ether#115-10-6#CH3OCH3#What is dimethyl ether used for?#Is dimethyl ether harmful?#What is the common name for CH3OCH3?#What is the common name of dimethyl ether?#CAS 115-10-6#China Dimethyl ether#Dimethyl ether price

1 note

·

View note

Text

Aliphatic SolventMarket New Innovations Trends, Research, Global Share and Growth Factor

Analysis of Aliphatic SolventMarket Size by Research Nester Reveals the Market to Grow with a CAGR of 5.1% During 2025-2037 and Attain ~USD 4.45 Billion by 2037

Research Nester assesses the growth and market size of global aliphatic solventmarket which is anticipated to be on account of the growing need for paints and coatings for the expanding number of commercial and residential structures brought on by increasing urbanization and population.

Research Nester’s recent market research analysis on “Aliphatic SolventMarket: Global Demand Analysis & Opportunity Outlook 2037” delivers a detailed competitors analysis and a detailed overview of the global aliphatic solventmarket in terms of market segmentation by type, application, and by region.

Growing Construction and Automotive Industry to Promote Global Market Share of Aliphatic Solvent

The growing need for paints and coatings due to the increasing number of residential and commercial buildings brought about by population growth and urbanization is anticipated to drive the global market for aliphatic solvents to rapid expansion during the forecast period. Furthermore, it is anticipated that in the years to come, the development of novel and inventive aliphatic solvents will be fueled by the increased emphasis on sustainability and the growing need for ecologically friendly solvents. The aliphatic solvents market is expected to see new growth prospects with the development of bio-based aliphatic solvents.

Some of the major growth factors and challenges that are associated with the growth of the global aliphatic solventmarket are:

Growth Drivers:

Surge in Rubber Sector Will Increase Need for Aliphatic Solvents

Rising Turpentine Substitution with Mineral Spirits

Challenges:

Workers who handle solvents in the course of producing aliphatic solvents and thinners frequently come into contact with them, which can be harmful to their neurological and respiratory systems. Producers of aliphatic solvents and thinners are now considering the use of organic solvents as an alternative due to the stringent restrictions controlling the use of solvents. Negative consequences and a transition to greener substitutes and high costare some of the major factors anticipated to hamper the global market size of aliphatic solvent.

Access our detailed report at:https://www.researchnester.com/reports/aliphatic-solvent-market/3328

By application, the global aliphatic solventmarket is segmented into paints & coatings, adhesives, rubbers & polymers, oil & gas, aerosol and cleaning & degreasing. The paints & coatings segment is to garner a highest revenue by the end of 2037 by growing at a significant CAGR over the forecast period. Aliphatic solvents are widely used as diluents and solvents for resins, binders, and pigments in the paint and coatings industry. The need for aliphatic solvents in the paint and coatings business is being driven by the growth of the construction industry, the requirement for high-performance coatings, and the trend toward low-VOC coatings. Two more important applications for aliphatic solvents are cleaning and degreasing, particularly in the industrial and automotive sectors. The growing building and construction sector are increasing the requirement for aliphatic solvents as thinners and diluents in paints and coatings. In addition to adhesives, paints, and coatings especially made for the building sector, processors employ these solvents as degreasing and cleaning agents.

By region, the Europe aliphatic solventmarket is to generate the highest revenue by the end of 2037. The market for traditional hydrocarbon solvents is shifting, especially in North America and Europe where strict environmental laws and regulations have made it possible to use bio-green hydrocarbon solvents. Aromatic solvents are predicted to gradually diminish whereas aliphatic solvents, which now have a significant market share, are predicted to climb steadily. The greatest market for hydrocarbon solvent applications is in painting and coatings, with printing ink, adhesives, and pharmaceuticals following suit.

Customized report@ https://www.researchnester.com/customized-reports-3328

This report also provides the existing competitive scenario of some of the key players of the global aliphatic solventmarketwhich includes company profiling of ExxonMobil Corporation, Reliance Industries Limited, Marathon Petroleum Corporation, E.I. Du Pont De Nemours and Company, PJSC Lukoil Oil Company, Valero Energy Corporation, Shell Plc, Honeywell International Inc., Janex S.A, and others.

Request Report Sample@ https://www.researchnester.com/sample-request-3328

Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates and executives to take wise decisions for their future marketing strategy, expansion and investment etc. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds. Our out of box thinking helps our clients to take wise decision in order to avoid future uncertainties.

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

0 notes

Text

A Comprehensive Guide to PAINT SPRAY GUN

About Paint Spray Gun

A spray gun is a device that uses air pressure to evenly distribute paint or varnish onto a surface. It can be used on a wide range of materials, including metal, wood, stone, ceramic, porcelain, plastic, glass, and textiles.

Working principle

Types

The three main types of spray guns are : airless, pneumatic, and HVLP (high-volume, low-pressure).

Airless paint sprayers

Paint sprayers are popular tools among both DIY enthusiasts and professionals in the home improvement industry due to their efficiency and ability to cover large areas quickly. Free paint sprayers, which utilize a suction tube to draw paint from a pot, are particularly effective for larger projects where speed and coverage are essential.

Pneumatic paint sprayers

Air pressure pistols, commonly referred to as spray guns, utilize compressed air from an air compressor to atomize paint into a fine mist or aerosol. This method allows for an even and controlled application of paint, making it ideal for various projects, including interior painting and finishing work. The ability to create a fog-like spray enables users to cover large areas quickly and achieve a smooth, professional finish.

HVLP Spray gun

HVLP sprayers are indeed gaining popularity due to their ability to produce a finer spray pattern while operating at lower pressure. This characteristic makes them particularly suitable for detailed work and applications on intricate surfaces, such as furniture, cabinetry, and crafts.

Airless paint sprayers are perfect for large-scale projects like painting interior and exterior walls.

HVLP sprayers excel at detailed work, making them ideal for cabinets, furniture, and precision tasks. However, their slower speed and need for frequent cup refills make them less suitable for larger jobs.

Compressed air systems are highly effective for painting metals, particularly in the automotive industry.

Primer?

Primers are essential in the painting process as they enhance the adhesion of paint to various surfaces, ensuring a smoother finish and improving the longevity of the paint job. Additionally, primers can help seal porous surfaces, prevent stains from bleeding through, and provide a uniform base for the topcoat.

Base coat?

A base coat serves several important functions in the painting process. It not only provides a smooth surface for the topcoat but also improves adhesion, ensuring that the finish coat adheres properly and lasts longer. Additionally, base coats can help to block stains and prevent them from bleeding through the topcoat, which is particularly useful when painting over surfaces with existing discoloration. The choice of base coat can significantly impact the final appearance and durability of the paint job.

Clear coat?

A clear coat serves as a protective layer over the color coat and primer in automotive and other painting applications. Its primary function is to shield the underlying layers from various environmental factors, including UV rays, oxidation, acid rain, road salt, and pollutants like bird droppings.

Solution for Paint Spray Gun

ATS ELGI offers SPRAY GUN for Primer painting, Base coat and Clear coat.

0 notes