#AWSSupplyChain

Explore tagged Tumblr posts

Text

Use AWS Supply Chain Analytics To Gain Useful Knowledge

Use AWS Supply Chain Analytics to unleash the power of your supply chain data and obtain useful insights.

AWS Supply Chain

Reduce expenses and minimize risks with a supply chain solution driven by machine learning.

Demand forecasting and inventory visibility, actionable insights, integrated contextual collaboration, demand and supply planning, n-tier supplier visibility, and sustainability information management are all enhanced by AWS Supply Chain, a cloud-based supply chain management application that aggregates data and offers ML-powered forecasting techniques. In addition to utilizing ML and generative AI to transform and combine fragmented data into the supply chain data lake (SCDL), AWS Supply Chain can interact with your current solutions for enterprise resource planning (ERP) and supply chain management. Without requiring replatforming, upfront license costs, or long-term commitments, AWS Supply Chain may enhance supply chain risk management.

Advantages

Reduce the risk of overstock and stock-outs

Reduce extra inventory expenditures and enhance consumer experiences by reducing the risk of overstock and stock-outs.

Increase visibility quickly

Obtain supply chain visibility quickly without having to make long-term commitments, pay upfront license fees, or replatform.

Actionable insights driven by ML

Use actionable insights driven by machine learning (ML) to make better supply chain decisions.

Simplify the process of gathering sustainability data and collaborating on supply plans

Work with partners on order commitments and supply plans more safely and conveniently. Determine and address shortages of materials or components and gather sustainability data effectively.

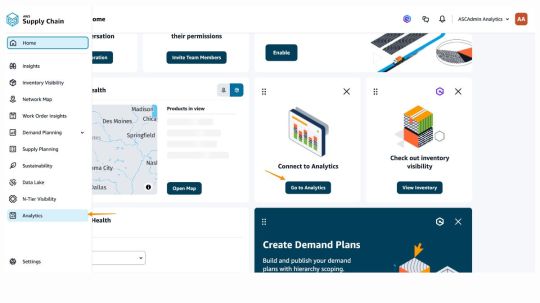

AWS is announcing that AWS Supply Chain Analytics, which is powered by Amazon QuickSight, is now generally available. Using your data in AWS Supply Chain, this new functionality enables you to create personalized report dashboards. Your supply chain managers or business analysts can use this functionality to visualize data, conduct bespoke analysis, and obtain useful insights for your supply chain management operations.

Amazon QuickSight embedded authoring tools are integrated into the AWS Supply Chain user interface, and AWS Supply Chain Analytics makes use of the AWS Supply Chain data lake. You may create unique insights, measurements, and key performance indicators (KPIs) for your operational analytics using this integration’s unified and customizable interface.

Furthermore, AWS Supply Chain Analytics offers pre-made dashboards that you may use exactly as is or alter to suit your requirements. The following prebuilt dashboards will be available to you at launch:

Plan-Over-Plan Variance: Shows differences in units and values across important dimensions including product, site, and time periods by comparing two demand plans. Seasonality Analytics: Provides a view of demand from year to year, showing trends in average demand quantities and emphasizing seasonality patterns with monthly and weekly heatmaps.

Let’s begin

Allow me to explain you about AWS Supply Chain Analytics’ features.

Turning on AWS Supply Chain Analytics is the first step. Go to Settings, pick Organizations, and then pick Analytics to accomplish this. You can enable analytics data access here.

Now you can add new roles with analytics access or edit roles that already exist.

After this feature is activated, you may choose the Connecting to Analytics card or Analytics from the left navigation menu to access the AWS Supply Chain Analytics feature when you log in to AWS Supply Chain.

The Supply Chain Function dropdown list then allows you to choose the prebuilt dashboards you require:

The best thing about these prebuilt dashboards is how simple it is to get started. All of the data, analysis, and even a dashboard will be prepared for me by AWS Supply Chain Analytics. You click Add to get started.

Then view the results when navigating to the dashboard page. Additionally, you can share this dashboard with your colleagues, which enhances teamwork.

You can go to Datasets and choose New Datasets if you need to add more datasets in order to create a custom dashboard.

You can leverage an existing dataset in this case, which is the AWS Supply Chain data lake.

You can leverage an existing dataset in this case, which is the AWS Supply Chain data lake.

After that, you may decide which table to use in your analysis. You can view every field that is provided in the Data section. AWS Supply Chain creates all data sets that begin with asc_, including supply planning, demand planning, insights, and other data sets.

Additionally, you can locate every dataset you have added to the AWS Supply Chain. One thing to keep in mind is that before using AWS Supply Chain Analytics, you must ingest data if you haven’t already done so in AWS Supply Chain Data Lake.

You can begin your analysis at this point.

Currently accessible

In every country where AWS Supply Chain is available, AWS Supply Chain Analytics is now widely accessible. Try using AWS Supply Chain Analytics to see how it can change your operations.

Read more on Govindhtech.com

#AWSSupplyChainAnalytics#AWSSupplyChain#riskmanagement#machinelearning#AmazonQuickSight#SupplyChain#Datasets#News#Technews#Technologynews#Technology#Technologytrendes#govindhtech

1 note

·

View note

Text

AWS Supply Chain: Amazon quiere mitigar riesgos en logística

AWS Supply Chain: Amazon quiere mitigar riesgos en logística

Como parte de los anuncios presentados en la segunda jornada de re:Invent de Amazon Web Services, la firma de tecnología dio a conocer AWS Supply Chain, aplicación en la nube destinada a mejorar la visibilidad de la cadena de suministro y brindar información para mitigar los riesgos de la cadena de suministro. AWS Supply Chain llega como una solución destinada a mejorar la situación logística…

View On WordPress

0 notes

Text

AWS Supply Chain Features For Modernizing Your Operations

AWS Supply Chain Features

Description of the service

AWS Supply Chain integrates data and offers demand planning, integrated contextual collaboration, and actionable insights driven by machine learning.

Important aspects of the product

Data lakes

For supply chains to comprehend, retrieve, and convert heterogeneous, incompatible data into a single data model, AWS Supply Chain creates a data lake utilizing machine learning models. Data from a variety of sources, including supply chain management and ERP systems like SAP S/4HANA, can be ingested by the data lake.

AWS Supply Chain associates data from source systems to the unified data model using machine learning (ML) and natural language processing (NLP) in order to incorporate data from changeable sources like EDI 856. Predefined yet adaptable transformation procedures are used to directly transform EDI 850 and 860 messages. Amazon S3 buckets may also store data from other systems, which generative AI will map and absorb the AWS Supply Chain Data Lake.

Insights

Using the extensive supply chain data in the data lake, AWS Supply Chain automatically produces insights into possible supply chain hazards (such overstock or stock-outs) and displays them on an inventory visualization map. The inventory visualization map shows the quantity and selection of inventory that is currently available, together with the condition of each location’s inventory (e.g., inventory that is at risk of stock out).

Additionally, AWS Supply Chain provides work order analytics to show maintenance-related materials from sourcing to delivery, as well as order status, delivery risk identification, and delivery risk mitigation measures.

In order to produce more precise vendor lead-time forecasts, AWS Supply Chain uses machine learning models that are based on technology that is comparable to that used by Amazon. Supply planners can lower the risk of stock-outs or excess inventory by using these anticipated vendor lead times to adjust static assumptions included in planning models.

By choosing the location, risk type (such as stock-out or excess stock risk), and stock threshold, inventory managers, demand planners, and supply chain leaders can also make their own insight watchlists. They can then add team members as watchers. AWS Supply Chain will provide an alert outlining the possible risk and the affected locations if a risk is identified. Work order information can be used by supply chain leaders in maintenance, procurement, and logistics to lower equipment downtime, material inventory buffers, and material expedites.

Suggested activities and cooperation

When a risk is identified, AWS Supply Chain automatically assesses, ranks, and distributes several rebalancing options to give inventory managers and planners suggested courses of action. The sustainability impact, the distance between facilities, and the proportion of risk mitigated are used to rate the recommendation options. Additionally, supply chain managers can delve deeper to examine how each choice would affect other distribution hubs around the network. Additionally, AWS Supply Chain continuously learns from your choices to generate better suggestions over time.

AWS Supply Chain has built-in contextual collaboration features to assist you in reaching an agreement with your coworkers and carrying out rebalancing activities. Information regarding the risk and suggested solutions are exchanged when teams message and chat with one another. This speeds up problem-solving by lowering mistakes and delays brought on by inadequate communication.

Demand planning

In order to help prevent waste and excessive inventory expenditures, AWS Supply Chain Demand Planning produces more accurate demand projections, adapts to market situations, and enables demand planners to work across teams. AWS Supply Chain employs machine learning (ML) to evaluate real-time data (such open orders) and historical sales data, generate forecasts, and continuously modify models to increase accuracy in order to assist eliminate the manual labor and guesswork associated with demand planning. Additionally, AWS Supply Chain Demand Planning continuously learns from user inputs and shifting demand patterns to provide prediction updates in almost real-time, enabling businesses to make proactive adjustments to supply chain operations.

Supply planning

AWS Supply Chain Supply Planning anticipates and schedules the acquisition of components, raw materials, and final products. This capability takes into account economic aspects like holding and liquidation costs and builds on nearly 30 years of Amazon experience in creating and refining AI/ML supply planning models. Demand projections produced by AWS Supply Chain Demand Planning (or any other demand planning system) are among the extensive, standardized data from the AWS Supply Chain Data Lake that are used by AWS Supply Chain Supply Planning.

Your company can better adapt to changes in demand and supply interruptions, which lowers inventory costs and improves service levels. By dynamically calculating inventory targets and taking into account demand variability, actual vendor lead times, and ordering frequency, manufacturing customers can improve in-stock and order fill rates and create supply strategies for components and completed goods at several bill of materials levels.

N-Tier Visibility

AWS Supply Chain N-Tier Visibility extends visibility beyond your company to your external trading partners by integrating with Work Order Insights or Supply Planning. By enabling you to coordinate and confirm orders with suppliers, this visibility enhances the precision of planning and execution procedures. In a few simple actions, invite, onboard, and work together with your trading partners to get order commitments and finalize supply arrangements. Partners provide commitments and confirmations, which are entered into the supply chain data lake. Subsequently, this data can be utilized to detect shortages of materials or components, alter supply plans with fresh data, and offer more insightful information.

Sustainability

Sustainability experts may access the necessary documents and datasets from their supplier network more securely and effectively using AWS Supply Chain Sustainability, which employs the same underlying technology as N-Tier Visibility. Based on a single, auditable record of the data, these capabilities assist you in providing environmental and social governance (ESG) information.

AWS Supply Chain Analytics

Amazon Quicksight powers AWS Supply Chain Analytics, a reporting and analytics tool that offers both pre-made supply chain dashboards and the ability to create custom reports and analytics. With this functionality, you may utilize the AWS Supply Chain user interface to access your data in the Data Lake. You can create bespoke reports and dashboards with the inbuilt authoring tools, or you can utilize the pre-built dashboards as is or easily alter them to suit your needs. This function provides you with a centralized, adaptable, and expandable operational analytics console.

Amazon Q In the AWS Supply Chain

By evaluating the data in your AWS Supply Chain Data Lake, offering crucial operational and financial insights, and responding to pressing supply chain inquiries, Amazon Q in AWS Supply Chain is an interactive generative artificial intelligence assistant that helps you run your supply chain more effectively. Users spend less time looking for pertinent information, get solutions more quickly, and spend less time learning, deploying, configuring, or troubleshooting AWS Supply Chain.

Read more on Govindhtech.com

#SupplyChainFeatures#AWSSupplyChain#supplychain#machinelearning#DataLake#AmazonQ#News#Technews#Technologynews#Technology#Technologytrendes#govindhtech

1 note

·

View note

Text

AWS Supply Chain Gets Four New Capabilities

AWS Supply Chain’s four new capabilities optimize supply chains with Amazon’s nearly 30 years of experience, managed service resilience, security, and business continuity. The 2024 capabilities will improve data lake, demand planning, and ML insights. AWS Supply Chain offers manufacturers and upstream supply chain processes like supplier orders supply planning, collaboration, sustainability, and generative AI.

Customers can forecast, plan, position, and replenish components and finished goods with AWS Supply Chain Supply Planning to reduce inventory costs and respond faster to demand changes and supply disruptions. Two, AWS Supply Chain N-Tier Visibility streamlines customer-multiple-tier supplier supply plan and demand change communication. Customers can securely collaborate with trading partners within clicks. Third, AWS Supply Chain Sustainability will centralize sustainability data request, collection, and audit. Finally, Amazon Q in AWS Supply Chain uses generative AI to summarize inventory, demand variability, and scenario tradeoffs.

AWS Supply Chain improves inventory visibility, minimises stock-outs and overstocks that damage consumer trust and raise carrying costs. AWS Supply Chain’s Demand Planning improves demand forecasts with Amazon’s supply chain and ML expertise. Machine learning-based AWS Supply Chain Insights recommends inventory and lead-time risk mitigation for customer supply chain data. Normalize ERP customer data with AWS Supply Chain. Customers want more upstream AWS Supply Chain Demand Planning and Insights support. Due to customer demand, 4 new capabilities were announced today.

They impress customers with supply chain management. Diego Pantoja-Navajas, vice president of AWS Supply Chain, said industry-leading analytics and ML help customers track and plan products from manufacturing to distribution. Inventory visibility, supply chain risk mitigation, cost reduction, and customer satisfaction improve with AWS Supply Chain. Generative AI-powered Amazon Q in AWS Supply Chain answers complex supply chain questions.

Enhanced upstream capabilities improve AWS Supply Chain visibility and insights

Supply chain leaders serve manufacturers, distributors, retailers, and suppliers. Integration of trading partners’ data stores often requires expensive customizations, long development cycles, or manual workarounds. Forecasts, order confirmations, shipment quantities, etc. are reconciled by supply planners. Siloed data, demand variations, supply disruptions, and vendor lead-time uncertainty make demand forecasting and inventory optimization difficult for many companies. Prices and availability of raw materials and components plague manufacturers.

Trading partner responses to customer data requests vary in quality, frequency, timeliness, and structure and are not always tracked or audited. Carbon emissions and hazardous materials have been reported via email, fax, and messaging apps without tracking or auditing. Many companies struggle to meet demand or stricter regulations with enough goods on time. Today, AWS Supply Chain helps customers manage their upstream supply chain, forecast materials and inventory, confirm supplier supply plans and commitments, and get accurate environmental data.

AWS Supply Chain Supply Planning’s advanced facility inventory prediction models use Amazon’s ML expertise. Supply Planning uses AWS Supply Chain Demand Planning demand forecasts, product, facility, BOM, and inventory data. Purchase orders and inventory transfer requests let customers order, store, and choose unit quantities.

Customers see their direct and multiple external trading partners with AWS Supply Chain N-Tier Visibility. Add trading partners with few clicks. Automation improves trade partner forecasting and communication. AWS Supply Chain N-Tier Visibility monitors trading partner inventory, demand forecasts, and purchase orders. Export purchase orders and supply plans to Amazon S3 for ERP integration. Chat and messaging from AWS Supply Chain simplify collaboration. Inventory managers can notify AWS Supply Chain of late component shipments. Shared supplier and manufacturer data helps customers identify sourcing risks and component shortages and reduce disruptions.

Sustainability professionals can securely access supplier network data and documents with AWS Supply Chain Sustainability. These customers can request, collect, and export product life cycle assessments, safety certificates, and hazardous substance reports through the supply chain. Customers can upload their own data collection form for suppliers to document sustainability issues, use a standard workflow process to remind them to respond, and communicate changes based on supplier responses. This feature lets customers report ESG compliance in one auditable document.

Customers can query supply chain data with generative AI

Customer want to easily identify causal relationships between factors that affect their supply chain decisions, such as demand fluctuations and supply disruptions, but it takes time and effort to gather and analyze data from many sources. Visualizing and trading complex supply chains is difficult. Without data, supply chain leaders plan and position inventory. Amazon Q in AWS Supply Chain answers data analysis and supply chain decision questions in natural language, boosting customer productivity.

Amazon Q, powered by Amazon Bedrock, intelligently answers AWS Supply Chain Data Lake “what?”, “why?”, and “what if?” questions using a natural language interface. Customers can customize Amazon Q to see complex supply chain tradeoffs. Customer asks AWS Supply Chain, “What is the financial impact of delayed replenishment orders in the Southeast?” “8 delayed replenishment orders could deplete 20 regional fast-moving products,” Q said. Revenue will drop $150K due to delay.”

Clients may ask “Why are we not moving product from other regions to make up this shortfall?” Amazon Q said network inventory is low next week. Customers ask, “What if I expedite air freight orders?” Amazon Q says, “Air freight typically arrives in 2 days and could reduce revenue impact by $95K, but adds $2.4K in expedite costs.” Amazon Q’s fast, accurate responses help supply chains.

BCG is an AWS strategic partner. BCG and AWS balance agility, resilience, service, cost, and sustainability to grow supply chains. Drake Watten, BCG managing director and partner, said the partnership deploys, scales, and promotes AWS supply chain solutions. “We are supporting projects with the generally available capabilities and preparing customers for the upcoming AWS Supply Chain releases that will improve material, component, and finished goods planning, partner management, and supply chain management with generative AI.”

The leading independent material-handling equipment supplier and rental source, Equipment Depot, has over 50 branches and 850 technicians. Equipment Depot Operations director Joakim Langkaas is excited to work with AWS on a massive digital transformation strategy for rapid growth. “AWS Supply Chain will improve inventory, planning, and data-driven supply decisions. Demand Planning, Supply Planning, and Insights predict low inventory and OEM delays and make real-time recommendations to improve service, customer experience, and equipment downtime. The early adopter of this technology expects these new capabilities to help their teams place parts on time.

Woodside is creative and determined in Australia. From WA to the Gulf, Woodside powers homes, lights, and industry. “They remote locations prevent us from using supply chain processes like overnight shipment of spare parts, so they rely on stocking the right parts across they warehouse network and leveraging multiple modes of transport to support they operated facilities,” said Woodside Energy Supply Chain vice president Tracey Simpson they shared vision with AWS Supply Chain improved supply chain visibility for they company.

Order Insights’ proactive order status, delivery issues, and recommendations should boost system and workflow efficiency if scaled. Rescheduling maintenance and reducing material expedites should help business. They are also excited about AWS Supply Chain‘s next phase, which includes advanced supply planning, partner collaboration, and generative AI to improve supply chain performance.

Read more on Govindhtech.com

#AWS#AWSSupplyChain#generativeai#AmazonQ#amazonbedrock#customerservice#technews#technology#govindhtech

0 notes