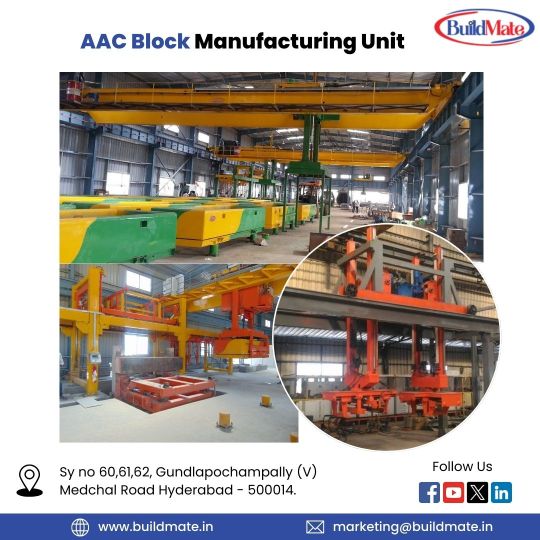

#AAC Industries

Text

Honoring Strength, Courage, and Hope

On World Cancer Day, CAPA stands with warriors, survivors, and caregivers around the globe. Let's unite in the fight against cancer, spreading awareness, supporting research, and offering love and compassion to those affected.

Together, we can make a difference. Together, we can bring light to the darkness. Join us in honoring the resilience and determination of cancer fighters everywhere. #WorldCancerDay #CAPACares #StrengthInUnity

To know more tile adhesives and waterproofing floors, epoxy grouts visit: https://capaindia.in/product/capa-flex/, https://capaindia.in/product/capaproof-hybrid-w/

#best tile adhesive in india#top tile adhesive brands in india#top building materials companies in india#tile adhesive manufacturers#tile adhesives for fixing natural stones#high strength flooring mortars#tile adhesive companies in india#floor repairs mortars in india#tile adhesives for vitrified tiles#block jointing mortar manufacturers in india#Flooring mortar#Tile and stone adhesive#Industrial Grouts#floor repairs mortars#epoxy grouts#Powder grouts#Ready mix plaster manufacturers#Machine sprayable plaster#Thin joint mortars#Thin joint mortars for AAC blocks#Waterproofing mortar#Waterproofing system#floor repairs mortars in India#best flooring solutions in india#best waterproofing mineral mortars in india#aliphatic polyurethane waterproofing coating#elastomeric waterproofing coating#flexible waterproofing mortar for crack bridging#waterproofing solutions for crack bridging#affordable waterproofing solutions

0 notes

Note

I have a request: the first paragraph of Industrial Society and its Future, courtesy of https://besser.tsoa.nyu.edu/howard/Anarchism/Unabom/manifesto.html

"The Industrial Revolution and its consequences have been a disaster for the human race. They have greatly increased the Iffe-expectancy of those of us who live in "advanced" countries, but they have destabilized society, have made life unfulfilling, have subjected human beings to indignities, have led to widespread psychological suffering (in the Third World to physical suffering as well) and have inflicted severe damage on the natural world. The continued development of technology will worsen the situation. It will certainly subject human being to greater indignities and inflict greater damage on the natural world, it will probably lead to greater social disruption and psychological suffering, and it may lead to increased physical suffering even in "advanced" countries."

String identified:

T ta t a t cc a a at t a ac. T a gat ca t -ctac t "aac" ct, t t a ta ct, a a g, a ct a g t gt, a t a cgca g ( t T t ca g a ) a a ct aag t ata . T ct t tcg t tat. t cta ct a g t gat gt a ct gat aag t ata , t a a t gat ca t a cgca g, a t a a t ca ca g "aac" ct.

Closest match: Euplexia lucipara genome assembly, chromosome: 11

Common name: Small angle shades

(image source)

#tumblr genetics#genetics#asks#requests#sent to me#science#biology#The Industrial Revolution and its consequences#fishing-wizard#bugs#insects#moths#small angle shades

241 notes

·

View notes

Text

No Capes AU

Bruce: Dr. Bruce Wayne is a beloved Gotham philanthropist, majority shareholder of Wayne Enterprises, and the sharpest man you'll ever meet. Everything he does is to protect Gotham and honor his parents' legacy. He's had a long string of romances that always seemed like they were going somewhere but never made it to the altar

Dick: Dick Grayson was a circus acrobat whose parents were killed by the mob when he was ten. He was then taken in and adopted by Bruce Wayne. He was an angry kid for a while, became a cop when he grew up and tried to change the system from the inside before Blüdhaven chewed him up and spit him out. He quit the force after the ordeal with Blockbuster and now he's an Olympic athlete/children's gymnastics coach

Jason: same origin as in canon but they just called the police on Ma Gunn. Jason was a happy kid! He graduated with honors and got a degree in nonprofit management. He runs a universal basic income project in Crime Alley and a harm reduction drug center

Cass: instead of the whole child assassin thing, Cass was one of those feral children found living alone in the wilderness at age seventeen. She never meets a magic man who rewires her brain to understand language this time. Cass uses an AAC program on a tablet to communicate. After five years in Gotham, settling in and taking lessons, she successfully auditions for the Gotham City Ballet. She goes on to become the prima ballerina

Tim: Tim was always that kid kinda on the fringes of the Wayne family's circle but then both his parents were tragically killed on a cruise, so Bruce offered to take him in. He knows the kid, after all. Tim goes to summer camp every year and has a tight knit group of friends from it. He graduates school like a normal person while also taking online college classes at night so that he can have a double graduation ceremony, not like a normal person. Eighteen year old CEO of Wayne Enterprises (Drake Industries is now a subsidiary)

Steph: Cass and Tim's bestie! She had a part time gig as the pianist for Cass's first ballet class and that's how they all met. Inseparable now. Steph was working her way through med school. Doc Thompkins is training her to take over the clinic one day when she retires. She did singlehandedly put her father in prison for life by proving he committed his crimes

Duke: lost his parents in a random mugging that Bruce witnessed. He obviously had to take the poor kid in, how could he not? Duke is a good kid, aspiring writer, still in high school but thinking about joining Jason's nonprofit. He gets fav sibling rights

Damian: Damian grew up incredibly privileged and sheltered until he was ten, as the only son and heir apparent of Dr. Talia Head and her many businesses. Bruce was SHOCKED to learn his ex wife lied about losing the baby. Who could've predicted that she would do that given the everything that went down. Anyway Damian acts like a little prince and is prickly and superior at first, but he's got a big heart and he's mellowing out

10 notes

·

View notes

Text

Welcome to my blog :]

Good morning, afternoon, evening, or night! I'm Luca, otherwise known as Mr. Tomlinson, or "the librarian." Here are a few things you should know before interacting:

I am autistic! It's difficult enough for me to interpret tone in real life, so it would really mean a lot to me if tone tags were used for clarification :] I'm also semi-verbal, so if you have questions about that, feel free to ask!

I don't appreciate unkind attitudes or actions, so please be considerate and respectful when messaging or replying to me. This blog is not a place for hate.

If you have any questions about the library, ask them! I love my books just as much as I love talking about them.

I'm not as open around the kids about this, but I'm gay and happy with it! I'm not looking for a parter at the moment, though, so keep your virtual legs closed or I'm launching you off the face of the planet.

I have a condition known as Functional Neurological Disorder. It does what it says on the tin--there's a disorder with my neurological functions. It may be a point of contention within the healthcare industry, but it's very real and affects me daily. I'm more than glad to answer any questions about that as well, because Lord knows how many of my kids ask me about my crutches whenever I need them, lol.

OOC: Admin here!

Hello! I'm Mitch, and Luca Tomlinson is my OC. Currently, he's in the FNaF Movie universe, alongside my friends' OC's, aptly titled The Fan-Fazgang.

Luca is 24 and a moderate-needs autistic. He's semi-verbal, and uses AAC and limited sign-language to communicate, unless he's comfortable enough to speak or deems it necessary for the situation he's in. He rarely masks, and because of this, the library is his dream job. A quiet environment, tons and tons of books, and easy, repetitive tasks that he loses himself in make him feel right at home. He got the job as a shot in the dark, as the previous librarian was retiring due to age, and Luca needed some form of income after moving back in with his mother, who herself was struggling.

Lo and behold, he got the job, and the town loves him! He mostly works with the schools in the area, as none of them have their own libraries, so his regulars tend to be children between the ages of 5 and 12. Due to trauma, he tries to keep himself scarce if any teenagers happen to stop by, but they've gotten nicer over the years. The kids are his favorite, though. They think Mr. Tomlinson is the coolest guy on the planet! At first, the parents thought he was an asshole (resting bitch face, thanks autism), but they immediately fell in love with him too after just a few visits.

Luca loves being a role model for the various disabled kids he sees throughout the day. Autistic kids, kids in wheelchairs, kids with crutches, ADHD kids--he loves teaching them and their parents about what it means to be disabled, and how it should be embraced. He's even made a little shelf where educational books about disabilities are stored, just in case someone wants to learn something new.

Deep down, Luca's biggest dream is to have a child of his own, someone he can love and support to help them become the best version of themself that they can be. Being the town's librarian is the closest thing he's got so far, and he can't help but flap his hands when he thinks about how exciting his future's going to be.

Luca loves life, and you should, too.

(Admin is 17, uses he/they/it, and lives in EST. Asks are open!)

#original character#oc#fan fazgang#fan fazgang oc#character rp#how the fart do i tag this#uhhhh#fnaf movie#<- oc is in this universe! sorry maintag folks

2 notes

·

View notes

Text

@ British Columbians!!!

The Ministry of Forests is accepting comments on the Kootenay Lake Timber Supply Area Review until July 4th. Click here to write your comments to:

Ian Wiles, Stewardship Officer, Selkirk Resource District ([email protected])

Shane Berg, Chief Forester ([email protected])

Honourable Bruce Ralston, Minister of Forests ([email protected])

Forest Analysis and Inventory Branch, Victoria ([email protected])

Add your location after your name, so they know that you’re local to the area.

Key issues to consider to write your comments

The most important message is that cut levels must be radically reduced to reflect the on-the-ground reality of our forests, the priorities of local communities and Indigenous Nations, and the health of our ecosystems.

Old Growth

The province must stop using an oldest-first harvest strategy in the Timber Supply Review Process. We should be protecting our old growth, not targeting these stands for logging.

In many parts of the Kootenay Lake TSA, less than 10% of the old growth forests are still standing. It’s time to stop logging old growth and to calculate the Annual Allowable Cut with the assumption that no more old growth will be cut.

The Annual Allowable Cut is based on the Timber Harvesting Land Base (the area of forest that is theoretically available for logging over time). Even though BC has deferred logging on 62,055 hectares of old growth forest in the Kootenay Lake Timber Supply Area, they still are including many of these areas in the Timber Harvesting Land Base, meaning other areas suffer even more logging because the calculations are based on forests that aren’t really available for logging. The chief forester has to adjust the AAC to account for the areas set aside for old growth.

Seventy-eight percent of designated Old Growth Management Areas (another designation meant to protect old growth) over two hectares in size in the Kootenay Lake TSR are actually in sub-alpine areas that cannot be logged anyways. Old Growth Management Areas should be designated where old growth can actually be protected from logging. Pretending to protect something that was never threatened by logging just inflates the numbers.

Protect Our Water

The current and projected AAC relies on harvesting community watersheds. Thirty percent of the Timber Harvesting Land Base is in community watersheds. We need a precautionary approach that excludes community watersheds from the Timber Harvesting Land Base. We have to protect our drinking water. Industrial logging in watersheds sends sediment downstream into our drinking water, reducing water quality. Logging large swaths of mature forest in watersheds also makes floods in our communities more likely. Recent literature suggests that after 30% of a watershed is logged, what used to be a once-in-a-century flood comes around every 15 years.

Climate Change Realism

We know that climate change will result in more fires and flooding, increased regeneration delays, more extreme weather, and more beetle outbreaks. That means less wood available. The Ministry says that we can’t forecast the exact quantitative effects of climate change, so they pretend those effects don’t exist. The Ministry must reduce cut levels to a precautionary level to account for climate change.

Look Forwards, Not Backwards In The TSR

The TSR process has to look forward and integrate reasonable assumptions about our future and on-the-ground realities into models used to calculate the Annual Allowable Cut. That means not only that old growth deferrals and community watersheds need to be taken out of the Timber Harvesting Land Base, but also that government commitments to shifting away from clearcut logging, improving forestry practices on the ground and ecosystem needs all must be incorporated into the model.

Thanks for speaking up!

4 notes

·

View notes

Note

3, 10, 15, and 16 ?

3. what, if any, disability aids do you use? (mobility aids, sensory aids, braces, communicative devices, IVs, etc. meds also count here). do you customize them/their containers/outsides?

Lots and lots! I use knee braces (they are hot pink & match my hair and I love them). I used to use forearm crutches, and might get a cane soon. I've had NG tubes before, and rely on supplemental oral nutrition rn. I use an AAC app for psychosis but I'm not a regular AAC user outside of that. Might not traditionally be considered aids, but things like mad mapping + my harm reduction supply toolkit with my sharps bin, safer supplies, stuff like that. I love customizing things-I'm a big fan of bright colors, stickers, sewing, diy, so almost everything I own has been customized in some way. I think I've posted photos of how i decorated my crutches, IV pole, and sharps container with stickers before.

10. already answered :)

15. what does disability pride mean to you?

disability pride means protest to me!!! for me pride is always going to be a protest and a lot of what I have learned about celebrating myself as a disabled person has come from the legacies of disabled people fighting back against a world that doesn't want us to exist. Disability pride means that I have the right to exist with everything that means for me, and that I don't need to love or be happy about every part of my experiences, but that I will fight for the right to have those be mine. disability pride means access intimacy and interdependence and disabled community where we can share that rage together and love the ways we exist together. Disability pride also means making room to honor my grief, and remembering everyone I've lost-their memories will always be present in my disabled community and I want to celebrate their lives and mourn together with my loved ones.

16. free space to talk about whatever disability issue or experience you want !

Ooh! I've been in a mood the past couple days to talk about intersex stuff. So will just mention again today that I personally view my intersex variation as both a queer identity and as a disability-I think that the social model of disability becomes very relevant when we look at the way intersex people are treated, our relationship with the medical industrial complex, and the way that intersex people are made disabled within it. I think that intersexism is rooted in ableism and that intersex liberation must be based on solidarity with the disability justice movement. I don't think that individual intersex people need to see their intersex variations as disabilities but I'm really drawn to how Dr Celeste Orr discusses intersex and/as/is/with disability in Cripping Intersex. and especially for my specific intersex variation, which depending on the subtype that you have, can require lifelong glucocorticoid therapy, can be the subtype with EDS, can have salt wasting crises, etc, it's clear why we might understand ourselves as disabled and chronically ill people. And at the same time, being intersex will always be queer to me, because we belong in LGBTQIA community and i want to honor how my intersex traits exist beautifully outside of the sex binary!

4 notes

·

View notes

Text

Revolutionize Construction: Introducing Magicrete Eco-Friendly Solutions

Discover the Future of Construction with Magicrete - India's Leading AAC Products,

Construction Chemicals & Precast Construction Solutions Provider.

At Magicrete, we're not just building structures but shaping a revolution in the construction

industry. Established in 2008 by a dynamic team of visionaries from prestigious institutions like

IIT Kharagpur, IIT Delhi, and IIM Lucknow, we've pioneered a new era of green building

materials and innovative construction technologies.

Our Vision: Empowering Homebuilders for a Better, Cheaper, and Faster Tomorrow.

Setting the Benchmark: Magicrete has become a beacon of modern construction technology

over the last decade. Our solutions have transformed the lives of over a million individuals,

gracing more than 500,000 homes nationwide.

Awards and Accolades: Our dedication to excellence has earned us numerous prestigious

awards, including the "Most Promising Brand Award 2019" for building materials by the Global

Real Estate Congress, "Most Preferred Brand 2018" for blocks/bricks by ET Now, and

nominations such as "Start-up of the Year 2015" by Forbes and "Entrepreneur of the Year 2015"

by Tiecon.

Championing Innovation: Magicrete's recent victory in the Global Housing Technology

Challenge, organized by the Ministry of Housing & Urban Affairs, speaks volumes about our

commitment to innovation. We successfully constructed 1000 houses in Ranchi within a year

using our groundbreaking 3D Modular Technology.

Driving the 'Housing for All' Mission: As we forge ahead, Magicrete is proud to play a pivotal

role in advancing the 'Housing for All' initiative. Our products are now integral to affordable housing projects nationwide, promising a brighter future for urban and rural homeowners in

India.

Discover the Magicrete advantage today and be a part of the revolution shaping the

construction's future.

For more information, visit our website or contact us at [email protected]

2 notes

·

View notes

Text

Concrete Blocks - Manufacturing, Classification & Uses

Concrete blocks are nowadays replacing bricks in masonry construction, notably in many multi-storeyed buildings. They are available in three types namely solid, hollow and cellular, widely used for the construction of filler walls and boundary walls in RC framework.

Concrete blocks are usually made in large sizes to make blockwork faster and consume less cement in joints than the brickwork. If the percentage of the voids is more than 25%, then they are hollow blocks and blocks with voids less than 25% are only perforated blocks.

The cellular concrete blocks are generally referred to as lightweight aerated concrete blocks. All these blocks are extensively used for compound walls and non-loadbearing walls.

Hollow blocks are specially made for loadbearing walls, which are useful in reducing a dead load of masonry in buildings. Blocks can also be with cement and sand called cement-sand blocks or with cement and soil called soil-cement blocks which are of low strength and use for low-cost construction.

Manufacturing of Concrete Blocks

BIS recommends a fineness modulus of the combined aggregate between 3.6 to 4 and coarse aggregates used are of size 6 to 12 mm. Lean mixes up to 1:8 are generally used. Concrete mix for concrete blocks should not be richer than one part of the cement to six parts of the volume of combined aggregate.

Concrete blocks can be handmade and also machine-made. The cast block is then cured in a water tank or yard for at least 14 days (water need to be changed at least every 4 days).

After curing, the blocks are dried for 4 weeks before being used in masonry construction. They should be stacked with voids in the horizontal direction to facilitate easy drying, or they should be steam cured and dried.

The whole process allows the complete shrinkage of the block to take place they are laid on the wall, which is very important for strong walls.

Classification of Concrete Blocks

Hollow concrete blocks

Open and Closed cavity-type hollow concrete blocks are classified into three grades:

Grade A - They possess a minimum density of 1500 kg/m³ and are used for load-bearing walls.

Grade B - They have a density below 1500 kg/m¬³ and used for load-bearing walls.

Grade C - These blocks are used for non-load bearing walls and have density more than 1000 kg/m³.

All these blocks are available in decorative facings like fluted facing to provide artistic effects.

Solid concrete blocks

They should be manufactured for specific concrete strength of 4.0 and 5.0 N/mm² in 28 days. These blocks are used as load-bearing walls and have a density of not less than 1800 kg/m³.

Paver blocks

These blocks are solid concrete blocks of different shapes specially made for exterior ground paving on sidewalks, parking lots, driveways, petrol pumps, industrial floors, etc.

AAC Blocks

AAC blocks refer as Autoclaved Aerated Concrete Blocks. These blocks are also termed as light-weight hollow blocks.

They are prepared as solid blocks from cement, water and materials like ground sand, pulverized fly ash together with additives to aerate and stabilize the air bubbles.

The final result is a mixture of thick liquid which is then poured into steel moulds to form large cakes. After some time, the mixture sets and ready to cut into a serious of individual blocks of required size using taut steel wires.

Very light blocks for partition and moderate-weight blocks for light loadbearing walls can be obtained from aac blocks. These blocks do not shrink on drying as the material is obtained by autoclaving.

The autoclaved cement product is crystalline, which is different from the product obtained by normal wet curing or by ordinary steam curing.

Sizes and Tolerances

The nominal dimensions of concrete block as per BIS are as follows:

Length - 600, 500, 450 or 400 mm

Height - 100 or 200 mm

Width - 50, 75, 100, 150, 200, 250 or 300 mm

Actual sizes will be less than 10 mm of mortar thickness. For Concrete and Hollow concrete blocks nominal length 390 mm and height 190 mm. The thickness for loadbearing walls is 190 mm, compound walls 140 mm and for filler walls 90 mm.

These dimensions can easily be achieved in machine-made blocks than handmade blocks. The width of blocks use for load-bearing walls is 200 mm and for parapet or filler walls is 100 mm.

Points to Remember:

The mortar strength should not be more than the strength of the blocks. With high mortar strength, cracks will be less and very large, but with low mortar strength, cracks will be small and distributed.

We should use only blocks that are cured properly for at least 14 days and dried for 4 weeks to avoid shrinkage during construction.

We should not wet the blocks while placing in masonry construction.

Freshly-made and uncured concrete blocks should never be allowed on the work.

Blockwork, particularly ordinary cement sand blocks and soil-cement blocks should not be used as loadbearing walls for concrete slab roof which favours to expand and contract with temperature.

The maximum difference in sizes allowed is ±5 mm in length and ±3 mm in height and width.

They should be protected from rains while being stored as they absorb moisture by wetting and shrinking on drying.

The main disadvantage of concrete blocks is shrinkage due to the movement of moisture content which is not present in bricks. As these blocks are much larger than bricks, any foundation movement will cause blockwork to crack more than the brickwork.

Cement blocks, Concrete blocks, Hollow concrete blocks, solid concrete blocks, Paver blocks, AAC blocks Concrete blocks in Hyderabad

#aac Blocks#aac blocks online#aac block size#Cement blocks#Concrete blocks#Hollow concrete blocks#solid concrete blocks#Paver blocks#AAC blocks

2 notes

·

View notes

Text

In the realm of modern construction, innovative building materials have revolutionized the way we construct sustainable and energy-efficient structures. One such groundbreaking material is Autoclaved Aerated Concrete (AAC) blocks. AAC blocks have garnered significant attention and adoption in recent years due to their remarkable properties and environmental benefits. This blog aims to delve into the world of AAC blocks, exploring their composition, advantages, and the positive impact they have on the construction industry and the environment.

#aac blocks#aac bricks#aac blocks manufacturers#aac panels#bricks suppliers#aac block manufacturers#modcrete aac blocks#modcrete aac blox#aac block

2 notes

·

View notes

Text

Elevate Your Projects with Our AAC Block Plant Solutions: Trusted Suppliers at Your Service

In the dynamic realm of construction, innovation is the cornerstone of progress. As the demand for sustainable building materials continues to rise, AAC (Autoclaved Aerated Concrete) has emerged as a game-changer, offering a greener and more efficient alternative to traditional construction materials. If you're ready to elevate your projects to new heights, our AAC Block Plant Solutions are here to meet your needs, provided by trusted suppliers committed to excellence.

The Rise of AAC in Construction Trends

In recent years, AAC has gained prominence in the construction industry for its eco-friendly nature and superior performance. This lightweight yet sturdy material is produced through a unique process that involves the introduction of air bubbles into a concrete mixture, resulting in a versatile and highly insulating building block. Here's a look at some of the latest trends in AAC construction that our suppliers are harnessing to transform the industry:

Sustainability Matters: With environmental concerns at the forefront of construction trends, AAC stands out as a sustainable option. Our suppliers are dedicated to providing AAC Block Plant Solutions that contribute to reduced carbon footprints and efficient resource utilization, aligning with the growing emphasis on eco-friendly building practices.

Energy Efficiency: AAC's excellent thermal insulation properties make it a preferred choice for energy-efficient buildings. By choosing our AAC Block Plant Solutions, you not only benefit from the material's inherent energy-saving characteristics but also align your projects with the increasing demand for sustainable and energy-efficient structures.

Versatility in Design: Creativity knows no bounds, and neither should your construction projects. Our trusted suppliers offer AAC Block Plant Solutions that cater to the growing demand for versatile design options. Whether it's intricate architectural details or modern minimalist designs, AAC allows for flexibility without compromising structural integrity.

Speedy Construction: Time is money in the construction industry, and our AAC Block Plant Solutions recognize the need for efficient project timelines. AAC blocks are known for their lightweight nature, making them easier to handle and speeding up the construction process. With our suppliers, expect timely deliveries and streamlined project schedules.

Strength and Durability: Beyond its lightweight properties, AAC is celebrated for its strength and durability. As construction trends lean towards long-lasting structures, our suppliers ensure that the AAC Block Plant Solutions deliver on the promise of robustness. Your projects deserve a foundation that withstands the test of time, and AAC is the answer.

Why Choose Our Trusted Suppliers?

Proven Expertise: Our suppliers boast a wealth of experience in the AAC industry, backed by a track record of successful projects. You can trust their expertise to guide you through the process, from selecting the right AAC blocks to optimizing production in your construction projects.

Cutting-Edge Technology: Staying ahead of the curve is crucial in the ever-evolving construction landscape. Our suppliers invest in cutting-edge technology to ensure that their AAC Block Plant Solutions are at the forefront of innovation, incorporating the latest advancements for optimal efficiency and performance.

Quality Assurance: Quality is non-negotiable when it comes to construction materials. Our trusted suppliers adhere to stringent quality control measures throughout the production process, guaranteeing that the AAC blocks you receive meet and exceed industry standards. Elevate your projects with the confidence that comes from reliable and high-quality materials.

Customized Solutions: Every construction project is unique, and our suppliers understand the importance of tailored solutions. Whether you're working on a residential development, commercial building, or infrastructure project, our AAC Block Plant Solutions can be customized to meet your specific requirements.

Conclusion: Building Tomorrow, Today

In a world where sustainable construction is no longer a choice but a responsibility, our AAC Block Plant Solutions, offered by trusted suppliers, pave the way for a greener and more efficient future. Elevate your projects with materials that not only meet but exceed industry standards, ensuring a legacy of durability, energy efficiency, and innovation. Choose our trusted suppliers and embrace the future of construction with confidence.

0 notes

Text

Transform Your Tiling Projects with CAPA FLEX!

Experience unparalleled precision and reliability with CAPA FLEX, our advanced tile adhesive solution. Featuring a unique gel-like texture, CAPA FLEX offers effortless application and superior adhesion on a wide range of surfaces, including vitrified tiles, natural stones, and large format tiles.

Say goodbye to worries about tile slippage or uneven surfaces – CAPA FLEX ensures a flawless finish, every time. Whether you're tackling residential renovations or commercial installations, trust CAPA FLEX to elevate your tiling projects to new heights of excellence.

Join the countless professionals who rely on CAPA FLEX for its unmatched performance and versatility. Step up your tiling game with CAPA FLEX today!

To know more about tile gel adhesive manufacturers and tile adhesives for vitrified tiles visit: https://capaindia.in/product/capa-flex/

#tile adhesive companies in india#tile adhesive manufacturers#top building materials companies in india#top tile adhesive brands in india#high strength flooring mortars#tile adhesives for vitrified tiles#tile adhesives for fixing natural stones#block jointing mortar manufacturers in india#best tile adhesive in india#floor repairs mortars in india#tile gel adhesive manufacturers#Flooring mortar#Tile and stone adhesive#Industrial Grouts#floor repairs mortars#epoxy grouts#Powder grouts#Ready mix plaster manufacturers#Machine sprayable plaster#Thin joint mortars#Thin joint mortars for AAC blocks#Waterproofing mortar#Waterproofing system#cement based tile adhesive#tileadhesive#tile adhesives for semi vitrified and ceramic tiles#tile adhesive for large format tiles#high strength cementitious tile grout

0 notes

Text

AEM aaCS aka Adobe Experience Manager as a Cloud Service

As the industry standard for digital experience management, Adobe Experience Manager is now being improved upon. Finally, Adobe is transferring Adobe Experience Manager (AEM), its final on-premises product, to the cloud.

AEM aaCS is a modern, cloud-native application that accelerates the delivery of omnichannel application.

The AEM Cloud Service introduces the next generation of the AEM product line, moving away from versioned releases like AEM 6.4, AEM 6.5, etc. to a continuous release with less versioning called "AEM as a Cloud Service."

AEM Cloud Service adopts all benefits of modern cloud based services:

Availability

The ability for all services to be always on, ensuring that our clients do not suffer any downtime, is one of the major advantages of switching to AEM Cloud Service. In the past, there was a requirement to regularly halt the service for various maintenance operations, including updates, patches, upgrades, and certain standard maintenance activities, notably on the author side.

Scalability

The AEM Cloud Service's instances are all generated with the same default size. AEM Cloud Service is built on an orchestration engine (Kubernetes) that dynamically scales up and down in accordance with the demands of our clients without requiring their involvement. both horizontally and vertically. Based on, scaling can be done manually or automatically.

Updated Code Base

This might be the most beneficial and much anticipated function that AEM Cloud Service offers to consumers. With the AEM Cloud Service, Adobe will handle upgrading all instances to the most recent code base. No downtime will be experienced throughout the update process.

Self Evolving

Continually improving and learning from the projects our clients deploy, AEM Cloud Service. We regularly examine and validate content, code, and settings against best practices to help our clients understand how to accomplish their business objectives. AEM cloud solution components that include health checks enable them to self-heal.

AEM as a Cloud Service: Changes and Challenges

When you begin your work, you will notice a lot of changes in the aem cloud jar. Here are a few significant changes that might have an effect on how we now operate with aem:-

1)The significant exhibition bottleneck that the greater part of huge endeavor DAM clients are confronting is mass transferring of resource on creator example and afterward DAM Update work process debase execution of entire creator occurrence. To determine this AEM Cloud administration brings Resource Microservices for serverless resource handling controlled by Adobe I/O. Presently when creator transfers any resource it will go straightforwardly to cloud paired capacity then adobe I/O is set off which will deal with additional handling by utilizing versions and different properties that has been designed.

2)Due to Adobe's complete management of AEM cloud service, developers and operations personnel may not be able to directly access logs. As of right now, the only way I know of to request access, error, dispatcher, and other logs will be via a cloud manager download link.

3)The only way for AEM Leads to deploy is through cloud manager, which is subject to stringent CI/CD pipeline quality checks. At this point, you should concentrate on test-driven development with greater than 50% test coverage. Go to https://docs.adobe.com/content/help/en/experience-manager-cloud-manager/using/how-to-use/understand-your-test-results.html for additional information.

4)AEM as a cloud service does not currently support AEM screens or AEM Adaptive forms.

5)Continuous updates will be pushed to the cloud-based AEM Base line image to support version-less solutions. Consequently, any Asset UI console or libs granite customizations: Up until AEM 6.5, the internal node, which could be used as a workaround to meet customer requirements, is no longer possible because it will be replaced with each base line image update.

6)Local sonar cannot use the code quality rules that are available in cloud manager before pushing to git. which I believe will result in increased development time and git commits. Once the development code is pushed to the git repository and the build is started, cloud manager will run sonar checks and tell you what's wrong. As a precaution, I recommend that you do not have any problems with the default rules in your local environment and that you continue to update the rules whenever you encounter them while pushing the code to cloud git.

AEM Cloud Service Does Not Support These Features

1.AEM Sites Commerce add-on

2.Screens add-on

3.Networks add-on

4.AEM Structures

5.Admittance to Exemplary UI.

6.Page Editor is in Developer Mode.

7./apps or /libs are ready-only in dev/stage/prod environment – changes need to come in via CI/CD pipeline that builds the code from the GIT repo.

8.OSGI bundles and settings: the dev, stage, and production environments do not support the web console.

If you encounter any difficulties or observe any issue , please let me know. It will be useful for AEM people group.

3 notes

·

View notes

Text

Innovations in Indian Cement: Spotlight on Shree Cement

Introduction:

Introduce Shree Cement as a pioneer in the Indian cement industry, known for innovation and sustainability.

Highlight its rapid expansion and growing influence.

Main Content:

Company Overview: Discuss Shree Cement’s journey from a small regional player to one of the top cement manufacturers in India.

Innovative Products:

Roofon: Specially designed for roofing applications.

Bangur Power: High-performance cement for durability.

AAC Blocks: Energy-efficient and eco-friendly building material.

Sustainability Initiatives: Highlight Shree Cement’s focus on reducing carbon emissions, using alternative fuels, and promoting green construction practices.

Expansion Strategy: Analyze Shree Cement’s growth strategy, including its aggressive capacity expansion and market penetration efforts.

Customer-Centric Approach: Examine how Shree Cement has built a strong brand reputation by offering high-quality products at competitive prices.

Conclusion:

Recap Shree Cement’s role as an innovator in the Indian cement industry and its potential for future growth.

Reference : L1Supply

0 notes

Text

Greenstone AAC Blocks: Revolutionizing Eco-Friendly Building with Advanced AAC Solutions

Introduction:

In the construction industry, materials that offer sustainability, efficiency, and long-term durability are in high demand. One such innovation is the use of AAC (Autoclaved Aerated Concrete) blocks. Among the leading manufacturers, Greenstone AAC Blocks has emerged as a reputable name, known for producing high-quality AAC blocks that cater to the growing demand for eco-friendly building materials. As one of the prominent autoclaved aerated concrete block manufacturers in Hyderabad, Greenstone continues to expand its market across various regions.

What are AAC Blocks?

Autoclaved Aerated Concrete (AAC) blocks are lightweight, precast building materials that offer superior insulation, fire resistance, and structural strength. Made from a mixture of cement, lime, sand, water, and an aerating agent, these blocks undergo a process where the mixture is poured into molds. Once set, it is cured under high-pressure steam in an autoclave. This curing process provides the blocks with their unique properties, making them lightweight, durable, and energy-efficient.

Benefits of AAC Blocks

1. Lightweight Nature: One of the most prominent benefits of AAC blocks is their lightweight nature. These blocks are approximately three times lighter than traditional red bricks. This reduced weight allows for faster construction, reduced structural load, and easier handling during building processes.

2. Fire Resistance: These blocks are fire-resistant, making them a safer choice for construction, particularly in areas prone to fire hazards. AAC blocks can withstand temperatures as high as 1600°C, providing superior safety for structures.

3. Eco-Friendly: AAC blocks are made using non-toxic materials and are 100% recyclable. Their manufacturing process requires less energy, and the blocks themselves are made using fly ash, a by-product of coal combustion, helping reduce industrial waste. Greenstone AAC Blocks ensures that their manufacturing processes are eco-friendly, contributing to sustainable construction.

Greenstone AAC Blocks: Commitment to Quality:

Greenstone AAC Blocks is a trusted name in the AAC block manufacturing industry, known for its consistent quality and innovative production techniques. Their state-of-the-art manufacturing facility is equipped with modern machinery, ensuring that each block meets the highest standards of precision and durability. As one of the leading AAC bricks manufacturers in Bangalore and autoclaved aerated concrete brick suppliers in Vijayawada, Greenstone continues to meet the growing demand for AAC blocks in major cities.

Applications of Greenstone AAC Blocks:

1. Residential Buildings: AAC blocks are widely used in residential construction due to their thermal efficiency and ease of installation. Homes built with Greenstone AAC Blocks are more energy-efficient, cost-effective, and environmentally friendly.

2. Commercial Buildings: Commercial projects, including office buildings, malls, and educational institutions, benefit from the strength and sound insulation properties of AAC blocks. Greenstone AAC Blocks ensures that their products provide the structural integrity needed for large-scale commercial projects.

3. Industrial Constructions: For industrial facilities, fire resistance and durability are critical factors. Greenstone AAC Blocks' fireproof nature makes them a reliable choice for factories, warehouses, and other industrial structures. As one of the trusted AAC blocks suppliers in Vishakhapatnam, Greenstone is committed to providing construction solutions that meet the unique needs of industrial projects.

Conclusion:

Greenstone AAC Blocks has established itself as a leader in the production of AAC blocks, meeting the demands of modern construction with a focus on sustainability, durability, and efficiency. As one of the top autoclaved aerated concrete block manufacturers in Hyderabad and AAC bricks manufacturers in Bangalore, they are committed to providing innovative building solutions. Their reach extends to being trusted autoclaved aerated concrete brick suppliers in Vijayawada and reliable AAC blocks suppliers in Vishakhapatnam, helping drive eco-friendly construction across key regions. With their commitment to quality, Greenstone AAC Blocks continues to play a significant role in the evolution of the construction industry, offering products that not only meet but exceed expectations in terms of performance and environmental impact.

0 notes