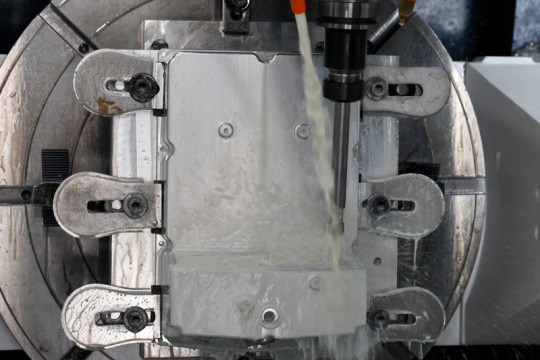

#5 axis machine

Text

Shenzhen Rapid Direct Co., Ltd. Unveils Cutting-Edge 5 Axis CNC Machining Services, revolutionizing precision engineering

0 notes

Text

We provide precision CNC machining services, CNC Milling and Turning (3 axis, 4 axis, 5 axis), can manufacture complex and multi-structure plastic and metal parts.

#cncmachining#5 axis machining#cnc milling services#cnc machining parts#rapid prototyping#precision machining

2 notes

·

View notes

Text

Maintenance Tips for Your CNC Turning Machine by MechPlus China

As a leading CNC turning machine manufacturing, MechPlus China understands the importance of proper maintenance to ensure precision and efficiency. Regular upkeep not only extends the machine's lifespan but also maximizes productivity and quality. Here are essential maintenance tips from MechPlus China to keep your CNC turning machine running smoothly and efficiently.

Keeping your CNC turning machine in top condition is crucial for optimal performance. Regular maintenance not only extends the machine's lifespan but also ensures precision and efficiency in your operations. Here are essential maintenance tips to keep your CNC turning machine running smoothly.

Daily Inspection and Cleaning

Start each day with a thorough inspection of your CNC turning machine. Check for any signs of wear and tear, and ensure all components are in good working order. Clean the machine daily to remove any debris, chips, and coolant residue. This prevents buildup that can affect performance and accuracy.

Lubrication

Proper lubrication is vital for the smooth operation of your CNC turning machine. Lubricate all moving parts as recommended by the manufacturer. This includes the spindle, guideways, and ball screws. Regular lubrication reduces friction, prevents wear, and extends the machine’s life.

Coolant Maintenance

Maintaining the coolant system is essential for the longevity of your CNC machine. Regularly check the coolant level and concentration. Replace or refill the coolant as needed. Also, clean the coolant tank and filters to avoid contamination that can damage the machine and workpieces.

Alignment and Calibration

Ensure that your CNC turning machine is properly aligned and calibrated. Misalignment can lead to inaccuracies in your machining processes. Regularly check and adjust the machine’s alignment and calibration according to the manufacturer’s guidelines. This ensures precision in your operations.

Check Electrical Components

Inspect the electrical components of your CNC turning machine regularly. Look for any loose connections, worn-out wires, or faulty switches. Address any electrical issues immediately to prevent machine downtime and potential safety hazards.

Monitor Machine Vibration

Excessive vibration can lead to poor machining quality and damage to your CNC turning machine. Monitor the machine for any unusual vibrations or noises during operation. Identify and address the source of the vibration to maintain optimal performance.

Regular Software Updates

Keep your CNC machine’s software up to date. Manufacturers often release updates that improve functionality and fix bugs. Regularly updating the software ensures your machine operates efficiently and takes advantage of the latest technological advancements.

Tool Maintenance

Regularly inspect and maintain the cutting tools used in your CNC turning machine. Sharp and well-maintained tools are crucial for high-quality machining. Replace worn or damaged tools promptly to ensure precise and efficient operation.

Preventive Maintenance Schedule

Implement a preventive maintenance schedule for your quick response machining tool. Follow the manufacturer’s recommended maintenance intervals for all components. Regular preventive maintenance helps identify potential issues before they become major problems, reducing downtime and repair costs.

Training and Safety

Ensure that all operators are properly trained in the maintenance and operation of the CNC turning machine. Regular training updates and adherence to safety protocols are crucial for preventing accidents and ensuring smooth operations.

Document Maintenance Activities

Keep detailed records of all maintenance activities performed on your CNC turning machine. Documenting maintenance helps track the machine’s condition over time and provides valuable information for troubleshooting and repairs with all types of customized machining parts.

In conclusion, regular maintenance of your CNC turning machine is essential for its longevity and performance. By following these tips, you can ensure your machine operates efficiently, reducing downtime and improving the quality of your machining processes. Implement these maintenance practices to keep your CNC turning machine in optimal condition.

#Prototyping solutions#SLA Rapid Prototyping manufacturing#SLS Rapid machining manufacturing#5 Axis CNC machining manufacturing#3D metal printing manufacturing

2 notes

·

View notes

Text

Top Boons of 5-axis CNC Machining

5 axis machining is now the most feasible choice for all types of machining jobs, not only the most difficult ones that require longer tool reach. 5-axis CNC machining is widely utilized for the most complex and precise jobs. This manufacturing approach is expected to provide significantly improved precision.

5-axis custom machining services provide a variety of advantages

Higher speed

5-axis machining allows the use of shorter cutting tools since the head may be lowered and the cutter is directed to the surface. You might expect better outcomes by increasing cutting speed and tool vibration.

Increased productivity

One of the most time-consuming parts of 3-axis machining is setting up a workpiece many times because it needs to be reoriented. This is required if an item needs to be machined on all or multiple sides, as the cutting tool remains at a fixed angle. A machinist must be physically present to rotate the component once machining on one side is completed for these 3-axis operations, and this human need can be a significant bottleneck in production.

5-axis machining by 5 axis machining manufacturer significantly minimizes the need for repeated setups since the movement of the table or spindle allows the cutting tool to approach the workpiece from various angles without removing it from the machine and resetting it. This leads to higher productivity throughout the whole process.

Hiring a dependable 5-axis machining services

Make sure your production team has been in operation for a significant amount of time. They should be highly experienced and qualified to ensure the quality of the job and timely completion. A corporation should be dependable and trustworthy.

Before selecting a firm, do not be afraid to ask questions regarding their 5-axis machining capabilities. A machine must also be of superior quality and capable of doing this task within a certain timeframe.

Inquire about the pricing of their services. Make sure you pay for what you get, and that the price matches the quality of the goods. Also, be informed of the materials they will be employing.

Main Source: https://bolesolutions.mystrikingly.com/

#5 axis machining manufacturer#5 Axis Machining Supplier#5 axis machining services China#5 Axis Machining Center

2 notes

·

View notes

Note

Bro just straight up pouring molten bronze like it's not the coolest thing in the world wtf

Right now I work in a wood & metals fabrication shop and As a man of many hats if I see a piece of machinery I make it my life goal to get my dirty little hands on operating it at least once (when i was on the pour team i did most jobs but pouring from the big crucible of metal was my favorite and i was pretty good at it. never did the crane bc i have a bad sense of direction and you have to be pretty quick when pouring molten metal)

My next target is this thing:

#5 axis cnc i will get you.#i currently specialize in the 3 axis but i havent been able to learn to toolpath this thing bc its significantly more complicated#and also our shop's is kind of .broken#but i toured a shop that had 7 axis cncs in enclosed cabinets and shit literally the most insane precision machining#idk if i would be able to work in a shop like that but a man can dream#m#answers

5 notes

·

View notes

Text

How 5-Axis CNC Machining Transforms Aerospace Manufacturing?

This blog delves into the game-changing role of 5-axis CNC machining in the aerospace industry. Unlike traditional methods, which often struggle with complex designs and tight tolerances, 5-axis CNC machining provides unparalleled precision and efficiency. Aerospace manufacturers can now create intricate parts with fewer setups, reducing both time and cost while ensuring the highest standards of quality. This technology plays a crucial role in enhancing aircraft performance and safety by delivering parts that meet stringent aerospace requirements.

Additionally, the blog emphasizes the adaptability of 5-axis CNC machining for handling various materials such as aluminum, titanium, and composites, commonly used in the aerospace sector. By minimizing material waste and optimizing production workflows, this advanced machining technique has become indispensable for manufacturers aiming to remain competitive in the ever-evolving aerospace market.

For a deeper understanding of how 5-axis CNC machining is revolutionizing aerospace manufacturing, read the full blog here.

0 notes

Text

As a leading company in the manufacturing and processing field, DADESIN hopes to become your manufacturing and supplier partner for CNC customized machining parts.

0 notes

Text

Revolutionizing Manufacturing With The Power of Vertical Turning Lathes and 5-Axis Turnmills

In the ever-evolving world of manufacturing, precision, efficiency and innovation are key drivers of success. The integration of advanced machineries such as Vertical Turning Lathes (VTLs) and 5-axis turnmills has revolutionized the production processes across various industries. These machines are not only enhancing productivity but are also pushing the boundaries of what’s possible in modern manufacturing.

Understanding Vertical Turning Lathes: Precision and Power Combined

A Vertical Turning Lathe (VTL) is a powerful machine tool designed for large, heavy workpieces that require precise turning operations. Unlike traditional lathes, which operate horizontally, VTLs position the workpiece vertically. This vertical orientation provides several advantages, particularly when machining large, heavy parts, as gravity helps to stabilize the workpiece, reducing the risk of distortion.

Key Advantages of VTLs:

Stability and Precision: The vertical orientation allows for greater stability, which is crucial when working with large or heavy components. This stability translates to higher precision in machining operations.

Space Efficiency: VTLs often take up less floor space compared to their horizontal counterparts, making them ideal for factories where space is at a premium.

Versatility: VTLs are highly versatile and can be used for a variety of applications, including turning, boring and milling, making them an essential tool in any modern manufacturing facility.

The Evolution of 5-Axis Turnmills: Unleashing Creativity in Machining

The 5-axis turnmill represents the pinnacle of machining technology, combining the capabilities of turning and milling in a single machine. The "5-axis" refers to the five degrees of movement that the machine offers—three linear axes (X, Y, Z) and two rotational axes (A and B). This advanced configuration allows manufacturers to machine complex shapes and geometries with unparalleled precision.

Benefits of 5-Axis Turnmills:

Complex Machining: The ability to move the workpiece along five axes allows for the creation of intricate and complex shapes that would be impossible or highly challenging with traditional 3-axis machines.

Reduced Setup Time: 5-axis turnmills can machine multiple faces of a component in a single setup, drastically reducing the time and labor required for repositioning the workpiece.

Enhanced Accuracy: By minimizing the need to move the workpiece between different machines or setups, 5-axis turnmills reduce the risk of errors, ensuring higher accuracy and consistency in production.

Special-Purpose Machines: Tailored Solutions for Unique Manufacturing Needs

In addition to VTLs and 5-axis turnmills, special-purpose machines (SPMs) play a crucial role in addressing specific manufacturing challenges. These machines are designed to perform specialized tasks that standard machines cannot, such as intricate drilling, specific cutting operations, or high-speed machining of particular materials.

Advantages of Special-Purpose Machines:

Customized Design: SPMs are built to cater to specific manufacturing needs, offering customized solutions that enhance productivity and efficiency.

Increased Productivity: By focusing on a particular task or process, SPMs can operate faster and more efficiently than general-purpose machines, leading to higher throughput.

Cost-Effectiveness: While the initial investment in an SPM may be higher, the long-term benefits of increased efficiency and reduced production time often result in significant cost savings.

Conclusion: WIDMA – Leading the Way in Advanced Machining Solutions

When it comes to cutting-edge machining solutions like Vertical Turning Lathes, 5-axis turnmills and special-purpose machines, WIDMA stands out as a leader in the industry. With a strong commitment to innovation and quality, WIDMA offers a range of advanced machines that are designed to meet the diverse needs of modern manufacturing.

WIDMA’s state-of-the-art technology, coupled with their expertise in custom machine design, ensures that manufacturers can achieve the highest levels of precision, efficiency and productivity. Whether you’re looking to enhance your production capabilities with a VTL, unlock new possibilities with a 5-axis turnmill, or invest in a special-purpose machine tailored to your unique needs, WIDMA provides the solutions that will drive your business forward.

0 notes

Text

Revolutionizing Manufacturing: Leading 5 Axis Machining Manufacturers in India.

Discover the top 5 Axis Machining manufacturers in India. Learn how 5 Axis Machining enhances precision, reduces setup time, and is cost-effective for various industries. Contact us at 9657039991 for more information.

In the rapidly evolving world of manufacturing, 5 Axis Machining stands out as a revolutionary technology that brings unparalleled precision and efficiency to the table. This article delves into the intricacies of 5 Axis Machining, the leading 5 Axis Machining Manufacturers in India, and why this technology is crucial for the future of manufacturing.

What is 5 Axis Machining?

5 Axis Machining refers to a process where a cutting tool moves across five different axes simultaneously. Unlike traditional machining that operates on three primary axes (X, Y, and Z), 5 Axis Machining includes two additional rotational axes (A and B), allowing for more complex shapes and designs. This advanced technology enables manufacturers to produce intricate parts with a single setup, reducing production time and improving precision.

Advantages of 5 Axis Machining

Enhanced Precision: With five axes of movement, manufacturers can achieve higher precision and more detailed parts. This is particularly beneficial for industries requiring intricate components, such as aerospace and automotive.

Reduced Setup Time: Traditional machining often requires multiple setups to achieve complex geometries. 5 Axis Machining eliminates the need for multiple setups, significantly reducing production time.

Improved Surface Finish: The ability to position the cutting tool closer to the surface results in a superior surface finish. This is crucial for components that require smooth and precise finishes.

Increased Tool Life: 5 Axis Machining allows for optimal positioning of the cutting tool, reducing wear and tear and extending the tool's lifespan.

Cost-Effective: Although the initial investment in 5 Axis Machining India equipment may be high, the long-term benefits, such as reduced production time and improved efficiency, make it a cost-effective solution.

Leading 5 Axis Machining Manufacturers in India

India has emerged as a hub for advanced manufacturing technologies, with numerous companies specializing in 5 Axis Machining. Here are some of the top 5 Axis Machining Manufacturers in the country:

ACE Designers Limited: Known for their innovative solutions and cutting-edge technology, ACE Designers Limited is a prominent player in the Indian machining industry. They offer a range of 5 Axis Machining services tailored to meet the specific needs of various industries.

Bharat Fritz Werner Ltd (BFW): BFW is a well-established name in the Indian manufacturing sector. Their advanced 5 Axis Machining capabilities ensure high precision and efficiency, making them a preferred choice for many industries.

Makino India: Makino is renowned for its high-performance machining centers. Their 5 Axis Machining solutions are designed to deliver superior accuracy and productivity, catering to the demanding requirements of modern manufacturing.

Jyoti CNC Automation Ltd: Jyoti CNC is a leader in the field of CNC machining in India. Their state-of-the-art 5 Axis Machining technology enables them to produce complex components with utmost precision.

Haas Automation India: Haas Automation is a global leader in CNC machine tools. Their Indian division offers a range of 5 Axis Machining solutions that are widely used across various industries for their reliability and performance.

Applications of 5 Axis Machining

The versatility of 5 Axis Machining makes it suitable for a wide range of applications. Here are some industries that benefit significantly from this technology:

Aerospace: The aerospace industry requires components with intricate geometries and high precision. 5 Axis Machining allows manufacturers to produce complex parts like turbine blades and structural components with exceptional accuracy.

Automotive: In the automotive sector, 5 Axis Machining is used to create engine parts, molds, and other components that demand high precision and fine finishes.

Medical Devices: The medical industry relies on 5 Axis Machining for the production of surgical instruments, implants, and other medical devices that require meticulous detail and precision.

Defense: Defense applications often involve complex parts that need to be manufactured to exact specifications. 5 Axis Machining ensures that these components meet the stringent quality standards required in the defense sector.

Energy: The energy industry, particularly in the production of turbines and other power generation equipment, benefits from the precision and efficiency of 5 Axis Machining.

Why Choose 5 Axis Machining in India?

India's manufacturing landscape is rapidly evolving, with a growing emphasis on advanced technologies and precision engineering. Choosing 5 Axis Machining in India offers several advantages:

Skilled Workforce: India boasts a skilled workforce trained in advanced machining technologies. This expertise ensures high-quality production and innovation in manufacturing processes.

Cost-Effective Solutions: Manufacturing in India offers cost advantages due to lower labor and production costs. This makes 5 Axis Machining services in India highly competitive without compromising on quality.

Technological Advancements: Indian manufacturers are increasingly investing in state-of-the-art machinery and technology. This ensures that they stay at the forefront of global manufacturing trends and deliver cutting-edge solutions.

Strategic Location: India's strategic location and well-developed infrastructure make it an ideal hub for manufacturing and export. This geographic advantage facilitates easy access to global markets.

5 Axis Machining is revolutionizing the manufacturing industry with its ability to produce complex parts with high precision and efficiency. As India continues to emerge as a global leader in advanced manufacturing technologies, the country's 5 Axis Machining India are well-positioned to meet the growing demands of various industries. By leveraging India's skilled workforce, cost-effective solutions, and technological advancements, businesses can achieve superior manufacturing outcomes.

Visit:- https://www.deccanew.com/5-axis-machining-parts-manufacturers-suppliers-india.php

Contact: 9657039991

0 notes

Text

CNC / VMC Machining Job Work & CNC Machining Components in India— Pitrukrupa Engineering

Pitrukrupa Engineering is country’s leading Manufacturer, Exporter and Supplier firm offering high performing CNC Milling and Turning Components since its inception in 2009.

Our CNC Machining Work

We are offering CNC Machining job Work to our clients. For accomplishing this work, experts bank on innovative machines and important tools.

CNC Machining Work

CNC Job Work

Precision Machining Work

VMC Machining Work

Milling Machining Work

HMC Machining Work

CNC Turning Machining Work

EDM Wire Cutting Work

CNC laser Cutting Work

CNC Bending Work

CNC Machining Components & Parts

We are offering CNC Components to our clients. For accomplishing this work, experts bank on innovative machines and important tools.

CNC Lathe Machining Component

5 Axis Milling Components

4 Axis Milling Components

CNC Turn Mill Components

CNC Turn Mill Machining Parts

Aerospace and Defence Machining Parts Manufacturing

Aluminium And Steel Precision Welding Fabrication

Aluminium High Pressure Die Casting

Aluminium Extrusion

For More Details

Click Here : https://www.pitrukrupaengineering.com/

#Machining Job Work#CNC Machining Work#CNC Job Work#5 Axis Milling Components#4 Axis Milling Components#CNC Turn Mill Machining Parts

0 notes

Text

How 5 Axis CNC Machining Produces Unmatched Flexibility and Precision

0 notes

Text

CNC precision machining parts

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#cnc precision machining#cnc precision#high precision#precision cnc machining#5axismachining#5 axis cnc machining#5 axis cnc#5 axis

0 notes

Text

GD prototyping is a Prototypes&low volume manufacturer, provide (3&4&5axis)CNC machining, 3d printing, sheet metal, vacuum casting rapid tooling and surface finish. https://www.gd-prototyping.com/

2 notes

·

View notes

Text

The Applications of 5 axis machining Across Industries

The keys to success in the field of advanced manufacturing are accuracy and effectiveness. 5 axis machining services are a ground-breaking strategy that has expanded the potential for producing complicated and sophisticated components. In this article, we explore the realm of 5-axis machining, examining its advantages, uses, and the radical changes it has brought about across several sectors.

5-axis Machining: Beyond Traditional Boundaries

To obtain the required form, traditional machining techniques frequently entail moving the workpiece along many axes. However, these techniques have drawbacks when it comes to creating intricate geometries. This is where 5-axis machining comes into play, expanding the realm of what is feasible.

5-axis machining adds two rotating axes (usually A and B), in contrast to 3-axis machining, which moves the workpiece along three linear axes (X, Y, and Z). This gives the tool an unmatched degree of flexibility in its movement, allowing it to approach the workpiece from several angles and orientations. A capacity for producing complex designs, speeding up production, and requiring fewer setups overall is the outcome.

5-axis Machining Shining Applications

· Aerospace: The aircraft sector requires complex, lightweight, yet robust components. In materials like titanium and aluminum, 5 axis machining enables the production of complicated geometries that are essential for airplane and spacecraft parts.

· Medical: The medical industry benefits from the accuracy of 5-axis machining in generating patient-specific components and sophisticated designs that support greater biocompatibility. This includes orthopedic implants and medical gadgets.

· Automobile: Precision 5-axis machining is utilized to create molds, prototypes, and crucial engine components in the highly competitive automobile industry, improving performance and reducing weight.

· Even in the creative sectors, such as art and design, 5-axis machining has a role. By using technology, designers, and artists can bring their imaginative ideas to life by producing elaborate sculptures, molds, and architectural models.

The Challenges and Innovations Ahead

5-axis machining is a constantly evolving field, much like any cutting-edge technology. Its capabilities are being further improved by advancements in automation, real-time monitoring, and adaptive toolpaths, which are turning it into a crucial resource in the industrial environment. Nevertheless, there are still issues like programming complexity and greater startup costs. To fully utilize the potential of 5-axis machining services at the 5 axis CNC machining center, it is imperative to understand the complexities of programming and engage in training.

Follow our Facebook and Twitter for more information about our product.

#5 axis machining#5 axis machining services#5 Axis CNC Machining Center#Custom 5 Axis Machining services#5 Axis CNC Machine Shop#5 Axis Machining Center

3 notes

·

View notes

Text

Different Types of Brush Making Machines

Nowadays, there is a booming demand for brush-making machines. With their growing popularity among various industries, looking for the best machines is of utmost importance. Your search for the best manufacturing team for these machines now comes to an end, thanks to our team from Sharma & Sons. We are offering the best brush solution you have ever laid your eyes on.

Being a leading professional company for all brush machines, we have been engaged in research and development for so many years now. Our main goal is to develop the best product machines that come in handy with the latest technology.

Major technical database:

We have a growing technical database, which has been around since the inception of our company. That makes us one of the leading names in the manufacturing field. We have an in-house team, comprising technical professionals and engineers to offer our clients premium ranges of brush machines.

We will develop the entire design range within our factories and will sell the final results to the international and domestic markets.

There is also an experienced marketing and sales team working with us to check out various aspects of customer feedback and sales regarding each consignment.

The types we follow:

Being associated with brush-making machines for such a long time, we have generated and created multiple types of brush-making machines. The differences will help in covering the maximum crowd at the same time and focus on their flexible needs. So, before you proceed further, we would like you to get the detailed information regarding the types of machines we have in store.

2 Axis Brush Tufting Machine:

Available in brand new condition and with the automatic grade, our 2 Axis Brush Tufting Machine is one to watch out for. It has the capability to produce around 2500 pieces in one go.

This machine is able to produce various kinds of brooms and brushes, which will have multiple filling angles by just changing the specified platforms.

It can be easily installed with just one tufting motor head to offer higher speed and cost-effective results in the end.

There are Touch panels and PLC control systems available from this machine with an English display on the top for better understanding.

There are different procedures performed by a single machine, which will reduce hair mechanic technology dependency.

3 Axis Brush Tufting Machine:

If you are planning to create brushed with curved surfaces, then 3 Axis Brush Tufting Machine might be the right option to get from our side. There are plastic brush pieces, which are to be moulded in advance within the available holes. These holes are now vertical to the surface at around 90 degrees and they cannot be tilted at any other angle. The generic brush size is around 350mmx 180mmx 360 degrees. However, we can customize some of the other sizes as per the requirement through our 3 Axis Brush Tufting Machine models.

There are mainly two grippers available holding two brushes on the work table. Under its automatic mode, it has the power to tuff brushes continuously in a non-stop manner.

4 Axis Brush Tufting Machine:

Another interesting choice of the machine while looking for brush making category from our side has to be 4 Axis Brush Tufting Machine.

All the wearing parts and the spare parts of this machine are designed in a standard manner.

It helps in reducing hair mechanic technology dependency.

Our machines have the power to create one, two, or three colored brushes in one go.

Once proficiently installed by our team members, these machines are subject to last the longest with a little bit of maintenance from your side.

5 Axis Brush Tufting Machine:

We have specially designed 5 Axis Brush Tufting Machine for you, which is used to tuff brushes with the help of stainless steel wires. It is always recommended that the plastic brush pieces need to be molded with holes before getting into the machine. On the other hand, the wooden brushes also need to be pre-drilled with holes in them.

Here, the working table is quite flexible and the nylon filaments or the SS wires can be tufted at different angles, which in turn, will look radial.

This machine helps in processing filaments in two different colours, with a maximum length is around 120mm in 5 Axis Brush Tufting Machine.

A hand controller is widely used here to manually enter the hole positions within the program, with one hole at a time.

The best Drilling and Tufting Brush Machine at your service:

We have the best Drilling and Tufting Brush Machine in store for you, which has been a result of years of research from our side. The machine consists of a main motor, which is sprightly procured from Italy and known for its high working head speed. Then you have a premium quality precision filament box, known to offer reliable and stable performance throughout. So, next time you are looking for one such brush-making machine, focusing on us at Sharma & Sons will be a great note to consider.

#5 axis brush tufting machine#brush tufting machine from india#brush making machine#brush making machine in india#brush tufting machine exporter#brush tufting machine supplier & exporter#brush making machine at best price in india#brush making machine manufacturers & suppliers#brush tufting machine#brush broom tufting machine#2 axis brush tufting machine#3 axis brush tufting machine#4 axis brush tufting machine

0 notes

Text

What Should Pay Attention to in the Operation of High-Speed 5-Axis Machining Center?

High-speed 5-axis machining center is an advanced processing equipment, with high precision, sound speed and high efficiency characteristics. It is usually used for processing complex and difficult parts, such as aerospace, medical equipment, automotive parts, etc. When operating a high-speed 5-axis machining center, special attention needs to be paid to the following points:

1. Familiar with the structure and principle of the equipment: the operator needs to be familiar with the structure and working principle of the high-speed 5-axis machining center, understand the name of each axis, the range of motion and restrictions, and master the control system and programming method of the machining center. Only with a deep understanding of the structure and principle of the equipment can we correctly operate and use the high-speed 5-axis machining center for processing.

2. Strictly follow the operating procedures: the operator should strictly follow the operating procedures, including wearing personal protective equipment, avoid body parts close to the moving parts, avoid strong light exposure, etc. In addition, safety devices such as safety doors, warning lights and emergency stop buttons need to be checked regularly to ensure that they are in good working condition.

3. Equipment inspection and maintenance: before use, it is necessary to maintain and check the equipment. First, check whether the tool is worn, and if it is worn, it needs to be replaced. Secondly, check whether the fixture is stable and firm. Clean the equipment to prevent dust and foreign matter from entering the equipment. At the same time, it is also necessary to carry out real-time monitoring of the equipment during the processing process to discover and deal with problems in time.

4. Material preparation and processing: before 5-axis processing, it is necessary to prepare the required materials and ensure the quality and accuracy of the materials. At the same time, in order to avoid temperature changes affecting the processing, the material should be placed in a constant temperature environment. After the processing is completed, it is also necessary to process the workpiece, including cleaning, inspection and maintenance.

5. Safety control: the operator needs to strictly control the safety risks in the processing process, such as the cutting and cutting methods, the length and diameter of the cutting county, and the setting of cutting parameters. In the processing process, it is also necessary to pay attention to observe the processing situation, adjust the cutting parameters and tool status in time, and avoid collision or over-cutting errors.

6. Programming and setting: the operator needs to be familiar with the programming language and programming method of the high-speed 5-axis machining center, and can perform the correct programming and setting according to the processing needs. In the programming process, it is necessary to pay attention to the planning of the tool path, the setting of cutting parameters, the distribution of machining allowance and other issues to ensure the stability and accuracy of the machining process.

7. Training and experience accumulation: operators need to go through professional training and practice, practice the accumulation of experience, and constantly improve their skill level and operational experience. Through continuous learning and practice, operators can better master the operation skills and maintenance methods of high-speed 5-axis machining centers, and improve the utilization rate and service life of equipment.

0 notes