#3D Printing Polymer Material

Explore tagged Tumblr posts

Text

Imagine if physicians could capture three-dimensional projections of medical scans, suspending them inside an acrylic cube to create a hand-held reproduction of a patient's heart, brain, kidneys, or other organs. Then, when the visit is done, a quick blast of heat erases the projection and the cube is ready for the next scan. A report in the journal Chem by researchers at Dartmouth and Southern Methodist University (SMU) outlines a technical breakthrough that could enable such scenarios, and others with widespread utility.

Continue Reading.

86 notes

·

View notes

Text

Flaps perform essential jobs. From pumping hearts to revving engines, flaps help fluid flow in one direction. Without them, keeping liquids going in the right direction is challenging to do. Researchers from the University of Washington have discovered a new way to help liquid flow in only one direction -- but without flaps. In a paper published Sept. 24 in the Proceedings of the National Academy of Sciences, they report that a flexible pipe -- with an interior helical structure inspired by shark intestines -- can keep fluid flowing in one direction without the flaps that engines and anatomy rely upon. Human intestines are essentially a hollow tube. But for sharks and rays, their intestines feature a network of spirals surrounding an interior passageway. In a 2021 publication, a different team proposed that this unique structure promoted one-way flow of fluids -- also known as flow asymmetry -- through the digestive tracts of sharks and rays without flaps or other aids to prevent backup. That claim caught the attention of UW postdoctoral researcher Ido Levin, lead author on the new paper.

Read more.

#Materials Science#Science#Fluid dynamics#Liquids#Biomimicry#University of Washington#3D printing#Polymers

38 notes

·

View notes

Text

Additive manufacturing, also known as 3-D printing, is a transformative approach to industrial production that is making lighter, stronger parts and systems a possibility.

This article will delve in the concept of additive manufacturing, its types, and the materials used in additive manufacturing.

What is the additive manufacturing?

Additive manufacturing is processes used to create a three-dimensional object by laying down successive layers of material under the control of a computer. Objects created can be of almost any shape or geometry and are created from digital model data. It is intended to construct a part from scratch but raw material, using digital data coming from a CAD file.

The familiar term of additive manufacturing is 3D printing. This is a popular type of additive manufacturing.

#science#materials science#engineering#materials science and engineering#materials#metals#polymers#composites#ceramics#biomaterials#3D printing#additivemanufacturing

2 notes

·

View notes

Text

Exploring the Acrylonitrile Butadiene Styrene (ABS) Market: Growth Drivers, Key Applications, and Future Outlook

Acrylonitrile Butadiene Styrene (ABS) is a versatile thermoplastic polymer known for its high impact resistance, toughness, and ease of fabrication. With wide-ranging applications across various industries, the ABS market continues to witness significant growth fueled by technological advancements, evolving consumer preferences, and the push for sustainable materials.

Market Growth Drivers

The global acrylonitrile butadiene styrene (ABS) market size is valued at USD 28.6 billion in 2023 and is projected to reach USD 39.9 billion by 2028, growing at a cagr 6.9% from 2023 to 2028.

Several factors are driving the growth of the ABS market. One of the primary drivers is the increasing demand from the automotive sector. As automakers seek lightweight materials to improve fuel efficiency and reduce emissions, ABS has emerged as a preferred choice for manufacturing interior and exterior components.

The electronics and consumer goods industries are also major contributors to market expansion. ABS’s excellent mechanical properties and aesthetic appeal make it suitable for applications such as smartphone casings, computer peripherals, and household appliances. Furthermore, the rise of 3D printing technology has bolstered the demand for ABS filaments, given its durability and ease of printing.

Key Applications of ABS

ABS finds extensive use in multiple sectors due to its unique properties:

Automotive Industry: ABS is used in manufacturing dashboards, wheel covers, and body panels. Its lightweight nature contributes to improved vehicle performance and fuel efficiency.

Electronics and Electrical: The polymer is a popular choice for manufacturing casings for electronic devices, including laptops, televisions, and smartphones.

Consumer Goods: From toys like LEGO bricks to kitchen appliances, ABS is favored for its durability and aesthetic finish.

Construction: ABS pipes and fittings are commonly used in plumbing applications due to their strength and resistance to corrosion.

3D Printing: The material’s ease of molding and excellent surface finish make it ideal for prototyping and manufacturing functional parts.

Emerging Trends in the ABS Market

Sustainability Initiatives: As environmental concerns grow, manufacturers are focusing on developing bio-based ABS and enhancing recycling processes. Efforts to reduce the carbon footprint associated with ABS production are gaining momentum.

Technological Advancements: Innovations in polymer science are leading to the development of ABS variants with enhanced properties such as flame retardancy and UV resistance, expanding its applicability in high-performance sectors.

Shift Towards Electric Vehicles (EVs): The rise of EVs presents new opportunities for ABS in lightweight components that contribute to better energy efficiency.

Smart Home Devices: With the proliferation of IoT and smart home technologies, the demand for aesthetically pleasing and durable casings made from ABS is on the rise.

Future Outlook

The future of the ABS market looks promising, with sustained demand from key industries and ongoing innovations shaping its trajectory. One notable area of focus is the integration of circular economy principles. Companies are increasingly investing in recycling technologies to produce high-quality recycled ABS that meets industry standards.

Moreover, advancements in additive manufacturing are likely to further boost the adoption of ABS in 3D printing, enabling the creation of complex, high-performance components. As industries continue to prioritize sustainability and innovation, the ABS market is expected to witness transformative growth.

Real-World Examples of Innovation

Leading manufacturers are already making strides in the ABS space. For instance, LG Chem has developed eco-friendly ABS grades with reduced carbon emissions. Similarly, automotive giants are incorporating ABS in electric vehicle components to achieve lightweight designs without compromising on safety and durability.

Download PDF Brochure :

The Acrylonitrile Butadiene Styrene (ABS) market is at the cusp of significant transformation. With growing demand from automotive, electronics, and construction sectors, coupled with advancements in material science, the market is poised for robust growth. Sustainability and innovation will be key themes, as manufacturers strive to meet evolving industry demands and environmental regulations.

As stakeholders across the value chain continue to invest in research and development, ABS is set to remain a critical material in shaping the future of multiple industries. Embracing eco-friendly practices and leveraging technological advancements will be essential for capitalizing on the opportunities in this dynamic market.

#Acrylonitrile Butadiene Styrene Market#ABS Market Growth#Automotive Industry Materials#Sustainable Polymers#3D Printing Materials#Market Trends#Circular Economy

0 notes

Text

Engineers develop affordable 3D printing method for customizable, recyclable soft plastics

- By Nuadox Crew -

Princeton engineers, led by Emily Davidson, have developed a scalable 3D printing method to create soft plastics with customizable stiffness, flexibility, recyclability, and affordability.

These materials, made from thermoplastic elastomers, leverage nanoscale block copolymer structures to allow precise control over mechanical properties, enabling stiffness in one direction and stretchiness in others.

The team’s process involves thermal annealing to enhance material properties, self-healing, and reusability. This approach, costing about $0.01 per gram, contrasts with expensive alternatives like liquid crystal elastomers. Applications range from soft robotics and medical devices to helmets and customized shoe soles.

The method can incorporate functional additives, such as molecules for UV-induced fluorescence, and create complex structures like flexible vases. The next steps involve exploring designs for wearable electronics and biomedical devices.

youtube

Video: "Stretchable, Flexible, Recyclable. This Plastic Is Fantastic" via SciTech Daily, YouTube.

Header image: Engineers can manipulate the material's internal structure to produce objects with various properties. Credit: Sameer A. Khan/Fotobuddy.

Read more at Princeton Engineering

Scientific paper: Alice S. Fergerson et al, Reprocessable and Mechanically Tailored Soft Architectures Through 3D Printing of Elastomeric Block Copolymers, Advanced Functional Materials (2024). DOI: 10.1002/adfm.202411812

Related Content

Scientists develop 3D printing technique using microwaves for faster, versatile manufacturing

Other Recent News

New Species Discovered in Peru: Scientists have discovered a new species of blob-headed catfish in Peru's Alto Mayo region.

12,000-Year-Old Wolf Remains: Remains of a 12,000-year-old wolf in Alaska show early signs of human interaction.

1 note

·

View note

Text

Advanced 3D Printing Polymer Materials: Unlocking New Possibilities

3D printing has revolutionized manufacturing across numerous industries, allowing for the creation of complex structures and highly customized products. One key element driving this innovation is 3D printing polymer materials, which offer versatility, strength, and adaptability to meet the demands of various applications.

Types of 3D Printing Polymer Materials

There are several 3D printing polymer materials available today, each catering to specific needs and industries. The most common types include:

PLA (Polylactic Acid): PLA is one of the most popular choices due to its ease of use and biodegradability. It is derived from renewable resources such as corn starch, making it an eco-friendly option for prototypes, consumer goods, and educational tools. PLA is known for its high printability and smooth surface finish.

ABS (Acrylonitrile Butadiene Styrene): ABS is a durable material with excellent impact resistance and toughness. It is widely used in industries such as automotive and electronics due to its ability to withstand high temperatures and mechanical stress. However, ABS requires a heated print bed for optimal results and can emit fumes during the printing process.

Nylon: Known for its flexibility and strength, nylon is ideal for functional parts and mechanical components. It has excellent wear resistance and can handle repeated use, making it a favorite in industries like engineering and aerospace. Nylon’s slightly porous nature can absorb moisture from the air, so proper storage is necessary to maintain its quality.

PETG (Polyethylene Terephthalate Glycol): PETG offers a balance between PLA and ABS, combining strength, flexibility, and ease of printing. It is highly resistant to impact and moisture, making it a good choice for products that need to endure harsh environments. PETG is commonly used for food-safe containers and medical devices.

Applications of 3D Printing Polymers

3D printing polymer materials have found applications in a wide range of industries. In healthcare, custom medical devices, prosthetics, and implants are created using biocompatible polymers. The aerospace and automotive sectors use polymers for lightweight yet durable components that reduce overall weight while maintaining strength.

In consumer goods, polymer materials enable the production of fashion accessories, home décor items, and even footwear. Additionally, the education sector has embraced 3D printing polymers to teach students about design, engineering, and manufacturing.

Future of 3D Printing Polymer Materials

As technology evolves, so does the development of 3D printing polymer materials. New materials with improved strength, flexibility, and sustainability are constantly emerging. This progress paves the way for even more innovative applications, from advanced medical solutions to cutting-edge automotive designs.

In conclusion, 3D printing polymer materials continue to expand the possibilities of additive manufacturing, making it accessible for various industries while offering a range of material properties that cater to diverse needs.

0 notes

Text

Ceramic Substrates Market Will Reach USD 11,740.8 Million By 2030

In 2023, the ceramic substrates market was valued at USD 7,721.3 million. Forecasts indicate it will grow significantly, reaching USD 11,740.8 million by 2030, with a projected compound annual growth rate (CAGR) of 6.3% between 2024 and 2030. This growth of the industry can be credited to the increasing need for such materials in many sectors and the trend of the reduction of electronic…

View On WordPress

#3D Printing Materials Market#ceramics#Competitive Landscape#composites#growth prospects#innovations#Investors#Key players#Manufacturers#market drivers#metals#polymers#regulatory landscapes#researchers#Technological advancements#Trends

0 notes

Text

I have a thermoplastic based ask for science side of Tumblr: do you know of thermoplastics that stick to pla and print at similar temperatures but have a higher glass transition point because I want to make the case for pla filament coextruded with another polymer to prevent warping while annealing pla, as annealed pla yields stronger and more temperature resistant parts.

1 note

·

View note

Text

"At the University of Maine, one of the world’s largest 3D printers is using sawdust from the state’s lumber industry to 3D print cozy wooden cabins.

It’s part of a move towards making 3D printing faster and more sustainable in a state where the housing shortage that has metastasized in most states around the country is dire.

It’s thought that 80,000 new homes will be needed over the next 5 years to keep pace with demand, and though it takes years for building codes to be changed, the technicians at the Advanced Structures & Composites Center (ASCC) at the Univ. of Maine hope their new toy can help address this need.

Guinness World Records certified the machine at ASCC as the world’s largest prototype polymer 3D printer, capable of creating a 600 square foot house 96 feet in length, 36 feet in width, and 18 feet tall entirely out of bio-based material at a rate of 500 pounds per hour.

In 2022, it could print the walls, floors, and roof of the house in just 96 hours, but the ACSS has been refining the design with the hope of doubling the printing speed and getting it down to a 48-hour timeline.

“When they’re doing concrete, they’re only printing the walls,” Habib Dagher, the executive director of ACSS told CNN. “The approach we’ve taken is quite different from what you’ve seen, and you’ve been reading about for years.”

Indeed, GNN has reported on a fair number of 3D printing projects, but most if not all involve printing only the walls. One fantastical exception is an Italian firm that is 3D-printing domed, beehive-like, modular concept homes inspired by the Great Enclosure in Zimbabwe.

STAND-OUT 3D-PRINTING PROJECTS:

First 2-Story Home to be 3D Printed in the U.S. Reaches for the Sky in Texas

The World’s Largest 3D Printed Building is a Horse Barn That Can Endure Florida Hurricanes

This 23-Year-Old Founder is 3D Printing Schools in Madagascar Aiming to be a ‘Stepping Stone’ for the Community

A Startup Is Using Recycled Plastic to 3D Print Tiny $25,000 Prefabricated Homes in LA

The ASCC is calling the house design the BioHome3D, and says it’s rare people who tour the concept version don’t ask when they “can have one up?”

The interior gives the feel of a modern Scandinavian wooden cabin, making it fit well with the Maine aesthetic. The ASCC is now doing work on how to incorporate conduits for wiring and plumbing “exactly where an architect would want them,” says Dagher.

WATCH a time-lapse video of the printer doing the job…

youtube

-via Good News Network, August 16, 2024. Video via The University of Maine, March 3, 2023.

#3d printing#housing#housing crisis#3d printed#architecture#sustainable architecture#biomaterials#maine#united states#good news#hope#Youtube

449 notes

·

View notes

Text

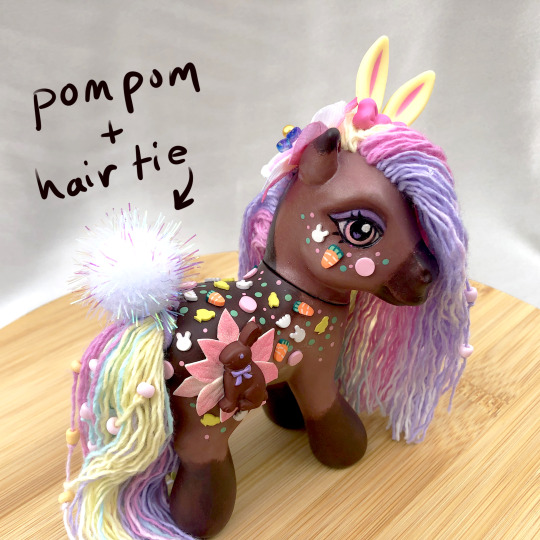

Hello! I wanted to share my process of how I made my Easter Pony! She is my second ever custom and she made all the trouble I had with the first one seem like a walk in the park in comparison ಥ_ಥ Let's begin!

DISCLAIMER: Custom ponies like this one are not to be played with by children nor made by children. This pony was made with the use of nail polish remover (acetone) which is toxic. You need to wash your hands throughly after use and use in a well ventilated area. This pony was also made with sharp tools such as an xacto knife, sewing pins, rehairing needles, and an awl.

First, the concept art! Trial and error caused her to look a little different than the concept art but I still love the end result!

I wanted to start with a white base to give myself a clean canvas for dyeing so I got this G3 Breezie off Ebay for only $3. I decided to first remove her mane and tail which requires removing the head. If you know anything about G3 pony customzing, you know their heads are difficult to get back on once they come off. Even when you run them under warm/hot water. So to get it back on for dyeing, I tried trimming a little excess of vinyl off the neck ring with my xacto knife. It slipped and got me right under my nail! Bad omen for what's to come!

After getting her prepped (removing her mane and tail, cleaning her, using acetone (nail polish remover) to remove her cutie mark) she was ready for a dye bath! I used Rit DyeMore as regular Rit Dye won't dye the vinyl material that ponies are made of. This was my first ever time dyeing anything that wasn't fabric so I was thrilled when she came out this warm rich brown! So pretty!

I read online that dyed ponies will leach dye onto other ponies if they touch, so I wanted to try and prevent this as much as possible with some matte sealer. Lesson #1: Even though she was dry, the matte sealer reactivated the dye! The smallest touch left a print! :(

I pushed forward! And tripped immediately after! I thought, "Surely matte Modge Podge will seal her just that much more" and to my dismay, the Modge Podge kept every brush stroke I made when it dried!! She looked like a leather hand bag! ˚‧º·(˚ ˃̣̣̥᷄⌓˂̣̣̥᷅ )‧º·˚ I learned later you can buy matte Modge Podge spray online but all I had was the type you brush on to your surface.

Thankfully, with the help of sixteen cotton balls and a q-tip with acetone, I managed to remove all the sealer but she was no longer that nice rich brown. Oh well I still loved her!

And whoever said the paint will protect the eyes from the dye has clearly never dyed a dark pony! Her eyes were so brown after this lol

Painting, adding of polymer clay easter themed confetti, and adding her 3D chocolate bunny cutie mark went great! It was all going well until the eyes.

I had never fully painted pony eyes before so the first attempt was pretty bad. Not even my multiple attempts at glitter and using clear nail polish as a cheap gloss on the eyes could save them.

It was so bad that I almost didn't take any pictures but when I went to seal her head, this weird white powder covered half of her face?? I had never seen this before and it freaked me out thinking I just ruined her. I managed to get it off with a cotton ball and some acetone but her paint was fully damaged.

Turns out this was caused because I didn't shake the can of sealer well enough. I needed a break....

While I took a break for a few days, I decided to watch tutorials on how to paint doll eyes and learned that it's actually pretty common to use high quality watercolor pencils; either Faber Castell or Derwent (which is what I ended up buying).

When I came back, I made the hard decision of removing all the paint and decorations from the head and starting over. Hours of work gone but it was so worth it! 🩷 Removing the paint with acetone ended up making her head lighter than her body so I had to redye her head lol. This time I mixed Derwent pencils with acrylic paints for her eyes.

Time for the hair! I've never done curls before and my original plan was to buy curly hair online but it's so hard to find in the color and curl size I wanted.

So my second idea was to buy small curlers to use on regular nylon doll hair bought from ShimmerLocks on Etsy. But when I tested them out on poor Flower Bouquet it looked so bad ಥ_ಥ

I discovered a Youtube channel you may know called Dollightful where in one of her Stock Box videos she used yarn that she unraveled to make super cute tight wavy hair for a doll. It was a perfect solution! It looks so good but omg it was tedious haha! I used it for her tail too; sectioning off the colors hoping they'd stay separated (they didn't lol).

She's nearly complete! Time for small decorations! I tried so many different ears from air dry clay to stealing some from bunny decorations I bought at the store and nothing was working! But I had one last idea...

I gave these old Littlest Pet Shop costume bunny ears some use with a flat top sewing pin and some glue so now my pony has bunny ears! Yay!

I forgot it in the concept art, but I originally wanted to add flowers to her mane but I couldn't figure out how to do that without glue which I didn't want to do, too permanent, so I opted for some beads I had on hand. I didn't have any light blue so I made some with the use of acetone (nail polish remover in my case) and boom! Light blue beads! Then I washed them off so the acetone wouldn't damage anything :)

I used a gold topped sewing pin, a butterfly charm, a felt flower and two faux flowers to create a cute hair accessory!

Finally I sewed a hair tie to a puffball to give her a removable cottontail if I ever wanted to take it off.

And DONE! She looks so good after so much time and effort! I worked on this girly for two weeks I think? She actually had a partner I designed but I've run out of time to make her :') Maybe next year? 👀 🩷🩷

#my art#art#horse#pony#equine#equine art#artist on tumblr#mlp#mlp art#mlp g3#my little pony g3#g3 mlp#custom pony#ooak#ooak doll#ooak mlp#ooak my little pony#custom mlp#my little pony#my custom ponies#easter#bunny#pastels#pastel rainbow#walkthrough#custom

131 notes

·

View notes

Text

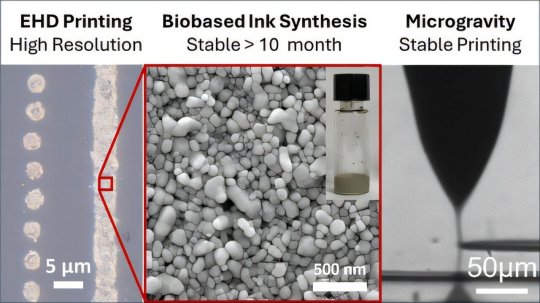

Nanoink and printing technologies could enable electronics repairs, production in space

An Iowa State University engineer floats in the air while other researchers hang tight to a metal frame surrounding and supporting their special printer. It's not the usual photo you see in a research paper. Tests aboard microgravity flights aren't your typical materials experiments, either.

The flight path to these experiments began when a research team led by Iowa State's Shan Jiang, an associate professor of materials science and engineering, and Hantang Qin, formerly of Iowa State who's now an assistant professor of industrial and systems engineering at the University of Wisconsin-Madison, wondered if their ink and printer technologies would work in the zero gravity of space.

The ink features silver nanoparticles synthesized with biobased polymers. After heat treatment, the ink can conduct electricity and can therefore print electric circuits. The printer uses electrohydrodynamic printing, or 3D printing that jets ink under an electric field at resolutions of millionths of a meter. The electric field could eliminate the need for gravity to help deposit ink.

If the technologies work together in zero gravity, astronauts could use them to make electric circuits for spacecraft or equipment repairs. And astronauts might manufacture high-value electronic components in the special, zero-gravity environment of space.

NASA wondered if it would work, too.

Diving into microgravity

Researchers bolted the printer to the floor of a jet and prepared for a "roller coaster, basically," Jiang said.

The NASA plane would continuously climb and dive, going in cycles from about 24,000 feet over Florida to 32,000 feet, then back to 24,000. The dive phase produced about 10 seconds of pure zero gravity.

"It was exciting and new," Jiang said.

Motion sickness was a problem for some. Others enjoyed the thrill of it. Jiang felt "frozen" the first time he experienced microgravity. "I was blank."

But that didn't last. "There was so much time and investment in this project. We wanted to achieve good results."

But printing for a few seconds at a time on a microgravity flight "is a very challenging experiment," Jiang said. "It's so easy on the ground where everything is stable. But if anything gets loose during the flight, you lose your printing."

The first microgravity flight was a good example. The printer wasn't adequately secured against the plane's shakes and vibrations.

"These are very intense experiments that require a lot of teamwork and preparation," Jiang said.

So, the team went back to work, made some changes, made more test flights and produced better results.

"This proof-of-concept microgravity experiment proves the unique capability of (electrohydrodynamic) printing under zero-gravity conditions and opens a new venue for future on-demand manufacturing in space," the researchers wrote in a paper published in Applied Materials & Interfaces.

Making a new nanoink

The key innovation by Jiang's research group was developing a new laboratory method to synthesize the ink with its silver nanoparticles.

"This is a new combination of materials and so we needed a new recipe to make the ink," Jiang said.

Both programs "strive to support innovative and leading research in Iowa," said Sara Nelson, director of the programs and an Iowa State adjunct assistant professor of aerospace engineering. "We are thrilled to have supported Dr. Jiang's research. His work has helped to build Iowa's research infrastructure and is an important part of NASA's strategic mission."

The project also makes use of an abundant Iowa resource, plant biomass.

The ink includes a biobased polymer called 2-hydroxyethyl cellulose, which is typically used as a thickening agent. But it is also a cost-effective, biocompatible, versatile and stable material for the inks necessary for high-resolution ink jet printing under an electric field.

"There is a lot of biomass in Iowa," Jiang said. "So, we're always trying to use these biobased molecules. They make a wonderful polymer that does all the tricks for us."

Jiang called that "the biggest surprise of this research. We didn't know that before. Now we know what we can do with these biobased polymers."

The Iowa State University Research Foundation has filed a patent on the new nanoink and the technology is currently available for licensing.

"This success is really just the beginning," Jiang said. "As humanity ventures deeper into space, the need for on-demand manufacturing of electronics in orbit is no longer science fiction; it is a necessity."

Next up for the researchers could be the development of 3D space printing for other electronic components such as semiconductors.

After all, Jiang said, "You can't just make one component and assemble an electronic device."

TOP IMAGE: Researchers—as well as a toy Cy the Cyclone—test their nanoink and printer technologies during a NASA microgravity flight. Pictured, left to right, are: Fei Liu, Yanhua Huang, Matthew Marander, Xuepeng Jiang and Pavithra Premaratne. Credit: Shan Jiang

LOWER IMAGE: Credit: ACS Applied Materials & Interfaces (2024). DOI: 10.1021/acsami.4c07592

6 notes

·

View notes

Text

Researchers at the University of California San Diego have developed a new type of material that could offer a sustainable and eco-friendly solution to clean pollutants from water. Dubbed an "engineered living material," it is a 3D-printed structure made of a seaweed-based polymer combined with bacteria that have been genetically engineered to produce an enzyme that transforms various organic pollutants into benign molecules. The bacteria were also engineered to self-destruct in the presence of a molecule called theophylline, which is often found in tea and chocolate. This offers a way to eliminate them after they have done their job. The researchers describe the new decontaminating material in a paper published in Nature Communications.

Continue Reading.

129 notes

·

View notes

Text

Researchers at the University of Toronto's Faculty of Applied Science & Engineering have used machine learning to design nano-architected materials that have the strength of carbon steel but the lightness of Styrofoam. In a new paper published in Advanced Materials, a team led by Professor Tobin Filleter describes how they made nanomaterials with properties that offer a conflicting combination of exceptional strength, light weight and customizability. The approach could benefit a wide range of industries, from automotive to aerospace. "Nano-architected materials combine high performance shapes, like making a bridge out of triangles, at nanoscale sizes, which takes advantage of the 'smaller is stronger' effect, to achieve some of the highest strength-to-weight and stiffness-to-weight ratios, of any material," says Peter Serles, the first author of the new paper.

Read more.

#Materials Science#Science#Machine learning#Computational materials science#Nanotechnology#Additive manufacturing#3D printing#Polymers#Carbon#University of Toronto#Strength of materials

18 notes

·

View notes

Text

@swradiogram Thursday 1930 ET broadcast 9265 AM

t¼ aiÝSntgp Before RSID: <<2025-01-24T00:31Z MFSK-32 @ 9265000+1500>>

0iDiDts0 IOe hnypwsvmuTut F

Welcome to program 386 of Shortwave Radiogram.

I'm Kim Andrew Elliott in Arlington, Virginia USA.

Here is the lineup for today's program, in MFSK modes as noted:

1:41 MFSK32: Program preview (now) 2:51 MFSK32: NZ mayor objects to Trump 'split the atom' claim 5:35 MFSK64: NASA develops a 3D-printed antenna* 10:46 MFSK64: Images of the week* 27:40 MFSK32: Closing announcements

with image(s)

Please send reception reports to [email protected]

And visit http://swradiogram.net

We're on swradiogram.bsky.social now

And X/Twitter: @SWRadiogram

tnop tn

From AFP via Phys.org:

New Zealand mayor goes nuclear after Trump claims US 'split the atom'

January 21, 2025

A small town mayor in New Zealand has picked a nuclear fight with Donald Trump, after the freshly sworn-in US president heaped praise on American scientists for splitting the atom.

Trump's inauguration address rattled off a list of crowning American feats such as ending slavery, launching into space, and the moment they "split the atom".

The mayor of Nelson in New Zealand's South Island seized on the sub-atomic slight, pointing out that work to split the atom was actually pioneered by Kiwi-born physicist Ernest Rutherford.

"I was a bit surprised by new President Donald Trump in his inauguration speech about US greatness claiming today Americans 'split the atom' when that honor belongs to Nelson's most famous and favorite son Sir Ernest Rutherford," mayor Nick Smith wrote on social media.

Credited with splitting the nucleus of an atom during experiments at UK's Manchester University in 1917, Rutherford was "the first to artificially induce a nuclear reaction by bombarding nitrogen nuclei with alpha particles", Smith said.

He added that he would invite the incoming US ambassador to visit the Rutherford memorial in Nelson, population 50,000, "so we can keep the historic record on who split the atom first accurate".

Widely regarded as the "father of nuclear physics", Rutherford was awarded the Nobel Prize for Chemistry in 1908 for earlier work on radioactivity.

He remains one of New Zealand's most famous sons, and his face still adorns the country's $100 bill.

Shortwave Radiogram now changes to MFSK64 …

Eheoetv*:Rf0P ¾kg6P Before RSID: <<2025-01-24T00:35Z MFSK-32 @ 9265000+1500>>

uA¡O0dbghYiUalk e i-oi tkc ovC¯e)kwNæ itFooce1—oo ekn

This is Shortwave Radiogram in MFSK64.

Please send your reception report to [email protected]

NASA's 3D-printed antenna takes additive manufacturing to new heights

by Kendall Murphy, NASA January 22, 2025

In fall 2024, NASA developed and tested a 3D-printed antenna to demonstrate a low-cost capability to communicate science data to Earth. The antenna, tested in flight using an atmospheric weather balloon, could open the door for using 3D printing as a cost-effective development solution for the ever-increasing number of science and exploration missions.

For this technology demonstration, engineers from NASA's Near Space Network designed and built a 3D-printed antenna, tested it with the network's relay satellites, and 1 k~hÎ an on a weather balloon.

The 3D printing process, also known as additive manufacturing, creates a physical object from a digital model by adding multiple layers of material on top of each other, usually as a liquid, powder, or filament. The bulk of the 3D-printed antenna uses a low electrical resistance, tunable, ceramic-filled polymer material.

Using a printer supplied by Fortify, the team had full control over several of the electromagnetic and mechanical properties that standard 3D printing processes do not. Once NASA acquired the printer, this technology enabled the team to design and print an antenna for the balloon in a matter of hours. Teams printed the conductive part of the antenna with one of several different conductive ink printers used during the experiment.

For this technology demonstration, the network team designed and built a 3D-printed magneto-electric dipole antenna and flew it on a weather balloon. A dipole antenna is commonly used in radio and telecommunications. The antenna has two "poles," creating a radiation pattern similar to a donut shape.

Testing

The antenna, a collaboration between engineers within NASA's Scientific Balloon Program and the agency's Space Communications and Navigation (SCaN) program, was created to showcase the capabilities of low-cost design and manufacturing.

Following manufacturing, the antenna was assembled and tested at NASA's Goddard Space Flight Center in Greenbelt, Maryland, in the center's electromagnetic anechoic chamber.

The anechoic chamber is the quietest room at Goddard—a shielded space designed and constructed to both resist intrusive electromagnetic waves and suppreseo /gr emission to the outside world. This chamber eliminates echoes and reflections of electromagnetic waves to simulate the relative "quiet" of space.

To prepare for testing, NASA intern Alex Moricette installed the antenna onto the mast of the anechoic chamber. The antenna development team used the chamber to test its performance in a space-like environment and ensure it functioned as intended.

Once completed, NASA antenna engineers conducted final field testing at NASA's Columbia Scientific Balloon Facility in Palestine, Texas, before liftoff.

The team coordinated links with the Near Space Network's relay fleet to test the 3D-printed antenna's ability to send and receive data.

The team monitored performance by sending signals to and from the 3D-printed antenna and the balloon's planned communications system, a standard satellite antenna. Both antennas were tested at various angles and elevations. By comparing the 3D-printed antenna with the standard antenna, they established a baseline for optimal performance.

In the air

During flight, the weather balloon and hosted 3D-printed antenna were tested for environmental survivability at 100,000 feet and were safely recovered.

For decades, NASA's Scientific Balloon Program, managed by NASA's Wallops Flight Facility in Virginia, has used balloons to carry science payloads into the atmosphere. Weather balloons carry instruments that measure atmospheric pressure, temperature, humidity, wind speed, and direction. The information gathered is transmitted back to a ground station for mission use.

The demonstration revealed the team's anticipated results: that with rapid prototyping and production capabilities of 3D printing technology, NASA can create high-performance communics ion antennas tailored to mission specifications faster than ever before.

Implementing these modern technological advancements is vital for NASA, not only to reduce costs for legacy platforms but also to enable future missions.

it d7pwte2

Image»l3D-printed antenna mounted to a ladder prior to testing at NASA's Columbia Scientific Balloon Facility in Palestine, Texas …

ttt& txtnáeSending Pic:133x201C;

This is Shortwave Radiogram in MFSK64.

Please send your reception report to [email protected]

This week's images …

? n n

"A joyful discovery in Vondelpark Amsterdam" photographed by artist Robin Rimbaud. https://tinyurl.com/26ygxofu …

xotnnk Sending Pic:130x241C;

tktsaru

A worker arranges dried incense sticks near Hanoi ahead of Lunar New Year celebrations, known in Vietnam as Tet. https://tinyurl.com/24bmhnvg …

R qn Sending Pic:181x191C;

rieu n½tn

A steam train travels through the Harz forest to the top of Germany's Brocken peak, January 13. https://tinyurl.com/2y6bkzoc …

tW ' qr Sending Pic:158x199C;

stR e mZpeu

A snow covered tree on Loch Achall near Ullapool, Scotland. https://tinyurl.com/23yukzos …

Net Ht Sending Pic:168x194C;

2hua

Fishing boats in Dunbar, Scotland. https://tinyurl.com/23yukzos …

Üdur:ru Sending Pic:206x106C;

Rtn

Skiing on Bourbon Street during the recent unusual snow in New Orleans. https://tinyurl.com/2ysa7wom …

aHd gMt Sending Pic:151x200C;

ttD

A poinsettia as it appears in its native habitat of Mexico and Central America, growing in the conservatory of the Minnesota Landscape Arboretum. https://tinyurl.com/2crwl3ja …

VrZt bRSoeSLg Pic:195x156C;

tRW

A narrow gauge railroad in Forest Park, Ma , Oregon, January

It's out of service, but there is a campaign to revive it. https://x.com/Myles_Younger/status/1881105146878521367 …

aòyA Sending Pic:151x204C;

tnoZt

Our painting of the week is "Fleurs" (1952) by Nicolas de Staël (1914-1955). https://tinyurl.com/2atd89sr …

tJoi 3Z ÷ Sending Pic:158x236C;

nQzR tn

Shortwave Radiogram returns to MFSK32 …

vfnIo°¢R Before RSID: <<2025-01-24T00:57Z MFSK-64 @ 9265000+1500>>

This is Shortwave Radiogram in MFSK32 …

Transmission of Shortwave Radiogram is provided by:

WRMI, Radio Miami International, http://wrmi.net

and

WINB Shortwave, http://winb.com

Please send reception reports to [email protected]

And visit http://swradiogram.net

X/Twitter (for now): @SWRadiogram

I'm Kim Elliott. Please join us for the next Shortwave Radiogram.

x©ti¦tGb- 5 o e-äQetrnj tng

2 notes

·

View notes

Text

Medical Polymer Market Outlook: Trends, Innovations, and Global Dynamics

The medical polymer market has become a pivotal sector, growing due to advancements in healthcare materials. Known for durability, flexibility, and biocompatibility, these polymers are essential across devices, surgical instruments, implants, packaging, and drug delivery systems. The rise in demand reflects industry trends, technological breakthroughs, and growing regulatory standards shaping this market.

The global medical polymer market is valued at USD 41.1 billion in 2024 and is projected to reach USD 60.5 billion by 2029, growing at 8.0% cagr from 2024 to 2029.

Key Market Trends

Biocompatibility Innovations: Biocompatible materials are essential in medical applications where patient safety is paramount. To meet this need, polycarbonate, polypropylene, and polyethylene polymers are engineered to strict medical standards, creating materials that offer safe, effective performance within the body.

Surge in Disposable Devices: Single-use medical products like gloves, syringes, and catheters are gaining traction, especially post-pandemic. Disposable polymers allow manufacturers to produce cost-effective, hygienic products, addressing modern healthcare’s need for cleanliness and infection control.

3D Printing Advancements: Customization has transformed through 3D printing, as tailored prosthetics and surgical tools become accessible. Polymers like PEEK are favored here for strength and adaptability, enabling precise medical solutions suited to individual patient needs.

Sustainability Drives: With heightened environmental awareness, medical manufacturers are focusing on bio-based and recyclable materials. This shift aims to reduce the ecological impact of medical products, reflecting the global push towards sustainable solutions.

Enhanced Drug Delivery Applications: Drug delivery systems require polymers that ensure controlled, sustained release of medication. Bioresorbable polymers are particularly beneficial here, facilitating targeted treatment in chronic and long-term therapies without additional interventions.

Growth Drivers in the Medical Polymer Market

Demand for Minimally Invasive Devices: Polymers are ideal for minimally invasive surgery tools due to their flexibility and durability. As demand for less invasive procedures grows, so does the need for these high-performing materials, making them integral to medical advancements.

Aging Population and Chronic Disease: The global increase in chronic health conditions and an aging population drive demand for medical-grade polymers in implants, devices, and products for ongoing care. This market growth reflects the need for durable, biocompatible materials to improve patient care.

R&D and Technological Investments: Innovations in polymer chemistry and healthcare applications expand the versatility of these materials. Significant R&D investment is pushing the boundaries, enabling entry into new applications and meeting stringent regulatory demands across regions.

Regional Market Insights

The market for medical polymers is expanding globally, with strong growth in North America, Europe, and Asia-Pacific. North America leads due to its advanced healthcare sector and robust R&D focus, while the Asia-Pacific region experiences rapid growth driven by healthcare expansion, population increases, and rising disposable incomes in emerging economies like China and India.

Emerging markets hold considerable growth potential, especially as they build their healthcare infrastructure and address increasing medical needs. Access to quality polymers helps these regions expand their healthcare capabilities, catering to larger populations with advancing healthcare needs.

Challenges and Future Prospects

The medical polymer market faces challenges, such as meeting rigorous regulatory requirements, managing high development costs, and addressing environmental concerns. Compliance with medical standards is necessary but can slow down product development and increase expenses. Additionally, the medical industry’s reliance on single-use polymers prompts a need for eco-friendly, recyclable solutions.

To know more Download PDF Brochure :

The future remains promising. The market’s growth, driven by healthcare demands and technological advances, opens new opportunities in medical material innovation. Companies prioritizing sustainability, compliance, and R&D will be well-positioned to capitalize on the evolving needs of this essential industry.

As materials science and healthcare continue to intersect, medical polymers are set to play a critical role in advancing medical technologies, improving patient outcomes, and meeting global healthcare needs.

#medical polymer market#biocompatible materials#disposable medical devices#3D printing in healthcare#sustainable polymers#biodegradable polymers#drug delivery systems#minimally invasive devices#chronic disease treatment#aging population healthcare#medical-grade polymers

0 notes

Text

by Australian Institute for Bioengineering and Nanotechnology (AIBN)

Researchers at The University of Queensland (UQ) are developing new 4D printing technology that produces shape-shifting liquid metals for soft robotics.

4D printing is an extension of 3D printing, where solid objects are created using materials that can change shape when exposed to certain stimuli like heat, water or light.

At UQ's Australian Institute for Bioengineering and Nanotechnology (AIBN), researchers are printing 4D structures using new liquid metal polymers that can be coaxed into performing a range of mechanical tasks with infrared lasers.

Lead researchers Dr. Liwen Zhang and Dr. Ruirui Qiao said the unique preparation methods developed by their lab allow them to produce 4D designs that are solid and durable while also being able to bend, grasp, lift, and release items five times their weight, or revert to a pre-programmed shape.

"4D printing takes traditional 3D printing and adds a new dimension—the dimension of time," Dr. Zhang said. "Our method allows us to produce smart liquid metals that can be customized, shaped and prompted to change over time without needing wires or circuits.

"This is a new era for robotics applications and a game-changer for additive manufacturing."

4D printed objects are usually prepared with a 3D printer using specific ingredients that give the finished product new qualities and abilities.

#robot#robotics#3d printing#Australian Institute for Bioengineering and Nanotechnology#soft robotics

15 notes

·

View notes