#230w

Explore tagged Tumblr posts

Text

Chargeur HP 230W ORIGINAL 19.5V / 11.8A Connecteur 7.4mm x 5.0mm

Puissance de sortie: 230 watts Tension de sortie: 19.5 volts Courant de sortie: 11.8 ampères (11.8A) Connecteur: 7.4mm x 5.0mm

Commander en ligne: https://ktecstore.com/produit/chargeur-hp-230w-original-19-5v-11-8a-connecteur-7-4mm-x-5-0mm/

Voir d'autres modèles de chargeur HP: https://ktecstore.com/produit-categories/chargeur/chargeur-hp/

#ktecstore #Chargeur #HP #hpelitebook #HpLaptop #hppavilion #algerie #algeria #alger #dz

#ktecstore#chargeur#algeria#chargeur original#chargeur hp#chargeur hp 230w#chargeur hp original#hp chargeur

0 notes

Text

Claiming What Was Promised

Also on AO3 [230w] @codex-week - day 5: intimate vulnerability

“Congratulations, Commander Rex! So General Skywalker finally got his head out of his ass and promoted you to the rank you’ve been acting as for the last two and a half years.”

“I mean, it only happened because I prodded him into submitting the formwork. The delay was getting ridiculous, really.”

“Oh. In that case… is that all you came to a decision about?”

“...No, that too. As you say, I decided it was past time. Cody, back at the start of everything, you said that you hoped we could be colleagues, friends, brothers… but that so long as there was such a rank gap between us, particularly within the chain of command, we could never be anything more. And that was reassuring, in it’s way. Because I had so many emotions that I didn’t know what to do with, but then I didn’t have to take the risk, because you took the decision and set the boundaries for me.

“But this is war. And it’s honestly something of a miracle that we’ve both made it this far. Something big is coming, and I don’t want either of us to be left with the regret of any more missed chances. That is, if… if you still want me?”

“Rex. I love you in whatever ways you will have me. And I am so proud of you. Now c’mere.”

#codexweek2025#captain rex#commander cody#rex/cody#developing relationship#power imbalance addressed#bingo fill#ficlet

24 notes

·

View notes

Text

Okies. Question. This doesn't say it's for a Lenovo Legion BUT it's got the same output and it's 170w like the ruined one. Cheapest I could find (don't like eBay) - it will work, yes? The next cheapest I could find is one that's 230w on Amazon.

#real life#mlc checks in#question#for a relatively smart person#i can be kinda dumb sometimes#so i have to ask questions

6 notes

·

View notes

Text

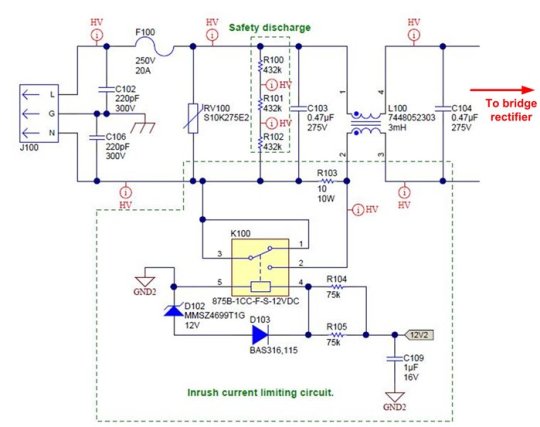

Reading more about inrush current control techniques now, all I knew before this was that you use Negative Temperature Coefficient parts to control it without affecting overall efficiency too much.

I've never had to design a board that drew much power, or didn't just use an off the shelf power supply. Power supply design is black magic so even major companies usually just buy certified open frame units to avoid redoing a ton of regulatory work, it's what's best for everyone. All the appliances at First Job just had a 24V Great Wall open frame units jammed in there, plus consumer 12V supplies for the network gear.

You can do some clever things involving having the NTC take itself out of the loop with a relay and a zener diode if you have really high efficiency targets to hit or you don't want to fry your NTC as the current picks up. I love these kinds of self-contained feedback tricks, they're super handy. And of course there's digital current controllers for high precision applications.

Figure 5 shows the relay circuit for a 1kW power supply. The relay is initially turned off. During power up, the input current flows through a 10Ω/10W cement resistor. Once the power supply is energized, a regulated bias voltage, 12V2, turns on the relay to minimize the power dissipation on the current-limiting circuit during normal operation.

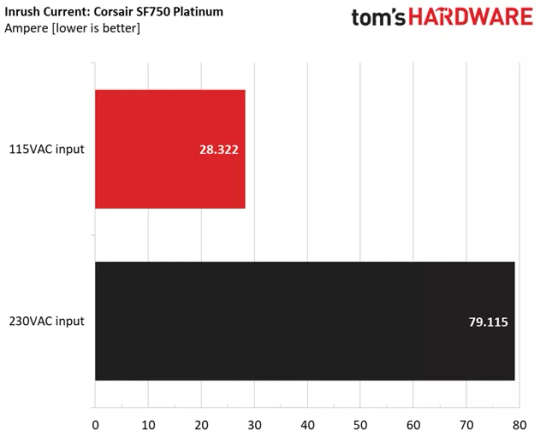

Anyway. Reading specs it looks like there's a systematically higher inrush current in computer PSU's when you connect them to 230V, which is probably just Ohm's Law at work. A lot of supplies with really good 110V inrush limiting have utterly dogshit 230V inrush limiting.

An interesting problem I realize this might cause is that, because most tech reviewers are Americans with 110V, they won't pick this up as often. E.g. the highly recommended SF750 from Corsair has fantastic 120V inrush of ~30A but on 230W it's almost 80A, which would definitely trip a lot of home breakers.

10 notes

·

View notes

Text

I think I've finally figured out the issue with my computer.

The chargers that I have always used (and the one the computer came with) is 230W, and for the first few years that I've had it where I wasn't using it to game, it worked completely fine, but once I started running games on it, the charger started to act up.

So whilst my computer can 100% handle these games, the chargers cannot—as it is always my charger overheating, and not my computer, and suspiciously, it always overheats during video games. So I think what I need to do is upgrade to something of higher wattage. I can't even begin to know what I should be looking for in that field, but so far, that's the best theory I got.

3 notes

·

View notes

Text

Máy giặt Lumias WS030WH

Máy giặt Lumias WS030WH có công suất giặt 230W, cho phép giặt 3kg đồ ướt, nhỏ gọn với kích thước 345 x 395 x 610mm, có 10 chương trình giặt đa dạng. Xem ngay: https://lumias.vn/may-giat-say-lumias-ws030wh/

0 notes

Text

Máy giặt quần áo Lumias WS028WH 230W có 10 chế độ giặt, giặt nhiệt độ cao 60-80°C loại bỏ nhanh vết bẩn, vi khuẩn. Khối lượng giặt 3kg, đáp ứng nhu cầu giặt giũ hàng ngày của gia đình có em bé, người độc thân hoặc gia đình nhỏ https://gigadigital.vn/dien-gia-dung/may-giat-say-lumias-ws028wh

0 notes

Text

why is my stupid laptop soo greedy

bought the highest watt charger they had at the store (180W) bc i knew my specs were pretty high but i couldn't remember what the old charger said

get home and mine says 230W

0 notes

Text

Máy vặn vít cầm tay Makita TD0101 230W

Máy vặn vít Makita TD0101 là dụng cụ được dùng nhiều trong lĩnh vực cơ khí, sửa chữa. Thiết bị có thiết kế hiện đại, dễ dàng và an toàn khi thao tác nhờ có lớp tay cầm cách điện tuyệt đối.

Đặc trưng máy vặn vít Makita TD0101

Máy vặn vít Makita có vỏ ngoài làm bằng nhựa tổng hợp, chịu lực tốt, chống biến dạng, giúp cho sản phẩm có tuổi thọ lâu dài hơn hẳn các loại máy bắt vít thông thường khác. Tay cầm máy có độ ma sát cao, tác dụng chống trượt tốt và cách điện hiệu quả, mang đến sự an toàn cho người dùng trong quá trình làm việc

Máy vặn vít TD0101 230W nổi bật nhờ những ưu điểm gì?

Thao tác với máy không rườm rà, thuận tiện di chuyển trong nhiều không gian, giúp đem lại hiệu suất làm việc cao nhờ trọng lượng nhẹ, thiết kế gọn gàng.

Cấu tạo đơn giản, sử dụng dễ dàng, nhanh chóng.

Lực vặn 100Nm, lực đập 3.200 lần/phút.

Vặn ốc máy M5 – M10 và ốc tiêu chuẩn M5 – M14.

Nút điều khiển điện tử cực nhạy bén.

Nơi bán máy vặn vít Makita TD0101 chính hãng

Để sở hữu một chiếc máy vặn vít Makita TD0101 hàng chính hãng, giá tốt, quý khách có thể đặt hàng online trực tiếp trên website maykhoanmakita.net, hoặc liên hệ theo hotline 0904810817 để được hướng dẫn cụ thể.

#maykhoan #maykhoanmakita #thbvietnam #579phamvandong #275flythuongkiet

0 notes

Text

Chargeur HP 230W ORIGINAL 19.5V / 11.8A Connecteur 7.4mm x 5.0mm

Le chargeur HP 230W original est un adaptateur secteur conçu pour alimenter les ordinateurs portables HP compatibles avec cette puissance et cette connectique spécifique. Voici une description détaillée de ses caractéristiques :

Puissance de sortie : Le chargeur délivre une puissance de sortie de 230 watts, ce qui en fait un adaptateur secteur extrêmement puissant conçu pour alimenter les ordinateurs portables HP qui ont des besoins énergétiques élevés. Il est particulièrement adapté aux ordinateurs portables de jeu ou aux stations de travail.

Tension de sortie : Il fournit une tension de sortie de 19,5 volts, ce qui est la tension standard pour la plupart des ordinateurs portables HP compatibles avec ce chargeur.

Courant de sortie : Le courant de sortie est de 11,8 ampères (A), ce qui permet une recharge rapide et efficace de la batterie de l'ordinateur portable.

Connecteur : Le chargeur est équipé d'un connecteur de 7,4 mm x 5,0 mm. Cette taille de connecteur est spécifiquement conçue pour se connecter aux ordinateurs portables HP compatibles avec cette configuration de connecteur.

Original : Il s'agit d'un chargeur HP original, ce qui signifie qu'il est fabriqué par HP lui-même ou par un fabricant agréé. Les chargeurs originaux sont généralement de meilleure qualité et plus fiables que les chargeurs génériques.

Le chargeur HP 230W original est conçu pour alimenter efficacement les ordinateurs portables HP compatibles avec cette connectique spécifique. Sa puissance élevée en fait un choix idéal pour les ordinateurs portables hautes performances. Assurez-vous de vérifier la compatibilité avec votre modèle spécifique d'ordinateur portable HP avant d'acheter le chargeur pour vous assurer qu'il convient à votre appareil.

KtecStore sur : Facebook / Instagram / Pinterest / TikTok / Tumblr

0 notes

Text

212th Bingo - Masterpost

Bingo card started: June 2023 Fills posted: 21 (3,450 words) Bingos completed: 3 lines

Events cross-posted: Jedi June, 212th appreciation week 2023, Codywan week, 2023 & 2024, Haunted clones week 2023, Whumptober2023, AI-less whumptober 2024, Coday 2.2.24 Bingos cross-posted: 501st bingo, Coruscant Guard bingo

Over the course of the various events, I’ve managed to fill out most of this bingo sheet. Mostly drabbles, with a couple of more interesting formats (poem, comic, image edit, craft) mixed in. I’m amused to realise that the 212th and Codywan get given most of my lighter shenanigans-based plot bunnies. And most of the Codywan fills can be interpreted as either romantic or platonic.

Fills

I’ve continued my new method of ordering the below fills according to angst level; sorted into humour, hurt/comfort, and hurt no comfort.

Coday 2.2.24 bonus

Anniversaries | Cody plushie | craft

Fluff and shenanigans

Magical mishaps | Distraction (affectionate) (AO3) | drabble | Cody/Obi-wan Cody tries to reason with his General, who is distracted by other priorities.

Snuggling | Tea Party (AO3) | script and comic | Obi-wan & 212th Obi-wan likes taking his tea in the communal rec room, likes when his troopers come past to say hello. But this might be taking it a bit too far…

Force sensitivity | Training Exercise (AO3) | double drabble | 212th There are multiple methods of practicing a new skill. Some are more fun than others.

[free] | Saint Cody of Wi-fi | image edit | Cody With all his antennas, Commander Cody is a veritable wi-fi hot spot. And his battalion reveres him as such.

Mistaken identity | Reputation(AO3) | drabble | 212th & 501st The 501st has a reputation that makes the 212th look positively reasonable by comparison. And the 212th exploit it.

Trading weapons | Bringing a Lightsaber to a Duel(AO3) | drabble | Cody & Dooku It’s unintentional, but Commander Cody collects lightsabres. Jedi, Sith - somehow, they all end up on his belt. So he learns how to use them.

Hurt/comfort

Accidentally hurt by a friend | Sueing for Emotional Damages (AO3) | drabble | Cody & Obi-wan, Palpatine Cody might have his General back, but he’s still upset that he was tricked into thinking he’d been killed in the first place. And he knows just who to blame.

Recovery| In our hearts a hopeful song (AO3) | ficlet: 250w | Obi-wan & 212th There are many things that Obi-wan was not expecting when he was given a battalion of clone troopers to lead, but by far the most interesting is the singing.

Awful first meetings | First Time Reunion (AO3) | ficlet: 590w | 501st OC & 212th OC & CG OC Clarry - once CT-9845 now CT-3937 - has never met these troopers before, but she knows exactly who they are. CT-3936 and CT-3939. Keys and Flick. CT-3937’s batchmates. This is just another one of countless awkward reunions, as GAR troopers finally come to check on their Guard batchmates only to find that the numbers they are looking for no longer belong to the person they left behind.

Small displays of affection | Memento (AO3) | drabble | Waxer & Boil It's hard saying goodbye to new friends, but easier when you can carry a reminder with you.

Hurt/comfort | Taboo (AO3) | poem: 230w | Cody/Obi-wan A clone trooper’s helmet is as much their face as the one they were created with; something deeply personal to those who have so little. But when Obi-wan tentatively asks to try on Cody’s, he doesn’t refuse him. His own feelings are no less taboo.

Misunderstandings | Wave, I can see you (AO3) | fanfic: 540w | 212th OCs 501st brothers line the ridge, ready to spring their trap. Figures in 212th gold creep through the trees, Flick’s familiar paint bright in the gloom. Keys can’t believe that the Umbarans stole his batchmate's armour, it feels wrong on so many levels.

Comfort from a nightmare | There Were Two in the Bed, and the Little One Said... (AO3) | drabble | Obi-wan/Cody Nightmares are never fun, but company makes the aftermath easier.

Rescue missions | Taking the Bait (AO3) | ficlet: 410w | Darth Sidious & Obi-wan Kenobi & Cody & Boil Darth Sidious kidnaps Commander Cody to lure out Kenobi. He takes the bait.

Hurt no comfort

Angst | Sunrise or Sunset (AO3) | drabble | Cody When Cody looks at the sunrise newly painted on his armour, he can't help the creeping feeling that perhaps it is a sunset instead.

Outsider POV | Degrees of Trust (AO3) | drabble | Cody & Obi-wan Cody doesn't understand why his General's ‘I trust you’ suddenly stopped being a promise and instead became a pain-filled thing of guilt and grief.

Dreams | The Nightmare (AO3) | drabble | Cody The Nightmare is unsettling in a visceral way, but after years of the nightly visions they are used to the feeling. And they always wake up. He just needs to wait until he wakes up...

2 notes

·

View notes

Text

Sharpy Light 7R – High-Performance Beam Light

Upgrade your lighting setup with the Sharpy Light 7R from ATI Pro Technologies, designed for DJs, stage performances, concerts, and event lighting. This powerful and compact moving head beam light delivers sharp, bright, and concentrated beams, perfect for creating dynamic lighting effects in any professional setup.

Equipped with a 230W 7R lamp, this Sharpy Light produces intense and vibrant beams with multi-color effects, fast movement, and precise gobo patterns. The durable and lightweight design ensures easy installation and long-lasting performance, making it ideal for clubs, weddings, and live shows. With its high-speed pan and tilt movement, this beam light enhances any event with spectacular lighting effects.

0 notes

Text

Buying a cheap 230W charger and just...hoping that all these problems I'm currently facing are due to me having bought a poorly timed dud charger. Because if not...that means it's the charging port, and if that's the issue, I am quite literally fucked when it comes to writing.

#texts from the underbrush#my mother tried to comfort me and say “well you can always plug in a keyboard to your phone!....and then tap your phone to your head so you#see the screen...”

2 notes

·

View notes

Link

https://www.hemenlikit.com/smok-g-priv-3-kit-230w-elektronik-sigara-antalya/

0 notes

Text

Máy giặt Lumias 3 kg WS030 Pro công suất 230W, dung tích lồng giặt 13L, giặt được tối đa 3kg đồ ướt, trang bị 10 chế độ giặt, hẹn giờ lên đến 24 tiếng. Xem ngay: https://gigadigital.vn/dien-gia-dung/may-giat-mini-lumias-ws030-pro

0 notes