#· Hastelloy C276 Pipes & Tubes Stockists

Explore tagged Tumblr posts

Text

Hastelloy C276 Pipes & Tubes Manufacturers

Hastelloy C276 Pipes are used in a wide variety of industries. Also, It has excellent corrosion resistance, especially in the harshest environments. These pipes are commonly used in chemical process applications, petrochemical, nuclear, and oil and gas industries. These pipes are also used in the water treatment and pollution control industries.

#· Hastelloy C276 Pipes & Tubes#· Hastelloy C276 Pipes & Tubes Manufacturers#· Hastelloy C276 Pipes & Tubes Suppliers#· Hastelloy C276 Pipes & Tubes Stockists#· Hastelloy C276 Pipes & Tubes Exporters#· Hastelloy C276 Pipes & Tubes Manufacturers in India#· Hastelloy C276 Pipes & Tubes Suppliers in India#· Hastelloy C276 Pipes & Tubes Stockists in India#· Hastelloy C276 Pipes & Tubes Exporters in India

0 notes

Text

Hastelloy C276 pipes and tubes are integral components in various industrial applications, particularly in chemical processing, owing to their exceptional properties and reliability. Understanding the advantages of these materials is crucial for optimizing their utilization in demanding environments.

Chemical Composition: Hastelloy C276 is a nickel-molybdenum-chromium alloy renowned for its superior corrosion resistance. Comprising nickel, molybdenum, chromium, and other elements, this alloy offers excellent resistance to a wide range of corrosive substances encountered in chemical processing environments.

Corrosion Resistance: The hallmark feature of Hastelloy C276 pipes and tubes lies in their exceptional resistance to corrosion. They can withstand attacks from aggressive chemicals, including acids, alkalis, chlorides, and organic solvents, ensuring prolonged service life and minimal maintenance requirements.

Weldability: Hastelloy C276 pipes and tubes exhibit excellent weldability, attributed to their low carbon content, which minimizes carbide precipitation during welding. This characteristic ensures that the material retains its corrosion resistance even in welded conditions, making it suitable for various fabrication processes.

High Temperature Performance: Another significant advantage of Hastelloy C276 pipes and tubes is their outstanding performance at high temperatures. They maintain their mechanical properties and corrosion resistance even when subjected to elevated temperatures, making them ideal for applications where thermal stability is critical.

Applications: Hastelloy C276 pipes and tubes find extensive applications across diverse industries, including chemical processing, petrochemicals, pharmaceuticals, oil and gas, pulp and paper, and power generation. They serve crucial roles in conveying corrosive fluids and gases within processing plants and industrial facilities, ensuring operational efficiency and safety.

Conclusion: In conclusion, Hastelloy C276 pipes and tubes offer unparalleled benefits in chemical processing applications, where corrosion resistance, reliability, and performance are paramount. Their unique combination of properties makes them indispensable assets in various industries, enabling efficient and safe operation in challenging environments. Embracing the advantages of Hastelloy C276 pipes and tubes is essential for maximizing productivity and ensuring the longevity of industrial infrastructure.

For more Information Visit website: https://www.deepsteelalloys.com Email: [email protected] Contact: 9930466755

#Hastelloy C276 Pipes & Tubes Manufacturers#Hastelloy C276 Pipes & Tubes Suppliers#Hastelloy C276 Pipes & Tubes Stockists#steel#manufacturers#metal#suppliers

0 notes

Text

Anand Steel: Hastelloy C276 Round Bars: Supplier and Stockist in Saudi Arabia

Hastelloy C276 is a versatile nickel-molybdenum-chromium alloy regarded for its first-rate corrosion resistance in an entire lot of severe environments. It is especially immune to pitting and pressure-corrosion cracking, making it a desired material within the chemical processing, oil and gas, and marine industries. For the ones in Saudi Arabia seeking out a reliable supplier and stockist of Hastelloy C276 spherical bars, Anand Steel is a prominent call that ensures first-rate and well timed delivery.

Understanding Hastelloy C276

What is Hastelloy C276?

hastelloy c276-round bars Manufacturer in saudi arabia is an alloy composed of nickel, molybdenum, chromium, and tungsten. Its specific aggregate of elements offers advanced resistance to a massive variety of chemical environments, which includes oxidizing and decreasing conditions. This alloy is specifically effective in the direction of pitting and crevice corrosion, which may be not unusual troubles in harsh commercial settings.

Key Properties of Hastelloy C276

1. Corrosion Resistance: Hastelloy C276 offers extremely good resistance to each oxidizing and lowering acid, making it suitable for numerous chemical strategies.

2. High-Temperature Stability: This alloy maintains its mechanical properties at improved temperatures, this is crucial for plenty of commercial applications.

Three. Versatility: Its robustness in competition to diverse types of corrosion and chemical reactions makes it high-quality for a couple of industries, which consist of chemical processing, oil and gasoline, power era, and marine environments.

Applications of Hastelloy C276 Round Bars

Chemical Processing Industry

In the chemical processing organization, substances regularly come across especially corrosive materials. Hastelloy C276 is utilized in reactors, heat exchangers, and piping structures due to its potential to resist the cruelest chemical substances without degrading.

Oil and Gas Industry

The oil and gasoline agency faces excessive situations, both in phrases of temperature and chemical exposure. hastelloy c276-round bars Manufacturer in saudi arabia are used in drilling system, downhole tubing, and other vital additives that want to undergo corrosive environments and mechanical strain.

Power Generation

In energy vegetation, specially those utilising fossil fuels, additives are uncovered to high temperatures and competitive environments. Hastelloy C276's resistance to high-temperature oxidation and sulfidation makes it an outstanding preference for various electricity generation packages.

Marine Environments

Marine programs require materials which could resist corrosion from seawater. Hastelloy C276 is employed in marine hardware, propeller shafts, and other tools uncovered to saline situations, ensuring durability and reliability.

Anand Steel: Leading Supplier and Stockist of hastelloy c276-round bars Manufacturer in saudi arabia

A renowned call in the region of uniqueness alloys. As a main Hastelloy C276 spherical bar producer in Saudi Arabia, they offer great materials that meet stringent worldwide standards.

Why Choose Anand Steel?

Quality Assurance

Guarantees that every one their products, which include Hastelloy C276 spherical bars, are synthetic to the very first-class wonderful necessities. They adhere to rigorous finding out and awesome manipulation strategies to make sure their merchandise meet or exceed industry specifications.

Extensive Inventory

With a huge inventory of Hastelloy C276 spherical bars, they can meet the needs of clients directly. This massive inventory guarantees that clients acquire their materials without useless delays, which is essential for preserving assignment timelines.

Technical Expertise

The crew possesses deep technical information about place of expertise alloys. They offer professional advice on cloth choice and application, assisting customers pick out the nice solutions for his or her particular dreams.

Customer Support

Prides itself on incredible customer service. From the preliminary inquiry to after-income aid, they make follow-ups for their clients.

Applications of Hastelloy C276 Round Bars

Chemical Plants

In chemical plants, Hastelloy C276 is used in components like reactors, condensers, and heat exchangers, where its resistance to corrosive chemical compounds guarantees green and steady operations.

Oil Refineries

Oil refineries make use of Hastelloy C276 round bars in processing gadgets that ought to withstand the difficult conditions of crude oil refining, along with exposure to sulfur compounds and excessive temperatures.

Marine Applications

In marine environments, Hastelloy C276 is employed in critical additives exposed to seawater, consisting of valves, pumps, and propeller shafts, wherein its corrosion resistance enhances durability and performance.

Conclusion

Hastelloy C276 spherical bars are critical in industries that require substances able to withstand excessive environments. Whether in chemical processing, oil and gasoline, energy era, or marine packages, Hastelloy C276 offers remarkable corrosion resistance and mechanical energy.

For the ones in Saudi Arabia, Anand Steel stands proud as a prime dealer and stockist of Hastelloy C276 round bars. Their willpower to excellent, giant inventory, technical knowledge, and fantastic customer support lead them to the move-to deliver for high-common performance alloys. By selecting Anand Steel, agencies can make sure they are prepared with the super substances to fulfill their operational disturbing situations and gain their challenge goals.

0 notes

Text

What industries use fasteners?

Fasteners play a critical role in construction, manufacturing, and engineering. As a leading force in the industry, Bullion Pipes & Tubes LLP stands out as the premier fasteners manufacturer, supplier, stockist, and exporter worldwide. With an extensive range that includes Bolts, Nuts, Screws, Washers, Studs, Rivets, Self-Clinching Fasteners, and more, our commitment is to provide top-notch solutions that cater to diverse project requirements.

This blog post aims to shed light on the diverse industries that heavily rely on fasteners, emphasizing the broad spectrum of applications our products cater to.

Types of Fasteners We Offer

With us, we offer fasteners with a variety of Types and Features, including the following;

Bolts: These threaded fasteners require corresponding nuts for secure connections. Choose from an array of head styles, including hex head, socket head, and round head.

Nuts: Complementing bolts, nuts secure connections. Opt for hex nuts, lock nuts, or wing nuts based on specific application requirements.

Screws: Known for versatility, screws find use in diverse applications. Choose from different head styles like Phillips, flat, or hex, and opt for self-tapping or machine screws.

Washers: Flat and disk-shaped, washers play a pivotal role in distributing fastener loads and protecting surfaces. Types include flat, lock, and spring washers.

Studs: Characterized by threaded rods without heads on one end, studs are ideal for dual-threaded connections and situations where nuts are impractical.

Rivets: Permanent fasteners with a cylindrical shaft and deformed head create a secure connection.

Pins: Cylindrical fasteners for alignment, securing, or support, including types like dowel, cotter, and clevis pins.

Anchors: These fasteners affix objects to hard surfaces, such as concrete. Common types involve wedge, sleeve, and drop-in anchors.

Clips and Clamps: Secure items like hoses and cables using clips and clamps, such as hose clamps, spring clips, and wire rope clamps.

Threaded Rods: Lengthy straight rods with continuous threading, frequently used for hanging and providing support.

U-Bolts: Featuring a U-shaped design with threads on both ends, they secure round objects to surfaces.

Eye Bolts: Equipped with a loop or "eye," these bolts are designed for lifting and securing heavy loads.

Stud Bolts: Threaded at both ends with an unthreaded portion in the middle, commonly used in flange connections.

Self-Clinching Fasteners: Specifically designed for sheet metal and thin materials, including self-clinching nuts, studs, and standoffs.

Hinges and Latches: Serving as fasteners for attaching doors, gates, and panels, they include hinges, hasps, and latches.

Materials Wise Grade We Offer – Fasteners

At, Bullion Pipes & Tubes LLP, provides a wide variety of fasteners, including;

Copper – CDA 102, CDA 101, CDA 110

Titanium – Titanium Alloy Gr 2 & Titanium Alloy Gr 5

Monel – Monel K500 & Monel 400

Carbon Steel – ASTM A193/194 & ASME SA193/194 Carbon Steel

Brass – Alloy 260, Alloy C48200 – C48500, Alloy 385, Alloy 360, Alloy 353, Alloy 330, Alloy 272, Alloy 464

Tantalum – RO5200, RO5400, RO5252(Ta2.5W), RO5255(Ta10W)

Inconel – Inconel 718, Inconel 600, Inconel 601, Inconel 625

Aluminum – he 20 65032 6061, he 30 64430, ASTM 6061, 6063, 6351

Nickel – Nickel Alloy 200/201

SMO 254 – ASTM A 479 ASME SA 479

Duplex Steel – Duplex Steel UNS S32205, Duplex Steel UNS S31803

Hastelloy – Hastelloy C22 & Hastelloy B2, Hastelloy C276

Super Duplex Steel – Super Duplex Steel UNS S32750, Super Duplex Steel UNS S32760

Incoloy – Incoloy 800/800H/800HT, Incoloy 825

Alloy 20 – DIN 2.4460 Alloy Hexagonal Nut, Alloy 20 Bolts, UNS N08020 Alloy 20 Screws, Alloy 20 Washers

Industries Uses Fasteners

Here are some industries where fasteners are used extensively:

Construction: Fasteners such as bolts, nuts, screws, and anchors are widely used in the construction industry for connecting structural elements like beams, columns, and panels.

Automotive: The automotive industry relies heavily on fasteners for assembling vehicles. A variety of screws, bolts, nuts, and clips are used in the manufacturing of cars, trucks, motorcycles, and other vehicles.

Aerospace: Aerospace applications require precision and reliability. Fasteners play a critical role in assembling aircraft and spacecraft components, ensuring safety and structural integrity.

Manufacturing: In general manufacturing processes, fasteners are used to assemble a wide range of products across different industries, including appliances, electronics, and consumer goods.

Energy: Fasteners are used in the energy sector for assembling components in power plants, wind turbines, solar panels, and other energy infrastructure.

Shipbuilding: The shipbuilding industry relies on fasteners for assembling the various components of ships, including the hull, decks, and internal structures.

Railway: They are crucial in the railway industry for connecting rail tracks, assembling train components, and maintaining the structural integrity of railway infrastructure.

Oil and Gas: In the oil and gas industry, fasteners are used in the construction and maintenance of pipelines, platforms, and other infrastructure.

Electronics: Fasteners play a role in the assembly of electronic devices and equipment. They are used to secure components on circuit boards and in the housing of electronic products.

Medical Devices: Fasteners are used to ensure that components are held together in a precise manner in medical devices and equipment.

Furniture: In the furniture industry, fasteners such as screws, bolts, and nuts are used to assemble various types of furniture, from simple household items to complex office furniture.

Final Words! As a global Fasteners Supplier, Manufacturer Stockist, and Exporter, Bullion Pipes & Tubes LLP takes pride in contributing to the success of diverse industries. Our fasteners, available in an array of sizes, specifications, standards, grades, materials, and types, offer versatility and reliability. Whether it's bolts, nuts, screws, washers, studs, rivets, or self-clinching fasteners, our commitment to quality ensures that our customers can confidently choose the perfect solution for their project requirements. Contact us today at [email protected] or [email protected] to explore how our fasteners can enhance the strength and durability of your applications.

0 notes

Text

What is the use of Nickel Alloys in Power Cables?

In the world of electrical engineering, expertise the numerous nickel alloys uses is essential for making sure optimum efficiency, excessive conductivity, and lengthy-lasting durability in power cables. Among the nickel alloys, nickel chromium alloys Traders have garnered great attention for their terrific properties. As a outstanding iron nickel alloys Stockist specializing, MV Super Alloys takes delight in being the leading provider, trader, and dealer of nickel alloy merchandise throughout India. Renowned for our incredible inventory, we provide a massive variety of nickel alloy grades, together with hastelloy c276, hastelloy c22, nickel hundred/201, Inconel 600, Incoloy 800H/HT, Inconel 625, Incoloy 825, Monel four hundred, Monel adequate-500, Inconel 718, and Inconel 601. Our entire desire encompasses pipes, tubes, round bars, coils, shims, strips, wires, sheets, and plates, permitting our valued customers to select out the first-rate nickel alloy product that honestly aligns with their particular project necessities. Trust us for pinnacle-notch nickel steel properties and unmatched information in catering to diverse business goals.

In this weblog post, we are able to delve into the numerous applications and blessings of nickel alloys in strength cables.

The Role of Nickel Alloys in Power Cables:

Nickel alloys have become a desired choice for strength cables due to their splendid residences. Let's explore the important thing motives why these alloys are widely used in the production of strength cables.

High Temperature Stability:

In energy transmission, cables are subjected to extended temperatures. Nickel alloys like Incoloy 800H/HT exhibit wonderful balance at excessive temperatures, stopping degradation and making sure the non-stop and reliable go with the flow of energy.

Mechanical Strength:

The mechanical electricity of nickel alloys, exemplified by Monel 400 and Monel ok-500, contributes to the durability and resilience of strength cables. This energy is important in keeping the structural integrity of cables, specifically in disturbing commercial settings.

Conductivity:

Nickel alloys, consisting of nickel 200/201, own first-rate electrical conductivity. This assets enhances the efficiency of electricity transmission, ensuring minimum power loss and most effective performance of the strength cables.

Final Words! In the realm of electricity cables, the use of nickel alloys is not only a preference; it is a necessity. MV Super Alloys, as the most nickel alloy merchandise issuer in India, stands as a reliable companion for industries searching for top-notch satisfactory, various product options, and a dedication to excellence in every supply. To make stronger our dedication, every deliver of nickel alloys from MV Super Alloys comes observed through a Material Test Certificate (MTC). By leveraging nickel alloys uses, nickel chromium alloys Trader, iron-nickel alloys stockist, and nickel superalloy properties, we make certain that our clients acquire exceptional answers for their electrical engineering endeavors.

#nickel alloys uses#nickel chromium alloys Traders#nickel steel properties#iron nickel alloys Stockist#nickel superalloy properties

0 notes

Text

Revolutionizing Industries with Hastelloy Alloys: A Paradigm Shift in the Industrial Landscape

Hastelloy Alloy stands out for its exceptional performance and versatility in the ever-evolving landscape of industrial materials. At Jay Steel Corporation, we take pride in being the leading Hastelloy products manufacturer, supplier, stockist, and exporter globally. Our extensive range of Hastelloy alloys, including C22, C276, C2000, B2, and B3, in various forms such as Hastelloy Wire Mesh, Round Bar, Strips, Sheet and plates, Tube and pipes, Fittings, Flanges, Welding Rods and Fasteners and specifications, empowers industries across the world to elevate their projects to new heights.

In this blog post, we will delve into the fascinating world of Hastelloy alloy and explore how it is reshaping the industrial landscape.

Understanding Hastelloy Alloy:

Hastelloy alloys are primarily composed of nickel, chromium, molybdenum, and other elements to enhance specific properties. The unique combination of these elements results in alloys with remarkable resistance to corrosion, pitting, crevice corrosion, and stress corrosion cracking. Hastelloy alloys find applications in diverse industries, including chemical processing, petrochemicals, aerospace, pharmaceuticals, and more each contributing to the alloy's exceptional properties.

Properties of Hastelloy Alloys

Corrosion Resistance:

Hastelloy alloys exhibit outstanding corrosion resistance in a wide range of aggressive media, including acids, salts, and reducing agents. This unique property makes Hastelloy an ideal choice for industries such as chemical processing, petrochemicals, and pollution control, where exposure to corrosive substances is inevitable.

High-Temperature Stability:

One of the most significant advantages of Hastelloy alloy is its exceptional stability at high temperatures. This property makes it invaluable in applications involving extreme heat, such as in gas turbines, aerospace components, and industrial furnaces. The alloy's ability to maintain structural integrity in demanding thermal conditions contributes to its widespread use across diverse industrial sectors.

Versatility Across Industries:

Hastelloy alloys find applications in a myriad of industries, ranging from aerospace and energy to pharmaceuticals and marine engineering. Its versatility stems from the combination of its corrosion resistance, high-temperature stability, and overall durability. As industries evolve, the demand for materials that can withstand increasingly challenging conditions continues to drive the popularity of Hastelloy alloy.

Chemical Processing Excellence:

In chemical processing plants, where exposure to corrosive chemicals is constant, Hastelloy alloy plays a crucial role in ensuring the longevity and safety of equipment. Its resistance to pitting, crevice corrosion, and stress corrosion cracking make it a top choice for critical components in the chemical industry.

Pioneering Innovation:

The development of Hastelloy alloys has spurred ongoing research and innovation in the field of metallurgy. Engineers and scientists continue to explore ways to enhance the properties of Hastelloy, pushing the boundaries of what is achievable in terms of corrosion resistance, strength, and heat tolerance.

Applications of Hastelloy Alloys

These alloys are commonly used in various industries due to their unique combination of attributes. Here are some notable applications of Hastelloy alloys:

Chemical Processing Industry

Aerospace and Defense

Oil and Gas Industry

Pharmaceutical Industry

Power Controls

Pollution Controls

Pulp and Paper Industry

Marine Engineering

Waste Treatment

Nuclear Industry

Other Applications

Final Words!

Hastelloy alloys stand out among industrial materials due to their corrosion resistance and versatility. Jay Steel Corporation, as a leading Hastelloy products manufacturer, supplier, stockist, and exporter, is playing a pivotal role in transforming the industrial landscape. With a commitment to quality, a diverse product Hastelloy Alloy in C22, C276, C2000, B2, and B3 Products range Wire Mesh, Round Bar, Strips, Sheets and plates, Tube and pipes, Fittings, Flanges, Welding Rods and Fasteners, a global presence in various countries like Thailand, Singapore, Malaysia, India, Germany, Russia, France, Nigeria, USA, Saudi Arabia, Kuwait, Qatar, Egypt, Turkey, Oman, Jordon, Bahrain, Russia, Germany, United Kingdom, and Italy, and competitive pricing, we are empowering industries worldwide to achieve new heights of success in their projects.

Choose us for your Hastelloy Alloy needs and experience the difference in performance and reliability.

0 notes

Text

We are one of the leading importers, stockists and suppliers and manufacturer of Stainless Steel. We offer a wide range of raw materials both LONG & FLAT Products to meet a variety of applications/production Requirements i.e. Stainless Steel Pipes, Stainless Steel Tubes, Stainless Steel Sheets, Stainless Steel Plates, Stainless Steel Strips, Stainless Steel Rods, Stainless Steel Bars, Stainless Steel Wires angels, Stainless Steel Pipe,17-4ph bar and rods, 15-5 ph bars and rods, nickel bars and rods, nickel pipe and tubes, nickel sheet, nickel plates, nickel coils, nickel flanges, alloy bars and rod, alloy pipes and tubes, alloy plates, alloy sheets, alloy coils, alloy flanges, duplex rods, duplex bars, duplex coils, duplex sheet, duplex plate, duplex pipes, duplex tubes, carbon steel rods, carbon sheet bars, carbon steel pipes, carbon steel tubes, carbon steel plates, carbon steel coils, carbon steel sheets, carbon steel, aluminium bars and rods, auminium pipes and tubes, aluminium sheets, coils, plates, aluminium flanges, fittings as per International Codes / Standards.

#stainlesssteel#stainlesssteelbars#stainlesssteelbar#stainlesssteelrods#stainlesssteel304rod#stainlesssteelpipes#stainlesssteeltubes#stainlesssteelcoils#stainlesssteelsheet#aluminium#aluminiumpipe#aluminiumsheet#stainlesssteelplates#stainlesssteelflanges#forgedfitting#buttweldfitting#aluminiumtubes#aluminiumplate#aluminiumcoils#aluminiumbars#aluminiumrods#nickel#duplex#superduplex#hastelloy#alloy#hastelloybar#hastelloyrod#hastelloyplate#hastelloycoils

0 notes

Link

Hastelloy C276 werkstoff nr. 2.4819 seamless, ERW and Welded Pipes & Tubes stockist, Manufacturer, Exporter & Suppliers in India.

ASTM SB 622, B 619, B 775, B 516, B 626 UNS N10276 Hastelloy Seamless pipes & Welded tubes Tubes Suppliers, exporters, manufacturer and stockist in India.

1 note

·

View note

Text

PIPE FITTING COLLAR

COLLAR PIPE FITTINGS TUBING, COLLAR PIPE FITTINGS EXPORTER, CARBON STEEL COLLAR PIPE FITTINGS, SS 310/310S COLLAR PIPE FITTINGS, STAINLESS STEEL 316/316S COLLAR FITTINGS, ANSI B16.9 BUTTWELD COLLAR FITTINGS, COLLAR PIPE FITTINGS WITH FERRULE FITTINGS SUPPLIER, COLLAR PIPE FITTINGS CONNECTOR, ASME B16.9 BUTT WELD COLLOR, COLLAR PIPE FITTINGS STOCKIST, ALLOY STEEL COLLAR PIPE FITTINGS EXPORTER, SS 304/304L COLLAR FITTINGS, SS 904L COLLAR FITTINGS, NICKEL ALLOY COLLAR PIPE FITTINGS, COLLAR PIPE FITTINGS INSTRUMENTATION PIPE FITTING,LEADING COLLAR PIPE FITTINGS MANUFACTURER, INCONEL 600/601/625 COLLAR FITTINGS, STAINLESS STEEL COLLAR PIPE FITTINGS STOCKIST, HASTELLOY C22/C276 COLLAR FITTINGS.

We have specialization to manufacture customized ANSI/ASME B16.9 Butt Weld Collar per customers’ specifications, we welcome small quantity order.

Mcneil Instruments Inc (India) is Manufacturer, Stockists & Supplier of premium quality range of ANSI/ASME B16.9 Butt Weld Collar, Stainless Steel Flanges & Other Stainless Steel Pipe fittings that are manufactured under the expert guidance of our diligent workforce. we are highly experienced company in ANSI/ASME B16.9 Butt Weld Collar & other pipe fittings. our ANSI/ASME B16.9 Butt Weld Collar & Other Fitting products are manufactured using quality material and go through a rigorous quality check at all stages of production to ensure quality. Designed in compliance with international quality standards, these ANSI/ASME B16.9 Butt Weld Collar are corrosion resistance, sturdy and durable. we also supply ANSI/ASME B16.9 Butt Weld Collar & other pipe fittings Flanges in customized size. Our Product Supply Division offers a broad portfolio of Steel Flanges and ANSI/ASME B16.9 Butt Weld Collar. When you place an order with Mcneil Instruments Inc (India), you will receive the products that will stand up in service from people that will stand behind their product.

Checkout Technical Specification & Material of Construction — http://www.mcneilinstruments.com/collar-pipe-fitting.html

Copyright 2021 Mcneil Instruments — http://www.mcneilinstruments.com/

#plumber#fitting#pipe#industrial#valve#valveman#valvesupplier#pipeline#elbw#tee#vessel#chemical#contractor#waterplant

0 notes

Link

#Hastelloy C276 Pipe Fittings#hastelloy compression tubes#hastelloy products#shimsfoils#manufacturer#exporter#stockist

0 notes

Text

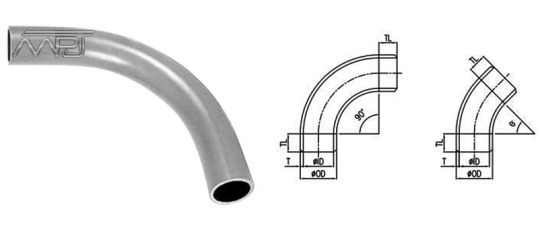

Piggable bends

M P Jain Tubing Solutions LLP is one of the leading Manufacturer, Stockist, and Exporter of ANSI/ASME B16.9 Piggable Bend in Mumbai, India. We are in this domain since 1972. We are ISO 9001:2015 certified company and most trusted Suppliers of Piggable Pipe Bends. We keep intensive stock of SS Piggable Bend to fulfill urgent requirements of our clients at reasonable prices.

One of the oldest Manufacturer, Stockist, Exporter of ANSI and ASME B16.9 Piggable Bend, Piggable Pipe Bends, Piggable Bend Suppliers at best price in India. We keep the largest stock of stainless steel Piggable bends, carbon steel Piggable bends, nickel alloy Piggable bends, alloy steel Piggable bends, Monel Piggable bends in all dimensions.

Benefits of Butt Weld Pipe Fittings

Butt welding fittings have the following benefits

Welded connection offers more robust connection

Continuous metal structure adds to the strength of the piping system

An option of various turn radius using Short Radius (SR), Long Radius (LR) or 3R Elbows

Cost effective compared to their expensive threaded or socket weld counterparts.

Stainless Steel Welded Fittings are also available in SCH 10, allowing a thinner wall option.

Stainless Steel Butt Weld Fittings are more common in SCH 10 and SCH 40 configuration.

allow a strong and leak-proof pipe to fitting connection

minimize the pressure drops and the turbulence along the pipeline

have a long service life

are rather cheap to purchase and deploy

Butt weld fittings with matching pipe schedules offer seamless flow inside the pipe. A full penetration weld and properly fitted LR 90 Elbow, Reducer, Concentric reducer etc. offers gradual transition via welded pipe fitting.

ANSI and ASME B16.9 Piggable Bend Specifications

Type: Butt weld (BW)

Standards: ASME / ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings’ ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’

Dimension: A NSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313

Thickness: Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc.

Schedule: Sch 5 TO Sch XXS.

Size: 1/2” TO 36”, (Seamless up to 24”), (Welded 8” TO 36”)

ANSI and ASME B16.9 Piggable Bend Material and Grades

Stainless Steel Piggable Bend:

ASTM A403 WP316/316L

ASTM A403 WP304/304L

ASTM A182 F316L, 304L

DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Carbon Steel Piggable Bend:

ASTM A234 Gr. WPB

ASTM A420 Gr. WPL6

ASTM A105

ASTM A350 Gr. LF2

Nickel Alloy Piggable Bend:

Monel 400 & 500

Inconel 600 & 625

Incolloy 800, 825

Hastelloy C22, C276

Hastelloy

Nickel

Monel

Inconel

Alloy20

Copper Nickel

Cupro-Nickel 90/10

Cupro-Nickel 70/30

Standard:

ASTM / ASME SB 336

UNS 10276 HASTELLOY C 276 Bend

UNS 2200 NICKEL 200 Bend

UNS 2201 NICKEL 201 Bend

UNS 4400 MONEL 400 Bend

UNS 8020 ALLOY 20 Bend

UNS 8825 INCONEL 825 Bend

UNS 6600 INCONEL 600 Bend

UNS 6601 INCONEL 601 Bend

UNS 6625 INCONEL 625 Bend

Alloy Steel Piggable Bend:

ASTM a234 wp1 / wp5 / wp9 / wp11 / wp22 / wp91

As a leading manufacturer, stockist, and exporters of ANSI and ASME B16.9 Piggable bend, we are providing high-quality Piggable bends, SS piggable bend, piggable bend radius at best price in India.

For More Details

Address: 205 Kika Street, Gulalwadi Mumbai, India

Tel: 022-23465538 / 022-23460403

Fax: +91-22-23424250

Mob: +91 9619390230

Email: [email protected]

Visit our site: http://www.mpjainco.com/

0 notes

Text

Hastelloy C276 Pipe Fittings Supplier Manufacturer Stockist Exporter

Hastelloy C276 Pipe Fittings Supplier Manufacturer Stockist Exporter

Hastelloy C276 Pipe Fittings supplied by Siddhagiri Metals and Tubes is a high quality Hastelloy C276 Pipe Fittings available in all forms and sizes at best price and fast delivery. Contact us on [email protected] or visit our website http://www.siddhagirimetals.com for more information.

View On WordPress

0 notes

Text

hastelloy tube fittings

Hastelloy Tube Fittings Manufacturers Supplier Stockist and ExporterWe are happy to announce that we domestically lead in the manufacture and supply of Hastelloy Tube Fittings. Out efficient and dedicated team is backed by superior infrastructure facilities and which has helped us become a market leader and top the list of manufacturers and suppliers of Metal Fittings We have large stock for Hastelloy C276 Tube Fittings, Hastelloy C22 Tube Fittings and Hastelloy B2 Tube Fittings.We offer Fittings in Hastelloy (butt weld, socketweld & threaded) 90 deg elbow, 90 deg long bend, 180 deg u bend, 45 deg elbow, 45 deg long bend, concentric reducer, eccentric reducer, equal tee, unequal tee, end cap / pipe cap, union, nipple, swage nipple, full & half coupling, cross, plug, bush. Olets: Insert Weldolet, Branzolet, Coupolet, Sweepolet, Elbolet, Weldolet, Sockolet, Nippolet, Swagged Nippolet, Threadolet.

0 notes

Text

What is Hastelloy c276

The Hastelloy C-276 alloy has emerged as a remarkable choice in advanced materials due to its corrosion resistance and versatile application capabilities. MV Super Alloys stands as the foremost destination for Hastelloy C-276 alloys. As a reputable Hastelloy C276 supplier, importer, trader, dealer, stockist, and exporter, we take immense pride in presenting top-tier products and exceptional services to our esteemed clientele. Our extensive range of Hastelloy C-276 alloys comes in various sizes, specifications, and forms of pipes, tubes, round bars, Coils, Shims, strips, wires, sheets, and plates, ensuring that you find the perfect fit for your project requirements. Whether you seek top-notch quality or competitive Hastelloy C276 price in India or Hastelloy C276 round bar Stockist, we are your trusted partners, committed to fulfilling your needs.

Hastelloy C276

In this article, we delve into the applications, benefits, and extensive reach of Hastelloy C-276 alloys.

Understanding Hastelloy C276

Hastelloy C-276 is a nickel-molybdenum-chromium superalloy that stands out for its exceptional corrosion resistance, even in the most severe environments. Its composition provides a remarkable level of resistance to a broad spectrum of corrosive media including oxidizing and reducing acids, pitting, crevice corrosion, and stress corrosion cracking. This makes it an invaluable asset in industries where maintaining the integrity of equipment and structures is paramount.

Properties of Hastelloy C276

Hastelloy C276 is a nickel-molybdenum-chromium superalloy known for its exceptional corrosion resistance and high-temperature strength. It is commonly used in various industries, including chemical processing, petrochemicals, and marine environments. Here are some key properties of N10276 alloys:

Exceptional resistance to a wide range of corrosive environments, including acids, chlorides, and oxidizing agents.

Can withstand high temperatures without losing its corrosion resistance properties.

Suitable for various industries like chemical processing, pollution control, marine environments, and other applications.

Offers good mechanical strength and can be used in demanding applications.

Can be easily welded using common techniques without significant loss of properties.

Can be formed and fabricated into various shapes for different applications.

Minimizes carbide precipitation during welding, maintaining corrosion resistance.

Resists both localized and general corrosion, making it suitable for various conditions.

Effective in environments where pitting and crevice corrosion are concerns.

Suitable for applications where magnetic interference is undesirable.

Mainly composed of nickel, molybdenum, chromium, and iron for its unique properties.

Benefits of Hastelloy C-276 Alloys

Corrosion Resistance: The primary benefit of Hastelloy C-276 alloys is their unparalleled corrosion resistance. They can withstand both strong oxidizing and reducing environments, making them suitable for a wide range of applications.

Versatility: The versatility of these alloys stems from their ability to perform reliably in diverse settings. Their resistance to corrosion, oxidation, and cracking makes them a preferred choice in many industries.

High-Temperature Stability: Hastelloy C-276 alloys maintain their mechanical properties even at high temperatures, making them suitable for applications in elevated-temperature environments.

Longevity: The durability of these alloys translates into longer equipment lifespan, reduced maintenance, and overall cost savings in the long run.

Reduced Downtime: By minimizing the need for frequent repairs or replacements due to corrosion, these alloys contribute to reduced downtime and increased operational efficiency.

Hastelloy C276 Specifications & Standards

Product Form - Sheet, Plate

ASTM - B575

ASME - SB 575

DIN - 17744

Product Form - Strips

ASTM - B575

ASME - B 575

DIN - 17744

Product Form - Rod, bar, forging

ASTM - B 574 B 564

ASME - B 574 B 564

DIN - B 574 B 564

Product Form - Wire

ASTM -

ASME -

DIN - 17744 17753

2.4819 Alloy Equivalent

Standard - Hastelloy C276

UNS - N10276

WERKSTOFF NR. - 2.4819

AFNOR - -

EN - NiMo16Cr15W

JIS - NW 0276

BS -

GOST - ХН65МВУ

Mechanical Properties of 2.4819 Alloys

Element - Hastelloy C276 Density -8.89 g/cm3 Melting Point - 1370 °C (2500 °F) Tensile Strength - Psi – 1,15,000, MPa – 790 Yield Strength (0.2%Offset) - Psi – 52,000, MPa – 355 Elongation - 40 %

Applications of Hastelloy C276

This alloy finds extensive use in various industries due to its unique combination of properties. Some of the key Hastelloy c276 applications include:

Chemical Processing

Oil and Gas Industry

Petrochemical Industry

Pharmaceutical Manufacturing

Power Generation

Aerospace and Aviation

Desalination Plants

Waste Treatment

Paper and Pulp Industry

Food and Beverage Processing

Nuclear Reactors

Marine Applications

Other Applications

Final Thoughts!

Witness the epitome of innovation and dependability when facing the most demanding conditions with Hastelloy C-276 alloys. These remarkable alloys offer unparalleled resistance to corrosion, unwavering stability at elevated temperatures, and remarkable durability. At MV Super Alloys, we take immense pride in being your reliable ally, presenting a comprehensive array of Hastelloy C-276 forms tailored to your distinct project prerequisites. As the foremost Hastelloy C-276 supplier and stockist in India, we furnish the raw materials complete with a Material Test Certificate (MTC), a testament to our unwavering commitment to top-tier merchandise, and exceptional client care.

Furthermore, our reach spans across India, encompassing numerous states such as Hyderabad, Gujarat, Chennai, Bangalore, Mumbai, Telangana, Rajasthan, Delhi, Punjab, and Himachal Pradesh. Experience the most competitive prices as we extend our offerings of Hastelloy C-276 through these regions.

#hastelloy c276 supplier#Hastelloy C276 round bar Stockist#Hastelloy c276 application#Hastelloy C-276 supplier and stockist in India

0 notes

Text

What industries are fasteners used for?

Fasteners might seem like small components, but they play a pivotal role in numerous industries, holding together structures and equipment that form the backbone of modern society.

As the leading Fasteners Manufacturer, Supplier, Stockist, and Exporter in India, Bullion Pipes & Tubes LLP understands the significance of these tiny yet mighty components across various sectors.

In this article, we'll delve into the wide array of industries where fasteners find their indispensable applications.

Fasteners

Fasteners are mechanical devices or components used to securely join or affix two or more objects together. They play a fundamental role in various industries and applications, providing the necessary connections that ensure structural integrity, safety, and functionality. Fasteners are designed to withstand different types of forces, such as tension, compression, shear, and torsion, depending on the specific application.

There are numerous types of fasteners, each with its own unique design and purpose. Some common types of fasteners include:

Screws: Screws have a threaded shaft and are used with a corresponding threaded hole or nut. They are rotated to create a strong, threaded connection between two objects. Screws are versatile and come in various head styles, including flat, round, pan, and more.

Bolts: Bolts are similar to screws but typically have a non-threaded portion (shank) and require a nut to create a secure connection. They are often used in applications requiring higher levels of tension or load-bearing capabilities.

Nuts: Nuts are paired with bolts to secure two objects together. They come in different shapes, such as hexagonal (hex nuts), square, or round, and are tightened onto the bolt's threaded shaft to create a strong joint.

Washers: Washers are flat, thin discs often placed between the nut or bolt head and the surface of the material being fastened. They distribute the load and prevent damage to the material while providing a more stable connection.

Rivets: Rivets are permanent fasteners used to join two or more materials together by deforming the end of the rivet to hold the materials in place. They are commonly used in applications where welding or screwing is not practical.

Pins: Pins are cylindrical fasteners that are inserted into holes in two objects to align and secure them. They can be held in place by friction or locking mechanisms.

Clips and Clamps: Clips and clamps are fasteners used to hold objects together or secure them in place temporarily. They often provide quick and easy solutions for assembling and disassembling components.

Anchors: Anchors are fasteners designed to provide a secure attachment to a base material, such as concrete or masonry. They are commonly used in construction and structural applications.

Materials & Grades - Fasteners Offered by Bullion Pipes & Tubes LLP

Copper Fasteners

Titanium Fasteners

Titanium Alloy Gr. 2 & 5

Monel Fasteners

Monel K500 & 400

Carbon Steel Fasteners

Brass Fasteners

Tantalum Fasteners

Inconel Fasteners

Inconel 718

Inconel 600

Inconel 601

Inconel 625

Aluminum Fasteners

Nickel Alloys Fasteners

Nickel 200/201

SMO 254 Fasteners

Duplex Steel Fasteners

Duplex Steel UNS S32205

Duplex Steel UNS S31803

Hastelloy Fasteners

Hastelloy C22, B2 & C276

Super Duplex Steel Fasteners

Super Duplex Steel UNS S32750

Super Duplex Steel UNS S32760

Incoloy Fasteners

Incoloy 800/800H/800HT

Incoloy 825

Alloy 20 Fasteners

Industries that use fasteners

Fasteners are used in a wide range of industries and applications to provide secure and reliable connections between various components. Here are some additional contexts where fasteners play a crucial role:

Aerospace and Aviation: The aerospace industry relies on fasteners to assemble aircraft components, such as wings, fuselage, and engine parts. Aerospace fasteners are designed to withstand extreme conditions, including high speeds, vibrations, and temperature fluctuations.

Marine and Shipbuilding: In marine applications, fasteners are used to construct ships, boats, and offshore structures. They must resist corrosion from saltwater and provide a strong bond in harsh marine environments.

Oil and Gas Industry: Fasteners are integral to the construction of oil rigs, pipelines, and refineries. They ensure the safety and reliability of equipment used in the extraction, processing, and transportation of oil and gas.

Medical Devices: Fasteners are used in the assembly of medical devices and equipment, ensuring that they remain securely in place during surgical procedures or patient treatment.

Railway and Transportation: Fasteners are crucial in railway tracks, securing rails to sleepers and ensuring the stability and safety of train operations. They are also used in the assembly of vehicles such as buses, trucks, and trains.

Electrical and Electronics: Fasteners secure components in electrical panels, circuit boards, and electronic devices, ensuring proper functioning and preventing damage due to vibrations and movement.

Furniture and Woodworking: In the furniture industry, fasteners hold pieces of furniture together, whether it's a simple chair or an intricate cabinet. They enable easy assembly and disassembly for shipping and storage.

Sports and Recreation Equipment: Fasteners are used in the manufacturing of sports equipment such as bicycles, skateboards, and snowboards, ensuring that the components remain securely attached during use.

Defense and Military: Military equipment and vehicles rely on fasteners for structural integrity and functionality. They are used in the assembly of tanks, armored vehicles, and aircraft used in defense operations.

Communication Infrastructure: Fasteners are used in the construction of communication towers and antennas, providing stability for broadcasting and wireless communication systems.

Renewable Energy: Fasteners play a role in solar panel and wind turbine installations, securing components and ensuring the efficiency of renewable energy systems.

Automated Manufacturing: Fasteners are used in automated manufacturing processes, where robots and machines assemble products quickly and accurately.

HVAC and Plumbing: Fasteners secure ductwork, pipes, and plumbing components in heating, ventilation, air conditioning, and plumbing systems.

Mining and Heavy Machinery: Fasteners are used in mining equipment, bulldozers, excavators, and other heavy machinery, ensuring their durability and safety during demanding operations.

Retail and Consumer Goods: Fasteners are employed in packaging and display fixtures, enabling efficient assembly and customization of retail spaces.

Final Words!.. A fastener contributes silently to the safety, stability, and progress of various industries, from tall skyscrapers to oil wells. As the premier Fasteners Manufacturer, Supplier, Stockist, and Exporter in India, Bullion Pipes & Tubes LLP's commitment to quality ensures that these small yet crucial components meet the highest standards.

With a wide range of fasteners tailored for diverse applications, We continue to be the preferred choice for industries across the spectrum. Moreover, we are also well-known fasteners exporters in various countries Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, Russia, and beyond. Contact us today to explore how our fasteners can elevate your projects across industries.

0 notes

Text

All you need to know about Butt Weld Fittings

Butt weld fittings are essential components used in various industries to join and connect pipes or tubes seamlessly. These fittings play a crucial role in creating a robust and leak-free piping system. As a leading butt weld fittings manufacturer and supplier, stockist, and exporter in India. Bullion Pipes & Tubes LLP offers an extensive range to suit various project needs. Our fittings are available in different sizes, specifications, material grades, and types, ensuring you find the perfect fit for your specific application.

In this comprehensive guide, we will delve into all you need to know about butt weld fittings and how they cater to the needs of different applications.

What Are Butt Weld Fittings?

Butt weld fittings are designed to have smooth inner surfaces, ensuring minimal friction and pressure drop in the flow of fluids. This characteristic makes them ideal for applications where flow velocity and efficiency are critical factors. Additionally, the absence of crevices or threads in butt weld fittings prevents the accumulation of debris, reducing the chances of contamination and facilitating easy cleaning and maintenance.

Comprehensive Range of Butt Weld Fittings

We take pride in offering a comprehensive range of buttweld pipe fittings, including

Butt Weld Elbows: Available in 45-degree, 90-degree, and 180-degree angles, providing flexibility in directing the flow of fluids.

Butt Weld Crosses: Ideal for intersecting pipelines, ensuring smooth fluid flow in multiple directions.

Butt Weld Caps: Used to seal the end of a pipe, protecting it from contaminants and preventing leakage.

Butt Weld Tees: Available as equal and unequal tees, facilitating even or uneven flow distribution.

Butt Weld Reducers: Both concentric and eccentric reducers for smooth transitions between pipes of different diameters.

Butt Weld Stub Ends: Facilitating easy flange connections without welding.

Advantages of Butt Weld Fittings

Excellent Structural Integrity: Butt weld fittings create a continuous and strong joint that enhances the structural integrity of the entire piping system. This is especially important in applications where safety and reliability are paramount.

Smooth Inner Surface: The absence of internal disruptions such as threads or flanges ensures a smooth inner surface, minimizing turbulence and pressure loss during fluid flow.

Strong and Reliable Joints: The welding process used to join the pipes ensures a permanent and robust connection, reducing the risk of leaks or failures.

Suitable for High-Pressure and High-Temperature Applications: Butt weld fittings are capable of withstanding extreme pressures and temperatures, making them suitable for critical and demanding industries.

Disadvantages of Butt Weld Fittings

Skilled Labor for Welding: Proper welding requires skilled labor, which may increase the installation cost compared to other types of fittings that do not require welding.

Slightly More Expensive: Butt weld fittings can be slightly more expensive than other fittings due to the welding process and the need for precision manufacturing.

Materials & Grades we offer - Buttweld Fittings

Stainless Steel Buttweld Fittings

SS 904L

SS 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347, 446

Titanium Buttweld Fittings

Titanium Alloy Gr 2

Titanium Alloy Gr 5

Monel Buttweld Fittings

Monel K500

Monel 400

Carbon Steel Buttweld Fittings

Inconel Buttweld Fittings

Inconel 718

Inconel 600

Inconel 601

Inconel 625

Alloy Steel Buttweld Fittings

Alloy Steel P5

Alloy Steel P9

Alloy Steel P11

Alloy Steel P12

Alloy Steel P22

Alloy Steel P91

Aluminium Buttweld Fittings

Nickel Buttweld Fittings

Nickel Alloy 200/201

SMO 254 Buttweld Fittings

Duplex Steel Buttweld Fittings

Duplex UNS S32205

Duplex UNS S31803

Hastelloy Buttweld Fittings

Hastelloy C22, Hastelloy B2

Hastelloy C276

Super Duplex Steel Buttweld Fittings

Super Duplex Steel S32750

Super Duplex Steel S32760

Incoloy Buttweld Fittings

Incoloy 800/800H/800HT

Incoloy 825

Alloy 20 Buttweld Fittings

Applications of Buttweld Fittings

Buttweld fittings are a type of pipe fittings used to connect pipes or tubes with a butt welding process. They are widely used in various industries for a range of applications due to their structural integrity and reliability. Some of the common applications of buttweld fittings include:

Plumbing and Water Supply

Oil and Gas Industry

Chemical Processing

Petrochemical Industry

Power Generation

Pharmaceutical Industry

Food and Beverage Industry

HVAC Systems

Shipbuilding

Construction

Nuclear Power Plants

Other Application

How to Select the Right Butt Weld Fitting?

Choosing the right butt weld fitting is essential to achieve an efficient and reliable piping system. Consider the following factors during selection:

Project Requirements: Understand the specific needs of your project, such as fluid type, pressure, temperature, and flow rate.

Material Compatibility: Ensure that the material of the fitting is compatible with the material of the pipes to prevent corrosion and ensure longevity.

Fitting Dimensions: Select fittings with dimensions that match the pipe size to achieve a secure and leak-free joint.

Industry Standards and Codes: Adhere to industry-specific standards and codes to maintain the quality and safety of the piping system.

Installation and Welding Process of Buttweld Fittings

Proper installation and welding are critical to ensuring the effectiveness of buttweld pipe fittings. Follow these steps for a successful installation:

Preparation: Clean the pipe ends and fittings thoroughly to remove any dirt, grease, or debris that could affect the quality of the weld.

Alignment: Ensure precise alignment of the pipes and fittings before welding to create a strong and reliable connection.

Welding: Employ the appropriate welding method, such as TIG or MIG, to create a robust and leak-proof joint.

Inspection: Thoroughly inspect the welds for defects using non-destructive testing methods to ensure the integrity of the joints.

Leak Testing: Before putting the system into service, conduct a leak test to verify the integrity of the joints and prevent potential leaks.

Final Thoughts!..

Butt weld fittings are vital components in creating strong and reliable connections within piping systems. Bullion Pipes & Tubes LLP stands at the forefront as the leading butt weld fitting supplier, manufacturer, stockist, and exporter in India. With an extensive range of fittings and a commitment to quality, we cater to diverse industrial needs across India and various countries as well including Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, and Russia. Our buttweld pipe fittings offer exceptional strength, leak resistance, and versatility, making them the ideal choice for critical applications. When selecting the right fitting, consider the specific project requirements, material compatibility, and adherence to industry standards.

Choose Bullion Pipes & Tubes LLP for all your butt weld fitting needs, and experience excellence in quality and service. Contact us today to explore our vast range of fittings and find the perfect solution for your piping requirements.

0 notes