Lectro Engineering is recognized as a worldwide leader in the areas of downstream blow molding line automation and plastic surface treating. Innovation meets excellence at Lectro Engineering's LectroTreat division. Connect with us today for the requirements.

Don't wanna be here? Send us removal request.

Text

MTM Spin Trimmer Equipment

MTM Systems Manufactures - Lectro Engineering!

MTM Systems manufactures a broad range of spin trimmers to meet virtually any dome trimming requirements.

All of our spin trimmers use our patented Heated Blade Technology for the ultimate in debris-free trimming.

Choose Lectro Engineering for all your trimming needs.

0 notes

Text

Plastic Trimmer | Finishing Trimmer

Best Suited for the Trimming of Plastic like PET and Polypropylene!

Upgrade your trimming game with our plastic trimmer from Lectro Engineering.

With its advanced technology and professional-grade performance, achieving a polished and smooth finish is now easier than ever.

Don't settle for less; choose Lectro Engineering for all your trimming needs.

0 notes

Video

youtube

MTM Spin Trimming Equipment

Our trimmers are the industry standard and best suited for the trimming of plastic like PET and polypropylene. The entire line is built with safety and durability in mind.

We also manufacture reliable, fast production spin trimmers such as our 2025, specifically designed for “log-style” (mouth to mouth) containers. This unit is designed for high-speed lines and can be built to handle virtually any log container.

0 notes

Text

Finishing Trimmer | Spin Trimmer

MTM Spin Trimming Equipment

Looking for a finishing trimmer that delivers precise and flawless results? Look no further!

Our plastic trimmer from Lectro Engineering is designed to give you that perfect finish every time.

Say goodbye to uneven edges and hello to professional-looking results.

0 notes

Text

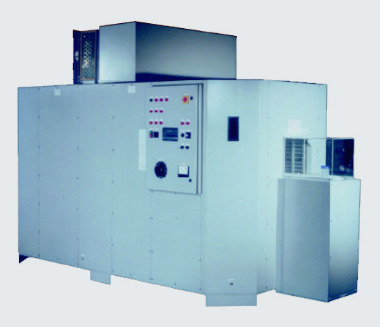

The Bulk LectroTreat surface treating system is the ideal surface treating solution when orientation of your parts is not required.

Parts can be either bulk fed or randomly placed onto the treating conveyor. Discover the features and benefits!

0 notes

Text

Plasma Treatment for Plastics

Plastic Surface Treater for 3-Dimensional Plastic Parts!

Transforming the plastic world, one treatment at a time! Did you know Lectro Engineering's plasma treatment technology increases adhesion and surface energy, making your plastics ready for any application?

The entire outside surface of the part is treated evenly insuring adhesion. Contact us now for a free consultation!

0 notes

Text

Plasma Treatment for Plastics

Bulk Lectrotreat Model from Lectro Engineering!

Transforming the plastic world, one treatment at a time! Did you know Lectro Engineering's plasma treatment technology increases adhesion and surface energy, making your plastics ready for any application?

LectroTreat, the entire outside surface of the part is treated evenly insuring adhesion. Contact us now for a free consultation!

0 notes

Text

Upgrade your manufacturing game with the latest plastic equipment from Lectro Engineering.

Say goodbye to inefficiencies and hello to increased productivity and cost savings. Trust us, your bottom line will thank you.

0 notes

Text

Plasma Treatment | Lectro Engineering

Plastic Surface Treating Machine!

Unlock the hidden potential of plasma treatment with Lectro Engineering.

Say goodbye to expensive and time-consuming treatments – our technology is efficient, cost-effective, and delivers amazing results. Trust us for all your industrial needs!

0 notes

Text

Cold Plasma Technology Treatment

Cold Plasma Technology System at Lectro Engineering

We offer a full line of plastic surface treating machines that feature an innovative open air, cold plasma technology.

Unique machine featuring an innovative open air, cold-plasma technology has expanded into a full line plastic surface treating machines.

0 notes

Text

Plasma Surface Treatment

LectroTreat Offers Plasma Surface Treatment!

Transforming ordinary surfaces into extraordinary ones with the power of plasma surface treatment!

As the experts at Lectro Engineering, we know firsthand the incredible benefits of this cutting-edge technology.

Contact us today and let's take your business to the next level!

0 notes

Text

Revolutionizing Plastic Manufacturing with Lectro Treat Equipment

In the dynamic world of plastic manufacturing, advancements in technology are constantly shaping the industry. One such revolutionary innovation is the integration of Lectro Treat equipment and plasma treatment in the blow molding process. These cutting-edge technologies are transforming the way plastics are treated and molded, offering unprecedented efficiency and quality.

Lectro-treat equipment has emerged as a game-changer in the realm of surface treatment for plastics. Whether it's enhancing adhesion, improving printability, or promoting better bonding, Lectro Treat provides a versatile solution for various plastic applications. This technology works by using a controlled electrical discharge to modify the surface properties of plastics, making them more receptive to subsequent processes.

When it comes to blow molding, plasma treatment for plastics takes the manufacturing process to new heights. Blow molding is a widely used method for creating hollow plastic products, such as bottles and containers. Plasma treatment acts as a crucial pre-treatment step in this process, ensuring that the plastic surface is properly prepared for molding.

The key advantage of plasma treatment lies in its ability to clean, activate, and modify the surface energy of plastic materials. This results in improved adhesion of labels, inks, and coatings, ultimately enhancing the overall quality and appearance of the final product. Additionally, plasma treatment helps eliminate any contaminants on the plastic surface, ensuring a pristine starting point for the blow molding process.

The integration of Lectro-treat equipment and plasma treatment in blow molding machines is a testament to the industry's commitment to sustainability. By optimizing surface treatment, manufacturers can reduce waste and enhance the recyclability of plastic products. This aligns with the growing demand for eco-friendly solutions in the plastics industry.

Moreover, the use of lectro treat and plasma treatment in blow-molding machines ensures consistent and precise results. The controlled nature of these technologies allows manufacturers to achieve uniform surface modifications, resulting in products with enhanced performance characteristics.

0 notes

Text

Lectro Treat Equipment

Full Line Plastic Surface Treating Machines!

Attention all engineers and manufacturers!

Say goodbye to manual welding and hello to efficiency with lectro treat equipment from Lectro Engineering.

Increase productivity and save time with our cutting-edge technology. Don't miss out, schedule a demo today!

0 notes

Text

Elevate your production game with Lectro Engineering!

As a leading provider of innovative solutions for the manufacturing industry, we're proud to offer cutting-edge technology and expert support to help you achieve your goals.

Let's take your business to new heights together!

0 notes

Text

Lectro Engineering | Lectro Treat

A Leader in Blow Molding Line Automation!

Since 1960, Lectro Engineering has been automating production lines around the world with the industry’s most comprehensive and innovative line of equipment.

Explore LectroTreat's work now! Join us as we continue to shape the future of surface treatment worldwide.

1 note

·

View note