Hangzhou Jiuhe Floor New Material Co., Ltd. was established in 2010, is a Sino-Australian joint venture, in the introduction of Australia's advanced coating technology, combined with the company's invention of the coating patent technology, successfully produced GREP epoxy flooring, is the world's first, a number of key technologies won the national patent and provincial science and technology achievement award. The company covers an area of more than 10,000 square meters, with many high-tech talents, the annual output value of more than 100 million yuan. Compared with PVC floor and epoxy floor, this kind of product has excellent performance, such as super pressure resistance, wear resistance, corrosion resistance, scratch resistance, fire prevention, anti-static, dust prevention, and convenient construction, easy to clean, cost-effective, green environmental protection.GREP products are produced by advanced technology and automation equipment, with stable product quality, diversified colors and varieties, and a wide range of applications, suitable for aerospace, petrochemical, chemical fiber weaving, power, electronics, biomedicine, medical equipment, food, new energy and high-end manufacturing and many other fields. The product has been applied in the market for more than ten years, and has won the favor and praise of the majority of users.Based on the business principle of mutual benefit and win-win, the company sincerely hopes to cooperate with all enterprises and individuals who are interested in the development of industrial floor materials and work together! https://www.kunhongintl.com/

Don't wanna be here? Send us removal request.

Text

Polyurethane Super Wear-Resistant Industrial Floor

Adopting a patented surface treatment scheme, the overall improvement of the floor's super strong wear resistance and scratch resistance, with a wear-resistant revolution of up to 21500, can ensure a 10-year wear-resistant service life in industrial environments.

The combination of super wear resistance and super scratch resistance ensures the long-term cleanliness and service life of the ground system of this product in heavy industrial environments.

Specifications of Polyurethane Super Wear-Resistant Industrial Floor:

Model

Specification

Remark

CF8401、8402、8307、8308

thickness : 1.4mm × width(2m-3m) ×length : 30m

Colors can be customized according to the Lauer color card

The supplied products have obtained EU CE certification and EU ROHS certification.

Features of Ultra Wear-Resistant Industrial Roll Flooring

1. Wear resistance: Over 20000 revolutions for corrosion resistance

Due to the high requirement for frequent use of industrial floors, the corrosion resistance revolution of industrial floors should be above 20000 revolutions to ensure the service life of the floor.

2. Product hardness: above Shore hardness D15:55

The transportation tool commonly used in industrial production workshops is forklifts, which have a heavy load and hard wheels. If the plate hardness is not enough, it will cause the floor to be unable to support and cause dents when the wheels are rolling over the ground. In this situation, once the forklifts turn, it will cause the floor to be twisted and damaged by the torque generated by the wheels, resulting in deformation, bulging, and wrinkling.

3. Residual value of depression: EN ISO 24343-1:2012 standard test result: average value 0.00mm

This parameter can reflect the compressive performance of the floor itself.

4. The product has a glass fiber stable layer, and the surface layer and bottom layer are produced using materials of the same composition. This structural layer is designed to prevent floor expansion and contraction.

5. The thickness of the surface polyurethane wear-resistant layer is above 0.7mm. The thicker the surface wear-resistant layer, the longer the ground service life.

(We provide proof of testing reports from national authoritative testing institutions)

Scope of Application:

★ Mechanical factory

★ Heavy Industry

★ Hangar

★ Turning worker

★ Electronic workshop

★ Transportation and warehousing

★ Light industry, chemical industry, textile

★ and other places with wear resistance requirements, workshops, etc

0 notes

Text

Outdoor Bamboo Floor

As an outdoor heavy bamboo floor, it is manufactured using international cutting-edge biomimetic technology. Firstly, the bamboo raw materials are processed through 18 thinning processes to produce bamboo filaments with basically uniform morphology. Then, under high temperature conditions, the sugar substances in the cell cavity are pyrolysed, and the bamboo filaments are immersed in a certain concentration of silica sol based formula solution, making the cell cavity filled with silica sol formula liquid. Afterwards, the bamboo fibers are dried, soaked in glue, molded, and finally thermally cured with glue under high temperature and pressure. At the same time, the silica sol also forms crystals under high temperature and pressure, precipitating in the bamboo fibers to form silicified bamboo, thus making the outdoor boards manufactured have strong corrosion resistance, high strength, and non moldy properties.

Specifications of Outdoor Silicified Bamboo Flooring:

Model

Specification

Remark

Series Products

1860mm×139mm

Customizable

The product has obtained ISO9001-2008 international quality system certification, ISO14001-2004 environmental system certification, and certification from the International Forest Management Organization FSC; EU CE certification, FSC certification, EPA certification, CARB certification, FloorScore certification.

Benefits of Outdoor Silicified Bamboo Flooring

1. Durability: Outdoor silicified bamboo flooring is known for its strength and durability. It is harder than many types of wood and therefore wear-resistant. It can withstand various outdoor environments.

2. Weathering resistance: Outdoor silicified bamboo flooring is usually treated with moisture, mold, and hardening, making it a good choice for passages, courtyards, decks, and other outdoor spaces.

3. Aesthetics: With a unique and natural appearance, it can add nature and beauty to the outdoor space. It comes in multiple colors and styles to meet different design preferences.

4. Environmental protection: Bamboo is a renewable resource that grows much faster than broad-leaved trees, making it a more sustainable choice.

5. Convenient maintenance: Outdoor silicified bamboo flooring is relatively easy to maintain. It can be cleaned or rinsed as needed and does not require any special cleaning products.

6. Comfort: Outdoor silicified bamboo flooring is very durable and comfortable to cut feet.

7. Installation: Usually adopts a snap on design, making installation quick and convenient.

8. Cost effectiveness: Although the initial cost of bamboo flooring may be higher than other options, its durability and low maintenance requirements make it a cost-effective choice in the long run.

0 notes

Text

Laminate Flooring

Kunhong composite flooring covers multiple categories and dozens of products

Solid wood composite flooring: SPC super crystal flooring, VSPC series, LSPC series, bamboo flooring, outdoor silicified flooring, etc.

PVC flooring: includes dozens of categories, including homogeneous and transparent flooring, compact base, indoor/outdoor sports series flooring, stone plastic sheet series flooring, electrostatic conductive series flooring, dance specific flooring series, children's professional flooring, solid color series, commercial series, cartoon series, rubber series, etc.

Kunhong Composite Flooring Production Technology

The SPC super crystal flooring series products are the true ABA co extruded flooring products in the industry, with excellent quality. They are innovatively developed based on German production processes and technologies, and have obtained US patent certificates. The products have been sold to more than 50 countries and are widely praised.

Key Points For Composite Floor Construction

Ground condition: Hard, flat, dry, with a ground humidity of less than 3% and an air humidity range of 20% -75%.

Adhesive: Use professional matching single component adhesive and two component adhesive, and purchase according to the opinions provided by Kunhong Company.

Construction tools: Equipped with professional cutting knives, scraper plates, press clips, rubber hammers, and other tools.

Construction personnel: Construction must be carried out by a professional construction team. All product construction can be taught or guided by Kunhong technical personnel.

Installation requirements:

1. The base layer should be flat and dry.

2. There should be no sanding on the ground.

3. The ground should be smooth and free of oil, dust, and impurities.

4. Ground cracks shall not exceed a width of 1.0mm.

5. Before construction, the moisture content of the ground should be less than 8% and the ground should be kept dry.

Maintenance method:

1. Timely clean the debris on the composite floor.

2. Floors cannot be soaked in water for a long time. If soaked in water for a long time, it will reduce the service life of the floor and attention should be paid to protection.

3. In public places, if there is significant wear and tear, the maintenance cycle should be shortened and the frequency of ground maintenance should be increased.

0 notes

Text

Industrial Flooring

Industrial flooring is more resistant to the corrosion of dozens of chemical substances such as strong acids, alkalis, and oils than PVC flooring, while also being more wear-resistant, pressure resistant, and impact resistant. Industrial flooring is suitable for electronic and microelectronic industries that require high cleanliness, aesthetics, dust-free, and sterility, pharmaceutical industries that implement GMP standards, precision instruments, aerospace, and other fields. It has the advantages of seamless, solid texture, waterproof, moisture-proof, and anti-skid functions, convenient maintenance, and low maintenance costs. The difference from industrial floor tile flooring is that in addition to having the high strength, wear resistance, and pressure resistance of floor tiles, it also has a certain degree of elasticity and flexibility, lighter sound noise, better foot feel, and certain functions of warmth, sound insulation, and dust prevention, which cannot be met by floor tile flooring.

Compared with floor paint, industrial flooring has more obvious advantages, such as longer service life and better comfort. Due to the Thermal expansion of the ground surface, the floor paint is more likely to be damaged, dust is easily generated, and maintenance is frequent. And after repair, the color difference is different and the sensory perception is not ideal.

Industrial Flooring Types

Epoxy Polymer Industrial Flooring

The polymer industrial floor can achieve an ultra-high wear resistance of 21500 revolutions (tested with 180 grit sandpaper), and can be repaired and refurbished through polishing after damaging scratches are generated. The thickness of the wear-resistant layer on the floor surface layer is as high as 0.7-1.2 mm, and the wear-resistant layer is produced from pure material. There is no dust and no discoloration when polishing the floor, Polishing, waxing, or roller coating with water-based polyurethane can rejuvenate the old ground.

Epoxy Flooring Paint

Our products include solvent-free and water-based epoxy resin floor coatings, polyurethane floor coatings, ultra wear-resistant polyurethane covering materials, solvent-free colored sand self-leveling materials, and elastic acrylic floor materials. Representative inorganic products include emery wear-resistant aggregates, special cement-based self-leveling materials, rapid repair mortar materials, and inorganic grinding stone matching materials. This product has good permeability and sealing properties to concrete, improves the hardness of the base surface, and provides good adhesion, with good economy. Epoxy floor paint has the advantages of rich products, excellent quality, convenient construction, low price, and perfect after-sales service.

VIEW MORE

Epoxy Flooring Paint

01 02

Epoxy Polymer Industrial Flooring

Epoxy Flooring Paint

Sustainable And Eco-Friendly Options for Industrial Flooring

Sustainable development and meeting the requirements of environmental protection:

Cost reduction and efficiency enhancement: Epoxy polymer industrial flooring is cheap in price, with a service life of 8-10 years, and there is basically no need for high cost maintenance. Based on the two to three year renovation or maintenance of industrial flooring used in other categories, the product has a higher cost-effectiveness.

The product is easy to lay and can be installed without stopping production. At the same time, it can be loaded and used in one day, saving decoration time and costs for enterprises.

The product has good detection performance, does not contain harmful substances, meets the requirements of high-quality ambient air, and is energy-saving and emission reducing.

Maintenance And Cleaning of Industrial Flooring

Maintenance And Cleaning:

After 8 hours of paving, it can be pedestrian and loaded after 24 hours.

During use, sharp objects should be avoided from scratching the ground.

During use, people and objects should try to avoid bringing in coarse and hard gravel, and if there is any, it should be removed in a timely manner.

Regular Sweeping: Regularly sweep the floor to remove dust, dirt, and debris. This can prevent scratches and damage to the floor surface.

Use Appropriate Cleaning Solutions: Use a cleaning solution suitable for the type of industrial flooring. Avoid harsh chemicals that can damage the floor. Always follow the manufacturer’s instructions.

Regular Mopping: Mop the floor regularly to remove any stains or spills. For larger industrial spaces, an automatic floor scrubber may be more efficient.

1

When welding or installing heavy equipment in the paving area, necessary protective measures should be taken for the ground.

2

Adhering to daily maintenance and cleaning, keeping the workshop or work environment clean, is also beneficial for extending the service life of the floor panel and reducing the repair rate.

Quality Control Measures in Industrial Flooring Manufacturing Processes

1. Raw Material Inspection: The first step in quality control is to inspect the raw materials used in the manufacturing process. This includes checking the quality of cement, aggregates, and other materials to ensure they meet the required standards.

2. Process Control: This involves monitoring the manufacturing process to ensure that it is carried out correctly. This includes checking the mixing of materials, the pouring of the concrete, and the curing process.

3. Testing: Various tests are carried out on the finished product to ensure it meets the required standards. This includes strength tests, slip resistance tests, and durability tests.

4. Inspection: The finished product is inspected for any defects or irregularities. This includes checking for cracks, uneven surfaces, and other issues that could affect the performance of the floor.

Documentation: All quality control measures are documented for future reference. This includes recording the results of tests and inspections, as well as any actions taken to correct issues.

0 notes

Text

Indoor/Outdoor Sports Laminate Floor

Indoor/Outdoor sports laminate flooring is a popular choice for sports facilities due to its durability, versatility, and ease of maintenance. It is designed to withstand heavy use and harsh weather conditions, making it suitable for both indoor and outdoor sports facilities.

Specifications Of Indoor/Outdoor Sports Laminate Floor

Model

Specification

Remark

Gem pattern/lychee pattern

thickness(4.5mm)× width(1.8m) ×length(20m)

Please consult sales for size and color customization

Wood grain

Water Cube

Crystal sand pattern

Grid pattern

Gemstone pattern

thickness(5/8mm)× width(1.8m) ×length(15m)

Crystal sand pattern

thickness(4.5mm)× width(1.8m) ×length(20m)

Foam bottom

thickness(5mm)× width(2m) ×length(20m)

Whole body

thickness(3/4/5mm)× width(1.5m) ×length(15m)

Stdandar(unit)

Basketball

Tennis

Badminton

Pingpong

Volleyball

Description

Roll Length(m)

20

20

15

20

20

Roll Width (m)

1.8

1.5/1.8

1.42

1.5/1.8

1.5

Thickness(mm)

3.5/4.5/6.0

3.5/4.5/6.0

3.5/4.5/6.0

3.5/4,5/6.0

3.5/4,5/6

Wear Layer Thickness(mm)

1.0/1.2

1.0/1.2

1.0/1.2

1.0/1.2

1.0/1.2

Weignt(g/m)

2600/3100

2600/3100

2600/3100

2600/3100

2600/310

Sportcharacteristics

Hardness(HD)

120

115

115

120

115

Rebound values(%)

9

8

8

8

8

Shock absorption(%)

DIN18032

≥28

≥28

≥28

≥28

>28

Friction corefficient

DIN18032

0.45

0.45-0.65

0.45-0.65

0.45-0.65

0.45-0.6

Ball bounce(%)

DIN18032

≥97

≥97

≥97

≥97

97

Technicalcharacteristics

Indentation resistance(mm)

EIN1516

≤0.6

≤0.6

≤O6

≤0.6

<0.6

Abrasion Resistance(mg)

EINISO5470

≤300

<300

<300

≤300

≤300

Impact resistance(N/M)

DIN18032

≥8

≥8

≥8

≥8

≥8

Sound Insulation(DB)

EIN1SO717

19

19

19

19

19

Surface trealment

Resistance to staining

UV treatmenteasy to maintain and care

Chemicaldetection

Voltatile content(g/m)

≤35

5.26

5.26

5.26

5.26

5.26

Vinyl chioride monomer(mg/kg)

≤5

0.43

0.43

0.43

0.43

0.43

0 notes

Text

Homogeneous Transparent Coil Flooring

Homogeneous Transparent Coil Flooring

Homogeneous and transparent flooring: There are many varieties and decors available. Such as carpet patterns, stone patterns, wood floor patterns, etc. The pattern is realistic and beautiful, with rich and colorful colors, simple and easy to cut, easy to assemble, fully unleashing human creativity and imagination, and fully meeting the personalized needs of designers, different users, and different decorative styles. And it has no color difference, is light and radiation resistant, and will not fade after long-term use.

Specifications of Homogeneous Transparent Flooring:

Model

Specification

Remark

KLF series 、 ALB series

thickness(1.5-3.0mm)× width(2m) ×length(20mm)

Multiple decors and patterns available, with customizable sizes

Characteristics of Homogeneous Transparent Flooring Products

1. Environmental protection and health. PVC is used as raw material for production, without recycled PVC.

2. The wear resistance life is generally longer than that of multi-layer composite PVC flooring. According to EN685 classification, M-level or above can be used in high-flow commercial/industrial places. Due to the presence of stone powder, the floor surface has good heat resistance, and when heat marks are generated on the surface, they can be eliminated by polishing.

3.Installation and construction are fast, maintenance is convenient, and cement mortar is not needed. It can be used in 24 hours.

4. Widely used, inexpensive, and highly secure. Simply clean with a damp mop, saving time and effort. After installation, there is no need for waxing, and only regular daily maintenance is required to make it as smooth as new.

5. Environmentally friendly regeneration. The installation and construction of homogeneous transparent plastic flooring is relatively fast, easy to clean, maintenance free, and not afraid of water immersion, oil stains, dilute acids, alkalis and other chemical substances.

6. Homogeneous and transparent plastic flooring is the only ground material that can be recycled, which has great significance in protecting our natural resources and ecological environment on Earth.

7. Comfortable foot feel. The dense surface layer and high elastic foam cushion layer, after seamless treatment, have strong bearing capacity and buffer heavy glassware from falling to the ground, ensuring a comfortable foot feel.

Scope of Application

★ Education system: schools, training centers, kindergartens, etc

★ Medical system: hospitals, laboratories, pharmaceutical factories, sanatoriums, etc

★ Commercial system: shopping malls, supermarkets, hotels, entertainment and leisure centers, catering industry, specialty stores, etc

★ Sports system: sports venues, activity centers, etc

★ Office system: office building, conference room, etc

★ Industrial system: factory buildings, warehouses, etc

★ Transportation system: airports, train stations, bus stations, docks, etc

★ Home system: indoor, living room, bedroom, kitchen, balcony, study, etc

0 notes

Text

Epoxy Polymer Industrial Flooring

Epoxy coil floor products using the most advanced technology and automation equipment production, product quality is stable, diversified varieties, and low carbon environmental protection. Compared with PVC floor, epoxy floor, etc., it has excellent performance, such as super pressure resistance, wear resistance, corrosion resistance, scratch resistance, fire protection, easy to clean, and green environmental protection. Widely used in new energy, petroleum, chemical, chemical fiber, electricity, electronics, machinery manufacturing, building decoration, medicine, medical equipment, food, environmental protection and many other fields, over the years has served nearly 100 of the world's top 500 enterprises.

Characteristics of Epoxy Polymer Industrial Flooring

1. Antibacterial and mold resistant;

2. Anti static electricity;

3. Low temperature resistance: can be used normally at a low temperature of -30 ℃ without cracking, embrittlement, wear resistance, and heavy load resistance;

4. Preventing cracks on the ground;

5. Anti heavy load walking forklift;

6. Green and environmentally friendly;

7. Finished product installation;

8. The fire resistance and flame retardancy index can reach B1 level;

9. Sound absorption and noise prevention: The sound absorption can reach 12-20 decibels;

10. Ultra strong wear resistance;

11. High elasticity and super strong impact resistance;

12. Super strong anti slip;

13. Ultra light and ultra-thin;

14. Simple and easy cutting and splicing;

15. Fast installation and construction: The forklift can be driven in 24 hours;

16. Acid and alkali corrosion resistance: After inspection by authoritative institutions, polymer industrial flooring has strong acid and alkali corrosion resistance, and can withstand harsh environmental tests. It is very suitable for use in various production workshops, clean workshops, dust-free workshops, hospitals, laboratories, research institutes, and other places.

17. Environmentally friendly and renewable;

Super anti fouling and easy to clean.

Advantages of Epoxy Industrial Roll Flooring

1. The industrial floor is produced using high-density modified resin raw materials, without adding fillers during the production process. The industrial floor must have the high density characteristics of polymer structure construction, enhance the floor's resistance to heavy loads, wear, dirt, and service life.

2. Wear resistance: The required number of corrosion-resistant revolutions is 20000 or more. Because the frequency of use of industrial floors is much higher than that of ordinary commercial floors, industrial floors have high requirements for floor wear resistance. Industrial floors must have a corrosion resistance revolution of over 20000 revolutions to ensure their service life.

3. Product hardness: It is required to achieve a Shore hardness of D15:55 or above. The transportation tool commonly used in industrial production workshops is forklifts, which have a heavy load and hard wheels. If the floor hardness is not enough, it will cause the floor to be twisted and damaged by the torque generated by the wheels, resulting in deformation, bulging, and wrinkling.

4. Residual value of depression: EN ISO 24343-1:2012 standard test result requirement: average value 0.00mm. This parameter can reflect the compressive performance of the floor itself.

5. The product has a glass fiber stable layer and the surface layer and bottom layer are produced using materials of the same composition. This structural layer is set to prevent floor expansion and contraction, and is a necessary structural layer.

6. The thickness of the surface wear-resistant layer must be above 0.7mm. The thicker the surface wear-resistant layer, the longer the service life of the ground.

7. Industrial flooring must have excellent tensile strength (resistance to physical cracks caused by base expansion cracking), with a tensile strength of over 250%.

8. Industrial flooring has impact resistance, preventing severe physical damage to the ground when heavy objects fall.

9. Industrial floors have washability to prevent damage to the ground after repeated cleaning after use.

10. Conforming to European EN13501-1:2007+A1:2009 Section 9&EN ISO 9239-1:2010&EN ISO 11925-2:2010, Cor.1:2011 flame retardant standard Bf1-s1 level.

11. Wear resistance ≤ 1.6mm³ (Test standards EN660-2:1999 and EN649:2011).

12. All products have obtained EU CE certification and EU ROHS certification.

(All products have testing report certificates from national authoritative testing institutions)

Advantages of Epoxy Industrial Roll Flooring

Customization Options of Epoxy Polymer Industrial Flooring

1. Thickness: 1.6mm-4.0mm; Width: 2m-3m; Length: 10m-20m/roll.

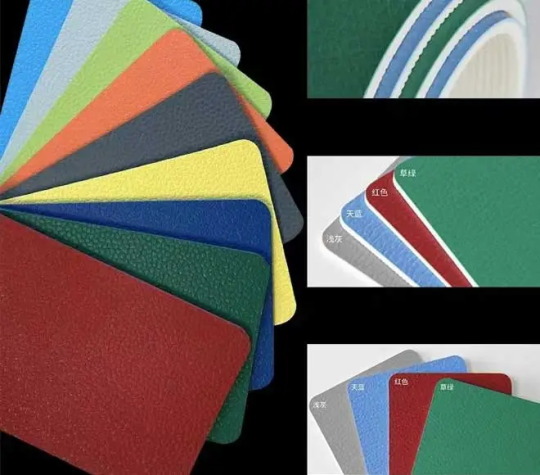

2. Color: Epoxy flooring is available in a wide range of colors. This allows businesses to choose a color that matches their brand or the aesthetic of their facility.

3. Patterns and Designs: Epoxy flooring can be customized with different patterns and designs. This can include simple geometric patterns, company logos, or more complex designs.

1 note

·

View note