Don't wanna be here? Send us removal request.

Photo

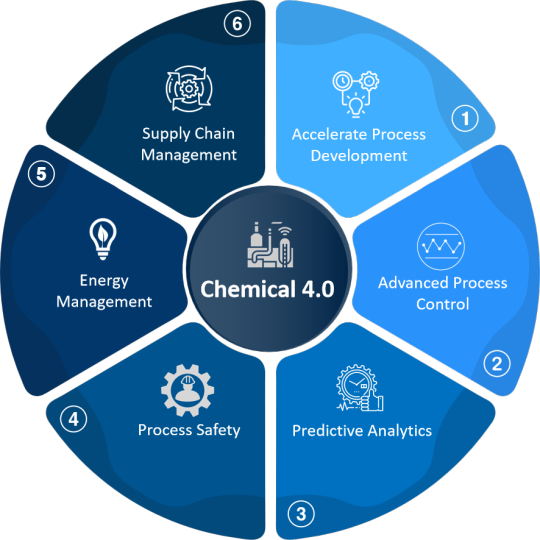

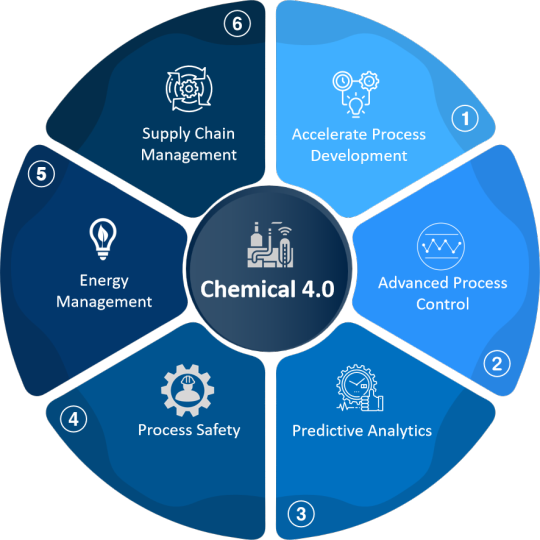

Chemical 4.0 for Process Industry to implement Manufacturing Excellence and Digital Transformation Solutions

0 notes

Text

Chemical 4.0 for Process Industry to implement Manufacturing Excellence and Digital Transformation Solutions

Tridiagonal Solutions Chemical 4.0 practice leverages Industry 4.0 tech stacks to implement Manufacturing Excellence and Digital Transformation solutions. We bring a combination of tools, techniques, expertise, and solutions to support various initiatives (such as APM, APC, Digital Twin, Remote monitoring, Sustainability, etc.) of our customers. As a part of Chemical 4.0/ Industry 4.0 implementation, we act as an Owners consultant to assist/guide through the entire roadmap.

Learn more about Chemical 4.0 for Process Industry @ https://dataanalytics.tridiagonal.com/

The Roadmap to Chemical 4.0

EVALUATE DIGITAL READINESS:

The roadmap to Chemical 4.0 for process industry starts by doing the assessment studies of underlying infrastructure, auditing data for its availability, quality, consistency & completeness and overall digital maturity of the teams (production, process, maintenance, IT, etc.). The current workflows of data (for e.g. manual data logging, offline excel sheets for calculations, manual reporting, etc.) are understood for automation needs.

IDENTIFYING THE GAPS AND PRIORITIZATION MATRIX:

Once the data audit is done, the gaps in data requirements are identified; keeping in mind the end objectives such as predictive analytics, Critical KPI monitoring, Energy monitoring & Sustainability needs. The data generation through additional sensor deployment is identified. The data integration needs (Historians, Datalake, Cloud migration, etc.) are finalized. The prioritization matrix is prepared keeping the business objectives and the impact/ROI analysis. The roadmap for digital transformation with milestones is finalized with all the stakeholders.

DEPLOYING THE RIGHT USE CASES AND SOLUTIONS:

The prioritization matrix gives the deployment roadmap and areas to focus on a short term, mid-term and long-term perspectives. The solutions are selected based-on the end objectives, end consumers of data analytics, scalability, adoption strategy.

For e.g.

Asset Performance Management (APM) – Condition-based monitoring, Predictive Maintenance, Real-time KPI-predictions, etc.

Advanced Process Control – To perform closed-loop implementations and automated process management

Energy Management

Process Safety

Remote monitoring of the entire plant.

Deriving Business KPIs

Futuristic use cases

CULTURAL TRANSFORMATION AND UPSKILLING

The success of Chemical 4.0 solutions for process industry depends on the people who are going to consume these solutions. The Culture transformation is an integral element of Chemical 4.0 deployments. Once the gaps in tools/skills are identified, we prepare a customized ‘Bridge the Gap’ program for upskilling the entire stakeholders. The upskilling is a continuous process along the entire process of digital transformation.

Get your Queries Solved @ https://dataanalytics.tridiagonal.com/contact-us/

0 notes

Text

Solution for Manufacturing Data Analytics and Data Science Services

Tridiagonal Solutions Process Analytics Group supports Data Science and Manufacturing Data Analytics initiatives of the organizations through its Guided Analytics Services & Solutions Framework. This framework enables organizations to devise KPI-based analytics strategy and selection of the right approach/methods/solutions for successful implementation at an enterprise level.

Read more here: https://dataanalytics.tridiagonal.com/consulting/

We fill the gap in terms of skillsets, know how and best practices in the data analytics space and help companies to get started in their data analytics journey. Our multi-skill teams consist of Domain experts in Chemical / Mechanical engineering with strong industry exposure in Oil & Energy, Chemicals, Pharmaceuticals, Metals & Mining, Cement sectors. The essential combination of data engineers, data scientists, and application engineers is instrumental in implementing data analytics solutions at our customer's end. We have a suite of solutions (Data analytics platform), which we implement as a part of our services.

Today most of the manufacturing data analytics is in the form of monitoring (what is happening) the current state of the system/ process or historical data investigation (What has happened); trying to understand the events. The basic application of statistics (such as covariance/ correlation) helps in doing deterministic analysis such as root cause analysis of the past events and identifying ‘Why’ such events happened.

There are different applications of data science and analytics, which can help in performing various levels of analytics from diagnostics to probabilistic to augmented data modeling. The Machine learning techniques and application of the right methods can unlock the data and give meaningful insights. However, to realize the benefits of this technology, the organizations need to have the right ‘Analytics Strategy’, skills, methods, and right solutions.

Following are the service offerings

Core Data Science Group - ML Modeling Center

Analytics implementation Strategy – Roll-out plan with Returns on Analytics (ROA)

Building Analytics & Data-driven models for various applications (processes) – Model construction, application or validation and implementation – Lab/ R&D, Process Dev., Manufacturing, Supply chain, etc.

Department-level Value creation (Lab, Process R&D/ Dev., Quality, Operations)

Augmented modeling for complex processes (Mechanistic + Data-driven), working with SMEs for advanced analytics (level 4, 5)

Custom Application for a specific purpose – Templatizing Analytics

Model Management & Tuning – Enhancing the value of models

Knowledge-creation and building Analytics Culture / Champions – Analytics Transformation

Center of Analytics (COA) – Management of Data Insights

Extended team for Data Mining and Manufacturing Data Analytics – Managing multiple plants/ assets

Dynamic reports and KPI/dashboards for global department heads (Asset-level/ Process level) – R&D, Quality, Operations, maintenance, CXOs

Working with Plant / Operations head-on Operational effectiveness and productivity analytics

Working with MSAT team on Process & Optimization Projects using Data Modeling & Analytics

Back-end ‘Analytics Production Team’ to the Data Science/ Digitalization leaders

Establishment of Best Practices for Data Analytics

Knowledge-building Workshops

Hands-on training on Data Analytics – Data Preparation & Pre-processing – Data Cleansing, Conditioning, descriptive statistics

Feature identification, reduction, Covariance methods

How to create Data Twin – System / Process representation for data modeling/ Analytics

Model construction, application / validation and implementation – Right Methods (Use case-specific)

Best Practices or Guide & Methods for Manufacturing Data Analytics

Advanced Data modeling techniques on your data and results

Data Analytics Solution (Software) – Implementation

Providing Industry leader – Advanced Analytics Solution

Proof-of Value development for Seeq evaluation

Configuration & Implementation Plan and Global roll-out

Establishing Logical Data Lake using Seeq Cortex Server

Training / Support post-implementation

Custom Application / Dashboards Development using Seeq API/SDK

Remote monitoring and KPI-driven dashboard creation for plants

Ask your query and talk to an expert here @ https://dataanalytics.tridiagonal.com/contact-us/

0 notes

Link

80-20 rule is a metric to be applied in analyzing the efforts, investment, approach, weightage during different stages of a Data Science or Analytics implementation projects. Know how 80-20 Principle is a key metric to apply in Manufacturing Data Analytics.

#80-20 Principle#Manufacturing Data Analytics#Data Analytics#Chemical 4.0#Process Analytics#Process Industry

0 notes

Link

Tridiagonal Solutions Process Analytics Group, supports Data Science and Manufacturing Data Analytics initiatives of the organizations through its Guided Analytics Services & Solutions Framework. This framework enables organization to devise KPI-based analytics strategy and selection of right approach / methods / solutions for successful implementation at an enterprise level.

0 notes

Link

#Monitor the Assets#Assets Performance Monitoring#Assets Monitoring#Pilot Guided Data Analytics#Manufacturing Data Analytics#Process Data Analytics#Chemical 4.0

0 notes

Link

Monitoring becomes a prominent approach when we are looking into the real-time variability analysis, but what signal to monitor, comes either from SMEs or through applying advanced ML/AI models. Advanced ML (supervised or unsupervised) helps us to identify the important KPIs depending upon the behavior of the data.

0 notes

Link

Soft-sensors are the key metric that dictates the efficiency and performance of any process or asset. The evaluation of these parameters becomes a necessity when monitoring the real-time performance of the system and enabling future predictions for failure prevention and performance assessment.

1 note

·

View note