#Chemical4.0 ChemicalIndustry Industry4.0 ManufacuringExcellence DigitalTransformation Chemical4.0forProcessIndustry ProcessIndustry RoadMa

Explore tagged Tumblr posts

Text

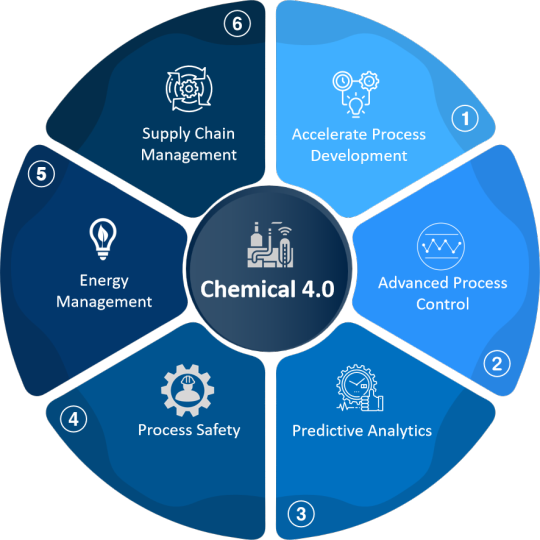

Chemical 4.0 for Process Industry to implement Manufacturing Excellence and Digital Transformation Solutions

Tridiagonal Solutions Chemical 4.0 practice leverages Industry 4.0 tech stacks to implement Manufacturing Excellence and Digital Transformation solutions. We bring a combination of tools, techniques, expertise, and solutions to support various initiatives (such as APM, APC, Digital Twin, Remote monitoring, Sustainability, etc.) of our customers. As a part of Chemical 4.0/ Industry 4.0 implementation, we act as an Owners consultant to assist/guide through the entire roadmap.

Learn more about Chemical 4.0 for Process Industry @ https://dataanalytics.tridiagonal.com/

The Roadmap to Chemical 4.0

EVALUATE DIGITAL READINESS:

The roadmap to Chemical 4.0 for process industry starts by doing the assessment studies of underlying infrastructure, auditing data for its availability, quality, consistency & completeness and overall digital maturity of the teams (production, process, maintenance, IT, etc.). The current workflows of data (for e.g. manual data logging, offline excel sheets for calculations, manual reporting, etc.) are understood for automation needs.

IDENTIFYING THE GAPS AND PRIORITIZATION MATRIX:

Once the data audit is done, the gaps in data requirements are identified; keeping in mind the end objectives such as predictive analytics, Critical KPI monitoring, Energy monitoring & Sustainability needs. The data generation through additional sensor deployment is identified. The data integration needs (Historians, Datalake, Cloud migration, etc.) are finalized. The prioritization matrix is prepared keeping the business objectives and the impact/ROI analysis. The roadmap for digital transformation with milestones is finalized with all the stakeholders.

DEPLOYING THE RIGHT USE CASES AND SOLUTIONS:

The prioritization matrix gives the deployment roadmap and areas to focus on a short term, mid-term and long-term perspectives. The solutions are selected based-on the end objectives, end consumers of data analytics, scalability, adoption strategy.

For e.g.

Asset Performance Management (APM) – Condition-based monitoring, Predictive Maintenance, Real-time KPI-predictions, etc.

Advanced Process Control – To perform closed-loop implementations and automated process management

Energy Management

Process Safety

Remote monitoring of the entire plant.

Deriving Business KPIs

Futuristic use cases

CULTURAL TRANSFORMATION AND UPSKILLING

The success of Chemical 4.0 solutions for process industry depends on the people who are going to consume these solutions. The Culture transformation is an integral element of Chemical 4.0 deployments. Once the gaps in tools/skills are identified, we prepare a customized ‘Bridge the Gap’ program for upskilling the entire stakeholders. The upskilling is a continuous process along the entire process of digital transformation.

Get your Queries Solved @ https://dataanalytics.tridiagonal.com/contact-us/

0 notes