#x ray fluorescence analyser

Explore tagged Tumblr posts

Text

Integrated NDE Solution in Pune: Pioneering Positive Material Identification for Quality Control and Safety Compliance

In the modern industrial landscape, ensuring the integrity and composition of materials is crucial for maintaining quality control and safety compliance. Positive Material Identification (PMI) is an essential non-destructive method used to verify the chemical composition of materials. Integrated NDE Solution in Pune offers comprehensive PMI services, utilizing advanced technologies such as X-Ray Fluorescence (XRF) analyzers and Optical Emission Spectroscopy (OES). This article delves into the intricacies of PMI, its benefits, and the cutting-edge services provided by Integrated NDE Solution.

Understanding Positive Material Identification

Positive Material Identification (PMI) is a non-destructive testing method used to verify the alloy composition of materials. PMI ensures that the materials used in manufacturing processes meet the specified chemical composition, thereby maintaining product quality and safety standards. This verification process is crucial for industries where material composition directly impacts performance, reliability, and safety, such as aerospace, oil and gas, power generation, and pharmaceuticals.

Importance of Positive Material Identification

Quality Control: Ensures that materials conform to the required specifications, maintaining the integrity and quality of the final product.

Safety Compliance: Verifies that materials meet industry safety standards, reducing the risk of failures and accidents.

Material Verification: Confirms the correct alloy composition of materials, preventing mix-ups and ensuring proper material usage.

Regulatory Compliance: Helps industries adhere to stringent regulatory requirements and standards.

Cost Savings: Prevents costly material failures and recalls by ensuring the correct material is used from the start.

How Positive Material Identification Works

Positive Material Identification is typically conducted using two main technologies: X-Ray Fluorescence (XRF) and Optical Emission Spectroscopy (OES).

X-Ray Fluorescence (XRF) Analyzers

XRF analyzers use X-rays to excite the atoms in a sample, causing them to emit secondary (fluorescent) X-rays. These fluorescent X-rays are characteristic of the elements present in the sample, allowing for a semi-quantitative chemical analysis. The key steps in the XRF process are:

Preparation: The surface of the material is cleaned to ensure accurate readings.

Excitation: The XRF device directs X-rays at the material, exciting the atoms within the sample.

Detection: The device detects the emitted fluorescent X-rays and measures their energy levels.

Analysis: The energy levels correspond to specific elements, allowing for the identification of the material's composition.

Optical Emission Spectroscopy (OES)

OES involves exciting the atoms in a sample using a high-energy spark or arc, causing them to emit light. The emitted light is then analyzed to determine the material's composition. The key steps in the OES process are:

Preparation: The surface of the material is cleaned and sometimes ground to create a flat, uniform surface.

Excitation: The OES device generates a spark or arc that excites the atoms in the material.

Detection: The emitted light is collected and passed through a spectrometer.

Analysis: The spectrometer measures the wavelengths of the emitted light, which correspond to specific elements, allowing for precise material identification.

Benefits of Positive Material Identification

Non-Destructive: PMI does not damage or alter the material being tested.

Accurate: Provides precise and reliable identification of alloy composition.

Quick and Efficient: Delivers immediate results, enabling rapid decision-making.

Versatile: Applicable to a wide range of materials, including metals and alloys.

Portable: PMI equipment is often portable, allowing for on-site testing.

Integrated NDE Solution in Pune: Leaders in Positive Material Identification

Integrated NDE Solution in Pune is a leader in non-destructive testing, offering a broad spectrum of services, including Positive Material Identification. Their expertise, state-of-the-art equipment, and commitment to quality make them a trusted partner for industries requiring reliable material verification.

Comprehensive NDT Services Offered

Positive Material Identification (PMI)

Remote Visual Inspection (RVI)

Magnetic Particle Inspection (MPI)

Ultrasonic Testing (UT)

Radiographic Testing (RT)

Liquid Penetrant Testing (LPT)

Eddy Current Testing (ECT)

Portable Hardness Testing

Ferrite Testing

Industries Served

Integrated NDE Solution in Pune caters to a diverse array of industries, including:

Aerospace: Ensuring the safety and reliability of aircraft components.

Automotive: Inspecting critical parts to prevent failures.

Construction: Verifying the integrity of structural components.

Oil and Gas: Ensuring the reliability of pipelines and equipment.

Power Generation: Maintaining the integrity of infrastructure components.

Pharmaceuticals: Verifying the composition of materials used in drug manufacturing.

Positive Material Identification in Action

Case Study: Oil and Gas Pipeline Inspection

In the oil and gas industry, the reliability of pipelines is crucial. Integrated NDE Solution was approached by a leading oil and gas company to conduct PMI on pipeline materials. Using advanced XRF analyzers, the team verified the alloy composition of the pipeline materials, ensuring they met the specified standards for corrosion resistance and mechanical strength. The inspection helped prevent potential failures and ensured the safety and reliability of the pipeline network.

Case Study: Aerospace Component Verification

A major aerospace manufacturer required PMI for critical components used in aircraft engines. Integrated NDE Solution employed both XRF and OES technologies to verify the alloy composition of the components. The precise identification confirmed that the materials met the stringent specifications required for aerospace applications, ensuring the safety and performance of the aircraft engines.

Advanced Positive Material Identification Equipment

Integrated NDE Solution in Pune utilizes the latest PMI equipment to ensure the highest level of accuracy and reliability in their inspections. Some of the advanced equipment includes:

Handheld XRF Analyzers: Portable devices that provide rapid, on-site analysis of alloy composition.

Stationary XRF Analyzers: High-precision instruments used for detailed laboratory analysis.

Mobile OES Units: Portable units that offer precise material identification in the field.

Stationary OES Systems: Advanced systems used for comprehensive laboratory analysis of materials.

The Role of Certified Technicians

The effectiveness of Positive Material Identification largely depends on the expertise of the technicians conducting the tests. Integrated NDE Solution in Pune employs certified technicians who undergo rigorous training and continuous professional development. Their skills and knowledge ensure that clients receive the highest quality of service.

Commitment to Quality and Safety

Integrated NDE Solution in Pune is dedicated to maintaining the highest standards of quality and safety. They adhere to international standards and best practices, ensuring that all inspections are performed with utmost precision and reliability. This commitment to excellence has earned them a stellar reputation in the industry.

Customer-Centric Approach

At Integrated NDE Solution in Pune, customer satisfaction is a top priority. They work closely with clients to understand their specific needs and tailor their services accordingly. Whether it’s a small-scale inspection or a large industrial project, they provide personalized solutions that meet the highest standards of quality and reliability.

Why Choose Integrated NDE Solution in Pune?

Expertise: Extensive experience and technical know-how in NDT services.

Technology: Utilization of the latest and most advanced testing equipment.

Quality: Commitment to providing accurate and reliable results.

Customer Service: Focus on building long-term relationships through excellent service.

Compliance: Adherence to all relevant industry standards and regulations.

Conclusion

In industries where precision and reliability are non-negotiable, Integrated NDE Solution in Pune stands out as a leader in non-destructive testing, particularly in Positive Material Identification. Their dedication to quality, use of advanced technology, and customer-centric approach make them the go-to choice for businesses across various sectors. By partnering with Integrated NDE Solution, companies can ensure the integrity and safety of their materials and components, safeguarding their operations and reputation.

Integrated NDE Solution in Pune continues to set the standard for excellence in non-destructive inspection. Their expertise in Positive Material Identification and other NDT services is pivotal in industries where safety and reliability are crucial. As technology advances and industries evolve, Integrated NDE Solution remains at the forefront, offering unparalleled service and support to their clients.

In conclusion, for businesses seeking the highest standards in Positive Material Identification, alloy composition verification, and comprehensive NDT services, Integrated NDE Solution in Pune is the trusted partner that delivers results. Their innovative approach, advanced technology, and unwavering commitment to quality ensure that every inspection meets the stringent requirements of today’s demanding industrial environments.

#positive material identification#alloy composition#non destructive method#semi quantitative chemical analysis#material verification#material identification#quality control#safety compliance#x ray fluorescence analyser#optical emission spectroscopy

0 notes

Text

https://www.databridgemarketresearch.com/jp/reports/global-x-ray-fluorescence-analyser-market

0 notes

Text

Stationary Metal Analysers: A Powerful Tool for Metal Analysis

Stationary metal analysers are indispensable instruments in industries requiring precise metal analysis. These devices provide highly accurate results, ensuring the quality and composition of metals used in manufacturing, construction, and other sectors.

Key Features of Stationary Metal Analysers

High Accuracy: These analysers deliver reliable results with minimal error, crucial for industries requiring precision.

Wide Application: Ideal for ferrous and non-ferrous metals, these tools are used in foundries, steel plants, and metal processing facilities.

Durability: Designed for stationary use, they are robust and suitable for continuous operation.

Advanced Technology: Equipped with Optical Emission Spectrometry (OES) or X-ray fluorescence (XRF) technology, they ensure precise measurements of metal composition.

Benefits of Using Stationary Metal Analysers

Efficiency: Quick analysis saves time in production processes.

Quality Control: Ensures that materials meet industry standards and specifications.

Cost-Effectiveness: Prevents waste by detecting impurities early in the process.

Applications

Stationary metal analysers are extensively used in sectors like:

Aerospace and automotive industries.

Metal recycling plants.

Research laboratories.

Manufacturing units focusing on alloy production.

Final Word

Stationary metal analysers play a crucial role in ensuring the accuracy and reliability of metal analysis. Their precision, durability, and efficiency make them a must-have for any industry dealing with metals. Invest in a stationary metal analyser today to enhance your operational excellence!

Looking for reliable and advanced solutions? Metal Power offers high-quality stationary metal analysers tailored to your needs. Contact Metal Power now to elevate your metal analysis processes!

0 notes

Text

How Do Toy Product Testers Assess the Use of Non-Toxic Paints and Materials?

Toys are an integral part of childhood, sparking creativity and imagination in children all over the world. However, ensuring that toys are safe to use is of paramount importance. One of the most critical aspects of toy safety involves the materials used, particularly the paints and coatings applied to toys. Many paints and materials contain chemicals that may be harmful to children, especially when they come in contact with skin or are ingested.

Toy product testers are responsible for assessing whether toys meet safety standards for non-toxic paints and materials. In this blog, we will explore the methods and processes toy product tester use to evaluate the use of non-toxic paints and materials in toys. We will also discuss why this testing is essential for ensuring the safety of children.

1. Why Is Testing for Non-Toxic Paints and Materials Important?

Children often place toys in their mouths, rub them against their skin, or come into close contact with them during play. As a result, it is crucial to ensure that the materials and paints used in toys are free from harmful chemicals that could pose health risks. Some of the toxic substances commonly found in paints and materials include:

Lead: A neurotoxin that can cause developmental delays, cognitive impairments, and behavioral problems.

Cadmium: A metal that can cause kidney damage and other health issues when ingested.

Phthalates: Chemicals used to soften plastics that can disrupt hormone function and lead to reproductive health problems.

Formaldehyde: A carcinogen that can cause respiratory issues and skin irritation.

To mitigate these risks, regulatory bodies like the Consumer Product Safety Commission (CPSC) in the U.S. and the European Union Toy Safety Directive set strict guidelines for toy manufacturers regarding the use of non-toxic materials. Toy product testers play a vital role in ensuring that toys adhere to these safety standards.

2. How Toy Product Testers Assess Non-Toxic Paints and Materials

Toy product testers follow a detailed, systematic process to assess whether the paints and materials used in toys are non-toxic. Below are the primary methods they use to evaluate these substances.

1. Chemical Analysis of Paints and Materials

One of the most critical steps in testing for non-toxic paints and materials is conducting chemical analyses to identify harmful substances. Toy testers use advanced laboratory techniques to detect and quantify the presence of toxic chemicals in the paint and materials used in toys. Here are some of the common methods used:

Gas Chromatography-Mass Spectrometry (GC-MS): GC-MS is a sophisticated analytical technique used to identify and quantify the chemical composition of substances. Toy testers use GC-MS to detect the presence of harmful chemicals, such as phthalates and formaldehyde, in paints and materials.

Inductively Coupled Plasma Mass Spectrometry (ICP-MS): ICP-MS is used to measure trace amounts of metals, such as lead and cadmium, in toy materials. It can detect metals at incredibly low concentrations, ensuring compliance with safety standards.

High-Performance Liquid Chromatography (HPLC): HPLC is another technique used to analyze the presence of harmful chemicals in toys. It is particularly useful for testing plastics and other synthetic materials used in toy manufacturing.

These chemical analyses ensure that no harmful substances are present in the paints and materials used in toys, and help verify that the toys comply with safety regulations.

2. Surface Testing for Toxicity

In addition to chemical analyses, toy product testers perform surface testing to assess the safety of paints and coatings. Since children often place toys in their mouths, it is essential to ensure that the outer layer of toys is free from harmful chemicals that could be transferred to the skin or ingested.

X-Ray Fluorescence (XRF): XRF testing is a non-invasive technique that allows toy testers to detect heavy metals on the surface of toys without damaging the product. This method is particularly useful for testing the paint on toys, as it can quickly identify the presence of lead, cadmium, or other toxic metals.

Leaching Tests: In some cases, toy testers conduct leaching tests to evaluate the potential for toxic substances to be released from the paint or material when exposed to saliva or moisture. These tests simulate conditions children may encounter, ensuring that no harmful substances leach from the toy during use.

These surface testing methods are crucial in evaluating the overall safety of painted toys, ensuring that any potential contact with toxic substances is minimized.

3. Compliance with Safety Standards

Toy product testers also assess the use of non-toxic paints and materials by evaluating whether toys comply with relevant safety standards and regulations. These standards set limits on the amount of toxic substances that can be present in toys and require that manufacturers use non-toxic materials in the production process. Some of the key safety standards that toy product testers consider include:

ASTM F963: This standard, set by the American Society for Testing and Materials (ASTM), outlines safety requirements for toys sold in the U.S. It includes specific guidelines regarding the use of non-toxic materials and paints, setting limits on the presence of harmful chemicals like lead, phthalates, and cadmium.

European Toy Safety Directive (EN71): The EN71 standard applies to toys sold in the European Union and includes similar requirements for non-toxic materials. Toy product testers evaluate whether the paint and materials used in toys meet these rigorous safety guidelines.

ISO 8124: This is an international standard that sets safety requirements for toys, including regulations on non-toxic paints and materials. Toy product testers check if toys adhere to ISO 8124 to ensure their safety and compliance with international regulations.

By evaluating whether toys comply with these standards, product testers ensure that manufacturers are using non-toxic materials and paints in accordance with global safety guidelines.

4. Toxicology Testing

Toxicology testing is another essential aspect of assessing the safety of paints and materials in toys. In this type of testing, toy product testers analyze the potential health risks posed by the materials used in toys, such as the risk of poisoning or allergic reactions.

Oral Toxicity Testing: This test simulates the potential for a child to ingest harmful substances from a toy by evaluating how toxic the material is if ingested. It helps identify any substances in the toy that could be dangerous if swallowed.

Dermal Toxicity Testing: This test assesses the potential for skin irritation or allergic reactions caused by contact with the toy. Toy testers evaluate whether any harmful chemicals in the paint or material could cause a rash, burns, or other skin conditions.

These toxicology tests provide additional assurance that the materials and paints used in toys are safe for children and pose no significant health risks.

3. Why Is Non-Toxic Paint and Material Testing Essential for Toy Safety?

Testing for non-toxic paints and materials is crucial for ensuring that toys are safe for children to use. Given that children often put toys in their mouths and have delicate, developing bodies, it is essential to minimize their exposure to harmful chemicals. Non-toxic paints and materials help prevent health issues such as lead poisoning, skin irritation, allergic reactions, and long-term developmental problems.

Moreover, with an increasing demand for safer, environmentally-friendly products, consumers are becoming more conscious of the materials used in toys. Manufacturers who prioritize non-toxic paints and materials and undergo rigorous testing build consumer trust and enhance their brand reputation.

4. Conclusion

Toy product testers play a vital role in assessing the use of non-toxic paints and materials in toys. Through advanced testing methods such as chemical analysis, surface testing, compliance checks, and toxicology evaluations, they ensure that toys meet strict safety standards and do not contain harmful substances. These tests help prevent health risks and ensure that toys are safe for children, offering parents peace of mind when selecting toys for their kids.

By adhering to safety regulations and using non-toxic materials, manufacturers can contribute to a safer, healthier environment for children, promoting the development of safe, fun, and environmentally-conscious toys.

#toy product tester#toy product testers#toy testing#toy testing lab#testing labs#testing lab near me

0 notes

Text

What to Expect from a RoHS Testing Lab in Abu Dhabi: A Comprehensive Guide | +971 554747210

In today’s global marketplace, businesses in the electronics industry must adhere to a variety of standards and regulations to ensure that their products are safe, reliable, and environmentally friendly. One of the most critical compliance requirements for electronics manufacturers and exporters is RoHS (Restriction of Hazardous Substances), a directive that restricts the use of certain hazardous materials in electronic and electrical equipment. RoHS compliance is crucial for gaining access to global markets, especially in regions like the European Union (EU), where strict environmental regulations are enforced.

For manufacturers based in Abu Dhabi, working with a reputable RoHS testing lab is essential to ensure that their products meet the required safety standards. In this comprehensive guide, we will explore what you can expect when working with a RoHS testing lab in Abu Dhabi, the benefits of certification, and how it can help your business stay ahead in the competitive electronics market.

What is RoHS Testing?

Before diving into what to expect from a RoHS testing lab, it’s essential to understand the basics of RoHS testing. RoHS is a regulation that limits the use of six hazardous substances in electronic and electrical products. These substances are:

Lead (Pb)

Mercury (Hg)

Cadmium (Cd)

Hexavalent Chromium (Cr6+)

Polybrominated Biphenyls (PBB)

Polybrominated Diphenyl Ethers (PBDE)

RoHS testing ensures that electronic products do not exceed the allowed limits of these substances, promoting safer products and a healthier environment. RoHS testing labs perform detailed analyses to verify whether products comply with these limits, ensuring manufacturers meet the requirements of this regulation.

The Role of RoHS Testing Labs in Abu Dhabi

RoHS testing labs in Abu Dhabi play a pivotal role in helping electronics manufacturers achieve compliance with global environmental standards. As Abu Dhabi is a central business hub with a growing electronics manufacturing sector, it is important for businesses to ensure that their products meet both local and international regulations. Here’s what you can expect from a RoHS testing lab in Abu Dhabi:

1. Comprehensive Testing Services

A reputable RoHS testing lab in Abu Dhabi will offer a wide range of testing services to ensure that your products meet RoHS standards. These tests are designed to detect the presence of the six restricted substances in various materials used in electronics products, such as circuit boards, connectors, plastics, and cables. Depending on the product, labs may use techniques like X-ray fluorescence (XRF), Inductively Coupled Plasma Mass Spectrometry (ICP-MS), and Atomic Absorption Spectroscopy (AAS) for precise analysis.

Testing labs will analyze your product components thoroughly, often breaking down each part to test for the presence of harmful chemicals. The results will provide manufacturers with a clear understanding of whether their products meet RoHS limits or if changes are needed before market release.

2. Expert Consultation and Guidance

RoHS compliance can be complex, especially for businesses that are new to the requirements. When you work with a RoHS testing lab in Abu Dhabi, you can expect to receive expert consultation and guidance throughout the process. These labs are staffed with professionals who are highly knowledgeable about the RoHS directive and the various testing methods used to ensure compliance.

Consultation services typically include:

Assistance in understanding RoHS requirements: The testing lab can help you navigate the various aspects of RoHS compliance, including how to interpret the results of the tests.

Recommendations for product improvement: If your products do not meet the RoHS standards, experts can provide suggestions on how to reformulate or redesign your products to comply.

Guidance on documentation and reporting: RoHS compliance often requires documentation and certification, which testing labs can assist with. This ensures that you have the necessary paperwork to demonstrate compliance during audits or regulatory inspections.

3. Fast and Accurate Results

In today’s fast-paced business world, time is a critical factor. RoHS testing labs in Abu Dhabi are equipped with advanced tools and technologies that allow them to deliver quick and accurate test results. This is especially important for manufacturers with tight production schedules or deadlines for product releases.

Many labs also offer expedited services, ensuring that your products can undergo testing and certification without causing delays in production. These fast turnaround times allow manufacturers to meet customer demand and stay competitive in the market.

4. Cost-Effective Solutions

While RoHS testing is essential, it is also important to keep costs manageable. Testing labs in Abu Dhabi offer cost-effective solutions to help businesses comply with RoHS without overspending. By choosing a local lab, manufacturers can avoid the high shipping costs and long waiting times associated with sending products abroad for testing.

Furthermore, investing in RoHS testing upfront can help prevent expensive product recalls or regulatory fines in the future. When you test your products early in the development process, you reduce the risk of non-compliance and the associated financial and reputational damage.

5. RoHS Certification

Once a product passes RoHS testing, the testing lab will provide a RoHS compliance certificate. This certification is a valuable asset for electronics manufacturers, as it demonstrates that their products are compliant with international standards. The certificate is also essential when exporting products to markets that require RoHS compliance, such as the EU, U.S., and Japan.

Having RoHS certification enhances your brand’s credibility and reassures customers and regulators that your products are safe and environmentally friendly. It also gives you a competitive edge in the market, as more consumers and businesses are prioritizing sustainability in their purchasing decisions.

The Benefits of Using a RoHS Testing Lab in Abu Dhabi

1. Compliance with Global Regulations

As an electronics manufacturer in Abu Dhabi, it is crucial to meet international regulations like RoHS, especially if you plan to export products worldwide. RoHS compliance is a requirement in the European Union, United States, and many other global markets. By testing your products with a RoHS testing lab in Abu Dhabi, you ensure that your products are ready for export and can reach these international markets without delays.

2. Environmental Responsibility

The goal of the RoHS directive is to reduce the environmental impact of electronics waste. By working with a RoHS testing lab, you can contribute to a more sustainable future by ensuring that your products do not contain hazardous substances that can harm the environment. This aligns with the growing consumer demand for environmentally responsible products and strengthens your brand’s commitment to sustainability.

3. Minimized Risk of Product Recalls

Non-compliance with RoHS regulations can result in costly product recalls, which can damage your reputation and lead to significant financial losses. By investing in RoHS testing before releasing your products to market, you minimize the risk of recalls and ensure that your products are safe for consumers and compliant with regulations.

Conclusion

Choosing a RoHS testing lab in Abu Dhabi is a critical step for electronics manufacturers who want to stay competitive, compliant, and environmentally responsible. These labs provide comprehensive testing services, expert guidance, and fast, accurate results to help businesses meet global RoHS standards. By working with a RoHS testing lab in Abu Dhabi, you can ensure that your products are ready for export, enhance your brand’s reputation, and contribute to a more sustainable future.

With the ever-growing demand for safe, environmentally friendly electronics, partnering with a trusted RoHS testing lab will give you the confidence to navigate regulatory challenges and expand your reach in the global marketplace.

0 notes

Text

0 notes

Text

Fuel Sulfur Content Detector Market Industry Outlook, Size, Share, Growth, Trend and Forecast to 2031

Fuel Sulfur Content Detector Market

The latest study released on the Global Fuel Sulfur Content Detector Market by Market Strides, Research evaluates market size, trend, and forecast to 2032. The Fuel Sulfur Content Detector Market consider covers noteworthy inquire about information and proofs to be a convenient asset record for directors, investigators, industry specialists and other key people to have ready-to-access and self-analysed study to help understand market trends, growth drivers, openings and up and coming challenges and approximately the competitors.

Some of the key players profiled in the study are:

Malvern Panalytical Ltd

Hitachi High-Tech Analytical Science

Olympus Corporation

LANScientific Co.Ltd.

Danaher Corporation

Jiangsu Skyray Instrument Company

Thermo Scientific

Rigaku

Get Free Sample Report PDF @ https://marketstrides.com/request-sample/fuel-sulfur-content-detector-market

Scope of the Report of Fuel Sulfur Content Detector Market :

The report also covers several important factors including strategic developments, government regulations, market analysis, and the profiles of end users and target audiences. Additionally, it examines the distribution network, branding strategies, product portfolios, market share, potential threats and barriers, growth drivers, and the latest industry trends.

Keep yourself up-to-date with latest market trends and changing dynamics due to COVID Affect and Economic Slowdown globally. Keep up a competitive edge by measuring up with accessible commerce opportunity in Fuel Sulfur Content Detector Market different portions and developing territory.

The titled segments and sub-section of the market are illuminated below:

By Type

X-ray Fluorescence

Ultraviolet Fluorescence

By Application

Diesel

Gasoline

Kerosene

Natural Gas

Other

Get Detailed@ https://marketstrides.com/report/fuel-sulfur-content-detector-market

Geographically, the detailed analysis of consumption, revenue, market share, and growth rate of the following regions:

• The Middle East and Africa (South Africa, Saudi Arabia, UAE, Israel, Egypt, etc.)

• North America (United States, Mexico & Canada)

• South America (Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, etc.)

• Europe (Turkey, Spain, Turkey, Netherlands Denmark, Belgium, Switzerland, Germany, Russia UK, Italy, France, etc.)

• Asia-Pacific (Taiwan, Hong Kong, Singapore, Vietnam, China, Malaysia, Japan, Philippines, Korea, Thailand, India, Indonesia, and Australia).

Objectives of the Report:

•To carefully analyze and forecast the size of the Fuel Sulfur Content Detector Market by value and volume.

• To estimate the market shares of major segments of the Fuel Sulfur Content Detector Market

• To showcase the development of the Fuel Sulfur Content Detector Market in different parts of the world.

• To analyze and study micro-markets in terms of their contributions to the Fuel Sulfur Content Detector Market, their prospects, and individual growth trends.

• To offer precise and useful details about factors affecting the growth of the Fuel Sulfur Content Detector Market

• To provide a meticulous assessment of crucial business strategies used by leading companies operating in the Fuel Sulfur Content Detector Market, which include research and development, collaborations, agreements, partnerships, acquisitions, mergers, new developments, and product launches.

Key questions answered:

• How feasible is Fuel Sulfur Content Detector Market for long-term investment?

• What are influencing factors driving the demand for Fuel Sulfur Content Detector Market near future?

• What is the impact analysis of various factors in the Global Fuel Sulfur Content Detector Market growth?

• What are the recent trends in the regional market and how successful they are?

Buy Fuel Sulfur Content Detector Market Research Report @ https://marketstrides.com/buyNow/fuel-sulfur-content-detector-market

The market research report on the Global Fuel Sulfur Content Detector Market has been thoughtfully compiled by examining a range of factors that influence its growth, including environmental, economic, social, technological, and political conditions across different regions. A detailed analysis of data related to revenue, production, and manufacturers provides a comprehensive view of the global landscape of the Fuel Sulfur Content Detector Market. This information will be valuable for both established companies and newcomers, helping them assess the investment opportunities in this growing market.

Region Included are: Global, North America, Europe, APAC, South America, Middle East & Africa, LATAM.

Country Level Break-Up: United States, Canada, Mexico, Brazil, Argentina, Colombia, Chile, South Africa, Nigeria, Tunisia, Morocco, Germany, United Kingdom (UK), the Netherlands, Spain, Italy, Belgium, Austria, Turkey, Russia, France, Poland, Israel, United Arab Emirates, Qatar, Saudi Arabia, China, Japan, Taiwan, South Korea, Singapore, India, Australia and New Zealand etc.

At long last, Fuel Sulfur Content Detector Market is a important source of direction for people and companies.

Thanks for reading this article; you can also get region wise report version like Global, North America, Europe, APAC, South America, Middle East & Africa, LAMEA) and Forecasts, 2024-2032

About Us:

Market Strides, a leading strategic market research firm, makes a difference businesses unquestionably explore their strategic challenges, promoting informed decisions for economical development. We give comprehensive syndicated reports and customized consulting services. Our bits of knowledge a clear understanding of the ever-changing dynamics of the global demand-supply gap across various markets.

Contact Us:

Email: [email protected]

#Fuel Sulfur Content Detector Market Size#Fuel Sulfur Content Detector Market Share#Fuel Sulfur Content Detector Market Growth#Fuel Sulfur Content Detector Market Trends#Fuel Sulfur Content Detector Market Players

0 notes

Text

Official Authentics: Your Trusted Partner in Memorabilia Verification

In an industry often plagued by counterfeits and forgeries, ensuring the authenticity of collectibles is crucial. Official Authentics.com based in Switzerland, has established itself as a trusted authority in memorabilia authentication. Their mission is to protect collectors by offering comprehensive and precise authentication services.

Official Authentics employs a meticulous, multi-step process that combines expert visual inspections with advanced scientific analyses. Their team of specialists uses state-of-the-art techniques such as carbon dating, X-ray fluorescence, and infrared spectroscopy to verify the authenticity of each item. Additionally, thorough provenance research is conducted to trace the history and ownership of the memorabilia, further ensuring its legitimacy.

0 notes

Text

The Significance of Metal Testing: Ensuring Quality and Safety

Metals are the backbone of many industries, serving as the building blocks for countless applications, from construction and manufacturing to aerospace and healthcare. The reliability and quality of these materials are paramount, as they directly impact the performance, durability, and safety of products and structures.

Ensuring the quality of metals involves a comprehensive process known as metal testing. We at Dutco Tennant LLC, are noted as a trusted name for supplying industrial equipment which also includes providing the necessary tools and solutions for efficient metal testing.

In this comprehensive blog, we shall cover the importance of metal testing process and the need for high-quality metal testing equipment.

What is Metal Testing?

Metal testing is a comprehensive process that assesses the properties and characteristics of different metals and alloys. It involves a range of techniques, from examining the composition and structure of metals to analysing their mechanical properties and determining their ability to withstand environmental conditions.

If you ever wonder why metal testing is so significant? Well, then let's delve deeper into its relevance and importance in various industries.

Quality Assurance

One of the primary purposes of metal testing is to ensure the quality of materials. Substandard or inconsistent metal can lead to structural failures, which can be catastrophic in critical applications such as aerospace, automotive, and construction. By rigorously testing metals, manufacturers can verify that the materials meet specified quality standards, ensuring product reliability and performance.

Material Selection

Selecting the right metal or alloy for a particular application is crucial. The choice of material can significantly affect the end product's durability and safety. Metal testing helps in determining the suitability of a specific metal for a given purpose, considering factors such as strength, corrosion resistance, and heat resistance. This informed selection enhances the longevity and safety of the final product.

Safety and Compliance

In industries like aerospace and automotive, safety is of utmost importance. Metal testing is a key component of safety protocols, ensuring that critical components can withstand extreme conditions, stress, and fatigue. It also ensures compliance with industry standards and regulations, which are designed to protect public safety.

Cost Reduction

Frequent equipment breakdowns or failures due to subpar materials can be costly in terms of repairs, downtime, and reputation. By investing in metal testing, companies can reduce these costs in the long run. Quality assurance through testing minimises the risk of unexpected failures, resulting in substantial savings.

Research and Development

For research and development efforts, understanding the properties of new materials and alloys is essential. Metal testing provides valuable data that researchers can use to develop innovative materials with improved performance characteristics. This is especially significant in industries like aerospace and healthcare, where lightweight yet robust materials are in high demand.

The Metal Testing Process

Metal testing encompasses a variety of techniques and methods, including:

Chemical Analysis: This involves determining the composition of a metal or alloy, including the presence of specific elements and impurities. It's essential for verifying the material's compliance with industry standards. Techniques like X-ray fluorescence (XRF) and inductively coupled plasma (ICP) spectroscopy are commonly used for chemical analysis.

Mechanical Testing: This category includes tests for strength, hardness, ductility, and more. These tests evaluate how a metal will perform under different loads and conditions.

Tensile Testing: This test measures a material's resistance to a stretching force. It helps determine the yield strength, ultimate tensile strength, and elongation of the material.

Hardness Testing: Hardness tests, such as the Brinell, Rockwell, and Vickers tests, measure a material's resistance to penetration or indentation.

Charpy and Izod Impact Tests: These tests assess a material's toughness and ability to withstand sudden impact or shock.

Fatigue Testing: Fatigue tests assess a material's performance under cyclic loading and help determine its fatigue life.

Non-Destructive Testing: Techniques like ultrasonic testing, radiography, and magnetic particle testing allow the evaluation of a material's integrity without damaging the test piece. This is particularly important in industries where preserving the integrity of a component is essential.

Ultrasonic Testing (UT): UT uses high-frequency sound waves to detect internal flaws, voids, and cracks in metals.

Magnetic Particle Testing (MT): MT uses magnetic fields and magnetic particles to identify surface and near-surface defects in ferrous materials.

Dye Penetrant Testing (PT): PT uses a coloured liquid to identify surface defects like cracks and porosity in metals.

Radiographic Testing (RT): RT employs X-rays or gamma rays to examine the internal structure of metal parts.

Metallurgical Analysis: Examining the microstructure of metals can reveal important information about their properties, such as grain size, phase composition, and the presence of defects. This involves preparing thin sections of metal samples, polishing them, and examining them under a microscope to understand the microstructure, grain size, and inclusion content of the metal.

Corrosion Testing: Assessing a metal's resistance to corrosion is crucial, especially in industries where exposure to harsh environmental conditions is common. Common methods include salt spray testing, humidity testing, and electrochemical corrosion tests.

Heat Treatment Testing: This verifies that metals have been subjected to the correct heat treatment processes, such as annealing, tempering, or quenching, to achieve the desired material properties.

Dutco Tennant LLC: Your Trusted Partner in Metal Testing

When it comes to procuring high-quality metal testing equipment, Dutco Tennant LLC is a name you can trust. As a renowned supplier and distributor of industrial equipment, we have a vast range of products and solutions to support the metal testing process.

Dutco serves as a bridge between metal tester distributors and end-users, ensuring that industries have access to advanced metal testing equipment. Our comprehensive catalogue includes a wide range of metal testing equipment from leading manufacturers.

Our team of experts can guide you in choosing the right metal testing equipment, based on your specific requirements. Whether you need to perform chemical analysis, mechanical testing, or non-destructive testing, we have the tools and expertise to meet your needs.

Conclusion

The significance of metal testing cannot be overstated in industries that rely on the quality and performance of metals. It is a crucial process for ensuring the safety, reliability, and compliance of materials used in various applications.

For those seeking reliable and high-quality metal testing equipment, Dutco Tennant LLC stands as a dependable partner. With our vast expertise and a comprehensive range of metal testing solutions, we are the go-to source for all your metal testing needs.

0 notes

Text

BLUE AMBER AND LARIMAR DOMINICAN REPUBLIC

18.10.2023.20:26, Cathy Jonathan [email protected]

Dear LARIMAR & AMBER ART.

Larimar is the trade name for blue pectolite, which has been used as a gem material for several decades. GIA first reported on Larimar in 1986 in our journal Gems & Gemology, and we published an extensive article on this material in 1989. The following article citations will provide more information about Larimar.

“Gem news: pectolite,” by Emmanuel Fritsch, Gems & Gemology, 1986 Fall; v. 22, n. 3; p. 187-177. Abstract: Pectolite is known under the trade name "Larimar."

“Blue pectolite from the Dominican Republic,” by Robert E. Woodruff and Emmanuel Fritsch, Gems & Gemology, 1989 Winter; v. 25, n. 4; p. 216-225. Abstract: "Blue pectolite from the Dominican Republic, also known by the trade name Larimar, has recently entered the U.S. market. Large quantities of this attractive ornamental stone have been found in cavities and veins of altered basalt. Most of the gemological properties are consistent with those previously reported for pectolite; the cause of color in this material is believed to be related to the presence of small amounts of Cu2+. The color appears to be stable to light, but does react to irradiation and to the heat of a jeweler's torch. It is easily separated from similar-appearing materials."--p. 216

https://www.gia.edu/gems-gemology/winter-1989-blue-pectolite-woodruff

“Atlantis Trading & Larimar, a rare blue gemstone from the Caribbean,” Bangkok Gems & Jewellery, 2001 May; v. 14, n. 10; p. 60, 62. Abstract: Larimar has a hardness of 5 to 7 on the Mohs scale. The stone is more or less translucent and its color can range from azure blue with white marbling to milky greenish shade. Larimar has only been found in a mountain region in the Dominican Republic. The name Larimar was given to the stone by a Dominican man, who named the stone after his daughter LARIssa and the Spanish word for sea: MAR.

“Gem profile: Larimar,” by David Federman, Modern Jeweler, 2009 Jan; p. 17-18. Abstract: Larimar is a sky-blue pectolite found only in the Dominican Republic.

“Gemmological research on Larimar stone from Dominica,” by Yi-Hong Xie, Journal of Gems & Gemmology, 2010; v. 12, n. 2; p. 7-10. Abstract: "The gemstone which is called Larimar occurs in the Chinese jewelry market now. The gemmological characteristics, chemical compositions, X-ray powder diffraction and infrared spectrum of the Larimar sample are analysed in the paper in order to define its mineral group. The results show that the Larimar sample is mainly composed of pectolite. The ultraviolet-visible absorption spectrum of the sample suggests that the absorption characteristic of the sample is related to Cu. It is supposed that the blue colour of Larimar probably could be caused by the diffusion of Cu-bearing sulfide distributed in pectolite according to its absorption spectrum and gemmological characteristics and chemical compositions. The definition of the mineral group of Larimar could be of significance to its identification and naming."--p. 7 Chinese text with English abstract

“Gems that inspire: Larimar,” by Jeff Prine, Watch & Jewelry Review, 2010 Mar; v. 77, n. 3; p. 18-19. Abstract: Larimar is a blue pectolite found in the Dominican Republic. Characteristics are described.

“Imitation Larimar,” by Lore Kiefert and Peter Groenenboom, Gems & Gemology, 2013, vol. 49, no. 2.

https://www.gia.edu/gems-gemology/summer-2013-gemnews-imitation-larimar

“Larimar,” by Sharon Elaine Thompson, Lapidary Journal Jewelry Artist, 2015 Nov; v. 69, n. 6; p. 38-39. Abstract: Larimar is a blue colored pectolite.

“What to cut: Caribbean Larimar,” by Russ Kaniuth, Rock & Gem, 2017 Jan; v. 47, n. 1; p. 54. Abstract: "Larimar is a very beautiful and distinctive-looking stone found in the Caribbean. The stone itself is actually a pectolite (calcium-sodium silicate); however, its blue, blue-green, and white hues, as well as the fact that it stems from one location, make it a one-of-a-kind stone. The difference in pectolites that gives larimar its distinctive blue coloring comes from the copper replacing the calcium. Although the stone was originally found over 100 years ago, it wasn't until Miguel Fuentes rediscovered it in the mid-1970s that it was introduced into the jewelry world. The stone's name combines part of his daughter Larissa's name (Lari-) and the Spanish word for "sea'' (mar). Larimar has a notorious love/hate reputation with lapidary artists: love of its beauty and hate for the difficulties of working with this material. Though it's a relatively hard material, it tends to fracture, chip, flake and break on you at the most inopportune times!"--p. 54

“Caribbean gold: Larimar,” Jewellery World (Australia), 2017 Jun; Abstract: Larimar, a sodium calcium silicate mineral possibly colored by copper, is described.

I hope this information will be helpful. If I can be of further assistance, please let me know.

Sincerely,

Cathy

Cathleen A. Jonathan, G.G. Senior Research Librarian Richard T. Liddicoat Gemological Library and Information Center T +1 760 603 4074 F +1 760 603 4256 E [email protected]

Our company Larimar & Amber Art creates unique exclusive handmade products from natural high quality larimar stone and blue amber of the Dominican Republic.

We are always the most unique exclusive creativity and the highest quality of our work and all our materials.

Welcome to the bright world of the power of magic of natural gems

LARIMAR & AMBER ART.

琥珀(こはく) C40H64O4 数千万年の気が遠くなるような時間を超えて来た松柏類などの樹脂の化石です。 英語でアンバーAmberと呼びます。

古来より琥珀は、その輝きと美しい色合い故に太陽の��、人魚の涙と呼ばれて愛されてきました。

西欧では10年目を琥珀婚とし、11月の誕生石でもあります。

琥珀はオーガニック・ジュエリー(有機質の宝石)と呼ばれる様に植物性有機物質ですから、濃い塩水に浮きます。 汗にも強く石鹸で洗っても大丈夫です。 更に天然の宝飾品としては最も軽いものの一つ言えますので、余り重さを感じさせないことも優れた特徴ではないかと思われます。 夏は肌に涼しい優しさ、冬は暖かみを感じさせてくれるソフトな感触、そして軽くて豊かな量感と魅惑的な輝きは、一度身に付けたら手放せない魅力を秘めています。

琥珀の色彩とその表情は千差万別ですから一つとして同じものはこの世に存在しません。 なかでも、幻の琥珀として、以前より注目されているのが、海のような神秘的な輝きを放つ ドミニカの青色琥珀(ブルーアンバー) です。 ブルーアンバーは、つい十数年前発見された新しい琥珀です。

ブルーアンバーは黒い布などの上で太陽光線にかざすとそれまで茶色に見えていたものが、突然、胸が踊る様な素晴らしい青色の蛍光色を発し輝き始めます。 自然の太陽光線と同じ分光分布(スペクトラム)を持つ宝石鑑定用の人工太陽灯や街路の夜間照明用の水銀灯は勿論、青のスペクトルを多く放出するLEDや蛍光灯の光でも少しは青く輝きます。 更に、紫外線のブラックライトを当てると、トルコ石に似た目の覚めるような明るい青緑色を呈します。 しかしながら、白熱電球では青の光を殆ど出しませんので、青く光らないで、普通の茶黄色に見える不思議な琥珀です。

ドミニカでは琥珀資源の保存のため機械掘りは禁止されており、人力に頼らねばなりません。 琥珀が眠っている地層までスコップとツルハシで横に坑道を掘ったり、ピットと言う深い縦穴を掘って採掘しています。 現在、ブルーアンバーの産出量は一週間に僅か2〜3Kg、この中で良質のものは1Kg程度で、 最高級品のネイビーブルーアンバーは数百グラムのみと言われております。 この様にブルーアンバーの産出は限定されているため大変に希少価値があります。

ブルーアンバーがなぜ青く輝くのか、その仕組みは未だ明らかではありません。 その中に銅等の不純物が包含されていて、そのイオンの色ではないか、また原子内の電子の状態に多少の不整が起こっているために特定の波長の光が吸収されて色が見えてくる等とも諸説がありますが定かではありません。 ブルーアンバーを研磨していますと、温泉の硫化水素の匂いがしますので、火山活動と何らかの関係があったものと思われます。

ミヤンマー(旧ビルマ)の青色琥珀(ブルーアンバー)や赤色琥珀(レッドアンバー) はバーマイトBurmiteと呼ばれ、黄、茶、赤、紫、青色と多彩です。 時代は日本の久慈琥珀と同じ、約8000万年から1億1000万年前の白亜層から産出します。 中でもブルーアンバーはやや赤色或いは紫色掛かった青色です。

インドネシアのスマトラ島の青色琥珀(ブルーアンバー) は2年位前に、石炭層の中ら発見されたもので、茶、赤、紫、青色等と多彩で、ブルーアンバーはドミニカ産のブルーアンバーより青いものがあります。

メキシコの赤琥珀(レッドアンバー) は黒に近い赤色から透明で淡い赤色まで色々あります。 昔、イタリアのシシリー島で採れた赤琥珀(現在、枯渇し採れません。)に似ています。

虹色琥珀(レインボーアンバー)は数年前、メキシコの赤琥珀を研磨中に、偶然、発見した希少な真紅の琥珀です。

白熱電球や蛍光灯の下でも赤色をしていますが、太陽光線や道路端の水銀灯或いは今流行のLEDの光で部分的に素晴しい緑色や青色の蛍光色を帯びて輝きます。

元々は紅い琥珀ですが、黒い布などの上で太陽光線に当てますと、ある時はブルー、またある時は、グリーン、イエローと、様々な彩りを持つことから、特に青や緑の輝きが際立って良いものを 虹色琥珀(レインボーアンバー) と私が名付けました。 赤琥珀10個の内1個程しか出て来ませんので希少性が高く高価格になります。メキシコ琥珀も、ドミニカ琥珀と同様、全て天然のままの、いわゆる熱処理をしない自然な琥珀です。

ブルーアンバーもレインボー・アンバーも約2,500万年前の、日本のケヤキに似た、琥珀の木(アルガロボ、Algarrobo)の樹脂で、ドミニカではこの木の子孫ガ現在も生存しています。そのブルーアンバーやレインボー・アンバーを、都会的なセンスと、日本一の品揃えで、今回お届けいたします。

バルト海やドミニカの琥珀は、地質学的な研究の結果、今から2,000万年から4,000万年前の琥珀の木の樹脂から生まれたものです。 因みに、日本の秋田・新潟地方の石油ガス田が、地質年代で言いますと、いわゆる新生代第三紀の地層に賦存しております事から、同じ様な年齢です。

その他、太古のロマンを秘めたたタイムカプセルと言われる 花・葉っぱ・虫入り琥珀 など、他では見られない種々の琥珀を取り揃えてお待ちしております。

様々な模様と色調の琥珀、時を超えた美しい輝きをお楽しみ下さい。

本物志向のあなたに、何時もお守りとしてお傍に、そして御家族の末代までの家宝として伝えて下さい。

(保存方法)

悠久のロマンとファンタジィを秘め、時を超えて神秘的に輝き続ける魅惑の琥珀も、本来は松脂の様な樹脂ですから簡単に燃えます。

琥珀は地下に何千万年も眠っていた位ですから酸やアルカリに対して大変丈夫で、汗や脂をとる為に石鹸水で洗っても大丈夫です。 そして綺麗な柔らかい布やタオルでふいて下さい。 但し、若い琥珀のコーパルはアルコールや除光液に溶け、白く曇ります。

琥珀の弱点は、人間の皮膚と同じで、乾燥に弱いことです。 直射日光に何日も長時間晒しますと、表面に小さなひび割れが発生することがあります。 特にドミニカの虫入り琥珀は、何年も使用しないときは、水で湿らせて、ポリ袋に入れて置いた方が良いと思います。

また、琥珀の硬さは指の爪より少し硬い位ですので、砂などの硬いもので傷つきますから、気を付けて下さい。傷付いた琥珀は再研磨で元の様になりますので、ご安心下さい。 もし軽い傷が付いた場合には、#1000番程度のサンドペーパーで傷を取り、その後自動車のワックスで磨きますと簡単に直ります。

ペンダント・トップのバチカンなど、K18或いはシルバーのパーツの磨きには通常、街中の宝飾品店などでも買えると思いますが、商品名:ポリマール(研磨用つや出し布)を使います。 但し、琥珀やメガネは磨かないで下さい、曇ってしまい、後でバフ(仕上げの研磨)を掛ける必要が出てきます。 金や銀メッキなどでは、メッキがはがれて仕舞いますので要注意です

Amber (Amber) C40H64O4 It is a fossilized resin of pine trees and other species that has survived over tens of millions of years. It is called Amber in English.

Since ancient times, amber has been loved as the stone of the sun and mermaid's tears because of its brightness and beautiful colors.

In Western Europe, the 10th year is considered amber marriage, and it is also the birthstone for November.

Amber is called organic jewelry because it is a plant-based organic material, so it floats in strong salt water. It is resistant to sweat and can be washed with soap. Furthermore, it is one of the lightest natural jewelry, so it is considered to be an excellent feature that it does not feel too heavy. It has a cool and gentle feel on your skin in the summer, a soft touch that warms your skin in the winter, and a light, rich volume and enchanting shine that you won't want to let go of once you wear it.

Amber has a wide variety of colors and expressions, so no two pieces are the same in this world. Among these, his Dominican blue amber, which has a mysterious sea-like shine, has been attracting attention as a phantom amber. Blue amber is a new type of amber that was discovered just over ten years ago.

When Blue Amber is placed on a black cloth and held up to sunlight, what previously appeared to be brown will suddenly begin to glow with a stunning blue fluorescent color that will make your heart dance. Not only artificial solar lamps for jewelry appraisal, which have the same spectral distribution (spectrum) as natural sunlight, and mercury lamps for street lighting at night, but also LED and fluorescent lamps, which emit a large amount of the blue spectrum, will give a slight blue glow. . Furthermore, when exposed to ultraviolet black light, it takes on a striking bright blue-green color similar to turquoise. However, incandescent light bulbs emit almost no blue light, so it is a mysterious amber that does not glow blue and looks like a normal brown-yellow color.

Mechanical digging is prohibited in Dominica in order to preserve amber resources, and mining must be done manually. Mining is done by digging horizontal tunnels with shovels and pickaxes, or by digging deep vertical holes called pits, to reach the strata where amber lies. Currently, the production amount of blue amber is only 2 to 3 kg per week, of which only about 1 kg is of good quality, and the highest quality navy blue amber is said to be only a few hundred grams. In this way, the production of blue amber is limited, making it extremely rare and valuable.

The mechanism behind why blue amber shines blue is still unclear. It may contain impurities such as copper, and the color may be due to the ion's color, or there may be some irregularity in the state of the electrons within the atom, which absorbs light of a specific wavelength and causes the color to appear. There are various theories that it will come, but it is not certain. When I was polishing blue umber, I could smell the hydrogen sulfide from the hot springs, so I think it had something to do with volcanic activity.

Blue amber and red amber from Myanmar (formerly Burma) are called Burmite and come in a variety of colors: yellow, brown, red, purple, and blue. It is produced from the chalk layer that dates from about 80 to 110 million years ago, the same age as Kuji amber in Japan. Among them, Blue Amber is a blue color with a slight red or purple tint.

Blue amber from Sumatra, Indonesia was discovered in a coal seam about two years ago, and comes in a variety of colors, including brown, red, purple, and blue. Blue amber is the same as blue amber from Dominica. There is something bluer.

Mexican red amber comes in a variety of colors, from almost black red to transparent and pale red. It resembles the red amber that was once mined on the Italian island of Sicily (currently, it is depleted and cannot be mined).

Rainbow Amber is a rare crimson amber that I accidentally discovered several years ago while polishing red amber from Mexico.

It remains red under incandescent bulbs and fluorescent lights, but when exposed to sunlight, roadside mercury lamps, or the current trendy LED light, parts of it glow with a wonderful green or blue fluorescent color.

Originally, it is a red amber, but when exposed to sunlight on a black cloth, it sometimes takes on a variety of colors, sometimes blue, other times green, and sometimes yellow. I named the one with outstanding color rainbow amber. Only about 1 out of 10 pieces of red amber comes out, making it highly rare and expensive. Mexican amber, like Dominican amber, is completely natural amber that is not heat-treated.

Both Blue Amber and Rainbow Amber are resins from the amber tree (Algarrobo), which is similar to the Japanese zelkova tree, and which dates back approximately 25 million years, and descendants of this tree still survive in Dominica. We now offer Blue Amber and Rainbow Amber with an urban flair and the largest selection in Japan.

As a result of geological research, amber from the Baltic Sea and Dominica was created from the resin of amber trees 20 to 40 million years ago. Incidentally, the oil and gas fields in the Akita and Niigata regions of Japan are of similar age, as they are located in the so-called Tertiary Cenozoic strata in geological terms.

We also carry a variety of amber that cannot be found anywhere else, including amber with flowers, leaves, and insects, which are said to be time capsules of ancient romance.

Enjoy the timeless beauty of amber with its various patterns and tones.

For those of you who like the real thing, please keep it close to you at all times as a talisman, and pass it down as an heirloom to your family for generations to come.

Preservation method

The enchanting amber, which has an eternal romance and fantasy and continues to shine mysteriously over time, is originally a resin like pine resin, so it burns easily.

Amber has been underground for tens of millions of years, so it is extremely resistant to acids and alkalis, and can even be washed with soapy water to remove sweat and oil. Then wipe it with a clean soft cloth or towel. However, young amber copal dissolves in alcohol or nail polish remover and turns white and cloudy.

Amber's weakness is that it is susceptible to dryness, just like human skin. If exposed to direct sunlight for many days, small cracks may appear on the surface. Especially for Dominican amber with insects, if you are not going to use it for many years, I think it is better to moisten it with water and store it in a plastic bag.

Also, the hardness of amber is slightly harder than a fingernail, so please be careful as it can be scratched by hard objects such as sand. Rest assured that scratched amber can be re-polished to its original state. If there is a slight scratch, remove it with #1000 sandpaper and then polish with car wax to easily repair it.

To polish K18 or silver parts such as the Vatican pendant top, I usually use Polymer (polishing cloth), which can be purchased at jewelry stores around town. However, please do not polish amber or glasses, as they will become cloudy and will require buffing (finish polishing) later. Please be careful when using gold or silver plating as the plating will peel off.

Welcome to the bright world of the power of magic of natural gems

LARIMAR & AMBER ART.

1 note

·

View note

Link

Analyses of Pompeii victims with X-ray fluorescence suggests they died of asphyxiation – The Lifestyle Insider

0 notes

Text

How Alumina Crucibles Shape Modern Science

Introduction: The Crucible of Possibilities

In the realm of scientific experiments, precision and control are paramount. Alumina crucibles, crafted from high-purity aluminium oxide, have become the go-to vessels for researchers, enabling them to manipulate materials at extreme temperatures and controlled environments. These crucibles act as miniature laboratories, offering an ideal setting for various experiments that have redefined scientific paradigms.

The Marvel of Alumina: Composition and Properties

Alumina crucibles owe their remarkable properties to their composition. Comprising nearly 100% aluminium oxide, these crucibles exhibit exceptional resistance to high temperatures, chemical corrosion, and thermal shock. This makes them perfect for applications that involve aggressive chemicals, molten metals, and rapid temperature changes. Their non-reactive nature ensures that the materials being worked upon remain uncontaminated.

Versatility in High-Temperature Reactions

At the heart of many scientific endeavours lies the need to conduct reactions at elevated temperatures. Alumina crucibles provide a safe and controlled environment for such reactions, whether it’s the synthesis of new materials, the investigation of phase transitions, or the analysis of thermal properties.

Precision Melting and Sample Analysis

The controlled melting of materials is a cornerstone of various scientific fields. Alumina crucibles facilitate accurate and consistent sample melting with their high melting point and excellent heat retention. This is vital for industries like metallurgy, where alloys with specific properties must be precisely formulated.

Crucibles in Chemical Synthesis: Catalyst Carriers

Catalysts drive numerous chemical reactions, and the effectiveness of catalysts often depends on their carriers. Alumina crucibles provide an inert, stable, and heat-resistant platform for catalysts, ensuring efficient reactions and optimal yield in chemical processes.

Growing Crystals for Technological Innovations

The growth of single crystals is pivotal in various technological advancements, from electronics to photonics. Alumina crucibles, with their ability to withstand high temperatures and create a controlled growth environment, contribute significantly to producing flawless crystals with desirable properties.

Crucial Role in Analytical Techniques

Analytical techniques like X-ray fluorescence and infrared spectroscopy require stable and reproducible sample preparation. Alumina crucibles offer a contamination-free medium for sample handling, enabling accurate analysis and reliable results.

Crucibles and Modern Material Science

The field of material science demands meticulous testing and experimentation. Alumina crucibles provide researchers with a dependable container to subject materials to various conditions, aiding in understanding their behaviour and unlocking novel material properties.

Pushing the Boundaries of Nanotechnology

Nanotechnology hinges on precision and control at the nanoscale. Alumina crucibles, with their ability to maintain integrity at high temperatures and resist reactive substances, serve as ideal vessels for synthesizing and manipulating nanomaterials.

Crucibles in Metallurgy and Alloy Development

Metallurgy relies on alloy development to create materials with tailored properties. Alumina crucibles allow researchers to precisely combine metals at controlled temperatures, creating innovative alloys for diverse applications.

Ensuring Purity: Crucibles in Spectroscopy

Spectroscopic techniques demand pure samples for accurate readings. Alumina crucibles prevent contamination, ensuring that the samples under study remain untainted, thus upholding the integrity of spectroscopic analyses.

Crucibles as Tools for Quality Control

Quality control is a cornerstone of manufacturing. Alumina crucibles play a role in various quality control processes, from ensuring consistent glass compositions to assessing the purity of metals, contributing to producing reliable and high-quality products.

Art and Science: Crucibles in Glass Making

The art of glass-making marries creativity with science. Alumina crucible aid in melting and moulding glass at precise temperatures, allowing artisans to create intricate glass pieces while embracing the scientific principles that underlie the process.

Crucibles in Space Exploration

Even in the vast expanse of space, alumina crucibles find their purpose. They are utilized to conduct experiments aboard spacecraft and rovers, providing a controlled environment to explore reactions and materials in microgravity.

Sustainability and Recycling of Crucibles

In a world focused on sustainability, even crucibles find their role in recycling processes. Alumina crucibles, known for their durability, can be recycled, contributing to reducing waste in scientific and industrial applications.

Conclusion

The unassuming alumina crucible symbolizes how seemingly small elements can immensely impact modern science. From shaping new materials to unravelling the mysteries of the universe, these vessels have proven to be indispensable tools for researchers and innovators. Their versatility, coupled with their unwavering performance under extreme conditions, cements their legacy in scientific advancements.

Read More:ceramic crucibles

0 notes

Text

XRF Analyzer Market Outlook: World Approaching Demand & Growth Prospect 2023-2028

Latest business intelligence report released on Global XRF Analyzer Market, covers different industry elements and growth inclinations that helps in predicting market forecast. The report allows complete assessment of current and future scenario scaling top to bottom investigation about the market size, % share of key and emerging segment, major development, and technological advancements. Also, the statistical survey elaborates detailed commentary on changing market dynamics that includes market growth drivers, roadblocks and challenges, future opportunities, and influencing trends to better understand XRF Analyzer market outlook. List of Key Players Profiled in the study includes market overview, business strategies, financials, Development activities, Market Share and SWOT analysis are:

Bruker (United States)

Helmut Fischer GmbH (Germany)

SPECTRO Analytical Instruments GmbH (Germany)

Rigaku Corporation (Japan)

Thermo Fisher Scientific (United States)

HORIBA (Japan)

Oxford Instruments (United Kingdom)

Skyray Instrument (United States)

Olympus (Japan)

Hitachi (Japan)

XRF is an X-ray fluorescence spectroscopy which is a non-destructive analytical technique. It is used in determining the elemental composition of materials such as glass, metals, ceramic, and other. The handheld XRF analysers works by measuring the fluorescent X-rays emitted from a sample when excited by a primary X-ray source. It also provides seamless testing of solid and liquid material samples and offer accurate results. Moreover, it has wide range of applications in oil and gas, pharmaceuticals, metal and mining, as well as environmental research.

Key Market Trends: Growing Usage of X-Ray Fluorescence Spectrometers in Tablet Formulation Processes

Opportunities: Rapid Increase in Disease Burden in Industry

Wide Range of Applications

Market Growth Drivers: Compact Design and Ease of Use of Spectrometers

Technological Advancements to Make XRF Analysers More Applicable for Health Care

Challenges: Stiff Competition Among the Major Players

The Global XRF Analyzer Market segments and Market Data Break Down by Type (Energy Dispersive XRF, Wavelength Dispersive XRF), End Users (Metal and Mining Industries, Pharmaceutical, Oil and Gas, Environmental Research, Art and Archaeology), Modularity type (Portable/ Handheld, Benchtop), Distribution channel (Direct sales, Indirect sales)

Presented By

AMA Research & Media LLP

0 notes

Text

The first palaeontologist on Mars

(Image: Artist’s impression of NASA’s Perseverance rover on Mars)

Today NASA’s Perseverance rover landed on Mars. I don’t usually talk astronomy on this blog, but this time it’s relevant because—as you might have read���Perseverance is more or less the first palaeontologist on Mars!

Let me explain.

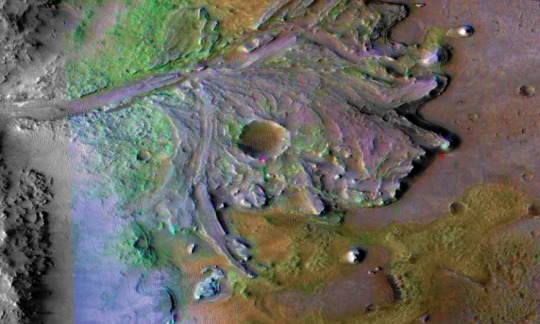

(Image: Satellite topography map of Jezero Crater, the site where Perseverance landed)

The site where Perseverance is landing, Jezero Crater, is a meteor impact crater near Mars’s Equator (say that 10 times fast!). It has evidence of a delta—the geomorphic feature that occurs when running water enters a large body of water. Orbital analyses also suggest it’s filled with carbonate rock—the kind that tend to deposit at the bottom of bodies of water.

Jezero Crater is not filled with water today. But the evidence strongly suggests it once was. If we’re going to find evidence of life on Mars, this is a good place to start looking.

Microbial fossils

When you think of fossils, most people think of giant T. rex skeletons, or frozen woolly mammoths, or neanderthal skulls. Maybe you’ve been around the block a bit, and you think about corals, or plant fossils, or tiny fossil shells. But some of the most common and important fossils on Earth are even tinier. Microbial fossils are commonly made by bacteria, archaea, and the like.

(Image: A cross-section of a stromatolite fossil, showing the multiple layers)

Some of the earliest fossils on earth are called stromatolites. They occur when bacterial colonies grow together in a mat—then, over time, sediment deposits over the colony, and the bacteria form another layer on top of the previous layer. Over time, many layers can be formed.

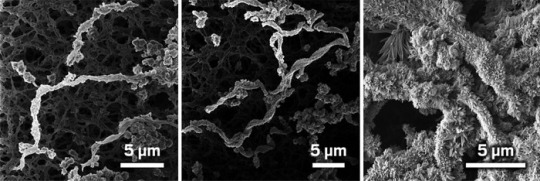

(Image: Helium Ion Microscopy image of iron oxide filaments formed by bacteria)

Although we breathe in oxygen and breathe out carbon dioxide, many microbes are not quite so restricted, and can breathe anything from sulphur to iron to methane or ammonia. When they do this, they often leave behind solid waste products, such as the above iron oxide filaments, that give away their presence. We can tell these apart from normal minerals in a number of ways, including by the relative proportions of different isotopes in them.

(Image: Schematic digram showing how molecular fossils form and are studied)

However, some of the most important fossils are molecular fossils. Living organisms produce a variety of different organic molecules; even long after the bodies of these organisms decay, those molecules can stay behind in an altered form for millions or even billions of years. If we’re looking for evidence of life on Mars, this might be our best bet.

Enter Perseverance

(Image: Diagram of Perseverance rover showing different instruments)

The Perseverance rover is overall similar in design to the Curiosity rover that landed in 2012, but there are some key differences—and most relevant here is that it’s a geological powerhouse. It’s got a number of instruments designed to carry out detailed geologic investigations:

RIMFAX is a ground-penetrating Radar unit. Like normal Radar, it works by sending radio waves into the ground; different materials affect the radio waves differently, as do transitions between different materials. This will allow us to, for the first time, study the geology of Mars below the surface to get an idea of what has been going on down there.

(Image: This is the kind of result produced by ground-penetrating radar—a rough image of the stratigraphy below the surface.)

PIXL (Planetary Instrument for X-ray Lithochemistry) shoots x-rays at samples and examines how they fluoresce in reaction. This allows for the detection of the elemental composition of a sample—helping us better understand the geology of the area, and potentially detect signatures of life.

SuperCam is a multi-function laser spectrometer that uses four different spectroscopy methods to examine the composition of samples. They all work in similar ways—essentially, different molecules react to laser stimulation differently, and different amounts of energy are required to make different molecules vibrate. The way that these molecules react can help us identify their composition, and the hope is that this may allow us to detect molecular fossils (these methods allow us to detect molecular fossils on Earth!)

SHERLOC (Scanning Habitable Environments with Raman & Luminescence for Organics & Chemicals) is another spectroscopic instrument—this one, however, is more precise, and optimised for detecting trace biosignatures in samples. It works similar to the above, using an ultraviolet laser to scan a 7 × 7 mm zone for evidence of organic compounds.

In addition to studying samples in situ, Perseverance will package small samples and leave them behind on Mars. A planned future mission will collect these packaged samples and launch them into space, where an orbiter will collect them and—hopefully—return them to Earth. This would be the first time that samples have ever been recovered from Mars, and would go a long way in increasing our understanding of the Martian environment and geology.

There’s no way of knowing yet what Perseverance will find—but even the fact that a robot palaeontologist is on Mars is incredibly exciting. Here’s to many years of discovery!

3K notes

·

View notes

Text

Shroud of Turin

IT’S JESUS CHRIST!

(5-minute read)

𝐋𝐮𝐤𝐞 𝟐𝟑:𝟓𝟑 "𝐀𝐧𝐝 𝐭𝐚𝐤𝐢𝐧𝐠 𝐡𝐢𝐦 𝐝𝐨𝐰𝐧, 𝐡𝐞 𝐰𝐫𝐚𝐩𝐩𝐞𝐝 𝐡𝐢𝐦 𝐢𝐧 𝐟𝐢𝐧𝐞 𝐥𝐢𝐧𝐞𝐧, 𝐚𝐧𝐝 𝐥𝐚𝐢𝐝 𝐡𝐢𝐦 𝐢𝐧 𝐚 𝐬𝐞𝐩𝐮𝐥𝐜𝐡𝐞𝐫 𝐭𝐡𝐚𝐭 𝐰𝐚𝐬 𝐡𝐞𝐰𝐞𝐝 𝐢𝐧 𝐬𝐭𝐨𝐧𝐞 ..."

During the September-October 1978 exhibition of the Shroud in Turin, more than three-and-a- half million people viewed the relic.

The viewing was followed by a sindonological congress of experts on October 8–13 wherein a detailed, around-the-clock, 120-hour scientific examination of the Shroud was conducted, producing more than 30,000 photographs of various kinds. The congress was conducted primarily by scientists from the United States who had brought 72 crates of equipment weighing eight tons for application of ultraviolet, visible and infrared spectrometry, X-ray fluorescence spectrometry, microscopy, thermography, pyrolysis-mass-spectrometry, laser-microprobe Raman analyses, and microchemical testing.

Known as the Shroud Turin Research Project (STURP), the U.S. group composed of 31 top scientists reported unanimously that the man on the Shroud was not painted on the cloth but that a mysterious and rapid chemical reaction selectively darkened threads of the Shroud’s linen fiber so as to make a three-dimensional negative image of a man with accurate details valid when magnified 1,000 times.

Among STURP’s findings:

a) X-ray, fluorescence and microchemistry tests on the fibers preclude the possibility of paint being used as a method for creating the image. Ultraviolet and infrared evaluations confirm these studies. The Shroud image was not painted, nor printed.

b) Both kinetics studies and fluorescence measurements support the hypothesis that the image was formed by a low-temperature process. The temperature was not high enough to change cellulose, and no char was produced. Thus, the Shroud image was not made by pressing the cloth on a heated bas-relief.

c) The Shroud's image is superficial as the color resides on the outer surface of the fibers that make up the threads of the cloth. Recent measurements on image-fibers of the Shroud confirmed that the coloration depth is extremely thin, about 200 nanometer (200 billionths of a meter, or one fifth of a thousandth of a millimeter, which corresponds to the thickness of the primary cell wall of a single linen thread).

d) The shallow coloration of the Shroud image is due to an unknown process that caused 'oxidation, dehydration and conjugation of polysaccharide structure of fibers, to produce a conjugated carbonyl group as the chromophore.'

e) The image seen at the macroscopic level is an areal density image. This means that shading is not due to a change of color, but to a change in the number of colored fibers per unit area at the microscopic level.

f) The image fading has three-dimensional information of the body encoded in it.

g) The blood stains tested positive for human blood, and there is no image beneath the blood. This means the image must have occurred after the blood flowed onto the cloth. As a consequence, the image was formed after the deposition of the corpse.

h) On the Shroud there are no signs of putrefactions, which occur at the orifices about 40 hours after death. This means that the image does not depend on the gases of putrefaction and the corpse was wrapped in the Shroud no longer than two days.

i) There is a perfect anatomical consistency of blood and serum versus wounds, including the presence of birilubin, which is invisible at the naked eye. These subliminal features require knowledge of anatomy and of forensic medicine not available before the XIX century.

Using the STURP findings, ENEA or the Italian National Agency for New Technologies, Energy and Sustainable Economic Development, published a report on five years of experiments (2011-2015) conducted at its Excimer Laser Laboratory at Frascati on the "shroud-like coloring of linen fabrics by ultraviolet radiation."

ENEA scientists discovered that "the total power of VUV (Vacuum Ultra-Violet) radiations required to instantly color the surface of linen (with the image) for a human of average height, body surface area is equal to 2000 MW/cm2 X 17000 cm2 or 34 thousand billion watts, making it impractical today to reproduce the entire Shroud image using a single excimer laser, since this power cannot be produced by any VUV light source built to date (the most powerful available on the market come to several billion watts )."

3 notes

·

View notes

Text

How Diesel Testing Labs in the UAE Ensure Fuel Quality Compliance | +971 554747210