#water tank pressure booster

Explore tagged Tumblr posts

Text

Optimizing Water Flow: Pressure Pumps or Boosters for Overhead Tanks

To effectively increase water flow from your water tank, consider installing a pressure pump for overhead tank. A pressure pump helps enhance water pressure, ensuring a steady and reliable flow throughout your home. Additionally, a water tank pressure booster can be used to further improve water pressure and distribution. Understanding how to increase water flow from your water tank involves choosing the right pump or booster based on your system's needs and maintaining these components for optimal performance. Using these tools will help you achieve better water pressure and flow from your tank.

#pressure pump for overhead tank#water tank pressure booster#how to increase water flow from water tank

0 notes

Link

Pressurized tanks used for pressurizing liquids or gases are called expansion tanks . It is also called pressure tank, expansion tank, balance tank.

Expansion tanks are closed containers that hold liquids at a pressure different from ambient pressure. They are used in pressure boosting and boiler systems.

0 notes

Text

The Woman she Is

gif by azertyrobaz

req: maybe just a tiny one-shot? I know you’re win the middle of writing many fics so no pressure. But Ava Coleman x fem!reader? Where r and Ava have been in a relationship and no one knew bc it was secret, r has a daughter and just loves Ava, even calling her Mom. You can decide the kids name maybe she could be mixed? but basically one day the kid has like a bad day and won’t talk to Miss Howard and finally gets r to try and talk to her but she wants to talk to Ava. (I haven’t seen anyone write for mom!ava) idk what else. But I’m just in the mood for mom Ava. Also, please put mom figure Melissa to y/n and Mel has her happy ending in relationships :,)

Been waving this one off for a while so here ya go anon! :)

Their daughter’s name is Hallie and it’s implied that she’s mixed.

————————————

“I even cut your strawberries into hearts!” Ava exclaimed placing a plate of pancakes in front of Hallie, she also put some fruit on the plate and a placed a small glass of orange juice on the table. “Tank you, mom!” She smiled, she ate her breakfast quickly, throughly enjoying her strawberries and taking nibbles of her pancake at a time. Y/n was upstairs getting ready, already having eaten. Ava was packing the little girls lunch, making sure to put her water bottle in the pocket of her backpack.

“Good morning to my two favorite girls!” Y/n smiled, placing her bag down on one of the chairs placing a kiss on Hallie’s bunny cheeks. “Good morning, Mama!” “Good morning, baby”

Y/n also placed a small peck on Ava’s lips, she might’ve been stubborn and might not do her job sometimes, but she really cared for the kids, she always wanted to be a mom.

Now, that dream has come true, she’s a mom to the cutest daughter, though, she might not be hers biologically that didn’t stop the little girl from calling her Mom. The best part was she gets to help raise this little girl with the love of her life. She may have been a player but she knew when she saw y/n that she was the one. As cheesy as it sounds, Ava couldn’t have fallen faster or harder. Falling for y/n was like falling face first into pavement for Ava.

They all got into Ava’s car, Hallie sat in her booster seat and happily played on her iPad as they drove to the school. Her backpack, sat next to her the sequins shining in the sunlight. Ava never thought that she was gonna actually fall in love with one of her Co-workers. She’d flirt, yes, but never actually date any of them. That was were y/n came in, she transferred to Abbott as a new first grade teacher. She charmed everyon

Ava was playing ‘Pick Up Your Feelings’ by Jazmine Sullivan, it was one of her favorites, actually. Even Hallie seemed to have learned some of the lyrics from how many times Ava’s played it. Though, if anything, Ava listens to Beyoncé the most.

You need to hurry and pick up your, ooh, feelings While I'm up cleaning

Boy please (boy please, oh) I don't need you (I don't need you)

Y/n let a smile take over her face as she looked out her window, nothing could’ve ruined this moment. Everything she could’ve needed was right here. Her life was perfect as it was and she wouldn’t change it for anything.

Her job might’ve not been a six figure paying job but it brought her memories that were priceless, her job might’ve been stressful but it helped the next generation. She couldn’t have wished for anything more. “You okay, baby?” Ava asked, placing a hand on her thigh, the principal’s brows furrowed, stealing a glance at her girlfriend.

”Yeah, just a little tired, I could go for some coffee right now” The woman yawned, regretting her choice of just drinking orange juice. Ava smirked, she made a U-turn to Starbucks, “We have some extra time anyway so why not make a pit stop?” Hallie giggled in the back, “Can I get a cake pop, pwease!”

Y/n nodded, she thought it was cute when she got lazy and forgot to pronounce the ‘L’ sound. It seemed like yesterday she couldn’t talk at all. “Well, I already know what to get everyone, then!”

——————

Ava made jokes about how the barista looked like 50 cent the whole ride to Abbott. They arrived a little bit early but they didn’t mind, Getting out of the car, Ava unbuckled Hallie out of her seat. “Ready for school, lil’ curly fry?” She smiled, chuckled as she tousled the little girl’s curly hair that was nicely slicked back into a half up, half down hairdo.

Hallie threw up a thumbs up, holding Ava’s hand and y/n’s in the other, not many cars were parked in the lot. The three entered the only person visible was Mr. Johnson.

He nodded at the to grown woman and smiled at the little girl. It was safe to say that Mr. Johnson was Hallie’s favorite person at school, besides Mel and Barb.

Ava gave y/n a soft kiss, and gave Hal a peck on the forehead. “Have a good day, you two” she said before walking to the break room, y/n unlocked her classroom door, letting Hallie in, she flicked on the lights. She usually just let her color until the bell rang signaling that she needed to go to Barb’s class.

“I have to go to the break room, will you be okay by yourself for a few minutes?” Y/n asked, placing a hand on her daughter’s shoulder. The little girl nodded, her attention not faltering from her coloring page.

Leaving her classroom, she trusted her young daughter to finish the coloring page, quickly coming into the break room she grabbed a donut happily munching down on the sweet treat, “There ya are! Was wondering you was! Where’s the kid?” Melissa questions, looking around to make sure she wasn’t hiding. Y/n laughed, leaning against the counter, “In my room, I’ll go grab her for you”

Being a woman of her word, the teacher walked back to her class, before she reached the door she heard a thud and a “uh oh..”

Y/n hurried into the room to see Hallie standing next to her desk, a cup in hand. She tried hiding the coffee puddle that was clearly on the ground, even her clothes were stained a dark brown color.

“Hal..what did you do!” She exclaimed, picking up the little girl and sitting her on the chair, quickly cleaning up the mess. “I’m sorry Mama, I didn’ mean to” her little head fell to her lap, seeing her clothes now ruined, she pouted, hating when she made her mama upset.

“It’s alright, sweet girl. Just be more careful, okay?” She cooed, kissing her cheek with a smile to let her know she wasn’t upset. “Go see your Mom while I clean this up,” the girl nodded, hopping off the chair and hurriedly running out of the classroom.

On the way, Hallie saw Melissa she waved and hugged the second grade teacher, “Mornin’ to you too, kid” she said sweetly, missing the coffee stains on the child’s clothes. Continuing her journey to her Mom’s office, she knocked and spoke in between the crack between the door and frame. “Mommy!” She called, the sounded muffled by the metal, shuffling was heard on the other side, Ava opened the door with a sweet smile.

A cough was heard behind the girl, The principal lifted her head to see a whole camera crew behind her. “Oh, damn” she let her jaw drop, ushering her daughter into the office, she stared the crew down as they all wore shocked faces.

“Go on doing whatever it is y’all do”

Ava closed the door, turning to the little girl who was sitting in her chair looking at the picture of Y/n, Hallie, and Ava. It was the picture they took at when they had gone on vacation last year. “You like it, baby girl?” She chuckled, grabbing some news clothes in the makeshift closet The principal made in her closet. It was quite impressive how she could hardly do her job as a principal but somehow renovate a old storage room into a high fashion closet in less than a day.

Hallie quickly got her clothes on, hugging the taller woman tightly. “Bye Mommy!” Though the morning was joyful and peaceful, since the coffee accident Hallie’s little day went tragically wrong. She had miss placed her lunch, hurt her knee during P.E., she couldn’t color inside the lines, She couldn’t even sleep during nap time because this girl in her class sleep kicked, At lunch time. Miss Howard had sat the little girl down.

“Sweetheart, what’s the matter? You’ve been upset all day!” She exclaimed, listening intently for an answer, the little girl only crossed arms and huffed, realizing she had no other way to get her to crack due to y/n being in a meeting. She brought her to the break room, “Melissa, help me with this one. Do you want to tell Aunt Mel what’s the matter?” Hal only, hugged into the red headed teacher, “Oh, hon..what’s got you in all worked up, huh?” She asked, Hallie finally spoke up huffing, she really did have her mothers attitude.

“I want my Mommy!” She pouted, crossing her arms, Barb groaned, “She’s more stubborn than her Mother, but we can’t get y/n she’s in a meeting!”

No one on the staff had figured out y/n was dating Ava let alone it was serious, Hallie had done a pretty good job keeping it on the down low too. Everyone didn’t really put two and two together when they’d see Ava coming out of her car with y/n. Now that Melissa thinks about it, maybe they’re not bestfriends.

Though, Melissa couldn’t jump to conclusions, “Well, I dunno, I guess we’ll-” Melissa was interupted by the sound of a familar sound of yawning as the breakroom door opened, “Oh hello, you three! Everything alright?” Y/n said, dropping her keys and lanyard on the counter, ripping open a granola bar that she had grabbed from the shelf.

“She’s been upset all day and won’t tell anybody the reason why..” Melissa cooed, booping th kindergarteners nose, she only cuddled closer and pouted even more, “she says she wants her Mommy, so here ya go!” The redhead stood up placing the little girl in her mothers arms, y/n sighed knowing it wasn’t her that she wanted.

Y/n comtemplated fessing up, Ava and had had been keeping it under wraps for so long, so surely, they’ll understand. Melissa was like y/n’s work mom, or real mom actually.

”Okay, don’t make a big deal out of this..but i’m dating Ava! Surprise!” Y/n smiled, Barb’s face dropped in shocked, Mel lit up, “I KNEW IT!” she exclaimed, clapping her hand together and jabbing her finger in the younger teachers direction.

Really, the young woman thought their reactions would be more complicated, Well, at least Barb’s. She just kept standing their with her mouth agape. As if the two had been stalking, Janine and Jacob stumbled in, “GREGORY OWES ME!” Jacob squealed, Janine happily shuffled from side to side with that big smile. Gregory stands speechless, looking at the two who’ve dragged him into another one of their adventures.

“Well, I’m gonna take this one to Ava, see y’all!”

—————

“Well, a knock would’ve been nice but come in wit’ yo’ fine self” Ava smirked, biting her lower lip as she eyed her up and down. Y/n rolled her eyes, “what? Acting like you can give me attitude knowing I can eat that body up like Megan Thee Stallion” She slapped her hand on her desk, laughing hard at her own joke. Y/n huffed, closing her eyes trying to hold onto any piece of patience she had left with her girlfriend, someday she really might explode from these jokes. In the mean time, she’ll secretly like them.

“Why you huffin’ and puffin’ like a choo-choo train?” She asked, y/n went to go tell her the reason why she was even in here but Ava was determined in finishing. “Chugga, Chugga, CHOO CHOO!” She howled and slapped her knee, almost falling out of her chair, Hallie began to laugh too. “You kinda do soun’ like a train, Mama” Ava smirked as y/n groaned, “That’s my lil’ curly fry!” She laughed, opening her arms up for the little girl. Hallie giggled, squealing when the principal would tickle her sides.

Y/n’s frustrations quickly disappeared, it had only been 6 months, yet, Ava’s changed so much. They’d been dating for 4 months, only recently did Hallie start saying Mom to Ava. Now that y/n takes a moment to see the impact this woman had on her life and the little human she called her daughter she melted.

Maybe Melissa was wrong for once. They may think that Ava’s rude or stupid for not doing her job, but she cared, no doubt about it. She’d Show softness here and there but never frequently, Lord help them if she ever was caught being nice to Janine.

Y/n noticed too, Ava seemed a little nice since they’d gotton together. Melissa just thinks she’s up to something but y/n couldn’t help but think it was because she was changing as a person, principal, and now…parent.

“She wanted her mommy” Y/n mocked, smirking as Ava’s eyes lit up. She loved that little girl more than any other little girl. She would knowingly drop everything for that girl. “Really? Oh, come ‘ere you cutie!” She hugged her tight, y/n playfully sighed, looking away with her hand on her forehead. Ava chuckled, “You too, doofus” the woman opened her arm out for her girlfriend kissing her lips softly.

A shriek was heard at the door, they whipped their heads around to see the same familiar faces at the door. Melissa’s face was most likely impressed (then again you never know), Janine was probably the one that shrieked as she jumped up and down, Gregory’s eyes were wide, Jacob was frozen like Barbara.

“Uhm, suprise?” Y/n chuckled, looking at Ava kissing her cheek sweetly turning back to them with a large smile.

———

The two women explained to them how long they’ve been dating, the Abbott crew listened carefully and happily. Barb was still in shock, Ava and y/n wasn’t something they thought would actually get together. Sure, they were polar opposites but they fit so well together. The rest of the school day was quite interesting with Melissa lecturing Ava on how if she ever hurt y/n she’s got a guy who take care of the principal real quick. “I got my eye on you, Coleman” Melissa said, with a stern tone, slowly walking back to her class while staring the tall woman down. Y/n snorted, “don’t mind her, she’s just trying to scare you” y/n smiled, hugging Ava tightly, “I know, but I don’t think I’d ever willingly leave you, baby. Someone would have to physically restrain me, I love you and lil’ Hal too much” She admitted all too easily, to her this was all she wanted for the rest of her life. Of course, someday she’d get down on a bended knee, she planned on getting married, maybe even get a dog?

Who knows, only time will tell.

But maybe this won’t even work, then someday they’ll see this as a learning experience. But if there was one thing they everyone knew, was that they were meant to be together, whether or not if it was the right time, place, or even moment.

They’d up together, that’s how it was in every universe. So, whatever happened in this one, maybe they’d mess up and separate or even just drift apart. They needed each other, in every universe.

Time is something no one is Master of, but this story surely ends happily.

——

As the day ended, Melissa waved bye to her colleagues, smiling as she saw y/n and Ava give each other a small peck on the lips, they were cute together that was for sure. Maybe someday she’d-

“Oh my gosh! I’m so sorry!” A voice apologized profusely, Mel had been too focused on the couple in the distance she wasn’t even focusing on where she was walking.

“It’s fine, really” Melissa chuckled, fixing her hair before looking up to see..damn. The woman in front of her was absolutely gorgeous, she felt her heart flutter for second. “Erm, hi, I’m lissame! No, sorry, Melissa! Melissa Schemmenti” she gave a bashful smile, securing her bag onto her shoulder once more.

“I’m Georgia Prescott, the new librarian”

huh. Looks like Abbott’s in for another love story.

———————

the whole thing was rushed 😭

forgive me for this 🙏

#open requests#ava coleman#abbott elementary#melissa schemmenti#barbara howard#ava coleman x reader#i actually cant#like seriously#she’s so silly#just like me <3#melissa schemmenti x reader

291 notes

·

View notes

Text

OTD in 1969, The Iconic XB-70 Valkyrie Mach 3 Super Bomber Made Its Last Flight

February 4, 2021 Military Aviation, Military History

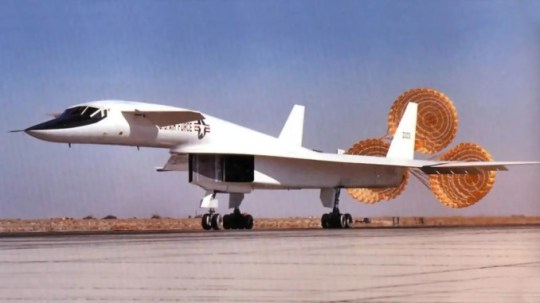

Three drag chutes were needed to slow down the landing roll of the XB-70. (Image credit: Reddit edit The Aviationist)

The massive XB-70 Valkyrie is the largest and heaviest airplane ever to fly at Mach 3.

The North American XB-70 Valkyrie was the most ambitious super-bomber project of the Cold War. The massive six-engine bomber was slated to be the ultimate American high-altitude, high-speed, deep-penetration manned nuclear bomber designed to fly high and fast, so as to be safe from Soviet interceptors.

Two Valkyrie prototypes were been built at North American Aviation before the Kennedy Administration cancelled the program as a consequence of the doubts that surrounded the future of manned bombers believed to be obsolete platforms. The threat posed by Soviet SAMs (Surface-to-Air Missiles) put the near-invulnerability of the strategic bomber at high altitudes in doubt. In low-level penetration role, the B-70 offered little performance improvement over the B-52 it was designed to replace (!) and it was much more expensive with shorter range.

Some fascinating variants of the aircraft were proposed. Some envisaged the B-70 carrying an Alert Pod, or flying as a Supersonic Refueler or as a Recoverable Booster Space System (RBSS). You can find all the details about these crazy concepts in this story we have posted last year.

Ezoic

The B-70 program was canceled in 1961 and development continued as part of a research program to study the effects of long-duration high-speed flight with the two XB-70A.

XB-70A number 1 (62-001) made its first flight from Palmdale to Edwards Air Force Base, CA, on Sept. 21, 1964. The second XB-70A (62-207) made its first flight on Jul. 17, 1965. The latter differed from the first prototype for being built with an added 5 degrees of dihedral on the wings as suggested by the NASA Ames Research Center, Moffett Field, CA, wind-tunnel studies.

While the 62-001 made only one flight above Mach 3, because of poor directional stability experienced past Mach 2.5, the second XB-70, achieved Mach 3 for the first time on Jan. 3, 1966 and successfully completed a total of nine Mach 3 flights by June on the same year.

Photo of the XB-70 #1 cockpit, which shows the complexity of this mid-1960s research aircraft. On the left and right sides of the picture are the pilot’s and co-pilot’s control yokes. Forward of these, on the cockpit floor, are the rudder pedals with the NAA North American Aviation trademark. Between them is the center console. Visible are the six throttles for the XB-70’s jet engines. Above this is the center instrument panel. The bottom panel has the wing tip fold, landing gear, and flap controls, as well as the hydraulic pressure gages. In the center are three rows of engine gages. The top row are tachometers, the second are exhaust temperature gages, and the bottom row are exhaust nozzle position indicators. Above these are the engine fire and engine brake switches. The instrument panels for the pilot left and co-pilot right differ somewhat. Both crewmen have an airspeed/Mach indicator, and altitude/vertical velocity indicator, an artificial horizon, and a heading indicator/compass directly in front of them. The pilot’s flight instruments, from top to bottom, are total heat gage and crew warning lights; stand-by flight instruments side-slip, artificial horizon, and altitude; the engine vibration indicators; cabin altitude, ammonia, and water quantity gages, the electronic compartment air temperature gage, and the liquid oxygen quantity gage. At the bottom are the switches for the flight displays and environmental controls. On the co-pilot’s panel, the top three rows are for the engine inlet controls. Below this is the fuel tank sequence indicator, which shows the amount of fuel in each tank. The bottom row consists of the fuel pump switches, which were used to shift fuel to maintain the proper center of gravity. Just to the right are the indicators for the total fuel top and the individual tanks bottom. Visible on the right edge of the photo are the refueling valves, while above these are switches for the flight data recording instruments. (Image credit: NASA)

A joint agreement signed between NASA and the Air Force planned to use the second XB-70A prototype for high-speed research flights in support of the American supersonic transport (SST) program.

However, on June 8, 1966, the XB-70 62-207 was involved in one of the most famous and tragic accidents in military aviation when it collided with a civilian registered F-104N while flying in formation as part of a General Electric company publicity photo shoot over Barstow, California, outside the Edwards Air Force Base test range in the Mojave Desert. The aircraft were flying in formation with a T-38 Talon, an F-4B Phantom II, and a YF-5A Freedom Fighter.

North American XB-70A Valkyrie just after collision. Note the F-104 is at the forward edge of the fireball and most of both XB-70A vertical stabilizers are gone. (U.S. Air Force photo)

As explained in a previous post here at The Aviationist:

Towards the end of the photo shooting NASA registered F-104N Starfighter, piloted by famous test pilot Joe Walker, got too close to the right wing of the XB-70, collided, sheared off the twin vertical stabilizers of the big XB-70 and exploded as it cartwheeled behind the Valkyrie. North American test pilot Al White ejected from the XB-70 in his escape capsule, but received serious injuries in the process. Co-pilot Maj. Carl Cross, who was making his first flight in the XB-70, was unable to eject and died in the crash.

The root cause of the incident was found to be wake turbulence: wake vortices spinning off the XB-70’s wingtip caused Walker’s F-104N to roll, colliding with the right wingtip of the huge XB-70 and breaking apart. As explained in details in this post, wingtip vortices form because of the difference in pressure between the upper and lower surfaces of a wing. When the air leaves the trailing edge of the wing, the air stream from the upper surface is inclined to that from the lower surface, and helical paths, or vortices, result. The vortex is strongest at the tips and decreasing rapidly to zero nearing midspan: at a short distance from the trailing edge downstream, the vortices roll up and combine into two distinct cylindrical vortices that constitute the “tip vortices.

Although research activities continued with the first prototype with a first NASA flight on April 25, 1967, the last one was on Feb. 4, 1969.

The only remaining XB-70 Valkyrie super bomber in on display at the National Museum of the U.S. Air Force at Wright-Patterson AFB in Dayton, Ohio. In October last year, it had to briefly moved outside for display maintenance. Here you can watch a video of the monumental move.

A view of the six massive afterburners on the XB-70 Valkyrie as the aircraft is towed out of its display hangar temporarily for museum maintenance. (Photo: National Museum of the U.S. Air Force via YouTube)

About David Cenciotti

David Cenciotti is a journalist based in Rome, Italy. He is the Founder and Editor of “The Aviationist”, one of the world’s most famous and read military aviation blogs. Since 1996, he has written for major worldwide magazines, including Air Forces Monthly, Combat Aircraft, and many others, covering aviation, defense, war, industry, intelligence, crime and cyberwar. He has reported from the U.S., Europe, Australia and Syria, and flown several combat planes with different air forces. He is a former 2nd Lt. of the Italian Air Force, a private pilot and a graduate in Computer Engineering. He has written five books and contributed to many more ones.

@TheAviationist via X

21 notes

·

View notes

Text

It’s been a while since I’ve visited and done Gacha, so I’ve done a little redesigned on my OC: Elemental (Jade in her disguise AKA Ultra Ego)

Here are some facts about her costume!:

SHORTS:

Comfortable spandex, easy movement

Dresses will be dirtied in battle have to be washed

ARM BRACES:

Act as a limiter if she uses too much of her power

Safety precaution that is similar to Clean Bubbles/Quirky

POCKETS:

In case she's drained of energy, she can use elemental cards from the pockets of the belt (which she does not use in most cases)

The extra pocket on her left thigh can have anything she packs in there.

The majority of the time, there would be an Energy Replenisher Orb that restores energy overuse of elements, six Mini-Capsules containing 6 ounces of water called Mini-Tsunamis Tanks in case she doesn't have water in the fighting environment, a harmless explosive called Firework Flarings that provides her warmth and the extra flames she needs, or Pure Bubbles, which are 15 transparent orbs that contain 5-8 milliliters of pure oxygen.

BOOTS:

They are high-pressure cushion boots

Although heels would be more stylish and appealing, the boots both balance style and practicality

Allow her to boost high into the air or propelling

Inspired by the concept of the LittleBigPlanet Boosters

Has a filter when making contact with an underwater environment, but it takes time for collecting oxygen from a watery environment.

#my ocs#original character#gacha oc#gacha life 2#ocs#tf ocs#gacha life 2 oc#gl2#gl2 oc#gacha life two#IDA#Interdimensional Arcane#Interdimensional Arcane [IDA]#IDA OC: [ Jade Tran/Elemental ]#IDA OC: [ Clean Bubbles/Quirky ]

2 notes

·

View notes

Text

Ariane 6 upper stage visits ESA's temple of boom

The upper stage for Europe's newest rocket Ariane 6 passed its final tests at ESA's facilities in the Netherlands last week, qualifying the upper stage for a launch on the most powerful, four-booster, variant of the Ariane 6 rocket.

Five tests at different acoustic levels confirmed the upper stage is ready for a launch on Ariane 6 with four boosters. The tests were carried out by ArianeGroup teams at ESTEC—ESA's European Space Research and Technology Center in the Netherlands—using the upper stage hot-fire test model, which was used for the hot-fire test campaign at the German aerospace center, DLR, test site in Lampoldshausen, Germany, between 2022 and 2024.

Rocket launches are loud—even when standing several kilometers from the launch pad. The rocket itself takes the largest brunt of the acoustic attack and so the upper stage test model of Ariane 6 was subjected to the sounds of a rocket launch at Europe's loudest sound system, the Large European Acoustic Facility (LEAF) at ESA's technical heart in the Netherlands.

Ariane 6 is a rocket that can be launched in different configurations, including with two boosters or four, adapting its power to the destination required and the weight of the satellites it launches. Ariane 6's inaugural flight was a perfect launch to orbit in July 2024 with two boosters. When Ariane 6 launches with four boosters from 2025 onward, they will create almost double the thrust at liftoff but the upper stage will also endure 60% more acoustic pressure.

Sitting at the top of the launcher, about 34 m above the rocket engines, the upper stage for Ariane 6, technically known as the Upper Propulsion Liquid Module (UPLM), was designed to withstand a four-booster launch, far exceeding the sound levels experienced on its first, two-booster, launch.

In advance of the full power of an Ariane 6 liftoff with four boosters, the UPLM has now been subjected to a week of tests reenacting the acoustic vibrations it will endure. More than 6 meters tall, the upper stage is the heaviest and largest object ever to be tested inside LEAF.

The upper stage was tested upright as it would be on liftoff in the LEAF. Its propellant tanks that are filled with liquid hydrogen and oxygen on flight were filled with water and glycerine to increase the accuracy of the test. Two hundred sensors recorded the structure's reaction to the acoustic waves. The black covers used for testing recreated the intertank structures and acoustic protection provided by the main stage of the rocket on the launch pad.

TOP IMAGE: This picture shows the LEAF with its doors open after testing, the facility has half-a-meter thick walls and doors to contain the barrage of noise emitted when active. Credit: ESA–A. Conigli

LOWER IMAGE: Ariane 6 blueprint poster showing the configurations that Europe's heavy-lift rocket Ariane 6 can be launched. Credit: European Space Agency

2 notes

·

View notes

Text

Astronaut AU Definitions

Since we're getting into more mission oriented chapters and I'm not sure how technical things will get, a definition post that I will link on future chapters and add to as needed:

Flight Controllers: CAPCOM: Capsule communicator; direct line of contact between astronauts and mission control

CDH: Command and Data Handling Officer; manages computer systems, software, data, and display interfaces on Orion

EECOM: Emergency, Environmental, and Consumables Officer; monitors environmental controls, life support systems, and emergency procedures in Orion

FAO: Flight Activities Officer; manages and coordinates the flight plan to meet mission objectives, including timeline of all crew activities

FIDO: Flight Dynamics Officer; monitors the trajectory of Orion through the entire mission

Flight: The flight director; oversees all mission control activity

GNC: Guidance, Navigation, and Control Officer; operates and monitors navigation and flight control software on Orion

INCO: Integrated Communications Officer; monitors Orion's communication systems (data, telemetry, and video)

MPO: Mechanical and Power Officer; monitors electrical, mechanical, structural, and landing/recovery systems on Orion including batteries, solar arrays, thermal protection, etc.

PAO: Public Affairs Officer (Marge!); provides mission commentary, explains the mission and flight control operations to the public/media, and coordinates events between the media and crew/mission control

Prop: Propulsion Officer; monitors Orion's propulsion systems, engine burns, position control maneuvers

General Space Program/Mission Terminology: AGS: abort guidance system

ESA: European Space Agency

ESL: Earth Landing System - jettisons the crew capsule heat shield and releases the parachutes during re-entry into Earth’s atmosphere

EVA: Extravehicular activity (spacewalks and moonwalks)

G-LOC: Loss of consciousness due to G forces on the body; occurs when increased force of gravity causes blood to drain away from the head.

G-suit: a special flight suit worn by pilots to prevent blackout due to high G forces. Keeps blood from pooling in the lower body.

ISS: International Space Station

JSC: Johnson Space Center in Houston TX

KSC: Kennedy Space Center in Cape Canaveral, FL

Neutral Buoyancy Tank: Giant water tank at JSC used to simulate working in zero gravity

OCS suits: Orion Crew Survival suits; the space suits worn inside the spacecraft during critical mission phases and in an emergency situation

Launch and Other Spacecraft Terminology: APU: Auxiliary Power Unit; provides power/electricity to the spacecraft

Feet Wet: Navy and Air Force speak for being over water

“G” or Gs: the force of gravity (7 Gs is 7 times the force of gravity on Earth)

GLS: Ground Launch Sequencer; automated system that controls the countdown from about T-10 minutes on. Starting at this point, 'T-' is used instead of 'L-'

H-dot: the time derivative of height (the ascent rate of a space vehicle) during launch

ICPU: Interim Cryogenic Propulsion Stage; another stage of the SLS with more engines that are used to reorient the spacecraft after core stage separation

LEO: Low Earth Orbit

LLO: Low Lunar Orbit

Max q: maximum dynamic pressure on the rocket due to pushing through the thickest part of the atmosphere at high speeds

MECO: Main Engine Cut Off (literally cutting off the main engine)

NRHO: Near-Rectilinear Halo Orbit; the orbit that Orion will be in around the moon, balanced between the moon's gravity and the Earth's gravity; spacecraft in constant contact with and view of Earth

PGNS: pronounced “pings,” Primary Navigation and Guidance System

RRT: Re-entry interface - the moment the capsule re-enters Earth’s atmosphere

SRB: Solid Rocket Booster; solid propellant motors providing additional thrust (there are two on the sides of SLS)

TLI: Trans-Lunar Injection burn; firing the engines to get the spacecraft on a path towards the moon

4 notes

·

View notes

Text

"This STS-29 mission onboard photo depicts the External Tank (ET) falling toward the ocean after separation from the Shuttle orbiter Discovery. The giant cylinder, higher than a 15-story building, with a length of 154-feet (47-meters) and a diameter of 27,5-feet (8.4-meters), is the largest single piece of the Space Shuttle. During launch, the ET also acts as a backbone for the orbiter and solid rocket boosters. In separate, internal pressurized tank sections, the ET holds the liquid hydrogen fuel and liquid oxygen oxidizer for the Shuttle's three main engines. During launch, the ET feeds the fuel under pressure through 17-inch (43.2-centimeter) ducts which branch off into smaller lines that feed directly into the main engines. Some 64,000 gallons (242,260 liters) of fuel are consumed by the main engines each minute. Machined from aluminum alloys, the Space Shuttle's ET is the only part of the launch vehicle that currently is not reused. After its 526,000 gallons (1,991,071 liters) of propellants are consumed during the first 8.5 minutes of flight, it is jettisoned from the orbiter and breaks up in the upper atmosphere, its pieces falling into remote ocean waters."

Date: March 13, 1989

NASA ID: 8904587

#STS-29#Space Shuttle#Space Shuttle Discovery#Discovery#OV-103#Orbiter#NASA#Space Shuttle Program#external tank#space#earth#launch#March#1989#my post

12 notes

·

View notes

Text

Water Pressure Vessel vs. Expansion Tank: What’s the Difference?

Many people confuse water pressure vessels and expansion tanks, but they serve different purposes.

Choosing the right one is crucial for efficient water management, pump protection, and system performance.

This guide explains the key differences, applications, and how to select the right tank for your needs.

1. What is a Water Pressure Vessel?

Function:

Maintains stable water pressure in a system.

Reduces pump cycling, preventing excessive wear and tear.

Stores pressurized water to ensure consistent water flow.

How It Works:

Contains a bladder or diaphragm that separates air and water.

As water enters, the air compresses, creating pressure.

When a faucet or system demands water, it is released under pressure.

Common Applications:

✅ Booster pump systems to regulate water pressure. ✅ Residential water supply systems for steady pressure. ✅ Commercial & industrial water distribution. ✅ Irrigation systems to maintain water flow.

2. What is an Expansion Tank?

Function:

Absorbs thermal expansion in a closed-loop water heating system.

Prevents excessive pressure buildup that could damage pipes, valves, or water heaters.

Protects boilers, water heaters, and hydronic heating systems.

How It Works:

Divided into two sections: 🔹 Water chamber – Connected to the heating system. 🔹 Air chamber with diaphragm – Absorbs expanded water volume.

As water heats up, it expands into the tank, preventing pressure spikes.

Common Applications:

✅ Hot water heating systems (boilers & water heaters). ✅ Hydronic (radiator or underfloor) heating systems. ✅ Solar thermal water heating systems.

3. Key Differences: Water Pressure Vessel vs. Expansion Tank

FeatureWater Pressure VesselExpansion TankPurposeMaintains steady water pressureAbsorbs thermal expansionUsed InWater supply & booster pump systemsHot water & heating systemsPreventsPump cycling & pressure fluctuationsDamage from water expansionWorks WithPumps & pressurized water linesBoilers, water heaters, HVACDesignStores pressurized water for demandAllows expanded hot water to enterBladder/Diaphragm?Yes, to separate air & waterYes, to handle water expansion

4. Do You Need Both?

YES, if you have both a water supply system and a hot water heating system.

A pressure vessel is required for stable water pressure and pump efficiency.

An expansion tank is required to handle thermal expansion in closed-loop heating systems.

5. How to Choose the Right One

✔ For water pressure regulation: Choose a water pressure vessel based on system size & demand. ✔ For hot water systems: Use an expansion tank rated for your boiler or water heater. ✔ Check pressure ratings to ensure compatibility with your system. ✔ Consider tank material (stainless steel, composite, or coated steel) for longevity.

Water pressure vessels and expansion tanks serve different but equally important roles.

Pressure vessels are used in water supply systems, while expansion tanks protect heating systems.

Selecting the right tank ensures system efficiency, safety, and longevity. For more info contact Wates Pressure Vessel Supplier in UAE or call us at +971 4 2522966.

0 notes

Text

Best Water Pressure Pumps for Home Use: Boost Your Water Supply

Discover water pressure pumps designed for home use. Enhance your water supply and enjoy consistent pressure with our expert reviews and buying guide. Find the perfect pump for your needs today!

#water pressure pump for home#water pressure pump#pressure pump#pressure pump for overhead tank#water pressure booster

0 notes

Text

Versatility in Applications of Ebara Surface Pumps

Ebara surface pumps are designed with adaptability in mind, making them suitable for a wide range of applications across residential, commercial, and industrial sectors. Their advanced engineering and robust performance ensure reliability in diverse environments. Here's how Ebara surface pumps demonstrate exceptional versatility:

1. Residential Applications

Water Supply Systems: Ideal for maintaining consistent water pressure and supply in homes, especially in multi-story buildings.

Garden Irrigation: Efficiently handles small-scale irrigation needs for gardens and lawns.

Swimming Pools and Spas: Used for water circulation and filtration in residential pools.

2. Commercial Uses

Building Services: Supports HVAC systems, including heating and cooling applications, in commercial spaces.

Firefighting Systems: Reliable in emergency scenarios for maintaining high-pressure water delivery in fire suppression systems.

Booster Systems: Enhances water pressure in hotels, shopping malls, and office buildings.

3. Industrial Applications

Process Water Supply: Ensures a steady supply of water for industrial operations, such as cooling, cleaning, and production lines.

Chemical Transfer: Models made from corrosion-resistant materials are suitable for handling light chemicals.

Dewatering Operations: Efficiently removes water in mining, construction, and wastewater management projects.

4. Agricultural and Irrigation Needs

Field Irrigation: Provides the pressure and flow needed for sprinklers, drip systems, and flood irrigation.

Livestock Watering: Ensures a consistent water supply for large-scale livestock operations.

Drainage Systems: Used in draining fields or waterlogged areas after heavy rains.

5. Environmental and Sustainability Applications

Rainwater Harvesting: Facilitates water transfer from storage tanks for reuse in irrigation or domestic purposes.

Renewable Energy Integration: Compatible with solar-powered systems, enhancing sustainability in water management.

6. Specialized Applications

Aquaculture: Supports water circulation and aeration in fish farms.

Construction: Used for site dewatering and water supply in temporary setups.

Marine Uses: Stainless steel models can handle slightly saline water for coastal installations.

Features Enabling Versatility

Broad Flow and Pressure Range: Ebara surface pumps come in various models to meet different operational requirements.

Material Options: Pumps are available in stainless steel, cast iron, or composite materials for compatibility with different fluids and environments.

Self-Priming and Multistage Options: Tailored designs cater to specific needs like self-priming for remote areas or multistage pumps for high-pressure applications.

Easy Integration: Can be paired with other systems like filtration units, storage tanks, or automated controls.

The versatility of Ebara surface pumps makes them an invaluable asset for applications ranging from simple domestic tasks to complex industrial processes. Their ability to adapt to diverse environments, coupled with durability and efficiency, ensures they deliver outstanding performance across all sectors. For more info contact Ebara Pumps Middle East FZE or call us at +971 4 2522966.

0 notes

Text

William Mulholland the chief engineer of the Los Angeles aqueduct and reservoir system and much of its roads in the pacific palisades area.

As a long term resident of Malibu, I'd like to explain why I think the system ultimately failed catastrophically.

The open reservoir system in Los Angeles, implemented under William Mulholland's leadership, reflects both the prevailing engineering practices of the early 20th century and some of his limitations as a self-taught engineer. While the use of open reservoirs was standard at the time for water storage, the long-term consequences of this system—such as evaporation, contamination risks, and inefficiency—could suggest a lack of foresight or comprehensive understanding of more advanced alternatives.

As a self-taught engineer, Mulholland's approach relied heavily on practical experience and what was already proven to work. This sometimes limited his ability to anticipate or address long-term, systemic issues. His reliance on open reservoirs underscores some of the limitations of his expertise. His decisions were driven by immediate practicality and economic constraints rather than long-term planning or advanced theoretical understanding

The aqueduct system was designed primarily for efficiency in delivering water over long distances using gravity, but it lacked significant backup systems or alternative water sources for emergencies, such as fires. Fires often demand large amounts of accessible water in urban areas, but the aqueduct system did not include sufficient localized storage or auxiliary pipelines to ensure water delivery when the primary system was disrupted.

Formal training in civil or hydraulic engineering might have exposed Mulholland to concepts like system redundancy, emergency planning, and distributed water systems that could mitigate fire-related risks. Advanced knowledge of materials science and structural engineering might have led to more fire-resistant construction materials and methods.

Relying solely on gravity-fed water delivery in the Los Angeles Aqueduct system was a significant factor contributing to inconsistent or insufficient water pressure in fire hydrants, especially in urban firefighting scenarios. While gravity-based systems are cost-efficient and reliable under normal conditions, they come with inherent limitations that were exacerbated by Mulholland's design choices and the lack of complementary infrastructure.

Fire hydrants in areas that were uphill from the aqueduct or localized reservoirs often experienced low or no water pressure because the system lacked pumps or booster stations to maintain adequate flow.

Mulholland's reliance on a single, gravity-fed system prioritized efficiency and cost savings but ignored the diverse demands of urban water usage, including firefighting. Without auxiliary pumping stations or pressurized mains, the system could not adapt to localized needs like firefighting in dense or elevated areas.

The aqueduct provides water to various reservoirs and local tanks, which serve as key sources for firefighting efforts. If these reservoirs were depleted due to the high demand caused by the fires, it reflects a limitation of the system in handling emergency scenarios, despite the aqueduct delivering water to the area.

The aqueduct’s capacity to deliver water under gravity flow to distant areas like Pacific Palisades can be impacted by high demand, especially in areas with hilly terrain. The local distribution infrastructure connected to the aqueduct, including the reservoirs, struggled to meet the urgent need during the fire, leading to low pressure.

1 note

·

View note

Text

🌟#Ras_Al_Khair Project – Comprehensive Solutions for Optimal Performance🌟

As part of the Ras Al Khair labor housing project by MAPA INSAAT KSA, Advanced Pumps #supplied and #assembled a Duplex Water #BoosterPumps Set, featuring EBARA vertical multi-stage pumps and a Schneider Electric control panel, in full compliance with international standards.

Scope of Supply:

🔹️Pumps:

Two #EBARA vertical multi-stage pumps, model EVMSL 20-8.

▫️Power: 15 kW.

▫️Flow: 26 m³/hr.

▫️Head: 150 meters.

🔹️Associated Equipment:

▫️Stainless steel (304) suction and discharge manifolds.

▫️Non-return and gate valves to ensure operational efficiency.

▫️A 1000-liter pressure tank for enhanced system stability.

▫️ #Schneider Electric control panel with dry-running protection.

The system was fully assembled at #Advanced_Pumps’ facility using premium-quality materials to deliver optimal performance. This solution ensures high efficiency and reduced operational costs, meeting the project's requirements with precision and reliability.

#Construction #Infrastructure #RiyadhProjects #Engineering #ProjectManagement #saudiarabia

🌟مشروع راس الخير – حلول متكاملة لضمان كفاءة الأداء🌟

ضمن مشروع راس الخير لسكن العمال الذي تنفذه شركة MAPA INSAAT KSA قامت شركة المضخات المتقدمة بتوريد وتجميع مجموعة مضخات تعزيز المياه المزدوجة (Duplex Water Booster Pumps Set) باستخدام مضخات EBARA الرأسية متعددة المراحل ولوحة تحكم من Schneider Electric، بما يتوافق مع أعلى المعايير العالمية.

نطاق التوريد:

🔹️المضخات:

عدد 2 مضخة رأسية متعددة المراحل من طراز EVMSL 20-8.

▫️القدرة: 15 كيلوواط.

▫️التدفق: 26 متر مكعب/ساعة.

▫️الارتفاع: 150 متر.

🔹️المعدات المرفقة:

▫️مشعبات السحب والتصريف من الستانلس ستيل (304).

▫️صمام عدم رجوع وصمامات بوابية لضمان الكفاءة التشغيلية.

▫️خزان ضغط بسعة 1000 لتر لتحسين استقرار النظام.

▫️لوحة تحكم Schneider Electric مع حماية من التشغيل الجاف.

��م تصنيع وتجميع النظام بالكامل في #مصنع_شركة_المضخات_المتقدمة باستخدام مواد عالية الجودة لضمان الأداء الأمثل للمشروع. يضمن هذا الحل كفاءة عالية وتقليل التكاليف التشغيلية، ما يعزز من رضا العملاء ويحقق متطلبات المشروع بنجاح.

#البنية_التحتية #مشاريع_الرياض #المقاولات #تطوير_المشاريع #السعودية

0 notes

Text

How Can I Increase the Water Pressure In My House?

Low water pressure can be frustrating, whether it’s affecting your morning shower, your ability to water the garden, or your washing machine’s efficiency. If you’ve noticed that your water pressure isn’t up to par, there are several potential fixes to consider. Here’s a guide to help you troubleshoot and improve your home’s water pressure.

1. Check for Clogs in Pipes or Fixtures

Over time, mineral deposits and debris can build up in your plumbing or fixtures, reducing water flow. To address this:

Inspect Faucets and Showerheads: Remove and clean aerators or showerhead filters. Soaking them in vinegar can dissolve mineral deposits.

Examine the Pipes: If water pressure is low throughout the house, internal pipe blockages might be the issue. You may need professional help to clear significant clogs.

2. Inspect Your Pressure Regulator

Homes with a pressure regulator installed on the main water line can experience low water pressure if the regulator malfunctions or is set incorrectly. Here’s what you can do:

Test the Pressure: Use a pressure gauge to measure your home’s water pressure. Ideal pressure ranges between 40-60 psi.

Adjust or Replace: If the pressure is too low, adjust the regulator or replace it if it’s faulty.

3. Look for Leaks

Leaks in your plumbing system can significantly reduce water pressure. To check for leaks:

Inspect Visible Pipes: Look under sinks and in basements or crawl spaces for dripping or pooling water.

Use Your Water Meter: Turn off all water in your house and check your water meter. If it’s still running, you may have a leak.

Call a Professional: For hidden leaks, consult a plumber to locate and repair them.

4. Check the Main Shutoff Valve

The main shutoff valve controls the water flow into your home. If it’s not fully open, it could be the source of your low pressure. Locate the valve, often found near your water meter or where the main line enters your house, and ensure it’s turned to the fully open position.

5. Address Issues with Your Municipal Supply

Sometimes, the problem isn’t with your home’s plumbing but with the municipal water supply. To investigate:

Ask Neighbors: If others in your area are experiencing similar issues, it’s likely a municipal problem.

Contact Your Water Provider: Report the issue and ask if there are repairs or maintenance affecting water pressure.

6. Install a Water Pressure Booster

If your water pressure remains low despite addressing other issues, a water pressure booster pump might be the solution. These devices increase the flow of water coming into your home and can be installed by a professional plumber.

7. Upgrade Outdated Plumbing

Older homes often have narrow or corroded pipes that restrict water flow. Replacing outdated plumbing with modern materials like PEX or copper can significantly improve water pressure. This is a larger investment, but it’s a long-term solution to persistent pressure issues.

8. Check Your Water Heater

If you notice low water pressure only with hot water, your water heater might be to blame. Sediment buildup in the tank or partially closed valves can restrict hot water flow. Regular maintenance, such as flushing the tank, can help.

0 notes

Text

FT Gold Booster Pump: The Smart Solution to Consistent Water Pressure

Water is an essential part of our daily lives, but without adequate pressure, even simple tasks can become frustrating. Weak showers, slow-filling tanks, or uneven water flow can disrupt your day and lower efficiency in both homes and businesses. Fortunately, the FT Gold Booster Pump is designed to eliminate these issues, providing steady and reliable water pressure no matter the application.

In this blog, let’s dive into what makes the FT Gold Booster Pump a must-have for anyone dealing with low water pressure.

Understanding the Need for a Booster Pump

Low water pressure can result from a variety of factors, such as:

High-rise buildings: Water loses pressure as it travels upward.

Multiple water outlets: Simultaneous use of taps, showers, and appliances strains the system.

Municipal supply issues: Inconsistent or low pressure from the main supply line.

Remote locations: Rural or off-grid areas often face pressure challenges.

The FT Gold Booster Pump is the ideal solution, ensuring consistent water pressure that meets your needs, no matter the cause of the problem.

What Makes the FT Gold Booster Pump Stand Out?

1. Powerful Motor Performance

The heart of any pump is its motor, and the FT Gold excels here. Its high-capacity motor ensures constant water flow, even when demand is high.

2. Automatic Pressure Control

With built-in sensors and automatic controls, the pump adjusts its operation to maintain steady pressure. This eliminates the need for manual intervention and ensures seamless water delivery.

3. Durable and Corrosion-Resistant Design

Constructed from premium materials, the FT Gold Booster Pump is built to last. It resists wear and tear, even in environments with hard water or varying temperatures.

4. Compact and Quiet Operation

Despite its powerful performance, the FT Gold is compact enough to fit into tight spaces and operates with minimal noise, making it suitable for homes and offices alike.

5. Energy Efficiency

The pump’s advanced design minimizes energy consumption without compromising on performance. This means lower electricity bills and a reduced environmental footprint.

Top Benefits of the FT Gold Booster Pump

Strong, Consistent Showers: Enjoy spa-like showers every time, even on upper floors or during peak water usage.

Reliable Appliance Performance: Water heaters, washing machines, and dishwashers operate optimally with steady pressure.

Enhanced Efficiency: Whether filling tanks or watering your lawn, tasks are completed faster and with less waste.

Increased Property Value: A robust water system is a feature buyers love, making this a worthwhile investment for your home or business.

Applications of the FT Gold Booster Pump

The versatility of the FT Gold Booster Pump makes it suitable for a range of scenarios:

1. Residential Use

Ideal for individual homes, apartments, and villas.

Delivers consistent pressure to taps, showers, and kitchen appliances.

2. Commercial Use

Perfect for restaurants, gyms, hotels, and offices.

Ensures steady water supply for staff, customers, and equipment.

3. Agricultural Use

Boosts water flow in irrigation systems.

Supports small farms and gardens with reliable performance.

4. Industrial Use

Handles small-scale industrial applications like cooling systems, cleaning stations, and machinery.

Choosing the Right FT Gold Model

The FT Gold Booster Pump comes in a variety of models to suit different requirements. Here’s how to determine the right one for you:

Assess Your Water Demand: Calculate your household or facility’s daily water usage.

Understand Your System’s Needs: Consider factors like building height, number of water outlets, and existing infrastructure.

Consult Experts: Reach out to professionals or the FT Gold support team for guidance.

Real Customer Experiences

⭐️⭐️⭐️⭐️⭐️ "We installed the FT Gold Booster Pump in our 3-story home, and the difference is unbelievable! The showers are powerful, and there’s no more fighting over water pressure when someone’s doing dishes." — Meera D., Hyderabad

⭐️⭐️⭐️⭐️⭐️ "Our café used to struggle with low water pressure during rush hours. Since we installed the FT Gold Booster Pump, everything runs smoothly—even when all taps are in use!" — Ramesh P., Mumbai

Easy Installation and Maintenance

The FT Gold Booster Pump is designed for simplicity. Installation is quick, whether you’re a DIY enthusiast or relying on a professional plumber. Regular maintenance involves basic tasks like:

Cleaning filters to prevent blockages.

Ensuring electrical connections are secure.

Inspecting for wear and tear periodically.

Its user-friendly design ensures long-lasting, hassle-free performance.

Why Choose FT Gold Booster Pump?

With so many options on the market, the FT Gold Booster Pump rises above the competition due to its blend of:

Exceptional performance for homes, businesses, and industries.

Energy efficiency that saves money in the long run.

Trusted durability for years of reliable service.

Final Thoughts

Don’t let low water pressure slow you down. The FT Gold Booster Pump is a smart investment that delivers powerful, consistent performance, enhancing your daily routines and business operations.

Experience the difference today—upgrade to the FT Gold Booster Pump and enjoy water pressure that never lets you down!

Have questions or need help choosing the right model? Let us know in the comments, and we’ll guide you to the perfect water pressure solution. 🚿💧

0 notes