#warehouse pallet racking systems

Text

Boosting Profit Margins with Strategic Pallet Racking Solutions

In today's competitive market, businesses are constantly looking for ways to optimize operations and enhance profitability. One of the critical areas where efficiency can significantly impact the bottom line is in warehouse management. The organization and storage solutions you choose for your warehouse can either streamline your operations and reduce costs or become a bottleneck that leads to inefficiencies and increased expenses. Among the myriad of options available for optimizing warehouse space and operations, one solution stands out for its effectiveness and reliability: pallet racking systems.

0 notes

Text

Optimize Your Space with Modern Warehouse Racking Systems

A warehouse is a well-organized and planned space used to manage a company's merchandise. To effectively design a warehouse or distribution center, it is important to consider its purpose and desired outcomes, especially for your pallet racking.

Key Factors in Warehouse Layout Design

With that in mind, the following factors should be taken into account for the layout of our warehouse, depending on the product type and company characteristics:

A good storage system offers a range of benefits, including access to a vast number of references on pallets, as well as direct access to smaller references.

With the ability to constantly relocate items based on seasonal demand and group together similar lines, our system ensures maximum efficiency. Our pickers can work at top speed without interference from other pickers or stock replacements, allowing for seamless operations.

Additionally, you can monitor your stock in real-time and have full visibility of all products and references.

Racking systems and handling equipment are designed for optimal ergonomics, while our physical locations allow for easy placement of products based on their stock depletion levels (high, medium, or low).

All of this needs to be achieved at a controlled cost with a guaranteed return on investment. Plus, our maintenance services are designed to be profitable and we offer the flexibility to enable shift work as needed.

And, should your needs expand in the future with more references, pallets or picking units, our system can easily be extended and modified accordingly.

Components of a Warehouse or Distribution Centre's Layout

What are the components of a warehouse or distribution center's layout?

An essential aspect of the design of a warehouse or distribution center is its layout, which involves planning the distribution and organization of both external and internal spaces.

This process can have a significant impact on the supply chain, whether it is due to the acquisition of a new warehouse, expansion, or remodeling. The efficiency of managing stocks stored in the warehouse must be reflected in its layout, such as for storing raw materials or finished products.

The design should encompass multiple elements, including the interior and exterior arrangement of the warehouse, the number of floors, installations (electrical, architectural, ventilation), environmental conditions, safety measures, and industrial racking systems for different areas.

Key Components in Warehouse Layouts

Every efficient warehouse, no matter the size or industry, requires a set of key components that serve as the foundation for its layout. These components must be strategically placed and organized to ensure optimal efficiency for the entire operation. It is crucial to carefully consider the layout within each component, as they all play a role in the overall efficiency of the warehouse. Let's take a look at the essential components that should be included and well-arranged in any warehouse layout.

Receiving Area

The unloading, checking in, and sorting of incoming shipments takes place in the receiving area, located within the warehouse. This area is usually connected to a receiving bay, allowing for convenient access for trucks and vehicles delivering goods. Ideally, the receiving area should be situated next to the storage area for efficient movement of incoming items to their designated places.

Storage Area

The inventory is stored in a designated area until it is needed for order fulfillment. This storage space needs to be both orderly and easily accessible, with direct access to the receiving and packing areas.

Common features of a storage area include pallet racks and shelving units specifically used for storing inventory. By ensuring an efficient layout, the storage area can effectively minimize travel time, increase order picking precision, and improve overall inventory management efficiency.

Packing Area

The packing area is where orders are prepared for shipment after being selected. It is usually located adjacent to the storage area and shipping bay. To expedite the shipping process, packing areas should prioritize increased efficiency and precision while also prioritizing the well-being and safety of workers.

Shipping Area

The shipping area is where outgoing orders are processed and readied for delivery. Situated within the warehouse, it is the opposite of the receiving area. The location typically includes a connection to a shipping bay on one side and direct entry to the parking area on the other.

Efficient warehouse designs take into consideration ample space in the shipping area for tasks such as pallet wrapping and using machinery like pallet jacks and forklifts. Additionally, there is a room designated for organizing completed orders that will soon be transported by truck for distribution.

Facility Support Areas

Facility support areas, including restrooms, employee break rooms, and management offices, play a vital role in the daily functioning of the facility. Restrooms need to be conveniently located for workers, while office space should be situated near receiving and/or shipping areas to facilitate tasks such as processing invoices, communicating with clients, suppliers, and logistics companies, and managing other day-to-day responsibilities.

Conclusion

In conclusion, whether your business operates on a small scale or requires large-scale storage, Complete Warehouse Solutions in Lake Illawarra, NSW 2528, has the expertise to provide tailored warehouse racking solutions. With our commitment to maximizing space and improving efficiency, we can help you streamline your operations and boost productivity.

#pallet racking#warehouse racking#pallet rack systems#industrial racking#warehouse racking system#warehouse shelving racks#industrial storage racks#warehouse storage racks#warehouse pallet racks#industrial pallet racks#industrial racking systems#storage racking system#warehouse racking solutions#warehouse shelving systems#warehouse pallet racking system#warehouse rack and shelf#industrial racking shelves

2 notes

·

View notes

Text

#pallet rack warehouse & supply#pallet rack warehouse#pallet shuttle system#carton flow racking systems#industrial warehouse racking cincinnati ohio

1 note

·

View note

Text

What is a VNA Rack? Exploring the VNA Warehouse Racking System and Its Key Features

In modern warehouse management, selecting the appropriate storage racking system plays a crucial role in optimizing space and enhancing operational efficiency. One of the popular solutions today is the VNA rack. The article below will help you gain a better understanding of VNA racks, their structure, features, and applications in warehouses.

What is a VNA Rack?

VNA racks (Very Narrow Aisle racks) is a storage system designed with narrow aisles. The Very Narrow Aisle racking is utilized in warehouses with limited space that need to maximize vertical storage, thereby increasing storage capacity without the need to expand the warehouse footprint.

Dimensions of VNA Racks

VNA rack dimensions are designed with flexibility in mind. Below is the standard size chart for the Very Narrow Aisle (VNA) rack line internationally:

Load Capacity: 500 – 5,000 kg per level.

Height: From 5 to 17 meters.

Row Length: 2.5 to 4 meters or more, depending on the manufacturer's design.

Pallet Width Compatibility: Typically 800 mm, 1000 mm, or 1200 mm.

Beam Standards: 2700 mm, 2300 mm, 2700 mm.

Optimal Row Height: 15-18 meters (customizable based on warehouse scale).

Eurorack offers customized solutions, allowing size adjustments according to the specific requirements of each warehouse. This flexibility helps optimize storage space, enabling easy expansion or contraction as the business grows. Selecting the appropriate size not only enhances operational efficiency but also reduces warehouse management costs.

See more: Warehouse racking systems

Structure of VNA Racking Systems

The VNA racking system comprises the following main components:

Rack Frame: The primary load-bearing structure, typically made from high-grade steel to ensure durability and stability. The steel frame includes columns and connecting beams that support the entire system's load.

Beams: Connect between two load-bearing columns, ensuring the safe placement of pallets.

Guided Rails: Installed beneath the floor to assist forklifts in navigating through the rack rows.

Safety System: Includes barriers, guardrails, and partition doors to ensure worker safety and protect goods.

Columns, beams, and support bars are designed by Eurorack with modern safety locking systems, ensuring secure and reliable operations.

Video : Eurorack VNA racking system meet ISO 9001 standard

youtube

Features of VNA Racks

This heavy-duty VNA rack line boasts several outstanding features, making it a preferred choice for many businesses:

Space Optimization: The narrow design helps save warehouse space, making it ideal for small or limited-area warehouses.

Increased Storage Capacity: Efficiently utilizes vertical space, increasing the number of stored goods without needing to expand the warehouse area.

Easy Access: The lift system allows for easy retrieval and placement of goods, reducing search and handling time.

High Durability: Constructed with quality materials, VNA racks have a long lifespan and can support heavy loads.

Easy Installation and Maintenance: The simple design facilitates easy installation and maintenance, reducing operational costs.

Suitable Warehouses for VNA Racks

VNA racks are suitable for various types of warehouses, particularly:

Small and Medium Warehouses: With limited space, VNA racks help optimize the storage area.

Warehouses Storing Diverse Goods: Ideal for businesses needing to store various products of different sizes.

Warehouses with High Safety Requirements: Integrated safety systems ensure the protection of goods and workers.

Warehouses Needing Workflow Optimization: Helps reduce access and handling time, enhancing operational efficiency.

Industrial and Manufacturing Warehouses: Suitable for storing large quantities of uniform, fixed goods.

VNA Racking Suppliers in Vietnam

Choosing a reputable and quality VNA racking supplier is crucial to ensure the system operates effectively. In Vietnam, Eurorack is one of the leading suppliers of warehouse racking solutions, including industrial VNA racks. With years of experience and a professional team, Eurorack is committed to providing customers with high-quality storage rack products that meet all business storage needs.

Quote of racking system at:

Pallet storage racking price list

Why Choose Eurorack?

Product Quality: Utilizes high-grade materials, ensuring durability and safety.

Customized Design: Capable of designing racking systems tailored to each customer's specific requirements.

Professional Support Services: Experienced consulting and installation teams support customers from design to maintenance.

Competitive Pricing: Offers cost-effective solutions while maintaining high quality.

Safety Certifications and Reputable Imported Steel: Ensures compliance with safety standards and uses trusted materials.

Eurorack also provides regular maintenance during the warranty period. After the warranty expires, the technical support team continues to assist with any issues, ensuring customers have peace of mind when using Eurorack products.

VNA racks are an ideal solution for modern warehouses, helping to optimize storage space, enhance operational efficiency, and ensure safety. With a robust structure, outstanding features, and suitability for various types of warehouses, VNA racks are increasingly chosen by businesses. To ensure the racking system operates effectively, selecting a reputable supplier like Eurorack will bring numerous benefits to your enterprise.

If you are seeking an optimal storage solution for your warehouse, contact Eurorack today for expert advice and the most suitable VNA racking system tailored to your needs.

Contact:

Eurorack mechanical JSC

Hotline: 0938520379

Email: [email protected]

Website: www.eurorack.vn - www.eurorack.com.vn

Address: 5/3 Doan Thi Diem Street, Ward 1, Phu Nhuan District, Ho Chi Minh City, Vietnam

#vna racking#vna system#vna pallet racking#vna warehouse#very narrow aisle pallet racking#very narrow aisle racking#very narrow aisle racking system#vna racking system#price of vna racking#warehouse racking system#storage racking system#Youtube

1 note

·

View note

Text

Efficient Warehouse Storage Solutions for Supermarkets & Food Processing Equipment - Global Automation Ltd

Discover essential warehouse storage strategies, including pallet racking systems, mezzanine floors, and temperature-controlled storage. Optimize space and maintain product quality in supermarkets and food processing with Global Automation Ltd’s tailored solutions.

#Warehouse storage solutions#Pallet racking systems#Mezzanine floors warehouse#Temperature-controlled storage#Warehouse shelving systems#Supermarket storage strategies#Food processing equipment storage#Commercial refrigeration solutions#Inventory management software#Optimizing warehouse space

0 notes

Text

Designing for Space Mobile Compactor Storage System Manufacturers

Space efficiency is at the core of modern mobile compactor design. Mobile Compactor Storage System Manufacturers are dedicated to creating solutions that optimize every inch of available space. By employing advanced engineering principles and innovative storage solutions, these manufacturers ensure that their systems can handle large volumes of items in a compact footprint. Key elements such as adjustable shelving, robust track systems, and modular design are crucial for achieving optimal space utilization.

Mobile Compactor Design: What Sets the Best Manufacturers Apart

Leading Mobile Compactor Manufacturers distinguish themselves through innovation and quality. They incorporate cutting-edge technology and advanced materials to create storage systems that are both efficient and durable. Features like electronic control systems, automated movement mechanisms, and smart inventory management are examples of how these manufacturers push the boundaries of traditional storage solutions. By staying at the forefront of technological advancements, they offer superior products that meet diverse and demanding storage needs.

Design Process Behind Effective Mobile Compactors

The journey from concept to reality in mobile compactor design involves several critical stages. Mobile Compactor Storage System Manufacturers begin with detailed needs assessments and feasibility studies to understand the specific requirements of their clients. This is followed by conceptual design, prototyping, and rigorous testing to ensure that the final product meets all performance and safety standards. Collaboration with clients throughout the process ensures that the end result is a tailored solution that effectively addresses their space-saving needs.

Maximize Space Utilization in Mobile Compactors

Effective mobile compactor design incorporates several key elements to maximize space utilization. Adjustable shelves and racks allow for flexible storage arrangements, while high-density configurations ensure that more items can be stored in less space. The use of efficient track systems and compact, movable units enables easy access to stored items without sacrificing space. By integrating these design elements, Mobile Compactor Manufacturers can deliver solutions that provide significant space savings and improve overall storage efficiency.

The Art of Mobile Compactor Design

In the realm of mobile compactor design, balancing aesthetics with functionality is an art form. Leading manufacturers understand that while efficiency is paramount, the visual appeal of the storage system also plays a role in its overall effectiveness. Sleek, modern designs that complement the surrounding environment and intuitive user interfaces enhance the user experience. By harmonizing form and function, Mobile Compactor Storage System Manufacturers create products that are not only practical but also visually appealing.

Tailoring Mobile Compactors to Unique Space Needs

One of the key advantages of working with Mobile Compactor Manufacturers is their ability to offer customization and flexibility. Tailored solutions are essential for addressing the unique requirements of different spaces and industries. Whether it’s adjusting the dimensions of the compactor, incorporating specialized shelving, or integrating custom features, manufacturers can design systems that perfectly fit the client’s specific needs. This level of customization ensures that the storage solution is both functional and efficient.

The Role of Technology in Modern Mobile Compactor Design

Technology plays a pivotal role in the evolution of mobile compactor design. Modern Mobile Compactor Storage System Manufacturers leverage advancements such as automated controls, real-time tracking, and integration with warehouse management systems to enhance functionality. These technological innovations not only improve the efficiency of the storage system but also provide valuable data and insights for better inventory management. The incorporation of smart technology is a key factor in the continued advancement of mobile compactor solutions.

Successful Space-Saving Designs from Leading Manufacturers

Examining case studies from successful mobile compactor projects highlights the practical benefits of advanced design and technology. For instance, a leading Mobile Compactor Manufacturer might showcase a project where a customized compactor system significantly increased storage capacity in a constrained space, leading to enhanced operational efficiency. These real-world examples illustrate how innovative design and engineering solutions can effectively address complex storage challenges.

Mobile Compactor Design: Eco-Friendly Innovations

Sustainability is increasingly becoming a focal point in mobile compactor design. Many Mobile Compactor Storage System Manufacturers are adopting eco-friendly practices, such as using recycled materials, implementing energy-efficient components, and designing systems that minimize waste. These innovations not only contribute to environmental conservation but also help companies meet their sustainability goals. By integrating green practices into their designs, manufacturers are making a positive impact on both the environment and the industry.

Future Trends in Mobile Compactor Design

The future of mobile compactor design is poised to bring even greater advancements in space efficiency. Emerging trends include the integration of artificial intelligence for predictive maintenance, further automation to streamline operations, and the development of more versatile and modular systems. As technology continues to evolve, Mobile Compactor Manufacturers will play a crucial role in driving these innovations, shaping the future of space-efficient storage solutions.

#Industrial Slotted Angle Storage Rack Manufacturers#Mobile Compactor Storage System Manufacturers#Warehouse Pallet Storage Rack Manufacturers#Slotted Angle Storage Rack Manufacturers#Mobile Compactor Manufacturers

0 notes

Text

Comprehensive Commercial Storage Solutions: From Racks to Pallets

Explore our comprehensive range of commercial storage solutions tailored to meet your specific needs. From storage racks and cold storage to storage boxes and warehousing, we provide robust systems to optimize space and enhance efficiency. Our offerings include cable trays in various sizes, ideal for organizing and protecting your wiring infrastructure. As a leading pallet rack manufacturer, we deliver durable pallet racking systems and heavy-duty racks perfect for industrial applications. For retail environments, we offer specialized racks for shops, supermarket racks, and grocery store racks to maximize product display and storage.

Our slotted angle racks and plastic pallets ensure versatile and resilient storage options. Partner with us for top-quality storage products, including industrial pallets and vegetable display racks that cater to diverse warehousing needs. As a supermarket rack manufacturer and display rack for shop provider, we help businesses optimize space and improve customer experience. For cable management, our cable tray manufacturer services offer reliable solutions. Additionally, our warehouse storage solutions and plastic pallets provide robust support for various storage applications.

Website - https://suvidhass.com/

Call more information : +91 9682939624

#Storage Rack#Cold Storage#Storage Box#Warehousing#Cable Tray#Cable Tray Sizes#Pallet Rack Manufacturer#Racks for shop#Super Market Rack#Racks for Storage#Slotted Angel Rack#Plastic Pallets#Racks#Heavy Duty Rack Manufacturer#Storage Products#Pallet Racking System#Supermarket Rack Manufacturer#Display Rack for Shop#Cable Tray Manufacturer#Warehouse Storage#Grocery Store Racks#Industrial Pallet#Vegetable Display Rack#Plastic Pallet

1 note

·

View note

Text

choose the right one of heavy duty pallet storage rack manufacturers for your business-indostoragetechnologies

For more details visit: https://www.indostoragetechnologies.com/pallet-loading-racks-manufacturers.html

contact us:+91 97395 49891

#pallet#pallet racking#heavy duty racks#warehouse shelving#warehouse racking system#manufacturers#indostoragetechnologies

0 notes

Text

Unlocking the Art of Storage: Exploring Racking and Shelving Providers in UAE

Introduction: Embracing the Poetry of Organization

In the bustling landscape of the United Arab Emirates (UAE), where the rhythm of progress echoes through the skyscrapers, lies a silent symphony of organization - a harmony composed by racking and shelving providers. Among them, stands the esteemed company, Zyco, offering a poetic fusion of functionality and elegance to the art of storage.

1. The Melody of Racking and Shelving Companies in UAE

In the heart of UAE's industrial and commercial hubs, a chorus of racking and shelving companies orchestrates the storage solutions that fuel the nation's economy. These providers, including Zyco, blend innovation with tradition, offering a diverse array of storage systems tailored to every need.

1.1 Pallet Racking & Storage System in UAE: A Symphony of Efficiency

Pallet racking systems form the backbone of storage efficiency, transforming warehouses into organized symposiums of productivity. In UAE, companies like Zyco craft pallet racking solutions that dance seamlessly with the ebb and flow of inventory, ensuring optimal space utilization and accessibility.

1.2 Customized Industrial Racking in UAE: Crafting Unique Sonnets of Storage

Every industry has its own verse, its own unique narrative that demands bespoke storage solutions. Here, Zyco emerges as a virtuoso, composing customized industrial racking systems that resonate with the specific needs and nuances of each client, transforming storage into an art form.

2. Warehouse Racking Solutions Dubai: Painting Pictures of Precision

Dubai, the vibrant canvas where modernity meets tradition, is adorned with warehouse racking solutions that reflect the city's penchant for precision and elegance. Zyco, with its innovative designs and meticulous craftsmanship, adds strokes of brilliance to Dubai's skyline, redefining the essence of storage.

2.1 Heavy Duty Racking In Dubai: Forging Fortresses of Strength

In the crucible of Dubai's industrial landscape, where strength is revered as much as beauty, heavy-duty racking emerges as a testament to resilience. Zyco's heavy-duty racking solutions stand as citadels of strength, fortifying warehouses against the tides of time and demand.

Conclusion: A Poetic Ode to Zyco - Where Storage Meets Symphony

In the tapestry of UAE's storage landscape, Zyco shines as a beacon of innovation and artistry, weaving together the threads of functionality and aesthetics to create storage solutions that resonate with the soul. With each rack and shelf, Zyco composes a new stanza in the poetry of organization, enriching the UAE's narrative of progress and prosperity.

Unique FAQs: Unveiling the Mysteries of Storage

What sets Zyco apart from other racking and shelving providers in UAE?

Zyco distinguishes itself through its commitment to innovation, craftsmanship, and personalized solutions tailored to each client's needs.

How does Zyco ensure the durability of its storage systems?

Zyco utilizes premium materials and rigorous quality control measures to ensure the durability and longevity of its storage solutions, backed by comprehensive warranties.

Can Zyco accommodate specialized storage requirements for niche industries?

Yes, Zyco specializes in crafting customized storage solutions for a wide range of industries, adapting to the unique challenges and specifications of each sector.

Does Zyco offer installation services for its racking and shelving systems?

Absolutely, Zyco provides end-to-end solutions, including professional installation services conducted by skilled technicians to ensure seamless integration and functionality.

How can businesses in UAE access Zyco's range of storage solutions?

Businesses can easily connect with Zyco through its website or by contacting their dedicated customer support team to discuss their storage needs and explore tailored solutions.

0 notes

Text

How to Run a Warehouse with Lower Costs: A Practical Guide

Running a warehouse efficiently while keeping costs low is a challenge many businesses face. As operational expenses continue to rise, finding ways to reduce costs without compromising efficiency or service quality becomes crucial. In this guide, we'll explore practical strategies that can help you lower your warehouse costs, enhance productivity, and maintain smooth operations.

Optimize Space Utilization

One of the most effective ways to reduce warehouse costs is by optimizing space utilization. An organized warehouse allows for better management of inventory and reduces the time spent locating items. Implementing a Warehouse Pallet Racking System fromB&H Shelving can significantly increase storage capacity without expanding your facility. These systems allow you to maximize vertical space, which often goes underutilized. By using the right racking system, you can store more products in a smaller area, reducing the need for additional warehouse space.

Streamline Warehouse Processes

Streamlining warehouse processes is another crucial step in lowering costs. Begin by evaluating your current workflows to identify any inefficiencies or bottlenecks. Once identified, work on simplifying these processes, whether it’s by rearranging the layout, improving labeling systems, or automating repetitive tasks. Automation, in particular, can lead to significant savings in labor costs. Additionally, adopting an advanced inventory management system can help you keep better track of your stock, reducing the chances of overstocking or stockouts.

Invest in Quality Equipment

Investing in high-quality equipment may seem counterintuitive when trying to cut costs, but it can actually save money in the long run. Durable, well-maintained equipment reduces the frequency of repairs and replacements, which can be costly. A Warehouse Pallet Racking System from B&H Shelving is designed to be robust and long-lasting, ensuring that your investment will stand the test of time. High-quality racking systems not only enhance safety within your warehouse but also minimize the risk of damage to your goods, reducing potential losses.

Focus on Energy Efficiency

Energy costs can be a significant portion of your warehouse expenses. Start by upgrading to energy-efficient lighting systems, such as LED lights, which consume less power and have a longer lifespan. Additionally, consider installing motion sensors in areas that are not constantly in use to further reduce electricity consumption. Heating, ventilation, and air conditioning (HVAC) systems should also be regularly maintained to ensure they are running efficiently. Implementing these changes can lead to noticeable reductions in your utility bills over time.

Train and Engage Employees

Your workforce is one of your most valuable assets, and investing in employee training can help lower costs. Well-trained employees are more efficient, make fewer mistakes, and are better equipped to handle the demands of a busy warehouse environment. Regular training sessions on safety protocols, equipment handling, and inventory management can lead to increased productivity and lower the risk of accidents, which can be costly in terms of both time and money. Additionally, engaged employees who feel valued are more likely to contribute to process improvements and cost-saving ideas.

Regularly Review and Adapt Your Strategies

The business environment is constantly changing, and so should your strategies for running a warehouse efficiently. Regularly reviewing your warehouse operations and making necessary adjustments is essential for staying competitive and cost-effective. Analyze key performance indicators (KPIs) such as order accuracy, inventory turnover, and return rates to identify areas for improvement. By continuously adapting your strategies, you can keep your warehouse running smoothly while minimizing costs.

Conclusion

Lowering warehouse costs without sacrificing efficiency requires a combination of strategic planning, investment in quality systems, and ongoing process optimization. Implementing a Warehouse Pallet Rackingis a smart investment that can significantly enhance space utilization and improve overall warehouse efficiency. By focusing on these key areas, you can create a more cost-effective, efficient, and profitable warehouse operation.

Resource : https://bandhshelvings.blogspot.com/2024/09/How-to-Run-a-Warehouse-with-Lower-Costs-A-Practical-Guide.html

0 notes

Text

0 notes

Text

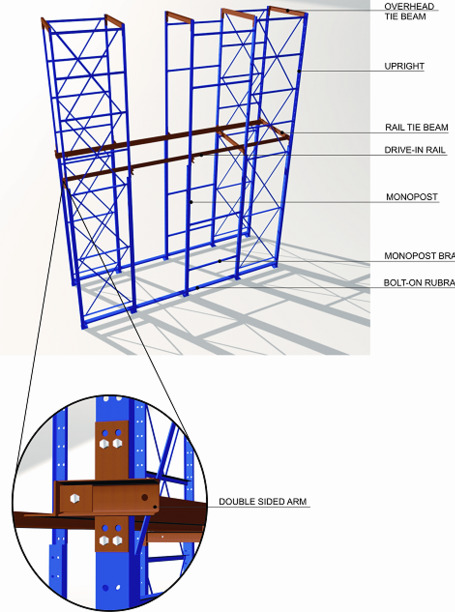

The Drive-In Racking system is an excellent solution for maximizing warehouse storage in high-density environments. Designed for storing large quantities of similar products, this system allows forklifts to drive directly into the rack structure, enabling deep storage of pallets in lanes. With no need for individual access aisles for each pallet, Drive-In Racking optimizes space by allowing more goods to be stored in a smaller area. It’s ideal for industries with high-volume, low-rotation products, such as cold storage and food processing. Eurorack’s Drive-In Racking is built to handle heavy loads while ensuring stability and safety.

#drive in racking system#pallet racking system#drive in racks#drive thru racking system#storage racking system#heavy duty racks#eurorack#warehouse racking system#eurorack drive in racks

1 note

·

View note

Text

Maximizing Efficiency: The Benefits of Using Storewell Shelves Pallet Racking System in Warehouses

In the dynamic world of warehouse management, the importance of an efficient storage system cannot be overstated. Storewell Shelves Pallet Racking System in UAE has emerged as a reliable solution, offering numerous benefits that contribute to streamlined operations and increased productivity. Let's delve into the advantages of incorporating this innovative storage solution in warehouses.

Optimized Space Utilization:

Storewell Shelves Pallet Racking Systems are designed to maximize vertical space, allowing warehouses to make the most of their available square footage. By utilizing vertical space efficiently, businesses can significantly increase storage capacity without expanding their facilities.

Enhanced Accessibility:

These pallet racking systems provide easy access to goods, facilitating swift and organized retrieval. With adjustable shelves and a well-thought-out design, Storewell Shelves ensure that warehouse staff can quickly locate and retrieve items, reducing downtime and improving overall operational efficiency.

Improved Inventory Management:

The systematic organization of goods on pallet racks simplifies inventory management. Storewell Shelves Pallet Racking allows for a clear view of stock levels, aiding in inventory tracking and minimizing the risk of stockouts or overstock situations.

Durability and Longevity:

Storewell Shelves Pallet Racking Systems are known for their robust construction and durability. Built to withstand the demands of heavy-duty warehouse operations, these systems provide a long-lasting storage solution, reducing the need for frequent replacements and maintenance.

Cost-Effective Solution:

Investing in Storewell Shelves Pallet Racking Systems proves to be a cost-effective solution in the long run. The increased storage capacity, improved accessibility, and durability contribute to lower operational costs and a higher return on investment for warehouse owners.

Customization Options:

Every warehouse is unique, and Storewell Shelves understands this. Their Pallet Racking Systems come with customizable features, allowing businesses to tailor the storage solution to their specific needs. This flexibility ensures that the system aligns seamlessly with the warehouse layout and requirements.

Safety Measures:

Storewell Shelves prioritizes safety with their pallet racking systems. Built-in safety features, such as load-bearing capacities and secure locking mechanisms, contribute to a safer working environment for warehouse personnel, reducing the risk of accidents and injuries.

Quick Installation and Scalability:

Storewell Shelves Pallet Racking Systems are designed for quick and hassle-free installation. Moreover, they offer scalability, allowing warehouses to adapt to changing storage needs easily. As the business grows, the pallet racking system can be expanded or reconfigured to accommodate increased inventory.

Conclusion:

In conclusion, the adoption of Storewell Shelves Pallet Racking Systems in UAE warehouses brings a multitude of benefits. From maximizing space utilization and improving accessibility to enhancing inventory management and ensuring durability, these systems play a pivotal role in creating efficient and well-organized warehouse spaces. Consider incorporating Storewell Shelves Pallet Racking for a strategic and effective storage solution that meets the demands of modern warehouse management.

0 notes

Text

Warehouse Racking Market and its Vital Role in Supply Chain Optimization

The global warehouse racking market size is expected to reach USD 12.41 billion by 2030, registering a CAGR of 4.1% according to a new report by Grand View Research, Inc. The demand for warehouse racking is expected to witness significant growth owing to the rising awareness of the benefits of systematic storage and easy material handling processes.

Warehouse racks manufactured using steel are popularly used in automotive, retail, manufacturing, and other applications as it is robust and durable. The warehouse racks manufactured using steel exhibit superior durability. The cost of steel-based warehouse racks is low, and these products can be constructed for normal floor units and high-rise shelving systems.

The product manufacturers operating in the market include Hannibal Industries, Georgia-Pacific, Dematic, SSI Schaefer, EMRACK INTERNATIONAL, and others. These market players introduce warehouse racking systems incorporated with advanced technologies such as sensors, robotics, and others. The use of the aforementioned technologies helps in making warehouse operations more efficient.

Expansion of various application industries such as automotive, manufacturing, retail, food and beverage, and others across the globe is projected to promote the demand for storage of goods. Rising demand for warehouse space in order to store and gain easy access to the products is anticipated to propel the need for optimizing the warehouse space.

The warehouse racking market players offer collision-resistant, earthquake-resistant, clean, wire mesh racking systems focusing on the safety and protection of the workplace. The manufacturers are inclined towards warehouse management software systems and other automation techniques to minimize the retrieval and processing time in the warehouse and the control systems enabling the workers' safety.

For More Details or Sample Copy please visit link @: Warehouse Racking Market Report

Warehouse Racking Market Report Highlights

The growing demand for cantilevers in warehouse racking is likely to drive its growth at a CAGR of 5.0% over the forecast period. The use of cantilever racks is expected to emerge as one of the fastest-growing product segments driven by the ease of storage and retrieval of products with varying weights, sizes, and lengths. These racks exhibit an easy installation and assembly with only a few components needed to build the product storying and holding structure

The selective pallets segment is expected to reach USD 5.8 billion in revenue by 2030, owing to its superior selectivity in warehouse applications. Selective pallets are the most common and widely used racking system and are expected to witness high demand from various application industries such as retail, food & beverages, automotive, and others. The system provides efficient use of space and quick access to the load or product stored using any type of forklift. However, the system requires numerous aisles for higher selectivity, making it a low-density option when compared to the other type of racking system

The retail segment is anticipated to dominate the market accounting for 34.35% of the market in 2022. The retail application segment accounts for the largest share and acts as vital to the overall growth of the market owing to the increasing number of warehouses, online retail, supermarkets, hypermarkets, food retails, and others. Increasing demand of product multi-channel fulfillment, sales cycles, and storage density requirement of large volume products are the key factor that is adding significant growth to the overall market for warehouse racking

The U.S. accounted for a market share of 65.3% of the North America warehouse racking market in 2021. The economy caters large e-commerce market, superior infrastructure & automation facility, and a highly skilled workforce which is further expected to make the same economy more favorable for growth. Timely movement of goods and a cost-effective racking system is the major factor driving the market for warehouse racking in U.S.

Innovators majorly deal with introducing robotics, software, and remote-controlled processes and automation in the racking systems. The market witnessed the acquisition of robotics startup companies by some of the prominent players. It enhances the product portfolio of the companies and enables them to offer automation

#Warehouse Racking#Storage Solutions#Supply Chain Management#Global Racking Market#Pallet Racking#Ware housing Innovation#Distribution Centers#Efficient Storage#Logistics Infrastructure#Vertical Storage#Storage Systems#Racking Designs#Modern Ware housing#Industrial Logistics#Supply Chain Efficiency#Racking Trends#Storage Management

0 notes

Text

Drive-In Racking System | Drive-Through Racking System I Camara Industries, Inc

Drive-In Rack and Drive-Through Rack Systems are Ideal for high-volume, low-SKU applications . Lane depth can reach over 10 pallets deep and are a practical way to redeem pallet efficiency by using this high density storage system method. Contact Camara Industries, Inc to learn about our cost-effective drive in racking systems and start improving your storage capacity!

#Rack Drive#Drive In Racking System#Drive-Thru Pallet Rack Systems#Drive-In Rack#Drive-In Pallet Rack Systems#Drive-Thru Rack#Cold Warehouse Storage#Structural Drive-In Rack#Structural Drive-Through Rack

0 notes

Text

Rashmi Racks provide best Pallet racks in pune, warehouse pallet racks in pune, steel pallet racking in pune, industrial pallet racking systems in pune, industrial racks for warehouse in pune at best cost. It is the best pallet racking Suppliers Company in pune, Mumbai, Nashik, Ahmadnagar, Gujarat, Karnataka, Bangalore, and Delhi India.

#Pallet racks in pune#warehouse pallet racks in pune#steel pallet racking in pune#industrial pallet racking systems in pune#industrial racks for warehouse in pune#Pallet Racking#Pallet Racking System#Pallet racks manufacturer#Pallet racks supplier#Pallet racking system#Heavy Duty Pallet racks#Heavy Duty Pallet racks manufacturer & supplier#Industrial Racks for warehouse#Industrial pallet racking system#Steel Pallet Racking#warehouse storage racks#warehouse pallet racks#Pallet racks manufacturer & supplier in pune#Pallet racks manufacturer & supplier in Mumbai#Pallet racks manufacturer & supplier in Nashik#Pallet racks manufacturer & supplier in Gujrat#Pallet racks manufacturer & supplier in Delhi#Pallet racks manufacturer & supplier in Karnataka#Pallet racks manufacturer & supplier in Indore

0 notes