#vfd repairing

Explore tagged Tumblr posts

Text

Maximizing Your Industrial Efficiency: A Comprehensive Guide to ABB Drive Repair

Industrial equipment, like ABB drives play a vital role in the powering and optimization of industrial processes. They are engineered to function efficiently, with precision and dependability. But even the most sophisticated drives can be subject to wear and tear as time passes. If these happen, they will adversely affect your production and the bottom line. That’s why ABB repair of your drive comes in.

Unique Power Technologies is a prominent supplier of ABB repair solutions for drive. Our skilled team of technicians and engineers specialize in fixing ABB drives efficiently and quickly while minimizing downtime and increasing the efficiency of your business. In this article we’ll look at the significance of ABB repair for drives as well as the advantages it can provide, and the reasons Unique Power Technologies is the ideal choice for your repair requirements.

Why ABB Drive Repair is Important

ABB drives are high-tech electronic devices that regulate the speed of torque, direction, and speed of motors. They are employed in many industrial applications, including conveyors, pumps, fans and many other things. ABB drives are engineered to last for a long time however they require periodic maintenance and repairs in order to keep them running at their peak efficiency.

Here are a few reasons to consider ABB repair to the drive is vital:

Reduces Downtime: Time spent in downtime is costly for industrial processes. When a drive malfunctions it could take days or even hours to repair or replace it. ABB repair of the drive can be completed quickly to minimize downtime and keep your business running smoothly.

Reduces Cost: Reparing an drive can be cheaper over replacing it. ABB repair to your drive can prolong the life of your drives, and also make it easier to avoid expensive replacements.

Improves Efficiency: A repaired drive will operate at more efficiency, reducing energy usage and boosting your profit margin.

Benefits of ABB Drive Repair

ABB drive repair can provide many advantages to industrial operations which include:

Greater Reliability: Drives that have been repaired tend to be more reliable than brand new drives because they’ve been thoroughly examined as well as repaired by experienced technicians.

Better Performance: Drives that have been repaired are able to perform more precisely and efficiently which can improve the performance of your industrial operation.

Extra Lifespan ABB Repair of your drives can prolong the life that your drive has, which can reduce the requirement for expensive replacements.

Improved Safety: Drives that are not in good condition could pose a danger to safety. Repairing them could help avoid injuries and accidents.

Why Choose Unique Power Technologies for ABB Drive Repair

When it concerns ABB repair for your drive it is essential to find a service that you can be confident in. Unique Power Technologies has been offering expert solutions for repair of drives for more than 20 years. Here are a few reasons why Unique Power Technologies is the ideal option for your ABB repair needs for your drive:

Highly skilled engineers and technicians Our technicians and engineers are proficient and knowledgeable in repairing ABB drives. We employ the latest technology and diagnostic equipment as well as repair methods to ensure that your drives are repaired properly and swiftly.

Complete Repair Service: We provide complete service repair to ABB drives, which include repair, refurbishment, as well as preventive maintenance.

Quality Parts: We employ only the highest-quality, authentic components in our repairs to guarantee the highest degree of performance and reliability.

Speedy Turnaround: We recognize the importance of reducing downtime. We offer quick turnaround times for our ABB repair services for drives.

Conclusion

ABB drives are essential elements of industrial processes, and their failures can be a major impact on the efficiency and profitability. ABB repair of drives is an affordable and effective solution to ensure that your drives are operating at maximum efficiency. In Unique Power Technologies we are specialized in offering expert ABB repair services for your drives that exceed the most stringent standards in terms of quality, reliability and performance. Contact us today to find out how we can enhance the efficiency of your business by assisting you with ABB repair services for your drives.

#Benefits of ABB Drive Repair#ABB Drive Repair#ABB Repair#ABB Ac Drive Repair#ABB DC Drive Repair#ABB VFD Drive Repair#ABB servo motor repair#vfd repairing

0 notes

Text

and i think this reflects the human condition so beautifully. You take something you know is doomed, going to be destroyed in all certainty and yet you inspect it, read it, try to find out some semblance of hope that no, everything will turn out fine. Your heart lit up when Strauss was waiting for the children outside. Your heart lit up when Montgomery said he knew what the assistant was up to. Your heart lit up when you realised Hector could hope. Your heart lit up at the trial, when Olaf is accused of his crimes and Strauss finally incriminates him. All through the story, your heart lit up in hopes that the title was wrong, the narrator was wrong, the narrator would review the notes to find out that the house did not indeed burn, and the Baudelaires were happy.

We look at a tragedy like a puzzle, something which could be solved with a little more inspection, with a little more hope. Maybe there was some part that they missed, that you could give back. You know how it ends, but you just hope maybe that's not really the end, because you are here now. You'll find the sugarbowl, the watch glass, hector's balloon, and the great unknown. There has to be a happy ending hidden somewhere there.

a series of unfortunate events is really the blueprint for characters doomed by the narrative like i think that series changed my brain chemistry forever… the title tells you how the story will end and the author repeatedly tries to warn you away but still you pick up the book. the first sentence is that it’s a tragedy and you keep reading anyway.. you read through the whole story and it’s terrible and tragic and unfortunate and then after you’ve stayed up late reading it under your covers with a flashlight, you go to your school library as soon as class is over and check out the next book in the series because you need to know what happens even though really, you already know. the end is right there in the title, it’s there in every page .. before the story even begins you know it’s a tragedy and you read it anyway and—

#reminds me of that one post#“the first sentient robot to realise deceased humans and animals can’t be repaired or backed up on a server is gonna be so devastated”#maybe we are that little robot#lemony snicket#asoue#a series of unfortunate events#all the wrong questions#beatrice baudelaire#snicketverse#vfd#atwq#violet baudelaire#klaus baudelaire#sunny baudelaire#kit snicket#justice strauss#jacques snicket#asoue netflix#beatrice baudelaire ii#count olaf#esme squalor#arthur poe#uncle monty#aunt josephine#quagmires#quigley quagmire#duncan quagmire#isadora quagmire#fiona widdershins

3K notes

·

View notes

Text

Reliable VFD Repair Near Me in Pune

Looking for expert VFD repair services in Pune? Our skilled technicians provide prompt and reliable solutions for all your variable frequency drive (VFD) repair needs. From diagnostics to complete repairs, we ensure your equipment is up and running efficiently. Get top-notch service right here in Pune.

0 notes

Text

Variable Frequency Drives (VFDs) are critical components in modern industrial and commercial operations. These devices control the speed and torque of electric motors, offering numerous benefits such as energy savings, reduced mechanical stress, and improved process control. However, like any complex piece of machinery, VFDs can experience issues over time, necessitating expert repair services to maintain their functionality. This is where Adhunik comes into play, offering specialized VFD repair services that ensure your equipment runs smoothly and efficiently.

Understanding the Role of VFDs

Before diving into the repair process, it's essential to understand the significance of VFDs in various industries. VFDs are used in a wide range of applications, from HVAC systems to manufacturing processes, water treatment facilities, and beyond. They allow for precise control of motor speed, leading to energy efficiency and enhanced performance. For instance, in a manufacturing plant, a VFD can adjust the speed of a conveyor belt to match production needs, thereby saving energy and reducing wear and tear on the equipment.

Common VFD Issues

Despite their robust design, VFDs are susceptible to various problems due to their complex electronic nature. Some of the common issues include:

Overheating: Excessive heat can cause VFD components to fail, leading to malfunctions. This is often due to inadequate ventilation or cooling, incorrect installation, or prolonged operation at high loads.

Power Supply Problems: Fluctuations in the power supply, such as voltage sags, surges, or harmonics, can damage VFD components, leading to erratic behavior or complete failure.

Faulty Wiring and Connections: Poor or loose connections can cause intermittent faults or complete failure of the VFD. Over time, vibrations, environmental conditions, and improper installation can lead to wiring issues.

Software and Firmware Issues: VFDs rely on embedded software or firmware to operate correctly. Corruption or bugs in the software can lead to erratic operation, requiring a professional diagnosis and reprogramming.

Component Failure: Over time, components such as capacitors, diodes, and transistors can wear out or fail due to age, excessive load, or environmental factors.

Why Choose Adhunik for VFD Repair?

Adhunik has established itself as a trusted partner for VFD repair, offering comprehensive services that address all possible issues. Here's why Adhunik stands out:

Expert Technicians: Adhunik employs a team of highly skilled technicians with extensive experience in diagnosing and repairing VFDs. They are trained to handle a wide range of VFD brands and models, ensuring that your equipment is in capable hands.

Advanced Diagnostic Tools: To accurately diagnose VFD issues, Adhunik uses state-of-the-art diagnostic tools. These tools allow technicians to pinpoint problems quickly, reducing downtime and ensuring a more cost-effective repair process.

Quality Replacement Parts: When repairs require component replacement, Adhunik uses only high-quality, genuine parts. This ensures that the repaired VFD performs reliably and has a longer lifespan.

Preventive Maintenance: Beyond just repairs, Adhunik offers preventive maintenance services. Regular maintenance can help identify potential issues before they become major problems, saving you time and money in the long run.

Rapid Turnaround Time: In industries where downtime can be costly, Adhunik understands the importance of quick and efficient service. Their streamlined repair process ensures that your VFD is back in operation as soon as possible.

Comprehensive Testing: After repairs, Adhunik conducts thorough testing to ensure that the VFD is functioning correctly. This includes checking for proper voltage levels, motor speed control, and overall system performance.

The Adhunik Repair Process

Adhunik's repair process is designed to be thorough and efficient:

Initial Assessment: Upon receiving the VFD, technicians perform an initial assessment to determine the extent of the damage. This includes visual inspections and preliminary tests.

Detailed Diagnosis: Using advanced diagnostic equipment, technicians identify the root cause of the problem. This step is crucial for ensuring that all issues are addressed during the repair.

Repair and Replacement: Once the diagnosis is complete, technicians proceed with the repair, which may involve replacing faulty components, reprogramming software, or correcting wiring issues.

Testing and Quality Control: After the repair, the VFD undergoes rigorous testing to ensure it meets operational standards. This step is essential for verifying the effectiveness of the repair.

Customer Communication: Throughout the repair process, Adhunik keeps customers informed, providing detailed reports and recommendations for future maintenance.

Conclusion

VFDs are vital components in many industrial and commercial systems, and ensuring their proper operation is crucial for maintaining productivity and efficiency. When issues arise, having a reliable partner like Adhunik for VFD repair can make all the difference. With their expertise, advanced tools, and commitment to quality, Adhunik ensures that your VFDs are repaired quickly and effectively, minimizing downtime and maximizing the lifespan of your equipment.

Whether you’re dealing with a minor fault or a major breakdown, Adhunik is your go-to solution for all VFD repair needs. Trust in their expertise to keep your operations running smoothly and efficiently.

0 notes

Text

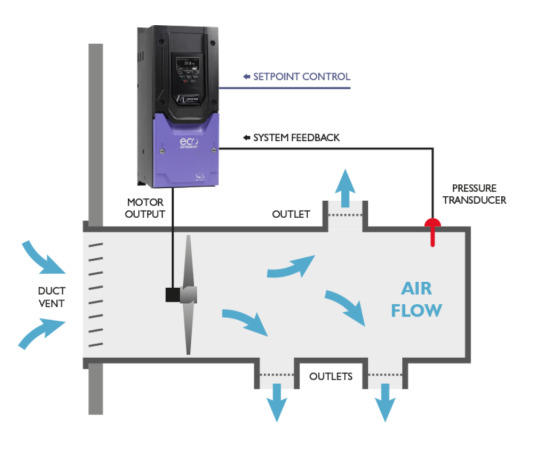

PID Closed Loop Feedback Control

The Optidrive Eco VFD has a PID controller built in that is fully integrated with both HVAC and energy efficient features and is packaged in a user friendly way to ensure ease of use and fast commissioning. Now in the majority of applications it has become possible to eliminate the need for external controllers.

#invertek#acdrive#drives#vfd#industrial controls#automation#hvac controls#hvac services#hvac repair#hvac contractor#hvac installation#ac maintenance#ac installation#hvac#pid controller#optidrive#usa

0 notes

Text

We are driven by values

We are putting forward an effort by connecting the talented industrial professionals directly to industrial consumers. With direct transfer of services we want to create an ecosystem where direct providers & consumers of services are prime beneficiaries.

We invite all the freelancers, people looking for second income source, side hustlers, small startups to onboard with us as providers.

We are inviting the industries to use direct services of talents who have been supporting you over time & see the difference yourself.

1 note

·

View note

Text

@asouefanworkevent day 1, violet's invention

A couple of stagehands hurry towards Beatrice. "Miss Beatrice," one of them says, "we think it's unwise to let kids play with the props - especially broken ones that already need repairing."

Beatrice raises an eyebrow, "And what do you think Violet is doing?"

The stagehands exchange looks with each other. "Uh," another one of them ventures, "we have professionals for this, Ma'am."

Beatrice strategically positions herself between Violet and the stagehands move in to surround them. Violet, on the other hand, is not focusing on the conversation between the adults, but rather her attention is all on implementing the new sliding mechanism for one of the stage props. Along with Beatrice, they've examined the contraption together and Violet came up with a new design for it. An improvement so it won't be so easily broken again. Now she's almost completed with all of her necessary steps, with just some final testing required. It's always important to test one's invention before allowing it to be used on stage, Mother has said.

Beatrice smiles, easily. Charmingly. "Well, I'll let them know if I need them, yeah? Thanks for the message, of course." As long as the process is safe - and most importantly as long as Violet is safe - Beatrice doesn't mind letting Violet take charge of fixing broken stage props or even designing new ones. She keeps an eye out on things, keeps close watch to make sure everything is safe, like she always does with Violet and Klaus. But safety isn't just shielding them forever and not letting them have the chance to explore their skills. That's never worked. She's not Ishmael.

Violet's skills have improved a lot ever since she first started, and she's getting new ideas for inventions every day. Getting the experience is important, so as long as it's safe to do so, Beatrice always makes sure Violet gets the opportunity to explore her idea, to get the chance to construct an actual thing from the initial design on paper. Some people at the theater don't quite trust a child to do this - Beatrice sometimes has to remind herself that not everyone is used to a child being competent, especially when they didn't grow up in VFD. But Beatrice knows Violet's capable so she does not back down, regardless of some people voicing opinions of worrying Violet might accidentally break something and maybe they'll have to delay a play or whatever.

The first stagehand takes a look at the watch, then says, "Well, we can let her play with it until 3pm, I suppose. But then we'll have to call our repair guy in for actually fixing it."

3pm, Beatrice thinks. Probably more than enough for Violet, anyway. "Fine by me," she says.

11 notes

·

View notes

Note

❝ what happened? tell me what happened. ❞ (Jacob to Lemony or Kit)

Kit's usual stoic demeanor had been cracked to its very foundation on this night, this was the night that her heart was broken forever, shattered into a billion little peaces. Her best friend had killed her fiance's father and spurred him to join the opposite side of the schism, her brother was wanted for a murder he didnt commit, everything seemed to be unraveling the way a knitted scarf would unravel if the loose thread was pulled on.

"The fire chief is dead, Lemony is wanted for his murder, and now the schism is as fractured the VFD so deeply, I wonder if it can ever be repaired. What will happen to everyone now?" Kit choked out softly as she sat on the grand staircase in the opera house. When she woke up this morning she had never thought she would have been here, that everything that had happened would have happened.

11 notes

·

View notes

Text

Advanced Technology in Ebara Surface Pumps

Ebara surface pumps incorporate state-of-the-art technology to provide superior performance, efficiency, and reliability across various applications. These pumps leverage innovative solutions that ensure optimized operation, reduced maintenance, and enhanced safety. Here’s a detailed overview of the advanced technologies integrated into Ebara surface pumps:

1. Energy-Efficient Motor Technology

IE3 and IE4 Motors: Ebara pumps are equipped with high-efficiency motors that comply with international energy efficiency standards (IE3, IE4). These motors reduce energy consumption while maintaining optimal performance, leading to significant energy savings and reduced operational costs.

Variable Frequency Drive (VFD) Integration: Many Ebara pumps are compatible with or come equipped with Variable Frequency Drives (VFDs), allowing for precise control over the motor speed. This feature ensures that the pump operates only when needed and adjusts performance to meet changing demand, further enhancing energy efficiency.

2. Smart Monitoring and Diagnostics

Real-Time Performance Monitoring: Ebara surface pumps are equipped with smart sensors that monitor critical parameters such as pressure, flow rate, and motor temperature. This real-time data enables operators to optimize performance and address any potential issues before they become critical.

Automated Alerts and Diagnostics: Advanced diagnostic systems in Ebara pumps can identify potential problems, such as low pressure or mechanical wear, and send automated alerts to operators. This helps in proactive maintenance, reducing downtime and preventing costly repairs.

Remote Monitoring Capabilities: For enhanced convenience, some Ebara surface pumps are equipped with remote monitoring options, allowing operators to track performance and receive alerts through mobile apps or web interfaces, ensuring system reliability from anywhere.

3. Self-Priming Technology

Automatic Priming: Ebara surface pumps with self-priming capabilities are designed to start automatically without manual intervention. These pumps can quickly remove air from the system and begin operation, reducing setup time and ensuring that the pump works efficiently even when air pockets are present.

Enhanced Air Handling: Self-priming models are designed to handle air within the system, preventing airlocks and ensuring smooth, uninterrupted operation. This is particularly beneficial in applications where water levels fluctuate or in remote areas where manual priming might be difficult.

4. Advanced Hydraulic Design

Optimized Impeller Design: Ebara pumps feature advanced impeller designs that maximize hydraulic efficiency, reducing energy losses while maintaining a steady flow rate. This leads to higher performance and ensures that the pump can operate effectively even under varying pressure conditions.

Multi-Stage Pumping: For high-pressure applications, Ebara offers multi-stage surface pumps that provide consistent and reliable performance in environments requiring higher head and pressure. The multi-stage configuration allows for efficient water delivery over longer distances or greater vertical heights.

5. Corrosion-Resistant Materials

Stainless Steel Construction: Many Ebara pumps use corrosion-resistant stainless steel in critical components such as the impeller, casing, and motor shaft. This makes the pumps ideal for handling aggressive fluids, extending their operational life, and reducing maintenance requirements.

Composite and Coating Technology: Ebara’s use of composite materials and protective coatings ensures pumps can withstand harsh environmental conditions, including exposure to chemicals, saltwater, and high temperatures.

6. Intelligent Control and Automation

Intelligent Control Systems: Ebara surface pumps come with integrated control systems that automatically adjust pump speed, flow, and pressure based on system demands. These systems enhance the pump’s efficiency, ensure optimal performance, and reduce wear on components.

Automatic Start/Stop Functions: These pumps can be set to start and stop automatically based on system needs, ensuring that the pump is only running when necessary, thus conserving energy and reducing wear.

7. Noise and Vibration Reduction

Dynamic Balance: Ebara uses precision engineering to balance key components such as the impeller and motor shaft, which reduces vibrations during operation. This helps in minimizing noise levels, making Ebara pumps suitable for environments where quiet operation is a priority.

Acoustic Dampening: Special materials and design features are used to further reduce noise and vibration, ensuring that the pump operates smoothly without disturbing surrounding environments.

8. Overload and Thermal Protection

Overload Protection: Ebara pumps are equipped with built-in overload protection mechanisms that shut down the pump in case of excessive current draw or abnormal operational conditions, preventing potential damage to the motor and other components.

Thermal Protection: The inclusion of thermal sensors ensures that the pump shuts down if it overheats, protecting the motor and extending the pump’s lifespan.

Applications Benefiting from Advanced Technology

Residential Water Supply: Efficient water delivery with smart monitoring systems for homes, ensuring minimal energy consumption and optimal water pressure.

Commercial and Industrial Systems: Provides reliable water circulation, HVAC support, and pressure boosting in large-scale commercial buildings, factories, and other industrial facilities.

Agricultural Irrigation: Optimizes irrigation systems, ensuring that water is distributed efficiently across fields with minimal energy usage.

Ebara surface pumps incorporate cutting-edge technology to enhance performance, efficiency, and reliability across a variety of applications. From energy-efficient motors to smart monitoring systems, these pumps are designed to meet the challenges of modern pumping needs while reducing maintenance and operational costs. For more info contact Ebara Pumps Middle East FZE or call us at +971 4 2522966.

#ebara pump dealers#ebara pumps#ebara pump suppliers in uae#ebara pump middleast#ebara#ebara pumps middle east fze

0 notes

Text

Optimizing Static Pressure in Industrial Blower Systems

Static pressure is a critical factor in the performance and efficiency of industrial blower systems. Maintaining optimal static pressure ensures proper airflow, reduces energy consumption, and extends the lifespan of your equipment. This blog post will guide you through best practices for maintaining optimal static pressure, tips to boost efficiency, and answers to frequently asked questions about blower static pressure.

What Is Static Pressure in Blower Systems?

Static pressure refers to the resistance a blower must overcome to move air through a system. High static pressure can lead to reduced airflow and increased energy consumption, while low static pressure may indicate inefficiencies or system leaks. Understanding and managing static pressure is essential for achieving the best performance from your industrial blower system.

Best Practices for Maintaining Optimal Static Pressure

Design the System Correctly

Ensure the ductwork is sized appropriately to minimize resistance.

Avoid sharp bends and obstructions in the airflow path.

Regular Maintenance

Clean filters and ducts periodically to prevent clogs.

Inspect for and repair leaks in the duct system.

Check the condition of the blower impeller and housing.

Monitor Static Pressure Regularly

Use static pressure gauges to monitor system performance.

Establish baseline measurements to identify deviations quickly.

Upgrade Components When Necessary

Replace outdated blowers with high static pressure blowers designed for modern systems.

Invest in energy-efficient motors and advanced control systems.

Balance the System

Ensure air distribution is even across all zones in the system.

Use dampers and variable frequency drives (VFDs) to control airflow effectively.

Tips to Increase Efficiency and Reduce Operational Costs

Choose the Right Blower: Select a blower specifically designed for industrial applications with high static pressure requirements. Central Blower offers a range of high static pressure blowers engineered for superior performance.

Optimize Duct Layout: Streamline ductwork to minimize resistance and reduce energy usage.

Automate Controls: Utilize sensors and automation to adjust blower speed and maintain optimal static pressure dynamically.

Conduct Energy Audits: Regularly review energy consumption and identify areas for improvement, such as upgrading to more efficient equipment or retrofitting existing systems.

FAQs About Static Pressure in Blower Systems

1. What causes high static pressure in a blower system? High static pressure is often caused by clogged filters, poorly designed ductwork, or obstructions in the airflow path.

2. How can I measure static pressure in my system? Static pressure can be measured using a manometer or pressure gauge at designated points in the system.

3. What happens if static pressure is too low? Low static pressure may result in inadequate airflow, leading to reduced system performance and potential equipment damage.

4. Why should I choose a high static pressure blower? High static pressure blowers are designed to overcome greater resistance, making them ideal for complex industrial systems with extensive ductwork.

5. How does Central Blower address static pressure challenges? Central Blower provides tailored solutions for industrial applications, including blowers optimized for high static pressure and advanced system controls.

By implementing these best practices and leveraging high-quality equipment like Central Blower’s industrial solutions, you can optimize static pressure, improve efficiency, and reduce operational costs in your blower system. Regular monitoring and proactive maintenance are key to achieving long-term success.

For more information on how Central Blower can help you address static pressure challenges, contact us today!

0 notes

Text

PCB Repair for Automotive Electronics

In today's increasingly sophisticated vehicles, Printed Circuit Boards (PCBs) play a critical role in controlling various electronic systems. From engine management to infotainment systems and advanced driver-assistance systems (ADAS), PCBs are the backbone of modern automotive electronics. However, these intricate boards are susceptible to damage from various factors, including vibration, extreme temperatures, and electrical surges. When PCB failures occur, they can lead to vehicle malfunctions, safety hazards, and costly downtime.

Common PCB Failures in Automotive Electronics

Component Failures: Individual components like resistors, capacitors, transistors, and integrated circuits can fail due to wear and tear, overheating, or manufacturing defects.

Open Circuits: Breaks in the conductive traces on the PCB can interrupt electrical signals, leading to malfunctions.

Short Circuits: When conductive traces come into contact, it creates a short circuit, potentially damaging components or causing electrical fires.

Corrosion: Exposure to moisture, chemicals, or high temperatures can corrode the PCB, affecting its conductivity.

Physical Damage: Vibrations, impacts, and extreme temperatures can cause physical damage to the PCB, such as cracks, fractures, or broken traces.

The Importance of Timely PCB Repair

Faulty PCBs can lead to a range of issues, including:

Engine performance problems: Issues with engine control units (ECUs) can affect fuel efficiency, emissions, and overall engine performance.

Safety hazards: Malfunctions in safety systems like airbags, anti-lock brakes (ABS), and electronic stability control (ESC) can pose serious safety risks.

Infotainment system failures: Issues with the infotainment system can disrupt navigation, audio, and other in-car entertainment features.

Vehicle diagnostics: Faulty PCBs can interfere with vehicle diagnostics, making it difficult to identify and address other underlying problems.

Shreemeera Electronic Services, a leading provider of AC DC, Servo, and VFD Drive Repair Services in Pune, offers comprehensive PCB repair solutions for the automotive industry.

Their team of skilled technicians possesses the expertise and advanced equipment to diagnose and repair a wide range of automotive electronic PCBs, including those found in:

Engine control units (ECUs)

Transmission control units (TCUs)

Anti-lock brake systems (ABS)

Airbag control modules

Instrument clusters

Infotainment systems

Telematics units

Benefits of Choosing Shreemeera Electronic Services:

Expertise and experience: Their team has in-depth knowledge of automotive electronics and PCB repair techniques.

Advanced technology: They utilize state-of-the-art equipment for precise diagnosis and repair.

Quick turnaround time: Minimizing vehicle downtime is crucial, and Shreemeera Electronic Services strives to provide fast and efficient repairs.

Quality assurance: They adhere to strict quality control measures to ensure the reliability and safety of repaired PCBs.

Competitive pricing: They offer competitive pricing without compromising on the quality of service.

By choosing Shreemeera Electronic Services for your automotive PCB repair needs, you can ensure the safe and reliable operation of your vehicles while minimizing downtime and repair costs.

#industrial machine pcb repair services in pune#ac dc drives repair services in pune#pcb repair services in pune#shreemeera electronic services

0 notes

Text

Need ABB repair for your unique power technologies? Discover the comprehensive guide to restoring power, enhancing reliability, and maximizing efficiency through ABB repair and maintenance services. Ensure the longevity of your systems and minimize downtime with expert insights and essential practices.

#ABB AC Drive repair#ABB AC Motor repair#ABB VFD repair#ABB Inverters repair#ABB Bypass Units Repair#ABB Soft Start Controls service#ABB product

0 notes

Text

The Versatility and Benefits of Using Variable Frequency Drives (VFDs) in Industrial Automation

In industrial automation, the need for energy efficiency, precision, and flexibility has never been greater. One of the most effective solutions that have revolutionized the way industries operate is the use of Variable Frequency Drives (VFDs). VFDs provide superior control of electric motors, ensuring smoother operations, reduced energy consumption, and enhanced equipment life. At Dropship Automation, we understand the critical role VFDs play in modern industrial automation, and we are committed to providing innovative solutions that leverage the full potential of these drives.

What Are Variable Frequency Drives (VFDs)?

Variable Frequency Drives (VFDs) are electronic devices that control the speed, torque, and operation of electric motors by adjusting the frequency and voltage supplied to the motor. VFDs enable precise control over motor speed, making them indispensable in applications where speed and efficiency are crucial. From pumps to conveyor systems, VFDs are used across various industries to optimize performance and enhance operational flexibility.

Key Benefits of Using VFDs in Industrial Automation

Energy Efficiency One of the most significant advantages of VFDs is their ability to reduce energy consumption. By adjusting the motor speed to match the load requirements, VFDs ensure that the motor operates at optimal efficiency. This energy-saving feature helps businesses reduce their overall electricity usage, leading to lower energy costs and a smaller carbon footprint.

Improved Process Control and Precision VFDs allow for smooth and precise control over motor speeds, making them ideal for applications that require fine-tuned adjustments. Whether it’s a pump, fan, or conveyor system, VFDs provide excellent process control, ensuring that machinery operates at the exact speed needed for each task. This precision helps improve product quality, reduces waste, and enhances overall system performance.

Extended Equipment Life VFDs contribute to the longevity of industrial equipment by reducing mechanical stress on motors and components. By operating at optimal speeds and avoiding unnecessary high speeds or sudden starts and stops, VFDs minimize wear and tear, which can prolong the lifespan of machinery and reduce maintenance costs.

Reduced Mechanical Stress and Noise VFDs help in reducing mechanical stress by providing gradual acceleration and deceleration of motor speeds. This controlled start-up and shutdown minimize the likelihood of damage to the equipment and reduce noise levels, contributing to a quieter and more efficient workspace.

Cost Savings By optimizing energy use, reducing maintenance costs, and extending the lifespan of equipment, VFDs offer significant cost savings. The reduced need for repairs and replacements, combined with lower energy bills, makes VFDs a smart investment for industrial automation systems.

Why Choose Dropship Automation for VFD Solutions?

At Dropship Automation, we specialize in providing tailored automation solutions that incorporate the latest VFD technology. Our team works closely with your business to ensure seamless integration and optimal performance. Whether you are looking to improve energy efficiency, extend equipment life, or enhance process control, Dropship Automation has the expertise and experience to meet your needs.

Conclusion

The use of Variable Frequency Drives (VFDs) in industrial automation offers numerous benefits, including improved energy efficiency, enhanced precision, and reduced operating costs. At Dropship Automation, we provide innovative VFD solutions that help businesses optimize their operations, reduce costs, and increase productivity. To learn more about how VFDs can enhance your business, visit Dropship Automation today.

1 note

·

View note

Text

Professional VFD Repair Near You in Pune

Swastika offers expert VFD repair services near you. Trust our experienced technicians to diagnose and fix your Variable Frequency Drive (VFD) issues promptly and efficiently. Contact us today for reliable VFD repair services.

0 notes

Text

Emergency electronic service in dubai

Inverters repairing shops in UAE

Horizon Electronic is the best electronics repair service in Dubai. Known as electronic drive repair services in Dubai, Horizon is one of the best electronics repair service companies. In Dubai Here are the best CNC board service companies and Kone PCB repair companies Sigma Lift board repair and Otis circuit board repair are other services offered by Horizon Electronics Horizon is one of the best control panel kits in the US. United Arab Emirates I offer emergency electrical services, popular AC DC drive repairs, HMI display repairs and Horizon main services, Mitsubishi Elevator Boards, an Inverter Repair Shop in Dubai, Electronic PCB Repair Services, and VFD Repairs. Leading in Dubai, best elevator repair services near me, elevator parts distributors in Dubai, elevator repair companies, elevator repair services, electronic components in Dubai, Medical Equipment Repair Near Me, and Marine Electronic Repair Here are the main repair services that Horizon Electronic provides in the United Arab Emirates: Horizon is the best CNC board service company for high-quality repairs and maintenance. And I have the best elevator repair services Horizon is the leading elevator parts supplier in Dubai. They provide high-quality components for all brands of elevators. Horizon Elevator Repair Company offers professional elevator repair services to ensure safe and efficient operation. They provide premium quality electronic components in the United Arab Emirates. a medical equipment repair shop near me Horizon is a reliable marine electronics repair service in Dubai. They provide leading AC/DC drive repair services for industrial and commercial needs...

0 notes

Text

Medical equipment repair near me

Marine electronic repair service in dubai Top AC DC drive repair

Horizon Electronic is the best electronics repair service in Dubai. Known as electronic drive repair services in Dubai, Horizon is one of the best electronics repair service companies. In Dubai Here are the best CNC board service companies and Kone PCB repair companies Sigma Lift board repair and Otis circuit board repair are other services offered by Horizon Electronics Horizon is one of the best control panel kits in the US. United Arab Emirates I offer emergency electrical services, popular AC DC drive repairs, HMI display repairs and Horizon main services, Mitsubishi Elevator Boards, an Inverter Repair Shop in Dubai, Electronic PCB Repair Services, and VFD Repairs. Leading in Dubai, best elevator repair services near me, elevator parts distributors in Dubai, elevator repair companies, elevator repair services, electronic components in Dubai, Medical Equipment Repair Near Me, and Marine Electronic Repair Here are the main repair services that Horizon Electronic provides in the United Arab Emirates: Horizon is the best CNC board service company for high-quality repairs and maintenance. And I have the best elevator repair services Horizon is the leading elevator parts supplier in Dubai. They provide high-quality components for all brands of elevators. Horizon Elevator Repair Company offers professional elevator repair services to ensure safe and efficient operation. They provide premium quality electronic components in the United Arab Emirates. a medical equipment repair shop near me Horizon is a reliable marine electronics repair service in Dubai. They provide leading AC/DC drive repair services for industrial and commercial needs...

0 notes