#vertical case erector

Explore tagged Tumblr posts

Text

Enhance your Secondary Packaging with Nichrome’s Horizontal Flow Wrap Machine

Nichrome's Integrated Packaging System is a complete packaging solution that combines multiple machines and processes into a single, cohesive system. Our system includes a range of machines, including filling machines, sealing machines, and labeling machines, which work together seamlessly to deliver efficient, high-quality packaging. Our Integrated Packaging System is fully customizable to meet the unique needs of each customer, and is designed to increase productivity, reduce downtime, and improve overall packaging efficiency.

Secondary packaging is an important aspect of the product packaging process that involves the wrapping of the primary packaging of a product to ensure its safety during transport and storage. The use of a Horizontal Flow Wrap Machine in this process can enhance the quality of your secondary packaging, providing several benefits for your business.

Nichrome is a leading manufacturer of secondary packaging machines and is a prime Shrink Wrapping Machine Manufacturer that offers a wide range of solutions for the packaging industry. Our Flow Wrap Machine & Shrink Wrapping Machine is a popular choice among manufacturers for enhancing secondary packaging.

1. Increased Efficiency

Nichrome’s Horizontal Flow Wrap Machine is designed to handle high-speed packaging processes, making it an ideal choice for manufacturers looking to increase their production efficiency. This machine can wrap several products at once, reducing the time taken to wrap each product manually. This, in turn, can increase your output, making your business more profitable in the long run.

2. Consistent Quality

The Horizontal Flow Wrap Machine is equipped with advanced technology that ensures consistency in the wrapping process. The machine can handle different sizes and shapes of products, ensuring that each product is wrapped with the same level of quality. This consistency in packaging can enhance the overall appearance of your products, improving customer satisfaction and brand recognition.

3. Versatility

Nichrome’s Case Eractor & Flow Wrap Machine can handle a wide range of packaging materials, including polypropylene, cellophane, and laminated films, among others. This makes it a versatile packaging solution for manufacturers who work with different types of products. The machines can also handle different types of packaging styles, including pillow bags, gusset bags, and stand-up pouches, among others.

4. Reduced Labor Costs

Using Nichrome’s Horizontal Flow Wrap Machine you can significantly reduce the need for manual labor in the secondary packaging process. This can save your business time and money while also reducing the risk of errors in the packaging process. With this machine, you can automate your packaging process, freeing up your employees to focus on other important tasks.

5. Enhanced Product Protection

A high level of protection for your products during transport and storage is crucial and Nichrome ensures you the same. The Horizontal Flow Wrap Machine creates a tight seal around each product, protecting it from moisture, dust, and other external factors that could damage the product. This, in turn, can reduce product waste and increase the shelf life of your products.

In conclusion, the Horizontal Flow Wrap Machine from Nichrome is a versatile and efficient packaging solution for your industry looking. With its advanced technology, consistent quality, and versatility, this machine can provide several benefits for your business, including increased efficiency, reduced labor costs, and enhanced product protection. Consider investing in this machine to improve the quality of your secondary packaging and grow your business.

We are also a leading provider of ghee jar filling machine, tin packaging machine, tin can filling and sealing machine, bottle capping machine, automatic bottle filling machine and automatic case erector , horizontal cartooning machine , vertical case erector and bulk bag filling machine.

#ghee jar filling machine#tin packaging machine#tin can filling and sealing machine#bottle capping machine#automatic bottle filling machine#automatic case erector#horizontal cartooning machine#vertical case erector#bulk bag filling machine#Integrated Packaging System#Horizontal Flow Wrap Machine#Shrink Wrapping Machine Manufacturer#Flow Wrap Machine

0 notes

Text

During a period when Mistress was too focused on work to play with her submissives, I became too tight for her to comfortably fit two fingers into. As punishment, I've been assigned to train on the Motorbunny Buck, Mistress's fucking machine of choice, daily for a month.

Day 1: Is this supposed to be a punishment? This doesn't seem like a punishment at all.

Day 2: I'm already tired of having to run an extra load on the dishwasher every day, since it has the all-important "Sanitize" cycle for cleaning up the Motorbunny attachments.

Day 3: Daily training is starting to pay off. That last session felt good. Really good.

Day 4: Riding the fucking machine is not the punishment, it's having to clean up afterwards every day. I asked Mistress if I could have permission to move the Motorbunny to next to the guest showers. (She said no.)

Day 5: Barely avoided disaster today. I forgot to lock up the door to the dungeon when the municipal water inspector came by to look around the basement. Fortunately, I spotted my mistake while he was still taking his boots off upstairs.

Day 6: Skip day. Mistress was home from work, and she called "dibs".

Day 7: Experimented more with the higher vibration settings today and probably overdid it. I’m going to have to take it easy for the next few days while my poor sissy booty heals.

Day 8: Switched from the spiral dildo to the precision probe. Today's training consists of trying to find exactly where all of my spots are.

Day 9: Skip day. I had a doctor's appointment. Real life takes priority!

Day 10: To make up for skipping a day, I switched to the larger Doc Johnson attachment. It was too large to ride, so I had to use the vertical wedge stand to be taken from behind. Taking something that large felt sooo good.

Day 11: Oh crap. While moving the Motorbunny back upright, I heard a crack. The plastic casing of the adapter plug cracked in half. I jury rigged back together (with some scary sparks!), but that is going to be a problem.

Day 12: A warranty replacement for the adapter is already on its way. I am more impressed by the customer service than how good I felt after today's session.

Day 13: Skip day. Mistress came home from work early because she was feeling sick. My time was spent taking care of her and lecturing her about the importance of diet and daily exercise. Writing this down in my punishment journal, I'm glad she was too sick to notice the irony.

Day 14: After some experimentation, the Motorbunny hits my spots best if I’m leaning all the way forward or arching backwards. I'm pretty sure I should stick to arching back in photosets.

Day 15: Mistress is still sick, which makes these daily training sessions extra hard. When she's healthy, I know that riding the fucking machine is a warmup for being played with later, but now I know it's going to leave me extra frustrated for the rest of the day.

Day 16: I’m starting to crave something in my mouth during these daily rides. I’m not sure how to deal with that. Maybe I should bring a box of Triscuits to the dungeon tomorrow? Will that work?

Day 17: Bringing a ball gag down to the dungeon definitely helps with my oral cravings, but I feel kind of silly doing it. It doesn’t help that 🐶 is staring at me like he’s judging my technique at chewing a ball. "Bloody amateur can't even keep in in her mouth without a safety strap."

Day 18: Mistress had some time to personally supervise my training today. The splash image on this post comes from this session.

Day 19: The warranty replacement adapter just arrived! I think I'll leave the broken one in place and keep the new one as a backup. I said it once, and I'll say it again: I am seriously impressed by the level of customer service Motorbunny has.

Day 20: Pondering upgrades to the Motorbunny using the Bondage Erector Set. Reflective Desires has so many ideas that I want to steal.

Day 21: The cursed LureVibe fucking bear is now making the rounds. I wonder if I should upgrade from Motorbunny to Motorbear. https://lurevibe.com/products/doll-automatic-thrusting-vibrating-swing-machine-female-masturbation-device

Day 22: Mistress is upset that most of the pictures she took makes me look hunchbacked. I need to find a way to ride the Motorbunny that's more photogenic, apparently.

Day 23: Gross! I accidentally put another layer of condom and lube on the attachment and didn’t peel it off before washing. Now I have a layer of cooked on dry lube to scrub off my dildo.

Day 24: I can't figure out how to advance my training. Mistress wants me to train to be penetrated at a wider variety of angles (instead of the one that feels really, really good but looks awful on camera). What even is the best to train for that? Wiggle around on the dildo every day?

Day 25: Following a friend’s advice, I’m trying yoga on the Motorbunny to improve my range of positions. This is a weird experience, and not just because of how hard it is to hold a stretch while being fucked.

Day 26: Skip day. After Pride Weekend, I can't move.

Day 27: Flexibility training continues. I’ve learned I’m not going to be able to move which spots feel good, but I can move the rest of my body. Biggest bang for my buck seems to be in getting more dramatic back arches, followed by working on my range of leg motion.

Day 28: Taking a break from trying to improve my form. Instead, I'm putting in the thickest attachment I can handle and enjoying the ride.

Day 29: I'm putting off today's training to edit and post this punishment journal. I'm hitting post now so I can get back to training.

69 notes

·

View notes

Text

Nichrome’s Smart Secondary Packaging: A Step Ahead in Efficiency and Innovation

Nichrome has always been at the forefront of packaging innovation, offering cutting-edge technology that enhances your product packaging process. From primary to secondary and tertiary packaging, Nichrome provides a complete range of solutions tailored to your business needs. With a legacy built on quality and efficiency, Nichrome’s secondary packaging solutions are designed to streamline your operations and deliver cost-effective, reliable results.

What is Secondary Packaging?

Think of secondary packaging as the protector of your products. It’s the second layer that keeps your goods safe during transit and ensures they reach their destination in top condition. Secondary packaging also groups multiple products together for easier handling and shipping. Whether it’s overwrapping, outer packaging, or end-of-line packaging, it plays a crucial role in safeguarding products while improving operational efficiency.

Say goodbye to manual, labor-intensive packaging! Today, automated secondary packaging has taken center stage, delivering precision, faster output, and safer working conditions.

Why Choose Automated Packaging Solutions?

Automation is the future, and Nichrome is your gateway to that future. With automated packaging, you’ll enjoy:

Boosted Productivity: Achieve smooth, high-speed packaging operations without delays or inconsistencies.

Lower Labor Costs: Automation reduces manual labor, freeing up resources and cutting costs.

Organized Processes: Automated systems ensure orderly, efficient packaging every time.

Consistent Quality: Automation delivers precision, ensuring each package is perfect.

Nichrome’s Secondary Packaging Solutions

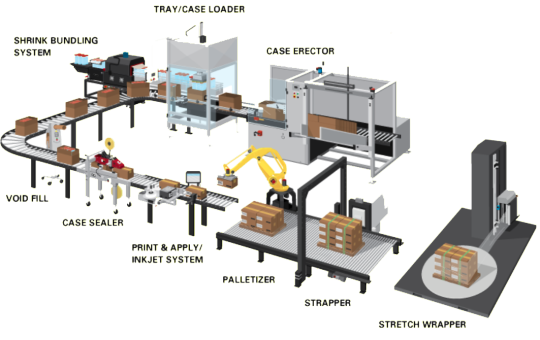

Nichrome offers a range of high-performance secondary packaging machines that meet the highest standards. From case erection to flow wrapping, here are some key solutions:

Case Erector

Nichrome’s case erectors tackle common challenges with corrugated boards. Our unique mechanism ensures cases are reliably opened and formed with precision, no matter the quality of the materials.

Flow Wrap Machine

For efficient pouch bundling, the Flexiwrap 700 is your go-to. It handles a wide range of pouches, up to 700mm in width, with speed and reliability.

Automated Case Packer

The Auto Case Packer is a fully automated solution that forms, counts, collates, and inserts cartons into cases, sealing them with precision. It can handle up to six shippers per minute, making it ideal for high-volume operations.

Automatic Baling Machine

The Flexibale 450 is a game-changer for bulk secondary packaging. Integrated with a primary vertical form fill seal (VFFS) machine, it requires only one operator to handle the entire packaging station, maximizing efficiency and minimizing labor.

HDPE Bag Filling Line Machine

Nichrome’s Flexibale SR is designed for maximum productivity with minimal manpower. A single operator can manage the entire packaging process, ensuring consistent output with minimal investment.

Horizontal Cartoning Machine

Nichrome’s Horizontal Cartoning Machine efficiently processes up to 180 cartons per minute, handling various packaging styles including tuck-in and gluing options.

Vertical Cartoning Machine

The Vertical Cartoning Machine offers a durable and efficient solution, processing up to 120 cartons per minute, with advanced features for precise and flexible cartoning.

Automatic Pouch Collation & Flow Wrapping

Nichrome’s Flexiwrap ST seamlessly integrates with existing form fill seal machines, offering automatic counting, stacking, and flow wrapping of individual pouches into retail-ready packs.

Conclusion: Package Smart, Choose Nichrome

In the fast-paced world of manufacturing, smart packaging is essential. Nichrome’s automated secondary packaging solutions not only offer protection but also optimize your operations, reduce costs, and increase productivity. Ready to elevate your packaging game? Nichrome is here to deliver solutions that pack a punch! Book your inquiry now and step into the future of packaging with Nichrome – because with us, your products are in good hands.

#SecondaryPackaging#AutomatedPackaging#NichromePackaging#PackagingInnovation#EfficiencyInPackaging#SmartPackaging

0 notes

Text

Parts for All End-of-Line Packaging Equipment

Stretch Wrappers: We provide parts for both automatic and semi-automatic stretch wrappers, including turntable, vertical rotary arm, and horizontal stretch wrappers. These machines are vital for high-volume applications, demanding speed, accuracy, and efficiency.

Case Packers: Our parts for case packers are engineered to support various formats, from film-only to wrap-around applications. These packers are essential for facilities handling diverse product ranges, offering flexibility and adaptability to evolving client demands.

Palletizers: We supply parts for palletizers, integral to arranging products onto pallets in pre-determined patterns for secure transport. Our parts help maintain high productivity and accuracy, essential for streamlined packaging lines.

Case Equipment: Our range includes parts for case erectors and sealers, crucial for forming and securely sealing boxes. Automating case handling with our reliable parts can significantly improve your production efficiency.

For all your end-of-line packaging equipment parts needs, Quick Pak Inc is your go-to solution. Contact us today at 813 242 6995 or [email protected] for a quote, tailored to your specific equipment requirements.

#quickpakinc#stretch film pricing#pricing news#coreless film#quick pak inc#stretch film#resin pricing#free pallet wrapper#youtube#free machine#parts#wrapper paets#end of line packaging#equipment parts for packaging

0 notes

Text

Planetary Gearbox Manufacturer in India | SMD Gearbox

Planetary gearboxes play a crucial role in the packaging industry by providing precision, speed control, and torque multiplication for various packaging machinery. The Selection of planetary gearbox depends on factors such as torque requirements, speed control, space limitations, and the specific packaging machine's needs. These gearboxes are known for their reliability, compact design, and ability to handle high torque, making them a valuable component in various packaging applications. Following are applications, planetary gearboxes commonly used in the packaging industry:

Conveyor Systems

Filling and Capping Machines

Labelling Machines

Palletizers and Depalletizes

Carton Erectors and Sealers

Form-Fill-Seal Machines

Wrapping Machines

Case Packers and Unpackers

Vertical Form-Fill-Seal Machines

To learn more about SMD Gearbox please visit https://www.smdgearbox.com/

#gearboxsupplier#packagingmachinemanufacturer#gearboxmanufacturer#labellingmachine#inlinegearbox#epicyclicgearbox#planetarygearbox#servogearbox#smdgearbox

0 notes

Text

Streamline Your Product packaging Method using a Vertical Cartoning Machine

In today's fast-paced organization environment, optimizing production and product packaging procedures is essential for firms to stay competitive. One important aspect of productive product packaging is the application of innovative devices that will automate and enhance the method. One device which has transformed the packaging industry is the Vertical Cartoning Machine. In the following paragraphs, we shall check out the advantages and uses of straight cartoning machines and how they may enhance your product packaging procedures.

Streamlined Packaging with Straight Cartoning Models:

Vertical cartoning machines are professional equipment created to speed up the entire process of constructing, satisfying, and shutting cartons. These machines are widely used across numerous businesses, which includes meals and refreshment, pharmaceuticals, beauty products, and consumer products. They offer several positive aspects that contribute to improved wrapping productivity, cost benefits, and improved product or service business presentation.

Improved Pace and Performance:

Straight cartoning equipment are capable of great-speed surgical procedures, drastically raising wrapping throughput. By automating the carton erection, product or service installation, and closure procedures, these machines get rid of the need for manual labor, reducing the chances of faults and improving general productivity. With precise and consistent overall performance, they make certain that each carton is correctly filled and enclosed, decreasing product waste materials and maximizing efficiency.

Flexible Packaging Options:

Straight cartoning equipment are adaptable and might take care of a variety of packaging formats, including bottles, blister packs, pouches, pipes, plus more. Whether you must bundle specific products or pack several items, these machines can easily be tweaked to accommodate various sizes, shapes, and layouts. This overall flexibility permits suppliers to evolve to altering industry demands and branch out their item offerings without making an investment in more packing devices.

Increased Product Protection and Business presentation:

With specific control of the packaging method, top to bottom cartoning models make certain that merchandise is securely and neatly loaded. The devices can integrate additional features like leaflet insertion, set programming, marking, and tamper-apparent sealing, which not just shield the item but in addition provide important info and branding elements to consumers. The regular and expert packaging improves the general presentation and recognized price of the item.

Enhanced Traceability and Compliance:

Straight cartoning models can integrate with serialization and monitor-and-locate methods, which can be important in market sectors like pharmaceuticals and healthcare units to guarantee merchandise safety and regulatory concurrence. By employing these systems, suppliers can easily trace and authenticate specific items through the provide chain, reducing the chance of counterfeiting and improving client assurance.

Verdict:

In today's competing marketplace, organizations must embrace innovative packing answers to stay ahead of time. Vertical cartoning equipment supply a selection of benefits, from greater product packaging velocity and efficiency to functional product packaging options and improved product safety. By investing in this innovative machinery, companies can optimize their packaging functions, decrease expenses, boost product business presentation, and ultimately obtain a competitive edge. To learn the great deal of straight cartoning models along with other wrapping remedies accessible, pay a visit to AFAsystemsinc.com and take a phase towards revolutionizing your wrapping functions.

For more info:-

Bottle Case Packer

horizontal cartoner

Used Cartoners

case erector bottom sealer

0 notes

Text

A Comprehensive Guide to Understanding the 2198-C4020-ERS Model

For machine makers, network design is made simpler by Rockwell Allen Bradley Kinetix 300 servo drive. The Kinetix 300 enables customers to standardise on a single communication network for simpler commissioning, configuration, and restart thanks to its EtherNet/IP indexing functionality. The new drive allows for the connection of the whole control system—including the HMI, programmable automation controllers, I/O, and motion—over a common EtherNet/IP network.

The Kinetix 300 servo drive is perfect for indexing tables, intermittent horizontal and vertical form/fill/seal machines, as well as basic sleevers, case packers, and erectors. It can accommodate up to five indexing types and 32 indices. It also has a small size and the voltage and power ranges needed to fulfil a variety of machine requirements around the world, including applications in the manufacturing and assembly, alternative energy, and packaging sectors.

A single-axis industrial servo drive from the Allen-Bradley Kinetix 5300 series of servo drives and accessories, the Allen-Bradley/Rockwell Automation 2198-C4020-ERS is designed and produced. This servo drive is a piece of open-type industrial machinery that fits into a Size 2 frame and should be installed in an enclosure for protection while it is in operation because it is vulnerable to damage from liquids and debris. The continuous output power rating, continuous output current rating, and peak output current rating of the 2198-C4020-ERS servo drive are 3.9 kilowatts, 7.3 amps RMS, and 23.8 amps RMS, respectively. Additionally, the 3-phase RMS voltage range for the 2198-C4020-ERS single-axis servo drive ranges from 342 to 528 volts.

The single-axis servo Allen-Bradley/Rockwell Automation Kinetix 5300 2198-C4020-ERS Drive is compatible with the Kinetix 5300 2198-DB08-F AC line filter from Allen-Bradley/Rockwell Automation. To be used in the European Union and to meet CE regulations, it must be equipped with this line filter. When installing the AC line filter, it must be separated from the servo drive by at least 1.97 inches (50 millimetres) and have the shortest cable feasible. The 2198-C4020-ERS servo drive's nominal voltage range is between 380- and 480-volts AC. This single-axis servo drive can handle wiring torques of 4.4 to 5.3 pounds per inch, or 0.5 to 0.6 Nm, and wire gauges of 24 to 12 AWG OR 0.2 to 2.5 square millimetres.

A DC-bus power source for the Kinetix 5700 servo drive is the Allen-Bradley 2198-P141. Its three-phase AC input voltage ranges from 324-528V (480V nominal) RMS to 47-63 Hz. It features an 85mm module width. It has a peak AC input current of 148.7A, a max inrush current of 33A, and a main AC input current of 49.6A. The output current to the bus is continuously at 46.9A and maximally at 140.8A. The output power to the bus is 31 kW continuous and 93 kW peak, respectively. The internal shunt resistance and shunt power of the 2198-P141 are 13.5 and 200W, respectively. With a 1640 F internal capacitance and a 362 J capacitive energy absorption, it boasts a 99% efficiency.

0 notes

Text

Revolutionizing Packaging and Logistics: The Power of Industrial Automation Equipment

In today's fast-paced world of packaging and logistics, meeting customer demands while maintaining a competitive edge is paramount. Fortunately, industrial automation equipment has emerged as a transformative force, introducing advanced technologies that streamline processes, boost productivity, and ensure precise handling of goods. In this comprehensive blog, we will delve into the profound impact of industrial automation equipment in packaging and logistics. Our focus will be on key equipment solutions that drive efficiency, optimize operations, and pave the way for future growth and success.

Section 1: Automated Packaging Equipment

1.1 Robotic Packaging Systems:

Robotic pick-and-place systems have revolutionized the packaging industry by offering unparalleled speed, precision, and flexibility. These robots can quickly and accurately pick products from a conveyor and place them into packaging containers.

Collaborative robots, or cobots, work alongside human operators, enhancing safety and enabling collaborative packaging tasks. They are designed to handle delicate or irregularly shaped items with care.

Automated case erectors and carton sealers streamline the packaging process by efficiently erecting and sealing boxes, eliminating the need for manual labor and reducing the risk of errors.

Robotic palletizing and depalletizing systems automate the loading and unloading of products onto pallets, optimizing efficiency and reducing physical strain on workers.

1.2 Automated Filling and Labeling Machines:

Automatic filling machines are employed in a wide range of industries, including food and beverages, pharmaceuticals, and personal care. These machines accurately fill containers with liquids, powders, and granules, ensuring consistent product quality and reducing waste.

High-speed labeling systems are capable of applying labels to products at remarkable speeds, enhancing efficiency and accuracy. These systems often integrate vision systems for label verification and quality control, ensuring labels are placed correctly and legibly.

Automatic capping and sealing machines ensure secure and uniform closure of containers, preventing leakage or contamination. These machines guarantee consistent and tamper-proof packaging, promoting product integrity.

1.3 Conveyor Systems and Sortation Equipment:

Conveyor systems play a vital role in packaging and logistics, facilitating the smooth flow of goods throughout the process. Belt conveyors, roller conveyors, and modular conveyor systems are widely used to transport products between various stages, reducing manual handling and minimizing bottlenecks.

Automated sorting and diverting systems utilize advanced sensors and algorithms to sort and redirect packages based on predefined criteria such as destination, weight, or size. These systems optimize the packaging and distribution process, ensuring accurate and timely delivery.

Conveyor belt scales accurately weigh and measure products during the packaging process, enabling precise inventory control and ensuring compliance with regulatory requirements.

The integration of barcode scanning and Radio Frequency Identification (RFID) technologies with conveyor systems enhances tracking and traceability, improving inventory management and supply chain visibility.

Section 2: Automated Warehouse and Distribution Solutions

2.1 Automated Storage and Retrieval Systems (AS/RS):

High-density AS/RS solutions maximize space utilization by vertically storing and retrieving products using automated cranes or robotic systems. These systems optimize storage capacity, reduce manual labor, and facilitate efficient inventory management.

Automated crane systems perform vertical and horizontal movements within warehouses, efficiently retrieving and placing items. These systems increase operational speed, accuracy, and overall productivity.

AS/RS with integrated inventory management and order picking systems provide seamless control over inventory levels, order fulfillment, and stock rotation. The integration of automation equipment streamlines processes, minimizes errors, and enhances overall efficiency.

In the context of cold chain logistics, AS/RS solutions offer temperature-controlled storage, ensuring the integrity and safety of perishable goods.

2.2 Autonomous Mobile Robots (AMRs):

AMRs have emerged as a game-changer in warehouse and distribution operations. These intelligent robots navigate autonomously within the facility, performing various tasks such as goods transportation, order picking, and inventory replenishment.

Collaborative AMRs work hand in hand with human operators, creating a harmonious work environment that leverages the strengths of both humans and robots. They assist in order picking, minimizing physical strain and improving overall productivity.

The integration of AMRs with warehouse management systems (WMS) enables real-time communication and coordination, ensuring optimized task allocation and resource utilization.

AMR fleet management and coordination systems enhance operational efficiency by intelligently managing and coordinating the movement of multiple robots, minimizing congestion and optimizing workflow.

2.3 Automated Guided Vehicles (AGVs):

AGVs have become indispensable in automating material transport within warehouses and distribution centers. These vehicles are equipped with advanced navigation systems, such as laser guidance, magnetic guidance, or vision-based systems, enabling them to navigate and transport goods autonomously.

AGVs seamlessly integrate with conveyor systems and picking stations, facilitating the efficient movement of products throughout the facility.

AGVs are also utilized for loading and unloading goods from trucks or containers, reducing manual labor and enhancing operational efficiency.

Section 3: Data Integration and Optimization

3.1 Warehouse Management Systems (WMS):

WMS software plays a critical role in managing warehouse operations, including inventory control, order management, and resource allocation. WMS provides real-time visibility into inventory levels, locations, and movements, facilitating effective decision-making and efficient resource utilization.

The integration of WMS with automation equipment enables seamless operations and real-time synchronization of inventory data. This integration optimizes order fulfillment, minimizes errors, and enhances customer satisfaction.

Advanced analytics and reporting capabilities offered by WMS provide valuable insights into warehouse performance, enabling data-driven decision-making and continuous process improvement.

3.2 Enterprise Resource Planning (ERP) Integration:

Integrating automation equipment data with ERP systems streamlines end-to-end processes, from order processing to invoicing and financial management. The synchronization of data ensures accurate and timely information exchange, reducing manual errors and enhancing operational efficiency.

Inventory synchronization between automation equipment and ERP systems enables real-time visibility into stock levels, ensuring effective demand planning and preventing stockouts or excess inventory.

The integration of automation equipment data with ERP systems enhances supply chain visibility, enabling stakeholders to track and manage inventory, monitor production, and make informed decisions based on real-time data.

3.3 Predictive Analytics and Machine Learning:

Predictive maintenance techniques leverage data from automation equipment to identify potential equipment failures before they occur. By analyzing sensor data and performance metrics, predictive analytics algorithms can anticipate maintenance requirements, allowing for proactive interventions that minimize downtime and maximize operational efficiency.

Machine learning algorithms are employed to analyze historical data and identify patterns, enabling accurate demand forecasting and optimization. By understanding demand trends, businesses can optimize inventory levels, production schedules, and distribution strategies, ultimately reducing costs and improving customer satisfaction.

Real-time analytics capabilities enable route optimization and delivery time estimation, empowering logistics operations to respond dynamically to changing conditions, minimize transit times, and enhance customer experience.

Continuous process improvement, driven by data-driven insights obtained from automation equipment, fosters innovation and operational excellence. By analyzing operational data, identifying bottlenecks, and implementing targeted improvements, businesses can optimize processes, reduce waste, and achieve higher levels of efficiency. The advent of industrial automation equipment has revolutionized packaging and logistics operations, bringing unprecedented levels of efficiency, accuracy, and customer satisfaction. From robotic packaging systems to automated warehouse solutions, the integration of advanced technologies has redefined industry standards and opened up new avenues for growth. By embracing industrial automation equipment and harnessing its capabilities, businesses can streamline packaging processes, optimize warehouse operations, and ensure timely and accurate delivery of goods. In an increasingly competitive market, leveraging the power of industrial automation equipment is essential for staying ahead of the curve and meeting the evolving demands of customers and the industry at large.

#industrial automation#marine spare parts#industrial equipment#marine automation#industrial spare parts#industrialpower supply#industrial automation equipment#industrial and marine automation equipment#auto2mation

0 notes

Photo

With sturdy high-quality construction and easy setup & operation, our net linear scales support smooth operational value for packaging machines. Check Planitpackaging.com.

Linear Net Weigher are capable of handling various product from fruit/nuts, candy, chips, powders and much more and could be easily integrated on any packaging machines. Visit Us : https://planitpackaging.com/linear-scale/

0 notes

Text

Enhance your Secondary Packaging with Nichrome’s Horizontal Flow Wrap Machine

Nichrome’s Integrated Packaging System is a complete packaging solution that combines multiple machines and processes into a single, cohesive system. Our system includes a range of machines, including filling machines, sealing machines, and labeling machines, which work together seamlessly to deliver efficient, high-quality packaging. Our Integrated Packaging System is fully customizable to meet…

View On WordPress

#Automatic Bottle Filling Machine#automatic case erector#Bottle Capping Machine#bulk bag filling machine#flow wrap machine#ghee jar filling machine#horizontal cartooning machine#horizontal flow wrap machine#integrated packaging system#shrink wrapping machine manufacturer#tin can filling and sealing machine#tin packaging machine#vertical case erector

0 notes

Text

four years late to my own AU with starbucks

@dirgeofcerberus111 wanted to hear about the Diamondverse AU from… I want to say, late 2015? I don’t remember all of it, of course, but I do still have bits and pieces of information regarding the plot and alterations. In order to keep it at least vaguely in line with canon, I’ll be making some big changes to the stuff I’d already posted back then.

I probably will not be returning to this, because I haven’t been all that interested in Steven Universe for some time now, but I did want to see if I could clean the concept up a little in case anyone else wants to use it.

Now, without further ado, let’s get down to it.

Per the original premise, the AU stars Steven and his three Gem protectors, living alongside humans in the remains of a global war against their Homeworld; however, now that we know what the Diamonds are actually like, I’ve made a major change to the formula.

The Diamonds are not the Diamonds. It is now a title one can hold, because the original Diamonds lost the war and were outcast from Homeworld. Our Gem protagonists are still connected to the original Diamonds, but they are entirely different Gems, although they do carry the term as their group name. Rose Quartz was still Steven’s mother, and the only original Diamond among the team.

Each team member now has a unique role that does not necessarily follow the plot lines of the canon Crystal Gems. Some threads are similar, but they will not fit cleanly into any one role.

In Yellow Diamond’s team role, we have an Imperial Topaz, who is a perma-fusion between a Saffron Zircon and off-color Citrine. They were cast out as off-colors, then later fell in love while fighting for the rebellion under Rose Quartz; however, unlike Garnet, Imperial has always been very clear and almost boastful about being a fusion, and her personal issues, while related to that, come from a very different source because neither Zircon nor Citrine were ever under the impression that Homeworld was a safe or appropriate force to serve. Zircon’s triangular Gem is located just below the left collarbone and shoulder, while Citrine’s is on the right; it is difficult to tell them apart, the biggest difference being Zircon’s turtle-faced cut compared to Citrine’s rounded trillion cut. The closest placement parallels for a human would be the muscles Pectoralis Major.

This represents the mutual support and balance of the relationship, related to shoulders, but also emphasizes the strength of pectoral muscles, the importance of lungs and oxygen in the body, and “looking over your shoulder” as a reference to Imperial’s anxiety and trauma from the war. Imperial often feels as though she is carrying the weight of the world on her shoulders, and despite the fact that Gems don’t need to sleep, she greatly values it as a way of unwinding from her persistent stress.

After Rose and her Pearl were separated during the war, Imperial stood by as the ex-Diamond’s bodyguard; she grew to see Rose as a mentor. She had also befriended Pearl prior to the tragic battle where the renegade was lost, and considered it her obligation to protect Rose until they could reunite. By the time Greg came into the picture, though, they had both lost hope of seeing Pearl again, and Imperial celebrated the new relationship as a way of ignoring her guilt over not only failing to protect her friend, but also giving her role to someone else. As such, she sees Steven as a second chance at fixing the situation and creating a happy ending Pearl would still be proud of.

The title of Blue Diamond is carried by a Blue Lace Agate, who was made much earlier than the Holly Blue we know in canon. Lace is technically the oldest Gem of the remaining three, but was captured by Homeworld soldiers, sealed as the power source for a “Warden Unit” for a few thousand years after the war, and spent much of that time watching over the corrupted prisoners. She was only spared from the Diamonds’ song because the Warden Unit was reinforced to stop any and all outside influence from tampering with the hardware. Eventually, she was found by Rose and Imperial, and joined their team as a warrior and “corrupted-whisperer”.

Her circular cabochon gem is situated on her lower back, at the top-middle of the Erector Spinae; similar to Lapis and Holly Blue, this is because she is always watching her back for danger, and is incredibly vulnerable due to a glaring weak spot, but also values old traditions of the world she left behind and incorporates whatever she can salvage from it into modern tactics. She knows her moral compass is still shaky, and is more than willing to put herself in a place of vulnerability to learn from others in order to steady it. Though nostalgia is a powerful, almost addictive force for her, she sees the past as a cautionary tale.

Lace considers herself a leader, although she feels her potential is wasted while Rose and Imperial are in charge; this brings out a rebellious streak, in which she not only “turns her back” on her usual team duties, but also opens her up to an attack from behind by those she eagerly volunteers herself to lead. In her attempts to take the leadership role, she bends over backwards to impress others, even when it may put her in danger; the more she tries without results, the weaker her self-esteem becomes, and she begins to believe that she is a burden upon the other, more responsible Gems. Because of this, she leans on Steven for the validation the others don’t know she’s looking for, by taking on a sisterly role similar to Amethyst’s.

Last but not least, White’s role is played by a Gem who appears to be an off-color Black Spinel, but is actually an incredibly rare Musgravite (which, of course, is different from Spinel, but closely related; this becomes very important later on), created as an actress to perform for the original Diamond, but overcooked and temporarily sealed due to her Kindergarten’s neglect during the war. To take another cue from Amethyst, Musgravite emerged thousands of years after the fighting ended, shortly before Lace would be rescued from the Warden Unit. In fact, it was Lace who helped Rose and Imperial find her in the first place; Musgravite did not stay in the Kindergarten, choosing instead to leave and study the world outside.

Her Gem is placed on her forehead, a vertical Marquis cut that runs from her widow’s peak hairline to the dip at the beginning of her nose. Like Pearl and Peridot, sharing their placement, she has remarkable intelligence and perception; however, she isn’t generally seen as the brain of the group, but the “third eye”. She is fascinated with humans and the intricacies of their belief systems, but generally is most interested in things like dead languages and ancient mythology, with a bit of sociology and psychology thrown in to help her work out historical context for a species that she otherwise wouldn’t understand nearly as well. The third eye as a concept is one of the few modern metaphysical themes that she relates to, not only because her gem look like one, but it matches up with her endless curiosity, as well as her interest in philosophy, soft sciences, and all of the incredible living oddities that live on the planet she calls home.

Once found, she picked up the nickname “Moose”, partially because her full Gem name was a mouthful, and partially because of an inside joke between her and Lace about one exploration trip where she tried to befriend a calf, only to get poofed less than a minute later by the enraged mother. Luckily, it sounds a lot worse than it actually was in the moment; they still look back and laugh at it sometimes, and Moose credits that as the event that led her to learn her first little bit of non-lethal self defense. She spent quite a bit of time with Rose during her time as a Diamond, although she never got a solid answer as to why they still didn’t have a stand-in for White Diamond after thousands of years. It was never explicitly stated, likely because Rose just didn’t want to talk about it, but judging by what she’s filled in via eavesdropping, she has a theory that the title of White Diamond was supposed to go to the renegade Pearl from the original uprising, and Rose never quite got over losing her.

The Diamonds have been hiding out on Earth ever since the revolution, although at first they won’t tell Steven why. They make up excuses about finding a way to heal, or at least control, corrupted Gems; it’s a bit difficult to believe when they all know there is no cure in their current reach. If there was one somewhere on Earth, they would have found it already. They know the damage can be treated by Rose’s healing tears, but not for long, and the change is mostly superficial. It’s not until a battleship from Homeworld arrives that Steven begins to get a better mental picture of how the revolution actually went down.

In the aftermath of the Authority’s exile, a small group of Gems took advantage of the gap in government power to install themselves as the new leaders. Although they allowed Gems to switch jobs to whatever they had the skill and motivation to actually excel in, and fusion between different Gem types became an acceptable and even common practice, they also rewrote the guidelines for determining who was considered Off-Color. These Gems were offered new jobs… In the army, intense manual labor, unsafe work environments, or anything else that would be too dangerous or difficult for “normal” Gems. Non-Off-Colors who protested were also sent to work in the lower ranks.

If they were not able to complete their tasks, or were unable to work, they would get another chance to contribute via a new, incredible invention, built to keep Homeworld running smoothly with polished automation, massive reach, and nearly endless power: The Mainframe.

Y’know the Cluster? Imagine that, but it was built to last, and instead of just little shards of Gems, it’s made up of nearly-whole Gems with a single chunk cut out for the records. They called it the Resonance, and hooked it up to a massive computer, built from the husk of another dead planet and pulled into Homeworld’s orbit. The Resonance can reform if it wants to; there’s plenty of room in that hollow shell, and besides, it’s not going to break out. It doesn’t want to. They keep it happy by getting performers on the planet below to set up entertainment, whether that means music, art, comedy, literature… Whatever they can find, they show to the Resonance, which has the added bonus of having that information stored in the Mainframe.

The Resonance isn’t evil, and it isn’t in pain, but it also knows that once a Gem is added to it, they rarely ever get pulled back out. That’s just… What life is, now. Very few pieces of it actually chose to become part of the Mainframe. Those with regrets vastly outnumber those with hope; with so many little voices lamenting their existence, it’s hard not to listen. It’s hard not to feel sorry for being alive.

So the Mainframe has been slowing down. The Resonance isn’t giving it the energy it needs, and has instead been looping it back into itself. Nobody’s quite sure why; surely, it hasn’t forgotten basic survival instincts! It knows that if it takes in too much, it’ll bloat, it’ll fester, it’ll infect everything around it until it cannibalizes itself, and then nothing will be left but a bunch of shards and an empty moon hanging over the blacked-out planet.

Our Pearl is considered an Off-Color. Rose is considered an Off-Color. Every one of the Diamonds and their Crystal Gems is, as far as Homeworld is concerned, inherently damaged and unfit for work. Because when faced with the evolution of their species, they ran away.

The Mainframe’s caretakers believe that it’s slowing down because it needs more components. The Diamonds weren’t the only ones who left; millions of Off-Colors and sympathizers fled after the Resonance was unveiled. Now, the caretakers are sending out “rescue fleets” to bring them all back.

Quite a few different rebel factions have cropped up, including two with some very familiar faces: Pearl’s Crystal Gems, and Flourite’s… I don’t know, Prism Breakers?… That’ll work. The point is, our heroes aren’t alone, but getting in contact with anyone who can help will be quite the challenge.

The problem they’re not telling anyone about, though, is that the Resonance has started to sing. It sounds eerily familiar - almost like the voice of a Diamond, though not one heard on Homeworld before. Coincidentally, corrupted sightings have been increasing for the last few centuries. It’s starting become a real problem; they don’t have anywhere to put them all. So they go to - yep, you guessed it - the Resonance.

Oh, and by the way, the planet-harvesting thing is still happening. It’s not as high on the priority list for our unfriendly visitors, but it’s definitely an added bonus, as long as they can catch the runaways first.

Eventually, Steven and the Diamonds are forced to take action. However this pans out is up to interpretation. I imagine they would have to go out and find the old Diamonds - Yellow first, Blue second, White third - as a major step in figuring out how to heal corruption, but the rest is up to you.

7 notes

·

View notes

Text

Packaging Automation

Packaging automation can be a powerful tool for businesses that need to ship large quantities of products quickly. If you would like to increase productivity and shorten the time it takes to deliver products to customers, automated packaging systems and processes might be the answer.

With so many options available, you may be wondering which solution is the best for your operations. Don’t worry, we’ve got you covered!

We will define packaging automation, explore different types available and look at some of the key advantages and frequently asked questions related to packaging automation.

Packaging automation entails introducing automated equipment and machinery into your packing operation to accelerate the packing process.

This helps to assure consistency, avoid material waste, and save money overall. It also enables you to reallocate valuable resources to high-value jobs or in the most efficient method for your operation. Most areas of the packaging process can be improved by introducing automated packaging systems; from picking and packing to conveying and wrapping, there are packaging machines for it all.

What are the different types of packaging automation?

Erecting boxes, taping cartons, and wrapping pallets for shipment can all be automated.

We distinguish between semi-automated and automated packing methods:

A semi-automated packing process combines both human involvement with elements of automation. For example, an operator can start the process, but an automatic packing system will finish it. If you want to use automation but have a restricted budget, this is usually the most cost-effective option.

An automated packing process is pre-programmed from start to end. It can handle everything from picking products, and packaging to palletizing for shipping. This option is a good solution for operations where demand is high or that predict significant grow.

We distinguish between the following automation solutions, based on the product you’re using:

Box automation – including solutions, such as case and box erectors, fully and semi-automated auto boxing machines as well as void reduction systems.

Tape automation – e.g., semi, and fully automatic tape dispensers, in-line taping machines and carton sealers.

Bag automation – e.g., automated bagging machines and bulk bagging equipment.

Protective automation – including semi and fully automated void fill machines, air cushioning and air pillow machines.

Paper automation – e.g., paper wrapping equipment, paper void fill machines and paper cushioning systems.

Strapping automation – solutions such as: semi and fully automated strapping machines, friction welders, battery powered strapping tools and banding tables.

Stretch automation – e.g., fully, and semi-automatic pallet wrappers, vertical and horizonal stretch wrapping machines and rotating arm stretch wrap machines.

Shrink automation – e.g., shrink-wrapping machines, heat shrink tunnels, heat sealers, impulse heat sealers and vacuum packing machines.

Auxiliary equipment – solutions, such as: automated labelling equipment, case stackers, sorters, palletizers, and conveyor systems.

Packaging automation offers many benefits. It can help you to:

-Boost productivity, allowing you to pack more cases in less time.

-Save space, using fewer packaging SKUs and, therefore, saving storage space before cases are packed (less packaging stored on site), as well as cubage, which saves transport space.

-Lower operating costs, resulting in savings on labor, storage, transportation, packing materials, and productivity.

-Streamline workflow, ensuring your packaging process runs as smoothly as possible.

-Reduce volume handling, relieving operational strain and helping better manage spikes in demand.

-Assure pack optimization and consistency, ensuring that the appropriate quantity and type of packaging is used every time.

-Minimize material waste, making sure you only use the right amount of material required to protect your product during transit and avoiding overpacking.

-Reduce transport and fuel costs, enabling you to pack more products onto a pallet. This will also help reduce your carbon footprint, as less fuel means fewer CO2 emissions.

-Ensure customer satisfaction, providing smart, beautifully packaged products that arrive with your customers damage-free.

-Future-proof for growth and demand, increasing your capacity and helping control costs as your business grows.

How do I automate my packing process?

There are many ways to automate your packing process. You can automate almost any part of it, but if you need pointers of where to start, you will need to review your packing operation first. This will help you identify any bottlenecks or processes that could be improved or automated.

Some of the common bottlenecks include:

Picking accuracy – miss-picks can be a sign that something is not working or that demand is outstripping capacity.

Packing times – have packing times met targets? Are packers taking longer to process orders? During high-pressure times, packing times can be a bottleneck if processes aren’t efficient and packing materials aren’t easy.

Shipping lead times – do your lead times keep increasing and getting longer? This can be in response to high demand, but it can also suggest that processes need to change.

Damages – are customers reporting an increase in damages? This can be an indicator that packing isn’t being completed properly or that the packing materials being used aren’t sufficient.

How to choose the right packaging machine equipment?

The type of automation solution you need will depend on your products, processes, productivity goals and space in your warehouse. You will also need to factor in your budget.

What will packaging automation cost me?

Packaging automation can be an investment, depending on the solution you’re looking at. There may be a large upfront cost to purchase an automated packaging system, but the money you will save elsewhere in your operation will counterbalance this overall.

Not every system requires an initial outlay – many are available for rental or can be purchased through finance agreements. A free trial is available on many machines, which gives you the opportunity to test if the solution is right for your business. Plus, there are some cost-effective automation options out there.

How do I calculate return on investment (ROI) for packaging automation?

The ROI for packaging automation is calculated by comparing the costs associated with implementing automation to the benefits it brings, including cost savings and increased productivity.

When calculating the cost of automation for your business, there are several factors to consider, including your initial investment, equipment costs, installation setup fees, staff training, and any projected long-term costs, such as maintenance and repair. Then, think about how much money you can save each year with packaging automation. This can include reducing labor costs, increasing productivity and throughput, reducing material waste, as well as improving product quality and consistency.

How do I futureproof the investment in packaging automation?

When you invest in packaging automation, it is important to make strategic decisions and put processes in place to keep your packaging automated system running smoothly and up to date with the latest technologies and industry developments. Consider things such as regular and preventative maintenance, staff training, periodic calibration, and testing of equipment as well as spare parts inventory.

At Quick Pak Inc, we work closely with our customers on a case-by-case basis to find the best automated packaging solutions for their requirements.

We can offer a wide choice of automated packaging solutions to fit various demands and budgets, whether you need a pallet wrapper, shrink equipment, labeling and marking, carton sealer, case erector, or anything in between.

Contact us today at 813 242 6995 or [email protected]

#packaging automation#less packaging#pack faster#better packaging#pricing news#quickpakinc#stretch film pricing#stretch film#resin pricing#free pallet wrapper#coreless film#youtube#quick pak inc#free machine

0 notes

Text

issuu

vertical cartoning machine | Afasystemsinc.com

Want to buy a case erector bottom sealer? Afasystemsinc.com is a renowned platform to buy the vertical cartooning machine. We offer a high-quality cartooning machine in various models at affordable prices. Check out our site for more details.

0 notes

Text

Choose us to avail best and efficient machines that will assist you in your packaging industry.

Gone are those days when having absolute man power in your industry is the sign of growth and achievement. With revolution in technology, we recognized that with more man power in a particular section the probability of error increases significantly. Hence, lately industries are shifting towards technical assistance in their firm to mitigate such errors. However, with evolution in technology in our contemporary period industries are fully equipped with machines that enable you to have processed and error free products. Hence, we are here to provide you with all the machines that will assist you in packaging industries and help you to strengthen your grip in the market.

Plan it packaging is a locally owned and operated company that strives to give you all the paid mechanical assistance that your packaging firm may require. The mere substitution of your large manpower but with efficiency as equal as them, such machine can be avail by you with our provision. We provide you with all the machines that ensure your process from fast to last in a fraction of time. With us you can avail Filling machine that includes multi-head scale, Auger powder filling, net linear scales, convoying machine, End of line packaging that includes pre-made pouch Bagging packaging, horizontal form, fill and seal packaging, vertical form fill and seal packaging, flow wrapping, automatic feeding scales, case erector, inspector system and many more.

To facilitate you buying from us we too have an online portal that is easy to use and provides you with all the lucid information about us. Our machines are efficient and value to money. Hence, we are recognized as the best in this line of work. Hence, make sure to visit us online at http://www.planitpackaging.com/

0 notes

Text

Juniper Publishers- Journal of Physical Fitness, Medicine & Treatment in Sports

Static and Dynamic Balancing and Gait Training in Shooters Leading to a Better Efficacy-A Prospective Study- Juniper Publishers Introduction

The ability to walk upright is a defining characteristic of man. Gait is the way walking is performed and can be normal, antalgic, or unsteady [1]. Gait analysis can be assessed by various techniques but is most commonly performed by clinical evaluation incorporating the individual’s history, physical examination, and functional assessment. Gait abnormalities can be more precisely examined using gait laboratories. These laboratories utilize surface EMG activity of muscles, force plates, and kinematic evaluation of the lower limbs. They are highly specialized units that assess various gait abnormalities from individuals with neuromuscular disorders to high-level athletics. A proper clinical evaluation should always precede any gait lab assessment [2]. The determination of abnormal gait requires one to first understand the basic physiology and biomechanics of normal gait [3]. The gait cycle is a time interval or sequence of motion occurring from heel strike to heel strike of the same foot. The gait cycle has been broadly divided into two phases: stance phase and swing phase. These phases can then be further subdivided and discussed in terms of percentage of each within the gait cycle (Figure 1).

The stance phase is 60 percent of the gait cycle and can be subdivided into double-leg and single-leg stance. In double-leg stance, both feet are in contact with the ground. At an average walking speed, it represents 10percent of the entire gait cycle, but decreases with increased walking speed and ultimately disappears as one begins to run. At slower walking velocities the double-leg support times are greater. Single-leg stance comprises up to 40 percent of the normal gait cycle [4]. The muscles that are active during the stance phase act to prevent buckling of the support limb. These include the tibialis anterior, the quadriceps, the hamstrings, the hip abductors, the gluteus maximus, and erector spinae. The swing phase is described when the limb is not weight bearing and represents 40 percent of a single gait cycle. It is subdivided into three phases: initial swing(acceleration), mid swing, and terminal swing (deceleration). Acceleration occurs as the foot is lifted from the floor and, during this time, the swing leg is rapidly accelerated forward by hip and knee flexion along with ankle dorsi flexion. Midswing occurs when the accelerating limb is aligned with the stance limb. Terminal swing then occurs as the decelerating leg prepares for contact with the floor and is controlled by the hamstring muscles.

Determinants of Gait and Energy Conservation

During gait, three main events occur in which energy is consumed. This includes controlling forward movement during deceleration toward the end of swing phase, shock absorption at heel strike, and propulsion during push off, when the center of gravity is propelled up and forward. A human’s center of mass (COM) is located just anterior to the second sacral vertebra, midway between both hip joints [5]. The least amount of energy is required when a body moves along a straight line, with the COM deviating neither up nor down, nor side to side. Such a straight line would be possible in normal gait if man’s lower limbs terminated in wheels instead of feet. This obviously is not the case, thus, our COM deviates from the straight line in vertical and lateral sinusoidal displacements. With respect to vertical displacement: the COM goes through rhythmic upward and downward motion as it moves forward. The highest point occurs at midstance, the lowest point occurs at time of double support. The average amount of vertical displacement in the adult male is approximately 5cm. With respect to lateral displacements: As weight is transferred from one leg to the other, there is shift of the pelvis to the weight-bearing side. The oscillation of the COM amounts to side-to-side displacement of approximately 5cm. The lateral limits are reached at midstance. Any pathology that increases the vertical distance between the high and low points, increases the energy cost of ambulation (Figures 2 & 3).

Methodology

A total of 32 shooters were examined clinically and gait analysis was performed on them thereafter with a proper consent for participation in the study at ABHINAV BINDRA TARGETING PERFORMANCE, INDIA from a period of January 2019 to May 2019 (Figure 4).

Aims & Objectives

Gait analysis and pelvis muscles assessment for shooters prior to training and comparing the assessment post training, effect of stability and strengthening for improving the efficacy of the shooters.

Discussion

The analysis of pre and post static balance as well as dynamic balance for both groups and the comparison of the post balance test of two groups were analyzed by using independent sample t-test. First, the GAIT assessment scoring of firm surface before the study among the control group was 5.14±1.069 and increased to 5.39±1.704, which did not show significant at 5% level of significance (ρ>0.05). while the scoring of foam surface before study was 7.79±0.851 and increased to 7.53±1.372, therefore it was not significant at 5% level of significance (ρ>0.05). On the other hand, the scoring of GAIT assessment for firm before the intervention among the experimental group was 5.34±1.269 and after the intervention training program, it reduced to 2.90±1.190 which showed significant improvement with ρ<0.05. The dynamic balance results were reported on left and right stance. The higher the score the better the dynamic balance of the individual.

The shooters scores of mean and standard deviation of left stance before the study among the control group before test was 77.36±4.137 and after test score was 74.79±7.156, which the improvement did not show statically significant; whereas in right stance, before test was 76.37±6.785 and after test was 72.58±7.960 after four weeks of study and the improvement did not show statically significant. However, the score for experimental group in left stance was 75.31±5.334 before the intervention and improved to 82.14±5.661 after a month intervention training, and it was significant at 5% level of significance (ρ<0.05). Meanwhile, the scoring of in right stance increased from 77.12±7.015-86.29±5.795 before and after intervention respectively. Thus, this showed that the result of left stance and right stance in SEBT indicated significant improvement (ρ<0.05). Meanwhile, for standing on firm surface, the mean score for the experimental group was 3.20±1.191 and for the control group was 5.79±1.504. The result indicated there was significant difference between the pre training and post training after a month’s study.

Result

The combination of the two exercises components in current study which were the balance exercises and jump landing training, gait training and static and dynamic balancing on firm and foam surface have drastically improved the ability of shooters to balance and aim accurately [6]. Thus, it is crucial that balance training should continue to be studied and promoted to ensure the improvement in static and dynamic balance and thus reducing the risks of injuries such as knee and ankle injuries and ensure the accuracy of shooters.

For more Open Access Journals in Juniper Publishers please click on: https://juniperpublishers.com

For more articles in Journal of Physical Fitness, Medicine & Treatment in Sports

please click on: https://juniperpublishers.com/jpfmts/index.php

For more about juniper publishers please click on: https://www.juniperpublishersgroup.com/

0 notes

Text

Robotic Random Case Erector Market Size, Trends, Latest Technology, Applications, Types, Components, Manufacturers, Industry and COVID-19 Pandemic Presenting Opportunities 2027

"

Robotic Random Case Erector Market is analyzed with industry experts in mind to maximize return on investment by providing clear information needed for informed business decisions. This research will help both established and new entrants to identify and analyze market needs, market size and competition. It explains the supply and demand situation, the competitive scenario, and the challenges for market growth, market opportunities and the threats faced by key players.

Sample Copy of This Report:https://axelreports.com/request-sample/116659

A 360 degree outline of the competitive scenario of the Global Robotic Random Case Erector Market is presented by Axel Reports Market Insights. It has a massive data allied to the recent product and technological developments in the markets.

It has a wide-ranging analysis of the impact of these advancements on the market’s future growth, wide-ranging analysis of these extensions on the market’s future growth. The research report studies the market in a detailed manner by explaining the key facets of the market that are foreseeable to have a countable stimulus on its developing extrapolations over the forecast period.

Reasons for buying this report:

It offers an analysis of changing competitive scenario.

For making informed decisions in the businesses, it offers analytical data with strategic planning methodologies.

It offers seven-year assessment of Global Robotic Random Case Erector

It helps in understanding the major key product segments.

Researchers throw light on the dynamics of the market such as drivers, restraints, trends, and opportunities.

It offers regional analysis of Global Robotic Random Case Erector Market along with business profiles of several stakeholders.

It offers massive data about trending factors that will influence the progress of the Global Robotic Random Case Erector

Get ToC for the overview of the premium report @ https://axelreports.com/industry-analysis/global-track-mounted-screening-plants-market/116659

By Market Players: Combi Packaging Systems Motion Controls Robotics Midwest Packaging Solutions Colonypackaging XPAK USA ABCO Automation, Inc Tomar Industries SWS Packaging Linkx Packaging Stephen Miller Packaging Endoline Automation SOCO SYSTEM Schneider Packaging Robopac By Type Software Hardware By Application Food & Beverages Electronics Consumer Goods Automobile Others

A detailed outline of the Global Robotic Random Case Erector Market includes a comprehensive analysis of different verticals of businesses. North America, Latin America, Asia-Pacific, Africa, and Europe have been considered for the studies on the basis of several terminologies.

This is anticipated to drive the Global Robotic Random Case Erector Market over the forecast period. This research report covers the market landscape and its progress prospects in the near future. After studying key companies, the report focuses on the new entrants contributing to the growth of the market. Most companies in the Global Robotic Random Case Erector Market are currently adopting new technological trends in the market.

Finally, the researchers throw light on different ways to discover the strengths, weaknesses, opportunities, and threats affecting the growth of the Global Robotic Random Case Erector Market. The feasibility of the new report is also measured in this research report.

Make an Enquiry for purchasing this Report :https://axelreports.com/enquiry-before-buying/116659

Table of Contents:

Global Robotic Random Case Erector Market Overview

Economic Impact on Industry

Market Competition by Manufacturers

Production, Revenue (Value) by Region

Production, Revenue (Value), Price Trend by Type

Market Analysis by Application

Cost Analysis

Industrial Chain, Sourcing Strategy and Downstream Buyers

Marketing Strategy Analysis, Distributors/Traders

Market Effect Factors Analysis

Global Robotic Random Case Erector Market Forecast

ABOUT US:

Axel Reports has the most comprehensive collection of market research products and services available on the web. We deliver reports from virtually all major publications and refresh our list regularly to provide you with immediate online access to the world’s most extensive and up-to-date archive of professional insights into global markets, companies, goods, and patterns.

Contact: Axel Reports Akansha G (Knowledge Partner) Office No- B 201 Pune, Maharashtra 411060 Phone: US +18488639402 Email: [email protected]/ Web: https://axelreports.com/

"

0 notes