#vertical baler manufacturers

Explore tagged Tumblr posts

Text

Vertical Baler Machine Manufacturer in India - Power Hydrotech

Vertical Baler Machine Manufacturer in India - Power Hydrotech

Power Hydrotech is a leading vertical baler machine manufacturer in India, specialising in high-performance vertical baler machines designed to streamline waste management processes in various industries. Established in 2019, Power Hydrotech has quickly gained a reputation for producing durable and efficient vertical balers that help businesses manage waste effectively, reducing operational costs and improving sustainability.

Wide Range of Vertical Baler Machines

As one of the leading vertical baler manufacturers in India, Power Hydrotech offers a diverse range of vertical baler machines tailored to meet the unique needs of various industries. These machines are engineered using advanced technology, ensuring consistent performance in compacting materials such as cardboard, paper, plastics, and other recyclables. By incorporating vertical balers into their waste management systems, industries can significantly increase their waste handling capacity while optimising valuable space in their facilities.

Types of Vertical Baler Machine

Paper Scrap Baler

Plastic Scrap Baler

Tyre Baler

Textile Baler Machine

Efficiency and Ease of Operation

The vertical baler machine from Power Hydrotech is designed for seamless operation and maximum efficiency. These machines are built to handle large volumes of materials, making them ideal for use in manufacturing plants, warehouses, retail stores, and recycling centres. With features such as robust construction, low maintenance, and powerful compaction capabilities, Power Hydrotech’s vertical balers deliver exceptional value in any waste management strategy.

Custom Solutions and Standard Models

Whether you are seeking a custom solution or a standard vertical baler machine for day-to-day operations, Power Hydrotech is committed to delivering the highest quality products and services. Their expertise as a vertical baler machine manufacturer ensures that businesses of all sizes can find a suitable machine for their specific needs. With an emphasis on innovation and customer satisfaction, Power Hydrotech stands out as a trusted name among vertical baler machine manufacturers in India.

Sustainable Waste Management with Vertical Balers

Power Hydrotech’s vertical baler machines provide an efficient and eco-friendly solution for waste handling and recycling. By choosing their machines, businesses can significantly reduce their environmental impact, improve operational efficiency, and create a cleaner, more sustainable workplace. Whether for compacting cardboard, paper, or plastic waste, Power Hydrotech’s vertical balers are the ultimate choice for any business looking to enhance their waste management practices.

Conclusion

For efficient waste handling and recycling solutions, Power Hydrotech’s vertical baler machines are the ultimate choice for businesses aiming to improve their environmental impact and operational efficiency.

For More Information:

9726044442

70, Swapnil -2, Industrial Park, Near Nayra Petrol Pump, Indore High-Way, Kuha, Ahmedabad-382433, Gujarat(India)

https://www.powerhydrotech.com/vertical-baler

#vertical baler#vertical baler machine#vertical baler manufacturers#vertical baler machine manufacturer#vertical baler machine manufacturer in india

1 note

·

View note

Text

Save 17 trees by recycling 1 ton of waste cardboard.

Waste cardboard baler machine is found to be one of the most efficient equipment for handling large waste cardboard generated by different industries. When it comes to an effective, cheap and environmentally friendly way to avoid cardboard pile up, this article if for you.

Do you know that recycling 1 ton of cardboard can save more than 17 trees?

The waste cardboard baler machine makes this process easy as well as makes businesses attain their sustainability objectives as a piece of cake.

Why Businesses Need a Waste Cardboard Baler Machine

Cardboard waste is one of the greatest challenges that industries dealing with businesses such as retail, logistics, as well as manufacturers face. Stacks of cardboard boxes, when not contained, lead to cluttering of working stations, a reduction in working productivity, as well as higher costs of disposal. This was the point that introduced the cardboard baler machine, a marvelous device that condenses heaps of loose cardboard into manageable bales ready for recycling. You may Check those link for learn more: https://www.nickbaler.net/FullAutomaticTieBalerMachine/Industrial-Cardboard-Baler.html https://www.nickbaler.com/sale-43166380-vertical-cardboard-baler.html https://www.nickbaler.com/sale-43166380-vertical-cardboard-baler.html

#BalerMachine#CardboardBalerMachine#CardboardBaler#CardboardBallingMachine Horizontal#VerticalCardboard#CardboardPressBallerMachine#ManualCardboardBaler#AutomaticCardboardBaler#SemiAutomaticCardboardBaler#WasteCardboard#WasteManagment

0 notes

Text

Vermeer Expands Equipment Line with Bunning Manure Spreaders A Game-Changer for Livestock Producers In a significant move that promises to revolutionize the agricultural equipment landscape, Vermeer Corporation has announced a strategic partnership with G. T. Bunning Sons Ltd, a renowned UK-based manufacturer of manure spreaders. This collaboration, unveiled on September 11, 2024, marks a pivotal expansion of Vermeer's product lineup, integrating Bunning's premium compost spreaders into their existing range of equipment designed for hay, forage, and livestock producers across North America. This article delves into the implications of this partnership, exploring how it enhances Vermeer's offerings and what it means for farmers and ranchers seeking efficient, reliable solutions for their operations. The Strategic Alliance: Vermeer and Bunning Join Forces The partnership between Vermeer and Bunning represents a confluence of expertise and innovation in the agricultural equipment sector. Vermeer, long recognized for its comprehensive lineup of farm machinery, including self-propelled balers, round balers, mowers, tedders, rakes, bale wrappers, bale processors, vertical mixers, and feed wagons, has now added another string to its bow with the inclusion of Bunning's compost spreaders. This strategic move is not merely about expanding a product catalog; it's a calculated step towards addressing the evolving needs of modern agricultural producers. Shane Rourke, managing director of Vermeer Forage Solutions, encapsulates the essence of this partnership: "This alliance with Bunning strengthens our ability to address the evolving needs of agricultural producers. It's a natural extension of our commitment to keeping farmers and ranchers productive and efficient." The Synergy of Experience and Innovation Vermeer's decision to partner with Bunning is rooted in a deep understanding of the agricultural sector's demands. Bunning brings to the table a 40-year legacy in premium spreader technology, complementing Vermeer's established expertise in forage and livestock equipment. This synergy promises to deliver solutions that are not just technologically advanced but also tailored to the practical needs of farmers and ranchers. The collaboration leverages Vermeer's extensive dealer network, ensuring that the new line of compost spreaders will be backed by the same level of support and service that Vermeer customers have come to expect. This aspect of the partnership cannot be overstated – in the world of agriculture, where downtime can have significant financial implications, reliable support is as crucial as the equipment itself. Expanding Horizons: North American Market Focus For Bunning, this partnership marks a significant milestone in their expansion into the United States and Canada. Chris Druce, sales director for Bunning, emphasizes the importance of this collaboration, stating, "This partnership with Vermeer marks a significant milestone for Bunning in the United States and Canada. This collaboration underscores both companies' commitment to supporting agricultural operations of all sizes with innovative solutions that can help improve productivity and streamline operations." The focus on the North American market is strategic. Witha growing demand for high-quality manure management solutions, particularly among livestock producers, this partnership aims to tap into a lucrative segment of the agricultural sector. By combining Bunning’s advanced compost spreaders with Vermeer's well-established market presence, both companies are poised to provide exceptional value, enhancing the ability of farmers and ranchers to optimize their operations. Benefits of the Bunning Manure Spreaders The inclusion of Bunning's equipment into Vermeer’s offerings means that livestock producers will gain access to a variety of benefits, including: Increased Efficiency: Bunning's compost spreaders are designed for optimal efficiency, reducing time spent on manure management.

With advanced technology, these machines distribute manure evenly and effectively, allowing for better nutrient management in pastures and fields. Environmental Responsibility: Proper manure management is critical for maintaining soil health and minimizing environmental impact. Bunning's innovative designs help ensure compliance with modern environmental standards, making it easier for farmers to operate sustainably. Versatility: The new line of compost spreaders can handle various materials, from solid and semi-solid manures to composts and organic fertilizers, providing flexibility and adaptability for diverse farming operations. Conclusion The partnership between Vermeer and Bunning marks a significant advancement in agricultural machinery, especially for livestock producers facing increasing demands for efficiency and sustainability. By integrating Bunning's compost spreaders into Vermeer's established lineup, they are set to address critical needs in manure management, enhancing productivity while supporting environmentally responsible practices. As both companies move forward, farmers can expect innovative solutions backed by robust support, driving the agriculture industry toward a more sustainable future. https://gardenreview.us/vermeer-expands-equipment-line-with-bunning-manure-spreaders-a-game-changer-for-livestock-producers/?feed_id=160&_unique_id=672d84cb51335 https://gardenreview.us/vermeer-expands-equipment-line-with-bunning-manure-spreaders-a-game-changer-for-livestock-producers/?feed_id=160&_unique_id=672d84cb51335

0 notes

Text

0 notes

Text

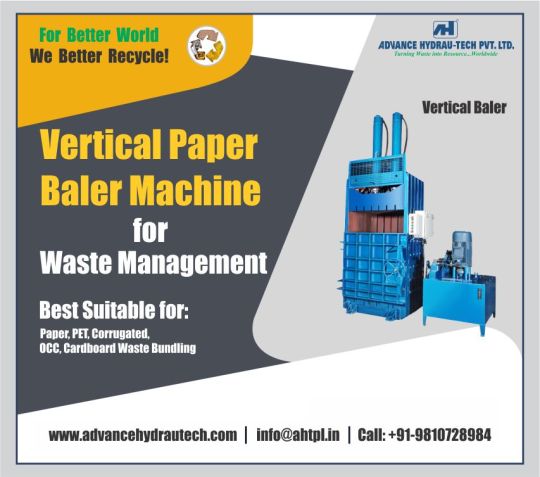

Waste Paper Compacting with Vertical Baler

Compact your low to medium of waste with vertical baler machine. Advance Hydrau-Tech’s manufacturing vertical baler machine is suitable for compressing paper, plastic, cardboard, occ, kraft paper etc. Compact design and small size make vertical balers ideal for customers with space issues. It easily fits into confined spaces. You can expect high productivity, operational efficiency and low maintenance with our double-cylinder vertical baling press. These vertical balers can compress waste into bundles measuring 30” x 48” and manually operated machines, which are available in both single compression and double compression models. For all types of scrap processing solutions, contact Advance Hydrautech.

0 notes

Text

How to choose a Baling Machine?

Choosing the right baling machine involves considering several factors to ensure it meets your specific needs and operational requirements. Here's a guide to help you select the most suitable baling machine:

1. Type of Material to be Baled:

Cardboard, Paper, Plastics, etc.: Identify the type and volume of material you plan to bale. Different balers are designed for specific materials, so choose one that suits your waste type.

2. Baling Capacity and Volume:

Volume Output: Determine the amount of material you need to bale daily, weekly, or monthly to select a baler with the appropriate capacity.

Size and Weight of Bales: Consider the desired bale size and weight, as some balers offer adjustable settings.

3. Available Space and Installation:

Footprint: Assess the space available for the baler. Vertical balers require less floor space than horizontal ones.

Installation Requirements: Consider power supply, clearance space, and access for loading materials.

4. Operational Efficiency:

Automation Level: Decide on the desired level of automation. Balers range from manual to semi-automatic and fully automatic.

Ease of Operation: Choose a machine with user-friendly controls and safety features to ensure ease of use.

5. Safety Features:

Safety Standards: Ensure the baler complies with safety regulations and standards. Look for emergency stop buttons, safety interlocks, and guards to prevent accidents.

6. Budget Considerations:

Initial Investment vs. Operating Costs: Balance the initial cost of the machine with long-term operating costs, including maintenance, energy consumption, and potential repairs.

7. Service and Maintenance:

Manufacturer Support: Consider the availability of spare parts, technical support, and servicing from reliable manufacturers or suppliers.

Maintenance Requirements: Evaluate the maintenance needs and frequency to ensure it aligns with your operational capacity.

8. Environmental Impact and Sustainability:

Recyclability: If recycling is a priority, choose a baler that produces recyclable bales suitable for the recycling industry.

Energy Efficiency: Consider energy-efficient models to minimize operational costs and environmental impact.

9. Regulatory Compliance:

Environmental Regulations: Ensure the selected baler complies with environmental and safety regulations relevant to waste handling and machinery.

10. User Reviews and Recommendations:

Research and Feedback: Read user reviews, seek recommendations, and consult industry experts to gain insights into the performance and reliability of different balers.

11. Trial and Testing:

Demo or Trial Runs: Whenever possible, request a demonstration or trial run of the baling machine to evaluate its performance and suitability for your specific needs.

12. Future Expansion and Growth:

Scalability: Consider future growth and expansion plans when selecting a baler to ensure it can accommodate increasing waste volumes if your operations expand.

Choosing the right baling machine involves a thorough assessment of your waste management requirements, operational needs, space constraints, and budget considerations. Evaluating these factors will help in selecting a baler that maximizes efficiency, meets regulatory standards, and aligns with your waste management goals.

0 notes

Text

Balers and Compactors: Streamlining Waste Management for a Sustainable Future

In today's world, waste management has become a critical aspect of maintaining a clean and sustainable environment. Businesses, industries, and even households produce substantial amounts of waste on a daily basis. This necessitates efficient and eco-friendly methods of waste disposal and recycling. Balers and compactors are two essential tools in this regard. They play a vital role in minimizing waste volume, reducing transportation costs, and promoting recycling. In this blog, we will delve into the world of balers and compactors, exploring their functions, types, benefits, and their significant contribution to a more sustainable future.

Balers: A Compact Solution for Loose Materials

Balers are machines designed to compress loose materials such as cardboard, paper, plastics, and even metal into compact, manageable bales. They are commonly used in industries, recycling centers, and waste management facilities to optimize waste handling. Here are some key points to consider when discussing balers:

Types of Balers:

Horizontal Balers: These machines compress materials horizontally and are suitable for high-volume waste production facilities.

Vertical Balers: Vertical balers are more compact and are designed for smaller operations and businesses with limited space.

Benefits of Balers:

Reduced waste volume: Balers compress materials into tight bales, significantly reducing the space required for storage and transportation.

Cost-effective: Smaller waste volumes mean lower transportation costs.

Eco-friendly: Balers facilitate recycling by making it easier to transport recyclable materials to recycling centres.

Improved workplace safety: Reduced clutter and safer waste handling processes.

Applications:

Cardboard recycling in supermarkets and retail stores.

Paper recycling in offices and print shops.

Plastic recycling in manufacturing facilities.

Compactors: Streamlining Solid Waste Management

Compactors, as the name suggests, compact solid waste into a smaller, denser form. These machines are versatile and come in various sizes and configurations to suit different applications. Here's a closer look at compactors:

Types of Compactors:

Stationary Compactors: Fixed in one location, these are ideal for large waste volumes generated by industrial and commercial operations.

Self-Contained Compactors: These compactors are suitable for businesses with wet or putrescible waste, such as restaurants and hotels.

Vertical Compactors: Vertical compactors are often used for residential waste disposal in apartment complexes.

Benefits of Compactors:

Space-saving: Compactors significantly reduce the volume of waste, saving valuable space.

Improved sanitation: By compacting waste, foul odours and pests are minimized.

Reduced waste handling: Fewer trips to the dumpster or landfill, leading to cost savings.

Enhanced sustainability: Compactors promote recycling by reducing the amount of waste that ends up in landfills.

Applications:

Restaurants and food service establishments for food waste.

Manufacturing plants for production waste.

Apartment complexes for residential waste.

Promoting Sustainability

Balers and compactors have a significant role in promoting sustainability. By reducing waste volume and facilitating recycling, they help conserve resources, reduce landfill usage, and minimize the environmental impact of waste disposal. As more businesses and individuals recognize the importance of sustainable waste management, these machines are becoming indispensable tools for a cleaner and greener future.

Conclusion

Balers and compactors are more than just industrial machines; they are powerful tools for improving waste management efficiency, reducing costs, and conserving resources. By compressing loose materials and solid waste, these devices enable businesses and communities to be more environmentally responsible. As the world continues to prioritize sustainability, balers and compactors will play an ever-increasing role in shaping a cleaner and more eco-friendly future.

0 notes

Text

Scrap baling machines: How It Helps In Investing in Sustainable Waste Management & Handling Solutions?

Imagine a world where waste management is a seamless process instead of a difficult one. Today, he introduces one of his great solutions to make that dream a reality: the scrap baler. But before we get to the point, let's first touch on a broader problem facing many businesses and public institutions: inefficient waste management.

The Challenge of Space in Waste Management

Waste management is a complex subject with many challenges. One of the most pressing concerns in this situation is the efficient use and management of space. In many businesses and organizations, waste disposal is often an afterthought, resulting in inefficient use of space and increased operating costs.

If not handled properly, waste can quickly fill designated disposal areas and form vast landfills. These landfills aren't just unsightly. It also leads to wasteful use of precious land resources. A World Bank study estimates that the total amount of waste produced by humans will increase by 70% by 2050 if current habits are left unchecked.

Landfills: Non-biodegradable waste such as scrap metal and scrap takes up a lot of space, leading to inefficient and bloated landfills.

Environmental Hazards: Improper storage of these materials can contaminate soil and freshwater sources.

Transportation: This waste takes up a lot of space, making it more difficult and expensive to transport.

Safety Risks: There is a risk of injury when handling the material itself.

These difficult problems require innovative solutions. That’s where baling machines come into the picture.

Introducing the Scrap Baling Machine

At the intersection of technology and environmental sustainability is EnvCure, a company dedicated to tackling environmental challenges by providing practical, efficient and economical solutions. One of the wonders of the company's product line is the vertical scrap baling machine.

Designed to compact waste, this machine compresses waste to a manageable size and offers many benefits.

Better Space Management: Balers improve space utilization and enable industry and public institutions to manage waste more efficiently.

Ease of Transportation: Compressed waste occupies less space, allowing businesses to transport larger volumes and save costs.

Ease of Handling: Compressed waste is easier and safer for workers, reducing the risk of injury.

Power Efficiency: Baler machine optimizes power consumption by designing to efficiency and high-performance standards.

A Versatile Solution

One of the main advantages of scrap balers is their versatility. It is not limited to scrap metal compaction only. Whether plastic, paper, cardboard, textiles or even agricultural waste, this machine can handle a wide variety of garbage.

Its versatility offers companies in various industries the opportunity to manage waste efficiently. Manufacturing industries, recycling centres, farms, hospitals, and educational institutions can all benefit from this dynamic solution. Not only does this machine help with waste management, but it also facilitates recycling, which is an integral part of sustainability.

Versatility Highlights:

Waste Material Diversity: The machine can compact a wide range of waste materials.

Industry-Wide Application: Usage is not limited to a specific type of business or industry.

Promotes Recycling: The machine compacts and manages waste to facilitate recycling and is a step towards environmental sustainability.

Economic Implications of a Baling Machine

It is important to recognize that incorporating balers into your waste management strategy not only contributes to environmental sustainability but also provides significant economic benefits.

Compressing and organizing waste materials makes transportation easier and saves transportation costs. In addition, compacted waste is easier to store, improving space utilization and potentially saving storage costs.

In industries where waste can be sold or recycled, balers can turn waste into a profitable resource. Compact bales of scrap are easy to sell to recyclers and other businesses, providing additional revenue for businesses.

Economic Highlights:

Transportation and Storage Savings: Compact waste reduces transportation and garage costs.

Revenue Generation: Compressed waste can be sold or recycled, providing an additional revenue stream.

Long-term Investment: Machines require an up-front investment, but the long-term savings and potential revenue generation are worth considering.

Embracing Sustainable Waste Management

Waste baling machines enable businesses to transform their waste management processes. Isn't that a daunting challenge? Rather, it becomes a manageable task that contributes to sustainability goals while reducing costs.

A scrap baler is more than just a tool. it's an investment. This contributes to the organization's long-term sustainability plans and strengthens its commitment to protecting the environment. It's not just big companies and waste treatment plants. Hospitals, universities, canteens, etc. can use this technology to better manage their waste.

Conclusion: Investing in a Sustainable Future with EnvCure

Now is the time to develop efficient waste management strategies for a more sustainable future. Using a scrap baling machine not only contributes to a healthier environment, it also makes your waste disposal process more efficient and cost-effective.

At EnvCure, we strive to create a healthier environment for everyone. Through a combination of technology, awareness and a commitment to environmental solutions, we can build a better world for future generations. Experience a sustainable future with EnvCure. Invest in a scrap baler today.

Source URL: https://www.envcure.com/scrap-baling-machines-how-it-helps-in-investing-in-sustainable-waste-management-handling-solutions/

0 notes

Text

THE ENVIRONMENTAL IMPACT OF BALING PRESS MACHINE IN WASTE RECYCLING

Welcome to our blog, where we explore the fascinating world of waste recycling and its impact on the environment. Today, we'll be diving into the realm of a Baling Press Machine and how they play a crucial role in making recycling more efficient and sustainable. So grab a cup of coffee, sit back, and join us as we uncover the environmental benefits of these impressive machines! Whether you're new to waste management or an avid eco-warrior looking for innovative ways to make a difference, this article is for you. Let's get started!

What Is A Baling Press Machine?

A Hydraulic Baling Press Machine, also known as a baler, is a device used to compress and package materials into compact bales. It is commonly used in industries such as waste management, recycling, agriculture, and manufacturing. The machine applies pressure to materials like paper, cardboard, plastic, metal, or textiles, compacting them into dense bundles. Baling presses come in different sizes and configurations, from small vertical balers to large horizontal balers. The process involves loading the material, compressing it with a hydraulic or mechanical mechanism, and securing the bale with straps or wires. Baling presses save space, facilitate recycling, and enhance storage and transportation efficiency.

How Does A Baling Press Machine work?

A Baling Machine, also known as a baler, works by compressing materials into compact bales.

Loading: The material to be baled, such as paper, cardboard, or plastic, is loaded into the baler either manually or through an automated system.

Compression: Once the material is inside the baler, a hydraulic or mechanical mechanism applies pressure to compress it. This compression process reduces the volume of the material and makes it more compact.

Binding: After the material is sufficiently compressed, it is bound together using straps, wires, or other fastening methods. This ensures that the bale retains its shape and remains tightly packed.

Ejection: Once the bale is securely bound, it is ejected from the baling press, usually onto a pallet or another suitable platform for easy handling and transport.

The Environmental Impact of Baling Press Machines

A Hydraulic Baler has a positive environmental impact by promoting efficient waste management and recycling practices. Here are some ways they contribute to environmental sustainability:

Waste Volume Reduction: Baler press machines compress materials, reducing their volume and optimizing storage space. This helps minimize the need for additional landfill space and decreases transportation requirements, reducing carbon emissions associated with waste disposal.

Recycling Facilitation: Compact bales created by baling press are easier to handle and transport to recycling facilities. They enable efficient sorting, processing, and recycling of materials like paper, cardboard, plastics, and metals. By promoting recycling, baling presses help conserve natural resources and reduce the demand for raw materials.

Energy and Resource Conservation: Recycling materials through the use of baler machines consumes less energy compared to manufacturing products from virgin materials. It also reduces the need for extracting, refining, and processing new resources, thereby minimizing environmental impacts associated with resource extraction.

Financial Incentives: These press machines allow businesses and industries to generate revenue by selling compacted bales to recycling companies or other end-users. This financial incentive encourages proper waste management and recycling practices, leading to increased recycling rates and reduced environmental burden.

Plastic Waste Mitigation: Baler press plays a vital role in addressing the plastic waste crisis. They enable the compaction of plastic bottles, containers, and other plastic waste into bales, making it easier to handle, store, and transport. This promotes the recycling of plastic materials, reducing the environmental impact of plastic pollution.

How To Recycle Responsibly With A Baling Press Machine

To recycle responsibly with a baling press, follow these steps:

Separate and Sort: Segregate recyclable materials such as paper, cardboard, plastics, and metals. Ensure that the materials are clean and free from contaminants like food residue or non-recyclable items.

Prepare the Baling Press Machine: Familiarize yourself with the operating instructions and safety guidelines of the specific baling press machine you are using.

Load the Material: Load the recyclable materials into the baling press machine, ensuring not to overload it beyond its capacity. Place materials evenly to achieve uniform bales.

Compress and Bale: Activate the compression mechanism of the baling press machine to compact the materials into dense bales. Follow the recommended compression settings for the specific materials being baled.

Secure the Bales: Once the bales are compressed, use appropriate strapping, wires, or fasteners to secure them tightly. This prevents the bales from coming apart during transportation or handling.

Label and Store: Label the bales with appropriate information, such as the material type and date. Store the bales in a designated area that is safe and organized, ready for transportation.

Coordinate Recycling Partners: Contact local recycling facilities or companies that accept the specific materials you have baled. Coordinate with them for pickup or drop-off of the bales.

Monitor and Improve: Keep track of your recycling efforts, including the amount of materials recycled and the environmental benefits achieved. Look for opportunities to improve recycling practices and identify areas for further waste reduction.

Conclusion

In today's world, where waste management and environmental conservation are paramount, baling press machines have emerged as a game-changer in the recycling industry. These powerful machines not only simplify the process of waste recycling but also yield significant positive impacts on our environment.

#BalingMachine#BalingPressMachine#Baling Press Machine in Gurgaon Bailing Press Machine in Delhi#HydraulicBaler#Balingmachinemfr

0 notes

Text

XTY-1500L Vertical Cutting Balers

High pressure with the special double-cutting design of the cutters makes the cutting more efficient and keeps the cutter service time longer.Independent emergency stop button and European safety standard of the machine ensure the safe operation.

Pressure: 150tons

Power: 22kw

Baling Chamber Height: 1530mm

Feed Opening Size (L*H): 1500*1530mm

Machine Weight: 3800kgs

Machine Size (L*W*H): 1900*1400*4300

0 notes

Text

Where to Buy the Best Paper Scrap Baler Machine in India?

Managing paper waste efficiently is crucial for businesses involved in recycling, printing, and packaging. A paper scrap baler machine helps compress large volumes of waste into compact bales, making storage and transportation easier. If you are searching for the best paper scrap baler machine in India, this guide will help you find the right supplier.

Why Invest in a Paper Scrap Baler Machine?

A paper scrap baler machine is designed to streamline waste management. Here’s why businesses across industries prefer using one:

Efficient Waste Handling : Reduces waste volume, saving storage space.

Eco-Friendly Solution : Encourages recycling and reduces landfill waste.

Cost Savings : Lowers waste disposal costs and improves operational efficiency.

Better Workplace Management : Keeps the workspace clean and organized.

Whether you run a recycling plant or a commercial printing business, investing in a high-quality paper scrap baler machine enhances sustainability and cost-effectiveness.

Factors to Consider When Buying a Paper Scrap Baler Machine

To ensure you select the best paper scrap baler machine in India, consider these key factors:

Machine Type

There are different types of balers available:

Vertical Balers : Ideal for small to medium businesses with limited space.

Horizontal Balers : Suitable for large-scale recycling units with high waste output.

Baling Capacity

Assess the machine’s capacity based on your daily paper scrap volume. Machines with higher compression force handle larger quantities efficiently.

Durability & Build Quality

Look for machines built with high-grade steel and corrosion-resistant components to ensure long-lasting performance.

Automation & Ease of Use

Opt for a baler with user-friendly controls, automatic feeding, and safety features for smooth operation.

Maintenance & After-Sales Support

Choose a manufacturer that offers easy maintenance, spare parts availability, and reliable customer support.

Best Places to Buy a Paper Scrap Baler Machine in India

India has a growing market for waste management solutions, and several manufacturers supply high-quality paper scrap baler machines. Here are some of the best ways to find a reliable supplier:

Direct Manufacturers

Buying from a manufacturer ensures you get a factory-direct price with customization options. Leading manufacturers in India offer a variety of balers suitable for different business needs.

Industrial Equipment Dealers

Authorized dealers provide various models and brands under one roof. They also offer after-sales services, making them a preferred choice for businesses seeking a hassle-free purchase.

Online Marketplaces

Platforms like IndiaMART, TradeIndia, and Alibaba list multiple suppliers. However, before making a purchase, check the company’s credibility, customer reviews, and after-sales service policies.

Local Distributors in Ahmedabad

If you’re looking for a paper scrap baler machine in Ahmedabad, explore local distributors and suppliers who can offer quick delivery and on-site support.

Conclusion

Investing in a paper scrap baler machine in India can significantly enhance your waste management process. With various options available, choosing the right supplier is key to ensuring efficiency, durability, and cost savings. For businesses in Ahmedabad looking for high-quality and reliable baler machines, Power Hydrotech Private Limited is a trusted name in the industry.

0 notes

Photo

Waste sorting equipment manufacturer share with you:

Paper baler machine has good toughness, good stability, beautiful appearance, convenient operation and maintenance, safety and energy saving, and low investment cost for equipment and infrastructure engineering. It is widely used in various waste paper mills, used materials recycling companies and other unit enterprises. It is suitable for packaging and recycling used waste paper and plastic straws.

It is a good equipment to improve labor efficiency, reduce labor intensity, save manpower, and reduce transportation costs. Waste paper baler is an electromechanical integrated product, which is mainly composed of mechanical system, control system, feeding system and power system.

The waste paper baler can be classified according to the following standards:

1. Manual baler: Generally, manual operation is required to complete the entire process. In general: electric heating, iron buckle clamping.

2. Semi-automatic packing machine: After the packing machine is manually inserted into the packing tape, the machine will automatically complete the process of packing, gluing, cutting and removing the packing tape, because each product requires manual operation.

3. Fully automatic baler: There is no need to manually insert the belt, and its triggering method is divided into a little movement, manual, continuous playing, ball switch, foot switch, and the packing can be automatically completed by simply pressing the switch, which is convenient and quick.

What kind of books can waste paper baler handle? The following introduces you:

1. Used books: second-hand books, no matter how used.

2. White paper: pure white, clean, no film.

3. Binding paper edge: Cut the paper edge when printing books, with a small amount of copper plate and plastic head.

4. Yellow board: The discarded boxes are mainly yellow.

5. Gray card: gray from outside to inside, no film, can bring color.

6. New newspapers: too many unused newspapers.

7. Old newspapers: used newspapers obtained from waste paper collection stations.

Newsprint: same as newspaper paper, but without color words.

Newsprint: same as newspaper paper, but without color words.

Paper cup: and the remaining paper in the production of paper cup.

Tetra pak packaging: such as milk cartons.

11. Pages: the paper is messy, no glue, no film, you can have text.

Qunfeng is a manufacturing company specialized in making waste hydraulic compress equipment. Our systems include ertical, horizontal waste transfer station project, composting project, waste solution system, hydraulic baler machine, weighing system, internet of things and weighing system, vertical waste transfer station system, environmental equipment, single stream waste.

0 notes

Text

SMART SECONDARY PACKAGING SOLUTIONS FROM NICHROME

Although Nichrome started out as a manufacturer of primary packaging machines, today, four decades down the road, it is so much more.

Nichrome offers the full gamut of packaging technology - primary, secondary and tertiary. It provides complete integrated packaging solutions, partnering with projects big and small, for Food, Pharma and other applications. With proven expertise and single-source convenience, Nichrome partners through the complete life cycle, innovating and integrating solutions that elevate productivity through performance.

WHAT IS SECONDARY PACKAGING?

Secondary packaging, as the name suggests, is the second layer of packaging around a product. It adds additional protection, and often, provides a marketing opportunity such as a carton around a bag of breakfast cereal. Secondary packaging is also designed to hold together multiple smaller units of a product to facilitate safe transportation to a warehouse or retailer.

Secondary packaging is also referred to as overwrapping, outer packaging and end-of-line packaging - all meaning packaging that enables safe and efficient distribution of a product from one location to the next.

BENEFITS OF SECONDARY PACKAGING

Traditionally, workers took care of the secondary packaging process: building cartons, filling them, sealing them and preparing them for palletization.

Today, manual labour is not a viable proposition. It not only limits growth, it adds risk in terms of potential injuries. Automated packaging processes are therefore essential to meet production goals.

Automated secondary packaging systems help to:

- increase throughput rates

- reduce costs of labour hiring, training and injury prevention

- ensure consistency and accuracy

- overcome manual and disorderly packaging

- compact space as compared to manual packaging

- improve employee wellbeing

NICHROME'S SECONDARY PACKAGING SOLUTIONS

Nichrome is a packaging solutions company providing automated packaging machinery backed by decades of industry experience. Nichrome produces and provides machines that can handle 24x7 uptime and high-volume operations with speed and reliability. Nichrome's secondary packaging solutions include:

Automatic Pouch Stacking & Wrapping System: It is a PLC-controlled, single operator driven system offering easy changeover. The system can be aligned in linear or right-angle direction as per floor space. The system includes an inclined conveyor, pouch orienter, pusher and flow wrapping machine - and enables auto pouch stacking as per the desired matrix.

HDPE Bag Filling System: The line includes a VFFS machine, pouch take up conveyor and a rotary bag holding & filling system. Machine construction is available in SS304, SS316 and MS painted. Both HDPE and PP bags may be used.

This PLC-controlled system with a digital LCD touch screen for display and settings provides fast changeover for different bag sizes, making it a must-have for companies packaging their products in pack sizes of 500 to 5000 gms.

Cartoning Machine: The machine structure is of MS sheet metal for durability, and handles a variety of cartons: parallel tuck in, opposite tuck in, lock bottom and glueing.

Some key features include an adjustable carton conveyor with chain type design, servo indexing drive to carton and product chain, motorized carton pick up with vacuum cups, and facility for product insertion inside carton through motor-driven product pusher. The rated output is 50-55 cartons per minute.

Flexibale 450 Baling Solution: Flexibale 450 packs pre-counted numbers of primary pouches in economical bulk secondary pouch aiming to replace existing packing methods which are labour intensive and less efficient.

The Flexibale 450 is designed to be directly coupled with a primary vertical form fill and seal (VFFS) machine enabling a single operator to manage a complete packaging station from automatic primary packaging to finished balers.

Automatic Milk Pouch Crating System: Nichrome's Crating System offers a complementary secondary packaging solution to count & fill milk pouches in crates in synchronization with Nichrome's high-speed Filpack Servo machines. The entire process becomes systematic, automated and fast. It helps to maintain quality and food safety standards as well as keep count of the number of pouches and crates.

The system has optional features of data logging and online crate weighing. The entire production data can be logged and saved on Cloud or central server system

The system also offers an optional Online Leak Detection Mechanism whereby each pouch from the pouch take-up conveyor passes through a pressing conveyor which removes excess air from leaking pouches through which the operator can easily differentiate leaky pouches.

CONCLUSION

Secondary packaging systems are an essential part of any modern packaging line. They protect the primary packaging, enable accurate packaging of multiple packs and ensure safe transportation of the product. Secondary packaging brings speed, accuracy and economy to end-of-line packaging, boosting overall productivity and profitability.

Nichrome, the leading packaging solutions provider in India, offers a variety of secondary packaging solutions to complement their own and other primary packaging equipment.

Nichrome's stacking & wrapping system, HDPE bag filling system, carton filling machine and crating system for milk pouches are all tough, trustworthy performers. They can also be customized as per requirements and available space – so customers get a secondary packaging solution tailored for optimization of space, performance and resources.

Consult Nichrome for your secondary packaging requirements today.

#secondary packaging systems#Automatic Pouch Stacking & Wrapping System#HDPE Bag Filling System#Cartoning Machine#Flexibale 450 Baling Solution#Automatic Milk Pouch Crating System#Secondary packaging

0 notes

Text

🌟 Paper Baler Machine! – The Ultimate Solution for waste management🌟

Our Paper Baler Machine is your ultimate solution for bundling paper, plastic, PET, cardboard, and more into easily manageable bales.

🔹 Why Choose Us?

We are India’s largest manufacturer of waste processing machines.

Wide range of machines for waste: Automatic baler, triple action baler, and vertical baler.

User-friendly operation and highly efficient performance.

🌱 Ideal for:

Recycling centres

Paper factories

Distribution centres

Manufacturing facilities

Warehouses

Waste disposal companies

Printing presses

Contact us for efficient waste management with Advance Hydrau-Tech's Paper Baler Machine. today! ♻️🌍

#paperbaler #wastebaler #WasteManagement #Recycling #Sustainability

0 notes

Text

Powered Agriculture Equipment Market Will Create Highest Returns by 2026

Powered agriculture equipment have a wider implication across various farming practices that are crucial for a healthy and sustainable crop production process. The various applications include water management, soil management, climate management, and others.

Report Overview is available at: https://bisresearch.com/industry-report/powered-agriculture-equipment-market-report.html

The powered agriculture equipment comprises a wide range of solutions such as tractors, sprayers, planters, combines, and other equipment such as balers and tilling equipment. Farm tractors account for the largest share in the market, followed by combine harvesters, planters, and sprayers, in that order. The adoption of powered agriculture equipment is increasing among farmers to improve yield, operational efficiency, soil fertility, and profitability.

The governing trends of the powered agriculture equipment market vary across different regions. The powered agriculture equipment market holds a significant share in various countries of North America, South America, the U.K., the Middle East and Africa, Asia-Pacific and Japan, and China. In 2019, Asia-Pacific and Japan led the global powered agriculture equipment market, with a large market concentration in India.

Trends such as high population growth, increasing disposable incomes, and booming urbanization in the Asia-Pacific and Japan region have resulted in a robust evolution in the consumption patterns amongst the population of the region. Hence, farmers of the region are focusing on increasing crop yield and having an all-year-round supply of agricultural produce to meet the escalating demand.

The global powered agriculture equipment market research study offers a broad perspective on the analysis of the industry. The research is based on extensive primary interviews (in-house experts, industry leaders, and market players) and secondary research (a host of paid and unpaid databases), along with the analytical tools that have been used to build the forecast and the predictive models.

Get the Report Sample at: https://bisresearch.com/requestsample?id=1243&type=download

The global powered agriculture equipment market encompasses a wide array of solutions such as tractors, combines, planters, sprayers, and other equipment such as tilling equipment, haymaking equipment, and balers. Farm tractors accounted for the largest share in the market, followed by combine harvester, planters, and sprayers. Farmers across the globe are increasingly adopting powered agriculture equipment to improve yield, soil fertility, operational efficiency, and profitability. The powered agriculture market includes agricultural machinery manufacturers that provide vertically integrated farm equipment solutions.

Agriculture equipment manufacturers around the world are experimenting with ways for electrical equipment to improve tractors and implements. Aspects of power source and power output of a tractor have seen significant development, and this development has been welcomed by consumers. One of the most promising product shifts with respect to tractors is battery-powered tractors. These tractors can perform all the functions of a standard tractor and also provide the benefit of electrification.

Agricultural OEMs have also come up with specialty tractors that suit distinct cases. Some of them include utility tractors for landscape maintenance and non-farm grading, wheat-land tractors with fixed wheels for heavy fieldwork, and row-crop tractors which possess adjustable tread width that allows tractors to pass down rows of crops without crushing them. In 2020, Escorts Ltd. launched its first Hybrid Concept Tractor, which is powered by fuel and battery both.

The key players in the powered agriculture equipment market are coming up with different product launch activities in order to generate public awareness about their new and upcoming products and technologies. Product development and innovation have helped these companies to compete with the competitors’ product portfolios. This strategy has been a widely adopted strategy by the players in this market. TeeJet Technologies led the market in terms of new product developments; however, others, including Deere & Company, BASF SE, Microsoft, Topcon Corporation, Agrivi, and The Toro Company, have also launched products during January 2019-December 2021. This suggests that all the companies are focusing on product launch strategies and trying to diversify their product portfolios.

#Powered Agriculture Equipment Market#Powered Agriculture Equipment Report#Powered Agriculture Equipment Industry#Powered Agriculture Equipment#Powered Agriculture

0 notes

Text

Top 5 Baling Press Machine Manufacturers In India :

A hydraulic baler machine is a device that uses hydraulic power to compress recyclable materials, such as paper or cardboard, into bales. These bales can then be transported and recycled more easily. Hydraulic baling press machines are often used in commercial recycling facilities, as they can process large quantities of material quickly and efficiently

A hydraulic baling press machine is a type of machine that uses hydraulic pressure to compress materials. These machines are often used in recycling facilities to compact materials such as paper, plastic, and metal. Baling press machines can vary in size and weight, but typically they are large and heavy duty. They also usually have a chamber where the material is placed before it is compressed.

Advantage of baling press machine :

The baling press machine is widely used in various industries, and it has many advantages.

The machine can be used to compress a variety of materials, such as paper, plastic, metal, etc.

The machine is very efficient and can compress a large amount of material in a short period of time.

The machine is very durable and can last for a long time if it is properly maintained.

This can be especially useful for businesses that generate large volumes of waste or have limited storage space.

By reducing the volume of waste or recyclable material, businesses can save on disposal or recycling costs,

Top 5 Baling Press Machine Manufacturers In India :

1.Kelvin Water Technologies :

Kelvin Water Technologies providing best and cost effective Advanced Technology for a Baling Press Machine. We have more than 15 years of experience in providing Waste Management Services all over the world. A baling press machine is a type of equipment used to compress and bind waste materials into compact bales. These machines are commonly used in recycling facilities, warehouses, manufacturing plants, and other industries that generate a large amount of waste materials.

2.Urmi Engineering :

Urmi Engineering's hydraulic baler machines are designed with advanced hydraulic technology to ensure efficient and reliable performance. These machines are available in different models and sizes to meet various baling requirements. Urmi Engineering also manufactures and supplies baling press machines that are used to compress and bind waste materials into compact bales. These machines are commonly used in recycling facilities, warehouses, and manufacturing plants.

3.Saroj Hydraulics :

Saroj Hydraulics is a company that manufactures and supplies various hydraulic equipment and machinery, including baling press machines. A baling press machine is a type of equipment used to compress and bind waste materials such as cardboard, paper, plastic, and metal into compact bales for easier storage, handling, and transport. Saroj Hydraulics' baling press machines are designed with advanced hydraulic technology to ensure efficient and reliable performance. These machines are available in different models and sizes to meet various baling requirements. Some of the key features of Saroj Hydraulics' baling press machines include:

4.Roshan Industries :

Roshan Industries is a company based in India that specializes in manufacturing and supplying a range of industrial machines and equipment, including baling press machines. There are different types of baling machines available, including vertical balers, horizontal balers, and automatic balers. The type of machine chosen will depend on the specific application, the type of waste material being baled, and the volume of waste material to be processed.

5.Shree Rameshwar Eng :

Shree Rameshwar Eng. Works also manufactures and supplies baling press machines. Baling press machines are designed to provide high compression force to efficiently compact the waste materials. Shree Rameshwar Eng. Works offers a range of baling press machines with different specifications and features to meet the varying needs of their customers.

0 notes