#vacuum pumps applications

Explore tagged Tumblr posts

Link

#market research future#vacuum pumps applications#vacuum pumps market types#vacuum pumps manufacturers#vacuum pumps market trends

0 notes

Text

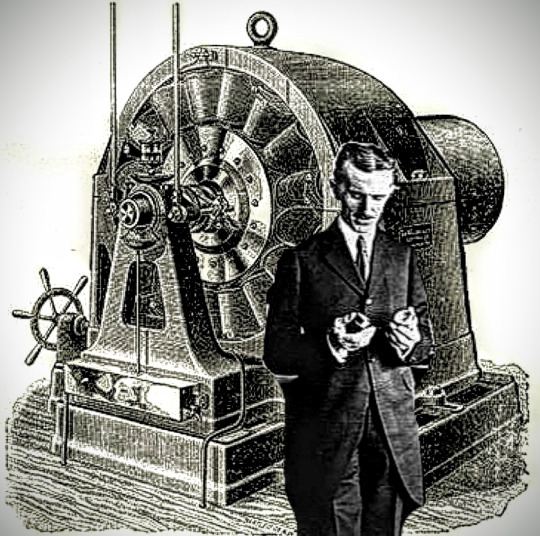

One of the Greatest Inventions of All Time

Nikola Tesla has many revolutionary inventions to his credit, but he is best known for his pioneering work in the development and promotion of alternating current (AC) electrical systems. Tesla's innovations in AC technology revolutionized the generation, transmission, and distribution of electrical power, becoming the foundation for the modern electrical power systems that we use today.

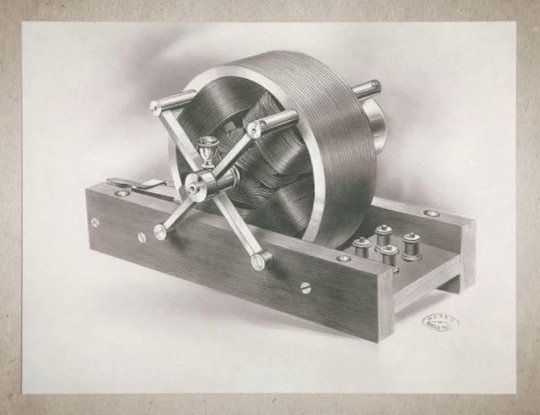

There is a common misconception made that Tesla was the first to invent, or discover, AC, but this is not true. It is well-known that Hippolyte Pixii was the first to discover AC in 1832. Pixii was an instrument maker from Paris who built an early form of an alternating current electrical generator (based on the principle of electromagnetic induction discovered by Michael Faraday), and thus started a new industry in power transmission. Tesla was not the first to discover or invent an AC motor, but he was the first to invent a practical AC induction motor with commercial value that could outperform all other motors. It must be noted that Italian inventor Galileo Ferraris also invented an induction motor similar to Tesla's, but it had no commercial value, and he even admitted himself that it was useless. Tesla's induction motor operates on the principle of electromagnetic induction, properly utilizing a rotating magnetic field that induces a current in a stationary conductor, resulting in rotational motion. The utilization of the rotating magnetic field makes the motor more simple, robust, versatile, efficient, and cost effective in that it has less moving parts reducing the likelihood of mechanical failure (as was common in other motors).

Tesla's induction motor became a fundamental component in the field of electrical engineering and is used today in various applications, being one of the most widely used devices in the world. The motors play a crucial role in transmitting electrical power to homes and businesses. They are commonly used in power generation plants to convert mechanical energy into electrical energy, which is then transmitted through the power grid for distribution to various locations. Induction motors are also widely employed in appliances and machinery within homes and businesses for various applications. These applications include conveyor systems, hoists, cranes, lifts, pumps, fans, ventilation systems, compressors, manufacturing machinery, wind turbines, washing machines, refrigerators, garbage disposals, microwaves, dishwashers, vacuums, air conditioners, robotics, electric vehicles, trains, power tools, printers, etc. Basically, anything that requires a spinning action for power.

The induction motor is widely considered one of the most important inventions in the history of electrical engineering. Its importance lies in its transformative impact on industries, its efficiency and reliability, and its role in the broader electrification of society.

#nikola tesla#science#history#invention#discovery#induction motor#electricity#power#goat#ahead of his time#ahead of our time

152 notes

·

View notes

Text

Top Gun Workouts - Slider

Everyone’s favourite [living] RIO

Disclaimer: I’m not a PT. In this series i break down characters muscle composition and how i think they’d exercise, if this may trigger you feel free to enjoy my other general shit posting!

Find the rest of the series under #top gun workouts :) So far there’s Mav and Ice

Slider is is also very interesting in his muscular make up. He’s tall, about 6’2 (?) and this DOES matter but not how you think and it’s something I’ll get into in more detail with Goose. Also keep in mind a lot of shirtless photos of Slider are during the volleyball scene so the actors will be in peak physique and probably have done some exercise before shooting to give themselves a ‘pump’.

I know forearms are a big deal for some of y’all and you’re right to be obsessed with them. Hold out out your arm in front of you as if you’re reaching for something. Does your for arm flex like Slider’s? Some might, some won’t. But for the hollow above the inside of your elbow to appear at the same time as the muscle at the top of your forearm (the sort facing the ceiling) that’s actually very impressive. It’s a combination of low body fat and muscle.

Sir, put them pits away. It’s pretty blurry but the concave of the arm pit, huge lateral bulge, front deltoid and shoulder are flexed here but even so, that doesn’t appear by itself.

Slider’s got a low body fat. Flexed on the left and relaxed on the right you can see his muscling pretty clear. Like with Maverick, we see those obliques. Unlike Mav, Slider’s got a slightly narrower waist. And those boulder shoulders are ginormous, well done Rick. His traps aren’t super big which makes sense when we look at his legs in a minute.

Everyone say thank you Rick for the effort he put in flying into sand and those arms. Full, well defined shoulders, good biceps and impeccable triceps. Yes flexed, no less impressive. Rick knows what hes doing in the gym. In the bottom photo you see those lats and scapular being flexed which shows us the muscle composition nicely. But like everyone, there’s thing that he didn’t focus on as much.

Slider please work on your legs. I’m kidding but it’s interesting to see that he’s got lean legs but next to know muscling. I have a theory for this but it’s more applicable to Goose so I’ll go into detail there with him. Something I’m noticing about the cast is that they don’t have huge chests. Like, these dudes are pretty built but they’re chests aren’t. Especially if you take a look at these guys either side of Goose.

Probably the typical 80’s lads. Beefier and more built chests. Perhaps there was a focus for the cast to have big stereotypical dude arms? I feel mean calling picking a part their lack of muscling in some areas but there is very few pectoral muscles on stand out in the cast. Hollywood and Ice perhaps being the only ones. Maybe a creative choice for the cast to focus on the ‘hotter’ parts of their body but also may have been a fitness trend in then80’s?

I hate to say it but the tag “Ron Slider Kener’s tits” isn’t…I’m sorry guys but these are not certified jugs im SORRY (I’m kidding, use that tag it’s hilarious and i love it)

Now onto what sort of exercise Slider would do? I have some ideas and a lot of them are built around this.

Slider you are a show OFF. This is a body building pose if I’m not mistake. He’s doing the vacuum stomach to flex his abs and angling his arms to show them off. Body building is time consuming and requires a certain diet so I don’t think Slider would be purposefully training whilst, I think he may have dabbled in it during College where he had a bit more freedom. Regardless he puts a lot into his physique.

Further more:

That’s an ankle wrap, now this might just be ankle support for beach volleyball but let me tell you something. If you’ve sprained your ankle badly, and I mean badly, that shit fucks you up for life if you don’t rehab it right. Now again, this may just be for support because both Ice and Slider have the same wrap on the same foot, but taking into account Slider’s lack of muscle on his legs, there’s a potential injury there. Which if you ever need to shunt Slider away out of a story, it’s a good option lmao (guilty as charged.)

If he’s not deadlifting then that may contribute to not having huge trapezoids. For how built his shoulders are I expected them to be bigger. I understood with Ice because his overall physique is just different but Slider confuses me.

Okay, now the actual exercises:

Back, bi’s and tri’s BABY. Over and over and over. They are his pride and joy.

Wide grip bicep barbell curls, hammer curls, arnold press, lateral raises. Tricep dips, tricep cable extensions. Anything and everything.

Rowing, either on the water or on a rowing machine. It takes the weight off his ankle. Potentially cycling too but he’d likely have bigger calves.

79 notes

·

View notes

Text

Unlock Efficiency with Oil Sealed Rotary Vacuum Pumps

When it comes to creating a reliable vacuum for industrial applications, oil-sealed rotary vacuum pumps are an industry favorite. These pumps are known for their superior performance, durability, and ability to handle demanding processes.

At Harsh Industrial, we offer top-of-the-line oil-sealed rotary vacuum pumps engineered for precision and efficiency. Whether you're in manufacturing, research, or processing, our pumps provide the reliable performance you need.

Why Choose Oil Sealed Rotary Vacuum Pumps?

Oil-sealed rotary vacuum pumps are widely used for their ability to create deep vacuums with exceptional efficiency. Their design and functionality make them ideal for applications such as:

Electronics Manufacturing: Achieving clean environments for sensitive equipment.

Medical Applications: Supporting sterilization and vacuum-assisted technologies.

Packaging Industries: Ensuring airtight seals in food and other packaging.

Laboratories: Creating controlled environments for experiments and testing.

With a robust design and versatile capabilities, these pumps are suitable for diverse industrial needs.

The Harsh Industrial Promise

At Harsh Industrial, we are committed to providing high-quality equipment that delivers on performance and reliability. Our oil-sealed rotary vacuum pumps are:

Durable: Built with premium materials to withstand rigorous use.

Efficient: Designed to optimize energy use and operational cost.

Low Maintenance: Engineered for hassle-free operation and longevity.

Versatile: Compatible with a range of industrial processes and fluids.

When you choose Harsh Industrial, you're investing in trusted technology backed by a team of experts dedicated to your success.

Discover the Perfect Solution for Your Industry

Optimize your operations with the precision and reliability of oil-sealed rotary vacuum pumps. Explore the wide range of solutions available at Harsh Industrial and experience the benefits of cutting-edge technology tailored to your needs.

Visit Harsh Industrial today to find the perfect vacuum pump for your business. Let us help you achieve unmatched efficiency and performance!

2 notes

·

View notes

Text

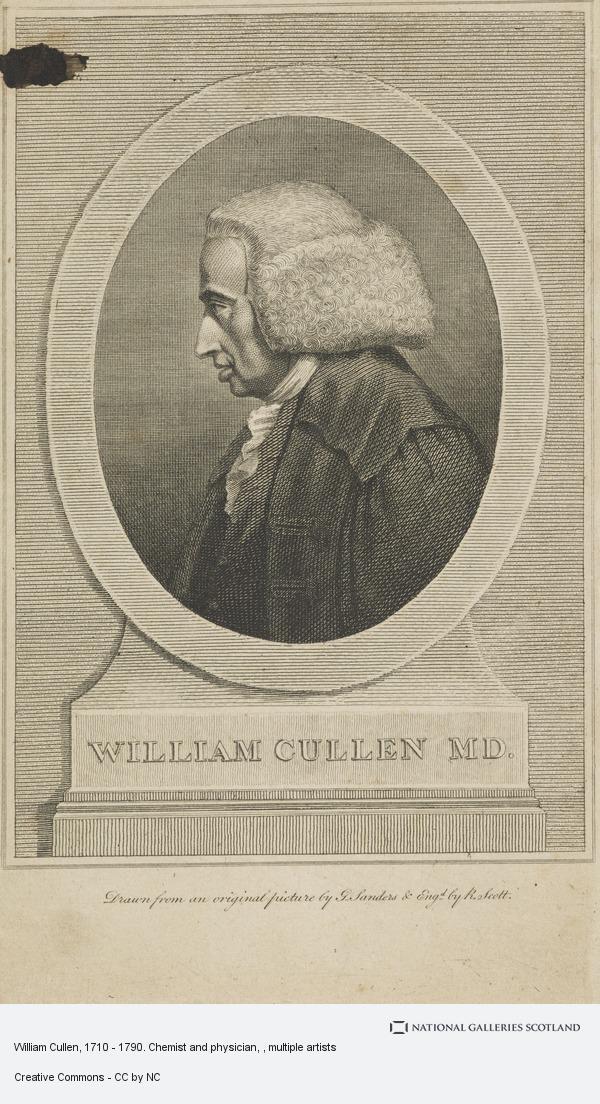

15th April 1710 saw the birth of William Cullen, physician, chemist and metallurgist in Hamilton.

Quite a day for the physicians/educators and key figures in The Scottish Enlightenment.

Cullen was born in Hamilton and educated at Glasgow where he became Professor of Medicine before moving to Edinburgh to take up a sequence of professorships at the University. Like a true "lard o' pairts" he became First Physician to the King in Scotland and President of the Royal College of Physicians in Edinburgh. In addition, he was a founder member of the Royal Society of Edinburgh.

William Cullen was a key figure in the Enlightenment. He was a friend of Adam Smith and David Hume but his achievements have not been so well recognized. Cullen was a great teacher who explored the relationship between medicine and science in a spirit of liberal inquiry and he played a major role in establishing the Edinburgh of his day as the world’s foremost medical centre. He attracted many students from overseas, and the medical schools and institutions founded by his pupils set the pattern for medicine in North America.

It was in Edinburgh, in 1756, that he gave the first documented public demonstration of artificial refrigeration. He used a pump to create a partial vacuum over a container of diethyl ether, which then boiled, absorbing heat from the surroundings. This created a small amount of ice, but the process found no commercial application.

William Cullen introduced the terms Neurosis and Neuroses and gave descriptions of anxiety disorders, eating disorders and other psychological problems 100 years before such disorders were acknowledged and accepted by physicians in general It was for these reasons that the Eating Disorders Services for adults was named the Cullen Centre by NHS Lothian.

He died on 5th February 1790 at his country house at Kirknewton in Midlothian, he is buried in the village Cemetery.

There’s a wealth of info on Cullen in this article here https://www.jameslindlibrary.org/articles/william-cullen-1710-1790/

6 notes

·

View notes

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Text

Instrumentation Tube Fittings Supplier & Manufacturer

We are a leading instrumentation tube fittings manufacturer and supplier for leak-free critical applications. Fittings are precision engineered with superior performance and durability, making it ideal for applications in oil & gas, petrochemicals, power plants, pharmaceuticals, and other industries.

Tube to Tube Fittings (Union, Elbow, Tee, Cross)

Tube to Pipe Fittings (Male & Female Connectors, Adapters)

Bulkhead Fittings

Ferrule Fittings (Single & Double)

Valves & Accessories

We also manufacture Pressure Gauge Manufacturers, Instrumentation Pipe Fittings, Quick Release Couplings, Valves, Manifolds Valve, Vacuum Pump Manufacturers in India, Tube Clamp Manufacturers.

0 notes

Text

Vacuum Priming Pumps Market Growth: Share, Value, Size, Trends, and Insights

"Vacuum Priming Pumps Market Size And Forecast by 2031

Global vacuum priming pumps market size was valued at USD 399.4 million in 2023 and is projected to reach USD 627.04 million by 2031, with a CAGR of 5.8% during the forecast period of 2024 to 2031.

the outlook for the Vacuum Priming Pumps Market remains optimistic, with significant opportunities for growth and innovation. The market’s competitive environment, shaped by leading companies and their strategies, underscores the importance of adaptability and foresight. With a focus on insights, trends, and data-driven analysis, this report serves as a comprehensive guide for stakeholders navigating the complexities of the Vacuum Priming Pumps Market.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-vacuum-priming-pumps-market

Which are the top companies operating in the Vacuum Priming Pumps Market?

The Top 10 Companies in Vacuum Priming Pumps Market are known for their strong presence and innovative solutions. These include industry leaders. Each of these companies has made significant contributions through cutting-edge products, strategic partnerships, and global reach. Their ability to adapt to market trends and consumer demands has helped them maintain leadership positions in the market, driving growth and setting industry standards.

**Segments**

- By Type: Liquid Ring Vacuum Priming Pumps, Dry Vacuum Priming Pumps, Rotary Vane Vacuum Priming Pumps, Others - By End-User: Chemical Industry, Food and Beverage Industry, Oil and Gas Industry, Pharmaceutical Industry, Water Treatment Plants, Others - By Distribution Channel: Direct Sales, Indirect Sales

The global vacuum priming pumps market is segmented based on type, end-user, and distribution channel. In terms of type, the market is categorized into liquid ring vacuum priming pumps, dry vacuum priming pumps, rotary vane vacuum priming pumps, and others. Liquid ring vacuum priming pumps are widely used across various industries due to their efficient performance and durability. On the other hand, dry vacuum priming pumps are gaining popularity for their low maintenance requirements. The end-user segmentation includes the chemical industry, food and beverage industry, oil and gas industry, pharmaceutical industry, water treatment plants, and others. Different industries have distinct requirements for vacuum priming pumps, leading to a diverse range of applications. Distribution channels in the market consist of direct sales and indirect sales, with manufacturers focusing on expanding their reach through both channels to cater to a wide customer base.

**Market Players**

- Gardner Denver - Atlas Copco - Pfeiffer Vacuum - ULVAC, Inc. - Busch Vakuumpumpen und Systeme - Graham Corporation - KNF Neuberger GmbH - Tsurumi Manufacturing Co. Ltd. - Aqseptence Group - EBARA CORPORATION

Key market players in the global vacuum priming pumps market include Gardner Denver, Atlas Copco, Pfeiffer Vacuum, ULVAC, Inc., Busch Vakuumpumpen und Systeme, Graham Corporation, KNF Neuberger GmbH, Tsurumi Manufacturing Co. Ltd., Aqseptence Group, and EBARA CORPORATION. These companies are actively involved in research and development activities to introduce innovative technologies and enhance their product portfolios. Collaborations, partnerships, and acquisitions are common strategies adopted by these players to strengthen their market presence and expand their foothold in the industry. With a focus on developing energy-efficient and sustainable solutions, market players are driving advancements in vacuum priming pump technologies to meet evolving customer demands and regulatory requirements.

https://www.databridgemarketresearch.com/reports/global-vacuum-priming-pumps-marketThe global vacuum priming pumps market is witnessing significant growth driven by several key factors. One of the primary drivers is the increasing demand for efficient and reliable vacuum technologies across various industries such as chemical, food and beverage, oil and gas, pharmaceutical, and water treatment plants. These industries require vacuum priming pumps for a wide range of applications, including degassing, distillation, crystallization, and sterilization, among others. The growing emphasis on process optimization, operational efficiency, and product quality is further fueling the adoption of advanced vacuum priming pump solutions.

Moreover, technological advancements in vacuum priming pump design and performance are also contributing to market growth. Market players are investing in research and development activities to introduce innovative features such as improved energy efficiency, reduced maintenance requirements, and enhanced durability. These advancements are enabling end-users to achieve higher productivity levels, lower operating costs, and improved operational safety. Additionally, the ongoing focus on sustainability and environmental regulations is driving the demand for eco-friendly vacuum priming pump solutions that minimize carbon footprint and energy consumption.

Furthermore, the rising trend of industry 4.0 and automation in manufacturing processes is creating opportunities for the integration of smart technologies in vacuum priming pumps. Market players are increasingly incorporating IoT (Internet of Things), AI (Artificial Intelligence), and data analytics capabilities in their pump systems to enable real-time monitoring, predictive maintenance, and remote control functionalities. These smart features enhance operational efficiency, optimize resource utilization, and enable proactive decision-making in industrial settings.

In terms of market competition, key players such as Gardner Denver, Atlas Copco, Pfeiffer Vacuum, ULVAC, Inc., and others are focusing on strategic initiatives to strengthen their market position. These initiatives include product launches, partnerships, collaborations, and acquisitions to expand their product portfolios, geographic presence, and customer base. Additionally, the market is witnessing a growing trend of customization and specialization in vacuum priming pump solutions to meet specific end-user requirements and application needs.

Overall, the global vacuum priming pumps market is poised for steady growth driven by the increasing demand for efficient vacuum technologies across diverse industries, technological advancements in pump design, the emphasis on sustainability and environmental regulations, the integration of smart technologies, and strategic initiatives by key market players. These factors are expected to shape the future trajectory of the market and offer opportunities for innovation, growth, and market expansion in the coming years.**Segments**

Global Vacuum Priming Pumps Market Segmentation: - **By Type:** Gas liquid Mixed, Water Ring Wheel, and Jet Type - **By Application:** Environmental Protection, Agriculture, Industrial, Others

The global vacuum priming pumps market is characterized by a diverse range of product types and applications. Gas liquid mixed, water ring wheel, and jet type pumps cater to different industrial needs, providing solutions for applications in environmental protection, agriculture, industrial processes, and various other sectors. The versatility of these pump types allows for flexible usage across multiple industries, driving the market's growth and adoption rates.

**Market Players**

- KSB SE & Co. KGaA (Germany) - Calpeda S.p.A. (Italy) - Lowara S.r.l. (Italy) - Xylem Inc. (U.S.) - BBA Pumps B.V. (Netherlands) - DLT Thurott S.r.l. (Italy) - PSG, a Dover company (U.S.) - Brown Brothers Engineers (NZ) Ltd. (New Zealand) - Cornell Pump Company (U.S.) - The Gorman-Rupp Company (U.S.)

The global vacuum priming pumps market is further enriched by the presence of key players such as KSB SE & Co. KGaA, Calpeda S.p.A., Lowara S.r.l., Xylem Inc., BBA Pumps B.V., DLT Thurott S.r.l., PSG, Brown Brothers Engineers, Cornell Pump Company, and The Gorman-Rupp Company. These market players contribute significantly to the industry through their innovative technologies, diverse product portfolios, and strategic initiatives aimed at market expansion and customer satisfaction. With a focus on quality, efficiency, and sustainability, these companies drive advancements in vacuum priming pump solutions, meeting the dynamic needs of various industries and applications.

The global vacuum priming pumps market is poised for continuous growth, propelled by the increasing demand for efficient and reliable pumping solutions across diverse sectors. As industries prioritize operational excellence, product quality, and environmental sustainability, the market players are stepping up their efforts to deliver cutting-edge technologies that address these requirements. The integration of smart features, advancements in pump design, and a focus on customization are key factors shaping the market landscape, offering enhanced performance, energy efficiency, and operational safety to end-users.

Moreover, the market's competitive landscape is characterized by robust strategies employed by key players to solidify their market positions. Collaborations, acquisitions, product launches, and geographic expansions are key tactics utilized by market players to stay ahead in the competitive arena. This dynamic environment fosters innovation, fosters healthy competition, and underscores the industry's commitment to meeting evolving market demands. Overall, the global vacuum priming pumps market is on a trajectory of continuous growth, driven by technological advancements, industry trends, and strategic partnerships that enhance product offerings and market reach.

Explore Further Details about This Research Vacuum Priming Pumps Market Report https://www.databridgemarketresearch.com/reports/global-vacuum-priming-pumps-market

Key Insights from the Global Vacuum Priming Pumps Market :

Comprehensive Market Overview: The Vacuum Priming Pumps Market is growing rapidly, driven by technological advancements and evolving consumer preferences.

Industry Trends and Projections: The market is expected to grow at a CAGR of X% over the next five years, with increasing automation and digitalization.

Emerging Opportunities: New market segments, such as sustainable and eco-friendly solutions, are creating significant growth prospects.

Focus on R&D: Companies are investing heavily in R&D to innovate and improve product offerings, ensuring market leadership.

Leading Player Profiles: Major player dominate the market with strong portfolios and strategic partnerships.

Market Composition: The market is diverse, with a mix of large enterprises and emerging startups driving competition and innovation.

Revenue Growth: The market has witnessed a steady increase in revenue, primarily driven by growing demand and product diversification.

Commercial Opportunities: There are considerable opportunities for business expansion in emerging regions and through technological innovations.

Find Country based languages on reports:

https://www.databridgemarketresearch.com/jp/reports/global-vacuum-priming-pumps-markethttps://www.databridgemarketresearch.com/zh/reports/global-vacuum-priming-pumps-markethttps://www.databridgemarketresearch.com/ar/reports/global-vacuum-priming-pumps-markethttps://www.databridgemarketresearch.com/pt/reports/global-vacuum-priming-pumps-markethttps://www.databridgemarketresearch.com/de/reports/global-vacuum-priming-pumps-markethttps://www.databridgemarketresearch.com/fr/reports/global-vacuum-priming-pumps-markethttps://www.databridgemarketresearch.com/es/reports/global-vacuum-priming-pumps-markethttps://www.databridgemarketresearch.com/ko/reports/global-vacuum-priming-pumps-markethttps://www.databridgemarketresearch.com/ru/reports/global-vacuum-priming-pumps-market

Data Bridge Market Research:

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]"

0 notes

Link

#market research future#vacuum pumps applications#vacuum pumps market types#vacuum pumps manufacturers#vacuum pumps market trends

0 notes

Text

OVERVIEW OF MEDICAL GAS MANIFOLDS

What is a Medical Gas Manifold? Unlike Medical Air Compressors and Vacuum Pumps that generate gas on-site, many gases used in healthcare settings are delivered to the facility in different types of containers and use manifolds to distribute into the rooms. Gases that can be delivered:

Oxygen – delivery pressure of 50psi Nitrous Oxide – delivery pressure of 50psi Medical Air – delivery pressure of 50psi Carbon Dioxide – delivery pressure of 50-100psi HeliOX blends – delivery pressure of 50psi Nitrogen – delivery pressure of 180psi Instrument Air – delivery pressure of 180psi The 2021 edition of the NFPA99 has the most recent developments in medical equipment and processes as well as new methods to reduce fire, explosion, and electrical hazards.

What Containers are used with Manifolds? Bulk tanks and micro-bulk tanks are gas containers that get refilled on-site. These are used for large applications and require additional equipment. Sometimes, these are collectively called a tank farm and the pad – which allows access for a truck with cryogenic gas to pull in and fill the tanks. Liquid Dewars and high-pressure cylinders are the types of gas containers that are delivered and replaced when empty. For example, there is an “H-type” high pressure cylinder, which is primarily hooked up to a high-pressure manifold in the healthcare setting. These are very common for ambulatory surgery centers and small outpatient facilities, most of the gases listed above outside of oxygen, still use this type.

Micro-Bulk Tank

Bulk Tank

High Pressure and Liquid Medical Gas Manifold Installation Discussing high pressure and liquid medical gas manifolds located indoors, the number one aspect is that it has to be a separate secured room with one hour fire rating used for no other purpose. Your manifold room can only have the manifolds and the container that is being replaced. You can store and keep connected what you’re actually using.

For example, if you have Dewars, you are only able to store Dewars, and then your high-pressure cylinders (H tanks) can go in there. Sometimes people put the vacuum pump and the oxygen manifold in the same room – that is not allowed and very expensive change order. Remember, your manifolds must be in a room all by themselves and be properly labeled.

Although this blog discusses the most common practices, Pattons Medical advises you to always work with your local municipality and local verifier to ensure that your design complies with your interpretation of whichever code they’re working on. Additionally, please note that any electrical devices in this room must be situated above five feet, and relief valves must be installed with copper piping that extends outside the room. The discharge should be turned down and screened for safety. Another important consideration is having a source valve located near the manifold.

When it comes to the insulation of the room, there are several other factors to take into account. Firstly, the temperature inside the room should not exceed 125 degrees. Additionally, ventilation must be carefully planned and implemented to ensure optimal conditions. You are able to naturally ventilate the room if your total gas falls below 3000 cubic feet. You can access gas volume charts on the Pattons Medical website.

Reference NFPA 99 5.1.3.3.2 (1-9) for design and construction details for locations of central supply systems and storage of positive pressure gases.

Indoor rooms can be heated by indirect means using steam or hot water if needed. The common rule of thumb for your liquid containers, your Dewars, is depending on the gas, it could be between 12 and 16 H cylinders. You will know where you are in that 3000 cubic feet threshold by the math and whether you want to do the mechanical versus the natural.

Liquid Dewars

High Pressure Cylinders

How do Medical Gas Manifolds Work? With medical gas manifolds, you will have two banks; the primary and the secondary, and they are required to be equal. In regards to space, the primary bank is the one currently supplying the gas, and then the secondary bank will be ready when the primary is depleted. The manifold is required to be fully automatic. Referring to the NFPA applications, the switchover must occur within the manifold, semi-automatic.

Discussing the manifold and the header bars, the header bars will need to be equipped with high-pressure shutoff valves outside the cabinet to allow for emergency isolation. You also will need to have integral check valves for each station. The header bar is going to be CGA gas specific. This means your H cylinder (your Dewar), has a certain threaded connection – similar to the header bar. The goal is to prevent a nitrogen, H cylinder from being hooked up to an oxygen manifold. With the CGA fittings, the manifold is equipped with pressure transduced – which will send information to the main circuit board for a remote signal. This is how it will talk to your master alarms. Since you will need to place this outdoors, the NEMA four gives you some weatherproofing. You will need to make it a NEMA four cabinet if you are going to do it outside. Pattons Medical recommends putting a cover or shelter over it.

What’s Inside a HP Manifold? The manifold is going to come equipped with a three-quarter inch shutoff valve, which makes up a manifold for high pressure. At the bottom of the diagram, is the pressure transducers that are telling you what pressure is happening in each side, your left and right bank, and your primary and secondary. Then, we go into the left and right bank dome regulators. The important part about using the dome biased regulators is that it’s what holds the pressure to allow the whole thing to work off pressure differential.

Above those, are the first line regulators. Then, the bank gauges at the top tell you what's going on in these headers. After that, there’s the pilot regulator, which is feeding pressure into the dome bias, so your dome bias regulator is about 25 – 30 PSI higher than the one that it’s currently feeding.

When a facility gets gas delivered to their site, they are paying for gas at a certain purity, when the gas gets delivered on site, there is no way to make it pure. Manifolds can affect the purity of the gas, so if you’re not using high quality regulators that are made for NFPA applications, then there is potential through the regulator to introduce some impurities into the gas as it flows through the manifold. The left bank is feeding the facility, but when it drops to 250 PSI, it is no longer satisfying the dome biased, then it’ll switch to the secondary bank.

In our second “true” line regulators, which is where it gets put it into the building. All of these regulators are preset at the factory depending on the gas. Discussing the delivery pressure being different depending on the gas, your bank of H cylinders is going to have different, depending on the gas. For example, a bank of oxygen, H cylinders track about 2200 PSI, but a bank of nitrous oxide cylinders only track about 750 PSI. So, these regulators all come preset from the factory gas specific. Then you go through the line regulator. The image shows both regulators being open, but when you are truly feeding the facility, only one regulator will be open.

The manual purge valve will test for purity. The pressure relief valve is there to let you know if something is wrong and it will relieve off. When you are determining the flow through the manifold, some spec sheets give you the flow with both your left line regulator and your right line regulator being open, flowing through both, but this is not accurate for an NFPA application. For maintenance, the left line regulator will be manually turned off and then the right line regulator will need to be turned on. That is strictly to keep the wear and tear equal within the manifold.

There are manifolds on the market that use what’s called a “switching,” which is when it switches to where the pressure is after one side no longer has any pressure. The issue with this is that they leak and cause a waste of gas. The other caveat is that they fail frequently in the middle, so they haven’t closed the left bank but they opened the right bank. So, you end up using both banks at once with no warning.

Heaters CO2 and nitrous are two gases that can potentially freeze up a manifold. This is caused by a pressure drop and flow across the regulators in the orifice in the manifold. If you’re going to use a manifold with a shuttle valve, you must have a heater for CO2 and nitrous oxide because they leak. Then, you will be left with a slow flow the eventually freezes, so you’ll need to use a heater. We have a high flow dome bias regulator in our manifold, our specification sheets do not specify a heater with a Pattons Medical manifold. It isn’t needed because Pattons Medical picked a regulator that would give us high flow. Pattons Medical also wanted to make it so that heaters weren’t needed because they add to the room which causes another fail point. The heaters basically work by switching on when the room temperature drops below 75 degrees.

Liquid x Liquid Manifold In larger facilities, the number of high-pressure cylinders required to meet the demand can become very high resulting in a huge space requirement and a very labor-intensive change out. In those instances, cryogenic containers become advantageous. If using cryogenic containers, there are options pertaining to the primary and secondary banks. If using a liquid manifold, a HP reserve manifold is required as back-up.

IntelliSwitch Manifold The IntelliSwitch manifold is the product we will need to use if you are using a liquid-by-liquid application or high pressure. One of the unique features of the IntelliSwitch manifold is the flexibility.

When you push the button on the front, it allows you to identify what is being connected to this manifold. What this manifold's able to do is when you tell it what is connecting to it, it will understand what pressure is supposed to see based on the containers being attached.

When you liquefy the gas in the container, it introduces some challenges with the gas being in a cryogenic state. IntelliSwitch is able to address some of those challenges. One of the first features is the economizer function. For this example, we will say, that this bank is feeding the facility. When this bank is feeding the facility, this container is generating head pressure because the gas does not want to be in a liquid state. When it generates too much head pressure, that's when you're going to pop your pressure relief valve to protect the container. In a traditional liquid by liquid manifold, it blows off into the room.

The IntelliSwitch is able to monitor the pressure on the bank, feeding the facility. Still, it’s also monitoring the pressure of the bank, not feeding the facility when it starts to register, that the head pressure is getting to. The economizer feature just bleeds some of that gas off so that it's able to be used downstream and you don't waste it. All of this happens in reverse with the lookback feature.

The lookback feature will do a soft switchover, and start drawing some of the gas from this bank, but then it keeps looking back. When this generates enough head pressure, it uses it. If it notices that there is no type of gas or that its completely empty, it’ll switch to the alternative. So instead of wasting 30% of gas in the container, only 5% will be wasted. The majority of verifiers say that this is a safer product because you are constantly getting readouts from both, meaning you know exactly what the pressure is.

Working with a verifier is essential. Take into consideration whether they are truly third parties or selling products as well.

Alarms For the manifold, there are local and master alarms. The local alarms are physically on the cabinet and are going to have either green or red lights. These lights will be next to a few phrases; ready, in-use, and replace.

For reference, you should have two green lights for ready, which means you now have a demand. For this example, let’s say this is your primary bank. When it’s depleted, the red light will be next to “replace” and the green light will be next to “ready” and “in-use.”

At your master alarm, you have a low-pressure line, high-pressure line, and reserve in use. They are actually being read by the main line pressure switch downstream of the source valve, but then you have your changeover alarm. Similarly to the local alarm, if the red light for “replace,” it is telling you to change over. You will need to address getting the bank changed out within a specified timeframe.

For liquid by liquid, we have those same three alarm points at the master, but we also have to have two more points at the master alarm, called reserve in use. As mentioned, for liquid-by-liquid applications, you have your two cryogenics and your high pressure. If your cryogenic containers have both failed, we will take off our “reserve-in-use” for the high-pressure reserves. The reserve manifold will trigger an alarm at the master.

0 notes

Text

Trusted Vacuum Pump Manufacturers Providing Global Excellence in Performance and Reliability

IVC Pumps Pvt Ltd stands as a trusted and distinguished name in the global vacuum technology landscape. With decades of expertise, the company has been at the forefront of designing, manufacturing, and supplying state-of-the-art vacuum pump systems. Known for engineering excellence, IVC Pumps provides solutions that cater to diverse industrial sectors, including pharmaceuticals, chemicals, food processing, and more. Their commitment to innovation and precision ensures every product delivers unmatched reliability and efficiency.

The team at IVC Pumps is dedicated to delivering products that not only meet but exceed customer expectations. By incorporating advanced technology and superior craftsmanship, their vacuum systems are built to withstand rigorous operational demands while optimizing productivity. Additionally, IVC Pumps offers comprehensive technical support and consultation to ensure smooth product integration and long-term satisfaction for their clients.

Take Your Business Further with IVC Pumps High-Quality Vacuum Systems

Recognized as leading vacuum pump manufacturers in Malaysia, IVC Pumps has earned global acclaim for providing top-notch systems tailored to specific industrial requirements. They are also one of the trusted vacuum pump suppliers in Johannesburg, making their products available to businesses in need of high-performing and reliable solutions.

Extending their global footprint, IVC Pumps has also established itself as one of the trusted vacuum pump manufacturers in UAE, providing robust systems for a range of applications. Their dedication to quality and precision is equally reflected in their operations as vacuum pump manufacturers in Jakarta, offering innovative technologies to boost industrial performance.

When you choose IVC Pumps Pvt Ltd, you partner with a globally recognized leader in vacuum solutions committed to enhancing operational excellence. Explore their extensive product range and experience the difference of high-quality systems designed to meet your unique needs. Contact IVC Pumps today to unlock the potential of advanced vacuum technology for your enterprise.

#vacuum pump manufacturers in Jakarta#vacuum pump manufacturers in UAE#vacuum pump suppliers in Johannesburg#vacuum pump manufacturers in Malaysia

0 notes

Text

Rotary Vane Pump – Efficient & Reliable Vacuum Solution | Tekman

Tekman’s Rotary Vane Pump delivers high efficiency, durability, and consistent performance. Ideal for various industrial vacuum applications.

0 notes

Text

Why Choose Gajjar Compressor ?

Why Choose Gajjar Compressor ?

When it comes to air compressor solutions, choosing the right manufacturer is crucial for efficiency, reliability, and long-term cost savings. Gajjar Compressor has established itself as a leading name in the industry, providing top-quality compressors designed for diverse applications. But why should you choose Gajjar Compressor over other brands? Let’s explore the key reasons why Gajjar Compressor stands out in the global market.

1. Unmatched Quality and Performance

Gajjar Compressor is committed to manufacturing air compressors that exceed industry standards. Every product undergoes rigorous quality control checks to ensure superior performance, durability, and efficiency. Whether you need a compressor for industrial, medical, or commercial applications, you can rely on Gajjar for top-notch quality.

2. Wide Range of Air Compressors

One of the biggest advantages of choosing Gajjar Compressor is the extensive product range. The company offers a variety of air compressors, including:

Screw Compressors – High efficiency and long-lasting performance for industrial applications.

Reciprocating Compressors – Robust and reliable options for various uses.

Oil Free Dental Compressors – Designed for medical and dental applications where pure, contamination-free air is needed.

Vacuum Pumps – Ideal for industries that require vacuum solutions.

Air Dryers and Filters – Ensuring moisture-free, clean air for better compressor efficiency.

3. Cutting-Edge Technology

Gajjar Compressor stays ahead of the competition by continuously investing in research and development. The company integrates advanced technology into its compressors to enhance efficiency, reduce energy consumption, and extend the lifespan of the machines. With state-of-the-art designs and innovative features, Gajjar products offer maximum performance with minimum maintenance.

4. Energy-Efficient Solutions

Energy efficiency is a major factor when selecting an air compressor. Gajjar Compressor designs products with energy-saving mechanisms to help businesses reduce operational costs. With features like variable speed drives and advanced cooling systems, these compressors consume less power while delivering optimal output.

5. Cost-Effective Pricing

Affordability without compromising quality is one of the key reasons why businesses choose Gajjar Compressor. The company offers competitive pricing, making it possible for industries of all sizes to access high-quality air compressors within their budget.

6. Customization to Meet Your Needs

Different industries have different requirements when it comes to air compressors. Gajjar Compressor understands this and offers customizable solutions tailored to meet specific needs. Whether you require modifications in power, size, pressure levels, or additional features, Gajjar can provide a solution that fits perfectly.

7. Global Reach and Strong Distribution Network

With a strong global presence, Gajjar Compressor serves clients worldwide. The company has a well-established distribution network that ensures timely delivery and excellent service, no matter where your business is located.

8. Reliable After-Sales Support

Buying an air compressor is an investment, and proper maintenance is essential for long-term performance. Gajjar Compressor provides excellent after-sales support, including installation guidance, technical assistance, and spare parts availability. Their dedicated team is always ready to help customers with any queries or maintenance needs.

9. Compliance with International Standards

Gajjar Compressor manufactures its products according to international quality and safety standards. The compressors meet ISO and CE certifications, ensuring they are safe, efficient, and reliable for use in various industries.

10. Durability and Longevity

Gajjar compressors are built to last. Made with high-quality materials and cutting-edge engineering, these compressors are designed to withstand tough working conditions and continuous operation, providing long-term reliability.

11. Low Maintenance Requirements

Another significant advantage of choosing Gajjar Compressor is the low maintenance requirement. The machines are designed with user-friendly maintenance features, reducing downtime and operational disruptions. This means businesses can save on maintenance costs and keep their operations running smoothly.

12. Trusted by Leading Industries

Gajjar Compressor has earned the trust of leading industries across multiple sectors, including:

Manufacturing – Powering machinery and tools efficiently.

Automotive – Used in painting, air tools, and assembly lines.

Healthcare – Essential for medical and dental air applications.

Food & Beverage – Ensuring contamination-free air supply.

Textile & Printing – Providing precision air solutions for seamless operations.

13. Sustainability and Eco-Friendly Practices

Environmental responsibility is a priority for Gajjar Compressor. The company incorporates sustainable practices in its manufacturing process, using eco-friendly materials and energy-efficient technologies to reduce carbon footprints.

14. Strong Research & Development (R&D) Team

The company has a dedicated R&D team that continuously works on developing new technologies and improving existing products. This focus on innovation ensures that customers get the latest and most efficient air compressor solutions.

15. Customer-Centric Approach

Gajjar Compressor prioritizes customer satisfaction above everything else. The company takes the time to understand each client’s needs and provides solutions that add value to their operations. Personalized consultations, prompt responses, and a commitment to excellence make Gajjar a preferred choice.

Conclusion: The Best Choice for Your Air Compressor Needs

Choosing the right air compressor manufacturer is critical for productivity and efficiency. Gajjar Compressor stands out as a trusted name in the industry, offering high-quality products, advanced technology, excellent customer support, and cost-effective solutions. Whether you need a reliable compressor for industrial, medical, or commercial applications, Gajjar Compressor is the brand you can trust.

Invest in performance, durability, and efficiency—choose Gajjar Compressor today!

More information visit a website : www.aircompressorindia.com

0 notes

Text

Why Is Regular Maintenance Crucial for Vacuum Pump Longevity

Vacuum pumps are vital in numerous industries, from manufacturing and pharmaceuticals to automotive and food packaging. They ensure smooth operations, enhance efficiency, and help maintain the necessary environments for various processes. However, just like any other machinery, vacuum pumps require proper care and maintenance to ensure they last and continue to perform optimally.

In this blog, we'll explore why regular maintenance is crucial for the longevity of your vacuum pumps and how it can save you time, money, and frustration in the long run. We'll also discuss how investing in the right Vacuum Pumps in Australia can further increase operational efficiency.

What Is a Vacuum Pump and Why Does It Need Regular Maintenance?

A vacuum pump is a mechanical device that removes gas molecules from a sealed volume, creating a partial vacuum. It is widely used in industrial applications to maintain systems that require a vacuum, such as air conditioning, refrigeration, and medical equipment.

Regular maintenance ensures that vacuum pumps continue to perform as needed, avoiding unnecessary breakdowns and preventing costly repairs. Without consistent upkeep, these pumps can experience various issues, from excessive wear and tear to complete failure.

Key Maintenance Practices for Vacuum Pumps

1. Regular Inspection

Regular inspections are one of the most effective ways to spot potential issues before they become serious. During an inspection, check for:

Unusual sounds or vibrations

Leaks or cracks in the pump or hoses

Excessive heat generation

Dust or debris buildup

Regular inspections allow you to catch small problems early on, preventing them from escalating and reducing downtime.

2. Cleaning and Replacing Filters

Vacuum Pumps Australia often have filters that trap contaminants. These filters can become clogged over time, reducing the pump's efficiency. Cleaning and replacing filters regularly will ensure optimal airflow and prevent dirt or debris from entering the pump system.

For systems that use oil-sealed pumps, it's essential to change the oil at regular intervals as per the manufacturer's guidelines. Clean oil helps lubricate the internal components, preventing friction and wear.

3. Lubrication

Proper lubrication is essential for vacuum pumps that require it. Ensure that the lubrication is applied regularly, especially in pumps that operate continuously. Lack of lubrication can lead to increased friction between moving parts, resulting in overheating, wear, and eventual failure.

Check the oil level regularly and replace the oil when necessary to ensure that the internal components are well-lubricated and free from contamination.

4. Monitoring Pump Performance

Keeping track of your vacuum pump's performance is another key aspect of maintenance. Monitoring the vacuum pressure, airflow, and pump speed can help identify performance issues early. If you notice any significant changes in performance, it may be a sign that something isn't functioning as it should.

You can also monitor the pump's energy consumption. If it starts consuming more energy than usual, it could indicate that the pump is struggling to maintain the Vacuum Pumps Australia and may need service.

5. Timely Repairs

No matter how well you maintain your vacuum pump, repairs will be necessary from time to time. Ensuring that repairs are done promptly is key to avoiding further damage. If a part is malfunctioning or worn out, it is better to replace it early than wait until it fails completely, which could lead to a more costly and time-consuming repair.

Conclusion

In conclusion, regular maintenance is essential for the longevity and efficient operation of vacuum pumps. By performing regular inspections, cleaning filters, ensuring proper lubrication, and monitoring performance, you can prevent costly repairs and ensure your Vacuum Pumps Australia work at their best for years to come.

Investing time and resources into maintaining your vacuum pump will pay off in the long run with increased productivity, lower costs, and a safer working environment. Remember, when it comes to vacuum pumps, prevention is always better than a costly repair.

0 notes

Text

The Advantages of Liquid Ring Vacuum Pumps Over Other Pump Types

Industrial vacuum pumps are regarded as important equipment in some industrial applications. If the vacuum pump you are using happens to be just ideal for that kind of process it does not just get the work done but rather also makes the operator more advanced, cost effective and reliable while at work.

Users view liquid ring vacuum pumps as the top choice for vacuum pumps. They're adaptable and exact yet tough enough to tackle some of the most demanding jobs in chemical processing, food and drink production, power generation, and drug manufacturing. In this blog, we will discuss how these liquid ring vacuum pumps are better than other pumps?

Let’s dive right in..!!

Advantages of Liquid Ring Vacuum Pumps

Top-Notch Reliability

The most special thing about liquid ring vacuum pumps is that they are very durable. You can use these pumps in any condition including processes involving wet gases, vapors, and even small solid particles. But if we talk about other vacuum pumps, they will either fail after being used in robust conditions or will require frequent maintenance. While liquid ring vacuum pumps work smoothly in every condition without any wear and tear.

For industries that want a reliable product, liquid ring vacuum pump manufacturers offer the assurance that you can trust the vacuum pump blindly.

Ability to Handle Diverse Applications

Liquid ring vacuum pumps are highly versatile. They are capable of tackling saturated gases, vapors as well as explosive gases. If you have noted, dry pumps really lag behind in regions where it rains and the climatic conditions become wet and there is a great wastage of time and resources used in the same process. Under these circumstances, results are given best by liquid ring pumps.This adaptability makes them ideal for industries like:

Chemical processing: For vapor recovery and distillation.

Pharmaceuticals: For vacuum filtration and drying processes.

Power plants: For condenser air extraction and vacuum priming.

Unlike other pumps, these pumps do not require additional components and modifications to work in a wide range of applications, thus you can save your money here.

Minimal Maintenance Requirements

With their simple design, liquid ring vacuum pumps are remarkably easy to maintain. It does not have those complex moving parts that mechanically may easily go bad. Also, the liquid ring acts both as a lubricant and a sealant: once again, minimizing chances of frequent regular maintenance or replacement.

In contrast, pumps like rotary vane or diaphragm pumps may involve complex components that demand regular upkeep, leading to downtime and higher operational costs.

Eco-Friendly and Safe Operation

Today's modern industries always give top priority to safety and sustainability. And Liquid ring vacuum pumps contribute to this.

These vacuum pumps are environmentally friendly, their liquids can be used again so you can minimize water wastage. In addition to that, manufacturers of liquid ring vacuum pumps make them in a manner that they take the least possible energy and generate the maximum possible output.

Apart from this, these pumps handle flammable and corrosive gases very carefully without any risk of spark. That is why these pumps are especially used in chemical and petrochemical industries today.

Quiet and Smooth Performance

Unlike other vacuum pumps that can produce significant noise and vibration, liquid ring pumps operate quietly and smoothly. These pumps are no less than a ward for those industries where noise pollution is the highest. Especially in food and beverage or pharmaceutical industries, noise pollution is also reduced by using these pumps.

Cost-Effective in the Long Run

Although a liquid ring vacuum pump system may have an initial investment comparable to other pump types, the ultimate value comes far more easily after the initial investment. Less operating cost, outstanding performance, and energy efficiency generally make significant savings possible in the long term.

With the best manufacturers of liquid ring vacuum pumps, a business ensures that the purchased equipment is quality and has worth.

Resistant to Wear and Corrosion

It is robust enough to withstand corrosive liquids and gases. Liquid ring pumps are made up of stainless steel or cast iron which can handle very high abrasion and aggressive chemical particulate concentration; thus suitable for handling those corrosive or reactive materials, and several industries demand this pump to handle such extremely corrosive liquids or gaseous chemicals.

Conclusion

So if you are also looking for the right vacuum pump for your industry then you may not find a better option than the liquid ring vacuum pump. In this blog we have shared all the information about this pump that we have experienced ourselves in the industries and heard from the industrial workers. From reliability and versatility to eco-friendliness and cost-effectiveness, these pumps deliver unparalleled value.

Whether you are in chemical manufacturing, power generation, or any other industry that requires strong vacuum solutions, you can be sure to get the best quality and durable systems when you partner with reputed liquid ring vacuum pump manufacturers.

1 note

·

View note

Text

Appion AV760 Full-Range Vacuum Gauge

The Appion AV760 Full-Range Vacuum Gauge is a high-precision tool designed for HVAC and refrigeration professionals. This device ensures accurate vacuum measurements, allowing technicians to confirm proper system evacuation before refrigerant charging. By achieving the right vacuum levels, users can prevent system failures, improve efficiency, and eliminate contaminants that might compromise system performance.

In this guide, we will explore the Appion AV760 in detail, covering its key features, applications, usage instructions, maintenance tips, pricing, and why it is a top choice among HVAC professionals.

Understanding the Appion AV760

The Appion AV760 is a wireless, full-range vacuum gauge that delivers precise and reliable readings. It is built for durability and ease of use, making it a preferred tool for professionals in the HVAC and refrigeration industry.

Key Features of the Appion AV760

Full-Range Measurement: The Appion AV760 provides vacuum readings from atmospheric pressure down to deep vacuum levels, ensuring accurate monitoring at every stage of system evacuation.

Wireless Connectivity: With its wireless capability, the AV760 can connect to smartphones and tablets, allowing remote monitoring and data logging through a mobile app.

Superior Accuracy: The device delivers precise measurements, helping professionals verify vacuum conditions before introducing refrigerants into the system.

Rugged and Durable Design: Designed to withstand harsh environments, the Appion AV760 is built with high-quality materials to ensure long-term reliability.

User-Friendly Interface: The digital display and intuitive controls make it easy to use, even for those new to HVAC vacuum measurements.

Compact and Lightweight: The small size and lightweight design make it easy to transport and use in tight spaces.

Low Maintenance Requirements: Simple cleaning and proper handling help maintain accuracy and extend the lifespan of the gauge.

Applications of the Appion AV760

The Appion AV760 is a versatile tool suitable for multiple HVAC and refrigeration applications, including:

Vacuum Pumping: Ensuring that the system is free from moisture and non-condensable gases before charging refrigerant.

Leak Detection: Identifying and confirming the presence of leaks based on vacuum level changes.

Refrigeration System Maintenance: Monitoring and maintaining proper vacuum levels to improve system longevity and performance.

Automotive Air Conditioning Service: Verifying the evacuation process before recharging automotive AC systems.

Industrial Refrigeration Applications: Used in large-scale refrigeration units to ensure proper vacuum evacuation.

How to Use the Appion AV760

Connecting the Gauge: Attach the AV760 to the system’s service port.

Powering On: Turn on the device and allow it to stabilize.

Reading Vacuum Levels: Monitor the readings on the device or via the connected mobile app.

Ensuring Proper Evacuation: Wait until the vacuum reaches the required level before proceeding with refrigerant charging.

Disconnecting and Storing: Once completed, disconnect the gauge and store it in a safe, dry place.

Cleaning and Maintenance of the Appion AV760

To maintain accuracy and prolong the lifespan of the Appion AV760, regular cleaning and maintenance are essential:

Cleaning the Exterior: Use a soft, dry cloth to clean the surface.

Sensor Maintenance: Follow the manufacturer’s guidelines to clean the sensor and prevent contamination.

Battery Care: Regularly check battery levels and replace them when necessary.

Proper Storage: Store the vacuum gauge in a dust-free environment to avoid potential damage.

Appion AV760 Price and Where to Buy

The Appion AV760 Full-Range Vacuum Gauge price varies depending on location, retailer, and included accessories. For the most accurate and up-to-date pricing, check online retailers, HVAC supply stores, or official Appion distributors. Prices may also fluctuate based on promotions, bulk purchases, or warranty options.

Why Choose the Appion AV760?

Unmatched Accuracy: One of the most precise vacuum gauges available, ensuring proper system evacuation.

Wireless Functionality: Allows convenient monitoring from mobile devices, reducing manual checking efforts.

Versatile Applications: Can be used in residential, commercial, and automotive HVAC and refrigeration systems.

Durability: Built for long-term use, even in demanding environments.

Ease of Use: User-friendly design makes it simple for both beginners and experienced technicians.

For More Information click on the Link:- visit Here

Email id:- [email protected]

0 notes