#vacuum pressure lifter

Explore tagged Tumblr posts

Text

Semiotic Standard for All Commercial Trans-Stellar Utility Lifter and Heavy Element Transport Spacecraft. April 16, 2078 by Ron Cobb for Alien (1979)

Transcribed color code: red - viable, alive, sound, alert white, grey - life-supporting condition: pressure, temperature black - vacuum, death, hazard yellow - harmful active process: molecular (heat) atomic, chemical blue - lowered thermal condition green - non-human biological substance, process

Recreation by Boris Tovmasyan:

Source on Behance

#alien 1979#alien isolation#alien romulus#alien franchise#nostromo#sevastopol station#iconography#semiotic standard#symbols#resources#graphic design#not mine

38 notes

·

View notes

Text

Oil Pumps: The Heart of Engine Lubrication

Oil Pumps: The Heart of Engine Lubrication Oil pumps are a critical component in internal combustion engines, ensuring that all moving parts are adequately lubricated and cooled. Without a functioning oil pump, an engine would quickly overheat and suffer catastrophic damage. In this article, we will delve into the workings of oil pumps, their types, and their importance in engine performance.Get more news about Oil Pump,you can vist our website!

What is an Oil Pump? An oil pump is a device that circulates engine oil under pressure to the rotating bearings, sliding pistons, and camshaft of the engine. This lubrication reduces friction and wear on the moving parts, allowing the engine to operate smoothly and efficiently. Additionally, the oil helps to cool the engine by carrying heat away from the moving parts.

Types of Oil Pumps There are several types of oil pumps used in internal combustion engines, each with its own unique design and function:

Gear Pumps: These are the most common type of oil pump. They use a pair of meshing gears to pump the oil. As the gears rotate, they create a vacuum that draws oil into the pump and then pushes it out under pressure. Gear pumps are known for their reliability and efficiency. Rotor Pumps: Also known as gerotor pumps, these use a rotor with external teeth that mesh with an internal gear. As the rotor turns, it creates chambers that draw in and expel oil. Rotor pumps are compact and can provide a steady flow of oil. Vane Pumps: These pumps use a series of vanes mounted on a rotor. As the rotor spins, the vanes slide in and out, creating chambers that move the oil. Vane pumps are less common in automotive applications but are used in some high-performance engines. How Oil Pumps Work The oil pump is typically driven by the engine’s crankshaft, ensuring that it operates whenever the engine is running. The pump draws oil from the oil pan through a pickup tube and forces it through the engine’s oil passages. These passages distribute the oil to critical components such as the crankshaft bearings, camshaft bearings, and pistons.

The oil pump must maintain a consistent flow of oil to ensure proper lubrication. If the oil pressure drops too low, it can lead to insufficient lubrication and potential engine damage. Conversely, if the oil pressure is too high, it can cause excessive wear on the engine components.

Importance of Oil Pumps Oil pumps play a vital role in engine performance and longevity. Here are some key reasons why oil pumps are essential:

Lubrication: The primary function of the oil pump is to provide continuous lubrication to the engine’s moving parts. This reduces friction and wear, allowing the engine to run smoothly and efficiently. Cooling: By circulating oil through the engine, the oil pump helps to dissipate heat generated by the combustion process. This prevents the engine from overheating and ensures optimal performance. Cleaning: Engine oil also helps to clean the engine by carrying away dirt, debris, and metal particles. The oil pump ensures that the oil is continuously circulated and filtered, keeping the engine clean and free of contaminants. Hydraulic Functions: In some engines, the oil pump also powers hydraulic systems such as variable valve timing and hydraulic lifters. These systems rely on a steady supply of pressurized oil to function correctly. Common Issues with Oil Pumps While oil pumps are generally reliable, they can experience problems that affect engine performance. Some common issues include:

Wear and Tear: Over time, the internal components of the oil pump can wear out, reducing its efficiency and causing a drop in oil pressure. Blockages: Dirt and debris can clog the oil passages, restricting the flow of oil and leading to insufficient lubrication. Leaks: Oil leaks can reduce the amount of oil available for circulation, causing a drop in oil pressure and potential engine damage. Conclusion Oil pumps are the heart of an engine’s lubrication system, ensuring that all moving parts are adequately lubricated, cooled, and cleaned. By understanding how oil pumps work and their importance in engine performance, you can better appreciate the critical role they play in keeping your engine running smoothly. Regular maintenance and timely replacement of worn-out components can help ensure that your oil pump continues to function effectively, prolonging the life of your engine.

0 notes

Text

Sheet Metal and Steel Profile Handling Equipments

In the previous blog, we have mentioned many times that the good partner of the laser cutting machine is our excellent Roll-Out Sheet Metal Rack. However, our racks with laser cutting machines are still a fly in the ointment. The missing link is the equipment to move the steel plates. Only in this way can it be more convenient and fast in the transportation process. Today, I will introduce in detail the equipment and methods for handling sheet metal and taking sheet metal, taking the Roll-Out Sheet Metal Rack as an example.

Three ways to move steel plate bundles onto rack

1. Crane Plus Lifting Chain with Hooks

2.Crane Plus wire rope or strap

3. Forklift

Two ways to access sheet metal

With crane:

In the case of crane, we can use the Vacuum Lifter, Lifting Chain with Hooks and Permanent Lifting Magnet collocation to access the steel plate. This method is not only efficient, but also high security. Vacuum Lifter: At the heart of the Vacuum Lifter lies an imported oil-free vacuum pump and valves that ensure high efficiency, safety, and rapid operation with minimal effort. It’s fitted with an accumulator and pressure monitoring to guarantee utmost safety during every lift. The adjustability of the suction pad positions and the ability to manually shut them off allows for tailored handling for each task, aligning with CE safety standards. For example, in the manufacturing industry, metal processing: in the handling of metal sheets, steel plates, aluminum plates, stainless steel plates and other materials, the vacuum hoist can be efficiently and safely operated to reduce the damage to the material surface. As well as in the handling of various mechanical parts, especially for large size, heavy parts, vacuum suction crane provides a convenient handling method. In the construction industry, like glass installation, in the installation process of building glass, window glass, large glass curtain wall, etc., the vacuum suction crane can easily and safely grasp and move the glass, avoiding the safety risks and damage risks in the traditional handling methods. And stone handling: In the handling and installation of marble, granite and other stone, the vacuum hoist can stably grasp and move heavy stone to improve work efficiency.

Lifting Chain with Hooks: Crafted from premium grade 100 chains, these lifting accessories are specifically designed to operate flawlessly in environments exposed to heat or chemicals, making them a perfect complement to construction sites and industrial settings, so I would recommend using hooks for the thicker steel plates. We provide a variety of configurations and hooks to suit the unique demands of your lifting operations. Sourced from the finest manufacturers in China and meticulously assembled by reputable rigging houses, our chains are synonymous with durability and reliability. Suitable for construction sites, chain hook is widely used in construction sites for lifting and moving heavy construction materials, such as steel beams, concrete prefabricated parts, etc. Its high strength and durability enable it to cope with a variety of harsh construction environments. At the same time, in the industrial manufacturing process, the chain hook is used for handling and loading and unloading heavy equipment and materials, such as machine parts, large steel plates, pipes and so on. They can withstand high loads, ensuring safe and efficient operation.

Permanent Lifting Magnet: Permanent Lifting Magnet, which are advanced permanent magnets, generate a magnetic field much more potent than standard magnets due to their composition of rare-earth elements and ferrite alloys. They are extensively utilized across multiple sectors for the purpose of moving metal objects or substantial loads. A distinct category of these magnets, known as permanent magnets, offers the advantage of being toggled between active and inactive states. This feature allows for the convenient relocation of the attached object to its designated location, after which the magnet can be deactivated. Opting for a Permanent Lifting Magnet to handle metallic objects such as plates, pipes, and disks represents a highly effective and economical method. In the automotive manufacturing industry, permanent lifting magnets are indispensable for moving hefty parts during the assembly process, thereby minimizing physical exertion and boosting productivity. And it is also crucial on construction sites and in steel workshops, facilitating the lifting and accurate placement of large steel structures like beams, columns, and plates.

2. Without Crane

If there is no crane, you can use the KBK CRANE or JIB CRANE with Vacuum Lifter to pick up goods. These two kinds of equipment are widely used in small and medium-sized workshops, flexible operation, and are not limited by the site.

KBK CRANE: The KBK CRANE is a modular design of lifting equipment, mainly composed of rails, brackets, tackles and cranes. Its tracks can be flexibly combined according to needs, suitable for a variety of working environments. The KBK CRANE is usually installed on top of the workshop, forming a lifting system that covers the entire work area. KBK CRANE is suitable for work environments that require coverage of a wide range of operations, especially in line production and large-scale warehousing. Specific applications include:

Automotive Manufacturing: On the automotive assembly line, KBK CRANE can cover the entire assembly area, facilitating the lifting and moving of individual components.

Machine building: In large machine building workshops, KBK CRANE can flexibly respond to different processing and assembly needs.

Warehouse logistics: In large warehouses, KBK CRANE can quickly and efficiently complete the access and handling of the steel plates.

JIB CRANE: JIB CRANE is a kind of lifting equipment with fixed arm, which is mainly composed of column, rotating arm and CRANE. The cantilever can be rotated and is usually mounted on a fixed column or wall, covering a fixed circular or semi-circular work area. JIB CRANE is suitable for small operating areas, especially where materials need to be lifted and moved frequently. Specific applications include:

Process assembly: On a small process assembly line, the JIB CRANE can easily complete the lifting and transfer of parts.

Machine tool assistance: In the machining shop, the JIB CRANE can be used as an auxiliary device of the machine tool for loading and unloading and workpiece handling.

The importance of handling tools

Through the above introduction, I believe you have a clear idea of what kind of handling tools you need. Handling tools not only play an important role in logistics and production processes.

Increase efficiency

Efficient handling tools can greatly reduce operation time and improve work efficiency. For example, the combination of driving and Lifting Chain with Hooks, wire ropes or straps can quickly and accurately complete the handling and placement of the plate. 2. Stay safe

Safe handling tools can reduce operational risks and ensure the safety of workers. For example, the use of Vacuum Lifter, permanent magnet hoist and other tools can be firmly fixed to prevent the sheet from slipping or tipping during handling.

The perfect combination of handling equipment and Roll-Out Sheet Metal Rack

Combining efficient handling equipment with Roll-Out Sheet Metal Rack maximizes production efficiency and operational safety.

Seamless connection

Efficient handling equipment such as truck, forklift, KBK CRANE and the hand drawer plate shelf seamless docking, can achieve the rapid transfer and access of steel plates. After the handling equipment transport the steel plate to the rack position, the plate can be stored in the drawer by hand operation, greatly simplifying the operation process. 2. Reduce labor intensity

The use of efficient handling equipment can reduce the labor intensity of manual handling and reduce the fatigue of workers during operation. Combined with the convenient design of Roll-Out Sheet Metal Racks, the work burden of workers is further reduced. 3. Improve production efficiency

Through reasonable design and use, efficient handling equipment and Roll-Out Sheet Metal Racks can greatly improve production efficiency. Fast and easy access reduces downtime and improves line continuity and stability.

How to choose the right handling equipment

When selecting transportation equipment, consider the actual requirements and working environment. Here are a few suggestions:

Consider your work environment

Different working environments have different requirements for handling equipment. For example, a workshop with a small space may be more suitable for JIB CRANE or KBK CRANE, while a large warehouse may have the option of a truck or forklift. 2. Consider sheet size

The size and weight of the plate are also important factors in the selection of handling equipment. For heavier plates, it is recommended to choose a driving or permanent magnet crane with strong carrying capacity; For lighter plates, wire ropes or strap with high flexibility can be selected. 3. Consider ease of operation

The convenience of operation directly affects the production efficiency. Choosing handling equipment that is easy to operate and maintain can reduce training time and improve the operational proficiency of workers.

Through the introduction of this article, we explain in detail the advantages of efficient handling equipment and Roll-Out Sheet Metal Racks and the method of combined use. Handling equipment plays an important role in logistics and production processes, directly affecting production efficiency and operational safety. The Roll-Out Sheet Metal Rack as an important supporting equipment of laser cutting machine, through its efficient access, space saving, safety and stability and flexible adaptation advantages, has brought great convenience to the production line. When selecting transportation equipment, you need to comprehensively consider the actual needs and working environment to ensure that the most suitable equipment is selected to improve production efficiency and operation safety. We can not only provide excellent racks, but also handling tools can be trusted! Looking forward to your contact! In the future, we will continue to be committed to providing customers with better products and services to help enterprises achieve efficient, intelligent and safe production management. If you have any needs or questions, please feel free to contact us. We will be happy to serve and help you.

1 note

·

View note

Text

Unlock the Power of Pressure Canning: Beginner's Guide

Pressure canning is a time-honored method for preserving food that can help you enjoy the flavors of summer well into the winter months. It's a technique that not only extends the shelf life of your favorite foods but also retains their nutritional value and taste. If you're new to this method, this beginner's guide will help you unlock the power of pressure canning, ensuring you can confidently preserve your bounty.

Understanding Pressure Canners At the heart of pressure canning is the use of specialized equipment known as pressure canners. Unlike traditional water bath canners, pressure canners are designed to reach higher temperatures, which is essential for safely canning low-acid foods such as vegetables, meats, poultry, and seafood. These foods require a temperature of at least 240°F (116°C) to effectively kill bacteria and spores, including the notorious Clostridium botulinum, which can cause botulism.

Getting Started with Pressure Canning Equipment You’ll Need Pressure Canner: The main piece of equipment. Make sure it has a dial gauge or weighted gauge to monitor the pressure accurately.

Canning Jars: Use mason jars specifically designed for canning. They come in various sizes to suit different foods.

Lids and Bands: Lids create the vacuum seal, while bands hold the lids in place during processing.

Jar Lifter: This tool is essential for safely removing hot jars from the canner.

Bubble Remover/Headspace Tool: Ensures air bubbles are removed and the correct headspace is maintained.

Canning Funnel: Makes it easier to fill jars without spilling.

Steps to Pressure Canning Prepare Your Food and Jars: 1. Wash and sterilize your jars and lids. 2. Prepare your food according to a tested canning recipe. 3. Fill the jars, leaving the recommended headspace (usually 1 inch).

Assemble Your Pressure Canner: 1. Place the rack in the bottom of the canner and add the recommended amount of water. 2. Load your filled jars onto the rack, ensuring they don’t touch each other.

Seal and Heat: 1. Lock the lid of the canner in place. Make sure the vent pipe is open. 2. Heat on high until steam flows steadily from the vent pipe. Allow the steam to vent for 10 minutes to expel air from the canner.

Processing: 1. After venting, close the vent pipe. As pressure builds, monitor the pressure gauge and adjust the heat to maintain the recommended pressure (usually 10-15 pounds per square inch, depending on your altitude and recipe). 2. Process the jars for the time specified in your recipe.

Cooling and Storing: 1. Once the processing time is complete, turn off the heat and allow the pressure to return to zero naturally. 2. Wait a few minutes before unlocking and removing the lid. 3. Use the jar lifter to carefully remove the jars and place them on a towel to cool. Do not disturb them for 12-24 hours. 4. Check the seals, label the jars with the date, and store them in a cool, dark place.

Safety Tips Follow Reliable Recipes:��Only use recipes from trusted sources such as the USDA, National Center for Home Food Preservation, or university extension programs.

Adjust for Altitude: Pressure and processing times vary with altitude. Ensure you make necessary adjustments.

Inspect Equipment Regularly: Check the rubber gasket, lid, and pressure gauge for wear and tear before each use.

Benefits of Pressure Canning Extended Shelf Life: Properly canned foods can last for years without refrigeration.

Nutritional Value: Pressure canning preserves the vitamins and minerals in your food.

Economic Savings: Home-canned foods can save money over store-bought alternatives.

Customization: Tailor recipes to your dietary needs and flavor preferences.

Unlocking the power of pressure canning opens up a world of culinary possibilities. From garden-fresh vegetables to hearty stews, the ability to preserve your favorite foods safely and efficiently is incredibly rewarding. With this beginner's guide, you're well on your way to becoming a pressure canning pro. Happy canning!

0 notes

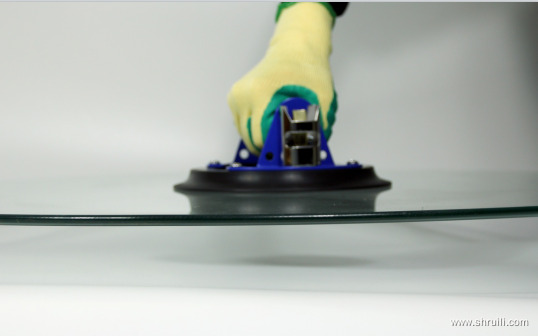

Photo

What is Vacuum Pump Glass Lifter: an exploration from principle to application? | RuiLi The vacuum suction cup, a seemingly simple tool, is actually rich in scientific principles. Its operating principle is based on vacuum technology, which achieves adsorption of various materials by creating a negative pressure environment inside the suction cup. This strong adsorption force makes vacuum suction cups have a wide range of applications in production, life and scientific experiments. First, the working principle of the vacuum suction cup The working principle of the vacuum suction cup is mainly to make use of atmospheric pressure. When the suction cup is in close contact with the adsorbed object, a negative pressure is formed inside the suction cup through a vacuum pump or vacuum generator, so that the external atmospheric pressure presses the suction cup tightly on the adsorbed object to produce adsorption force. The magnitude of this suction force depends on the size and shape of the suction cups, as well as the atmospheric and pumping pressures. Second, the application of vacuum suction cups Due to its unique adsorption capacity, vacuum suction cups have a wide range of applications in various fields. Here are some common use cases: Glass installation and maintenance: In the construction industry, vacuum suction cups are often used for the installation and maintenance of glass. By attaching the suction cups to the glass surface, they can be easily transported, positioned, and fixed, greatly improving installation efficiency. Plastic parts processing: In the plastic processing industry, because the plastic material is light and easy to deform, the use of vacuum suction cups can be easily handled and fixed, improving the processing accuracy and efficiency. Food packaging: In the field of food packaging, vacuum suction cups are often used to adsorb and move food products of various shapes, such as candy, chocolate, etc. This mode of operation is hygienic and efficient. Laboratory applications: In scientific experiments, vacuum suction cups are often used to move and fix various materials, such as glass sheets, plastic films, etc. It provides experimenters with a convenient and reliable way to manipulate experimental materials. Robotics: In the field of robotics, vacuum cups are used to perform the delicate operation and movement functions of robots. By controlling the adsorption and release of the suction cups, the robot can achieve stable grasping and precise placement of objects. Third, Advantages and disadvantages of vacuum suction cups Merit: (1) Easy operation: When using a vacuum suction cup, it only needs to be placed on the surface of the adsorbed object, and the negative pressure generated by the suction device can be adsorbed. The operation is simple and convenient. (2) Strong adaptability: The vacuum suction cup is suitable for the adsorption of various materials and surfaces, such as glass, plastic, paper, etc. It is capable of working in various environmental conditions, such as humidity, high temperatures, etc. (3) High safety: Since the adsorption force of the vacuum suction cup comes from the external atmospheric pressure, there is no risk of deformation or rupture of the object due to adsorption. Shortcoming: (1) Limiting factors: The adsorption force of the vacuum suction cup is limited by the atmospheric pressure and the size and shape of the suction cup. For some large or heavy objects, multiple suction cups or a more powerful vacuum system may be required to achieve reliable adsorption. (2) Material requirements: Some materials with rough surface or special coating may affect the adsorption effect of the vacuum suction cup. In addition, some soft materials may be deformed when adsorbed. (3) Maintenance requirements: In order to maintain good working condition, the vacuum suction cup needs to be cleaned and maintained regularly to remove surface dirt and other impurities. Conclusion As an efficient and reliable adsorption tool, vacuum suction cups play an important role in various fields. With the continuous advancement of technology and the diversification of application needs, the design and application of vacuum suction cups will be further developed and innovated. In the future, we look forward to seeing more vacuum cups with unique functions and excellent performance applied to production practices, bringing more convenience and benefits to people's lives and work. Welcome your visit and your suggestion. OEM & ODM welcomed! #handtool #powertools#bestrobotvacuum www.shruili.com

0 notes

Text

The electric type of vacuum suction device can be applied in feeding and blanking of the glass, sheet metal, marble, etc. material.

The maximum weight capacity can be 2500KGS.

We will ODM the most suitable sheet metal vacuum lifting equipment for you that ensure can use for almost 10 years without problem.

Easy for handle and operate, less humanity, less cost and high efficiency.

Vacuum lifter / Vacuum Suction Lifting Machine

For 500kg or below, we apply with pneumatic type, which apply with pure pneumatic system, no need to connect electricity, no charge, pneumatic lifting and pneumatic adsorption. For 500KG or above, we apply the electric type which is more safe and durable use

We adopting German Becker large-flow vacuum pump with extremely large flow and strong suction, which is safe and reliable, The vacuum pads we adopt high strength wear resistant acrylonitrile-butadiene rubber which with longer quality guarante period for 18 monthes

The suction cup is made of cast aluminum with one time high pressure die casting molding, which is light weight, high strength, detachable suction cup rubber, easy to replace environmental friendly.

Diverse Lifting Equipment for Meeting Your Needs

Three types to be designed as per your acutal needs, pneumatic type, electric type or battery type. For 500kg or below, we apply with pneumatic type, which apply with pure pneumatic system, no need to connect electricity, no charge, pneumatic lifting and pneumatic adsorption. For 500KG or above, we apply the electric type which is more safe and durable use.

Customerized size and lifting solutions, The pads quantity and size and vacuum pads position etc. details according to your actual use. Sucker position can be adjusted to meet size changes of different plates.

For some sheet with oil or uneven surface, especially for thin metal plates, our sucker device with special ball head design which can adsorb the material in uneven condition. And if the material with oil, actually it is better for our rubber have better air tightness.

Folk job also available.

Special Designs for Ensure Safty

Equiped with check valve and large capacity accumulator, when in the accidental power failure, the workpiece can still remain in the sucker position for 5-30 minutes for your handling.

Vacuum leak alarm system, which can ensure that the equipment works safely above the standard vacuum.

Special ball head design for our vacuum cups which can adsorb the material in uneven condition. And if the material with oil, actually it is better for our rubber have better air tightness.

For Vacuum Pads design, Normally we use pads with 2 sizes, one is Diameters 300mm, one is diameters 230mm, diameters 300mm can load 200kgs/pcs, and Diameters 230mm can load 100kgs, if the weight is 1000kgs, so we need at least 5 pcs of the Diamters of 300mm, normally will use 6pcs. For each device, we will consider with some extra capacity to make sure the safety to use.

0 notes

Text

What are the key benefits of using vacuum lifters for heavy lifting and load transfer?

Vacuum lifters have revolutionized the field of heavy lifting and load transfer by offering numerous key benefits. These innovative devices utilize vacuum technology to securely grip and move heavy objects, making them an ideal choice for various industries such as manufacturing, construction, logistics, and warehousing. Let's explore the key benefits of using vacuum lifters for heavy lifting and load transfer.

Enhanced Safety: One of the primary advantages of vacuum lifters is their ability to enhance safety during lifting operations. Traditional lifting methods, such as cranes or forklifts, often involve manual handling and pose significant risks to workers. Vacuum lifters eliminate the need for manual intervention, reducing the chances of accidents, injuries, and strains associated with heavy lifting. The secure vacuum grip ensures that the load remains stable throughout the lifting process, minimizing the risk of dropping or shifting.

Increased Efficiency: Vacuum lifters offer increased efficiency in heavy lifting and load transfer tasks. They provide quick and seamless lifting operations, reducing the time and effort required to move heavy objects. The vacuum technology enables swift attachment and detachment of loads, streamlining the overall workflow and enhancing productivity. Additionally, vacuum lifters can handle a wide range of load sizes and shapes, allowing for versatile applications in diverse industries.

Versatility and Adaptability: Vacuum lifters are highly versatile and adaptable, making them suitable for a wide range of lifting scenarios. They can be used to lift various types of materials, including glass panes, metal sheets, concrete blocks, machinery components, and more. Vacuum lifters are designed with adjustable suction cups and lifting frames, allowing them to accommodate different load sizes and configurations. This versatility enables operators to efficiently handle different lifting requirements without the need for multiple lifting devices.

Damage Prevention: Traditional lifting methods often involve the use of slings, hooks, or clamps, which can cause damage to the load being lifted. Vacuum lifters eliminate the risk of damage as they utilize vacuum suction to grip the load securely without exerting excessive force. The vacuum lifters distribute the load weight evenly across the suction cups, preventing any concentrated pressure points that could potentially cause damage. This makes vacuum lifters particularly suitable for lifting delicate or fragile materials, such as glass or ceramics.

Ergonomic Design: Vacuum lifters are designed with ergonomic considerations in mind, prioritizing the well-being of the operators. These devices are typically equipped with user-friendly controls, allowing operators to handle lifting operations with ease and precision. By minimizing physical strain and eliminating the need for repetitive manual lifting, vacuum lifters help reduce the risk of work-related injuries and musculoskeletal disorders among workers.

Cost-effectiveness: While the initial investment in vacuum lifters may be higher compared to traditional lifting equipment, they offer long-term cost savings. The efficiency and productivity gained from using vacuum lifters result in reduced labor costs and increased operational throughput. Moreover, the prevention of damage to lifted objects reduces the need for repairs or replacements, leading to additional cost savings over time.

In conclusion, vacuum lifters provide significant advantages in heavy lifting and load transfer applications. From enhanced safety and increased efficiency to versatility, adaptability, and damage prevention, these devices offer a reliable and efficient solution for various industries. The ergonomic design and cost-effectiveness further contribute to the appeal of vacuum lifters as a superior alternative to traditional lifting methods. By incorporating vacuum lifters into their operations, businesses can optimize their lifting processes, improve workplace safety, and achieve higher productivity levels.

Our Location: Vacuum lifting hire : 96 Annesley Street, Echuca, VIC 3564, AUS

0 notes

Text

The Best Vacuum Lifters for Your Business

The Different Types of Vacuum Lifters

Vacuum lifters are often used to move heavy objects. They can be used for many different purposes like moving furniture, lifting vehicles, and lifting other random heavy objects.

Vacuum lifters are not just bulky, expensive machines. They can also be found in many different forms like a vacuum lifter with a long hose or a vacuum lifter with wheels. . The uses of vacuum lifters are endless and they can be used in any situation. A vacuum lifter is an up-and-down hoist with a chamber or bellows, on either end of the cylinder, which creates a partial vacuum as the hoist moves up and down. The large piston at one end pushes air out through a small opening near.

Lifts All is one of the brands most known for vacuum lifters; they supply sack lifters, barrel lifters, box lifters, drum lifters, crate stackers, concrete block grippers, roll lifters, gas cylinder lifters, water tank lifters, clutch cover lifters, canister grabs, windscreen lifters, car door lifters, and plenty more - you get the gist. There’s a vacuum lifter for practically every purpose. Dale Lifting supplies this brand of vacuum lifter and many more material handling equipment.

What is Vacuum Lifting Equipment?

Vacuum lifters are used to move heavy items that would be difficult to lift by hand. They work by using a vacuum cleaner to create a seal around the object and then using the suction power of the vacuum cleaner to lift it.

Vacuum lifters are best for lifting objects that are too heavy for one person to move. They can also be used on surfaces that have a high risk of slipping, such as slippery floors or wet surfaces. Vacuum lifters can be expensive, but they are often worth the cost due to their versatility and how productive and efficient they can make your business operations. They are great for moving large pieces of furniture and heavy boxes, as well as any other item that is too heavy for one person to lift.

Conclusion: Start Buying the Correct Type of Vacuum Lifting Equipment Without Wasting Money On Wrong Ones

Vacuum lifting equipment is a device that lifts heavy objects using air pressure. Vacuum lifters are used to move heavy items that are difficult to carry, such as furniture, appliances, construction materials, etc. They can also be used to lift items from high places that cannot be reached by other means.

The best vacuum lifting equipment for your needs depends on your specific requirements: whether you are looking for a manual or an electric model; how often you will use it; if you need it for commercial or residential purposes; and how often you will transport items up flights of stairs. The most important features of a vacuum lifting equipment are the size, weight capacity, lift height, lift speed and power of the device. There’s a vacuum lifter for everything; you just have to find it. The best place to start is on the Dale Lifting website - they’re experts in all things to do with lifting equipment.

2 notes

·

View notes

Text

Get Vacuum Excavator Rental from the Most Reliable Organisation

A vacuum and compressed air are used in air vacuum excavator rental to break up the dirt, which is subsequently sucked into the tank. Usually, this procedure is employed to protect the integrity of subsurface services that cannot tolerate water pressure.

Hire a duct lifter, also known as a material hoist, are telescopic masts that may be controlled by hand and are used to move large items like ductwork and other construction supplies. A crane is a tool for lifting or moving objects. Hoists may be electro-hydraulic, manually controlled with a lever, base attached or pendant cranes.

Learn More in Detail about Licence from Experts

Consumers looking for fast fixes might rent affordable equipment from manufacturers to save further purchase and storage expenditures. They provide all the equipment you want, including boom forklifts, heavy equipment, and other devices.

Simple Operation: These elevators are very easy to use. Because operators can learn how to use it in a few days, this also suggests that you can utilise it with little to no downtime.

Small Size: A scissor lift is the smallest kind of aerial surface of the work piece you will ever come across.

Minimum Floor Space: Hoists are among the most transportable lifting devices, but other raised work platforms need a large amount of floor space to operate.

Since the entire amount of space required is almost equivalent to the size of the surface that can be elevated, these lifts are easy to store. As an alternative, you could equip it spinning so that in addition to lifting the platform, it can also spin.

Source

0 notes

Photo

https://www.skilifters.com/vacuum-lifter.htmlWe at SHREE KRISHNA INDUSTRIES are one of the leading Vacuum Lifters in India/manufacturers and suppliers of Vacuum Lifters in India, from Pune. Our vacuum lifter manufacturer company designs these equipment’s using the variety of premium standard components to meet the wider application requirements of our clients.

We provide vacuum lifters having horizontal handling system having maximum lifting capacity up to 200kg. They work in the single-phase voltages and comprise of suction cup type of vacuum lifter so it can easily carry greater amount of load with higher strength.

INFO AND ITS USES!

Vacuum Lifter is a kind of device which is used for transporting various products within the specific area like that of a manufacturing faculty or warehouse.

These Vacuum Lifters can be used in delicate applications like placing the eggs in egg cartons as well as for heavy duty loading works. The lifters use suction pumps for their working as these pumps create vacuum and the atmospheric pressure gets eliminated in the suction cup enclosure. They are capable of lifting, moving loads, loading and unloading loads etc.

For Ferrous and Non Ferrous and Similar Rigid Materials.Handling of Sheet Metal

Safe and Ergonomically – for many different Objects and Applications. Damage-free gripping and movement of laser-cut sheet metal, particularly those made from stainless steel; even with apertures and coated with oil.

Injury-free handling of heavy and unwieldy work pieces by a single person.

Gripping of parts made of non-magnetic steel and non-ferrous metals.

Reduced machine-loading times.

Energy-independent handling with the aid of existing overhead cranes.

Handling types : horizontal.

Ideal for Sheet Metal Handling From Stack or Storage Systems.

Cut Out Parts in the Range of Vacuum Lifters. Suction pads can be lifted.

Various possible dimensions metal sheets can be lifted.

https://www.skilifters.com/vacuum-lifter.html

https://www.skilifters.com/vacuum-lifters.html

https://www.skilifters.com/

#vacuumlifter#vacuumlifters#vacuumliftermanufacturersIndia#vacuumlifterssuppliers#vacuumliftermanufacturers#vacuumliftersuppliers

0 notes

Text

Injection mold china

Secrets to success — Injection Molding.... Having completed the Tools of the Trade arrangement on circuit board gathering, we should take a gander at a portion of the regular techniques for doing fenced in areas. In the first place, and perhaps the most widely recognized, is infusion shaping. This is the way toward taking hot plastic, spurting it through a little opening and into a hole, allowing it to cool, and afterward eliminating the solidified plastic framed looking like the cavity.

The actual machine has three significant parts; the container, the screw, and the shape. The container is the place where the plastic pellets are unloaded in. These pellets are small bits of plastic, injection mold china and if the item is to be shaded there will be colorant pellets added at some proportion. The container will likewise typically have a dehumidifier appended to it to eliminate however much water from the pellets as could reasonably be expected. Water botches the interaction since it disintegrates and makes little air bubbles.

Next the plastic bits go into one finish of the screw. The screw's responsibility is to turn gradually, constraining the plastic into ever more modest channels as it goes through a warming component, blending the softened plastic in with the colorant and getting reliable shading, temperature, and truly expanding pressure. When the plastic is coming out the opposite finish of the screw, and with the help of a water powered jack, it tends to be at many huge loads of pressing factor.

At long last, the plastic enters the form, where it courses through channels into the vacant depression, and permitted to sit momentarily to cool. The shape at that point isolates and ejector pins push the part out of the hole.

The form is the place where all the energizing activity occurs, and we'll zero in on that. Most shape are made out of one or the other aluminum or steel. Aluminum is incredible on the grounds that it takes into consideration modest tooling that can be made rapidly, yet it has the drawback of just going on for 5-50 thousand shots (a shot is the term for one pattern of the form to produce a section). Steel is utilized on most shape, and goes on for countless shots.

In some cases you can have a family shape, where you shoot numerous parts into a similar form. For instance, you may have a nook that has a front piece, back piece, and cover, all made out of a similar material. injection mold china It's smarter to have every one of the three in a similar shape not exclusively to diminish form costs yet in addition to lessen the measure of time to make the parts (three sections in each cycle). Different occasions you may have a little part yet need LOTS of them, similar to a jug cap. For these you need different cavities, where as opposed to shooting a solitary cap at a time and incurring the hour of sitting tight for each cycle for a solitary cap, you have heaps of indistinguishable pits and now you get loads of parts in a similar process duration.

For the ridiculously huge volumes, there are 3D shape that can deliver tremendous amounts of confounded parts. You can probably never manage the cost of a form like this one:

While sourcing a shape from China, there is a gigantic distinction in cost on one basic inquiry: homegrown or trade. A ton of US based infusion shaping organizations will reevaluate their form making to China, have the shape delivered to the US, and afterward run the parts in the US. These molds are made for send out and normally have more excellent steel, better cooling lines, and better consistency across different pits. A shape made for import typically remains in house and the Chinese organization creates your parts for you and boats them to you. They can bear to endure a shot on the expense of the shape since they are compensating for it in the expense of the parts.

Shape Features: Cooling Lines, Ejector Pins, Runners, and Sprue

There are a couple of highlights present in molds. Cooling lines aren't in every one of them, yet they serve a valuable capacity. As the form is utilized again and again, it warms up and would ultimately arrive at the temperature of the dissolved plastic. Normally, when you open the shape just liquefied plastic would dribble out. It's critical to keep the form hot enough that the plastic will stream to all pieces of the shape pit prior to cooling, however cool sufficient that it will solidify in a sensible measure of time to keep the process duration low.

Infusion formed toy leaves behind sprinters intactInjection shaped toy leaves behind sprinters flawless

Ejector pins are little pins that press the part out of the shape. Molds are planned so that each time they open the part will be stuck on a similar side of the form. At that point the ejector pins push them out. Normally the ejector pin is within the parts.

The spout is the place where the screw pushes the plastic in, and afterward the plastic goes through the sprue until it arrives at the sprinters, which course the plastic to the openings of every one of the pits, called entryways. In the event that you've at any point assembled a model plane, you understand what the sprinters and sprue are; they're the round channels that hold the plastic pieces together. Likewise significant is the splitting line, which is the line around the part where the two parts of the form meet up.

Molds with Multiple Parts

Most shape are basic in that they just require two sections that meet up and separated. They are way less expensive and last more. However, now and then it's important to have highlights that require undermines or side openings or things that are simply unrealistic with a straightforward form. There are still loads of inventive answers for keep away from this, and workarounds that get you close, however overall you should focus on a straight shape. At the point when that is impractical, however, you have sliders and lifters, which are portions of a form that roll in from a side, and altogether increment the expense and intricacy of a section. That is the reason you'll frequently see side openings off the splitting line; it's a method to make an opening without requiring a slider since it's only two parts of an opening set up at get together time.

Molds with slidesMolds with slides Generally you can take a gander at a section that has been infusion shaped and distinguish some exceptionally predictable highlights (it's a cycle that has been around for quite a long time, so a few dependable guidelines have been created). To begin with, you'll discover the splitting line. In the event that you see a snap include, you can search briefly separating line where a slide comes in. Next you'll discover the ejector nail imprints to within the part, generally in the sturdiest pieces of the piece. At that point you'll discover the door, which is the place where the plastic enters the pit.

On messy molds that have been run for quite a while, you'll see something many refer to as glimmer. This is the place where the metal has worn out, ordinarily at the splitting line or the ejector sticks, and slender fragments of plastic are framed in that unfilled space. Here and there it's less expensive to simply utilize somebody with a blade to remove the glimmer, yet typically it's a sign that it's the ideal opportunity for another form. You'll likewise see ribs, which add solidarity to the part without adding heaps of mass. Furthermore, you'll see that the entire part has a steady divider thickness.

configuration solid shape greenBosses (for holding screws) ought to be counterbalanced from the dividers to keep the dividers from being excessively thick there. At the point when you have thick segments, they will in general therapist when they cool, prompting a thing called a sink mark. You'll see them on inadequately planned parts. On the off chance that you need to actually contact these things, look at the Protomold Design Cube (or look at their broad assets for planning parts to be infusion shaped).

Getting Setup

Infusion shaping isn't modest, and isn't incredible on the off chance that you just need a couple of something. By and large, a manufacturing plant will charge an expense each time you need to do a run of parts since they need to pay for the critical measure of time it takes to embed your shape into the machine, run parts until the form is the correct temperature, and get all the plastic from the past work out and the shaded plastic for your work in the screw.

In case you're searching for model amounts, similar to one two or three hundred, there's another alternative called projecting, in which a positive is machined, at that point a silicon form is made around that positive, and afterward a gum is filled the shape (regularly under vacuum to make up for every one of the shortcomings and get the air rises out). This outcomes in a section that is like what might be made with infusion forming, however with a less expensive shape that is useful for simply a couple to two or three hundred shots relying upon the shape material and part intricacy. We'll cover projecting later.

There is likewise innovative work going into 3D printed molds. These are still new and the quality genuinely low, with the quantity of shots conceivable still very restricted, however it's promising. A third alternative, particularly for little parts, is the drill or arbor press technique, in which you make your own form utilizing a CNC out of aluminum, at that point heat up pellets and utilize the arbor press or drill press to compel it into the pit. One gathering even made a Kickstarter around the arbor press infusion form and figured out how to convey, and another person utilized a 3D printer to expel plastic straightforwardly into a shape.

Infusion shaped parts are all over the place, and there are a ton of assets for figuring out how to configuration parts. A great deal of things should be possible economically in high volume accepting you plan your part explicitly to be infusion shaped. In low volume, however, this isn't the droid device you are searching for.

0 notes

Text

Healthy Fitness Tips | Fitness Diet, Workout Routines

Fix Muscle Mass Faster

Recover quicker from a tough exercise by gently exercising the very same muscular tissues the list below day. Make use of a lightweight-- about 20 percent of the weight you could lift once-- and do two collections of 25 reps. This will provide much more blood as well as nutrients right into your muscles so they fix much faster.

Go for Stamina

Between sets, take 20 to 30 secs to stretch the muscular tissue you simply functioned. Boston scientists found that guys that did this raised their stamina by 20 percent.

Conserve Your Shoulders

Decrease the weight by 10 percent when you alter your grip. So if you have actually been benchpressing 135 extra pounds for 10 reps with a tool grip, drop to 120 pounds when you switch to a wide grip. "You'll be worrying your joints and also muscular tissues in a various way than they're utilized to, which can create injury," says Kinakin.

Eat Meat and also Grow

Eat meat-- 4 to 8 ounces each day-- to grow even more muscle mass. A research reported in the American Journal of Medical Nutritioncompared 2 groups of older male weight lifters: One team ate meat, the other really did not. Both groups expanded stronger, yet just the predators obtained substantial muscle mass. Poultry, turkey, as well as fish count, too.

Pay Currently, Construct Later On

Pay your instructor in advance. "You'll be most likely to follow up on exercise sessions," claims Mejia.

Flatten Your Intestine

Work your undetectable stomach muscles. Your transversus abdominis exists beneath your rectus abdominis-- the six-pack muscular tissue-- and also flattens your waistline when you suck in your gut. Work it with the vacuum: Draw your stubborn belly button toward your back and hold for 10 secs while taking a breath normally. Repeat 5 times.

Dress Better

Acquire only exercise garments that are black, white, or grey. They'll opt for every little thing, as well as you'll never ever once again lose time searching for a T-shirts that matches your gold-and-purple Lakers shorts.

Boost Speed

For faster foot speed in sports, try this relocation: Begin with your feet hip-width apart and your hands at your sides. Raise your left foot in front of you, touch it with your right hand, and reduced it to the flooring. Raise your right foot, touch it with your left hand, and lower it. Then touch your left foot behind you with your right hand, then your ideal foot behind you with your left hand. Go for 20 secs each time, moving as fast as you can, and also repeat for an overall of three to five sets.

Trip Extra Successfully

Method cycling one-legged to ride much more effectively. This pressures you to focus on pulling up below the stroke, which much better disperses the work amongst the significant leg muscle mass. Lock both feet on your pedals, but allow your left leg go limp while you do all the work with your best leg. Do this for 30 seconds, after that switch legs. Ride typically for 5 minutes, after that duplicate the drill. Proceed this way for a 20- to 30-minute workout.

3 notes

·

View notes