#vacuum forming machine manufacturer

Explore tagged Tumblr posts

Text

Ridat AVF: Automatic Vacuum Forming Machine with Dual Ceramic Heaters

Ridat's AVF Series: High-performance Industrial Vacuum Former designed for consistent production of thermoformable materials up to 12mm thickness. User-friendly touch screen controls, dual ceramic heaters, and fully sealed mould chamber. Ideal for automobile parts, aircraft components, bathtubs, toys, and more. Optional features available. Contact us today!

#vacuum former#vacuum forming equipment#vacuum forming machine#industrial vacuum former#vacuum forming machine manufacturer#vacuum forming equipment manufacturer

0 notes

Text

How to Start a Business with Thermoforming Packaging Machine

Hey you! 👋🎥 Ready to kickstart your manufacturing business? 🏭💼 In this artic, W'll show you the step-by-step process of starting a manufacturing business with a thermoforming machine. 💪🔥 Get inspired and take action today! #business #thermoforming

Thermoforming is a manufacturing process that involves heating a plastic sheet and shaping it into various forms using a mold. Thermoformed products are known for their versatility, cost-effectiveness, and durability, making them highly sought after in various industries. It is widely used in industries such as packaging, food, healthcare, and more. The thermoforming industry globally has seen…

View On WordPress

#business ideas#food packaging business ideas#manufacturing business ideas#mini manufacturing business ideas#new business ideas#new business packaging ideas#packaging machine business ideas#plastic thermoforming machine#plastic tray thermoforming machine#profitable manufacturing business ideas#small business ideas#thermoforming#thermoforming machine#thermoforming machine manufacturer#vacuum forming machine

0 notes

Text

Srisai Thermoforming Machines Manufactures with Quality

Sri Sai Thermoforming Machines is your go-to source for exceptional quality, reliable and cost effective Thermoforming Machines. Our products are designed to meet the highest industry standards while offering the best value for money.

Sri Sai Thermoforming provides reliable, cost-effective thermoforming machines to meet your production needs. Our machines are designed to provide quality and efficiency while helping you reduce costs. Get in touch with us today and start your journey towards improved productivity!

Sri Sai Thermoforming Machine Manufacturer is a trusted, reliable source for all your thermoforming needs. Our state-of-the-art machines are designed to provide efficient and reliable production of high quality plastic products. We offer the best price and

Are you frustrated with the slow and labour-intensive process of thermoforming? Our state-of-the-art thermoforming machine offers a revolutionary solution that makes the entire process quick and hassle-free. With our machine, you can save time, energy, and money, while producing high-quality products. Our customers are already raving about the speed and efficiency of our machine - with a 4.5/5 rating across all reviews. Invest in our thermoforming machine today and Are you looking to streamline your production process? Our Thermoforming Machine is the answer. It helps reduce manufacturing time and associated costs by up to 50%, allowing you to produce high-quality products faster and more efficiently. We have over a decade of experience in the industry and have sold thousands of our machines all over the world. With its advanced features, user-friendly interface, and 24/7 customer support, you can trust us to provide a reliable solution for your production needs.

Save Your Time Our Automatic Vacuum Forming Machine

Are you tired of manually vacuuming your floors? Our Automatic Vacuum Forming Machine simplifies the process in just a few steps. Simply turn it on and let it go. It will clean up dirt, dust, and debris from your floors quickly and efficiently. Plus, our product is easy to use, reliable, and affordable. Our customers are already raving about it with 5-star reviews. Don’t waste your time vacuuming manually – let our Automatic Vacuum Forming machine.

The Benefits of Using an Automatic Vacuum Former for Different Industries

Automatic vacuum forming machine is a highly efficient process that has become increasingly popular for manufacturing products in various industries. It offers many advantages over traditional methods, such as improved accuracy, cost savings, and faster production times. This article will explore the benefits of using an automatic vacuum former for different industries and discuss how it can be used to create high-quality products at a lower cost. We will also discuss the use cases of this technology and how it can be used to improve efficiency in various industries. Finally, we will look at the potential future applications of this technology and its implications for the future of manufacturing.

#Automatic vacuum forming machine#Thermoforming Machine Manufacturer#Machine Manufacturer#Thermoforming Machine Manufacture#Thermoforming Machine#srisaithermoforming

0 notes

Text

One of the Greatest Inventions of All Time

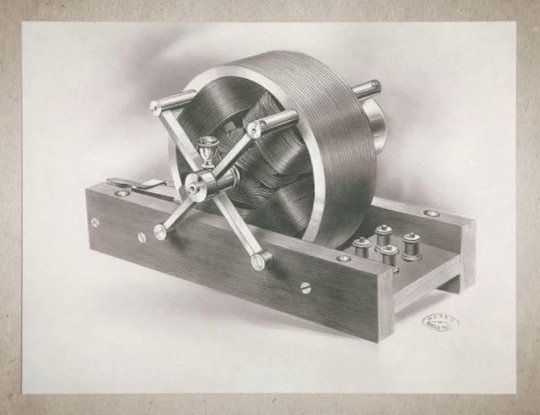

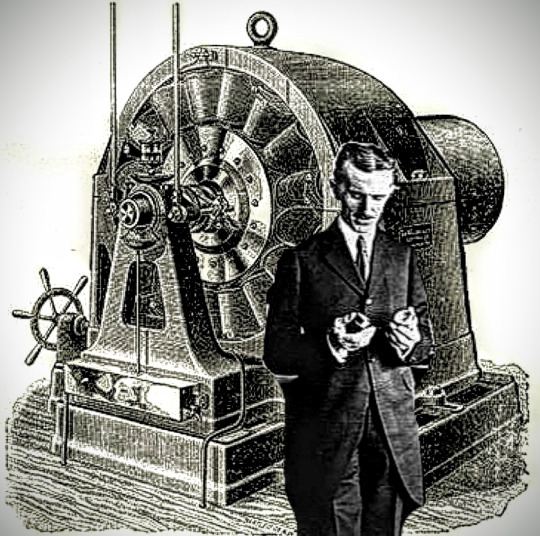

Nikola Tesla has many revolutionary inventions to his credit, but he is best known for his pioneering work in the development and promotion of alternating current (AC) electrical systems. Tesla's innovations in AC technology revolutionized the generation, transmission, and distribution of electrical power, becoming the foundation for the modern electrical power systems that we use today.

There is a common misconception made that Tesla was the first to invent, or discover, AC, but this is not true. It is well-known that Hippolyte Pixii was the first to discover AC in 1832. Pixii was an instrument maker from Paris who built an early form of an alternating current electrical generator (based on the principle of electromagnetic induction discovered by Michael Faraday), and thus started a new industry in power transmission. Tesla was not the first to discover or invent an AC motor, but he was the first to invent a practical AC induction motor with commercial value that could outperform all other motors. It must be noted that Italian inventor Galileo Ferraris also invented an induction motor similar to Tesla's, but it had no commercial value, and he even admitted himself that it was useless. Tesla's induction motor operates on the principle of electromagnetic induction, properly utilizing a rotating magnetic field that induces a current in a stationary conductor, resulting in rotational motion. The utilization of the rotating magnetic field makes the motor more simple, robust, versatile, efficient, and cost effective in that it has less moving parts reducing the likelihood of mechanical failure (as was common in other motors).

Tesla's induction motor became a fundamental component in the field of electrical engineering and is used today in various applications, being one of the most widely used devices in the world. The motors play a crucial role in transmitting electrical power to homes and businesses. They are commonly used in power generation plants to convert mechanical energy into electrical energy, which is then transmitted through the power grid for distribution to various locations. Induction motors are also widely employed in appliances and machinery within homes and businesses for various applications. These applications include conveyor systems, hoists, cranes, lifts, pumps, fans, ventilation systems, compressors, manufacturing machinery, wind turbines, washing machines, refrigerators, garbage disposals, microwaves, dishwashers, vacuums, air conditioners, robotics, electric vehicles, trains, power tools, printers, etc. Basically, anything that requires a spinning action for power.

The induction motor is widely considered one of the most important inventions in the history of electrical engineering. Its importance lies in its transformative impact on industries, its efficiency and reliability, and its role in the broader electrification of society.

#nikola tesla#science#history#invention#discovery#induction motor#electricity#power#goat#ahead of his time#ahead of our time

152 notes

·

View notes

Text

DC-2 (Drink Caddy 2) by Gene Beley (1982), Android Amusement Corp, Irwindale CA. The DC-2 achieved TV fame, appearing in an episode of "CHiPs" called "Day of the Robot" in January 1983.

“The next model, DC-2, one of which was bought by the actor James Caan and some other friends as a present for Mr. Hefner, has a sleek fiberglass body, a color television in its chest, a videotape recorder in its midriff, a color camera in its head, a black plastic drink tray in its chest and other features. Though Mr. Beley believes that technology that could adapt DC-2 to a true robotic form is not far off, he is convinced that the home robot industry will begin with robots that have more entertainment value than practical use. ''It's nice to say you're going to make a home robot that's going to do all kinds of wonderful things,'' he commented, ''but if you ask someone if they'll spend $20,000 for it and they say: 'Are you crazy. I can buy a vacuum cleaner for $200,' it doesn't make sense.'' " – DOMESTICATING THE ROBOT FOR TOMORROW’S HOMES, Peter Applebone, The New York Times, March 4, 1982.

“Dayton’s Department Store, Minneapolis, Minnesota, utilizes a DC-2 robot on a regular basis for promotions. The 4’2” tall robot [middle photo] features a baked-on enamel grey paint job over a sleek fiberglass body with green, flashing L.E.D.s. Electronics include a 9” color TV in the chest, JVC video camera in the turning head, and a VCR.” – ANDROID AMUSEMENT CORP.

“BEVERLY HILLS, Calif. – DC-2, the first robot ever arrested here, was released yesterday after two youngsters apologised in writing for creating a fuss with the 4-foot tall machine. … DC-2 took a remote-controlled walk along a block of North Beverly Drive in this wealthy Los Angeles suburb, passing out business cards bearing the name of Beley’s company, which manufactured it. Police responding to a call of a robot walking the street couldn’t find its human controller and ended up pulling DC-2’s batteries and carting it off – via a tow truck – to the pokey. “The kids had it without permission and were just screwing around.” said Lt. Russell Olson. “There will be no criminal filing.” When police neared the mechanical object, it was heard to say, “Help me! They’re trying to take me apart” ” – Robot back at home after arrest, jail stay, Associated Press.

24 notes

·

View notes

Text

the destiny of cooking oils: an creation to commercial oil press machine.

commercial oil press can be used for multi -plant oils inclusive of mustard, cottonseed, soybean, peanuts, tung seeds, oil sunflower, sunflower seeds and different oil seeds. business oil press gadget integrates an automatic temperature manipulation device. the device can alter the proper temperature to reap one of a kind uncooked substances, clean functions, and simplify the complexity of fried seeds. subsequent, benteng machinery will introduce the functions of commercial oil press machine.

on this basis, our agency released the new and bloodless dual -use multi -beneficial industrial oil press machine. the device has the feature of processing a spread of raw substances. on the equal time, the system is equipped with infrared heating, micro -power control and exquisite filter tool. squeezing oil, the raw additives are right away poured into the device and squeezed it out. it's miles filtered with well -filtered oil. it may be consumed immediately. the gadget is the first to apply 220 luo molybdenum carbon steel, this is more potent than ordinary manufacturers' carbon metallic machines. lifestyles is long, smooth to restore, easy to carry out, robust in response, and high oil output.

commercial oil press is a multifunctional spiral pre -squeezing machine composed of compacting, feeding device, spiral leader, faculty cake mechanism, equipment container and motor. the developments of the spiral pre-squeezing tool are that the hengli tielong works simultaneously, the squeezing is axial phase, and the shell is fixed with the middle thing of the single bolt of the tail tail bolt. warmth form cooling. industrial oil urgent system spirals are segmented structures. a maze -type sealing pads are used among the spiral and the band, which is prepared on the aspect of the spiral. this gadget has a novel design, low priced shape, and a feature of automatic manual college desserts. it can not forestall the hollow of the bore to clean up and update the dearth of harm. the processing amount is large, the energy consumption is small, the land is small, and the rate is low.

commercial oil pressing machines are mainly managed with the aid of automated electric powered manipulate, infrared heating, vacuum filtration, and the host makes use of materials. its processing and production improves the oil output price and the performance reaches the house degree. for all customers who purchase a multi -realistic oil press, all unfastened set up schooling, deliver elements all year spherical, lifelong protection, welcome new and vintage clients. multi -sensible industrial oil -filled oil press is suitable for gadgets and small oil factories, but moreover for people to squeeze present sale and outdoor processing.

our agency mainly produces business oil press machine, its collection of products, and a entire oil manufacturing line. we advise different machines in line with the particular needs of customers. unique raw materials, one of a kind outputs require exceptional varieties of oil press. we will offer you with exclusive customized services and intimate after -sales provider.

you're welcome to get in touch with us and inform us your requirement on oil mill!

2 notes

·

View notes

Text

Rockstar 400 Plate Manufacturers

Vandan Steel & Engg. Co. can become a recognized industry, capable of producing and supplying high-quality ROCKSTAR 400 blades. We are customer-oriented and supply these boards in several standards, widths, lengths, heat treatments and styles . Specifications for special applications also can be provided. Our products meet various quality standards. The wear-resistant ROCKSTAR 400 PLATTEN welding plate has good versatility, like formability, hardness, wear resistance and flatness. Manufacturing requirements.

The Rockstar 400 Plate is a high-strength, abrasion-resistant steel plate with a nominal hardness of 400 HBW (Brinell Hardness). It is specifically designed to endure wear and tear, making it an ideal choice for industries such as mining, construction, agriculture, and heavy equipment manufacturing.

Rockstar 400 has been delivered to customers on the average . Specially developed waste recycling can ensure minimal ductility.Rockstar 400 is right for yellow mining products. Kstar 400 is that the ideal solution for applications like excavators, crushers and truck linings. It also can be found in silos, excavators, conveyor pipes and silos. vacuum , sweeping and tilting the ground . The label is reinforced to make sure the mechanical properties of ROCKSTAR 400. it'll harden quickly and harden again when necessary. After use, it cannot maintain any exchange state outside the temperature range of 250°C. Rockstar 400 isn't suitable. Wear-resistant plates made from manganese, carbon, molybdenum, chromium, sulfur, phosphorus, silicon, boron, nickel and other chemical materials are often used. The palette are often utilized in a spread of applications. These inserts are equipped with heated cutting edges.Various processes like cutting, testing, forming, machining, grinding, etc. are usually performed on these plates with none problems.

Key Features of Rockstar 400 Plate

Wear Resistance With a hardness rating of 400 HBW, the Rockstar 400 Plate offers excellent resistance to abrasion and impact, ensuring a longer lifespan for machinery and structures exposed to harsh environments.

High Strength Its superior tensile strength makes it suitable for heavy-duty applications, reducing the need for frequent replacements and maintenance.

Toughness Despite its hardness, the Rockstar 400 Plate maintains good toughness, allowing it to withstand sudden impacts and harsh working conditions.

Ease of Fabrication The plate can be cut, welded, and machined with proper techniques, making it versatile for various fabrication needs.

ROCKSTAR 400 Plate Specification :

Item: Abrasion Resistant Plate

Thickness : 6mm to 75mm

Length : 6,000mm to 12,000mm

Width : 1,500mm to 2,500mm

Production : Hot-Rolled (HR) / Cold-Rolled (CR)

Applications : concrete industry, metallurgy, fan industry, coal industry, mining machinery, construction machinery,etc.

Heat Treatment: N, Q+T

Material : ROCKSTAR 400 Plates, ROCKSTAR 400 Abrasion Resistant Steel Plates, ROCKSTAR 400 Wear Resistant Plates

ROCKSTAR 400 PLATES CHEMICAL COMPOSITION

Plate ThicknessCMnPSSiCrNiMoBCEPCMmmMax %Max %Max % Max % Max %Max %Max %Max %Max %MaxMax6.0 – 20.00.161.600.0250.0100.700.500.250.250.00400.450.2821.0 – 32.00.181.600.0250.0100.701.000.250.250.00400.480.2932.1 – 50.00.221.600.0250.0100.701.400.500.600.00400.570.3350.1 – 75.00.221.600.0250.0100.701.400.500.600.00400.650.40

ROCKSTAR 400 PLATES MECHANICAL PROPERTIES

Hardness360-430 BHN (On a milled surface 0.5-2 mm below the plate surface)Yield Strength (MPa)Tensile Strength (MPa)% ElongationImpact at -30°C(L0=50 mm)(In Joules)Typical values for 20 mm100012501240

Advantages of Using Rockstar 400 Plate

Cost-Effective: Its long lifespan reduces maintenance and replacement costs.

Increased Productivity: Enhanced durability ensures that machinery operates efficiently with minimal downtime.

Lightweight Design: The high strength of the Rockstar 400 Plate allows for thinner plates, reducing the overall weight of equipment without compromising performance.

Conclusion

The Rockstar 400 Plate is a reliable choice for industries that demand superior wear resistance and toughness. By incorporating this versatile steel into heavy-duty applications, businesses can enhance productivity, reduce costs, and achieve long-term efficiency.

Whether it’s in mining, construction, or agriculture, the Rockstar 400 Plate continues to prove its worth as a durable, high-performance material that stands the test of time.

For more information

Contact: 8828813630

Email id: [email protected]

Address: 359 / 373, Flat -9, 2nd Floor, Minerva Mansion, Svp. Road, Khetwadi, Giragoan, Mumbai-400 004.

0 notes

Text

Welding Machine Supplier in Rajasthan

Success Technologies is a Manufacturer, and Supplier of Welding Machine in Rajasthan, India Our Registered Office and Manufacturing Unit are located in Ahmedabad, Gujarat, India. At Success Technologies, we specialize in offering high-quality welding machines that provide excellent performance, reliability, and versatility for various industrial applications. We design our advanced welding equipment to meet the needs of both professional welders and industrial applications, ensuring precision and efficiency in every weld. A welding machine is a device used to join materials, usually metals, by applying heat, pressure, or both. This process fuses the materials together, creating a strong bond. Welding machines come in various types, including manual, semi-automatic, and automatic systems, each suitable for different applications. You can use these machines for a wide range of welding processes, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), Stick, and Flux-Cored welding. Types of Welding Machine: Spot Laser Welding Machine Fiber Laser Welding Machine Vacuum Forming Machine Features of Welding Machine: High Efficiency: Ensures faster and more consistent welding results. Adjustable Settings: Tailored controls for various welding processes. Durability: Built with robust materials for long-lasting performance. Portability: Compact and lightweight designs available for on-site use. Safety Features: Equipped with overload protection and cooling mechanisms. Low Energy Consumption: Energy-efficient models for reduced operational costs. Can I use a welding machine for both indoor and outdoor projects? Yes, depending on the type of welding machine and its features (such as weather resistance and portability), welding machines can be used for both indoor and outdoor projects. Are there portable welding machines available? Yes, we offer a range of portable welding machines that are lightweight and compact, ideal for mobile welding jobs and on-site repairs. Success Technologies is a Welding Machine Supplier in Rajasthan, India Including Ajmer, Alwar, Anupgarh, Balotra, Banswara, Baran, Barmer, Beaware, Bharatpur, Bhilwara, Bikaner, Bundi, Chittorgarh, Churu, Dausa, Deeg, Dholpur, Didwalna-Kuchaman, Dudu, Dungarpur, Ganganagar, Gangapur City, Hanumangarh, Jaipur, Jaipur, Jaisalmer, Jalore, Jhalawa, Jhunjhunu, Jodhpur, Jodhpur, Karauli, Kekri, Kherthal-Tijara, Kota, Kotputli-Behror, Nagaur, Pali, Phalodi, Pratapgarh, Rajsamand, Salumbar, Sanchore, Sawai Madhopur, Shahpura, Sikar, Sirohi, Tonk, Udaipur. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#Ajmer#Alwar#Anupgarh#Balotra#Banswara#Baran#Barmer#Beaware#Bharatpur#Bhilwara#Bikaner#Bundi#Chittorgarh#Churu#Dausa#Deeg#Dholpur#Didwalna-Kuchaman#Dudu#Dungarpur#Exporter#Ganganagar#GangapurCity#Gujarat#Hanumangarh#India#Jaipur#Jaisalmer#Jalore

0 notes

Text

Rapid Prototyping in Prototype

Rapid prototyping refers to one or several prototypes made first according to the product appearance drawings or structure drawings for checking the appearance or structure reasonableness without opening the mould. With the development of technology, the definition and use of the handpiece has expanded, and it is now more often used to test and validate products, optimize product design, and even used directly as a finished product.

Historical Background and Definition Rapid prototyping technology originated in the 1980s, initially to solve the problems in traditional manufacturing methods, such as high cost and long cycle time. With the development of technology, rapid prototyping has gradually matured and has been widely used in various fields. It is not only suitable for product development, but also has a wide range of applications in software applications, architectural design and other fields.

Process Rapid prototyping processes include a variety of technologies such as Stereolithography (SLA), Fusion Deposition Modeling (FDM) and others. SLA technology initiates the polymerisation of photosensitive resins by means of a light source of a specific wavelength to form polymers, while FDM technology involves the extrusion of melted material in layers. In addition, traditional moulding methods such as vacuum infusion, low pressure casting and CNC machining are also widely used in the production of handmade boards. 1.3D printing: Prototypes are created using a 3D printer by adding material layer by layer. This method allows for fast, low-cost prototyping of products with complex structures. 2.CNC machining: Cutting and engraving of materials by means of computer numerically controlled machines, suitable for prototypes requiring high precision and complex shapes. 3.Vacuum casting: Liquid material is injected into the mould using a mould and then cured into shape, suitable for validation prior to mass production. 4.Rapid tooling: Creation of moulds by means of rapid tooling technology, followed by series production. 5.Injection molding: Mass reproduction using injection moulding machines for situations where mass production is required.

Material There is also a wide selection of materials for rapid prototyping, with common ones such as photosensitive resin and nylon. For small batch production, vacuum casting process can be used, using materials such as ABS and PMMA for replication, followed by subsequent processing such as sanding and spraying with oil. For metal parts, the machining services are mostly used.

Advantages 1.Rapid outputs: Compared to traditional manufacturing methods, rapid prototyping can complete prototyping in a short period of time, greatly reducing product development cycles which suitable for low volume manufacturing. 2.Low cost: 3D printing technology, in particular, allows for the low-cost production of complex structural prototypes and small batches. 3.High flexibility: Can be prototyped using a wide range of materials and techniques, adapting to different design needs. 4.High precision: The ability to accurately replicate the structure, detail and texture of a prototype provides a surface quality. 5.Variety of materials: Polyurethane materials with different properties such as rigid, elastic, transparent or various coloured materials can be selected according to requirements.

Applications 1.Manufacturing and Industrial Applications Rapid prototyping technology enables the rapid production of complex and accurate prototypes, helping designers and engineers to validate design concepts, perform functional testing and evaluate appearance. For parts that need to be produced in small quantities, it offers a cost-effective and flexible solution. 2.Automobile industry Automakers use rapid prototyping technology to rapidly develop prototype automotive parts for performance testing and validation.In addition, it enables the manufacture of personalised automotive parts, such as dashboard panels and door handles, and is used for production tooling. 3.Medical field Rapid prototyping technology enables personalized medical devices, implants and prosthetics to be tailored to a patient's body structure, providing better fit and comfort.In the field of bioprinting, it is used for research in tissue engineering and organ transplantation. 4.Others Rapid prototyping also plays an important role in a number of industries, including aerospace, consumer electronics, and artwork creation, and its applications will become more widespread as technology advances and costs are reduced.

Rapid Prototyping is the process of creating a simple model of a product or project in the early stages of development so that it can be used to validate and test design concepts, features and interfaces. It is a method of rapidly building physical prototypes and iterating on a design with few changes to improve the design.

#design#business#prototyping#autos#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#3d printing services#3d printing#metal 3d printing#3d printed#cnc machining service#vacuum casting#rapid tooling#rapid prototype

1 note

·

View note

Text

Tiger Rugs: A Blend of Elegance and Wilderness

Tiger rugs are more than just home decor; they are an artistic tribute to one of nature’s most majestic creatures—the tiger. These rugs, often featuring intricate designs that replicate a tiger's stripes or its form, bring a touch of wilderness-inspired elegance to any space. Whether crafted using traditional weaving techniques or modern manufacturing methods, tiger rugs are a statement of boldness and sophistication.

Design and Craftsmanship

Tiger rugs come in various styles, from realistic depictions of the tiger's body to abstract interpretations of its striking orange and black stripes. Handwoven tiger rugs are particularly prized for their detail and craftsmanship, often created by skilled artisans who draw inspiration from nature and cultural symbolism. Machine-made versions offer affordability while retaining the bold visual appeal of the tiger motif.

Symbolism and Cultural Significance

In many cultures, tigers symbolize strength, courage, and protection. Displaying a tiger rug in your home can evoke these qualities, while also serving as a focal point that sparks conversation. In Asian cultures, especially in China and India, tiger imagery often has spiritual significance, believed to ward off evil spirits and bring good fortune.

Material and Versatility

Tiger rugs are crafted using a range of materials, including wool, silk, and synthetic fibers. Wool rugs offer warmth and durability, while silk versions are celebrated for their sheen and softness. Synthetic options are budget-friendly and easy to maintain, making them suitable for high-traffic areas. These rugs can seamlessly blend with modern, bohemian, or rustic interiors, adding texture and personality.

Eco-Friendly Alternatives

With rising awareness of environmental sustainability, many brands now offer eco-friendly tiger rugs made from recycled or organic materials. These options allow you to enjoy the beauty of a tiger rug without compromising on ecological responsibility.

Care and Maintenance

Maintaining a tiger rug involves regular vacuuming to keep it free of dust and dirt. Spot cleaning with mild detergents is recommended for stains, while professional cleaning can help preserve the rug's vibrancy over time.

Conclusion

Tiger rugs are a unique fusion of art, culture, and nature. Whether you prefer a lifelike tiger print or a more stylized version, these rugs add character and charm to any room. They’re more than just floor coverings—they’re an homage to the untamed beauty of the wild, inviting a sense of adventure into your living space.

For more info:-

Tiger rugs

1 note

·

View note

Link

Elevate Your Packaging Game with Cutting-Edge Vacuum Forming Machines | Ridat

Explore Ridat, a pioneering UK manufacturer with 60+ years of expertise in Thermoforming Equipment. Unleash the power of advanced Vacuum Forming Machines, engineered for high productivity and long-lasting performance.

#Thermoforming machines#Vacuum forming machines#Pressure forming machines#Plastic molding machines#Plastic manufacturing solutions#Thermoforming#Vacuum Forming#Pressure Forming

0 notes

Text

The Robotic Revolution: How Intelligent Machines Are Changing Everything

Robotics is a field of science and engineering that focuses on designing, building, and using robots to perform tasks. These machines are created to make human life easier by automating repetitive tasks, performing dangerous operations, or even helping in areas like healthcare and education. With advancements in technology, robotics has become one of the most important industries shaping the future.

In this article, we’ll explore what robotics is, its history, types of robots, real-world applications, and the exciting future it promises.

What is Robotics?

Robotics is an interdisciplinary field that combines concepts from computer science, mechanical engineering, electrical engineering, and artificial intelligence. Robots are machines that can carry out tasks automatically or with some level of guidance from humans.

What Makes a Robot?

A robot typically consists of three main components:

Sensors: To gather information from the environment, like cameras, touch sensors, or microphones.

Processors: To process the information and make decisions, often powered by artificial intelligence.

Actuators: To carry out actions, such as moving arms, wheels, or tools.

Why is Robotics Important?

Robotics helps improve efficiency, reduce errors, and perform tasks in dangerous environments where human intervention would be risky. For example, robots are used in space exploration, disaster recovery, and even deep-sea diving.

The History of Robotics

The concept of robots is not new. The idea dates back to ancient civilizations, but modern robotics emerged in the 20th century.

Ancient Robots

Ancient Greece: Mathematicians like Archytas designed early mechanical devices, such as flying pigeons made of wood.

Medieval Period: Inventors created clockwork automatons, mechanical devices that mimicked human or animal movements.

The Industrial Revolution

During the 18th and 19th centuries, the invention of steam engines and mechanical systems laid the foundation for modern robotics. Factories started using automated machines to produce goods more efficiently.

Modern Robotics

The first modern robot, "Unimate," was introduced in 1961 in the automobile industry. It was used to weld car parts, revolutionizing manufacturing. Since then, robotics has advanced rapidly, incorporating AI and smart technologies.

Types of Robots

Robots come in many forms, depending on their purpose and design. Below are the most common types:

1. Industrial Robots

These robots are used in factories for manufacturing and assembly tasks.

Example: Robotic arms used to assemble cars.

Features: High precision, speed, and efficiency.

2. Service Robots

Designed to assist humans in tasks like cleaning, delivery, or personal assistance.

Example: Robotic vacuum cleaners like Roomba or delivery robots in restaurants.

3. Humanoid Robots

These robots are designed to resemble humans in appearance and behavior.

Example: Sophia, the social humanoid robot.

Applications: Customer service, education, and healthcare.

4. Autonomous Robots

These robots can perform tasks on their own, without human intervention.

Example: Self-driving cars and drones.

5. Medical Robots

Used in healthcare for surgeries, therapy, and rehabilitation.

Example: The Da Vinci Surgical System.

6. Military Robots

Used for defense purposes like bomb disposal and surveillance.

Example: Drones and unmanned ground vehicles (UGVs).

Applications of Robotics

Robotics is transforming various industries by providing innovative solutions to real-world problems. Here are some key areas where robotics is making an impact:

1. Manufacturing

Robots are widely used in manufacturing to automate tasks such as assembling, welding, and painting.

Benefits: Increases production speed, reduces costs, and minimizes errors.

2. Healthcare

In healthcare, robots are used for:

Surgery: Robotic arms assist surgeons in delicate procedures.

Patient Care: Robots help with lifting patients or providing companionship.

3. Agriculture

Farming robots are used for planting, harvesting, and monitoring crops.

Example: Drones that spray pesticides or inspect fields.

4. Space Exploration

Robots play a crucial role in exploring outer space, where human survival is impossible.

Example: NASA’s Mars rovers like Curiosity and Perseverance.

5. Education

Educational robots make learning interactive and fun for students. They teach coding, robotics, and problem-solving skills.

6. Hospitality

Robots are used in hotels and restaurants to greet guests, deliver food, and clean rooms.

Example: Robotic waiters in smart restaurants.

How Do Robots Work?

Robots operate based on the integration of various technologies. Here’s how they work step by step:

1. Input Stage

Robots gather information from their environment using sensors. For example, a camera can detect objects, and microphones can pick up sounds.

2. Processing Stage

The robot’s "brain" processes the input data to make decisions. This step often involves artificial intelligence and machine learning algorithms.

3. Output Stage

The robot performs actions based on the processed information. For instance, it might move, grab an object, or display information on a screen.

Challenges in Robotics

Although robotics is advancing rapidly, there are still challenges to overcome:

1. Cost

Robots are expensive to design, build, and maintain, making them inaccessible to smaller businesses.

2. Complexity

Developing robots that can perform human-like tasks is highly complex and requires advanced algorithms.

3. Ethical Concerns

The rise of robots in jobs raises concerns about unemployment. Additionally, the use of military robots brings ethical dilemmas.

4. Safety Issues

Ensuring that robots can safely operate in human environments is a significant challenge.

The Future of Robotics

The future of robotics is incredibly exciting. Here are some trends we can expect:

1. Collaborative Robots (Cobots)

Cobots are designed to work alongside humans in industries like manufacturing and healthcare. They are safer, smarter, and more interactive.

2. Artificial Intelligence

AI-powered robots will continue to improve in understanding and decision-making, making them more autonomous and versatile.

3. Soft Robotics

Robots made from flexible materials will perform delicate tasks like handling soft objects or interacting with humans more naturally.

4. Space Robots

The next generation of space robots will help build habitats on the Moon and Mars, making human space exploration more sustainable.

5. Everyday Robots

In the future, personal robots may become as common as smartphones, assisting us in our homes, offices, and daily lives.

Conclusion

Robotics is a game-changing technology that is revolutionizing industries and reshaping how humans interact with machines. From manufacturing to healthcare and space exploration, the potential of robotics is limitless.

1 note

·

View note

Text

What You Need to Know Before Buying a Vacuum Pump

Vacuum pumps are crucial in various industries, from manufacturing to HVAC systems and even automotive repair. If you're in the market for a vacuum pump, it's important to understand the different types, features, and applications to make the best choice.

In this guide, we’ll discuss everything you need to know before buying vacuum pumps in Australiato ensure you invest in the right tool for the job.

What Is a Vacuum Pump?

A vacuum pump is a device that removes gas molecules from a sealed volume to create a vacuum. This process is essential in many fields, including scientific research, chemical processing, and industrial manufacturing. Various types of vacuum pumps are available, and each type is designed to suit specific applications.

Types of Vacuum Pumps

Before purchasing a vacuum pump, you should know the main types available on the market. Here are three of the most common types:

Positive Displacement Pumps: These pumps trap a volume of gas and move it through the pump’s chamber to create a vacuum. They are ideal for achieving a low vacuum level.

Momentum Transfer Pumps: These pumps use high-speed jets to knock gas molecules out of the chamber. They are best for high and ultra-high vacuums.

Entrapment Pumps: These pumps capture gas molecules on cold surfaces or through chemical reactions. They are used when a near-perfect vacuum is required.

When choosing a vacuum pump, consider what type of vacuum you need and which type can best achieve that. Vacuum Pumps Australia offers various options to cater to different industries.

Key Factors to Consider Before Buying a Vacuum Pump

Once you’ve determined the type of vacuum pump you need, several factors must be considered to ensure you get the right pump for your specific application.

1. Pumping Speed

Pumping speed refers to how quickly a vacuum pump can remove gas from a system. Measured in litres per second (L/s), this is important if you're working with larger volumes or need to reach a vacuum level quickly.

2. Ultimate Pressure

Ultimate pressure is the lowest pressure a vacuum pump can achieve. This will depend on the type of pump and the application. For example, some processes require a rough vacuum, while others require a high or ultra-high vacuum.

3. Durability and Maintenance

Vacuum pumps are long-term investments, so choosing one that is durable and easy to maintain is essential. Look for pumps made from high-quality materials, and consider the ease of finding replacement parts and service. At Vacuum Pumps Australia, you'll find pumps from trusted manufacturers known for their reliability and long lifespan.

Typical Applications of Vacuum Pumps

Vacuum pumps are versatile tools used across various industries. Here are some of the most common applications:

HVAC Systems: Vacuum pumps remove moisture and air from refrigeration and air conditioning systems.

Automotive: Vacuum pumps are essential for braking systems and other vehicle components.

Medical Equipment: Vacuum pumps are used in devices like suction machines and sterilisers in the healthcare sector.

Manufacturing: Vacuum pumps are widely used in vacuum forming, packaging, and degassing processes.

No matter the industry, you’ll find suitable models for each application at Vacuum Pumps.

How to Maintain Your Vacuum Pump

Regular maintenance is key to ensuring the longevity and performance of your vacuum pump. Follow these tips to keep your pump in optimal condition:

Oil Changes: If you’re using an oil-sealed pump, regular oil changes are essential to maintain efficiency and prevent damage.

Leak Checks: Regularly inspect the pump and system for leaks; even small leaks can affect performance.

Filter Replacement: Change the filters periodically to prevent clogging and ensure smooth operation.

Conclusion

Buying the right vacuum pumps in Australia involves understanding your needs and considering key factors like pumping speed, ultimate pressure, and durability. Whether working in HVAC, automotive, or manufacturing, finding the right vacuum pump is critical to achieving the desired results.

0 notes

Text

Processing performance of Tantalum

Processing performance

Tantalum has good plasticity, low deformation resistance, and low process hardening. It can be processed into plates, strips, foils, pipes, rods and wires at room temperature.

Tantalum can be formed into various devices & parts using traditional processes, equipment and tools such as metal spinning, deep drawing, bulging, bending, punching & cutting, stamping and drawing.

Machinability

The mechanical properties of fully recrystallized pure tantalum are similar to soft copper. In order to meet the tolerance and surface roughness requirements, the following machining method can be used: turning, milling, grinding and reaming, boring, tapping and others.

Welding performance

Tantalum has the best welding performance amount all refractory metals, and can be welded with carbon steel, stainless steel, nickel alloy, titanium alloy, etc. Electron beam welding and inert gas shielded tungsten arc welding can be used to weld tantalum chemical equipment components with ductility-brittleness transition temperature below room temperature, which can meet the requirements of chemical industry. Tantalum-Steel composite materials can be prepared by explosive welding, which is an effective way for manufacturing tantalum lining of large-scale corrosion-resistant equipment. We can use silver solder, copper solder and several special high-melting metal solder alloys for tantalum soldering connection.

Welding and brazing must be performed under vacuum or high purity inert gas. Resistance welding or seam welding can be performed in air or underwater.

Heat treatment

For best processability, tantalum is often used at a stress-relieved or recrystallized temper. The recrystallization temperature is determined by the purity, the amount of cold work, and historical conditions. Recrystallization temperature of pure tantalum plate with specific thickness is 1000-1250 ℃.

https://www.etimaterials.org/tantalum/ https://www.etimaterials.org/tantalum/tantalum-plate/

0 notes

Text

Tooling for Cold Heading and Thread Rolling Machines: The Backbone of Fastener Manufacturing

In the fast-paced world of manufacturing, precision and efficiency are paramount. Among the many industrial processes, cold heading and thread rolling are critical for producing high-quality fasteners like screws, bolts, and nuts. At Taiwan Metiz Alliance (TMA), we specialize in designing and producing tooling solutions that cater to these essential processes. With over 25 years of expertise and innovation, TMA has established itself as a trusted global partner for manufacturers seeking reliable, efficient, and high-performing tooling for cold-heading and thread-rolling machines.

Understanding Cold Heading and Thread Rolling

Cold heading is a process where metal wire or rods are shaped into fasteners without heating, utilizing high pressure and advanced dies. This method produces parts with exceptional strength due to the preservation of the material's grain structure. On the other hand, thread rolling involves forming threads onto fasteners by pressing them between hardened dies, ensuring consistent thread profiles with minimal material waste.

Both processes rely heavily on the quality of the tooling used. Accurate tooling not only enhances the product's durability and functionality but also optimizes manufacturing efficiency by reducing downtime and material costs.

TMA’s Expertise in Cold Heading Tooling

At TMA, we offer a comprehensive range of cold-heading tooling designed to meet diverse manufacturing needs. Our products include:

Header Punches and Pins: Manufactured using premium Japanese and European steels, our punches are precision-engineered for creating complex slots such as marking, piercing, and forging. Available in standard formats like JIS (Japan), ANSI (US), and DIN (Germany), we also offer custom punches tailored to specific customer requirements.

Heading and Cutting Dies: These are crafted with advanced coatings like titanium nitrides and carbides, enhancing wear resistance and extending tool life.

Specialized Tools: From slugger punches to first-pass punches, we provide solutions for cold heading tasks involving intricate geometries and high tolerances.

Each TMA tool undergoes rigorous quality control and testing on high-precision European measuring equipment to ensure flawless performance in high-volume production environments.

Thread Rolling Tooling by TMA

Thread rolling tooling is another cornerstone of TMA’s product portfolio. We design and manufacture flat and profiled thread-rolling dies tailored to rolling metric and inch threads on fasteners, including self-tapping screws, bolts, and specialty products. Key highlights of our thread rolling tooling include:

Material Excellence: Made from high-speed steel (HSS) and high-alloy tool steels sourced from Japan and Germany, our dies are heat-treated for exceptional hardness and strength.

Precision Engineering: Our thread rolling dies are manufactured using state-of-the-art CNC machinery, ensuring dimensional accuracy and superior thread quality.

Durable Coatings: To enhance tool longevity, we apply advanced coatings like titanium carbides and nitrides, reducing wear and maintaining sharpness even in high-speed operations.

Custom Designs: TMA provides bespoke thread rolling dies to accommodate unique fastener designs, meeting the needs of industries like automotive, aerospace, and construction.

Why Choose TMA for Tooling Needs?

Quality Assurance: Our ISO 9001:2015 certification reflects our commitment to producing tooling solutions that meet the highest industry standards. Each product is subjected to strict quality inspections and testing to ensure flawless performance.

Advanced Technology: Equipped with modern EDM machines, vacuum furnaces, and CNC metalworking systems, TMA stays at the forefront of manufacturing innovation. We also utilize advanced computer-aided design software to develop precise tooling solutions.

Expertise and Customization: With over 25 years of experience, our team excels in creating custom tooling solutions tailored to specific production needs. Whether it’s a unique thread design or a specialized heading die, TMA can deliver.

Competitive Pricing: Thanks to Taiwan’s robust manufacturing ecosystem and competition among suppliers, we provide premium-quality tooling at affordable prices, ensuring excellent value for our clients.

Applications and Industries

The tooling solutions from TMA are widely used in industries such as:

Automotive: For high-strength bolts, screws, and specialty fasteners used in vehicle assembly.

Construction: For durable self-tapping screws and bolts in building projects.

Aerospace: For precision fasteners requiring tight tolerances and high durability.

Electronics: For small, intricately designed screws used in gadgets and appliances.

Our tools are trusted by manufacturers around the globe, and known for their durability, functionality, and cost-efficiency.

Partner with TMA for Superior Tooling Solutions

Cold heading and thread rolling are indispensable processes in fastener production, and the quality of tooling significantly influences their outcomes. At Taiwan Metiz Alliance, we take pride in delivering world-class tooling solutions that empower manufacturers to achieve excellence. From header punches and cutting dies to thread rolling dies, every TMA product reflects our unwavering commitment to quality, innovation, and customer satisfaction.Let TMA be your trusted partner for all your tooling needs. Contact us today at [email protected] or call +886-2-278-45675 to discuss how we can support your business.

0 notes

Text

How CNC Workholding Solutions Transform Manufacturing Processes

In the world of manufacturing, precision is everything. When it comes to CNC (Computer Numerical Control) machining, achieving this precision requires robust and reliable CNC Workholding Solutions. These solutions form the backbone of machining operations, ensuring that workpieces are securely held in place for maximum efficiency and accuracy. This blog delves into how CNC Workholding Solutions revolutionize manufacturing processes and why they are indispensable in the modern industrial landscape.

The Role of CNC Workholding Solutions in Manufacturing

Workholding refers to the tools and systems used to secure a workpiece during machining. Without stable workholding, achieving the desired results is next to impossible. Here's why CNC Workholding Solutions are critical in manufacturing:

Enhanced Stability: The workpiece remains firmly fixed, reducing vibrations and ensuring clean, precise cuts.

Safety Assurance: Proper workholding minimizes risks of the workpiece shifting or detaching, protecting both the operator and the machine.

Improved Accuracy: Secure workholding prevents errors, allowing machinists to meet tight tolerances consistently.

Core Types of CNC Workholding Solutions

1. Vises

Vises are perhaps the most ubiquitous workholding tools. These robust clamps secure flat or uniformly shaped parts, making them ideal for milling and drilling. Their simplicity and versatility make them a staple in every CNC shop.

2. Clamps

Clamps are indispensable for irregularly shaped or bulky workpieces. They can work alone or alongside other systems to provide additional stability. Clamps are available in various forms, including manual, pneumatic, and hydraulic options.

3. Fixtures

Fixtures are custom-designed solutions tailored to specific workpieces or tasks. They are ideal for high-volume production runs, ensuring consistency and accuracy across multiple parts.

4. Magnetic Chucks

Magnetic chucks use magnetic force to hold ferrous materials. This method is quick and effective, especially for thin or flat parts, and it minimizes the risk of surface damage.

5. Vacuum Systems

Vacuum systems are perfect for delicate or lightweight materials. By creating a vacuum seal, these systems hold parts firmly without exerting excessive pressure, making them ideal for plastics or composites.

How CNC Workholding Solutions Revolutionize Efficiency

The adoption of cutting-edge CNC Workholding Solutions has transformed manufacturing processes in several key ways:

1. Faster Setups

Modern workholding systems simplify and speed up the setup process. Quick-change solutions, for instance, allow operators to switch between parts or fixtures in seconds, reducing downtime significantly.

2. Greater Repeatability

In manufacturing, repeatability is crucial for producing identical parts in large quantities. CNC workholding ensures consistent placement of the workpiece, eliminating variations caused by human error.

3. Higher Production Rates

With reduced setup times and enhanced stability, machines can run faster and longer. This translates to higher production volumes without compromising on quality.

4. Reduced Waste

Secure workholding minimizes errors, reducing material wastage and rework. This contributes to cost savings and more sustainable manufacturing practices.

5. Longevity of Tools

When the workpiece is stable, cutting tools experience less stress, leading to slower wear and tear. This prolongs tool life and lowers maintenance costs.

Applications of CNC Workholding Solutions

1. Aerospace

The aerospace industry demands extreme precision and tight tolerances. CNC Workholding Solutions ensure that intricate parts, such as turbine blades, are machined to perfection.

2. Automotive

In automotive manufacturing, high volumes of components must be produced with consistent accuracy. Fixtures and modular systems are commonly used for engine components, chassis parts, and more.

3. Medical Devices

The medical field requires parts with impeccable precision. Magnetic chucks and vacuum systems are often used for machining delicate materials, such as titanium implants.

4. Electronics

For small, intricate parts like circuit boards, vacuum workholding is often the solution of choice, ensuring stability without damaging the components.

Emerging Trends in CNC Workholding Solutions

The field of CNC Workholding Solutions is constantly evolving, with new technologies enhancing capabilities and flexibility.

1. Automation

Automated workholding systems integrate seamlessly with CNC machines, enabling faster setups and real-time monitoring. These systems reduce human intervention, boosting efficiency and accuracy.

2. 3D Printed Workholding

With the advent of 3D printing, manufacturers can create custom fixtures tailored to unique workpieces. This approach is cost-effective and offers unmatched adaptability.

3. Modular Systems

Modular workholding systems allow machinists to reconfigure components for different tasks, making them ideal for shops that handle diverse machining jobs.

4. IoT-Enabled Solutions

Smart workholding solutions equipped with sensors can monitor force, alignment, and vibration during machining. This data-driven approach ensures optimal performance and prevents errors.

Choosing the Right CNC Workholding Solutions

Selecting the appropriate workholding solution depends on various factors:

Material Type: Different materials require specific workholding techniques. For instance, ferrous materials work well with magnetic chucks, while plastics may need vacuum systems.

Machining Process: Milling, drilling, grinding, or turning each demands tailored workholding solutions.

Production Volume: High-volume production benefits from fixtures or modular systems, while low-volume jobs may rely on vises or clamps.

Part Geometry: Complex or irregularly shaped parts often require custom fixtures.

Why Invest in CNC Workholding Solutions?

Investing in high-quality CNC Workholding Solutions is an investment in your machining operations. These systems:

Enhance productivity by reducing setup times and errors.

Improve precision, ensuring parts meet design specifications.

Contribute to cost savings by minimizing waste and extending tool life.

Elevate safety standards by securing workpieces effectively.

Conclusion

The importance of CNC Workholding Solutions in modern manufacturing cannot be overstated. These systems are the cornerstone of efficient, accurate, and safe machining processes. Whether you’re a small shop or a large-scale manufacturer, adopting advanced workholding solutions can transform your operations, boosting productivity and ensuring the highest quality standards.

As the industry continues to evolve, keeping up with innovations in workholding will position your business for success in an increasingly competitive landscape. From modular systems to IoT-enabled solutions, the future of CNC Workholding Solutions is bright, offering endless possibilities for manufacturers looking to excel in their craft.

0 notes