#usedinjectionmoldingmachine

Explore tagged Tumblr posts

Text

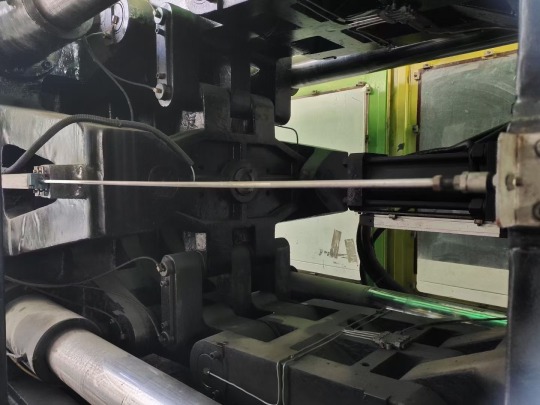

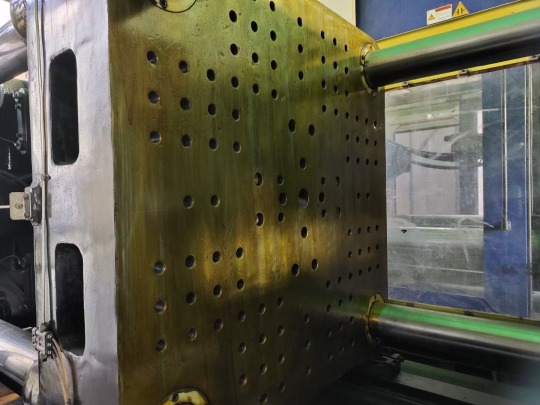

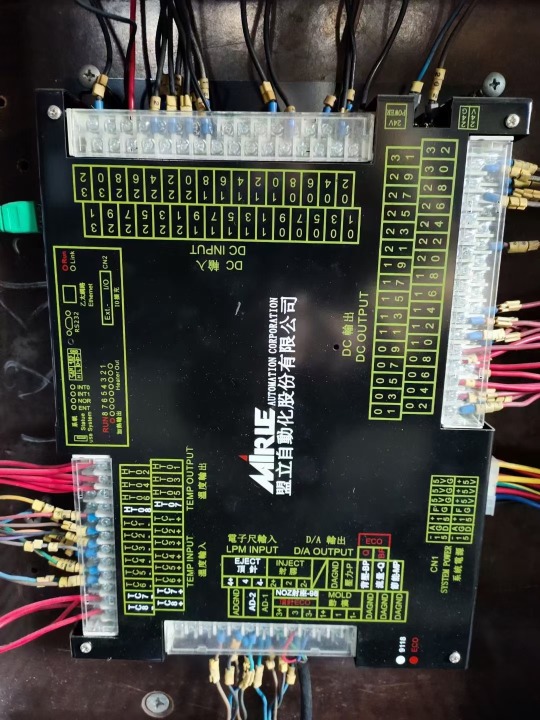

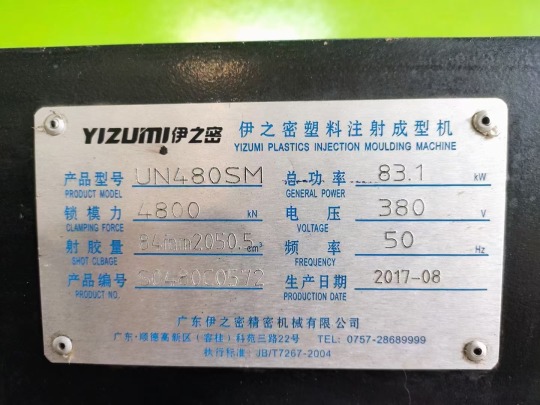

YIZUMI 480T injection molding machine in 90% new for sale.

Contact me on WhatsApp for quite good price: +8613511367730

0 notes

Text

Used injection molding machine in China,ماكينة قولبة بالحقن مستعملة في الصين

Haida 290T, it’s original servo machine,

tie bar distance; 630*630mm

injection glue weight: 1200g

Model: 2023year

payment term : T/T , BTC and USDT;

WhatsApp: wa.me/+8618576477029

#usedinjectionmoldingmachine

#usedplasticmachine

#injectionmoldingmachine

#plasticmachine

#plasticinjectionmachine

1 note

·

View note

Text

The Advantages Of Using A Servo Injection Moulding Machine

The manufacturers of injection molders are working to find new of optimizing their processes. Business owners primarily focus most of their attention towards the energy efficiency factor. Many molders of small and medium parts are now running on electricity. These devices are efficient both in production and in energy savings. On the other hand, hydraulic machines are facing serious issues to make the production process a cost-effective one. In such a situation, one must consider the Servo injection molding machine. The varied uses of servo motors make it difficult for buyers to understand its complex factors. Here you will learn a few things about these devices.

Cleanliness

As mentioned earlier, the medical industry is shifting to the use and manufacturing of electricity-driven molding machines. They improve quality, production speed while keeping everything cost-effective. One main reason why industrialists are opting for servo-driven Used injection molding machine is its cleanliness. The actuation systems of a hydraulic device can contaminate the environment. Even a single leak can result in shutting down of several parts and work cells. Then again, it isn’t worthwhile for medicine industrialists to keep working with a hydraulic molder. It can lead to the formation of a thin coat from the airborne mist exuded by hydraulic machines.

Energy cost reduction

You already know about the impending necessity of reducing production costs. If you aim to cut expenses, then you should consider buying a Servo injection molding machine. Hydraulic and pneumatic systems depend on compressors and energy-intensive pumps. They rely on these components to run continuously while maintaining constant pressure. It has to keep the pressure even when the molding equipment remains idle. As opposed to hydraulic machines, servo-driven devices only need electricity when you activate them. Studies indicated that electricity-driven machines consume lesser energy than hydraulic devices. You can even induce the same benefits on the mold of the injections.

Repeatability and accuracy

Servo motors are the best when it comes to precision and repeatability. It doesn’t matter whether you’re buying a Used injection molding machine of the same variety. If you want exceptional accuracy, then you can program the servo motors through its modified actuation sequences. It enables nuance in speed and force against mechanical latches while allowing better flexibility. The operator of the device won’t have to change the hardware of the lock manually. The machine has systems which you can tweak and automate it to alter its performance factors. Apart from enhanced precision, the controlled closure of servo-driven machines reduce the repeated stress on the molds.

The new generation

The advances in servo technology are introducing new opportunities to create molds. The updates are further allowing retrofitting the existing models. In the end, the manufacturing efficiency and speeds of old devices are increasing. Servo machines are so versatile that you can bring in various configurations. Several motors work together to perform a singular task whenever you need extra torque and force. On the other side of the picture, you can use one engine to activate valve gates for hot runner nozzles. The other motor will simultaneously work to unscrew the threaded parts.

0 notes

Video

instagram

Haituo 5 used injection molding machines deliver to iran! #plasticchair #chairmold #furniture #plasticstool #molddesign #plasticinjectionmold #plasticmold #injectionmold #injectionmoldingmachine #injectionmolding #plasticmolding #toolmaker #moldmaker #chinamachine #chinamold #molder #plasticproduct #usedmachine #newmachine #usedinjectionmoldingmachine (在 Ningbo China) https://www.instagram.com/p/CEjysVCDpCw/?igshid=1h6x9rj86207q

#plasticchair#chairmold#furniture#plasticstool#molddesign#plasticinjectionmold#plasticmold#injectionmold#injectionmoldingmachine#injectionmolding#plasticmolding#toolmaker#moldmaker#chinamachine#chinamold#molder#plasticproduct#usedmachine#newmachine#usedinjectionmoldingmachine

0 notes

Photo

Used HAITIAN 1300T super large injection molding machine, 95% new. Welcome to contact me via WhatsApp: +8613511367730 #usedinjectionmoldingmachine #secondhandinjectionmoulding #haitianmachine #haitianinjectionmachine https://www.instagram.com/p/Cowr_qXKzkP/?igshid=NGJjMDIxMWI=

1 note

·

View note