#ultra high molecular weight polyethylene

Explore tagged Tumblr posts

Text

Ultra-high Molecular Weight Polyethylene Market Focusing On The Basis Of Product, Application, Region And Forecast 2030: Grand View Research Inc.

San Francisco, 11 Sep 2023: The Report Ultra-high Molecular Weight Polyethylene Market Size, Share & Trends Analysis, By Product (Medical Grade & Prosthetics, Fibers, Sheets, Rods), By Application, By Region, And Segment Forecasts, 2023 – 2030 The global ultra-high molecular weight polyethylene market is anticipated to reach USD 5.59 billion by 2030, growing at a CAGR of 12.8% from 2023 to 2030,…

View On WordPress

#Ultra-high Molecular Weight Polyethylene Industry#Ultra-high Molecular Weight Polyethylene Market#Ultra-high Molecular Weight Polyethylene Market 2022#Ultra-high Molecular Weight Polyethylene Market 2030#Ultra-high Molecular Weight Polyethylene Market Revenue#Ultra-high Molecular Weight Polyethylene Market Share#Ultra-high Molecular Weight Polyethylene Market Size

0 notes

Text

Ultra-High Molecular Weight Polyethylene Market Outlook, Forecast 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the global ultra-high molecular weight polyethylene market size at USD 1,906.52 million in 2022. During the forecast period between 2023 and 2029, BlueWeave expects global ultra-high molecular weight polyethylene market size to grow at a significant CAGR of 12.03% reaching a value of USD 3,769.94 million by 2029. Major growth drivers for the global ultra-high molecular weight polyethylene market include an increasing demand from various end-use industries such as healthcare, automotive, electronics, and defense. The market is expected to further witness growth during the forecast period due to heightened demand for the product in defense applications and its exceptional physical attributes in comparison to alternative polymers. The utilization of ultra-high molecular weight polyethylene (UHMWPE) in defense applications is on the rise due to its exceptional properties, including resistance to chemicals, moisture, corrosion, and dirt. Also, the defense sector prefers UHMWPE over conventional metals and polymers due to its advantageous characteristics such as lightweight nature, low friction coefficient, self-lubrication, high impact strength, excellent energy absorption capacity, wide service temperature range, and remarkable wear resistance. In recent years, there has been a notable increase in the number of knee and hip replacement surgeries. Particularly, there has been a change in the pattern, with a growing preference among individuals aged 45 to 60 for these surgical procedures. Advancements in technology have played a significant role in the advancement of better prosthetics, providing patients with extended durability and increased comfort. The expanding elderly population in countries like the U.S., Canada, Germany, Japan, and other nations is projected to stimulate the demand for medical-grade UHMWPE during the forecast period. However, limited availability of raw materials and intense competition from substitutes are anticipated to restrain the overall market growth.

Global Ultra-High Molecular Weight Polyethylene Market – Overview

The global ultra-high molecular weight polyethylene (UHMWPE) market refers to the worldwide market for a type of thermoplastic polymer known as ultra-high molecular weight polyethylene. UHMWPE is characterized by its high molecular weight, typically exceeding 1.5 million g/mol, which gives it exceptional strength, impact resistance, and low friction properties. It is widely used in various industries, including healthcare and medical, automotive, aerospace, defense, food and beverages, and industrial manufacturing. The market encompasses the production, distribution, and consumption of UHMWPE and related products, such as sheets, rods, fibers, and other forms used in different applications. Factors such as increasing demand from various sectors, technological advancements, and the growing need for lightweight, durable, and high-performance materials contribute to the dynamics and growth of the global UHMWPE market.

Sample @ https://www.blueweaveconsulting.com/report/ultra-high-molecular-weight-polyethylene-market/report-sample

Impact of COVID-19 on Global Ultra High Molecular Weight Polyethylene Market

COVID-19 pandemic had a dual mixed impact on the global ultra-high molecular weight polyethylene (UHMWPE) market. While the market experienced a temporary setback due to the disruption in supply chains, labor shortages, and reduced industrial activities during the lockdown measures, it has shown resilience and demonstrated signs of recovery. The demand for UHMWPE in critical applications such as healthcare, medical equipment, and personal protective equipment (PPE) increased significantly during the pandemic. The need for UHMWPE in medical implants, protective gear, and other healthcare-related products contributed to the market's stability and provided growth opportunities amid the challenging circumstances.

Global Ultra High Molecular Weight Polyethylene Market – By Application

Based on application, the global ultra-high molecular weight polyethylene market is divided into Medical Grade & Prosthetics, Filtration, Batteries, Fibers, and Membranes segments. The medical grade & prosthetics segment held the highest share in the global ultra-high molecular weight polyethylene market in 2022. Ultra-high molecular weight polyethylene has emerged as a preferred material for manufacturing medical implants due to its remarkable resistance to wear and abrasion, along with its exceptional durability. UHMWPE is characterized by its long chains, offering flexibility and impressive impact strength. These materials exhibit a lighter weight compared to metals, contributing to their growing demand in medical applications in recent years. This trend is expected to persist throughout the forecast period. Also, the utilization of UHMWPE in joint replacement surgeries is anticipated to drive the demand for the product. Its versatility and effectiveness in such procedures make it a preferred choice. The increasing elderly population, sedentary lifestyles, and changing demographic patterns significantly contribute to the rising number of joint replacement surgeries globally. Consequently, this trend is expected to generate substantial demand for UHMWPE in the foreseeable future.

Competitive Landscape

Major players operating in the global ultra-high molecular weight polyethylene market include Celanese Corporation, LyondellBasell Industries N.V., Braskem S.A., Mitsui Chemicals, Inc., Asahi Kasei Corporation, DSM N.V., Honeywell International Inc., Quadrant Engineering Plastic Products AG, Ticona GmbH, Rochling Engineering Plastics SE & Co. KG, Crown Plastics Co., Inc., Teijin Limited, Toyobo Co., Ltd, Shandong Ningjin Xinxing Chemical Co., Ltd, and Zhejiang Zhongfu Industrial Limited. To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

Environmental Impact of Ultra-High Molecular Weight Polyethylene

A type of plastic recognized for its outstanding strength and durability is ultra-high molecular weight polyethylene or UHMW. It is frequently utilized in a range of commercial and industrial applications, including those in the transportation, manufacturing, and building industries. The manufacture and disposal of UHMW can affect the environment, just like any other substance.

A growing number of people are living longer, especially in developing countries like China and Japan, which is driving up demand for medical services and implants made of UHMW. Therefore, due to its favorable properties and tensile strength. It is extensively utilized by many industries, including electronics, industrial, automotive, industrial, and heavy equipment. Thus, these factors boost the market growth. In addition, according to a research report by Astute Analytica, the global Ultra-High Molecular Weight Polyethylene Market is likely to grow at a compound annual growth rate (CAGR) of 14.7% over the projection period from 2023 to 2031.

Understanding UHMW's environmental effects is crucial for the sustainability of the sectors that use it as well as the health of the environment.

UHMW Disposal

Environmental effects may result from the disposal of ultra-high molecular weight polyethylene, or UHMW. Their molecular structure makes it difficult to recycle, it is frequently dumped in landfills or burned. Methane, a potent greenhouse gas, can be produced due to landfill disposal, which can also affect the quality of the soil and water.

Burning UHMW may produce ash that must be dumped in landfills to emit greenhouse gases and particles into the atmosphere. There are currently few possibilities for the environmentally responsible disposal of UHMW. The development of technology that can disassemble into its constituent pieces for reuse is one effort being made to boost recycling rates. More research is necessary to develop workable options for this material's sustainable disposal.

UHMW Manufacture

Ultra-high molecular weight polyethylene is produced by some processes, including the removal of raw materials, the production of the polymer, and the creation of the final good. These procedures use energy and materials, and trash and emissions may be produced as well.

The utilization of heat and electricity, which can be produced from fossil fuels like oil, coal, and natural gas, accounts for the majority of the energy consumption during the production of UHMW. Different amounts of energy may be needed depending on the product grade being produced and the production process efficiency, different amounts of energy may be needed.

It is produced using ethylene, a hydrocarbon that may be found in crude oil or natural gas, therefore it doesn't require a lot of resources to produce. The processing and extraction of these raw materials may affect the environment, including water use and pollution risk.

Recycling UHMW can lessen the production's negative environmental effects. Recycling can aid in resource conservation and lower the need for new materials. However, it can be challenging to recycle due to its molecular makeup and there are currently few methods for doing so. Development and research finding more environmentally friendly ways to produce and dispose of UHMW.

Content Source: - Ultra-High Molecular Weight Polyethylene Market

#Ultra-High Molecular Weight Polyethylene#business#market research#market report#UHMW#environmental impact#Astute Analytica#Ultra-High Molecular Weight Polyethylene Market

0 notes

Text

1 note

·

View note

Text

Revolutionizing Material Performance: The Rise of Ultra-High Molecular Weight Polyethylene| MarketsandMarkets™

The thermoplastic polymer known as ultra-high molecular weight polyethylene (UHMWPE) has specific mechanical and physical characteristics, such as acceptable biocompatibility, a low coefficient of friction, strong impact strength at cryogenic temperatures, and good environmental stress-cracking resistance. This polyethylene typically has molecular masses between 2 and 6 million amu and has…

View On WordPress

0 notes

Text

Ultra High Molecular Weight Polyethylene Ropes Market Growth Statistics 2023 | Competitive Landscape and Restraining Factors

Ultra high molecular weight polyethylene (UHMWPE) ropes are high-performance synthetic ropes with excellent strength, durability, and low stretch properties. These ropes are commonly used in various applications, including marine, mining, oil and gas, and offshore industries.

Market Overview:

The global ultra high molecular weight polyethylene ropes market size was valued at USD 1.4 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 11.2% from 2021 to 2028.

Drivers and Restraints:

The increasing demand for UHMWPE ropes in various industries, such as offshore, mining, and marine, is driving the market growth. The advantages of UHMWPE ropes, such as high strength-to-weight ratio, low elongation, and excellent abrasion resistance, make them a preferred choice over traditional ropes.

The rising demand for oil and gas exploration and production activities is also driving the market growth. UHMWPE ropes are used in various applications, such as mooring lines, tow lines, and lifting slings, in the oil and gas industry.

However, the high cost of UHMWPE ropes compared to traditional ropes is a major restraint for the market growth. Moreover, the availability of alternative materials, such as aramid and polyester, may also hamper the market growth.

Product Type:

Based on product type, the market is segmented into 3-strand, 8-strand, and 12-strand UHMWPE ropes. The 12-strand UHMWPE ropes segment is expected to hold the largest market share during the forecast period due to its excellent strength and low elongation properties.

Application:

Based on application, the market is segmented into marine and fishing, mining, oil and gas, and others. The marine and fishing segment is expected to hold the largest market share during the forecast period due to the increasing demand for UHMWPE ropes in mooring lines, towing lines, and fishing nets.

Regional Analysis:

Based on geography, the market is segmented into North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Asia-Pacific is expected to hold the largest market share during the forecast period due to the increasing demand for UHMWPE ropes in various applications, such as mining, oil and gas, and marine.

Key Players:

Some of the key players operating in the market include Lankhorst Ropes, Samson Rope Technologies, Cortland Limited, Southern Ropes, Marlow Ropes Ltd., Touwfabriek Langman B.V., and Bridon-Bekaert The Ropes Group. These players are focusing on product innovation and strategic partnerships to expand their market presence.

Conclusion:

The global UHMWPE ropes market is expected to witness significant growth during the forecast period due to the increasing demand for high-performance synthetic ropes in various industries. The marine and fishing segment is expected to hold the largest market share, while Asia-Pacific is expected to be the largest market for UHMWPE ropes. The key players in the market are focusing on product innovation and strategic partnerships to gain a competitive edge in the market. However, the high cost of UHMWPE ropes may hinder the market growth.

#Ultra High Molecular Weight Polyethylene Ropes Market#Ultra High Molecular Weight Polyethylene Ropes Market Growth#Ultra High Molecular Weight Polyethylene Ropes Market Trends

0 notes

Text

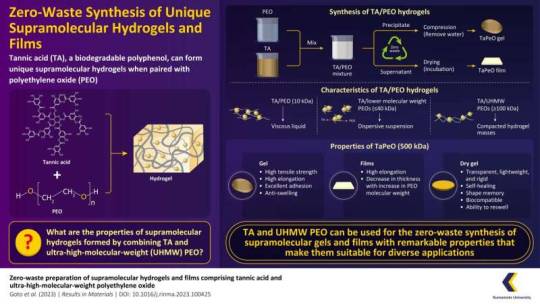

Zero-waste synthesis of new supramolecular materials with remarkable mechanical properties

Researchers from Japan have unlocked the potential of tannic acid and ultra-high molecular weight polyethylene oxide by using them to synthesize strong and smart supramolecular gels in a zero-waste process. These gels exhibit remarkable characteristics, such as high elongation, strong adhesion, resistance to swelling, shape memory, self-healing property, and biocompatibility. Going forward, these innovative, zero-waste gels can have promising applications as advanced medical materials, promoting a sustainable approach to material science. Recent advances in chemistry have allowed for the cost-effective synthesis of supramolecular materials with advanced properties. Due to their unique properties, such as toughness, elasticity, self-healing, biodegradability, and shape memory, these materials find diverse applications as advanced materials in various fields. However, their fabrication often involves time-consuming and complex processes, organic solvents, and waste production, resulting in low yields and high synthesis costs.

Read more.

#Materials Science#Science#Supramolecules#Mechanical properties#Materials synthesis#Gels#Kumamoto University

28 notes

·

View notes

Text

Leading Ultra High Molecular Weight Polyethylene Manufacturers In Saudi Arabia

Our company: Diode Trading Est is a key supplier of Ultra High Molecular Weight Polyethylene (UHMWPE) with high quality products of lasting endurance and function.

Read More:- https://diode.sa/

#ultra high molecular weight polyethylene manufacturers#ultra high molecular weight polyethylene supplier#Saudi Arabia

0 notes

Text

@already-know-this-story liked for a starter!

The doctor inspects the white glove hugging his hand, turning it over in silence and slowly closing his hand into a fist. The dark glasses hiding his eyes don't betray a single emotion. Eggman, usually flamboyant and expressive, is cold and robotic in this moment. Single-minded in his focus.

With a swift motion and a loud slam, he brings his fist down into the surface of the table. A sizable dent is left in the table as he brings his hand back up, unfazed.

Inspecting the glove once more and finding not a single blemish, the doctor smiles and turns to the seamstress. "I have to say, I don't know many tailors who can work with Ultra-High Molecular Weight Polyethylene and make it this comfortable. It seems Breezie hasn't steered me wrong for once. You're quite the talent Ms... Honey, correct?"

3 notes

·

View notes

Text

Choosing the Right High-Performance Plastic for Your Project

When embarking on a project that involves the use of plastic materials, it's crucial to select the right type of plastic. With a plethora of options available, making the correct choice can be a daunting task. However, understanding the properties and applications of high-performance plastics can be the key to success. In this comprehensive guide, we will delve into the world of high-performance plastics, their advantages, applications, and why they are becoming increasingly vital in various industries.

The World of High-Performance Plastics

The realm of plastics is vast, with over 90 base materials to choose from. Selecting the appropriate plastic for your project entails a thoughtful consideration of the desired properties while eliminating materials that don't align with your needs. Notably, some of the most prominent manufacturers of high-performance plastics are based in the United States, including industry leaders such as Ensinger Plastics, Roechling Plastics, Z/L Plastics, and Polymer Industries, among others. These manufacturers are renowned for producing top-quality performance plastics.

Advantages of High-Performance Plastics

High-performance plastics distinguish themselves from standard single-use plastics by possessing superior mechanical toughness, chemical resistance, and thermal stability. These exceptional properties enable their use in applications demanding durability and repeatability. High-performance plastics offer a range of benefits, making them increasingly popular:

Mechanical Toughness: They often outperform traditional materials, including steel, thanks to their impressive mechanical strength.

Chemical Resistance: High-performance plastics excel in resisting chemical degradation, making them suitable for environments where exposure to chemicals is a concern.

Thermal Stability: They can withstand extreme temperatures, allowing them to thrive in applications requiring longevity and performance in challenging thermal conditions.

Common High-Performance Plastic Materials

Several materials fall under the category of high-performance plastics, each with its unique set of characteristics. Some commonly recognized high-performance plastics include:

PTFE: Known for its low friction properties, it's used in applications where reduced friction is critical.

Copolymer Acetal: Offers excellent mechanical properties and dimensional stability, making it a preferred choice in various engineering applications.

UHMW (Ultra-High Molecular Weight Polyethylene): Known for its exceptional wear resistance and lightweight nature.

Nylon 6/6: Combines toughness with ease of processing, making it a versatile choice in many industries.

Polyamide-Imide (PAI): Recognized for its outstanding thermal and chemical resistance, ideal for demanding applications.

High-Performance Plastics in Applications

High-performance plastics are often chosen to replace steel and other substrates, offering superior wear resistance while being significantly lighter. They are also known for their resistance to impact and wear. Moreover, many high-performance plastics exhibit remarkable chemical resistance, making them indispensable in environments with harsh chemicals. Their ability to withstand extreme temperatures makes them ideal for applications demanding durability.

High-Performance Plastics in Construction and Engineering

The applications of high-performance plastics extend to the construction and engineering sectors, where they meet stringent requirements for fire safety. Some high-performance plastics exhibit exceptional resistance to fire and smoke, meeting code requirements for flammability and hazardous gas release. These qualities are particularly crucial in the construction industry. Furthermore, high-performance plastics offer cost-efficiency and reduced weight compared to traditional steel components.

Versatility and Benefits of High-Performance Plastics

High-performance plastics offer numerous advantages over conventional materials. Their flexibility in part design, ease of handling, and lightweight properties make them a preferred choice for various applications. They can effectively replace traditional materials like bronze, stainless steel, glass, wood, and copper, enhancing both quality and performance while potentially reducing costs.

High-Performance Plastics Across Industries

High-performance plastics find applications in diverse industries, such as:

Electric and Electronic Applications: Where their electrical insulating properties are valuable.

Lightweight Design: For creating lightweight yet robust components.

Charging Equipment: In the development of charging stations for electric vehicles.

Battery Solutions: Contributing to the advancement of battery technology.

Sensors for Automated Driving: Enabling the development of autonomous vehicles.

Motor Housings: Providing robust solutions for motor components.

E-Mobility Infrastructure: Including charging terminals for electric vehicles.

Environmentally Friendly High-Performance Plastics

High-performance plastics designed for repeated or multi-use applications contribute to a smaller carbon footprint than materials like glass, steel, or wood. Their durability and ability to perform well under extreme conditions make them environmentally responsible choices. Additionally, the majority of high-performance plastics can be recycled, further enhancing their sustainability.

Conclusion

High-performance plastics are playing a pivotal role in various industries, including transportation, medical, electronics, and industrial applications. Their exceptional properties, which include resistance to extreme temperatures, chemicals, and wear, make them indispensable in demanding environments. Consider high-performance plastics as your material of choice for projects that require top-notch performance and environmental responsibility. As technology continues to advance, high-performance plastics are poised to play an even more significant role in shaping our future.

youtube

Follow Us:

Blogger Weebly Twitter Gravatar Disqus Google Sites Youtube About me

2 notes

·

View notes

Text

The Ultimo Friflo Conveyor Impact Bed by Tega Industries is engineered to provide optimal support to conveyor belts at loading zones, effectively replacing traditional impact rollers. Designed without moving parts, it offers a maintenance-free solution that minimizes belt sagging and enhances sealing efficiency. The impact bed features a three-layer construction—aluminum, rubber, and ultra-high-molecular-weight polyethylene (UHMWPE)—ensuring durability and smooth belt movement. Customized using Finite Element Analysis (FEA) simulations, the structural frames are tailored to specific operational parameters, providing a robust and efficient solution for material handling needs.

0 notes

Text

0 notes

Text

Advantages of Using UHMW Plastic in home furniture near me

Ultra-High Molecular Weight Polyethylene (UHMW) is a high-performance engineering plastic that offers several advantages when used in home furniture near me manufacturing. Here are the key benefits:

Excellent Wear Resistance

Description: UHMW plastic is known for its exceptional wear resistance, which is superior to many other plastics and even some metals. This makes it ideal for home furniture near me parts that experience frequent use and friction, such as chair legs, table edges, and drawer slides.

Benefit: home furniture near me made with UHMW components will last longer and require less maintenance, reducing the need for frequent replacements.

High Impact Strength

Description: UHMW plastic has high impact strength, meaning it can withstand significant impacts without breaking or cracking. This is particularly useful for home furniture near me that may be subjected to accidental drops or heavy use.

Benefit: home furniture near me pieces are more durable and less likely to be damaged during normal use or transportation.

Self-Lubrication

Description: UHMW plastic has excellent self-lubricating properties, which means it reduces friction and wear between moving parts. This is beneficial for home furniture near me components that move, such as drawer slides and hinges.

Benefit: Reduces the need for additional lubricants, which can be messy and require regular maintenance. This also helps in maintaining the smooth operation of moving parts over time.

Low Coefficient of Friction

Description: UHMW plastic has a very low coefficient of friction, making it滑动性能极佳。This property ensures that surfaces slide easily against each other, reducing the effort required to move home furniture near me parts.

Benefit: Easier movement of home furniture near me components, such as drawers and doors, which enhances the user experience and reduces wear over time.

Chemical Resistance

Description: UHMW plastic is highly resistant to a wide range of chemicals, including acids, alkalis, and solvents. This makes it suitable for use in environments where home furniture near me may be exposed to chemicals, such as laboratories or industrial settings.

Benefit: home furniture near me remains intact and functional even in chemically harsh environments, reducing the risk of corrosion and degradation.

Lightweight

Description: UHMW plastic is lightweight, with a density of only 0.935 g/cm³, which is lower than most other engineering plastics and metals.

Benefit: home furniture near me made with UHMW components is easier to move and handle, making it more convenient for users, especially in commercial and residential settings where frequent rearrangement is common.

Biocompatibility

Description: UHMW plastic is biocompatible, which means it is safe for use in medical and food processing environments. This property is crucial for home furniture near me used in hospitals, clinics, and food preparation areas.

Benefit: Ensures that the home furniture near me is safe for use in sensitive environments, reducing the risk of contamination and health issues.

Easy to Fabricate and Weld

Description: UHMW plastic can be easily fabricated and welded using various techniques, such as hot air welding, vibration welding, and laser welding. This makes it versatile for creating complex shapes and structures.

Benefit: Allows for the production of custom home furniture near me designs and components, enhancing the aesthetic and functional aspects of the home furniture near me.

Recyclable

Description: UHMW plastic is recyclable, which means it can be processed and reused, reducing waste and environmental impact.

Benefit: Contributes to sustainability efforts and reduces the environmental footprint of home furniture near me manufacturing.

Conclusion

Using UHMW plastic in home furniture near me manufacturing offers a range of benefits, including durability, low maintenance, chemical resistance, and ease of use. These properties make UHMW plastic an excellent choice for a variety of home furniture near me applications, from high-traffic commercial settings to sensitive medical environments. By leveraging the advantages of UHMW plastic, home furniture near me manufacturers can produce products that are not only functional and aesthetically pleasing but also long-lasting and environmentally friendly.

0 notes