#Ultra High Molecular Weight Polyethylene Ropes Market

Explore tagged Tumblr posts

Text

Ultra High Molecular Weight Polyethylene Ropes Market Growth Statistics 2023 | Competitive Landscape and Restraining Factors

Ultra high molecular weight polyethylene (UHMWPE) ropes are high-performance synthetic ropes with excellent strength, durability, and low stretch properties. These ropes are commonly used in various applications, including marine, mining, oil and gas, and offshore industries.

Market Overview:

The global ultra high molecular weight polyethylene ropes market size was valued at USD 1.4 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 11.2% from 2021 to 2028.

Drivers and Restraints:

The increasing demand for UHMWPE ropes in various industries, such as offshore, mining, and marine, is driving the market growth. The advantages of UHMWPE ropes, such as high strength-to-weight ratio, low elongation, and excellent abrasion resistance, make them a preferred choice over traditional ropes.

The rising demand for oil and gas exploration and production activities is also driving the market growth. UHMWPE ropes are used in various applications, such as mooring lines, tow lines, and lifting slings, in the oil and gas industry.

However, the high cost of UHMWPE ropes compared to traditional ropes is a major restraint for the market growth. Moreover, the availability of alternative materials, such as aramid and polyester, may also hamper the market growth.

Product Type:

Based on product type, the market is segmented into 3-strand, 8-strand, and 12-strand UHMWPE ropes. The 12-strand UHMWPE ropes segment is expected to hold the largest market share during the forecast period due to its excellent strength and low elongation properties.

Application:

Based on application, the market is segmented into marine and fishing, mining, oil and gas, and others. The marine and fishing segment is expected to hold the largest market share during the forecast period due to the increasing demand for UHMWPE ropes in mooring lines, towing lines, and fishing nets.

Regional Analysis:

Based on geography, the market is segmented into North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Asia-Pacific is expected to hold the largest market share during the forecast period due to the increasing demand for UHMWPE ropes in various applications, such as mining, oil and gas, and marine.

Key Players:

Some of the key players operating in the market include Lankhorst Ropes, Samson Rope Technologies, Cortland Limited, Southern Ropes, Marlow Ropes Ltd., Touwfabriek Langman B.V., and Bridon-Bekaert The Ropes Group. These players are focusing on product innovation and strategic partnerships to expand their market presence.

Conclusion:

The global UHMWPE ropes market is expected to witness significant growth during the forecast period due to the increasing demand for high-performance synthetic ropes in various industries. The marine and fishing segment is expected to hold the largest market share, while Asia-Pacific is expected to be the largest market for UHMWPE ropes. The key players in the market are focusing on product innovation and strategic partnerships to gain a competitive edge in the market. However, the high cost of UHMWPE ropes may hinder the market growth.

#Ultra High Molecular Weight Polyethylene Ropes Market#Ultra High Molecular Weight Polyethylene Ropes Market Growth#Ultra High Molecular Weight Polyethylene Ropes Market Trends

0 notes

Text

Glass Fibers & Specialty Synthetic Fibers Market Challenges, Analysis and Forecast to 2034

The Glass Fibers & Specialty Synthetic Fibers Market is a dynamic segment within the materials industry, driven by the increasing demand for lightweight, durable, and high-performance materials across various sectors. These fibers are engineered for applications that require superior mechanical properties, thermal stability, and resistance to environmental factors

The market for glass fiber and specialty synthetic fibers is expected to increase at a compound annual growth rate (CAGR) of 6.4% between 2024 and 2034. According to an average growth trend, the market is expected to reach USD 144.58 billion in 2034. The global market for glass fibers and specialty synthetic fibers is expected to generate USD 85.59 billion by 2024.

Get a Sample Copy of Report, Click Here: https://wemarketresearch.com/reports/request-free-sample-pdf/glass-and-specialty-synthetic-fibers-market/1603

Glass Fibers & Specialty Synthetic Fibers Market Growth Drivers

Urbanization and Infrastructure Growth:

Increasing investments in construction and urban development drive demand for glass fibers.

Rising Defense Budgets:

Governments worldwide are increasing investments in protective equipment using synthetic fibers.

Shift Toward Renewable Energy:

Wind energy projects favor glass fibers for turbine blades.

Advancements in Material Engineering:

Innovations are improving the properties and reducing production costs of synthetic fibers.

Specialty Synthetic Fibers: Types

Aramid Fibers:

Examples: Kevlar, Twaron.

High tensile strength and resistance to impact and heat.

Used in bulletproof vests, fire-resistant clothing, and ropes.

Carbon Fibers:

Lightweight and exceptionally strong.

Applications: Aerospace, sports equipment, automotive (luxury cars).

Ultra-High-Molecular-Weight Polyethylene (UHMWPE):

Examples: Dyneema, Spectra.

Extremely lightweight with high impact resistance.

Used in personal armor, fishing lines, and medical implants.

Polybenzimidazole (PBI):

High thermal and chemical stability.

Used in firefighting gear and aerospace insulation.

Polyimide Fibers:

Heat-resistant fibers ideal for use in high-temperature industrial applications.

Glass Fibers & Specialty Synthetic Fibers Market Challenges

High Costs of Specialty Fibers:

The manufacturing process for carbon and aramid fibers is resource-intensive.

Environmental Impact:

Synthetic fibers contribute to pollution if not recycled properly.

Competition from Emerging Materials:

Natural fibers like hemp and bamboo, as well as metal composites, are gaining attention.

Emerging Trends

Integration with Smart Technologies:

Development of fibers with embedded sensors for structural health monitoring.

Circular Economy Initiatives:

Companies are investing in recycling technologies for glass and synthetic fibers.

Hybrid Materials:

Combining glass and synthetic fibers to create composites with enhanced properties.

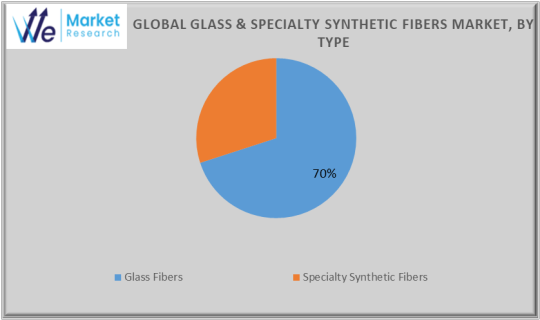

Glass Fibers & Specialty Synthetic Fibers Market Segmentation,

By Type

Glass Fibers

E-Glass

S-Glass

C-Glass

Others

Specialty Synthetic Fibers

Polyester

Nylon

Aramid

Carbon Fibers

Polypropylene (PP)

Others

By Application

Textile

Construction

Automotive

Aerospace & Defense

Marine

Consumer Goods

Packaging

Wind Energy

Others

Key companies profiled in this research study are,

The Global Glass Fibers & Specialty Synthetic Fibers Market is dominated by a few large companies, such as

Owens Corning

Jushi Group

PPG Industries

Saint-Gobain

China National Glass Industrial Group Corporation (CNG)

Nippon Electric Glass Co., Ltd.

Sika AG

DuPont

Solvay

Teijin Limited

Hyosung Corporation

Toray Industries

DSM (Dutch State Mines)

BASF

Asahi Kasei Corporation

Others

Glass Fibers & Specialty Synthetic Fibers Industry: Regional Analysis

Forecast for the North American market

North America will be a significant player in the glass fiber and specialized synthetic fiber industries, accounting for about 40% of the worldwide market in 2023. Due to its technological dominance and strong industrial base in the automotive, aerospace, and defense sectors, North America has a disproportionate amount. North America, particularly the United States, is a major market for glass fibers and specialty synthetic fibers.

Forecast for the European Market

Europe is an essential market for glass and specialty synthetic fibers due to the prevalence of the automobile and aerospace industries there. Countries like Germany, France, and the UK are investing in lightweight materials for cars and airplanes, which directly increases demand for fibers like glass and carbon fibers. The European Union's focus on sustainability and energy efficiency has led to a greater usage of advanced materials, such as carbon fibers for renewable energy applications like wind turbines and glass fibers for construction. Europe is the hub for research and development, particularly in the areas of lightweight composite materials and high-performance fibers for industrial applications.

Forecasts for the Asia Pacific Market

The growth of the Chinese, Japanese, and Indian industries is primarily responsible for the Asia-Pacific region's sharp increase in demand for glass fibers and specialty synthetic fibers. Particularly in countries like China, India, and Japan, the Asia-Pacific region is fast become increasingly urbanized and industrialized. This is driving the demand for glass fibers in the automotive, infrastructure construction, and building industries. The need for lightweight materials is rising in the Asia-Pacific automotive industry as a result of the rising popularity of electric vehicles (EVs) and fuel-efficient cars in countries like China and Japan. The need for glass and carbon fibers rises as a result.

Conclusion

The Glass Fibers & Specialty Synthetic Fibers Market is poised for robust growth, driven by advancements in material science, the increasing demand for lightweight and high-strength materials, and expanding applications across industries like construction, automotive, aerospace, and renewable energy. While challenges such as high production costs and environmental concerns persist, ongoing innovations in recycling and sustainable fiber production are paving the way for a greener future.

As industries worldwide prioritize efficiency, durability, and sustainability, the market for glass and specialty synthetic fibers is set to play a critical role in shaping the future of materials technology. With strong investments in R&D and the rise of eco-friendly initiatives, this market presents vast opportunities for growth and innovation.

0 notes

Text

The Ultra High Molecular Weight Polyethylene (UHMWPE) Rope Market is projected to grow from USD 235.7 million in 2023 to an estimated USD 455.7 million by 2032, registering a compound annual growth rate (CAGR) of 8.59% from 2024 to 2032. Ultra High Molecular Weight Polyethylene (UHMWPE) ropes have been gaining significant attention across various industries due to their high-performance attributes. Known for their remarkable strength, durability, and lightweight characteristics, UHMWPE ropes are designed to outperform traditional materials like steel and other synthetic fibers. The market for UHMWPE ropes has been on a steady rise in recent years, driven by growing demand from marine, defense, aerospace, oil & gas, and sports industries. This article explores the key drivers, trends, and future opportunities in the UHMWPE rope market.

Browse the full report at https://www.credenceresearch.com/report/ultra-high-molecular-weight-polyethylene-rope-market

Market Drivers

1. Rising Demand from the Marine Industry: The marine sector has been one of the largest consumers of UHMWPE ropes due to their lightweight and high-strength properties. Applications such as mooring lines, towing ropes, and winches rely heavily on the performance characteristics of these ropes. Additionally, UHMWPE ropes are highly resistant to UV radiation and saltwater, making them a suitable choice for long-term use in maritime environments. As global trade and shipping activities increase, the demand for reliable, durable marine ropes is expected to grow, pushing the UHMWPE rope market upward.

2. Growth in Offshore Oil & Gas Exploration: The offshore oil and gas industry is another significant driver of the UHMWPE rope market. Exploration and drilling activities require equipment that can perform reliably in harsh, remote environments. UHMWPE ropes are used in various offshore applications, such as anchor handling, platform positioning, and rigging operations. Their ability to withstand extreme loads and harsh environmental conditions makes them an ideal choice for these industries. The expansion of offshore oil drilling projects, particularly in regions like the Gulf of Mexico, the North Sea, and offshore Brazil, is expected to drive the demand for UHMWPE ropes further.

3. Defense and Aerospace Applications: In the defense and aerospace sectors, UHMWPE ropes are used for critical applications, including parachute lines, helicopter slings, and high-strength tethering systems. These industries require materials that offer high performance with minimal weight, which makes UHMWPE ropes a preferred option. As defense budgets increase worldwide and demand for advanced aerospace technologies rises, the UHMWPE rope market is expected to see continued growth.

4. Sports and Recreational Use: UHMWPE ropes are also gaining traction in sports and recreational activities, particularly in sailing, rock climbing, and paragliding. The ropes' strength-to-weight ratio, low water absorption, and ease of handling make them ideal for outdoor sports enthusiasts. As these activities become more popular globally, demand for UHMWPE ropes is likely to increase.

Market Trends and Innovations

The UHMWPE rope market is witnessing several emerging trends that are likely to shape its future growth trajectory. These include:

- Sustainability and recycling initiatives: As industries focus more on sustainability, the production of UHMWPE ropes with environmentally friendly practices is becoming more important. Manufacturers are increasingly looking for ways to reduce the carbon footprint of their products and promote recycling initiatives. - Technological advancements: Innovations in manufacturing processes are leading to the development of even stronger and more durable UHMWPE ropes. This includes the use of new coatings and treatments that improve resistance to wear, heat, and UV degradation, further extending the ropes’ lifespan.

- Customization and specialized products: With growing demand from diverse industries, there is an increasing focus on developing customized UHMWPE rope solutions tailored to specific requirements. For example, specialized ropes for extreme environments like deep-sea exploration or high-altitude aerospace applications are seeing growing interest.

Challenges

Despite its numerous advantages, the UHMWPE rope market faces some challenges, including high initial costs compared to traditional materials like steel or polyester ropes. Additionally, although UHMWPE ropes are highly durable, they are sensitive to high temperatures, which can limit their use in certain industrial applications.

Future Outlook

The future of the UHMWPE rope market looks promising, with steady growth anticipated in the coming years. According to market analysts, the global UHMWPE rope market is expected to witness a compound annual growth rate (CAGR) of 7% to 9% over the next decade. This growth will be driven by increasing demand from key industries such as marine, oil & gas, defense, and aerospace, along with innovations in product development.

Key players

Marlow Ropes Ltd.

Yangzhou Hyropes Co., Ltd.

Taizhou Hongda Rope & Net Co., Ltd.

Katradis Marine Ropes Ind. S.A.

Samson Rope Technologies, Inc.

Southern Ropes

Dynamica Ropes ApS

Cortland Limited

Teufelberger Holding AG

Yale Cordage Inc

Segments

Based on Product Type

3 Strands

8 Strands

12 Strands

Based on Application

Oil & Gas

Construction

Marine

Military & Aviation

Mining

Others

Based on Region

North America

U.S.

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/ultra-high-molecular-weight-polyethylene-rope-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Hand Pump Market Current Scenario and Future Prospects by 2032

Hand Pump Market provides in-depth analysis of the market state of Hand Pump manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Hand Pump in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Hand Pump Market Report:

The report offers a comprehensive and broad perspective on the global Hand Pump Market.

The market statistics represented in different Hand Pump segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Hand Pump are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Hand Pump.

Major stakeholders, key companies Hand Pump, investment feasibility and new market entrants study is offered.

Development scope of Hand Pump in each market segment is covered in this report. The macro and micro-economic factors affecting the Hand Pump Market

Advancement is elaborated in this report. The upstream and downstream components of Hand Pump and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/hand-pump-market-100563

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Global Orthotic Devices MarketMarket Growth

Machine Vision MarketMarket

Digital Experience Platform MarketMarket Share

Testing, Inspection, and Certification (TIC) MarketMarket Growth Rate

Industrial Casters MarketMarket Forecast

Global MIS Sacroiliac Joint Fusion MarketMarket Size

Halogenated Butyl Rubber MarketMarket Growth

Oncaspar MarketMarket Analysis

Neuroprosthetics MarketMarket Size

Global Call Center Software MarketMarket Share

Global Appointment Scheduling Software MarketMarket Growth

Anc Headset MarketMarket

Ultra High Molecular Weight Polyethylene (UHMWPE) Ropes MarketMarket Share

API Management MarketMarket Growth Rate

Agarose MarketMarket Forecast

Global Boat Docks and Lifts MarketMarket Size

Nanocellulose MarketMarket Growth

Automatic Palletizer MarketMarket Analysis

Hydrogen Sulfide (H2S) Scavenger MarketMarket Size

Global Augmented Reality and Virtual Reality (AR and VR) MarketMarket Share

Global Medical Bionic Implants MarketMarket Growth

Weatherstrip Seal MarketMarket

L-Leucine MarketMarket Share

Humidifiers MarketMarket Growth Rate

Online Coaching Software MarketMarket Forecast

Global Hydraulic Dock Leveler MarketMarket Size

Residential Furniture MarketMarket Growth

Industrial Rubber Products MarketMarket Analysis

Radio Taxi Service MarketMarket Size

Global Premium Pram and Baby Stroller MarketMarket Share

Global Pet Wearable MarketMarket Growth

Fortified Wine MarketMarket

Human-centric Lighting MarketMarket Share

Automatic License Plate Recognition (ALPR) MarketMarket Growth Rate

Zinc Waste Recycling And Reusing MarketMarket Forecast

Global Automatic Laser Tube Cutting Machine MarketMarket Size

Financial Grade Security Chip MarketMarket Growth

Mobile Scaffold Tower MarketMarket Analysis

Cable Tie Guns Market Market Size

Global Digital Ultrasonic Thickness Gauges MarketMarket Share

0 notes

Text

India’s Technical Textiles market has huge potential backed by a significant growth rate of 10%

The Ministry of Textiles in partnership with the Confederation of Indian Industry (CII) and Ahmedabad Textiles Industries’ Research Associations (ATIRA) organized a National Symposium on Advancements in Composites, Speciality Fibres and Chemicals here in New Delhi today.

India’s Technical Textiles market has a huge potential backed by a significant growth rate of 10% and placement as the 5th largest technical textiles market in the world, said Mrs Rachna Shah, Secretary, Ministry of Textiles while addressing the symposium.

She further said that that composites has distinct structural and physical features, which make them suitable for specific applications across various sectors. For example, in infrastructure development, aerospace, automotive sector, Military and Defence sector, medical devices, composite materials, among others. She highlighted the significance and importance of institutional buyers, user Ministries and industries in the adoption of technical textiles and products made out of specialty fibres and composites.

A collaborative approach among stakeholders including industry representatives, policymakers, researchers, and investors is imperative to address the cost implications in the field of composites and specialty fibres and work together in increasing awareness and education for wider adoption by the larger community for the growth of the sector, she added.

Dr Vijay Kumar Saraswat, Member, NITI Aayog, highlighted that the specialty fibres are the building blocks of the advanced composites and its choice is a strategic decision on a blend of performance requirements and cost consideration.

He mentioned that specialty fibres like aramids, carbon fibre, zylon, ultra-high molecular weight polyethylene (UHMWPE), glass fibre, ceramic fibre can be tailored for diverse applications and strategic needs, such as Fire Retardant fabrics, Bullet Resistant Jackets, ropes and cables, windmills (renewable energy) and in gas and chemical filtration respectively. He highlighted the top trends in composite materials including but not limited to high-performance resins and adhesives, carbon fibre based materials light weighting advanced polymer composites, biomaterials, nanocomposites, intelligence design and manufacturing.

He elucidated the advancements in material science are not just about creating stronger or lighter materials, but also about ensuring their sustainable use through material circularity. He also stressed that the demand for bio-composites is increasing due to growth in its adoption by the construction, furniture industry and increased compatibility in medical applications.

Dr Saraswat also said advanced composites and specialty fibres are continuously evolving with research, pushing the boundaries of fibre performance. Future developments will include fibres with even greater strength and stiffness, enhanced thermal properties and even self-healing capabilities. He also emphasised that although composite materials have been around for many years, the industry is still amid innovation and evolution. There is a need to adopt sustainable practices which will be a key feature of the composites industry going forward.

Shri Ajay Kumar Rana, Director General, RDSO during his address talked about the use of geotextiles and geo-composites in the railways sector. He highlighted the use of geotextiles, geogrids, pre-fabricated vertical drains (PVDs) for load bearing applications, slope erosion protection control application, drainage, separation, filtration etc. He also stated RDSO is actively working in developing new guidelines and standards for use of geo-composites in railways sector, in association with BIS.

Shri Rajeev Saxena, Joint Secretary, Ministry of Textiles suggested technical textiles is one of the fastest growing segment with a strong global demand. The technical textiles industry holds immense potential to drive productivity, efficiency, cost-effectiveness, and innovative solutions across engineering and general applications. He highlighted that NTTM is a flagship mission with a view to position India as the Global Leader in Technical Textiles. During his speech, Shri Saxena elucidated various guidelines under the NTTM mission related to Research & Innovation, Start-up, machinery development, internship, education and skilling.

While deliberating on the importance of composites, he stated that textile composite materials are replacing conventional materials in several fields.

Shri Nilesh M Desai, Director, Space Applications Centre (SAC/ISRO) said that SAC is the second largest research centre of ISRO with a long association with ATIRA. He said that space and aerospace is going to be a major area for composites applications, due to its light weight and durable properties. CFRP and Asto glass fibres are majorly used nowadays in space and aerospace sector.

Around 150 participants attended the conference including Officials and Representatives from Central Ministries, user Departments of Central and State Governments, industry leaders, scientific experts, researchers, and professionals related to technical textiles.

Source - PIB India

0 notes

Text

Analyzing Global Trends and Growth Opportunities in the Fender Rope Market: A Comprehensive Market Research Study

Rope Manufacturing is Estimated to Witness High Growth Owing to Technological Innovations in Material Sciences The fender rope market provides ropes used in ports to protect ships, boats and other watercraft from damage during docking and undocking. Fender ropes come in a variety of sizes and strengths depending on vessel size and dock conditions. Their high elongation properties enable them to cushion and absorb impact energy. The global fender rope market is valued at US$ 679.4 million in 2024 and is expected to exhibit a CAGR of 4.7% over the 2023-2030 forecast period. Key Takeaways Key players operating in the fender rope market are Samson Rope Technologies, Inc., Novabraid, New England Ropes, TEUFELBERGER Fiber Rope Corporation, Marlow Ropes Ltd., Langman Ropes, Southern Ropes, Lankhorst Ropes,Yale Cordage, Inc., FSE Robline, Gleistein Ropes, Hampidjan Group, English Braids Ltd., Gottifredi Maffioli, Liros GmbH. The key players are focusing on adopting advanced technologies to develop ropes with enhanced strength, abrasion resistance and durability. The rising maritime trade globally is expected to drive demand for new ports and expansion of existing ports creating opportunities for fender rope manufacturers. Furthermore, ongoing research and development of ultra-high molecular weight polyethylene and para-aramid materials for ropes is expected to bring stronger and longer lasting fender ropes. Market Drivers The increasing cruise industry and marine cargo transportation are the key factors driving the growth of the global fender rope market. As per industry estimates, over 27 million passengers traveled on cruise ships in 2018. This rapid growth of the cruise industry is resulting in more ships requiring fender rope protection at various ports globally. Furthermore, the expansion of existing ports and construction of new ports especially in developing countries will also boost market growth over the forecast period.Current Challenges in Fender Rope Market The fender rope market is facing various challenges such as volatile prices of raw materials. Raw materials used in the manufacturing of fender ropes such as polyester, nylon, polyethylene, and polypropylene are crude oil based products. Fluctuations in crude oil prices affect the prices of these raw materials. This increases the manufacturing cost for fender rope producers. Additionally, the availability of low quality synthetic rope substitutes at lower prices is reducing the sales of premium fender ropes. Counterfeiting is another challenge where unauthorized entities manufacture and sell low quality imitation fender ropes. These low quality products negatively impact the brand image of top players in the market. Strict maritime regulations regarding safety and performance standards also pose compliance challenges for fender rope makers. SWOT Analysis Strength: Fender ropes have high tensile strength and resistance to damage from impact, abrasion, chemicals and corrosion. They offer long durability in harsh maritime operating conditions. Weakness: Dependency on crude oil prices makes the raw material costs volatile. Substitutes offering similar functionality at lower prices will affect sales. Opportunity: Growth in international seaborne trade and port traffic is driving demand for modernized port infrastructure. This provides scope to supply specialized high performance fender ropes. Threats: Stringent compliance requirements for maritime safety raises compliance costs. Counterfeiting by unauthorized manufacturers also threatens brand value and revenue.

0 notes

Text

Shandong Santong Rope Co.,Ltd

Shandong Santong Rope Co., Ltd specializes in the production of high-end ropes and new materials. Our products mainly include ropes like braided ropes, nylon ropes, polyester ropes, PP ropes, PE ropes, dock lines, anchor lines, ultra-high molecular weight polyethylene fiber ropes and special ropes. These products are widely used in marine, aviation, military, rescue, outdoor, engineering and other fields. They are exported to the United States, the United Kingdom, France, Australia, the Middle East and other parts of the world, and are highly commended by domestic and foreign consumers. Our company has many patents, twelve for utility models, one for invention and two for design. We also boast two domestically registered trademarks and are the first rope company listed on the OTC market.

Mountain Climbing Rope manufacturers

1 note

·

View note

Text

0 notes

Link

0 notes

Link

Global Ultra High Molecular Weight Polyethylene Ropes Market Insights, Forecast To 2029 provides a specific tool for evaluating the global market, specifying the growth potentials, and supporting tactical and strategic decision-making.

0 notes

Text

Ultra High Molecular Weight Polyethylene Ropes Market Growth Dynamics 2023 Emerging Technologies and Supply Chain Analysis

Ultra High Molecular Weight Polyethylene (UHMWPE) ropes are made of a type of polyethylene material and synthetic rope that have become increasingly popular in various industries due to their exceptional strength and durability, that has a very high molecular weight, which gives it exceptional strength and durability. These ropes are made from a type of plastic that has a very high molecular weight, which gives them their unique properties. These ropes are commonly used in various applications such as mooring, towing, and lifting operations in the marine, offshore, and industrial sectors.

UHMWPE ropes are commonly used in marine, mining, and offshore industries, as well as for military applications. They are known for their ability to withstand harsh environments and extreme conditions, making them an ideal choice for heavy-duty tasks.

Market Overview:

The global Ultra High Molecular Weight Polyethylene ropes market is expected to grow at a significant rate during the forecast period of 2021-2026. The market growth is driven by the increasing demand for UHMWPE ropes in various end-use industries such as shipping, oil & gas, and construction.

Product Types:

The UHMWPE ropes market can be segmented based on product types such as 3-strand, 8-strand, 12-strand, and others. The 12-strand UHMWPE ropes segment is expected to dominate the market during the forecast period due to its superior strength and durability compared to other types.

Applications:

Based on applications, the UHMWPE ropes market can be segmented into marine & fishing, oil & gas, mining, construction, and others. The marine & fishing segment is expected to hold the largest market share during the forecast period due to the increasing demand for UHMWPE ropes in mooring, towing, and lifting operations.

Regional Analysis:

Geographically, the UHMWPE ropes market can be segmented into North America, Europe, Asia-Pacific, Middle East & Africa, and South America. Asia-Pacific is expected to dominate the market during the forecast period due to the increasing demand for UHMWPE ropes in the construction and oil & gas industries in countries such as China and India.

Key Players:

Some of the key players operating in the UHMWPE ropes market include Samson Rope Technologies, Inc., Bridon-Bekaert, Marlow Ropes Ltd., Southern Ropes, English Braids Ltd., Cortland Limited, Teufelberger Holding AG, Lankhorst Ropes, and Yale Cordage Inc.

Conclusion:

The global UHMWPE ropes market is expected to grow significantly during the forecast period due to the increasing demand for these ropes in various end-use industries. The market is highly competitive, and key players are focusing on developing innovative products to gain a competitive edge.

#Ultra High Molecular Weight Polyethylene Ropes Market#Ultra High Molecular Weight Polyethylene Ropes Market Growth#Ultra High Molecular Weight Polyethylene Ropes Market Trends

0 notes

Link

Over the forecast period, emerging applications such as sports and leisure activities where Ultra High Molecular Weight Polyethylene ropes are employed are likely to provide growth potential for participants in the Ultra High Molecular Weight Polyethylene Rope Market. Key businesses are developing UHMWPE ropes for use in sports and leisure activities, as well as the healthcare industry, in order to diversify their product range and broaden their customer base

0 notes

Text

Global Ultra High Molecular Weight Polyethylene Ropes (UHMWPE) Ropes Market Analysis Industry Outlook Current Trends and Forecast by 2027

0 notes

Text

Hammock Camping In The Rain – Proper Guideline For Hammock Lovers

Hammock camping in the rain?

Sounds wired! Right?

Yes, If you are adventurous hammock campers or a beginner, one must experience hanging in the rain in the middle of the wood. But Hammock Camping in the Rain is not bad at all.

If you are an adventurous hammock camper, then foul or rainy weather, can’t you stop to go in camping. Naturally camping in the fall season is not only an excellent and beautiful time to go but also ensures calming scenery to enjoy, which are surroundings around you.

But Hammock Camping in the rain can be the toughest job and becomes a problem for campers to stay dry in the rain. But that Does this mean that you shouldn’t go for camping in the rainy season or should pack up and go back home.

Despite that, by using the different gears and hammocks, you can easily make your Hammock Camping in the rain enjoyable and also memorable. So let’s check it.

Guideline on Hammock Camping in the Rain

To make your Hammock Camping comfortable, secure, and dry in the rain, follow this complete Guideline on Hammock Camping in the rain. This guideline gets you a perfect shelter and ensures to stay warm and dry on rainy days and nights out in the woods with the hammock.

Select the Right Tarp or Rain Fly

If you are camping in wet or rainy weather, purchase the hammock tarp or rain fly to get protection from the rain. There are various designs, sizes, styles, and brands of tarp available in the market.

A waterproof rain fly not only keeps you warm and dry but also sheltering you from the cold wind, rain, snow, and whatever cold elements nature throws your way. You can find some awesome hammocks with mosquito net also. But don’t forget to check the tarp before going camping.

Perfect Tarps Size

Tarp Sizes of the hammock should be eight to12 inches more extensive than the hammock and must cover the end of the tarp. It makes your hammock stay dry. Otherwise, water will soak the hammock all night, and a wet hammock isn’t good for sleeping. For backpacking hammocks, a 12ft long standard size tarp provides enough coverage to cover and also offers excellent service.

Moreover, it is lighter and easy to carry around. A more massive tarp will provide excellent coverage in a nasty storm, but it is challenging to move around because of its extra weight. So, when selecting the tarp size, must consider these few factors.

Choose the Perfect Tarp Styles

Usually, these Styles of hammock Tarps are found in the market, such as- rectangular, asymmetrical, hexagonal, centenary, or diamond (square) shapes. According to the style, they have a different form, different kinds of setup and anchor points, and also provide you different coverage.

Rectangular tarps

This is the most common type of tarps used in hammock camping. These tarps have four anchor points that are tied into hammock’s ridgeline and set up parallel to the hammock. Then the four anchors are staked to the ground, and it looks like a tent. As the hammock goes under this type of tarp, so it provides excellent coverage to the ends. But ventilation is limited in this trap, and it takes too much space. So it becomes over-weight and burdens in the wild.

Hexagonal tarp

This trap is like a regular rectangular tarp, but the corners of this trap are wrinkling inwards. So there’s no flapping sound, and rain can easily roll off the tarp. Because of its six anchor points, it is also known as hex-cut tarps. The ventilation system is good in this trap, and less material makes it lighter. But it is more expensive than rectangular tarps.

Asymmetrical tarp

Usually, these traps are narrow and diagonal and are suitable for a symmetrical hammock. These are not for the rainy season. It’s for casual or summer season.

Catenary Tarp

These types of traps are suitable for any kind of weather and are better from the hexagon and rectangular trap. Its unique curved cuts make it less weighty, reduces material usage, and easy to carry. It is one of the most versatile rainfly which doesn’t need ant ridgeline.

Because it’s especially cutting curved, it gives more coverage and doesn’t make any sound of sagging and flapping. Though it a little bit expensive but for hammock lovers, it is the best for camping.

Diamond (square) tarps

This square trap has only two points. So it is easy to set up, less weighty and suitable for rain coverage. This trap is much like rectangular, but the ridgeline is running down in the midline of the tarp. So it runs down the diagonally. It mainly provides end coverage of the hammock.

Hammock Tarps Material

Polyethylene, silnylon, and cuben fiber- these three materials are usually used for making hammock tarps.

Polyethylene

These tarps materials are easily found in any hardware store. They are budget-friendly, versatile, and also durable. But this tarp is very heavy to carry around and makes a lot of sound in windy or rainy weather. Polyethylene is an excellent choice for once backpacker or wagon camping.

Silnylon

These Silnylon tarps are made by silicon and nylon materials. So this material makes it lightweights, durable, and extremely waterproof. It is expensive than the basic plastic tarp but becomes popular among hammock campers.

Cuben fiber

Cuben fiber made from Ultra High Molecular Weight Polyethylene, which is exceptionally light, waterproof, and is tough to rip. This material makes it expensive than other materials. For the longtime backpacker, cuben fiber will be a good option.

How to Pitching the Tarp

Pitching a tarp will be easy if you practice it at home. Because you don’t want to get yourself or your hammock or hammock gear get wet in rainy weather. So to stay dry first don’t waste time and pitching your tarp first-

Hang the ridgeline

To keep hammock and essentials dry, first set up the tarp at each side at a different height. So water flows smoothly off the tarp. Then create a tarp ridgeline, which should be lower on the trees than the hammock suspension. Then create V with the guy lines to provide room for your hammock suspension.

Set the guy lines

Once the tarp is draped over the ridgeline, must secure it down with guy lines. Guy lines must be staked to the ground or secured to nearby supports like trees.

Use Drip Lines

Drip lines are tied to ridgelines to prevent rainwater droplets across the hammock and keep the water flowing down. Because of this, the water will come down from the drip line; instead of reaching the hammock, the water will be dripping to the rope.

How to Stay Comfortable in rain

Usually, it feels cold in rainy weather. So to stay warm, dry, sleep comfortably throughout the night and also enjoy nature properly must equip yourself with proper insulation, clothing and take these different tactics.

Always stay dry

Before entering into the hammock, you have to make sure that your clothes are dry. If they are damp or wet, you have to change them. Otherwise, your cozy, dry hammock becomes wet. Also, don’t wear an overdress inside the hammock. It creates overheat, sweat, and freeze. So before going inside the cozy hammock, take off your outer layer.

Sleeping pads

The hammock itself is one kind of sleeping bag. Then put a sleeping pad underneath it. This will add an extra layer. And these pads are a surefire way to keep you warm and maintain heat throughout the cold nights.

Foil blankets

Foil blankets reduce heat loss from the body. It captures the heat, keeping it near the body, and keeping you warm. To get extra comfort in the time of rain, consider hanging foil blanket above the hammock and under the tarp.

Top quilts and under quilts

As the temperature drops in cold or rainy weather, consider these quilts to stay warm. It also adds extra layers of insulation in your hammock.

Final Thoughts

If you are adventurous hammock campers or a beginner, one must experience hanging in the rain in the middle of the wood. But Hammock Camping in the Rain is not bad at all. It also gives you a memorable and enjoyable experience. All you have to do is prepared and handle the situation.

Try to stay dry and warm while the rain rages around you. In rainy weather, nature becomes more beautiful and greener. To enjoy this, choose and use your hammock equipment wisely and makes a pleasant trip.

The post Hammock Camping In The Rain – Proper Guideline For Hammock Lovers appeared first on Outdoor Expart.

source https://outdoorexpart.com/hammock-camping-in-the-rain/

1 note

·

View note

Text

Ultra-High Molecular Weight Polyethylene Market Analysis, Size, Share, Upcoming Trends, Segmentation and Forecast to 2022–2028

The Ultra-High Molecular Weight Polyethylene Market Report 2022 report provides the latest industry data and future industry trends. The report lists leading competitors and manufacturers in the Ultra-High Molecular Weight Polyethylene industry and provides strategic industry insights and analysis of factors influencing the competitiveness of the market. The geographical scope of the Ultra-High Molecular Weight Polyethylene market is studied. The forecast market information, SWOT analysis, market scenario, and feasibility study are the vital aspects analyzed in this report. Looking forward, Industry Data Analytics Group expects the market to grow at a CAGR of 9.5% during 2022-2028.

Request Sample Copy of this Report:

#Ultra-High Molecular Weight Polyethylene Market Analysis#Ultra-High Molecular Weight Polyethylene Market Research#Ultra-High Molecular Weight Polyethylene Market Size#Ultra-High Molecular Weight Polyethylene Market share

0 notes

Text

Ultra High Molecular Weight Polyethylene Market Worth USD 4.43 Billion By 2028

The global ultra high molecular weight polyethylene market size is anticipated to reach USD 4.43 billion by 2028, according to a new report by Grand View Research, Inc., growing at a CAGR of 12.3% over the forecast period. Increasing product demand from the medical & prosthetics application is expected to significantly drive the market during the forecast period. The product has been witnessing increasing acceptance as prosthetics in the medical industry for the past few years.

This rising acceptance can be attributed to its favorable physical and chemical properties, such as higher flexibility as compared to metals, and superior strength. Technological advancements have resulted in prosthetics having a longer operational life and being more comfortable for users. Over the recent years, the market participants have taken active steps to process ultra high molecular weight polyethylene (UHMWPE) and improve its properties. The product is majorly used for hip, knee, and spine implants.

The Asia Pacific region is anticipated to progress at the fastest CAGR of 13.1% over the forecast period. China led the regional market in 2020 and is anticipated to witness significant growth during the forecast period owing to the rising product demand in applications including medical grade & prosthetics, filtration, batteries, fibers, additives, and membranes. The increasing efforts by the government to improve public access to healthcare services and the rising incidences of chronic diseases are the major factors driving the product demand in medical-grade & prosthetics applications in the country.

In addition, increasing government expenditure to improve infrastructure and accessibility in rural and urban areas is expected to fuel the demand for medical devices. The aforementioned factors are projected to augment the demand for UHMWPE in the country over the forecast period. However, the recent outbreak of Covid-19 in countries, such as India, China, and Japan, are affecting the product demand in fibers, batteries, additives, and other applications owing to the slowdown in manufacturing activities, restrictions in supply & transport, and declining demand from end-use consumers, which is expected to hamper the overall market growth.

The fiber application segment is anticipated to progress at a robust growth rate over the forecast period. The product is used in the form of fibers for various applications, which include cut resistance gloves, ropes & fishing nets, protective armor, sports & leisure goods, and sling & braids. A surge in demand for high tenacity multifilament polyethylene yarns is expected to benefit the overall demand over the forecast period. In addition, increasing adoption of medical-grade UHMWPE fiber in cardiovascular, orthopedic, and trauma applications, such as implantable cardiac defibrillators, Cardiac Resynchronization Therapy (CRT) devices, vascular closure devices, central venous catheters, cranial plates, and scaffolds, is anticipated to drive the market growth in the coming years.

Gain deeper insights on the market and receive your free copy with TOC now @: https://www.grandviewresearch.com/industry-analysis/ultra-high-molecular-weight-polyethylene-market/request/rs15

0 notes