#turning durable tanks into brittle

Explore tagged Tumblr posts

Text

Common Causes of Water Heater Rust and How to Prevent It.

Your water heater is one of the hardest-working appliances in your home. With proper care, it can serve you for up to 20 years. However, rust is one of the leading causes of premature water heater failure, turning durable tanks into brittle, leaky messes.

Why Does Rust Occur in Water Heaters?

Rust is a natural reaction when metals like iron come into contact with water and oxygen. Let’s explore the top causes of water heater rust.

Failed Anode Rods.

Hard Water and Sediment Build-Up.

Damaged Glass Liners.

The Importance of Regular Water Heater Maintenance.

Scheduling routine maintenance for your water heater can help you avoid costly repairs and extend its life. Here’s what maintenance should include:

Flushing the Tank: Removes sediment and improves heating efficiency.

Inspecting and Replacing Anode Rods: Protects the tank from corrosion.

Testing the System: Ensures all components are working properly.

Protect Your Water Heater with Emergency Plumbing

At Emergency Plumbing, we specialize in water heater maintenance and rust prevention. Our team serves homes across North Shore and Northwest suburbs of Chicago IL, and beyond, offering reliable services for:

Plumbing

Drains & Sewers

Whether you need a system flush, anode rod replacement, or help choosing a water softener, we’re here to help.

Contact us today to schedule maintenance or get a free quote.

Phone 224-754-1984

#Common Causes of Water Heater Rust and How to Prevent It.#Your water heater is one of the hardest-working appliances in your home. With proper care#it can serve you for up to 20 years. However#rust is one of the leading causes of premature water heater failure#turning durable tanks into brittle#leaky messes.#Why Does Rust Occur in Water Heaters?#Rust is a natural reaction when metals like iron come into contact with water and oxygen. Let’s explore the top causes of water heater rust#1. Failed Anode Rods.#2. Hard Water and Sediment Build-Up.#3. Damaged Glass Liners.#The Importance of Regular Water Heater Maintenance.#Scheduling routine maintenance for your water heater can help you avoid costly repairs and extend its life. Here’s what maintenance should#• Flushing the Tank: Removes sediment and improves heating efficiency.#• Inspecting and Replacing Anode Rods: Protects the tank from corrosion.#• Testing the System: Ensures all components are working properly.#Protect Your Water Heater with Emergency Plumbing#At Emergency Plumbing#we specialize in water heater maintenance and rust prevention. Our team serves homes across North Shore and Northwest suburbs of Chicago IL#and beyond#offering reliable services for:#• Plumbing#• Drains & Sewers#Whether you need a system flush#anode rod replacement#or help choosing a water softener#we’re here to help.#Contact us today to schedule maintenance or get a free quote.#Phone#224-754-1984

1 note

·

View note

Text

Benefits of Using Industrial Coatings for Durability and Protection

Industrial coatings play a critical role in protecting and enhancing the performance of various surfaces used in industrial settings. From manufacturing equipment to heavy machinery, industrial coatings are designed to improve the durability and longevity of these surfaces while providing an additional layer of protection against the elements. In Industrial Coatings in India, these coatings are especially important due to the extreme weather conditions and harsh environments that industrial assets often face.

In this blog, we will explore the benefits of using industrial coatings to boost durability and provide superior protection, focusing on how these coatings are crucial for maintaining your assets’ efficiency and functionality.

1. Protection Against Corrosion

Shielding Metal Surfaces: One of the primary benefits of industrial coatings is their ability to protect metal surfaces from corrosion. In industries where equipment is exposed to moisture, chemicals, or salt, such as in coastal areas or industries that deal with aggressive chemicals, corrosion is a major concern. Industrial coatings form a protective barrier that prevents the metal from reacting with environmental elements, thus extending the lifespan of machinery and structures.

Enhanced Resistance: Coatings like epoxy or polyurethane provide excellent resistance to rust and oxidation, making them ideal for protecting industrial equipment from degradation. This added protection reduces the need for costly repairs and replacements.

2. Resistance to Harsh Chemicals

Chemical-Resistant Coatings: Industrial coatings are specifically formulated to withstand exposure to a wide range of chemicals. Whether in a manufacturing plant, oil refinery, or chemical processing facility, these coatings act as a barrier to prevent chemical damage to surfaces.

Safe and Durable Surfaces: The durability of industrial coatings ensures that industrial equipment, tanks, and pipes remain protected from corrosive substances like acids, alkalis, and solvents, improving their operational efficiency and safety.

3. Protection from Extreme Weather Conditions

Weathering Resistance: In Industrial Coatings in India, where temperatures can fluctuate drastically and monsoon rains can be intense, coatings provide essential protection against the elements. Whether it’s hot temperatures, heavy rain, or humidity, industrial coatings act as a shield to protect machinery and infrastructure from the damaging effects of weather.

UV Protection: Certain industrial coatings also provide UV protection, preventing surfaces from degrading or becoming brittle due to prolonged sun exposure. This is particularly important for outdoor machinery and structures that are continuously exposed to UV rays.

4. Enhanced Aesthetic Appeal and Cleanliness

Smooth Finish and Clean Surfaces: Industrial coatings improve the surface finish of equipment and structures, making them easier to clean and maintain. Smooth, coated surfaces are less likely to accumulate dust, dirt, or pollutants, ensuring that industrial equipment remains clean and visually appealing.

Color and Appearance: Not only do these coatings offer protection, but they can also enhance the appearance of industrial structures and machinery. This is particularly beneficial for industries where both functionality and aesthetics matter, such as in consumer-facing facilities or high-end manufacturing plants.

5. Cost Savings in the Long Run

Reducing Maintenance Costs: Industrial coatings reduce the need for frequent maintenance by protecting against wear and tear, corrosion, and chemical damage. As a result, businesses can save significantly on repair and maintenance costs.

Lower Downtime: With protected machinery and equipment, the likelihood of breakdowns or malfunctions decreases, which in turn reduces operational downtime. This leads to higher productivity and efficiency for businesses.

6. Increased Safety Standards

Slip-Resistant Coatings: Many industrial coatings are designed with safety in mind. Anti-slip coatings are commonly applied to floors, walkways, and stairways to reduce the risk of accidents in manufacturing or warehouse settings.

Fire Retardant Properties: Certain industrial coatings come with fire-resistant properties, helping to slow down the spread of fire and offering enhanced protection for workers and facilities. This can be particularly vital in industries where flammable substances are present.

7. Sustainability and Eco-Friendly Options

Eco-Friendly Coatings: As environmental concerns continue to rise, more manufacturers are opting for eco-friendly industrial coatings. These coatings are designed to be low in volatile organic compounds (VOCs) and are formulated with sustainable materials that do not harm the environment.

Long-Term Sustainability: By choosing high-quality industrial coatings, businesses can help reduce their carbon footprint by increasing the lifespan of their equipment and infrastructure. Sustainable coatings contribute to lower resource consumption and waste production, aligning with green manufacturing initiatives.

Conclusion: Industrial Coatings for Optimal Performance

Industrial coatings are essential for improving the durability and protection of equipment, machinery, and infrastructure across various industries. With the benefits of enhanced corrosion resistance, chemical protection, weather resistance, cost savings, and increased safety, the use of industrial coatings in India has become a necessity for businesses aiming to extend the lifespan of their assets and reduce maintenance costs.

At SBL Specialty Coatings, we provide high-quality industrial coatings that offer unmatched protection and performance. Whether you’re looking to safeguard your equipment from corrosion, chemicals, or weather, our coatings are tailored to meet your specific needs, ensuring your industrial assets remain durable and reliable for years to come.

0 notes

Text

What Are 904L Stainless Steel Material And Why Are They Popular?

904L Stainless Steel Material is a high-alloy austenitic stainless steel acknowledged for its exquisite corrosion resistance and sturdiness. This grade of stainless-steel changed into in the beginning developed to combat competitive environments, which include the ones determined in chemical processing industries. It includes higher levels of chromium, nickel, and molybdenum compared to traditional stainless-steel grades, making it especially proof against strain corrosion cracking, pitting, and crevice corrosion.

The chemical composition of 904L Stainless Steel Material includes 23-28% chromium, 19-23% nickel, four-five% molybdenum, and small quantities of copper, manganese, and silicon. This precise combination of factors affords amazing resistance to both oxidizing and lowering acids, inclusive of sulfuric acid, phosphoric acid, and acetic acid. As an end result, 904L is extensively used in industries in which exposure to harsh chemical compounds is common, together with petrochemical, pharmaceutical, and nuclear industries.

Advantages of 904L Stainless Steel

One of the primary reasons 904L Stainless Steel Material is so popular is its notable corrosion resistance in harsh environments. It outperforms many different chromes steel grades, especially when exposed to sturdy acids and chloride-wealthy atmospheres. The high nickel content prevents 904L from turning into brittle at low temperatures, while the addition of copper enhances its resistance to sulfuric and phosphoric acids.

Another advantage of 904L Stainless Steel Material is its outstanding mechanical homes. It has excessive tensile strength, proper formability, and weldability, making it appropriate for various industrial packages. The material’s potential to hold its mechanical houses even in severe temperatures, whether excessive or low, makes it relatively versatile.

The resistance to pitting and crevice corrosion also makes 904L a remarkable preference for marine applications. Saltwater environments are notoriously corrosive, and substances which can withstand this environment without degrading are essential for marine engineering, offshore oil rigs, and desalination flora.

Applications of 904L Stainless Steel

904L Stainless Steel Material is usually used in chemical processing gadget, which include warmness exchangers, garage tanks, and piping structures that cope with corrosive drinks. Its resistance to a wide variety of acids and the capability to keep its integrity in fantastically acidic environments make it a preferred desire in chemical flowers.

In the oil and fuel industry, 904L stainless steel material is often used in gadget that have to face up to high levels of sulfuric acid and hydrogen sulphide. These environments are in particular difficult for substances because of the risk of strain corrosion cracking, however 904L’s alloy composition enables it withstand those threats correctly.

Additionally, 904L has located its way into extra area of interest applications, along with the pharmaceutical and meals processing industries, where high purity requirements and corrosion resistance are essential. Its non-reactive nature with numerous compounds guarantees that no contaminants are delivered all through the manufacturing system.

Conclusion

The growing reputation of 904L Stainless Steel Material is rooted in its superior overall performance in relatively corrosive and difficult environments. Whether inside the chemical, oil, gas, or marine enterprise, the fabric’s excessive strength, splendid corrosion resistance, and versatile programs make it a leading preference for tasks requiring durability and reliability. As industries maintain to demand more sturdy materials capable of withstanding excessive situations, 904L Stainless Steel Material remains an invaluable aid for producers and engineers alike.

0 notes

Text

Samus Aran vs Master Chief

So, I saw this question and found answers to both sides, but I wanted to weigh in

Who would win in a fight? Samus Aran vs Master Chief

Well, before we can answer that, we better look at their capabilities

---

Samus Aran - Galactic Bounty Hunter

At a young age, Samus Aran's life was forever altered when her home was attacked by Space Pirates. These clone-happy aliens were lead on this galaxy spanning rampage by a powerful alien known as Ridley and secretly guided by the living super-computer, Mother Brain.

Luck was on her side even back then as she survived the attack and was found by some of the last known members of the ancient Chozo race. Though most of their technology and empire had fallen into myth, their greatest achievements lived on: Mother Brain, Metroids, and of course, the Power Suit.

Samus wasn't able to wield this impressive suit just yet though. She had to undergo intense physical and mental training just to handle the suits basic functions, but more importantly, her DNA was altered to include Chozo sequences, which allowed her to access all of their technology. When she came of age, she was given the suit and told of its abilities, and though many were lost over time, she could harness countless abilities and powers through the suit over the years that followed.

The basic suit allows her to fire off blasts of energy and survive hits that could crush a car, but only so long as its energy lasts. These basic abilities aren't to be counted out though, as both can be enhanced with minimal effort.

Sadly, her new family wasn't meant to be either, as Ridley returned to her life under Mother Brains orders and killed the Chozo that had saved her. Samus then set out on a mission that would become her life: Destroy the Space Pirates once and for all.

She's travelled across the galaxy in her ship, gaining access to countless powers and abilities as she went: The Morph Ball - The suit was able to suspend her physical form in energy and shift her down into a sphere, capable of moving at high speeds, placing energy bombs, power bombs, and using extraordinary powers. The morph ball was later powered up into various new forms, which granted abilites such as speed boosts, wall climbing, and more. The Varia Suit upgrade - This power-up allows the Power Suit to survive in even the most extreme of conditions, pushing through extreme heat and cold that would cause other metal to scorch on contact or become chillingly brittle. Some additional power to this suit can even allow her to submerge in lava and acid, allowing her to explore any area that she comes across. The Gravity Suit - This upgrade is actually an enhanced version of the Varia suit that also allows her to move unimpeded through liquids as well as resist gravity altering effects, just to name a few features. Charge shot and other beams - While her normal weapon is powerful in its own right, it can be enhanced with a charge function. Once charged, these shots can deal massive damage to targets. Along with her regular energy blasts, her arm-cannon can also be charged with elemental energy, radiation, and much more. With it, she's used fire, ice, kinetic, and even light. Missiles - Her cannon is capable of holding an entire gunships worth of missiles, super-missiles, and more. Super-missiles and Power-bombs can also be combined with a Charge-shot to create powerful abilities that range wildly in use and damage capabilities, including an ability capable of surrounding her in a powerful energy field that completely restores all of her energy tanks. Energy Tanks - Along with her natural suits power, Samus can find additional Energy tanks that grant her suit more power. So long as it has at least 1 energy, it can protect her from a blow. Along with all of these powers packed into the suit, Samus can also hold her own out of the suit. Once the Power suit is turned to energy, it can be stored in her body-suit, also known as the Zero-suit. This bit of clothing is surprisingly strong and durable, can be altered in appearance, and is no heavier than standard fabric. Once out of the powerful but clunkier Power Suit, Samus' training and genetics are shown off. She becomes deceptively fast, agile, and is dangerously strong compared to regular humans. Samus has been shown as able to jump over ten feet in the air with ease, pull doors on a starship open with her bare hands, and has gone toe-to-toe with armored enemies with nothing more than a stun pistol.

Using this massive arsenal, focus, and luck, Samus took the fight to the space pirates at every turn. She's destroyed Ridley and his clones several times, blown up Mother Brain, and even wiped out an entire species known as Metroids.

One thing Samus knows how to do is finish a fight

---

The Master Chief - The Halo-breaking Demon

Spartans are known in human history as some of the strongest, most dangerous soldiers to ever walk the Earth, so of course the name was used for the newest program of the military: The super-soldier Spartans.

These Spartans were taken as kids and experimented on, augmented physically, and tested mentally. Only the strongest would survive this process, cutting down the already limited pool of candidates. The survivors were considered successes and given their armor, making them go from human to Spartan.

Master Chief was one such specimen. Though he wasn't the strongest, fastest, or smartest of all the Spartans, he was versatile, stable, and most importantly, lucky. This allowed him to catch the attention of a special AI named Cortana.

Together, the two of them brought war to both the Covenant, the Flood, and more, though Cortana was mainly support, leaving all of the 'heavy lifting' to Master Chief.

As he travelled across the Galaxy on missions, he dealt with massive hurdles and used powerful weapons, though typically he keeps either an Assault Rifle or Battle Rifle on him while holstering a pistol on his hip. Other weapons he's used include things like: - Rocket Launchers - Plasma Rifles - Grenades - Energy Swords - Spartan Laser The only problem is that he relies on other sources to get these weapons as he only carries two weapons at a time with limited ammunition for each. When his ammo runs out, his Spartan enhancements come into play.

A Spartan is capable of incredible feats of strength and speed in their armor, smashing their way through doors and outrunning their fellow soldiers on the battlefield. The armor assists them by holding them together while exerting forces that would shatter their bones, letting them kick with enough force to jump over a car, or even single-handedly flip over vehicles.

With all of these skills, abilities, enhancements, a little help from his friends, and a load of luck, he's survived his way through intergalactic war and brought down countless foes.

---

Battle time!

To make it fair, we'll give both combatants plenty of their gear and litter the field with ammo and weapons.

The fight will be between only the two, so no random enemies to do damage to the two, and it will be on a random planet, giving neither of them a home-field advantage.

---

Blow-by-blow breakdown

With a collection of weapons and gear, Master Chief has his versatility, but this is over-countered by Samus and her abilities, allowing her to use her arm cannon as well as many weapons Chief has available, her lack of ammo requirements, elemental effects of her beams, and charge-shot powers.

Master Chief has Samus beat in melee strength, but her speed and mobility far out-matches his, and with her own melee capabilites and experience against melee-focused opponents, she'd have the advantage here as well.

When it comes to armor and shields, Samus outclasses Master Chief in every aspect. A fully shielded and armored Spartan can take, at most, 3 grenades to kill, and a direct rocket-hit can often prove lethal on its own. Samus on the other hand has multiple energy-tanks that can take hits from missiles, high-powered energy blasts, and even allow her to submerge in lava for short bursts. Even if Samus were to lose her armor, Chief wouldn't be out of danger, as Samus can shed her armor and use her Zero-suit to gain even faster speed, extreme mobility, and now has both hands free to fight with.

With their genetic enhancements, both have heighted senses, but Samus' suit also has a full scan-visor which is capable of analyzing any weapons, gear, and opponents she comes across, letting her pick her targets and find their weak spots in mere seconds. Her photographic memory allows her to use this information of the fly and means she's never out-classed for long.

Lastly, Samus' has the advantage built into her suit of gaining new weapon abilities that are energy based, so things like the plasma-rifles, Spartan laser, and possibly even the Energy Sword could potentially all be copied and used by her at will.

With all of this in mind, Samus would likely have little to no problem at taking down this Spartan

2 notes

·

View notes

Text

The Chemistry of Life: The Plastic in Cars

Even if cars soon start running entirely on electricity or hydrogen, they'll still need 100 gallons or more of oil to make their plastic parts, such as seats, dashboards, bumpers, and engine components. And some day that plastic may be recycled back into fuel.

Cars of old were mostly steel, but the use of lightweight alternatives has dramatically increased in the last couple of decades. Whereas almost no plastic could be found on a car from the 1950s, today's automobiles have more than 260 pounds (120 kilograms) of plastic on board, according to the Transportation Energy Data Book.

"It is expected that high oil prices and strict CO2 standards will accelerate the growth [in plastic use]," says Aafko Schanssema from PlasticsEurope, a plastic industry group based in Belgium.

Plastics improve fuel economy by reducing weight, but they also require petroleum as a raw ingredient.

"Plastics are in fact solidified oil," Schanssema explained.

Although different plastics have different recipes, it takes roughly 0.4 gallons of crude oil to make 1 pound of plastic. Globally, around 8 percent of the oil that comes out of the ground is used to make plastic.

The average car is a mix of materials: glass windows, rubber tires, lead batteries, copper wires, as well as traces of zinc, magnesium, tin, platinum and cobalt.

However, steel is still the single most important material in cars. It is strong, durable and malleable. On the flip side, though, it is relatively heavy. For this reason, car manufacturers have been trimming down on its use.

For domestic cars, the percentage of weight in steel and iron has dropped from 75 percent in 1977 to 63 percent in 2004, according to the Department of Energy's Transportation Energy Data Book.

Some of the steel has been replaced by lightweight aluminum, whose percentage has grown from 2.6 percent in 1977 to 8.6 percent in 2004. Plastic has seen a similar rise in prominence, going from 4.6 to 7.6 percent over the same 27-year period. (In Europe, the average car currently has closer to 11 percent plastic, Schanssema said.)

A 2005 PlasticsEurope study showed that every pound of plastic in a car replaces roughly 1.5 pounds of traditional materials.

Based on this weight reduction, the same study calculated that plastics provide a fuel savings of about 3.8 percent. However, cars haven't improved their gas mileage by that much.

"On the whole, U.S.-made cars have increased in total weight, so that whatever effect can be ascribed to plastics has been more than offset," said Michael Renner, a senior researcher for Worldwatch.

Renner thinks an emphasis on particular parts misses the bigger picture: the total size and power of new vehicles have been going in the "wrong direction" for many years. He does agree, however, that "the continued development of lightweight materials will still be critical."

Recycle plastic

Even if plastics can mitigate some of the fuel use, they are not exactly loved by environmentalists.

"The production of plastics is of course highly energy-intensive and polluting," Renner said. But he added that the same is true for steel and aluminum production.

One concern is that plastic recycling is not as fully developed as metal recycling of vehicle parts. Composite plastics are especially hard to separate and thus make available for re-use.

However, to Schanssema's thinking, this would not justify making cars from heavier metal parts,

"When looking at environmental impact from a life-cycle approach, it has been found that about 95 percent of the environmental impact of a car is during the so-called 'use phase,'" he said. "End-of-life contributes only marginally to the impact."

Besides reducing weight, plastics help to streamline the shape of vehicles, improve the performance of tires and increase the safety of windshields and fuel tanks.

Still, there are ideas for making plastics more sustainable. One way might be to use bio-degradable plastics, or ones that come from renewable resources, such as corn or sugarcane.

Another option is to recover the energy from discarded plastic parts. The company Plas2fuel, based in Washington state, can make a gallon of oil from melting down 8 pounds of plastic. In March, this process was used by Oregon-based Agri-Plas to turn plastic waste into 8,200 gallons of oil.

Ironically, then, the plastic in electric cars and fuel cell vehicles might one day be recycled into oil that could be burned in gasoline-powered cars.

We have customers ranging from manufacturing immaturity to international corporations that have as long a history in plastic parts as Rosti does. That said, we do have customers that surprise us and have been able to teach us about a particular design or material application. We value these interactions, as nothing is ever black and white. There are always compromises and trade-offs to be made. Conversely, we also have customers that believe they have “been there and done it all,” so extra care must be taken to prepare supporting evidence for our proposals. This would include simulation data, past product data, theoretical calculations, prototype tooling and other information.

Moisture conditioning Processors and end users who use nylon have become very familiar with the effects that water absorption has on that material. In applications where high loads are generated, such as in snapfit assemblies, nylon that is still close to its dry-as-molded state may exhibit brittle failure, and we have learned that this failure mode can be mitigated by conditioning the parts to bring them up to their equilibrium moisture content. This frequently solves problems with the assembly process. The moisture conditioning process takes many forms. Some simply pour a prescribed amount of water into molded parts contained in a moisture-proof package such as a polybag. Others prefer placing saturated paper towels into the package with the nylon parts and allowing the water to migrate out of the paper and into the nylon. Some go as far as boiling the parts. This not only increases the moisture uptake rate, but also ensures that the moisture is absorbed more uniformly throughout the wall of the part. While rapid moisture conditioning is a legitimate method for improving the impact resistance of nylon products, there should be concerns with using it indiscriminately. A nylon product may be temporarily brittle while it comes to equilibrium with the atmosphere. But it may also be brittle because the material has been degraded during the molding process. In such situations, the brittle condition is not simply a temporary symptom of low moisture content, but rather is a permanent condition brought about by reduced molecular weight. The problem is that this shortcoming can be covered up by pumping large amounts of moisture into the polymer. Under such conditions, the polymer becomes sufficiently flexible so that it no longer appears to be brittle. But a moisturizing process that is performed rapidly often introduces more moisture into the polymer than it can retain in the long term. If this happens, then when the excess moisture comes back out of the polymer, the brittle condition can return, usually after the part has gone into the application. Failure in the field This occurred in an application involving a critical part in a consumer product. Parts produced in an unfilled nylon 6/6 were received from the molder that appeared to be more brittle than usual. The explanation was that the parts had been molded just a few days earlier. It was winter in a northern state where the indoor humidity was very low and therefore moisture uptake was slow. The corrective action was to moisture condition the parts. However, this was done very aggressively, and the final moisture content of the conditioned parts was 3.2%. The parts worked initially, going through the assembly and testing process without any obvious problems. However, once in the field the parts began to fail. When the product was brought back in for evaluation, the moisture content of the product had declined to 1.5-1.6%. Field experience has shown that this is a consistent value that is obtained for parts that have been allowed to come to a true equilibrium with ambient surroundings. It will be higher in extremely hot, humid environments or in situations where the part is immersed in water or used in close proximity to water, but in most cases a part molded in unfilled nylon 6/6 can only hold about 1.5% water by weight. This experience contradicts a lot of the data published by material suppliers showing the conditioned moisture content at 2.5%. But much of this early work was performed using accelerated techniques that had a tendency to introduce more moisture into the polymer than it could hold in the long term. Field experience shows that values of 1.5% for an unfilled material are much closer to the norm. It is also important to emphasize that this value is by weight of polymer. If a material contains 33% glass fiber, then one-third of the polymer has been replaced by an inorganic material that is not hygroscopic, and therefore the amount of water that this compound can hold will be proportionally lower.

Cost Benefits

One of the biggest drivers of change across any industry is the cost of production. If there are lower cost alternatives that provide the same or better results, naturally a company should pursue those. When it comes to metal-to- plastic conversion, perhaps the biggest advantage of plastic parts is their ability to potentially provide an overall cost savings of 25-50% over metal.

Also, using plastic often streamlines the number of secondary operations commonly associated with metal parts and reduces the number of assembly steps required. With plastic, OEMs have the ability to combine multiple components into a single molded part design, as opposed to making numerous individual components out of metal and welding or fastening them together. OEMs can even create complex plastic parts with tight tolerances that require no secondary machining using scientific molding processes. Having fewer production steps and less assembly time can provide a significant cost savings, as well as provide more design flexibility.

Time Benefits

In addition to streamlining assembly, injection molding gives manufacturers the time-saving advantage of having the color and surface finish ready to go right out of the mold, instead of tacking on time-consuming steps afterwards, as is the case with metal parts. Also, the injection molding process typically has faster cycle times (more parts made per machine hour) than metal components, all while producing repeatable, durable parts.

Weight Benefits

Plastic parts are typically 50% lighter than their metal counterparts, and provide more production quantity — that is, you get more more parts per pound with plastic versus metal.

0 notes

Text

The Ultimate Revelation Of roofing.

This moisture can breed bacteria and mold and may develop into a health danger to you and your family. The good news is that you may keep away from all of these issues very affordably by discovering a trusted roofer to repair all of those issues for you. Along with homeowners, industrial business house owners also needs to be sure that to get periodic roof inspections. A reputable roofing company may have experience with every kind of economic roofing together with these in apartment complexes, retail procuring areas, restaurants, retirement houses, factories and warehouses. Along with inspections, your roofing firm also can repair all damages whether they are caused by vandalism, dangerous weather or shoddy repair work from the past. Guantee that whenever you choose an organization for your roofing wants, that they stand by their work in some manner, comparable to by providing a warranty.

Native suppliers of building products typically can point you to roofers in your area

Can be utilized on RVs and Trailer homes

Agrees on its own initiative for an interim and final inspection

How long have they been in business

Be certain that the roofer provides written proposals before beginning the job

Roofers: How to search out an excellent Roofing Contractor

Choosing a Roofing Contractor to your Roof Repair Challenge

Double Pores and skin Polycarbonate (21)

Chinese language slates are cheaper still however many skilled roofer’s have complained in regards to the brittleness of the product. Reclaimed roofing supplies offer an environmentally friendly various to your roof covering. If chosen appropriately used slates will provide a gorgeous and durable roof. It’s best to anticipate to pay about two pounds each for good reclaimed Welsh slates. In addition to uniformity and appearance it is advisable to test reclaimed slates for absorption. Check all Waunakee Movers below blueprint to guarantee they’ve been strengthened by the U.S. Division of Transportation earlier than using their shifting affiliations. Waunakee Movers are here to supply assist. After you’ve taught with a satisfactory number regarding long separation Waunakee movers takes a gander at, it’s a perfect chance to check if your movers have been fittingly supported by the U.S. Division of Transportation. As a last resort, all interstate transferring affiliations in Waunakee have to be picked with the DOT, for which they get key authorities-yielded USDOT numbers as enunciation of their awesome ‘ol shaped standing. Completely, the USDOT quantity is an unmistakable articulation quantity issued by the Federal Motor Service Security Administration (FMCSA) – each quantity is exceptional and licenses the lawmaking physique to track each single interstate transporter of family stock.

Find out more about varied firms.

The condition of your roof will decide the worth of your own home and it can be crucial to ensure that you just get your roof put in nicely and carry out common upkeep. SkyWaysRoofing (this website skywaysroofing.co.uk) Utilizing the wrong roofing materials for your house will have an effect on each the appearance and the performance of your property. Common inspection of the roof will help to determine any potential problems, and you’ll deal with them earlier than they turn out to be worse. You shouldn’t hire the primary or the most affordable one you find. Discover out more about varied corporations. Two good methods to research good contractors are phrase of mouth from mates and online searches. In the case of your roof, you should never utilize temporary fixes. You might imagine you’re saving money, but in the end you might need extra harm costing more in the long run. You need to take care of problems as early as potential before they cause serious damages.

Storage refers back to the storage tank the place rainwater is collected.

Nevertheless, roofing programs also can collect rainwater for future reuse. Rainwater assortment is the accumulation of rainwater for future use. Usually this occurs earlier than the rainwater reaches your local aquifer. The catchment area is the realm on which the rainwater is collected, usually the roof. Conveyance refers back to the transportation of the rainwater from the catchment area to the storage and is taken into account the gutters and downspots of a roof. Storage refers to the storage tank the place rainwater is collected. Inadequate ventilation can cause problems equivalent to ice damming and condensation may accumulate from frost and humidity. Correct air circulation prevents buckling, blistering, curling, and finally rotting, and dramatically reduces the percentages of leaks and repairs. Improperly installed shingles and ventilation might void the manufacturer’s guarantee. Ventilation aside, normal weathering of asphalt roofing shingles won’t cause leaking, however issues corresponding to ageing or broken flashings or wind damage might. It is important to repair harm shortly to forestall extra serious problems akin to rot. One of the best ways to prevent serious problems is common maintenance in the type of semi-annual or annual inspections. These inspections can catch issues comparable to collected debris (which has a tendency to retailer water), algae, loose shingles and problems with flashings. It is usually a good idea to maintain overhanging limbs trimmed back. Algae causes discoloration and it plagues properties all throughout the United States.

The hinges, screws and general materials must be very reliable. Ask for any maintenance that is free! Look into the contract effectively so that coatings and shingles might be maintained at an economical value in future. The wind and severe climate can cause pressure on the roof. Use the cleaning service offered by roofers in your locality. Contracts for cleaning are very beneficial as they enhance the life of your roof. His business card is of their wallets and purses or hung on their refrigerator. He has earned their belief and so they wouldn’t name anybody else. So the place can You find this guy to your roof estimate? Actually, it isn’t all that tough. If you don’t know him, you in all probability know any person who does. Heck, they say all people on earth is linked by simply six degrees of separation. Joe Girard (The World’s Biggest Automotive Salesman) figures the common individual is aware of about 250 individuals.

youtube

Generally, the roofing contractors provide the roofing that’s made up of a wide range of supplies. One can selected the material depending on their checklist of priorities. London roofing Lots of the roofing contractors additionally offer roofing providers. These companies embrace upkeep for the roofs which can be put in by them. Prospects can be at liberty to name them if they’ve any downside with their roof. The wide range of services provided by the roofing firms includes installing a new one. The roofing corporations provide companies for commercial and residential roofing. These corporations additionally assist you with the insurance claims for the roofing.

1 note

·

View note

Text

Baby Spinach, chapter 10

Summary: Gaster is stealthy, agile, and a decent marksman, in that order.

Word count: 2740

Sorry for the radio silence guys, I’ve had some Real Life stuff going on. But! It’s been mostly resolved, and I’m back for the foreseeable future!

Thank you ten million times to @spocksbedsidemanner, who is a fantastic editor and really helped me get this thing into shape.

Enjoy!

On this list of things Gaster doesn’t like to do, stealth ranks just below lying and deception. Luckily, he’s much more skilled at this one than the others. He takes a seat next to the imposter after dinner and starts a conversation about his work, asking questions about the nature of the blue human soul as he silently fishes the large keyring from his pocket. It’s nerve-racking work, but Gaster manages to palm the keys up his sleeve without attracting attention.

In spite of his disingenuous pretense, Gaster finds himself absorbed in the imposter’s explanations. His work, though gruesome, is fascinating; cobbling two functional monsters from bits and piece of incompatible souls is no small feat. Under different circumstances, this man could have been a brilliant scientist.

“But you only took small samples of the two souls,” Gaster asks, skipping over the details of where those souls came from, “What did you do to fuse them together?”

The imposter grins widely and ushers Gaster into the maze of shelves. He takes a series of twisting turns, chattering about the resilience of humanity. “It’s a shame they’re trying to destroy us,” he says as they pass another series of intersections.

The space opens into the center area, which is dominated by the covered cylinder and the varied equipment standing guard over it. The imposter takes a corner of the dropcloth and yanks it off, like a magician performing a trick. Gaster is momentarily blinded by the blue glare. He peers around his own arm at the human child’s soul, suspended in some kind of liquid-filled tank.

“I thought you took pieces of this?” he asks.

“I did,” the imposter replies. He’s looking at the soul with something close to reverence. “It healed.”

“What?”

“Let me explain: human bodies are slightly more durable than monster bodies because they expend energy on magic. But their souls are infinitely stronger! I’ve taken enough from this one that it should be nonfunctional, but each time it would generate enough material to repair itself.”

He conjures his own soul in one hand. Gaster gasps. It’s battered and painfully torn, missing pieces along the edges. Two sizeable fragments have been removed, leaving only two-thirds remaining. What must have once been an impressive blue glow now pulses irregularly, giving off bursts of light between long moments of dimness.

“This is what the human soul should look like,” the imposter says, staring his own damaged soul. “But it doesn’t. The human soul combined with the pieces of mine to bring my sons to life.”

This man willing mutilated himself in the hopes of breaking the barrier. Gaster shudders and averts his eyes. He tightens his fingers around the keyring in his pocket. Sans and Papyrus will not stay in this man’s custody for another day, he decides. They leave tonight.

-

The only source of light is the blue soul. It sits uncovered in its chamber, casting blue light over the various shelves. Some of the more reflective items bounce the light back; otherwise, the room is murky and dark.

The path to the door is short if done in a straight shot, but Gaster and the children skirt around and behind furniture to avoid being in the open. Sans is breathing quickly, but quietly. Gaster doesn’t dare breathe at all. Even Papyrus seems to understand the need for silence as they make their way across the room.

Finally, they reach the front door. Gaster hands Papyrus to Sans, pulls the keyring from his pocket, and begins flipping through the numerous keys. There must be more than a dozen, each unlabeled and barely distinguishable from the others. The keys to Sans’ and Papyrus’ rooms were found through trial and error, so Gaster tries each one on the two front door keyholes, hoping to complete the process without drawing attention.

Five minutes later, none of the combinations have worked.

“What’s wrong?” Sans hisses.

Gaster’s mouth thins into a long, irritated line. This was a completely predictably scenario. The imposter sacrificed a scientific career and at least ten years of his life on the children and the human heart, of course getting out wouldn’t be as easy as grabbing the keys from his pocket.

From behind him, someone clears their throat.

Gaster turns around.

In the stress of the moment, he missed that one of the things reflecting the human soul’s blue glow was a pair of reading glasses, perched at the end of the imposter’s nose. He’s sitting at one of the reading tables, pouring over one of the many stacks of paper that seems to live there. It’s hard to tell in the dim light, but he seems amused.

“Having some difficulty there, Doctor?” the imposter asks.

Gaster pushes the children behind him. “I’d like the keys.”

“And why would I give you those?”

“Because I’d like to leave.”

“And I suppose you intend to take my children with you?”

“I do.”

“I see.” He closes a notebook and puts it to the side. “Tell me, Doctor, what exactly gives you that right?”

“I don’t believe you’d understand my explanation,” Gaster replies.

The imposter removes his glasses and sets them on top of the notebook. “No matter what your intentions were in coming here, this is your place now. My sons’ destiny is to save monsterkind from this wretched cave system; yours is to help me prepare them for it. I’m sure you understand why I cannot allow you to leave.”

“I’m equally sure you understand why I can’t stay.”

The man stands and steps away from the table. He’s taller than when he first took his own shape, and his skin is beginning to take on an off-white color. “Then we seem to have reached an impasse,” he says through teeth that are now longer and sharper than his own.

Gaster throws both the children and himself behind the closest shelf as the imposter tries to grab his soul with a blue grip. Papyrus lets out a sharp cry as the shelf turns blue and books begin to fly in every direction.

“Hide!” Gaster yells over the deafening sounds of books hitting the walls and floor.

“He’s going to kill you!” Sans shouts back.

Papyrus wails.

“I won’t allow that,” Gaster says, steering both himself and Sans around the corner as another shelf’s contents explode into the room, “I’m still going to get us out of here. But to do that, I need to know that you’re safe. I wouldn’t have a reason to leave if anything happened to you.”

Sans is staring at him again. He seems to be developing a habit.

“I won’t let anything happen to you,” Gaster says over the din.

Sans clutches Gaster’s shirt with one hands and holds Papyrus close with the other. “Don’t die, okay?”

“I won’t,” Gaster promises. He squeezes Sans shoulder, then pushes him towards his room.

Gaster has been in exactly three fights. Two were due to misunderstandings, and the third was when the Royal Institution wanted to see if his new body would still work for testing purposes. While his overall shape was reminiscent of a human, the magic he carried over from his ghost form made him unsuitable for anti-human combat training. Not being able to help the war effort was a disappointment. But now, as purple energy forms between his palms and spins into long strands between his fingers, Gaster is quite pleased with how things turned out.

He dives out from behind the shelf just as it explodes, sending papers and wooden shards hurtling into the room; Gaster catches some of the debris in a hastily-spun web and hurls them back as he dashes for new cover. The imposter gives a dog-like yelp. He appears to have shifted into an enormous bipedal white dog with pointed ears. Gaster recognizes the form as one of the guards who covered the library crime scene after Sans and Papyrus were kidnapped. The imposter has clearly chosen physical prowess over agility in this fight. That, Gaster strategizes as he follows the lines of magic back to the imposter’s chest, might be what keeps him alive.

He throws out a purple line, aiming for the concentration of magic that hopefully contains his soul, but the imposter knocks the line aside with an enormous arm. Gaster’s accuracy is his best attribute, but his threads are brittle on their own; this one breaks upon contact and flutters to the ground. The imposter snarls and hefts a table over his shoulders in retaliation and hurls it across the room. Gaster throws himself to the side; the table smashes against the floor where he was standing, splintering into thousands of sharp pieces. His brain begins calculating the force of the impact (and if it would have outright killed him, or simply mangled his body enough for the imposter to catch him--), but he shoves the thoughts away and sprints into the maze of bookshelves for cover.

They volley back and forth as they wind through the narrow space between shelves. The imposter decimates anything Gaster uses as a shield, leaving the furniture in shambles; Gaster throws back what he can, but hasn’t been able to snag the imposter’s soul. They around each other, Gaster running ahead at each opportunity and the imposter slowly stalking after him.

Gaster ducks behind another shelf and finds himself in the open space made for the human soul and its monitoring equipment. He sprints to the center, vaulting over the machinery and scooting behind the bubbling container. Hopefully, the soul’s sparkling glow will hide Gaster long enough for him to form a strategy.

The imposter comes crashing around the same shelf a moment later, carrying one of the tables as an impromptu shield and leaving long gouges on the floor as his claws skid and dig into the tiles. Gaster watches as he sniffs the air with his newly canine nose. That, he reflects, is probably how the imposter has managed to track him so closely.

“I know you’re here,” the imposter says.

Gaster thinks it would be beyond foolish to reply, so he doesn’t.

“Well, I know you’re close,” the imposter corrects himself “I don’t know exactly where you are, but that makes this so much more exciting, don’t you think?”

He begins to move through the area. Gaster edges around the tank, keeping it between him and the man who is currently an eight-foot-tall dog with superior teeth and senses.

“Think of all we could have accomplished together, Doctor,” the imposter says as he stalks towards a control panel, “I hoped you would be able to put your emotions aside for the greater good, but I can see that was asking too much.”

Gaster takes the opportunity to slide behind a piece of machinery on the opposite side of the tank. He watches as the imposter sets down the table so it shields the panel, then starts fiddling with the computers. Gaster leans as far out of his hiding spot as he dares, but can’t get a clear shot.

“Do you know why I made the boys instead of taking the soul myself?” the imposter says as he continues to input commands into the console. “I wanted to have a backup plan in case I couldn’t complete the assignment. Human bodies are fragile, but their souls seem able to replenish themselves almost limitlessly.”

The soul dims slightly. The various monitors beep a quick warning, then go silent. Something hisses, and a piece of the containment unit begins to slide open.

“I can’t risk you going to the authorities with this information, Doctor.” He reaches into the opening and carefully removes the soul from its container. Its illuminates the small space. “Besides, I’ve always been curious about the world on the other side of the—”

The table is jerked out of the way.

The imposter spins around, looking for the cause.

Gaster summons a fistful of strings and pitches them directly at the imposter. They wrap around his wrists and pull both defending arms away from his chest—

“No!”

Several make contact with his soul. It momentarily lights up in its natural blue (dimmer than the human soul, Gaster notes), then floods with purple as Gaster’s magic takes hold. Gaster braids the strands connecting his hands to the imposter’s soul and pulls.

The imposter collapses to his knees. He thrashes against the purple magic, howling and lunging at the monster holding him down. He shifts into Lieutenant Donahue, into his own form, into something even larger and more intimidating than the royal guard Gaster fought, each form lasting just a moment before he discards it and moves on to the next, creating a hideous amalgam state between each. Gaster watches him struggle. The hatred in his chest, carried since this man first invaded his house and told him how Sans and Papyrus came into the world, slides aside just enough for a wisp of pity to come through. Gaster observes it, but doesn’t act on it.

Instead, he throws out a line for the dead human soul, pulsing silently on the floor where it was thrown in the imposter’s struggle. It fits easily in his palm. To someone else, the color might be considered beautiful.

Gaster considers the human soul in his hand, the man at the end of his magic, and the endless list of crimes this man has committed in the name of integrity. People’s lives have been ruined. Sans’ eyepatch. Papyrus’ fear of being left alone. Something vicious stirs in Gaster’s chest. The secondary poison inherent in his magic begins to leach into the imposter’s soul.

The imposter hisses as his health points begin to burn away. “This isn’t over,” he snarls.

Gaster doesn’t answer.

“This doesn’t end until I say it ends!”

He tightens the strands between his fingers until the tension makes his arm shake. The imposter grits his teeth and begins to tremble.

“Stop!”

Gaster startles out of his own thoughts as Sans comes hurdling out from behind a shelf. He throws himself into Gaster’s mid-section and throws both arms around him. “Don’t kill him,” he begs.

“Sans,” Gaster says quietly, “This man will never stop looking for you. Do you understand? He wants to turn you into a human-killing machine, he wants to turn Papyrus into a human-killing machine, and he won’t stop until that happens.”

The blue soul casts streaks of illumination over Sans’ face when he looks up. They catch on the gauze taped over his right eye and the watery tears welling in the left. “He’s my dad.”

Gaster looks at the undersized child clinging to his waist. He looks at the wretched man caught in his web, and the human soul stolen from a murdered human child in his hand. He takes a deep breath and thinks about his home: a playpen in the sitting room, kitchen cabinets stocked with baby food and ketchup, toys strewn about as they wait for two children to come back. Gaster lets the breath out slowly and feels himself settle.

“I’m sorry,” he says, storing the soul in his inventory so he can wrap the other arm around Sans, “I almost got carried away.”

“I want to go home,” Sans says.

Gaster pulls him in for a proper embrace. “Okay.”

-

The imposter apparently keeps the front door keys on a necklace, separate from the others on the ring. It takes some concentration to fish it out and keep him pinned down while Sans goes for help, but somehow, when Lieutenant Donahue comes charging shield first down the ladder, both Gaster and the imposter are alive and no further harmed. He gladly releases the imposter into Donahue’s custody, and gives a rough outline of the situation as other guards investigate the underground laboratory and process the imposter’s arrest. Sans keeps Gaster between himself and his father through the process, holding Papyrus close.

Donahue whistles. “Never would have suggested this if I’d known it’d put you in the middle of a fight,” she says, punching Gaster’s shoulder.

Gaster rubs the punch site with his opposite hand. “I must admit, the possibility did cross my mind, but I was prepared for it.”

She looks over Gaster’s shoulder at Sans. He’s staring at the ladder as the guards escort the imposter back to the royal facility, and he’s gripping the back of Gaster’s shirt tightly with his free hand. “Guess some things are worth fighting for,” she agrees.

- Baby Spinach - Part 10

[FIRST] [PREV] [NEXT]

#Spinach Productions#baby spinach#undertale#fanfiction#fanfic#undertale fanfiction#undertale fanfic#undertale gaster#undertale sans#undertale papyrus#baby bones

60 notes

·

View notes

Note

I'm working on a setting with some friends where raw materials are extremely hard to come by. The vast majority of resources are in the form of scrap left over from a collapsed civilization. How difficult do you think it would be to reinvent metallurgy without proper ores to work with, only finished metals?

Not too difficult, I would imagine. Now, would one of the characters have some knowledge of the chemical compounds of certain metals, and their reaction to heat? EG, chromed or galvanized metal containing zinc, which emits a scentless, invisible gas that is extremely toxic, and will kill you before you can get out the doors of the smithy. If there are any railroad track segments left in this apoc world, those make wonderful makeshift anvils. If someone can get access to surviving gas tanks (propane is especially good), it wouldn’t take a rocket scientist to make it emit a constant stream of pressurized gas and ignite it a bit away from its main vent, and use that as a very rudimentary forge. Although, on that note, regular wood was what a lot of medieval smiths used, when they couldn’t get access to coal, so setting up a crude cart to hold the burning wood and setting up a bellows (plywood and canvas, hand crank, a leftover fireplace bellows, it works) to pump up the heat, and you’re golden. Once you get fire, it’s only a matter of how hot you get it, to melt metals down. There will likely be a trial and error stage, in trying to make suitable casting molds to make solid ingots, which will likely entail either meltdowns, with molten metal splashing everywhere, or extremely brittle ingots, from not filtering out impurities while casting. Copper and bronze melt at a relatively low temperature, from around 1000-1500 degrees Farenheit (or 850-1080 degrees Celsius, otherwise), so that would be a good start to simple workings, since they don’t really need much heat to shape, and work-harden on their own as you hammer away at it. If you have access to tongs, that would be a godsend, frankly, because that would enable you to advance your capabilities, and can then turn finished metal scrap into everything you might need to survive. A lawnmower blade can become a wicked sharp knife, if you consider it carefully, leaf springs from trucks are made from a very high-grade steel known for its strength and durability, street signs, especially stop signs, can make for very good rudimentary shields, etc. Basically, once you have fire, tongs, decent hammers, and the creativity and inspiration to forge things anew, the world’s your radioactive, possibly mutated, still-smoking oyster. I hope this ramble helps in some way shape or form!

3 notes

·

View notes

Text

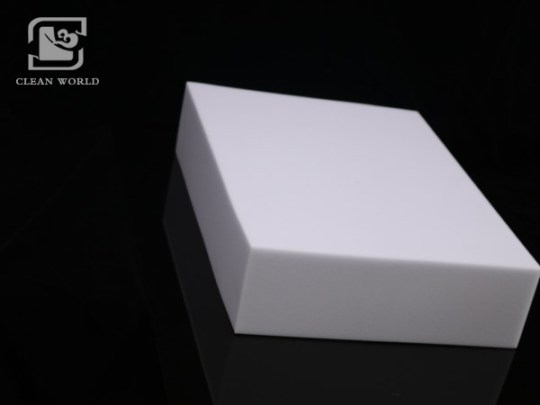

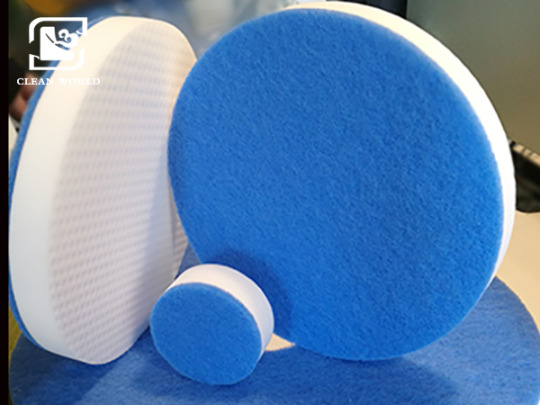

Melamine Foam Made By Enworld

Basic information about melamine foam

Our melamine foam easily erases stain or dirt with water. Our product is a strong multi-functional melamine foam bulk . Moreover,Enworld melamine foam can be cut into any size for a suitable shape. Made of eco-friendly materials consisting of ultrafine fibers and particles, the content of this cutting-edge product is as fine as 1/10 000 of hair. No retail box,items will be packaged safely in Bubble Bags. For different production batches,it maybe about 2 mm errors, but, it's the normal range.

Enworld Melamine Foam For Sale

Puyang Enworld New Material Co., Ltd. is devoted to the research and development, production and sales of melamine foam sheets. In addition,as a melamine foam manufacturer, Enworld values every detail of the whole production of That product melamine foam. In 5 years’ development, we sells our products to many other countries. Our customers uses These melamine foam for cleaning of kitchen and office, acoustic insulation materials for architectures and automotives and thermal material for hot tanks and pipes.

Little Useful Tips About Our Melamine Foam

When you use These melamine foam to wipe in one direction along the rub, you can prolong the service life of Enworld melamine sponges. Thatproduct is relatively brittle, so do not force tweaked to avoid breakage or damage to their organization structure. furthermore, our melamine sponges are more flexible than the other sponges,yet if you want to use longer, then use gentler.

More Information About Our Products

These melamine foam sponges are most commonly used as a cleaning scrubber for popular eraser products found in retail stores, and on our own private label. The characteristics of Those products are light-weight, flame resistant, retains properties from -200⁰C to 240⁰C, sound absorption, abrasiveness, thermal insulation and chemical resistance. Its diverse properties allow it to be used in numerous applications and industries, such as: consumer: cleaning sponges and erasers; construction & Industrial: acoustics: ceiling panels, wall panels, suspended baffles; insulation: pipe jackets, thermal tanks, solar collectors, HVAC systems; Medical: insulation and sound absorption for medical equipment; semiconductor: semiconductor wafer equipment cleaning; transportation: aviation: cabin insulation and ductwork, cars and buses: engine covers, firewalls, transmission tunnels, hood liners, rail: ceiling panels. In fact,our design and engineering expertise coupled with our diverse fabrication capabilities allow us to solve your complex product challenges. Contact us to learn more about melamine foam and how it may be suitable for your products’ needs.

Ordinary Density& High Density of Enworld Melamine Foam

Compared to traditional cleaning sponges, Enworld melamine foam blocks biggest advantage is the using physical decontamination mechanism. Reliance on melamine foam’s nano-dimensional open-cell three dimensional network structure to automatically absorb surface stains during wiping process. However, we can turn these ordinary melamine sponges into high-density melamine sponges in the process of compressed processing. High-density sponges are more durable and have higher detersive ability. Moreover, in order to increase the uses of melamine sponges, we have the compound sponges with PU or scouring pad. This design achieves that one sponge, more uses.

0 notes

Text

Benefits of Using Industrial Coatings for Durability and Protection

Industrial coatings play a critical role in protecting and enhancing the performance of various surfaces used in industrial settings. From manufacturing equipment to heavy machinery, industrial coatings are designed to improve the durability and longevity of these surfaces while providing an additional layer of protection against the elements. In Industrial Coatings in India, these coatings are especially important due to the extreme weather conditions and harsh environments that industrial assets often face.

In this blog, we will explore the benefits of using industrial coatings to boost durability and provide superior protection, focusing on how these coatings are crucial for maintaining your assets’ efficiency and functionality.

1. Protection Against Corrosion

Shielding Metal Surfaces: One of the primary benefits of industrial coatings is their ability to protect metal surfaces from corrosion. In industries where equipment is exposed to moisture, chemicals, or salt, such as in coastal areas or industries that deal with aggressive chemicals, corrosion is a major concern. Industrial coatings form a protective barrier that prevents the metal from reacting with environmental elements, thus extending the lifespan of machinery and structures.

Enhanced Resistance: Coatings like epoxy or polyurethane provide excellent resistance to rust and oxidation, making them ideal for protecting industrial equipment from degradation. This added protection reduces the need for costly repairs and replacements.

2. Resistance to Harsh Chemicals

Chemical-Resistant Coatings: Industrial coatings are specifically formulated to withstand exposure to a wide range of chemicals. Whether in a manufacturing plant, oil refinery, or chemical processing facility, these coatings act as a barrier to prevent chemical damage to surfaces.

Safe and Durable Surfaces: The durability of industrial coatings ensures that industrial equipment, tanks, and pipes remain protected from corrosive substances like acids, alkalis, and solvents, improving their operational efficiency and safety.

3. Protection from Extreme Weather Conditions

Weathering Resistance: In Industrial Coatings in India, where temperatures can fluctuate drastically and monsoon rains can be intense, coatings provide essential protection against the elements. Whether it’s hot temperatures, heavy rain, or humidity, industrial coatings act as a shield to protect machinery and infrastructure from the damaging effects of weather.

UV Protection: Certain industrial coatings also provide UV protection, preventing surfaces from degrading or becoming brittle due to prolonged sun exposure. This is particularly important for outdoor machinery and structures that are continuously exposed to UV rays.

4. Enhanced Aesthetic Appeal and Cleanliness

Smooth Finish and Clean Surfaces: Industrial coatings improve the surface finish of equipment and structures, making them easier to clean and maintain. Smooth, coated surfaces are less likely to accumulate dust, dirt, or pollutants, ensuring that industrial equipment remains clean and visually appealing.

Color and Appearance: Not only do these coatings offer protection, but they can also enhance the appearance of industrial structures and machinery. This is particularly beneficial for industries where both functionality and aesthetics matter, such as in consumer-facing facilities or high-end manufacturing plants.

5. Cost Savings in the Long Run

Reducing Maintenance Costs: Industrial coatings reduce the need for frequent maintenance by protecting against wear and tear, corrosion, and chemical damage. As a result, businesses can save significantly on repair and maintenance costs.

Lower Downtime: With protected machinery and equipment, the likelihood of breakdowns or malfunctions decreases, which in turn reduces operational downtime. This leads to higher productivity and efficiency for businesses.

6. Increased Safety Standards

Slip-Resistant Coatings: Many industrial coatings are designed with safety in mind. Anti-slip coatings are commonly applied to floors, walkways, and stairways to reduce the risk of accidents in manufacturing or warehouse settings.

Fire Retardant Properties: Certain industrial coatings come with fire-resistant properties, helping to slow down the spread of fire and offering enhanced protection for workers and facilities. This can be particularly vital in industries where flammable substances are present.

7. Sustainability and Eco-Friendly Options

Eco-Friendly Coatings: As environmental concerns continue to rise, more manufacturers are opting for eco-friendly industrial coatings. These coatings are designed to be low in volatile organic compounds (VOCs) and are formulated with sustainable materials that do not harm the environment.

Long-Term Sustainability: By choosing high-quality industrial coatings, businesses can help reduce their carbon footprint by increasing the lifespan of their equipment and infrastructure. Sustainable coatings contribute to lower resource consumption and waste production, aligning with green manufacturing initiatives.

Conclusion: Industrial Coatings for Optimal Performance

Industrial coatings are essential for improving the durability and protection of equipment, machinery, and infrastructure across various industries. With the benefits of enhanced corrosion resistance, chemical protection, weather resistance, cost savings, and increased safety, the use of industrial coatings in India has become a necessity for businesses aiming to extend the lifespan of their assets and reduce maintenance costs.

At SBL Specialty Coatings, we provide high-quality industrial coatings that offer unmatched protection and performance. Whether you’re looking to safeguard your equipment from corrosion, chemicals, or weather, our coatings are tailored to meet your specific needs, ensuring your industrial assets remain durable and reliable for years to come.

0 notes

Text

The Future of Carbon-Fiber Rims

Way back in the early 1970s, Michelin made a run of composite glass-fiber and resin wheels for Citroën’s SM-based rally car. The first car equipped with them won its first race, the 1971 Morocco Rally. By 1972 they were offered as a factory option for buyers of road-going SMs.

In the 1980s, Dodge and Carroll Shelby teamed up for the CSX, the final version of which, the 1989 CSX-VNT, wore a set of composite wheels called Fiberrides. Like the Michelin/Citroën wheels before them, the Fiberrides were a composite glass fiber construction.

Fast-forward to 2013, when boutique hypercar maker Koenigsegg began offering carbon-fiber one-piece wheels for its 250-plus-mph ground-bound spaceships. They’re quite a pretty penny, however: A set of four will set you back about $40,000—on top of the roughly $2 million price tag for one of its cars.

Carbon fiber’s ability to tolerate a wide range of temperatures without becoming brittle or deformable depends not on the carbon itself but on the epoxy that surrounds it.

Today, Porsche is the only mainstream automaker developing one-piece carbon-fiber wheels in-house, and there’s just one supplier, Carbon Revolution, manufacturing them for production cars, including the Ford GT, Mustang GT350R, and several upcoming models from other brands—though there are a number of other outfits making “hybrid” carbon/alloy wheels for the aftermarket. Carbon Revolution has big plans to scale up from the tens of thousands of one-piece carbon-fiber wheels it says it will produce this year into the hundreds of thousands if not millions as it moves into the next decade. Sooner if co-founder Brett Gass has his way.

“We’ve got a program underway that’s a 22-inch carbon-fiber wheel for a very serious off-road SUV,” Gass said. “And those types of volumes in that world, those are tens of thousands of vehicles. Those are big programs.”

Carbon Revolution is also working with Ferrari on wheels for the 488 Pista, as editor-in-chief Mike Floyd learned at this year’s Geneva auto show. “We were very demanding with the style,” Edoardo Rossi, Ferrari product marketing manager for the 488 Pista, said of Ferrari’s work with Carbon Revolution to develop the Pista’s special wheel option. “The spokes are not huge spokes that you see in normal carbon-fiber components. They are very thin, so it was an adjustment. Then we developed together the solution that you see inside, the white coating. It is basically a coating developed from aerospace to preserve the carbon wheel from the heating of the brakes.”

The Advantage

Although lighter weight is the primary benefit of a composite wheel—particularly a carbon-fiber one—there are also advantages to be gained in the noise, vibration, and harshness arena. Metal wheels, including steel and aluminum, transmit a great deal of high-frequency NVH from the road through the suspension and into the car’s structure. Carbon-fiber wheels damp that energy better, cutting it out of the equation where it begins. As a result, carmakers will be able to engineer quieter cabins without having to add pounds and pounds of sound insulation.

“Not only the light weight and the stiffness, but the damping characteristics really just get rid of that high-frequency [vibration], particularly in the luxury electric vehicle space, where you don’t have powertrain and exhaust noise and all those other things,” Gass explained.

Lighter wheels improve acceleration and dece-leration, as the engine and brakes no longer need to work against as much rotating mass. They also reduce gyroscopic effects, making initial turning behavior more sensitive and controlled, and the amount of unsprung weight at each corner—the byproducts of which are improved ride comfort and more desirable handling characteristics thanks to a lessening of the suspension’s overall workload.

There’s no part of a wheel that isn’t essential, but the strength and durability of the hub portion is central to transferring the torque of acceleration and braking from engine to road and back to the brakes.

Every aspect of the carbon wheel that aids per-formance also benefits efficiency for the same reason—physics: You’re able to do the same or more with less energy. The only difference is the goal. Rather than chasing terminal velocity and optimum lap times, lightweighting a hybrid or electric car helps to maximize its range. With less mass in the wheel to be spun up to speed and then dragged back down, there’s less energy going to waste every time the car speeds up or slows down, which can mean miles (or tens of miles) more to a charge or a tank.

The “But”

So carbon-fiber wheels can unlock greater performance potential, improve efficiency, and enhance comfort and quietness. They seem like the perfect solution, so why all the fear, uncertainty, and doubt? Two reasons: price and myths.

A set of Carbon Revolution’s aftermarket wheels will run you about $12,000. Although that’s competitive with the very top end of the custom forged alloy wheel aftermarket, there’s no $1,000-a-set option as yet in the carbon-fiber space. But that will change over time as volume—and eventually competition—increases.

“Today we’re not really a disruptive technology,” Gass said. “We’re too expensive, too exotic. When we get to gen three of the technology where we’re cost competitive with forgings and superior in every product attribute, now you’re disruptive. Now you’re a real threat to a good chunk of the aluminum market. We’re not far off. We’re one generation of production away from that, which could show up on the road in the next two to three years.”

What Gass calls the “rarest automotive light-weighting technology in existence” today (he claims there are more suppliers for the LaFerrari KERS hybrid system than for one-piece carbon-fiber wheels) could conceivably become ubiquitous within the next decade, wheels that not just supercars but potentially every car will roll on. But that will only happen if the mythmongers are proven wrong.

The Myths

Carbon is fragile! Carbon shatters! You can’t repair it! Carbon wheels will melt when they’re hot! They’ll crack when they’re cold! They leak air!

The litany of fake news fatal flaws of the carbon-fiber wheel is not quite endless, but it’s certainly extensive. And none of it is true—at least if the wheel is made correctly. The seed of the myths was planted by a handful of aftermarket wheels, most of them two- or three-piece “hybrids” (carbon barrels with alloy hubs and spokes), none of them tested to OEM standards for road use. They’re very different creations from the fully tested one-piece wheels from Porsche, Koenigsegg, and Carbon Revolution.

The Ford GT’s use of carbon fiber isn’t about style. It’s about speed. There’s zero chance the GT, bred for the track and loosed on the street, would be shod in carbon if the material weren’t up to the task.

The multipiece, multimaterial nature of hybrid carbon/alloy wheels presents additional points of failure compared to a traditional one-piece wheel, regardless of the material. The alloy center section has to be mated to the carbon-fiber barrel, typically by bolts, and each presents an opportunity for shear and strain to cause failure of the joint. Worse, when you bolt the aluminum center section to the carbon barrel, there’s likely to be some twisting that adds internal stresses and pulls the wheel out of true.

That’s not to say that all hybrid wheels are bad or inherently flawed. In fact, some hybrid wheels, including those produced by Carbo Tech (supplier of hybrid carbon wheels to BMW and Rolls-Royce as well as some of McLaren’s road-going carbon monocoques) and Geric, are built to meet or exceed the parameters of standard alloy wheels, not just in terms of stiffness but also of durability and toughness. Hybrid wheels are a factory option on the excellent BMW M4 GTS, a car vaunted for its handling and performance.

As for repair, carbon-fiber wheels—whether one-piece or hybrid—can be polished and resurfaced provided any scratching (hello, curb!) is limited to the surface epoxy layer and doesn’t disturb the carbon fiber below. That’s not too different from fixing an alloy wheel; no matter the material, you take a big enough chunk out of one or bend one too far, and there’s no repairing it back to its original strength and stiffness.

The ceramic-metallic coating on the inside of Carbon Revolution wheels can vary widely or get skipped altogether depending on the car the wheel was designed for.

Although concerns about carbon fiber’s ability to handle extreme temperatures are legitimate, they’re misplaced. Carbon fiber’s ability to tolerate a wide range of temperatures without becoming brittle or deformable depends not on the carbon itself but on the epoxy that surrounds it—and wheelmakers like Carbon Revolution have put a lot of science into their secret sauce, including the plasma coating inside the wheel to protect the epoxy from brake heat. The result is a wheel that’s as strong and as safe to use in the Arctic as it is at a midsummer Arizona track day—otherwise that wheel never would have ended up on a car like the Ford GT.

Present and Future